Method and device for improving fiber yarn forming performance

A fiber and performance technology, applied in the direction of textiles and papermaking, etc., can solve the problems of limited function, gray cloth color difference, end breakage, etc., and achieve the effects of reduced hairiness, improved evenness, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

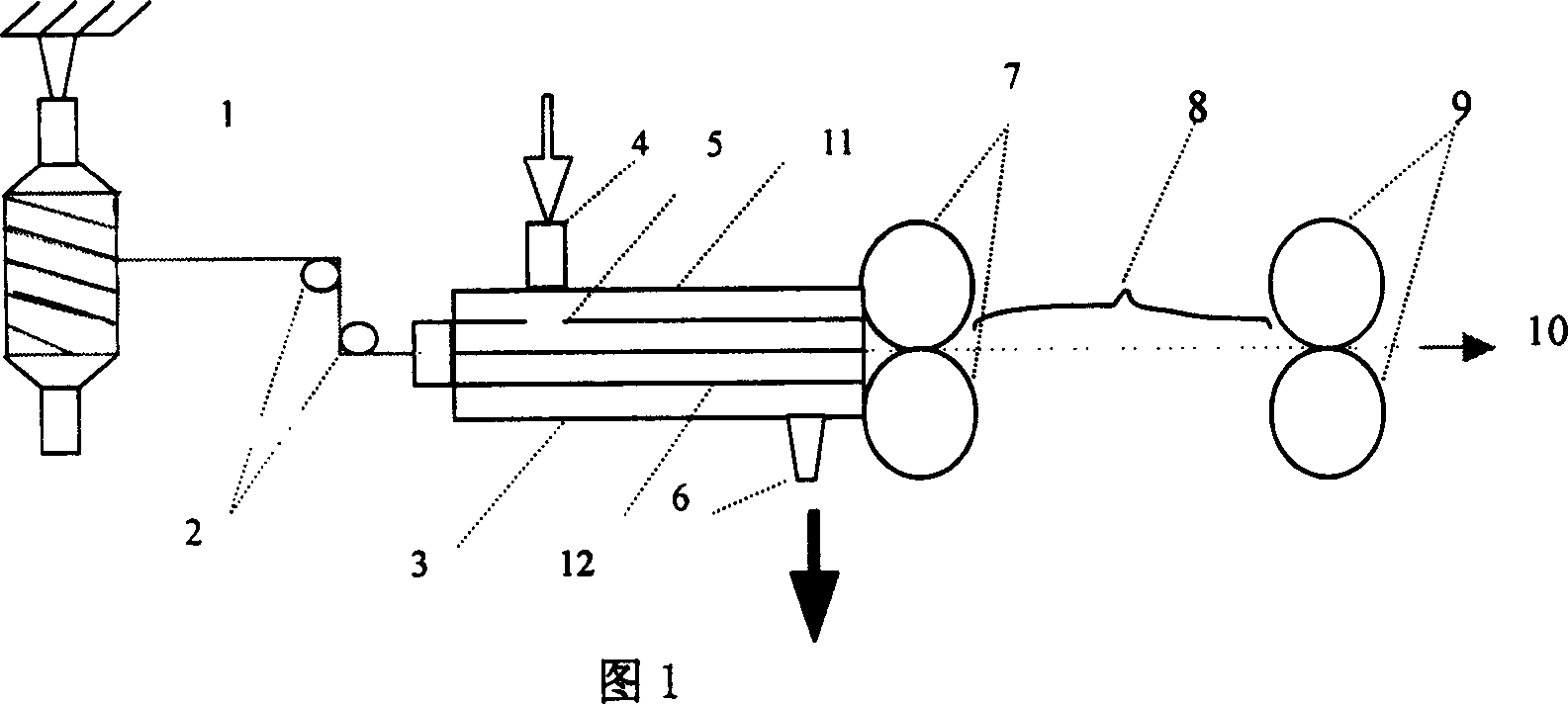

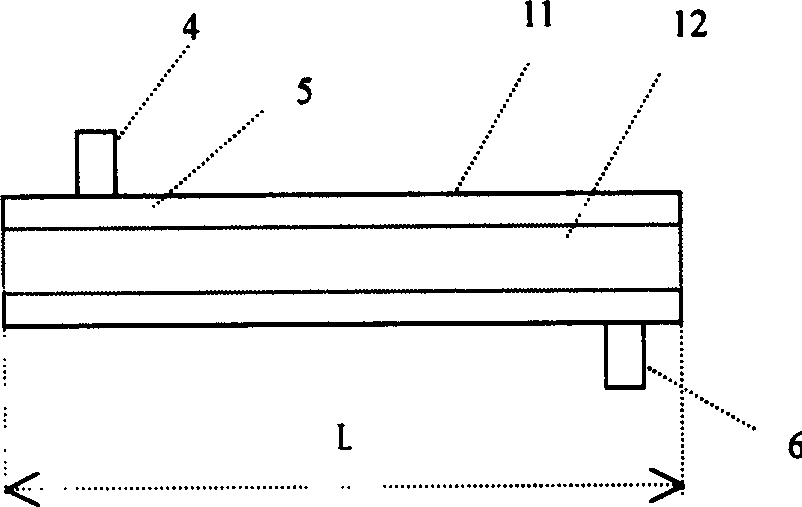

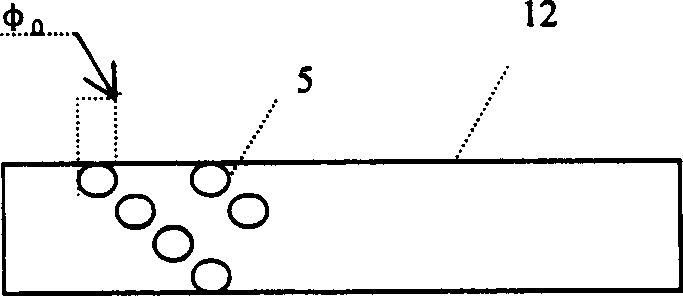

[0012] Taking the spinning frame as an example, the fiber bundles are made of rovings spun from Australian wool, and the high-temperature vapor medium adopts water vapor. The temperature of the water vapor is controlled at 120 degrees, and the relative humidity is 80%. The process is: Australian wool spun The roving 1 passes through the inner tube 12 of the heat-setting device 3 through the guide roller 2, and the water vapor with a temperature of 120°C and a relative humidity of 80% is sprayed into the inlet 4 of the heat-setting device 3, and part of the water vapor is excavated through the inner tube 12 The micropores 5 arranged in a spiral on the wall enter the inner tube 12 to soften and soften the roving spun from Australian wool. 12 is heated and finally discharged from outlet 6. After being softened and softened, the fiber bundle strands enter the drafting zone 8 through the rear roller 7, and are stretched and thinned by the front roller 9 to form a spun yarn 10. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com