Composite type air filter screen and preparation method thereof

An air filter, composite technology, applied in separation methods, chemical instruments and methods, membrane filters, etc., can solve the problems that the life of the filter cannot be displayed visually, affect the use effect of consumers, and cannot form a filter system. The effect of broad-spectrum bactericidal resistance, easy mass production, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

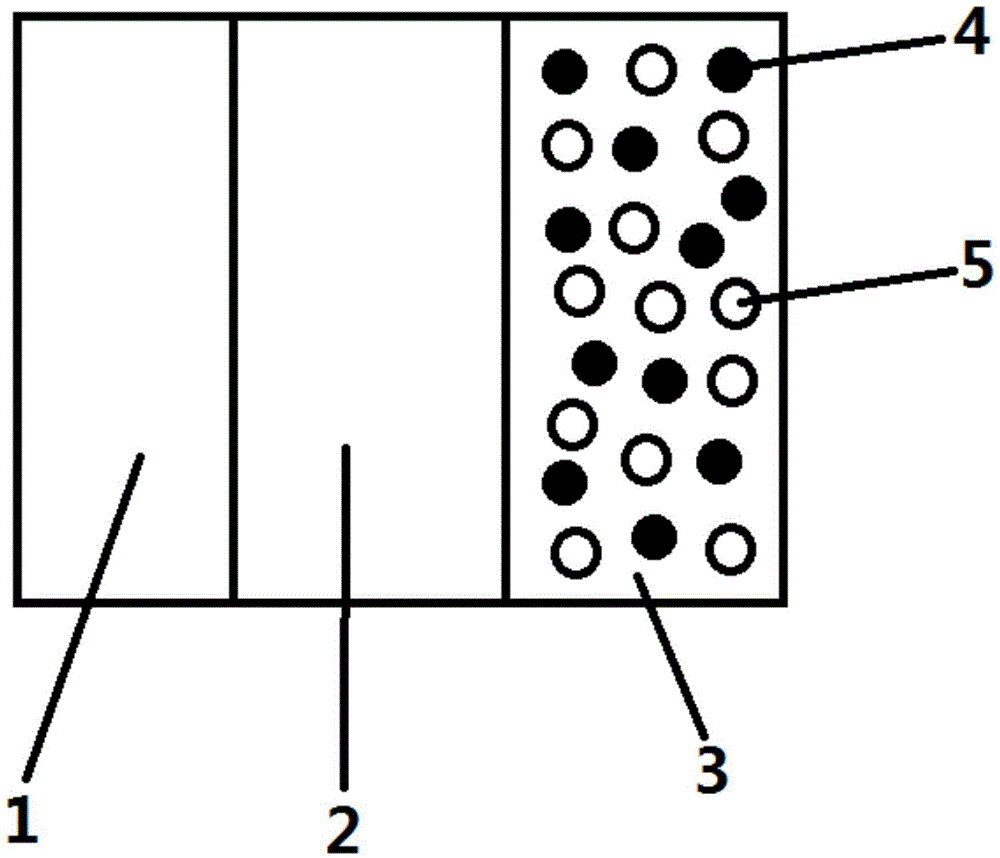

[0077] In this embodiment, the primary effect filter screen 1 adopts PP filament non-woven fabric with 40 meshes loaded with nano-silver antibacterial agent accounting for 0.1% of the mass of the primary effect filter screen 1; The melt-blown non-woven material with negative ion powder is prepared by discount glue coating process; the odor filter 3 is made by mixing coconut shell activated carbon material and zeolite molecular sieve loaded with potassium permanganate and filling it. After the above preparations, hot melt adhesive is used to bond and fix the primary effect filter 1, the particle filter 2 and the odor filter 3 in turn respectively; Net products; finally packaged by inflating or vacuum sealing.

Embodiment 2

[0079] In the present embodiment, primary effect filter screen 1 adopts the plastic net that 5 purpose loads have accounted for the nano-silver antibacterial agent of primary effect filter screen 1 quality 2.0%; The PTFE membrane is prepared by a discounted glue coating process; the odor filter 3 is made of coconut shell activated carbon material and alumina loaded with potassium iodide and sodium thiosulfate after mixing and filling. The preparation process is the same as in Example 1.

Embodiment 3

[0081] In the present embodiment, the primary effect filter screen 1 adopts 100 mesh loads of spunlace nonwovens that account for 5.0% of the primary effect filter screen 1 mass nano-silver antibacterial agent; 2 is the same; the odor filter 3 is made of zeolite molecular sieve loaded with ferric ammonium sulfate and alumina loaded with potassium iodide and sodium thiosulfate, mixed and filled. After the above preparations, the primary effect filter 1, the particle filter 2 and the odor filter 3 are respectively bonded and fixed around the four sides with polyurethane glue; then, the paper shell is used for edge wrapping to obtain a composite air filter Products; finally packaged by inflating or vacuum sealing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com