Bamboo fiber, Coolmax fiber and conductive fiber blended yarn and method for producing same

A technology of conductive fiber and processing method, which is applied in the field of spinning engineering in the textile industry, to achieve the effect of high strength and less hairiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Raw single fiber

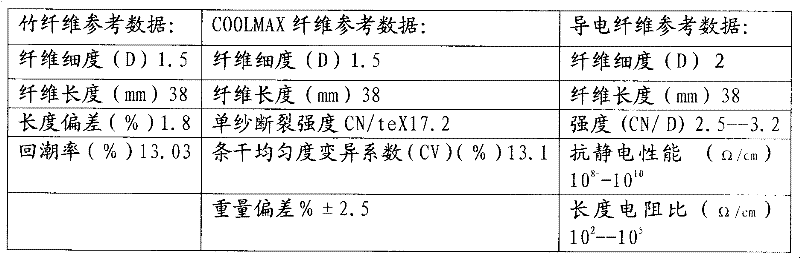

[0019] Bamboo fiber: 1.5D×38mm; COOLMAX fiber 1.5D×38mm; conductive fiber: 2D-38mm.

[0020] Physical and chemical indicators of raw materials

[0021]

[0022] Blending ratio:

[0023] Bamboo fiber 45%-55%; COOLMAX fiber 35%-45%; conductive fiber 0.1-3%.

[0024] Process flow:

[0025] A002D Cotton Picking Machine→A006B Cotton Mixing Machine→A036C Cotton Opener→A092A Cotton Box Inspection Machine→A076 Roller→186H Carding Machine→FA305 Drawing Frame (Pre-Drawing)→FA305 Drawing Frame (Three-way Mixing And) → A456C roving frame → Siro spinning FA506 spinning frame → 1332M winding machine.

[0026] Technical conditions of each process of spinning

[0027] ①Cotton opening and cleaning process: This process adopts the principle of light quantitative, more loose and light beating, combing instead of beating, less beating and early fall, loosening and good cotton bundles as much as possible, so as to achieve less damage to fibers. beater speed to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com