Smashing device with excellent screening effect for energy conservation and environment protection of building

A technology of building energy-saving and crushing device, applied in the direction of grain processing, etc., can solve the problem of poor crushing effect and other problems, and achieve the effect of good screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

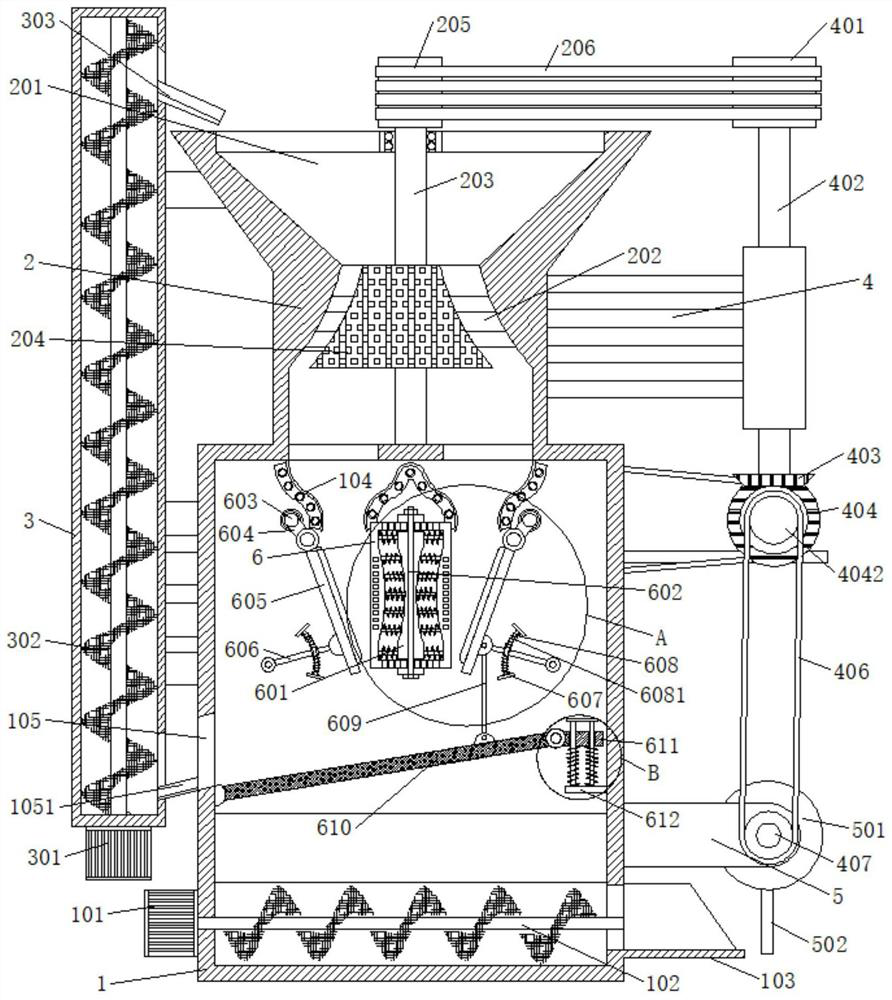

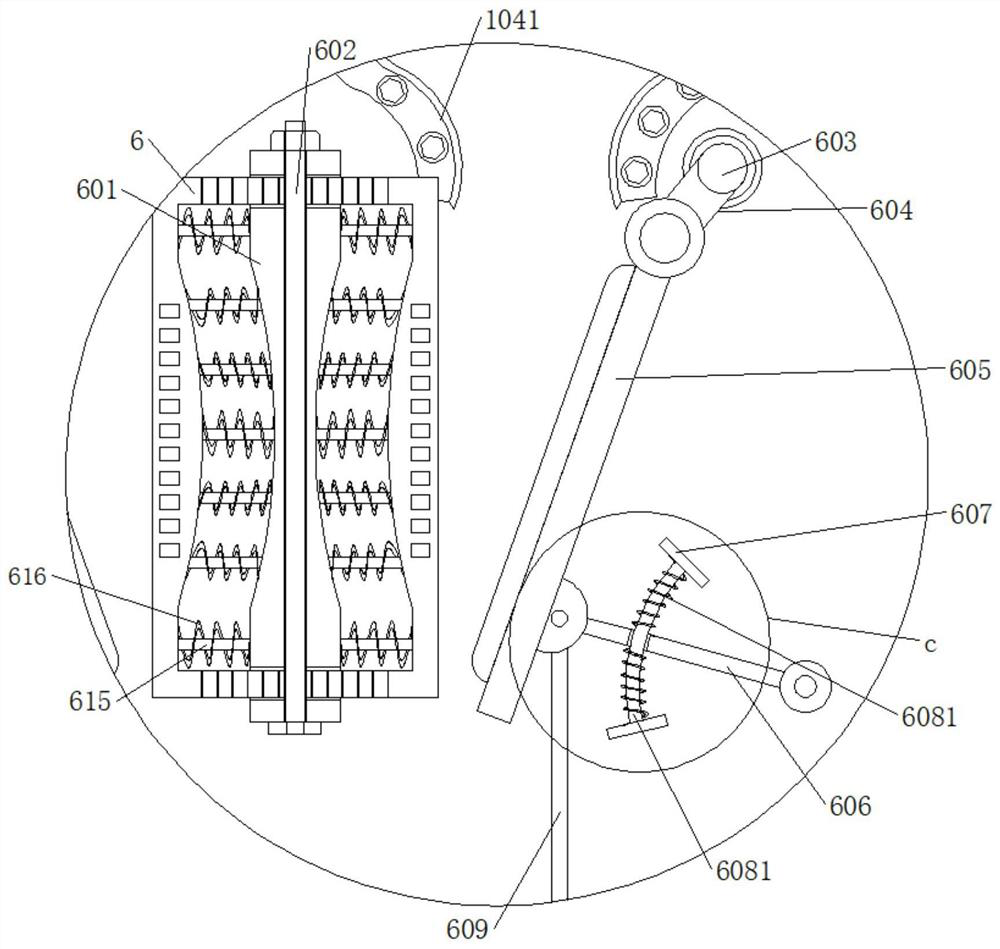

[0028] refer to Figure 1-5, a crushing device with good screening effect for building energy conservation and environmental protection, comprising a first box body 1 and a second box body 2, the second box body 2 is fixedly connected to the top of the first box body 1, and the top of the second box body 2 is opened There is a feed port 201, the second box body 2 is connected with a first crushing mechanism, the first box body 1 is connected with a second crushing mechanism, the inner wall of the first box body 1 is movably connected with a filter screen 610, the first box body 1 The side wall is connected with the first conveying mechanism, the bottom of the first box 1 is connected with the second conveying mechanism; the second crushing mechanism includes the movable jaw plate 605 and the static jaw plate 6, and the inner wall of the first box 1 is fixedly connected with the bracket 601 , the static jaw plate 6 is slidably connected to the bracket 601, and the bracket 601 i...

Embodiment 2

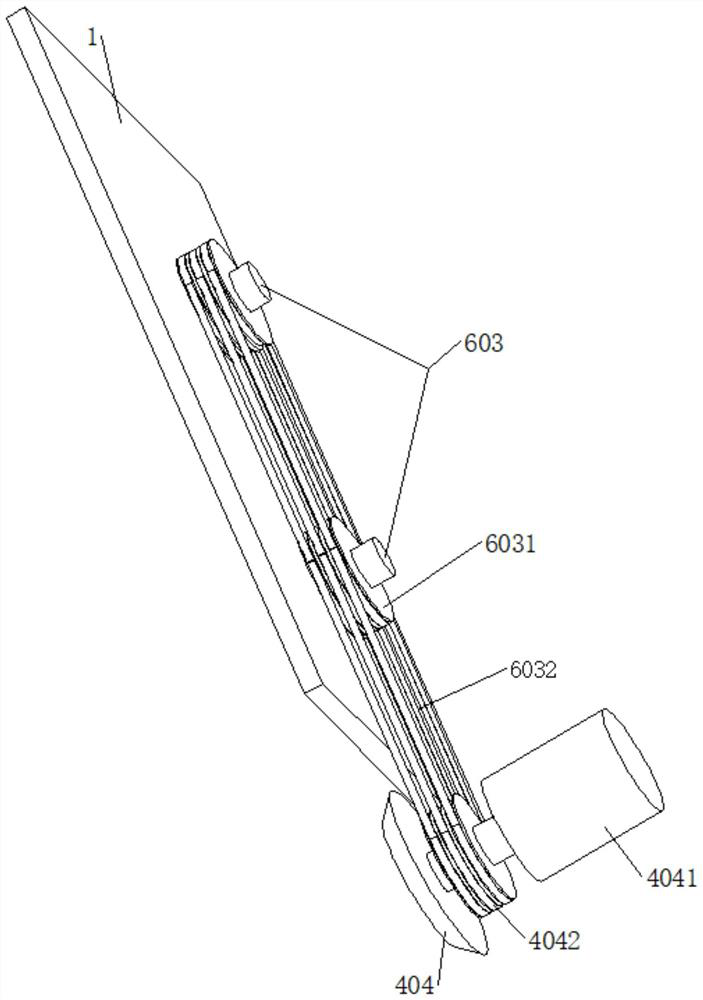

[0030] refer to figure 1 , image 3 The driving part includes a first motor 4041 connected to the side wall of the first box 1, the output end of the first motor 4041 is connected to a first pulley 4042, and the side wall of the first box 1 is connected to two second rotating shafts for rotation 603, a second pulley 6031 is fixedly connected to the second rotating shaft 603, a first belt 6032 is sleeved on the first pulley 4042 and the second pulley 6031, and a first rotating plate 604 is fixedly connected to the second rotating shaft 603, The end of the first rotating plate 604 away from the second rotating shaft 603 is connected to the movable jaw plate 605 in rotation, and the second rotating plate 606 is rotatably connected to the movable jaw plate 605, and the end of the second rotating plate 606 away from the movable jaw plate 605 is connected to the first box The inner walls of the body 1 are against each other, the side wall of the second box body 2 is fixedly connect...

Embodiment 3

[0032] refer to Figure 4 , the inner wall of the first box body 1 is fixedly connected with two symmetrical baffles 607, between the two baffles 607 is fixedly connected with an arc-shaped sliding bar 608, the arc-shaped sliding bar 608 runs through the second rotating plate 606, and the arc-shaped sliding bar The 608 upper casing has a first spring 6081, and the two ends of the first spring 6081 are respectively opposed to the baffle plate 607 and the second rotating plate 606, and the sliding of the second rotating plate 606 is realized through the arc-shaped sliding rod 608 smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com