Patents

Literature

45results about How to "Improve twisting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

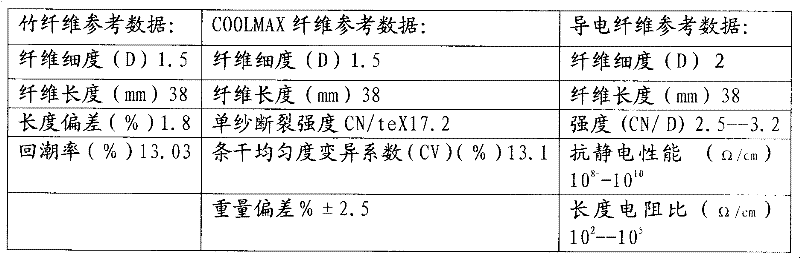

Bamboo fiber, Coolmax fiber and conductive fiber blended yarn and method for producing same

The invention discloses a bamboo fiber, Coolmax fiber and conductive fiber blended yarn and a method for producing the same. The bamboo fiber, Coolmax fiber and conductive fiber blended yarn has functions and characters of the three types of fibers, has complementary advantages, and has unique nobility by being spun by siro-spinning technology. The functional yarn can be used for knitting and tatting. A fabric made of the bamboo fiber, Coolmax fiber and conductive fiber blended yarns has the functions and characters of high strength, fine shape retention, high breathability, high moisture absorption, high sweat releasing, antibiosis, dust proofing, electrostatic resistance, ultraviolet resistance, environment-friendliness, easiness in caring, resistance to washing, stable size, softness and smoothness in touch and the like, is especially suitable for being made into knitted sports underwear, underpants, T-shirts, sportswear, shirts, hats and the like, and contributes to clothing grade increase and improvement on people's life quality, and commercial opportunities are supplied to textile enterprises. Therefore, great social benefit and economic benefit are achieved.

Owner:SHAOXING HENGMEI FANCY SILK +1

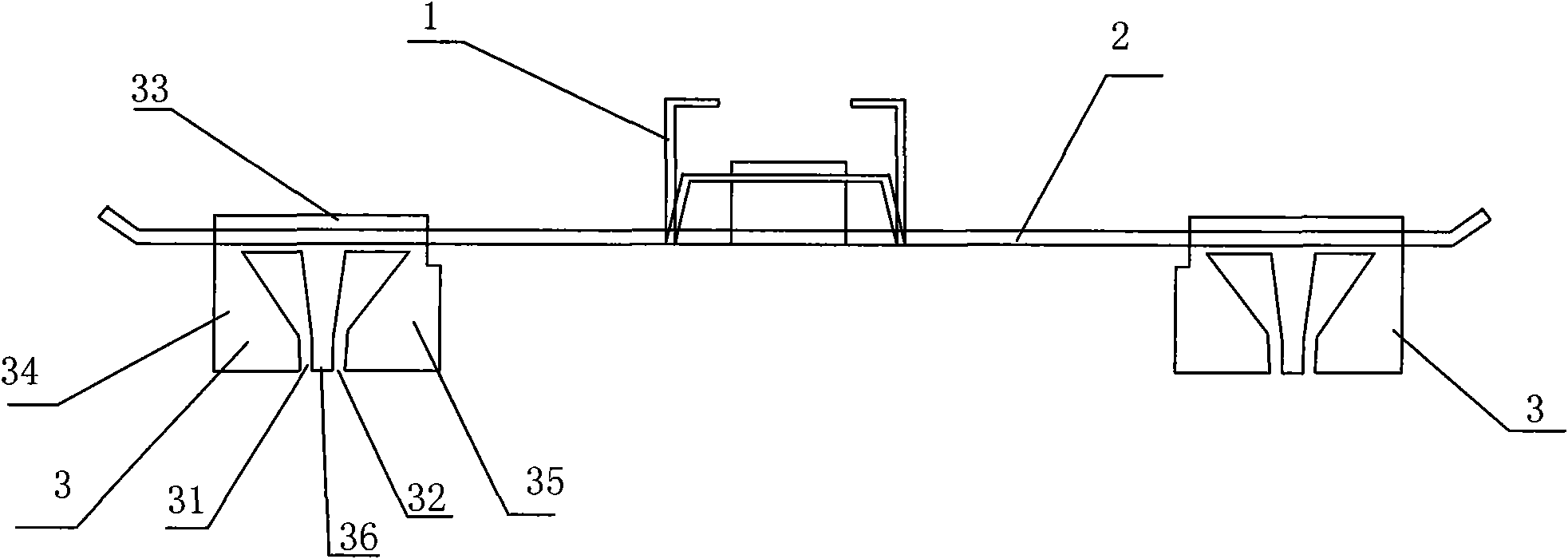

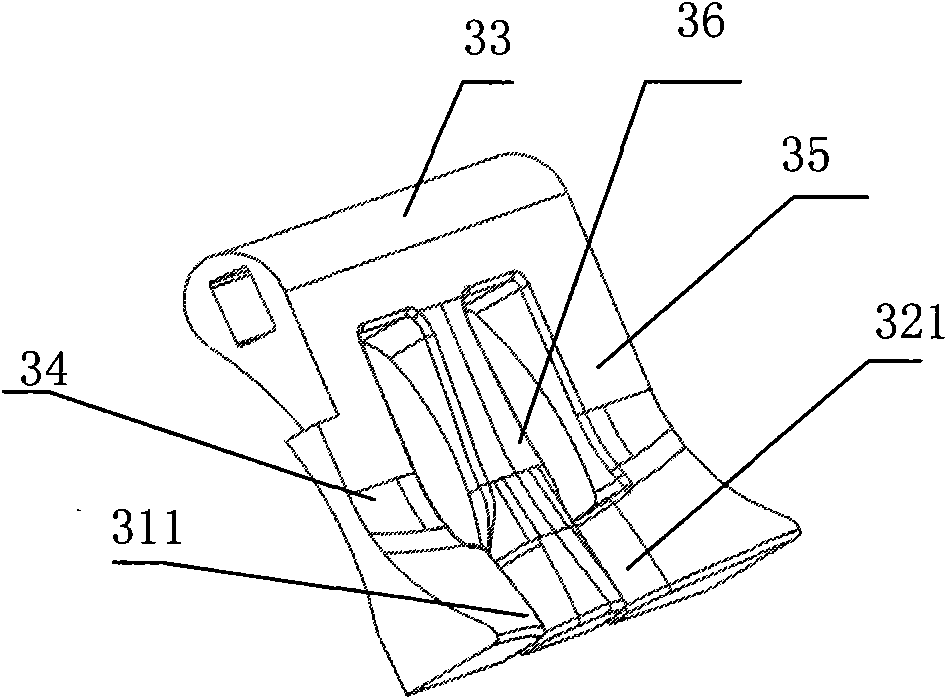

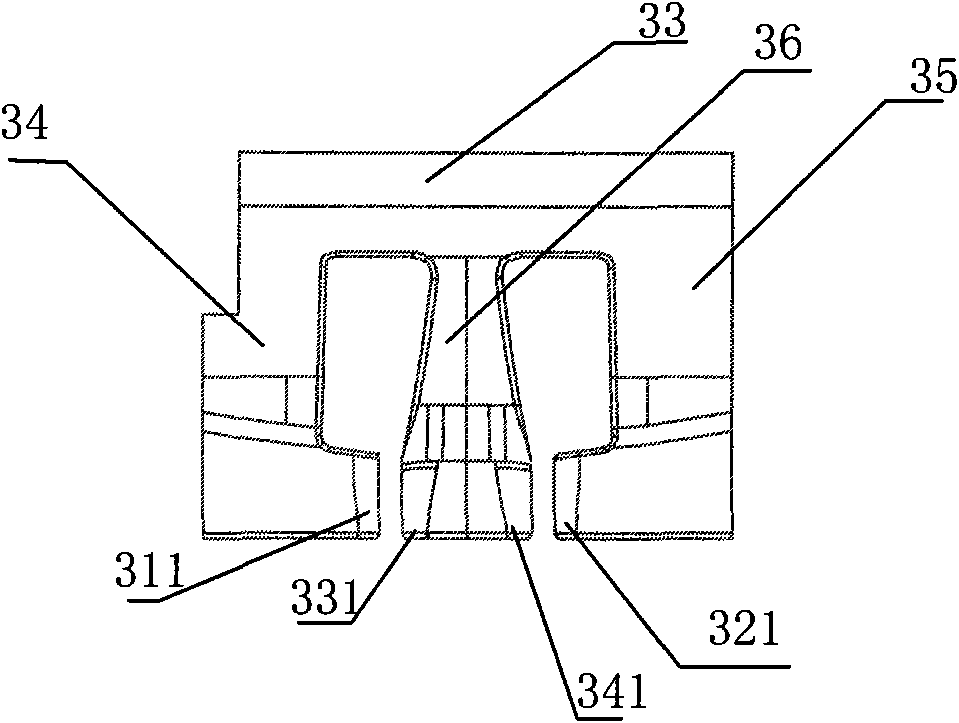

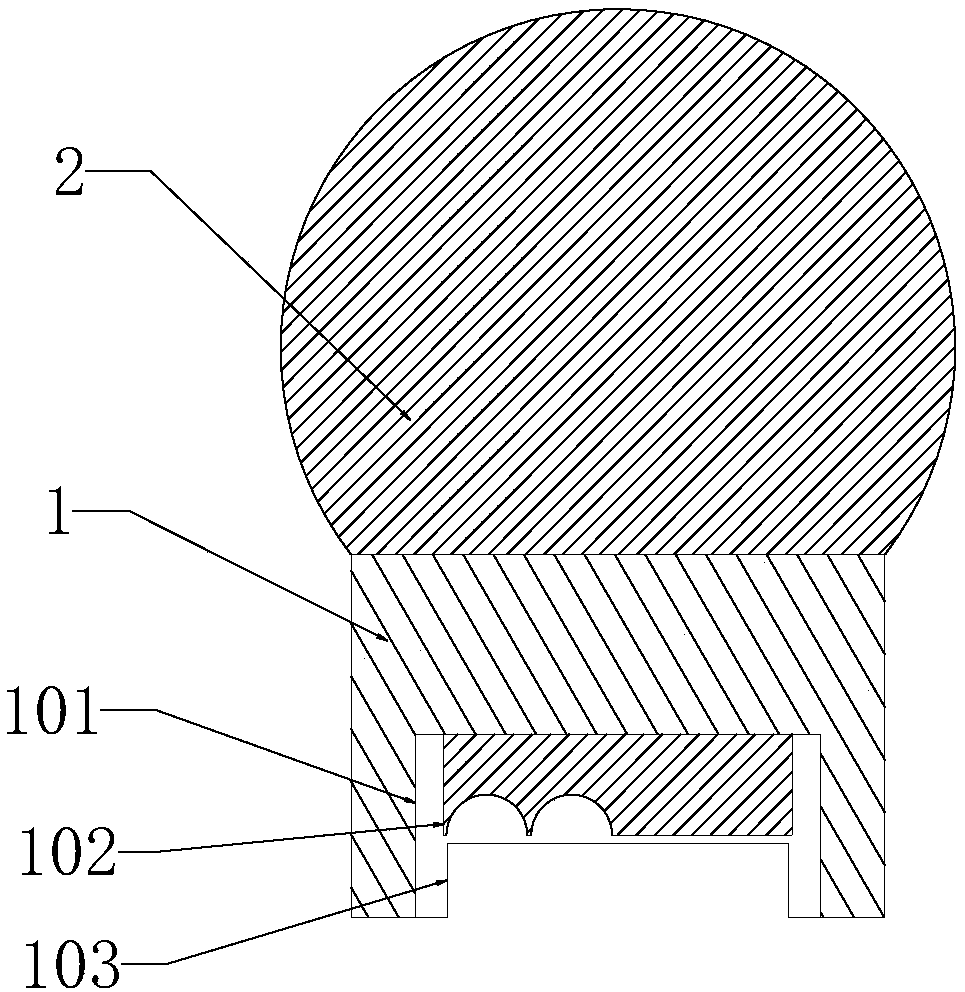

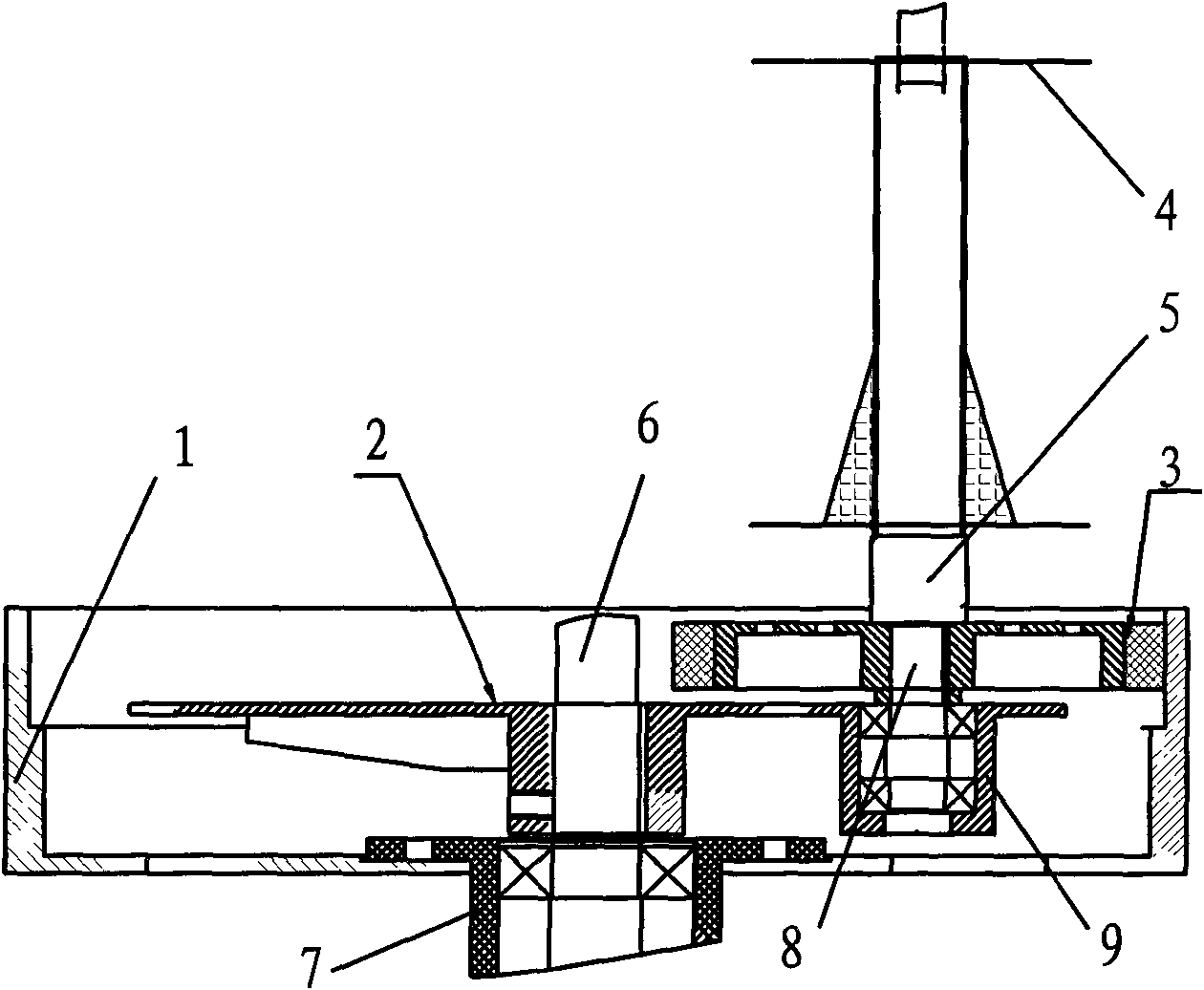

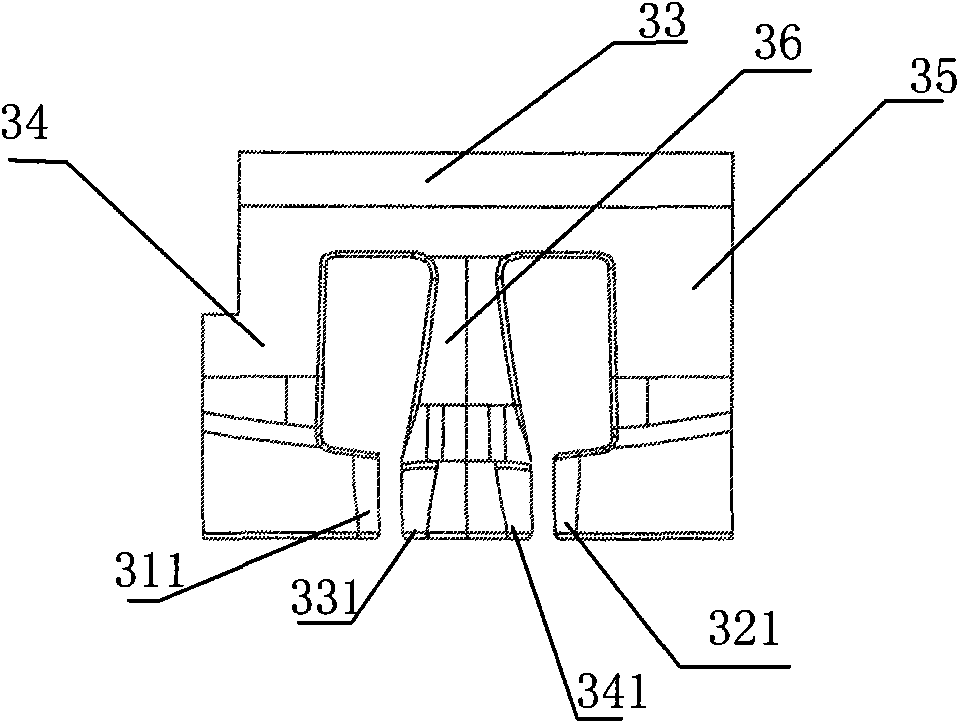

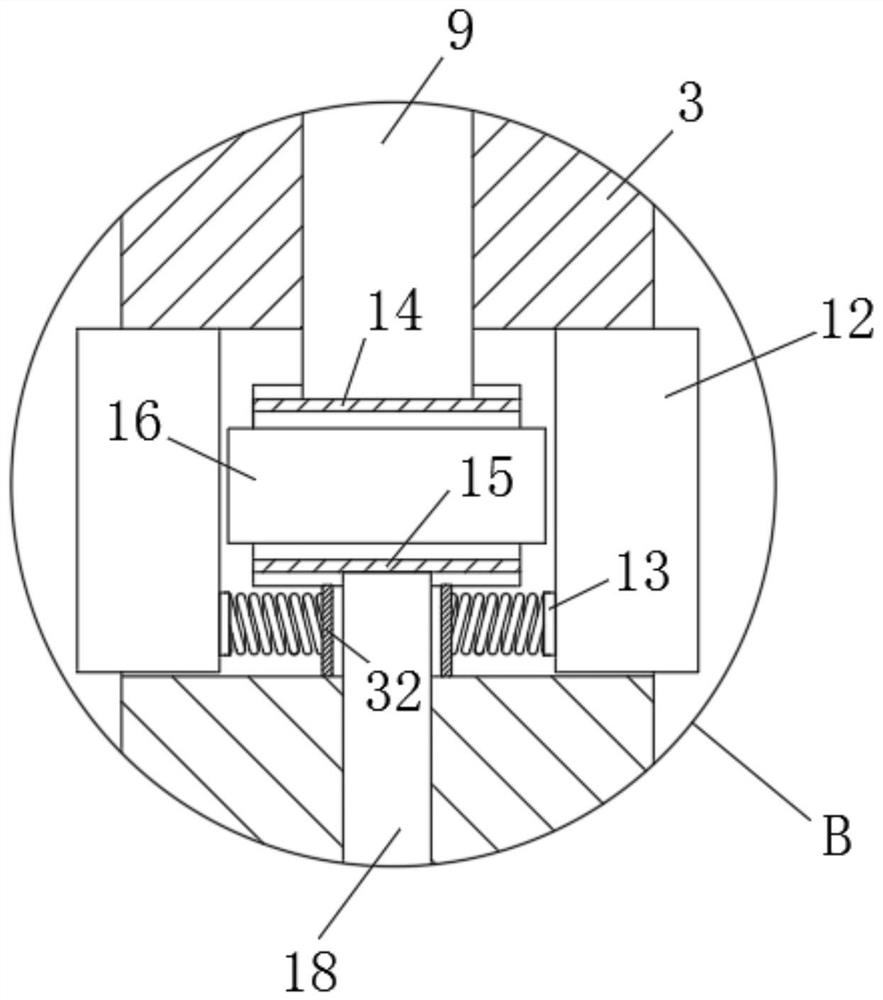

Special-purpose collecting component for cotton type siro spinning

InactiveCN101550620AReduction of hairiness in siro spinningHigh strengthDrafting machinesAgricultural engineeringYarn strength

The invention discloses a special-purpose collecting component for cotton type siro spinning, which comprises a steel wire hook, a connecting shaft and two collecting devices; the steel wire hook is positioned on the middle of the connecting shaft; and the collecting devices are disposed respectively on two sides of the connecting shaft. The invention is characterized in that: the collecting device is disposed with an A clustering port and a B clustering port which are isolated from each other; the width of the A or B clustering port is 1mm-3mm; and the center distance of the A and B clustering port is 3mm-11.5mm. Advantages: by disposing two isolated clustering ports on the collecting device and designing the width of the A or B clustering port as 1mm-3mm, the invention can cluster fibers effectively and reduce the siro spinning hairiness; and the center distance of the A and B clustering port is 3mm-11.5mm, two yarns is drawn by the front leather roller, then is respectively passed the A clustering port and the B clustering port, and the two yarns from respectively from the A clustering port and the B clustering port with even stresses form a larger triangle area with the jointing point, thereby, the invention achieves better twisting effect, improves siro yarn strength, and further reduces the siro spinning hairiness.

Owner:童云章

Reusable straw baling rope convenient for binding and loosening

InactiveCN111021112AElectrically insulatingGood stabilizerRope making machinesConjugated synthetic polymer artificial filamentsEpoxyFoaming agent

The invention discloses a reusable straw baling rope convenient for binding and loosening. The reusable straw baling rope is prepared from the following components of modified polypropylene, compositeepoxy resin, rubber, a plasticizer, a foaming agent, a stabilizer, an anti-aging agent and an anti-corrosive agent. The straw baling rope prepared from the above raw materials has high corrosion resistance, aging resistance and stability, and the service life of the straw baling rope is prolonged, so that the straw baling rope can be reused; moreover, the straw baling rope has elasticity, is convenient to bundle and loosen, and is convenient to use; a single-filament rope forming device used for producing the straw baling rope has the advantages that a process of automatically twisting a ropeby plastic monofilament fibers is completed, the automation degree is high, the working efficiency is improved, and the production yield is improved; through rotation of a twisting barrel and a forming barrel, two times of twisting is performed, so that the twisting effect of the straw baling rope is good, the twisting degree is high, and unraveling is not easy; and the device directly performs thermoplastic molding and cold setting, so that the finished product of the straw baling rope is obtained, and the production cost and the occupied space are reduced.

Owner:界首市宏利塑料股份有限公司

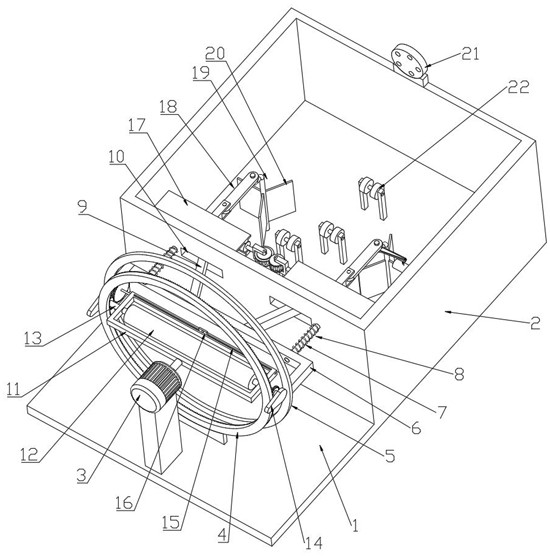

Yarn mixing and twisting device

PendingCN112877837AEasy to slipReduce processing efficiencyContinuous wound-up machinesYarnRubber ring

The invention discloses a yarn mixing and twisting device which comprises a base, wherein a box body is arranged at the top of the base, a first motor is arranged in the base, a first rotating shaft is connected with one end of the first motor, a placing plate is arranged at one end of the first rotating shaft, fixing rods are arranged at the top of the placing plate, the outer surface walls of the fixing rod are sleeved with bobbins, limiting structures are arranged on the upper portions of the outer surface walls of the fixing rods in a sleeving mode, coils are arranged at the top of the placing plate, a supporting plate is arranged in the middle of the interior of the box body, a wire guide hole is formed in the middle of the supporting plate, a second motor is arranged at the top of one side of the box body, a second rotating shaft is connected with one end of the second motor, a winding roller is arranged at one end of the second rotating shaft, and a bearing is arranged at one end of the winding roller. According to the yarn mixing and twisting device, by arranging the placing plate, the fixing rods, the bobbins, limiting rings, fixing pins, ceramic pieces and rubber rings, the twisting efficiency and effect are improved, yarn strands are prevented from being abraded, the bobbins are prevented from falling off, the product quality is improved, the cost is reduced, and the high use value is achieved.

Owner:JIANGSU HONGFENG THREAD TECH CO LTD

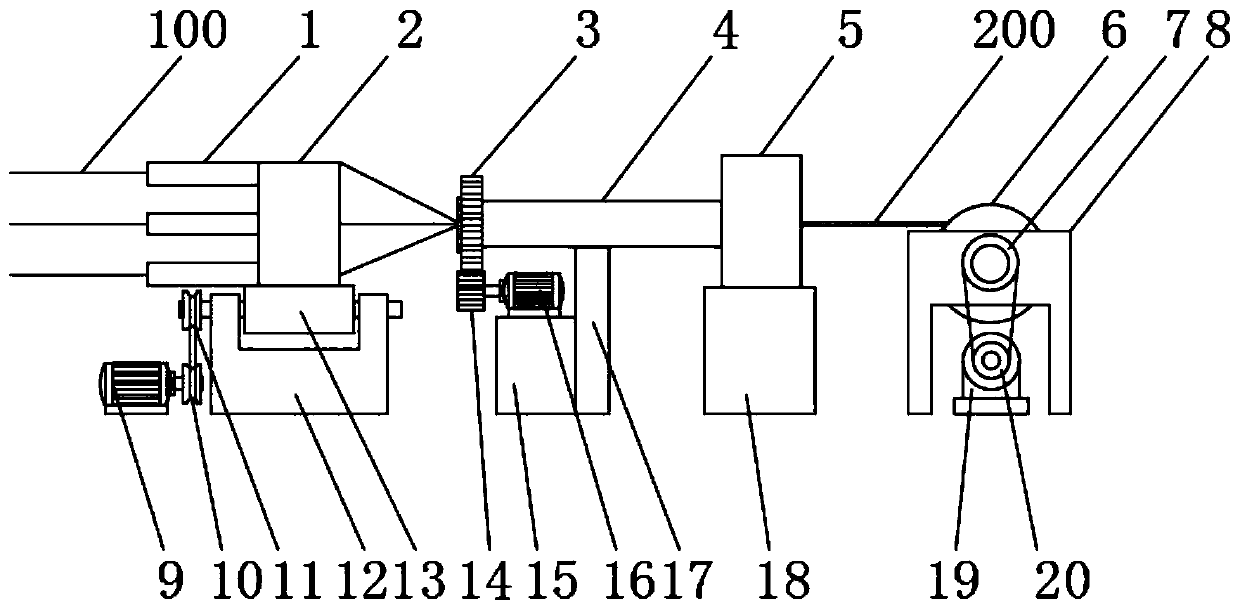

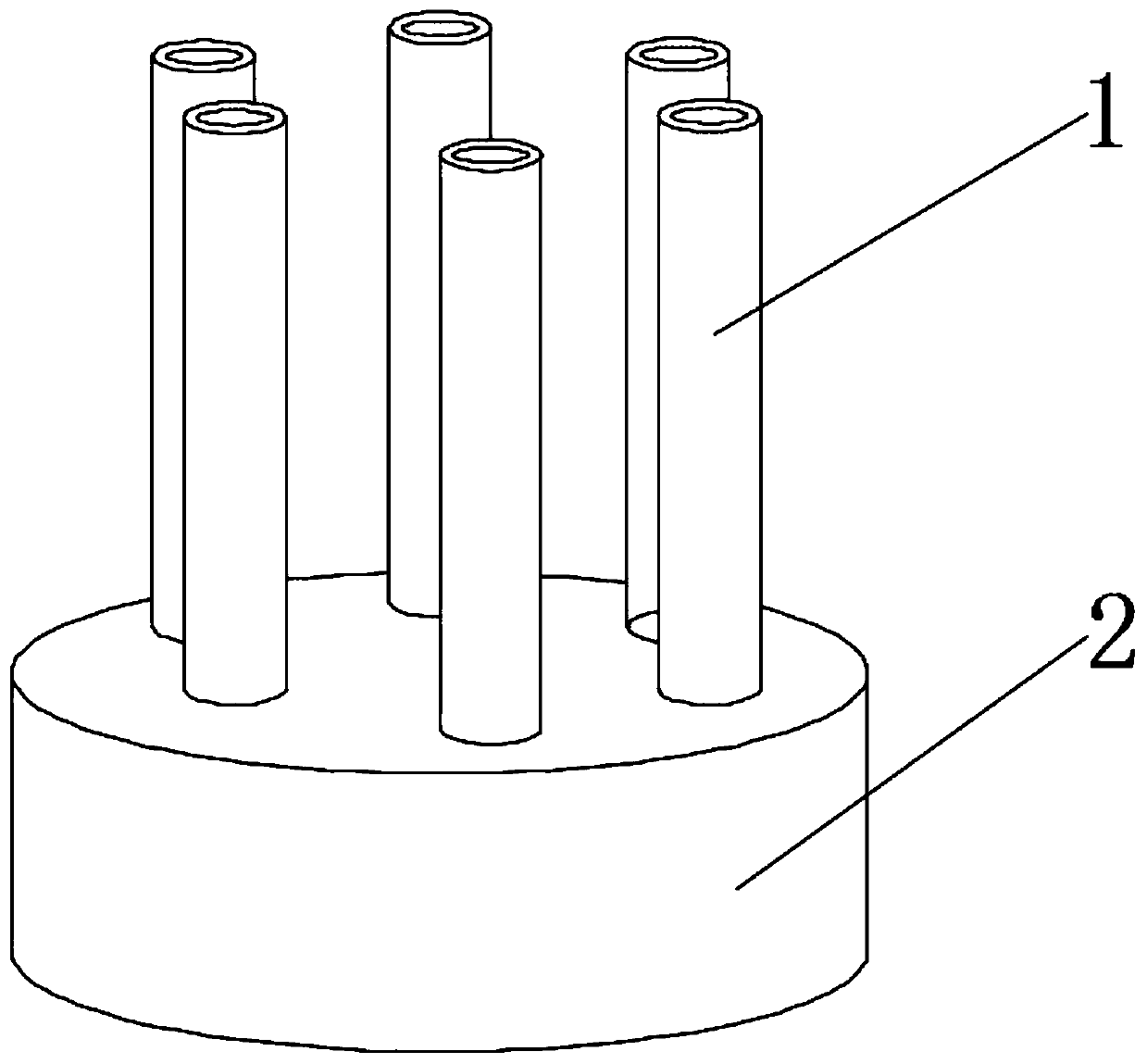

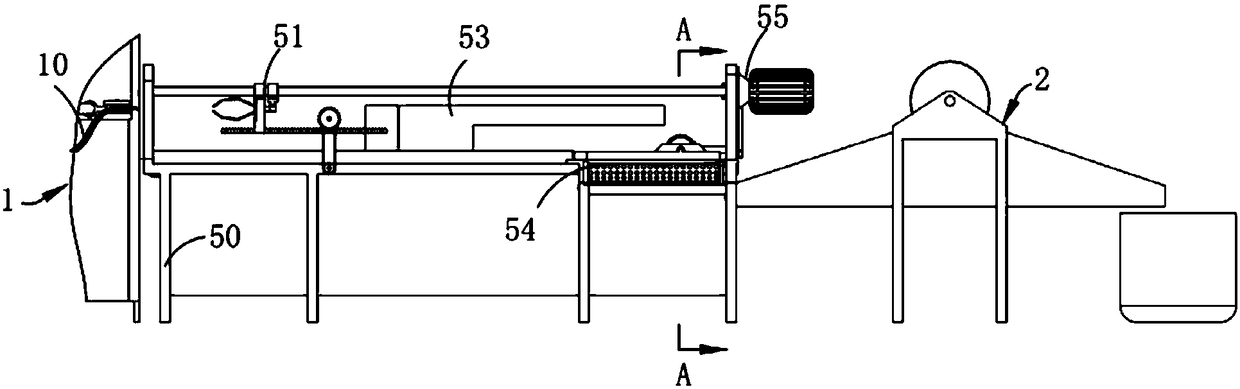

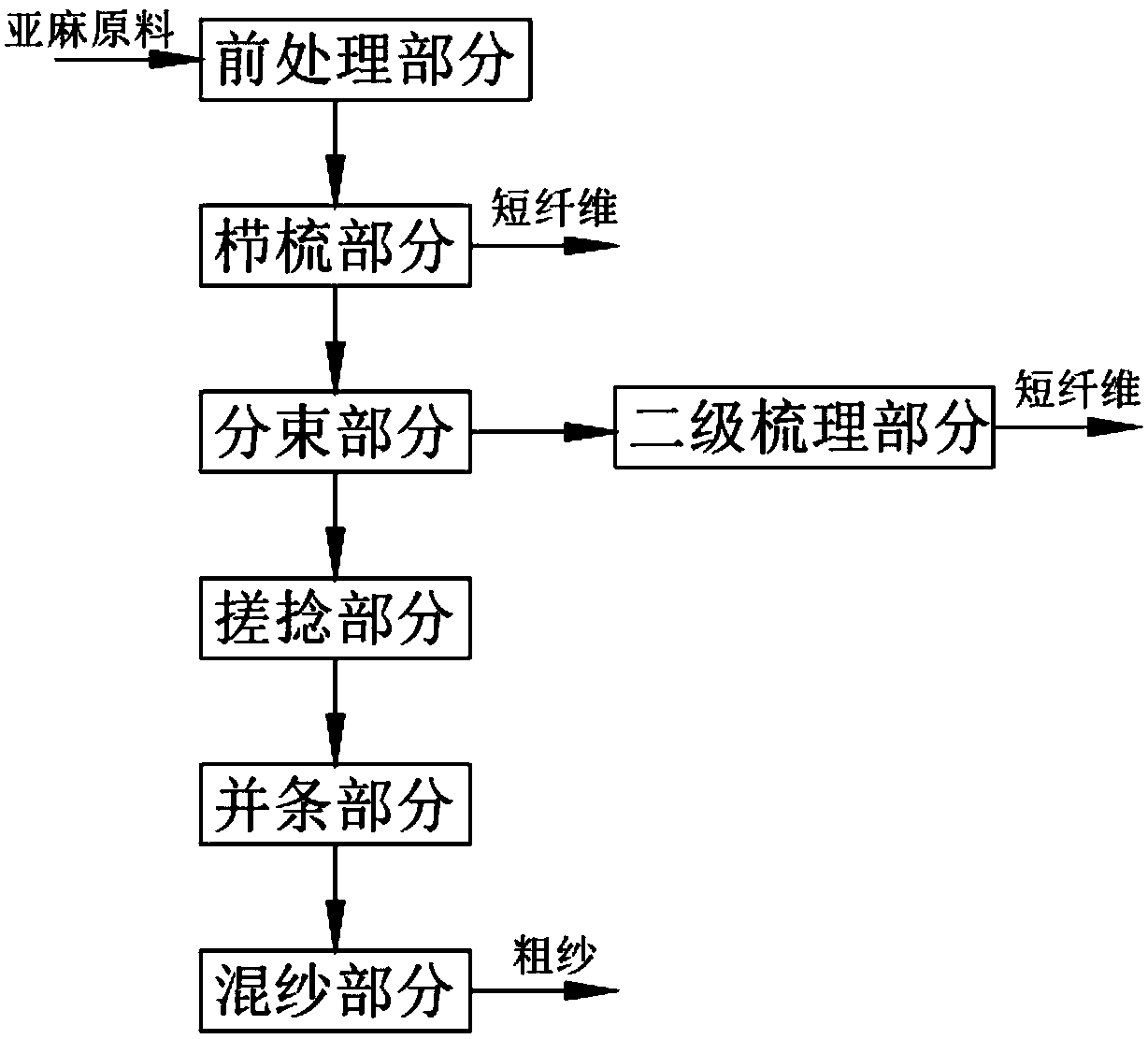

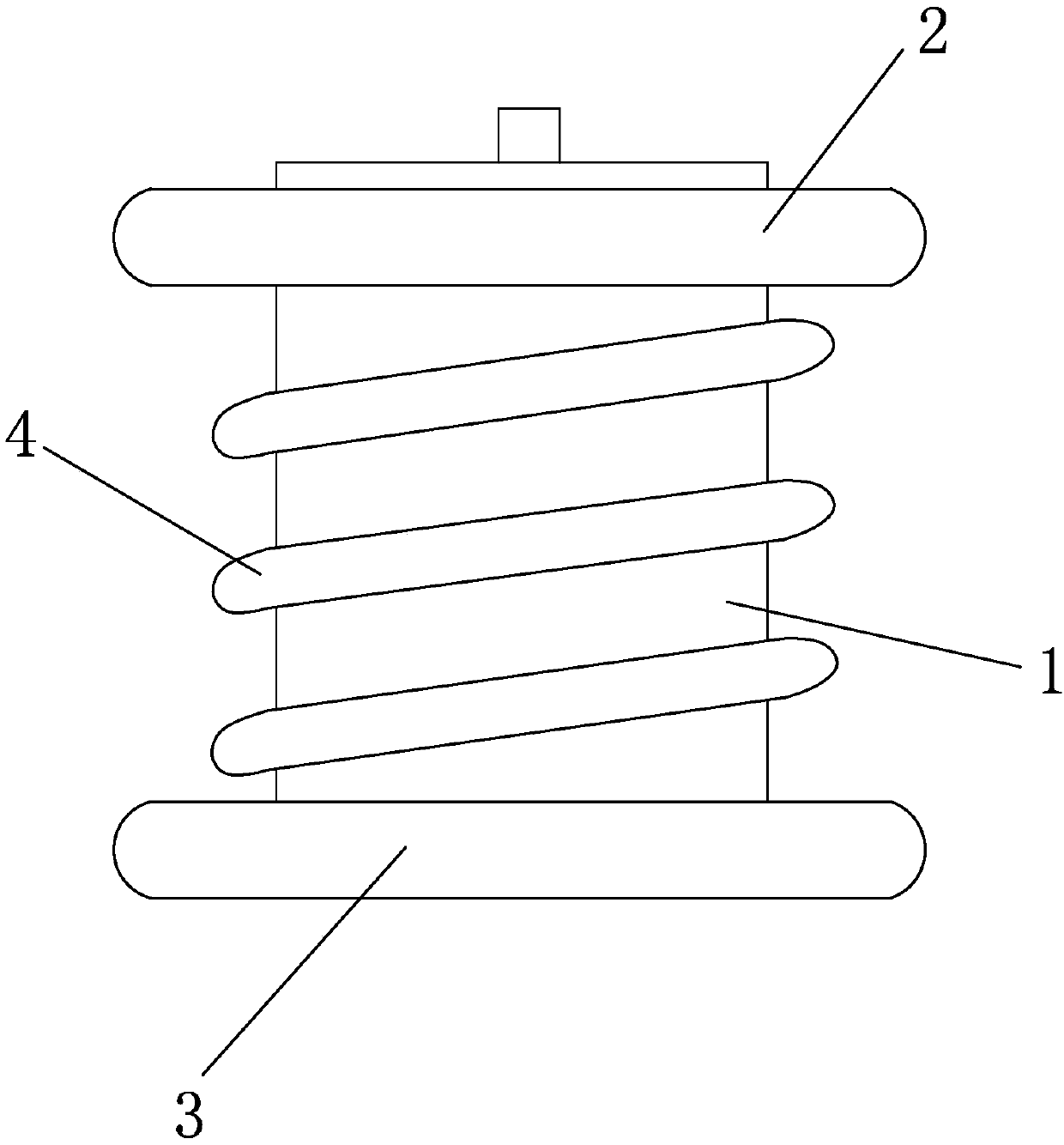

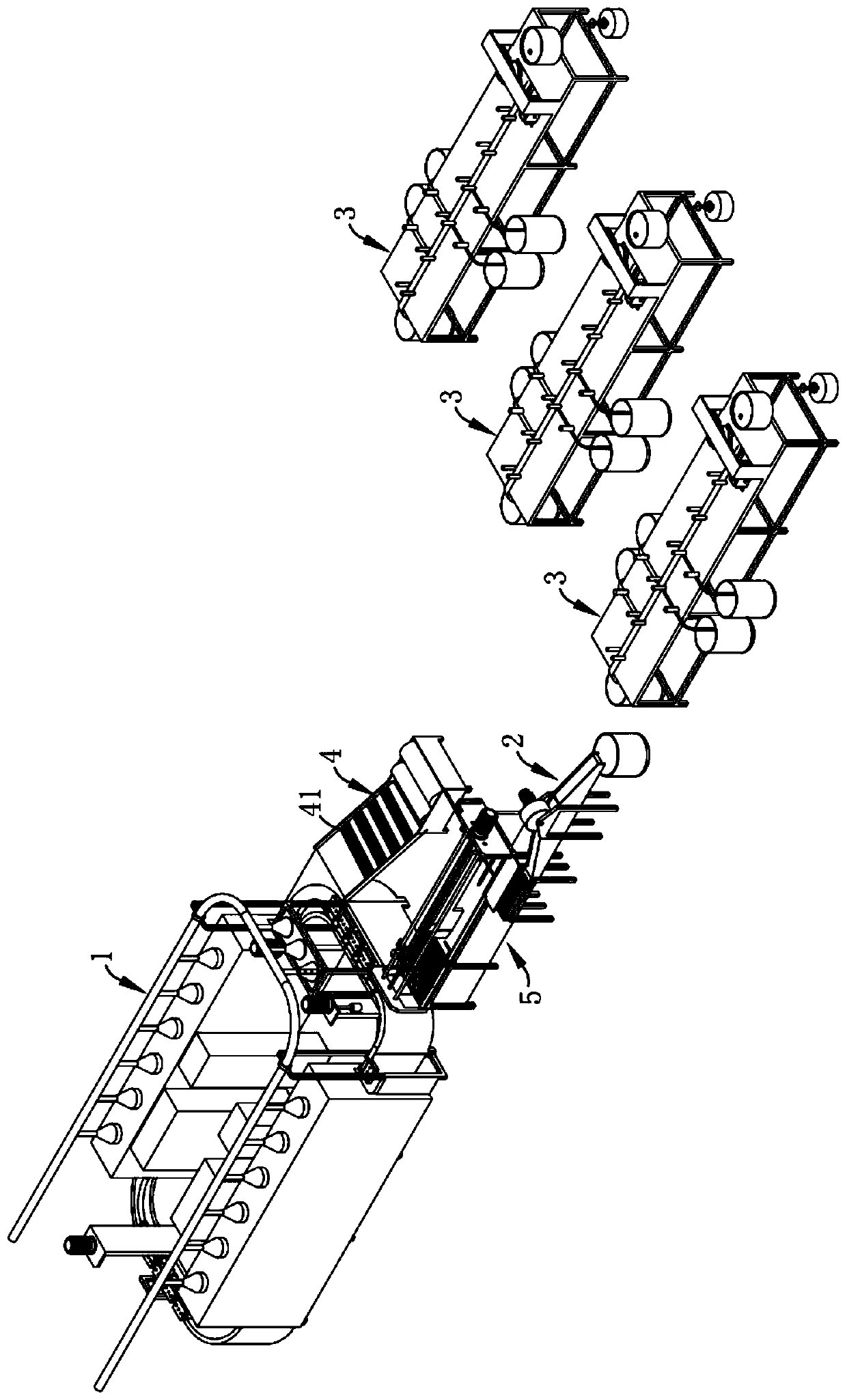

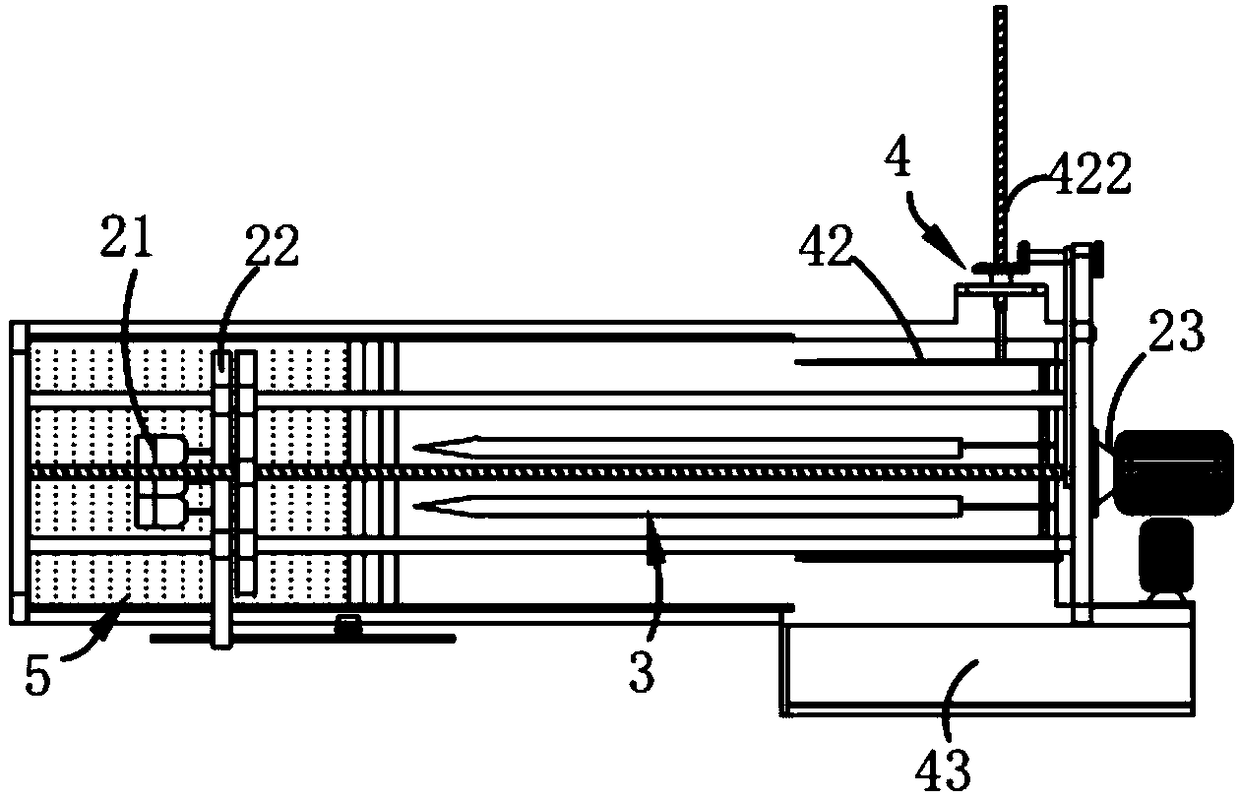

Continuous automatic production line for flax yarn

InactiveCN108950750AAutomate the connectionImprove reliabilityPiercing arrangementsContinuous processingState of artYarn

The invention relates to the technical field of flax yarn production, in particular to a continuous automatic production line for flax yarn. The production line comprises a raw material pretreatment device, a hackling machine, an automatic flax fiber material adding device, a drawing frame and a yarn mixing machine; the automatic flax fiber material adding device comprises a traction mechanism, asplitting mechanism and a material adding mechanism; a fiber bundle obtained after overlapping and winding is transferred into the drawing frame, a fiber rod is formed, and the fiber rod is made intorough yarn through the yarn mixing machine; by means of the traction mechanism, in the process of conducting directional transfer o the flax yarn, short fiber removing and fiber bundle separation areconducted on the flax yarn by cooperating with a carding mechanism and the splitting mechanism respectively, by combining the transmission connection characteristic of a lap joint mechanism and a driving mechanism, automatic winding in the end-to-end lapping process of the fiber bundle is achieved, high-quality automatic production of flax splitting and lapping is achieved, and the technical problem that in the prior art, due to the fact that manual splitting it not uniform, the yarn quality is not stable is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

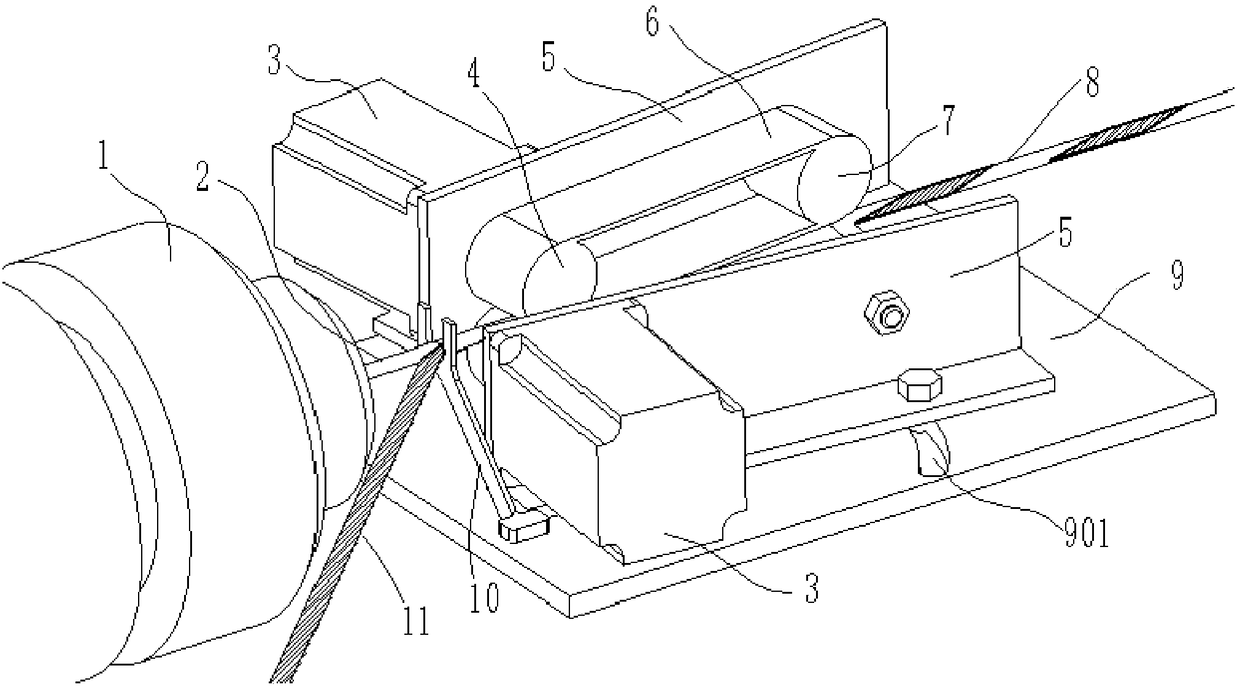

Electric wire copper wire connecting and twisting device

InactiveCN108365496AFacilitate strippingPrevent looseningLine/current collector detailsApparatus for removing/armouring cablesCopper wireEngineering

The invention discloses a electric wire copper wire connecting and twisting device, which comprises a pressing block, a groove, a peeling knife, a strip-shaped groove, movable rods, movable pins, a mounting base, a circular hole column, an annular base, a rotating base, a tapered groove, an L-shaped rod, a bolt, a threaded hole, a round block, a square groove and a rubber sleeve. The peeling knifeis used for cutting a plastic sheath of an electric wire, so as to achieve the effect of peeling off copper wires and the plastic sheath. One ends of electric wires to be connected and twisted together are fixed by means of the strip-shaped groove, thus the firm effect that the copper wires are twisted together is ensured. Through rotating the bolt and driving the round block to move downwards, the round block fixes the copper wire ends of the electric wires in an engaging mode, thereby avoiding the copper wires from loosening when being twisted. The electric wire copper wire connecting and twisting device has the advantages of convenient operation, high functionality and good twisting effect, is convenient for peeling off the plastic sheath of the electric wire, and is convenient for theuser to connect and twist two or more electric wire copper wires, thereby avoiding the occurrence of wire loosening when the user twists and connects the copper wires by hand.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

Production process of regenerated polyester slub yarn

The invention discloses a production process of a regenerated polyester slub yarn. The production process comprises the following steps of: compounding regenerated semi-dull MOY introduced by a raw yarn frame and a zero roller and regenerated semi-dull FDY introduced by the raw yarn frame through a roller; then feeding the compounded yarn bundle into a deformation hot box for heating treatment; then cooling the yarn bundle by a cooling plate, and inputting the yarn bundle into a false twister for twisting; enabling the twisted yarn bundle to pass through a second roller, a network nozzle, an auxiliary roller, a shaping hot box and a third roller; then oiling the yarn bundle by an oiling system; and finally winding the yarn bundle to form polyester slub DTY. The process method is stable inproduction process and high in production efficiency; and the polyester slub yarn finished product prepared by the process is more natural and attractive in color and better in performance.

Owner:浙江佳人新材料有限公司

Transmission device for friction pulley of rope twisting machine

The invention discloses a transmission device for a friction pulley of a rope twisting machine, belonging to a transmission device of a frication wheel. The device comprises a chassis, a tray and a rubber plate wheel, wherein the tray is arranged on the upper end of the chassis, the rubber plate wheel is connected with the tray, the outer wall of the rubber plate wheel frictionally contacts with the tray; the chassis is a basin-shaped wheel; and a rubber layer is arranged on the outer wall of the rubber plate wheel. When the rope twisting machine works, power drives a main shaft to rotate, themain shaft drives the tray to run, the running of the tray enforces the rubber plate wheel to frictionally run along an incircle of the chassis in acceleration; and under the action of the rubber plate wheel, a coil plate automatically rotates to form throwing and twisting. The invention has advantages that frictional transmission is adopted, and rubber is paved on the contacting surface of the rubber plate wheel, so the device has low transmission noise and high and stable running speed without lubricating, thereby improving the production yield, reducing the manufacture cost of the machine,saving the occupied space and improving the effect of twisting ropes.

Owner:韩百峰

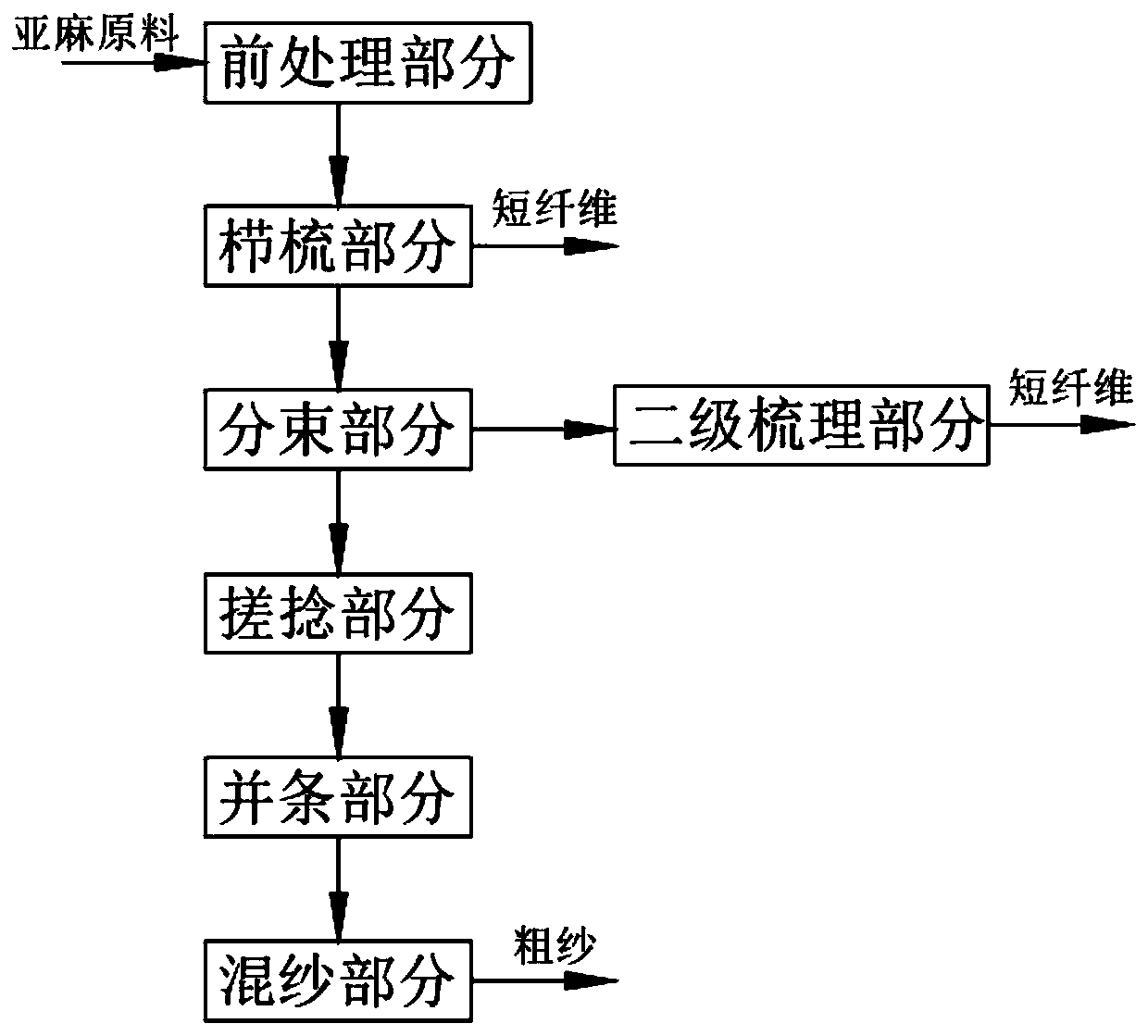

Continuous automatic production method of linen yarn

The invention relates to the linen yarn production technology field and especially relates to the continuous automatic production method of a linen yarn. A front processing portion, a heckling portion, a beam splitting portion, a twisting portion, a drawing portion and a blended yarn portion are included. After a linen raw material is split into a plurality of raw material bundles, a hackling machine carries out carding on the raw material bundles so as to obtain long fibers and short fibers. When the long fibers are transferred, the long fibers are split into bundles and the fiber bundles aresequentially pushed into an output component. Through the output component, the previous group of fiber bundles and the next group of fiber bundles in the output component are overlapped in an end-to-end mode, and during an output process, the fiber bundles are staggered and intertwined. A bundle splitting mechanism is used to split the long fibers in a directional transfer process through a guiding splitting mode, and then, the two adjacent groups of fiber bundles are directionally output in an end-to-end overlapping manner, and at the same time automatic winding is performed so as to realize the high-quality automatic production of linen splitting and lap joint. The technical problem of unstable yarn quality due to uneven artificial bundle splitting existing in the prior art is solved.

Owner:湖北蜀峰线业发展有限公司

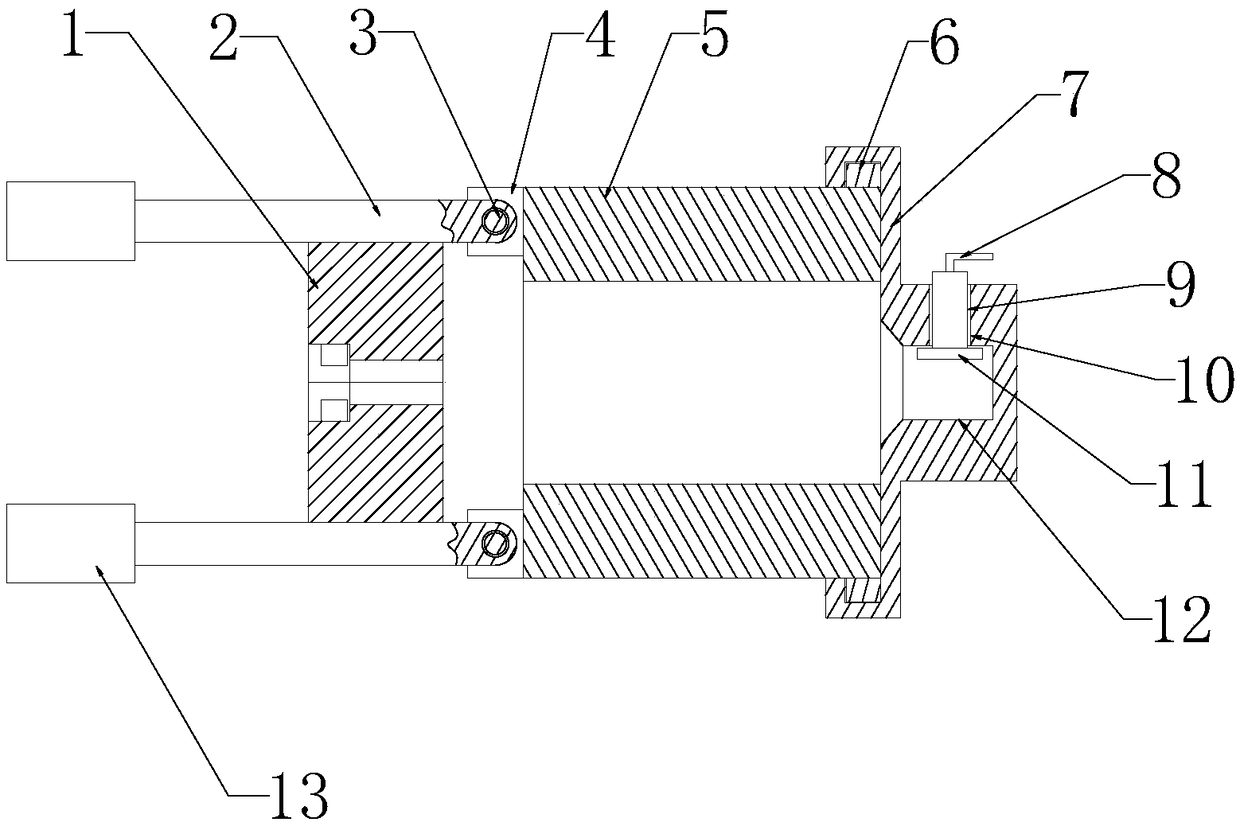

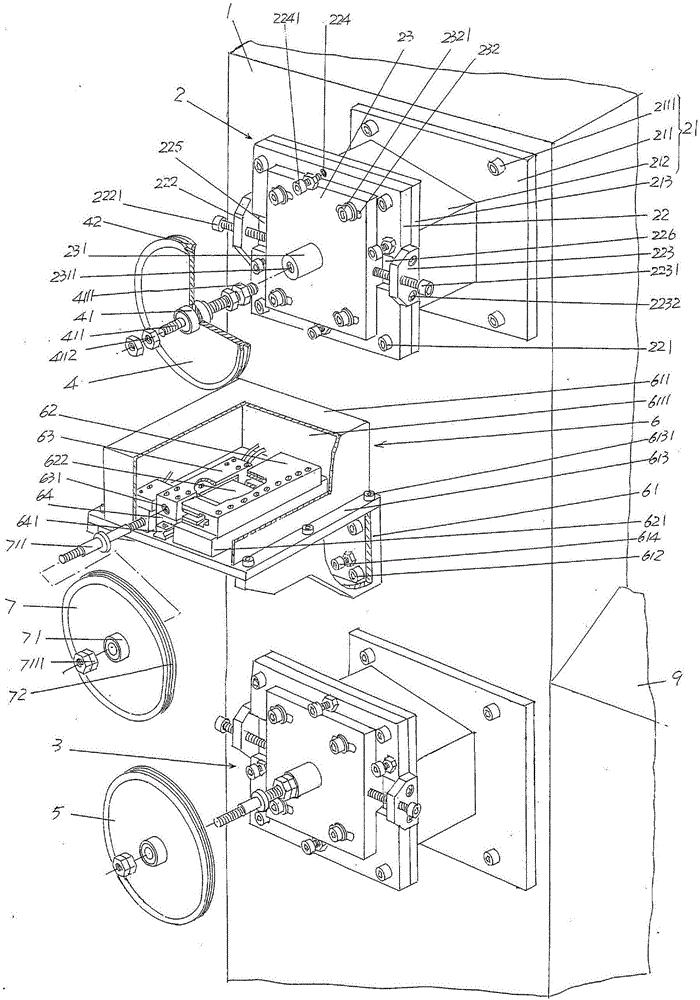

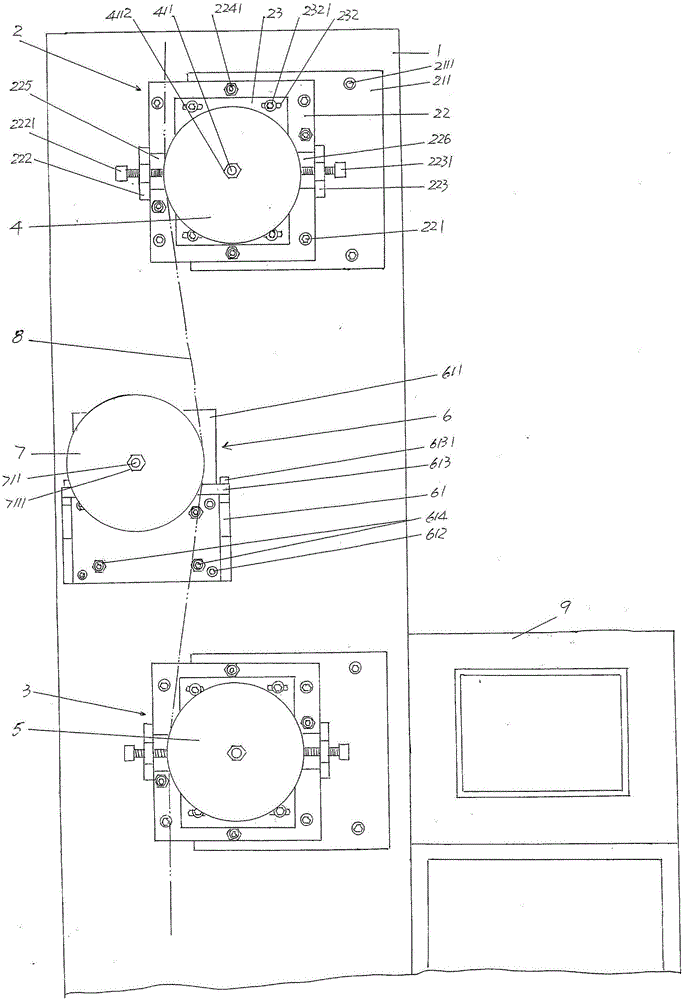

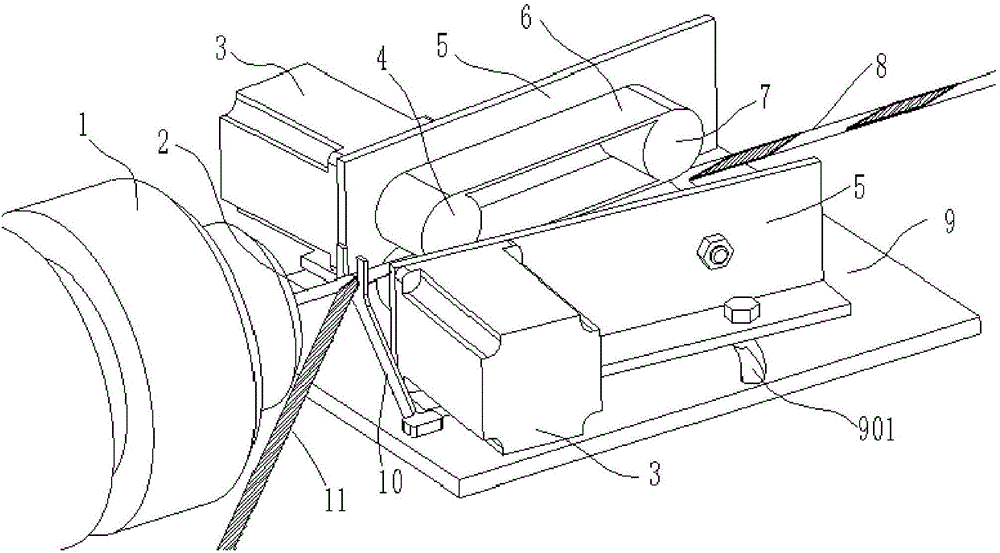

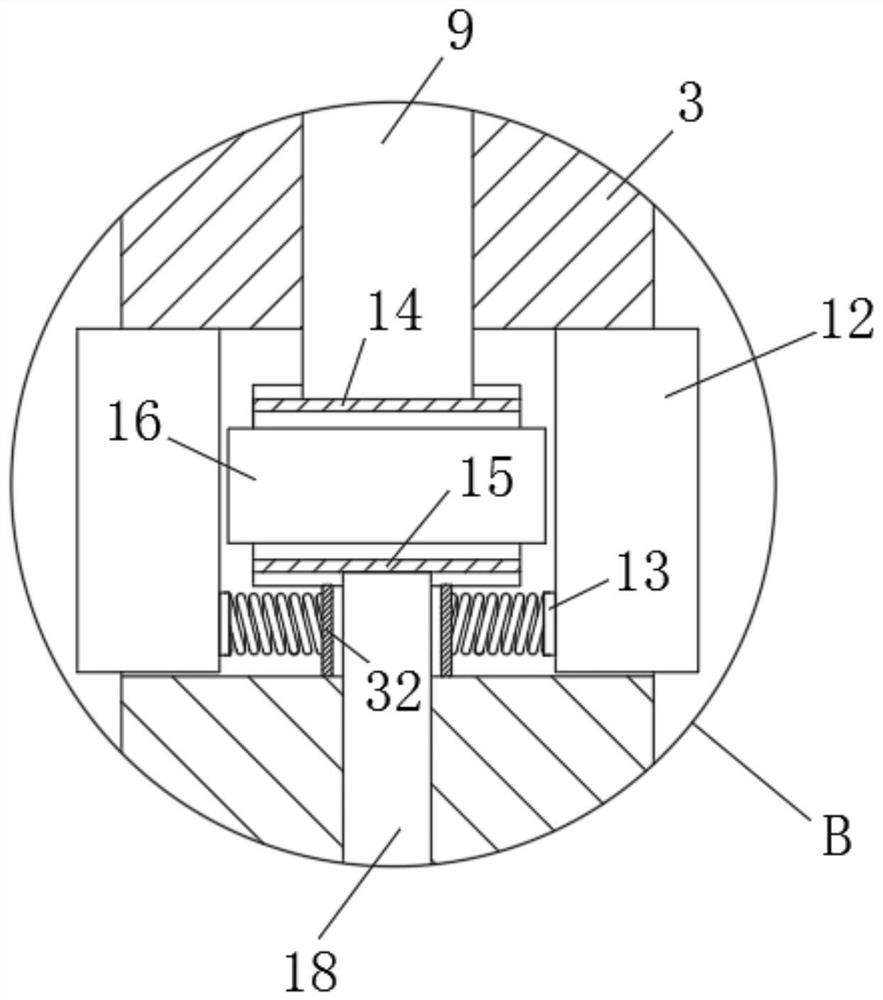

Optical fiber rub twist device

ActiveCN106630588AAvoid damageGood twisting effectGlass making apparatusGlass productionEngineeringMechanical engineering

The invention discloses an optical fiber rub twist device, and belongs to the technical field of auxiliary facilities in optical fiber production. The optical fiber rub twist device comprises a machine frame, a rub twist wheel reciprocate driving mechanism, and a rub twist wheel; an upper orientation wheel supporting mechanism and a lower orientation wheel supporting mechanism are arranged on the machine frame in an upper-lower opposite manner; an upper orientation wheel is arranged on the upper orientation wheel supporting mechanism, a lower orientation wheel is arranged on the lower orientation wheel supporting mechanism; the upper orientation wheel and the lower orientation wheel are arranged in an opposite manner; the rub twist wheel reciprocate driving mechanism is arranged on the machine frame between the upper orientation wheel supporting mechanism and the lower orientation wheel supporting mechanism; the rub twist wheel is connected with the rub twist wheel reciprocate driving mechanism; the distance from the upper orientation wheel to the rub twist wheel is equal to that from the lower orientation wheel to the rub twist wheel; optical fiber is introduced into the rub twist wheel via the upper orientation wheel, and is delivered out from the lower orientation wheel under rub twisting conditions by the rub twist wheel; the moving path of the optical fiber shapes like S. Damage of optical fiber is avoided, optical fiber coating layer concentricity is ensured, and optical fiber PMD is reduced effectively.

Owner:QINGHAI ZHONGLI OPTICAL FIBER TECH CO LTD

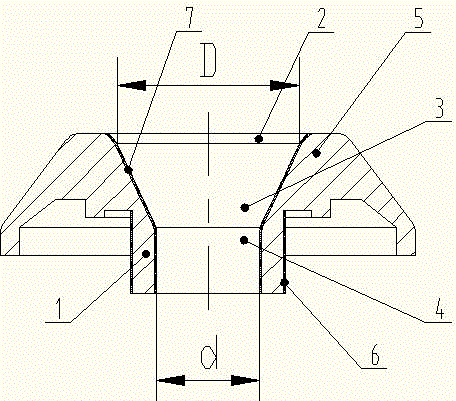

Novel efficient twisting device

The invention discloses a novel efficient twisting device. The novel efficient twisting device comprises a tapered ring at the upper part, and a shaft sleeve at the lower part; the tapered ring and the shaft sleeve are integrated; a yarn feeding propping hole, a twisting hole and a releasing hole are formed in the tapered ring and the shaft sleeve from top to bottom; wearable layers I are arranged on the walls of the yarn feeding propping hole, the twisting hole and the releasing hole. The novel efficient twisting device is characterized in that a wearable layer II is arranged on the outer wall of the shaft sleeve; the diameter D of the twisting hole is 2 times the diameter d of the releasing hole. The novel efficient twisting device is high in wear resistance, long in service life, and high in twisting effect.

Owner:JIANGSU TAIDA TEXTILE

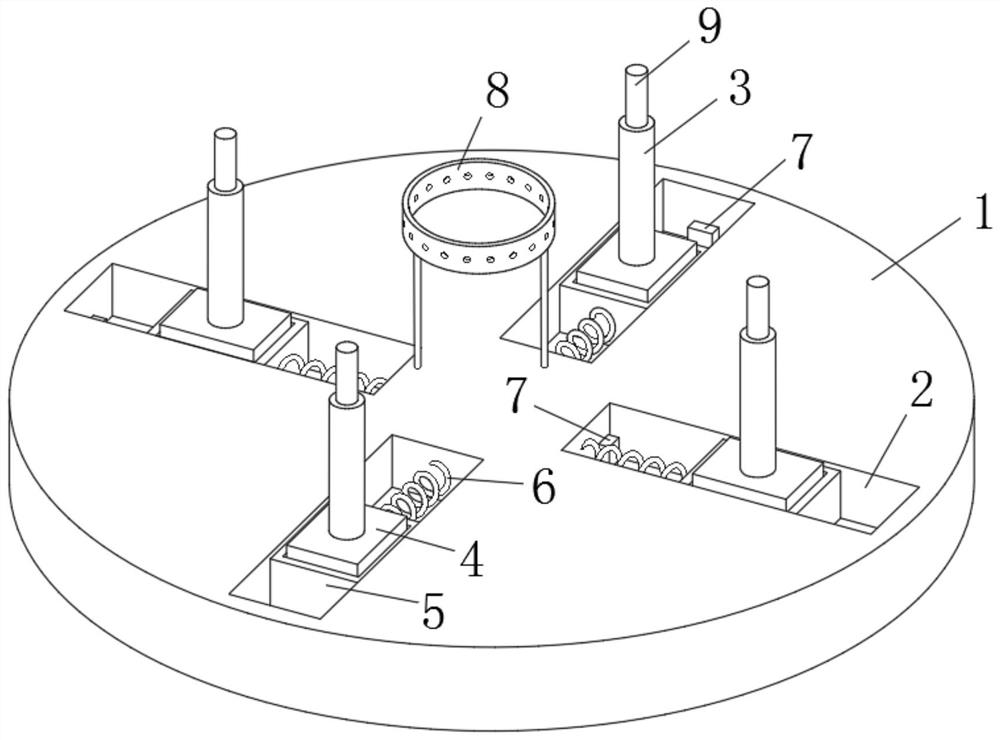

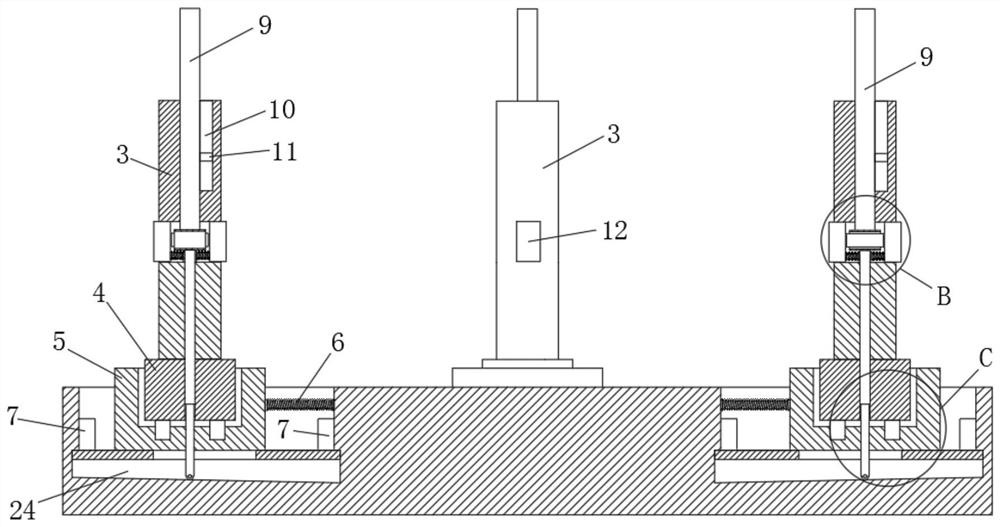

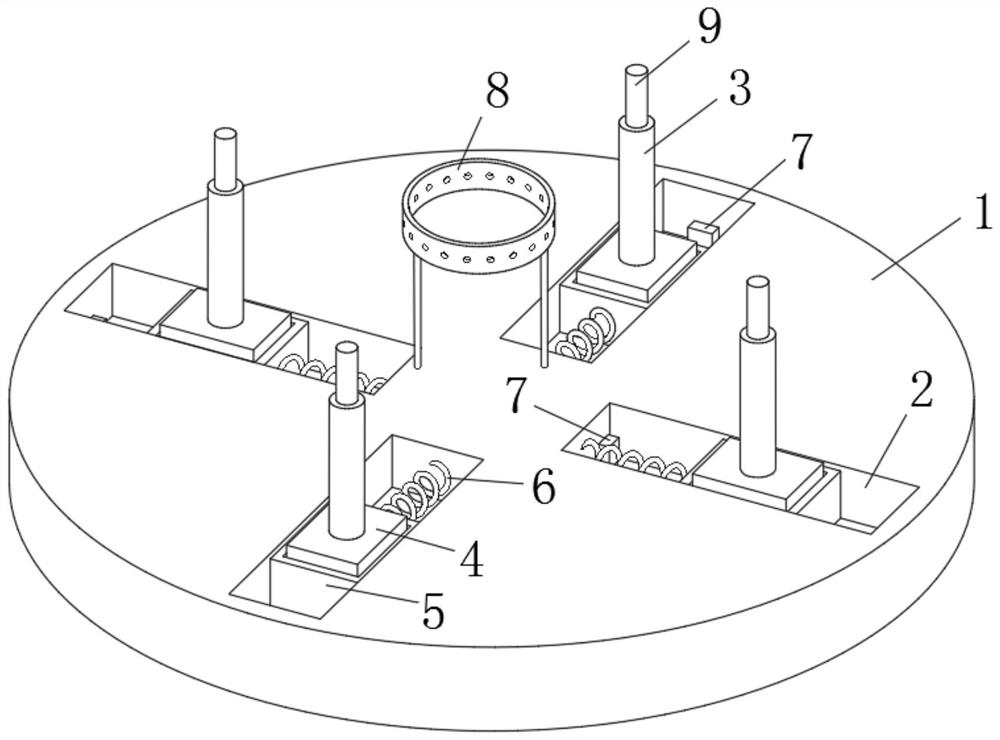

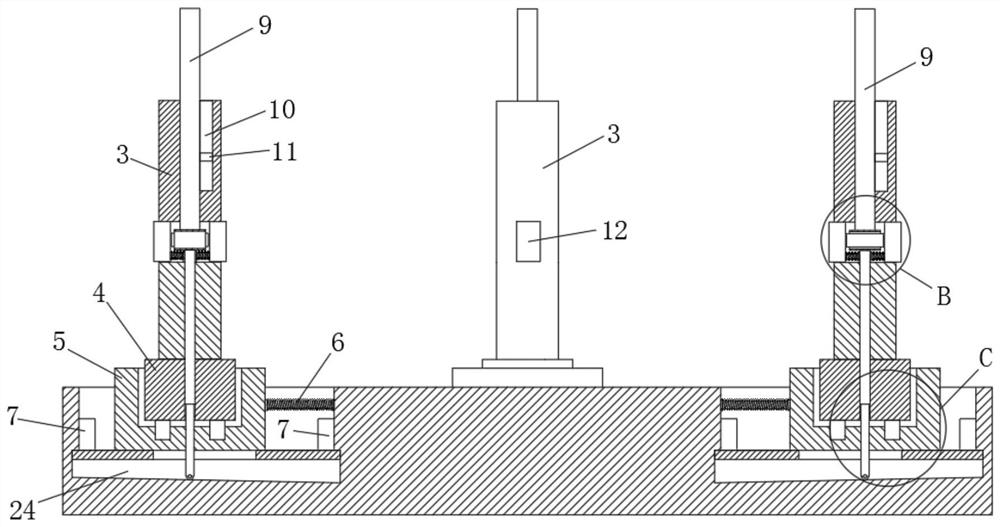

Twisting mechanism for spinning machine

The invention relates to the field of spinning machines, in particular to a twisting mechanism for a spinning machine. The twisting mechanism comprises a rotary table; a plurality of sliding grooves are formed in the rotary table; sliding blocks are slidably connected inside the sliding grooves; grooves are formed in the tops of the sliding blocks; fixed blocks are connected inside the grooves; vertical rods are fixedly connected to the tops of the fixed blocks; a rotating ring is connected to the upper portion of the center of the rotary table through a connecting rod; thrust springs are arranged at the ends, close to the rotating ring, of the sliding blocks; the two ends of each thrust spring are fixedly connected with the inner wall of the corresponding sliding groove and the corresponding sliding block; switches are mounted on the side walls, close to one side of the rotating ring, of the sliding grooves and the side walls, away from one side of the rotating ring, of the sliding grooves; a top sliding rod is vertically and slidably connected to the center of each vertical rod; an upper sliding plate is rotatably connected to the bottom of each top sliding rod; a lower sliding plate is arranged below each upper sliding plate; an air bag is arranged between each upper sliding plate and the corresponding lower sliding plate; side plates are arranged on the two sides of each air bag; the upper sliding plates and the lower sliding plates are slidably connected with the side plates; friction blocks are arranged at the two ends of each air bag; and the friction blocks penetrate through the side walls of the vertical rods and are in sliding connection with the side walls of the vertical rods.

Owner:JIANGSU NASKA NEW MATERIAL TECH CO LTD

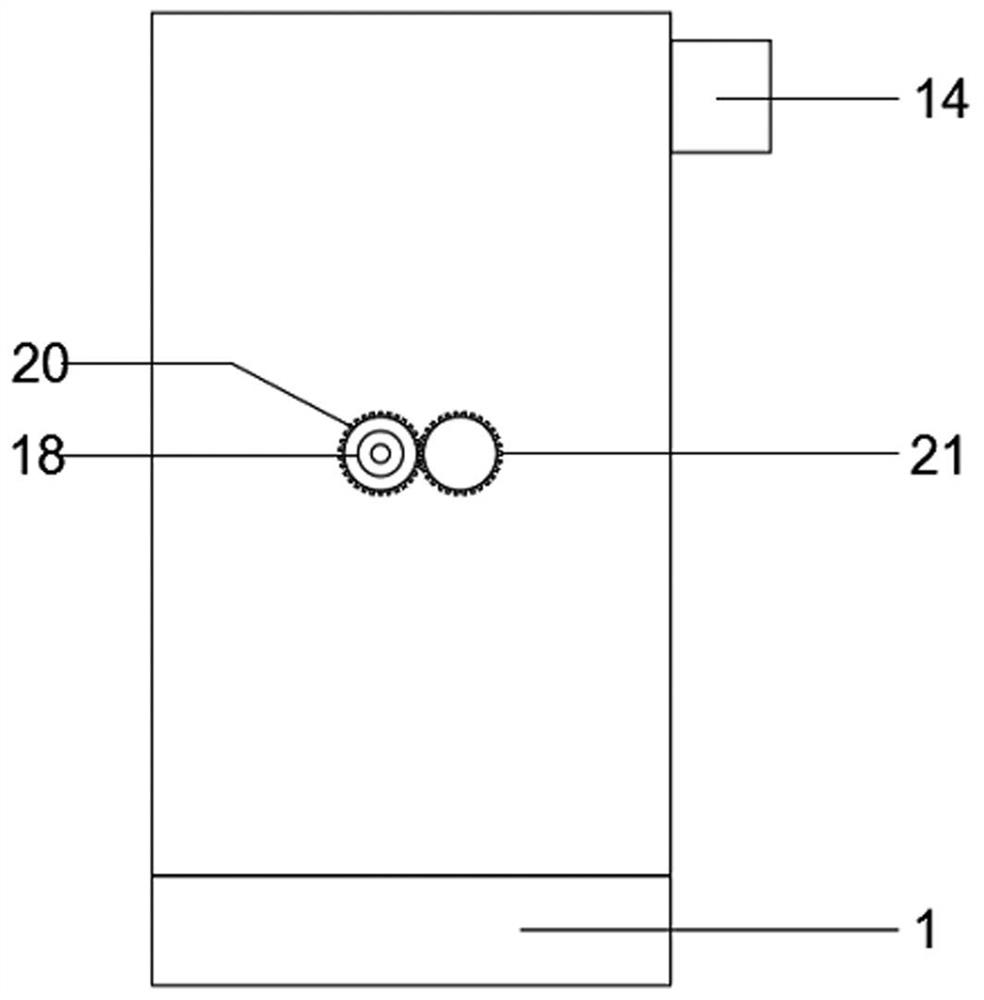

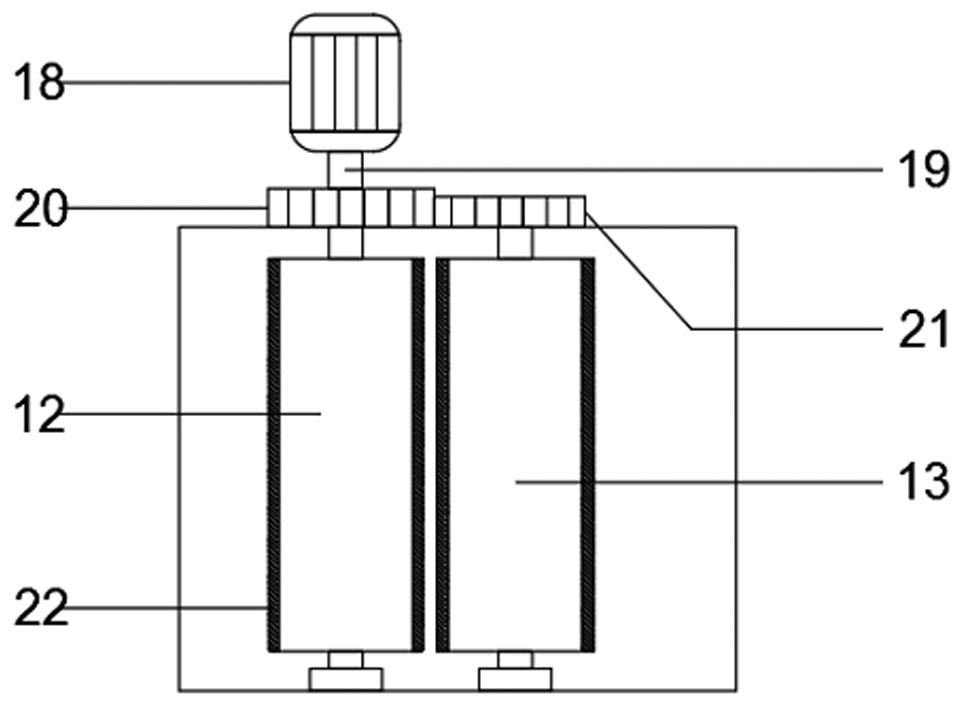

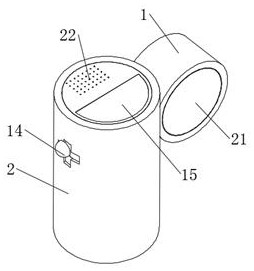

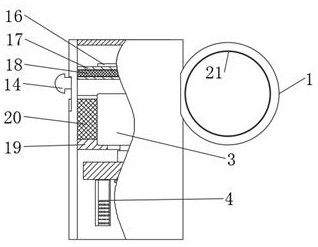

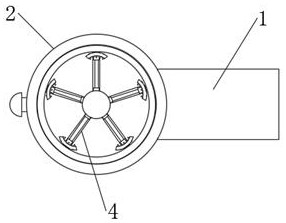

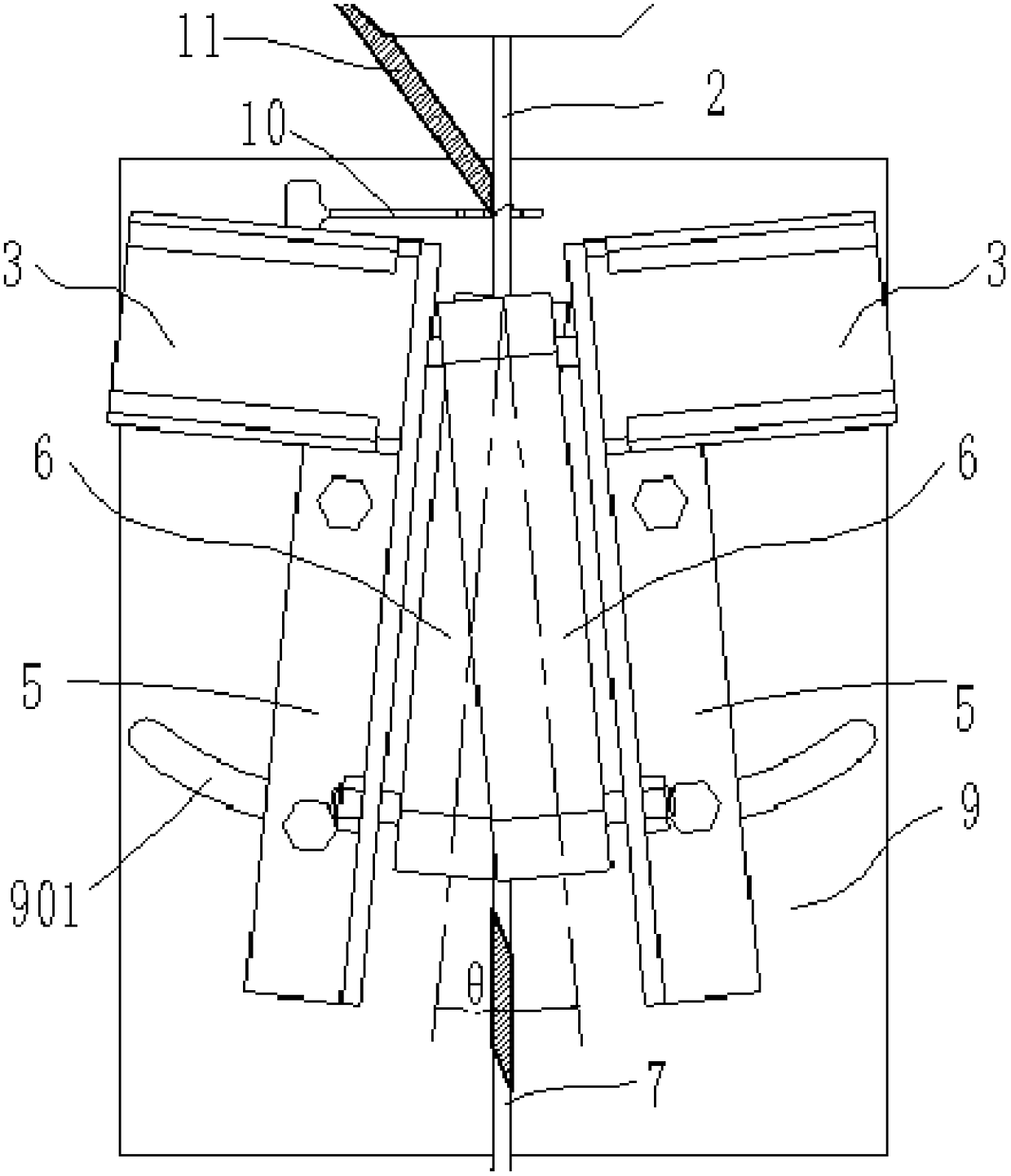

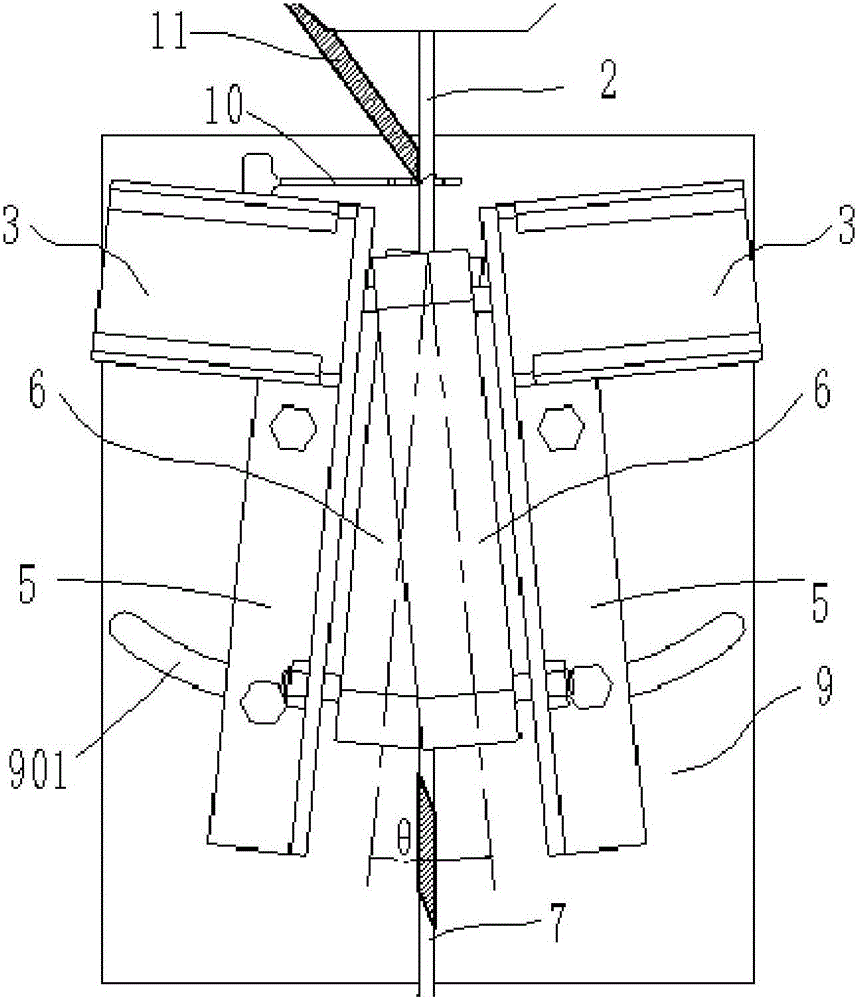

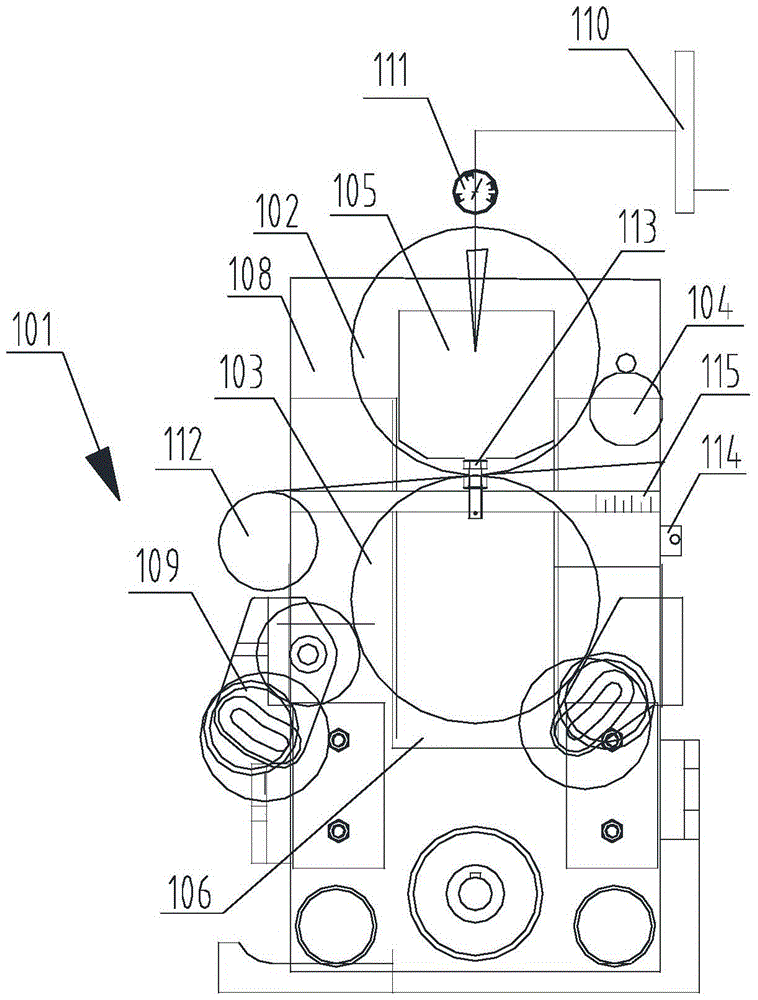

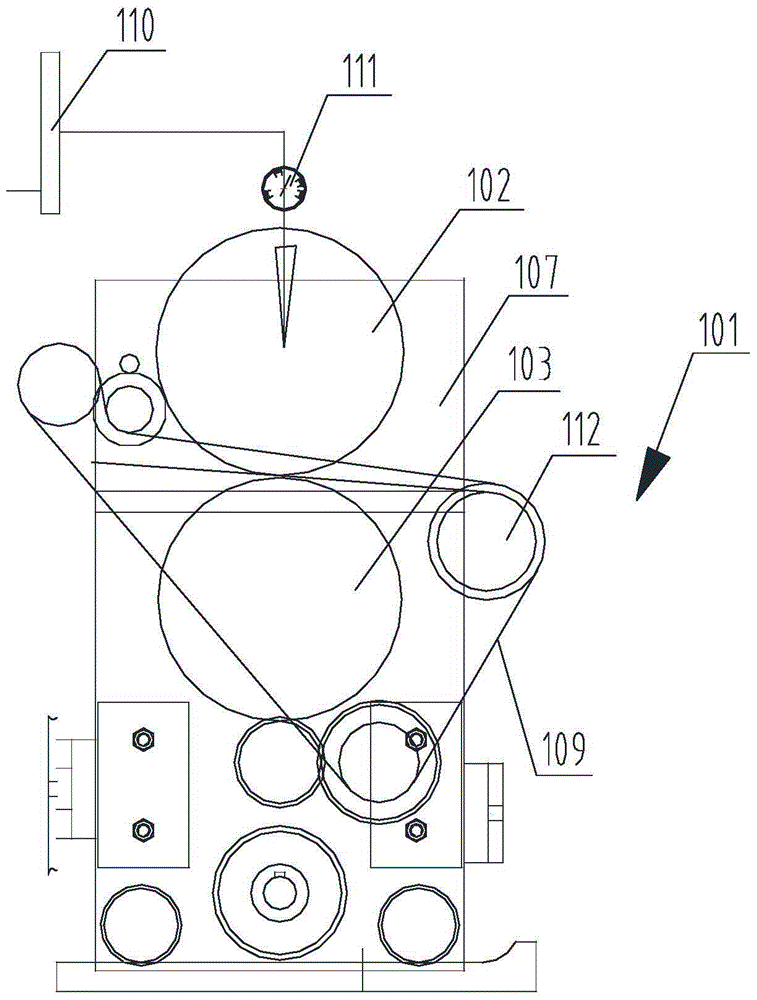

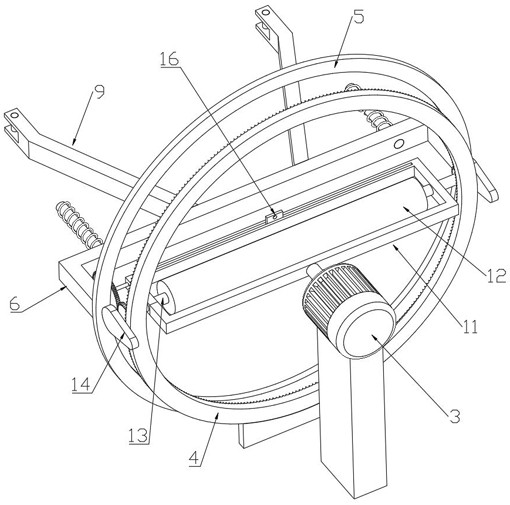

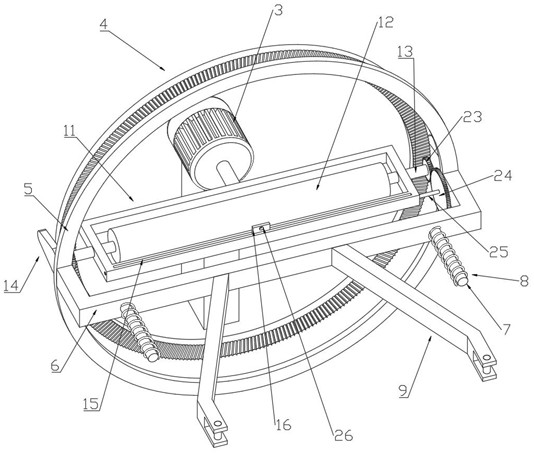

Acupuncture and moxibustion auxiliary needle twister

The invention provides an acupuncture and moxibustion auxiliary needle twister, and belongs to the technical field of medical auxiliary supplies. The acupuncture and moxibustion auxiliary needle twister comprises a ring, a needle twister shell, a motor, a needle twisting device and a control device; the ring is installed on the side wall of the needle twister shell; the center line of the ring is perpendicular to the center line of the needle twister shell; the motor and the twisting needle device are both arranged in the needle twister shell; the motor is installed in the needle twister shell through a fixing frame; meanwhile, an output shaft of the motor is connected with the twisting needle device; the twisting needle device is arranged at the end, provided with an opening, of the needle twister shell; and the control device is arranged on the needle twister shell, and meanwhile the control device is electrically connected with the motor. The acupuncture and moxibustion auxiliary needle twister is convenient to use, can be worn on the hand of an operator, can effectively control the needle twisting action of acupuncture and moxibustion, improves the needle twisting effect of medical staff, and meanwhile effectively improves the working efficiency of doctors.

Owner:洪世君

Hip swing device

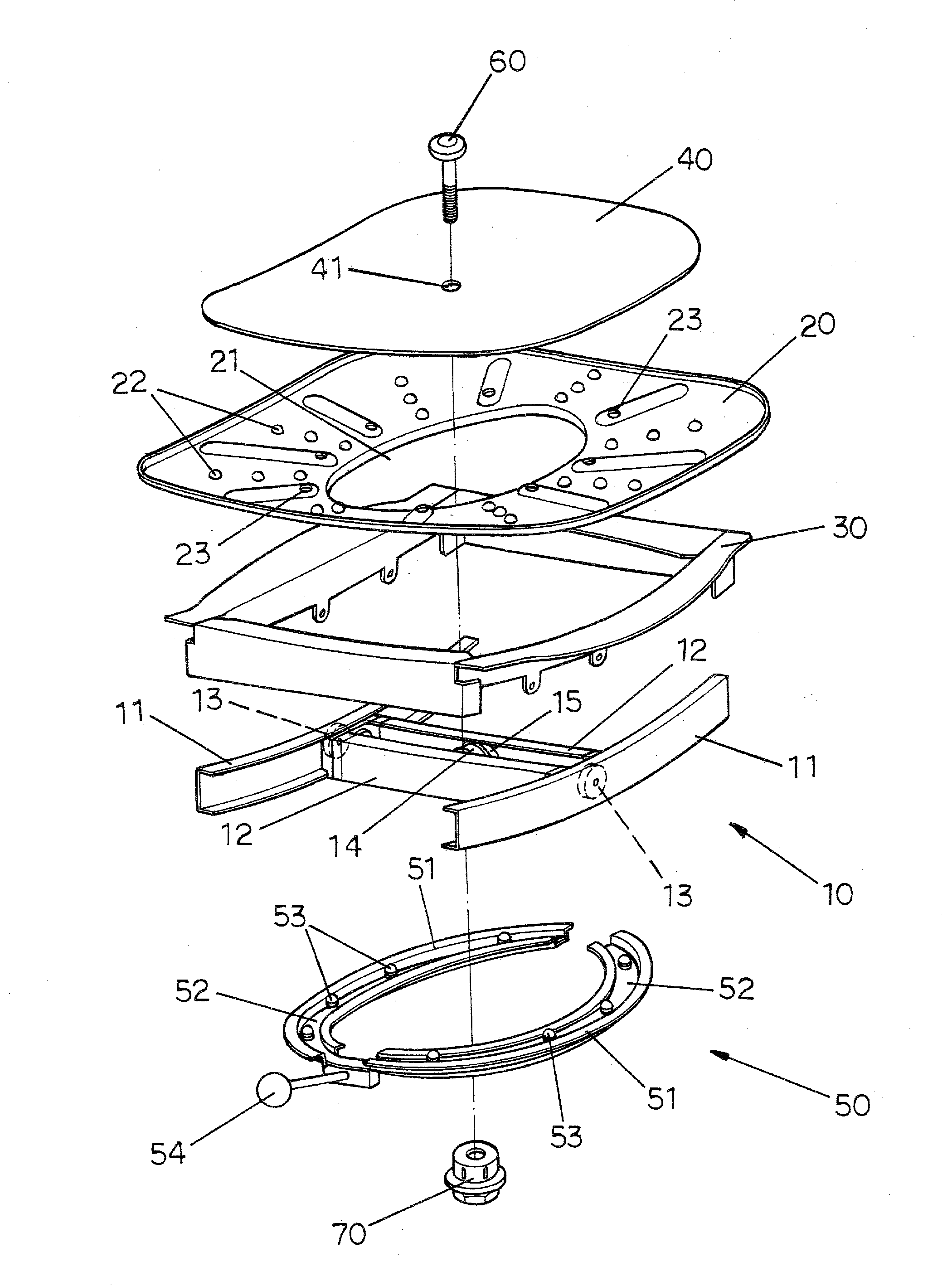

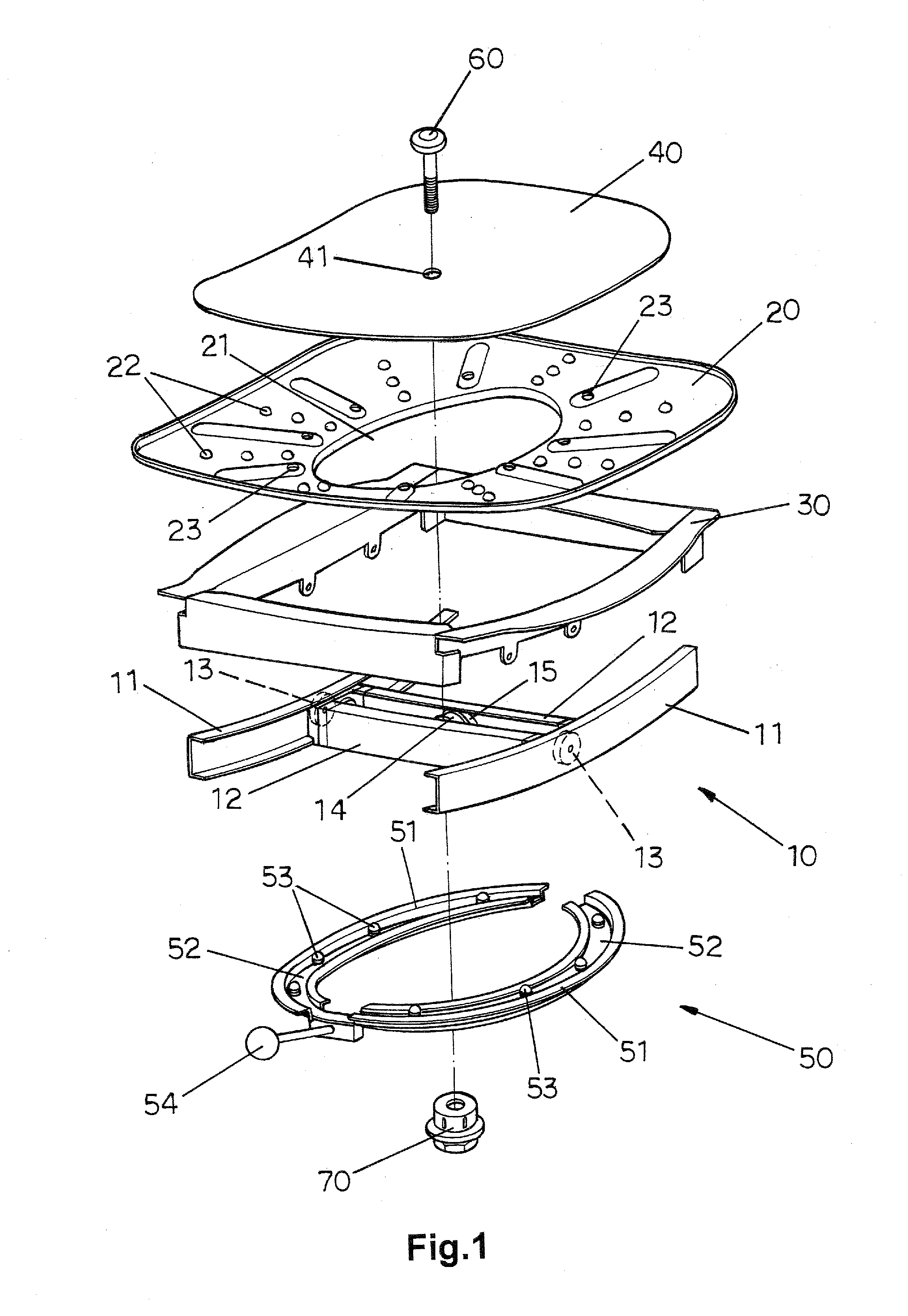

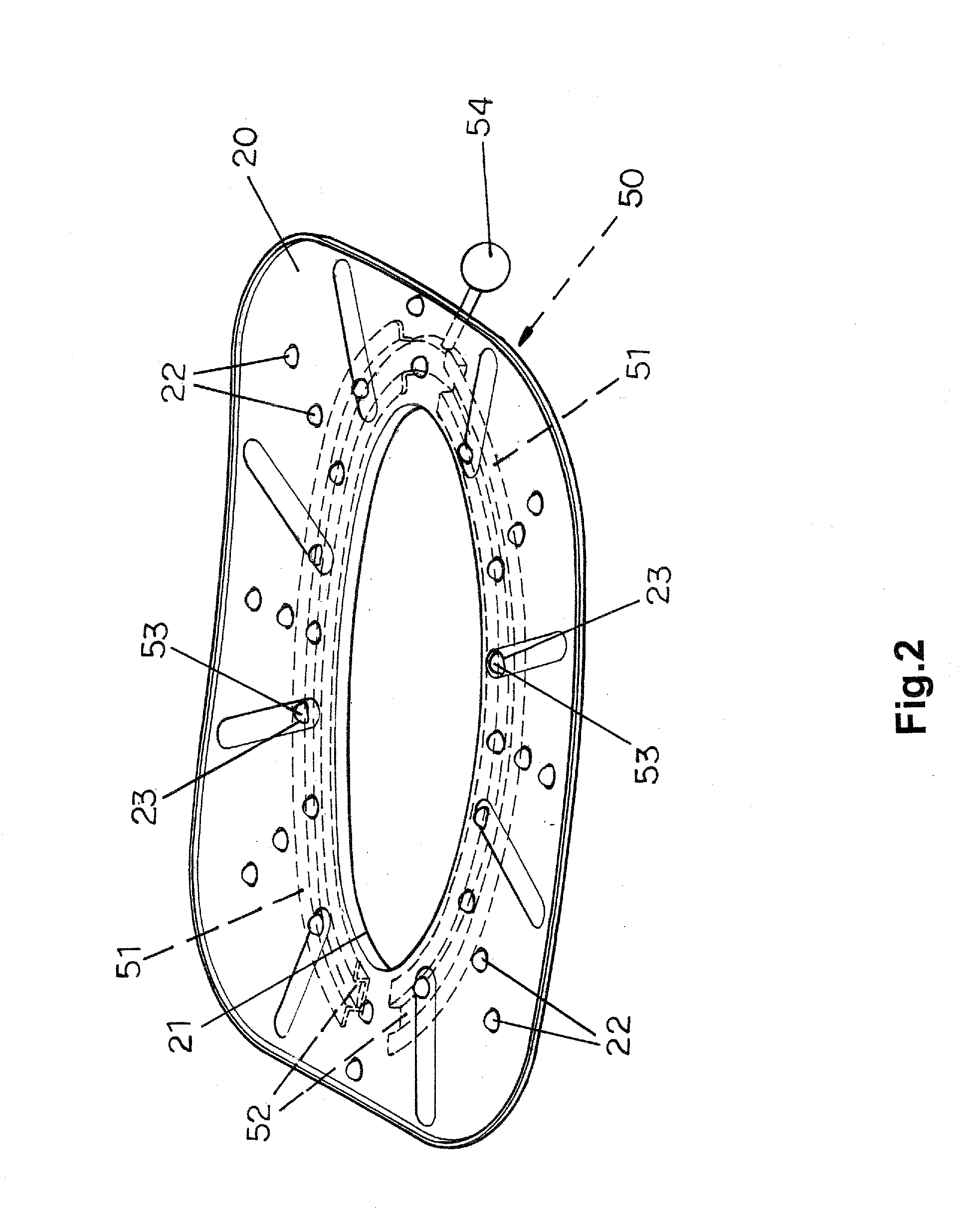

InactiveUS20150273262A1Improve twisting effectStiltsMovement coordination devicesLumbarComputer engineering

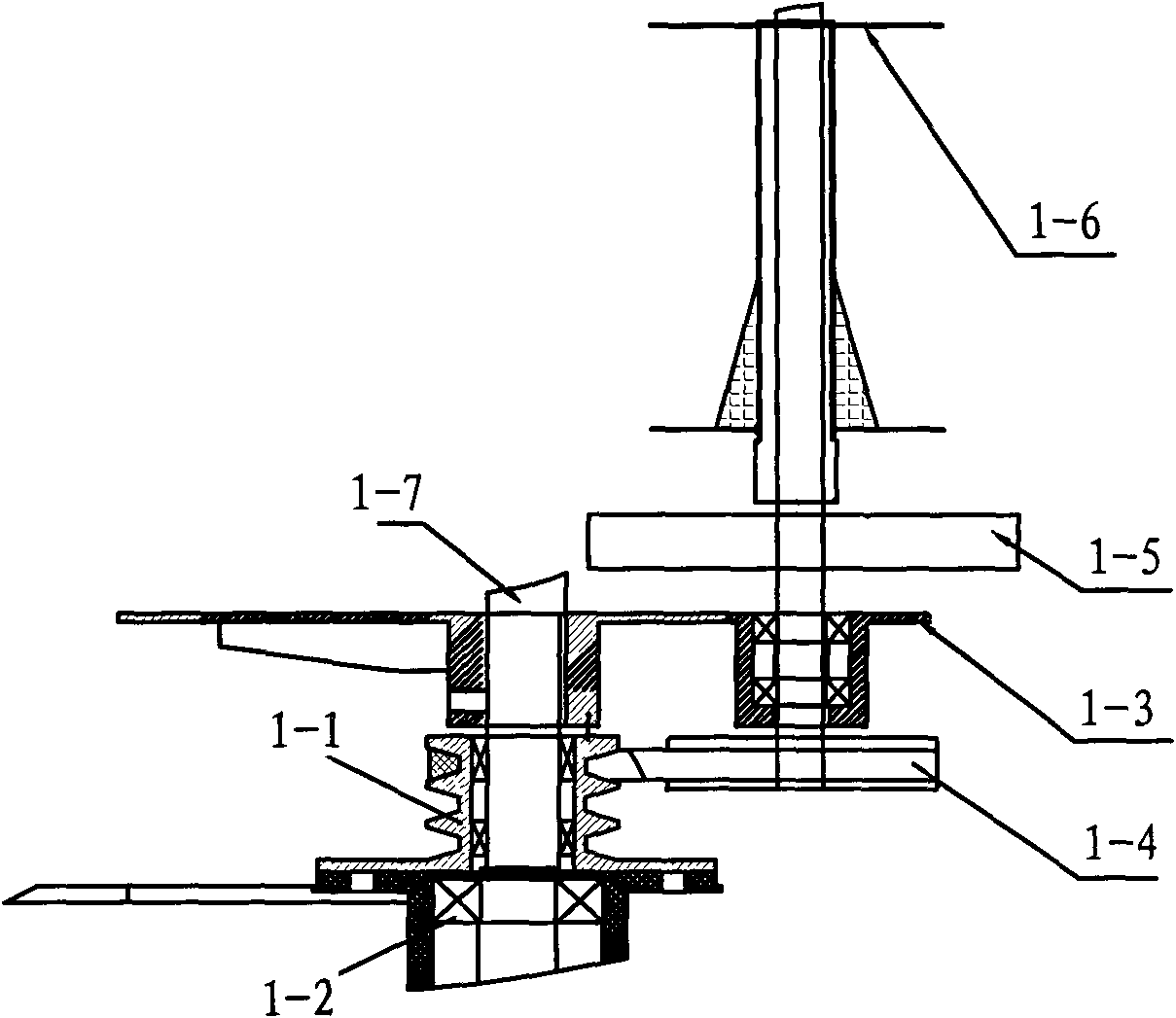

A hip swinging device comprises a rail unit, a fixed disk and a movable disk. The rail unit includes two straight rails, two transverse rails sliding along the straight rails, and a movable element sliding along the transverse rails. The fixed disk is defined with a through hole and a plurality of movable balls. The movable disk is connected to the movable element via the through hole and is abutted against the balls. The movable disk can slide back and forth with the to and fro sliding of the transverse rails along the straight rails, the movable disk can slide from left to right with the to and fro sliding of the movable element along the transverse rails, and the movable disk also can rotate. The movable disk allows the user to achieve better waist and hip twisting effect while sitting.

Owner:HSIEH TIEN WU

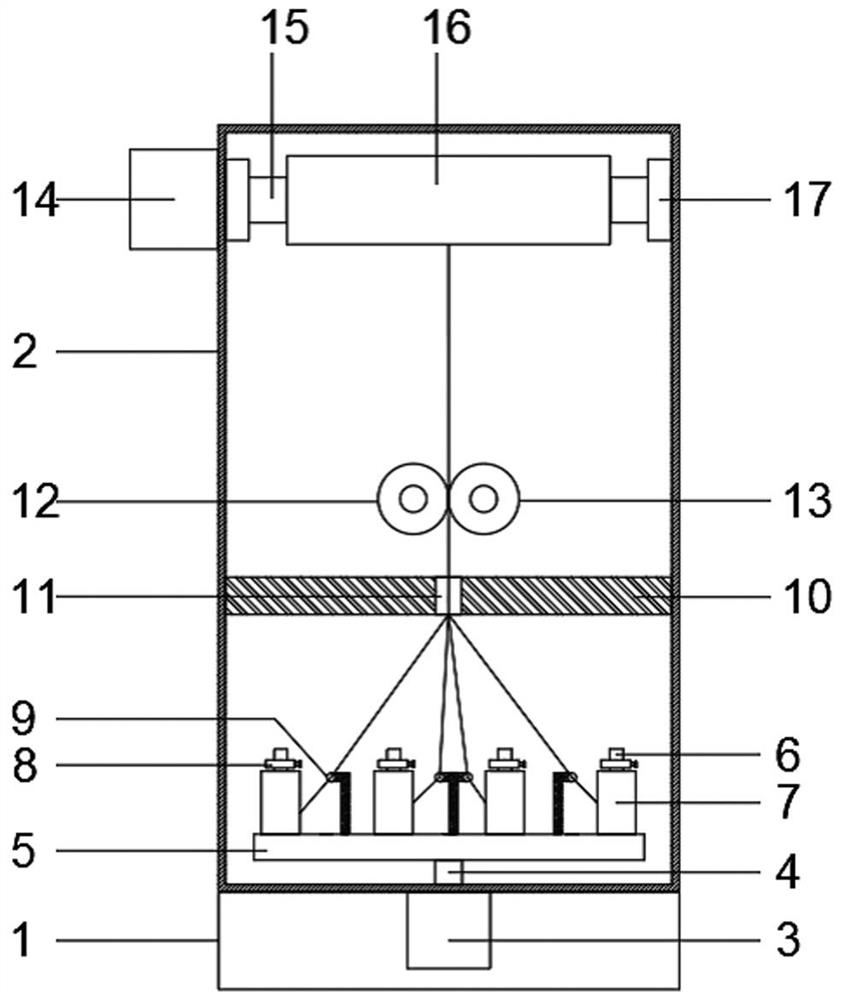

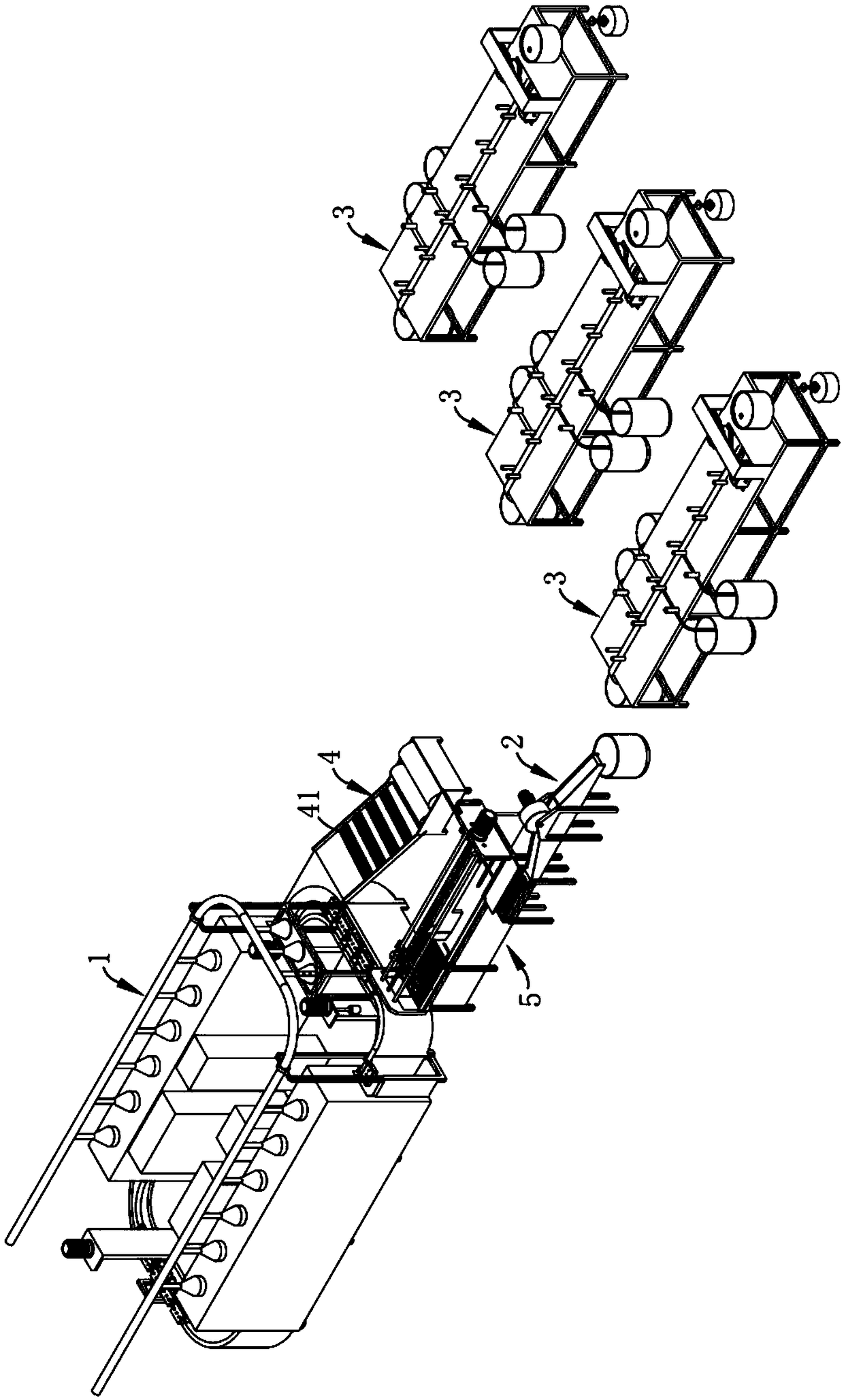

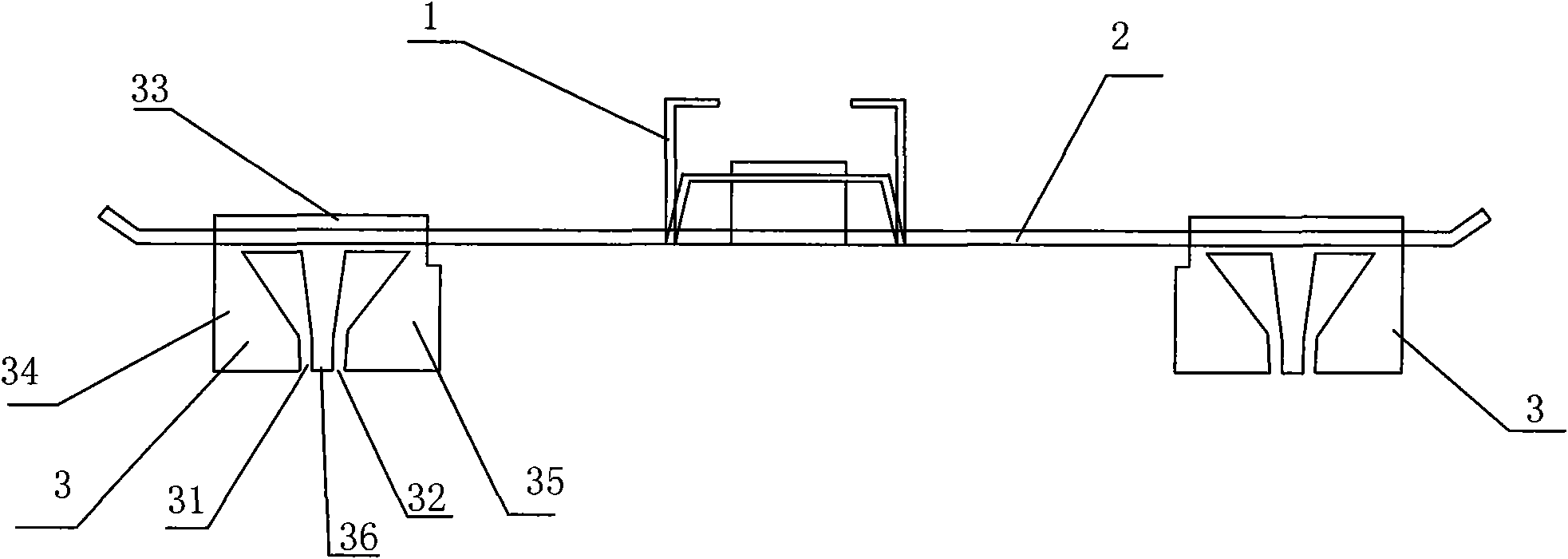

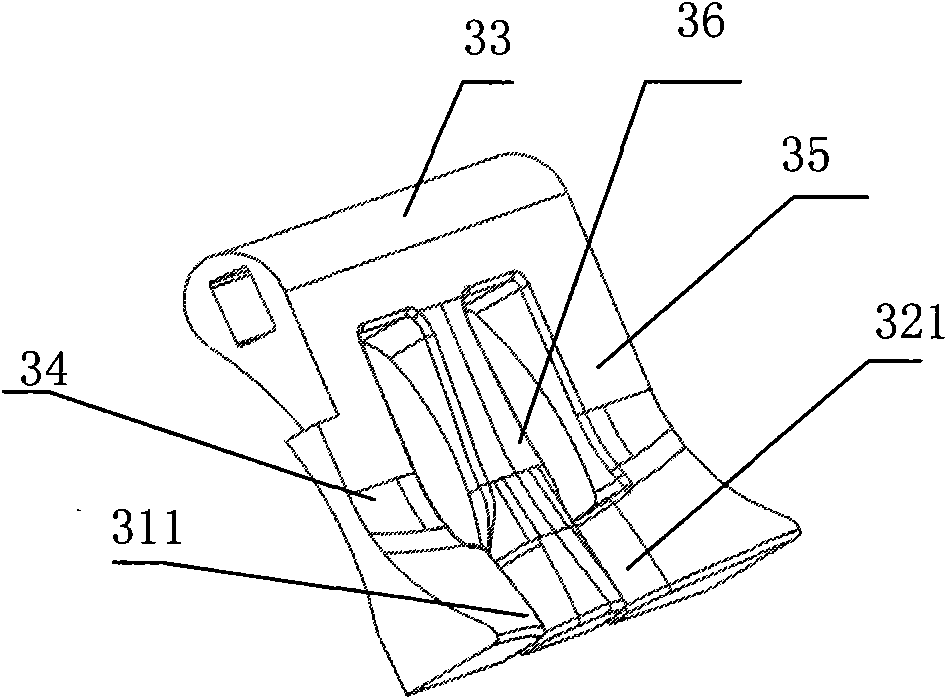

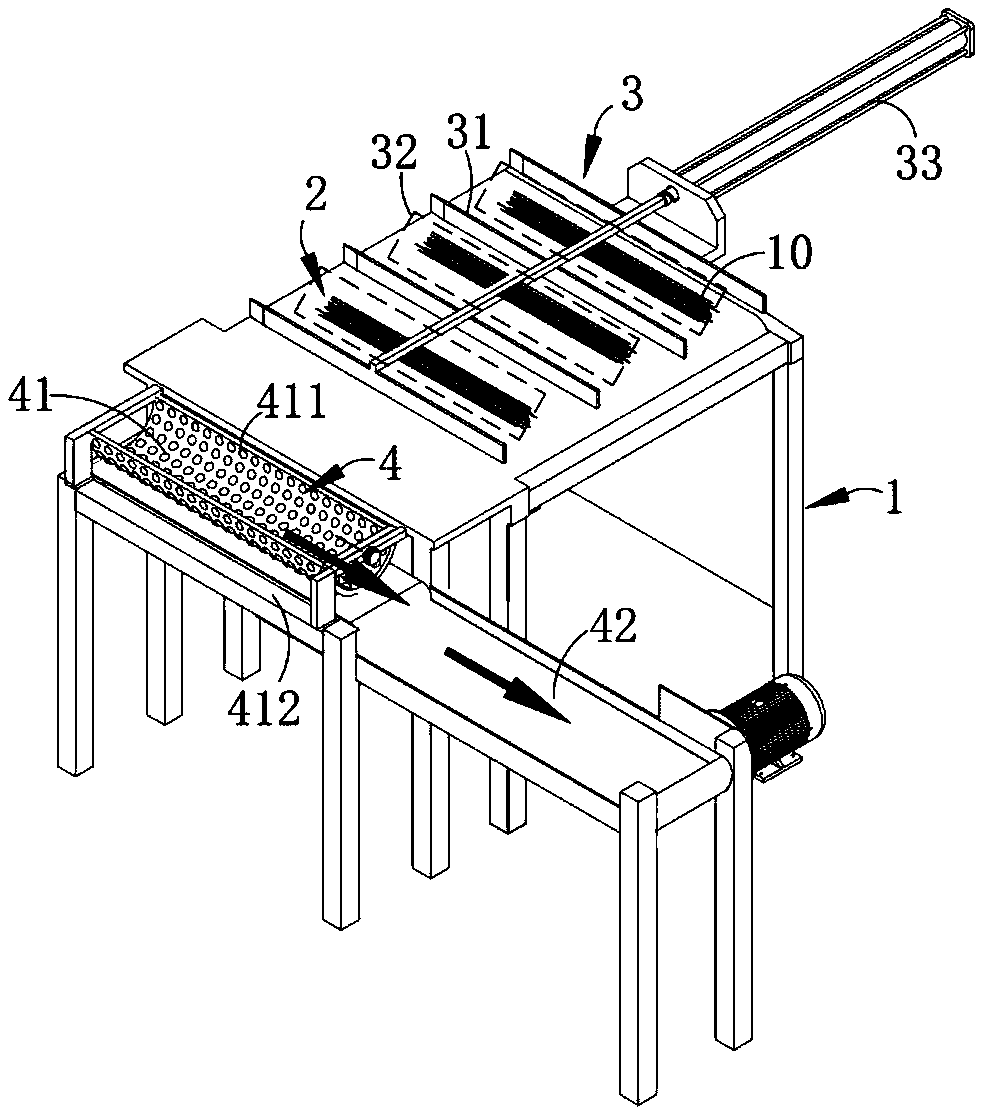

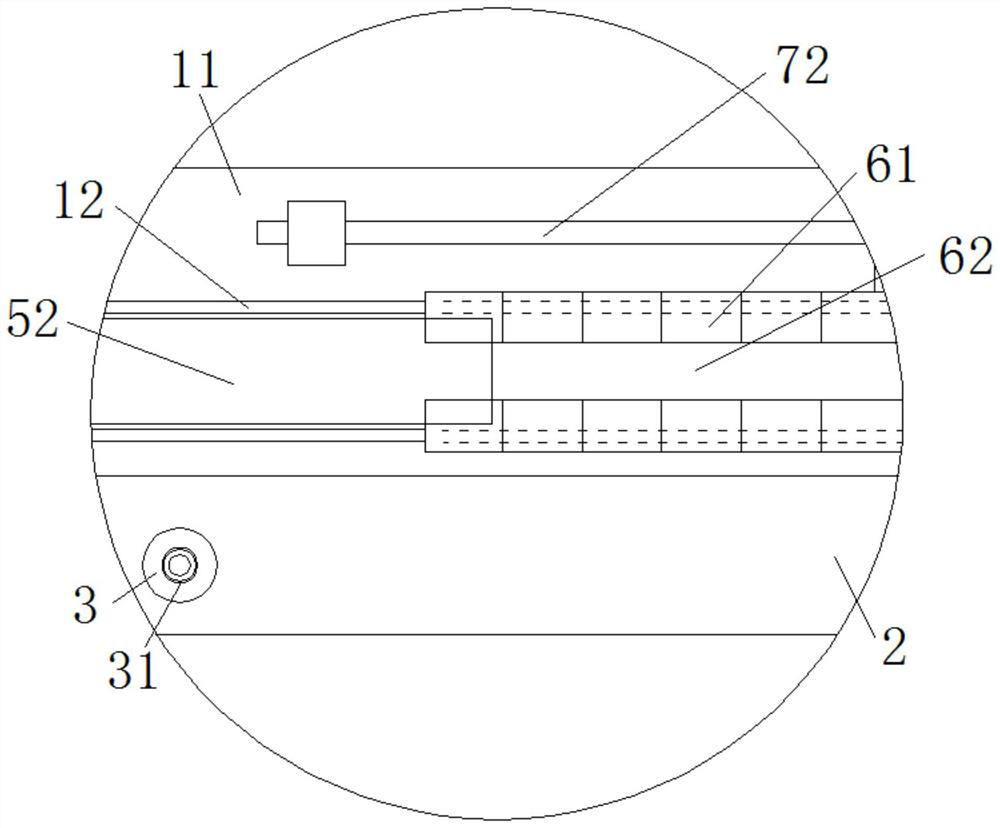

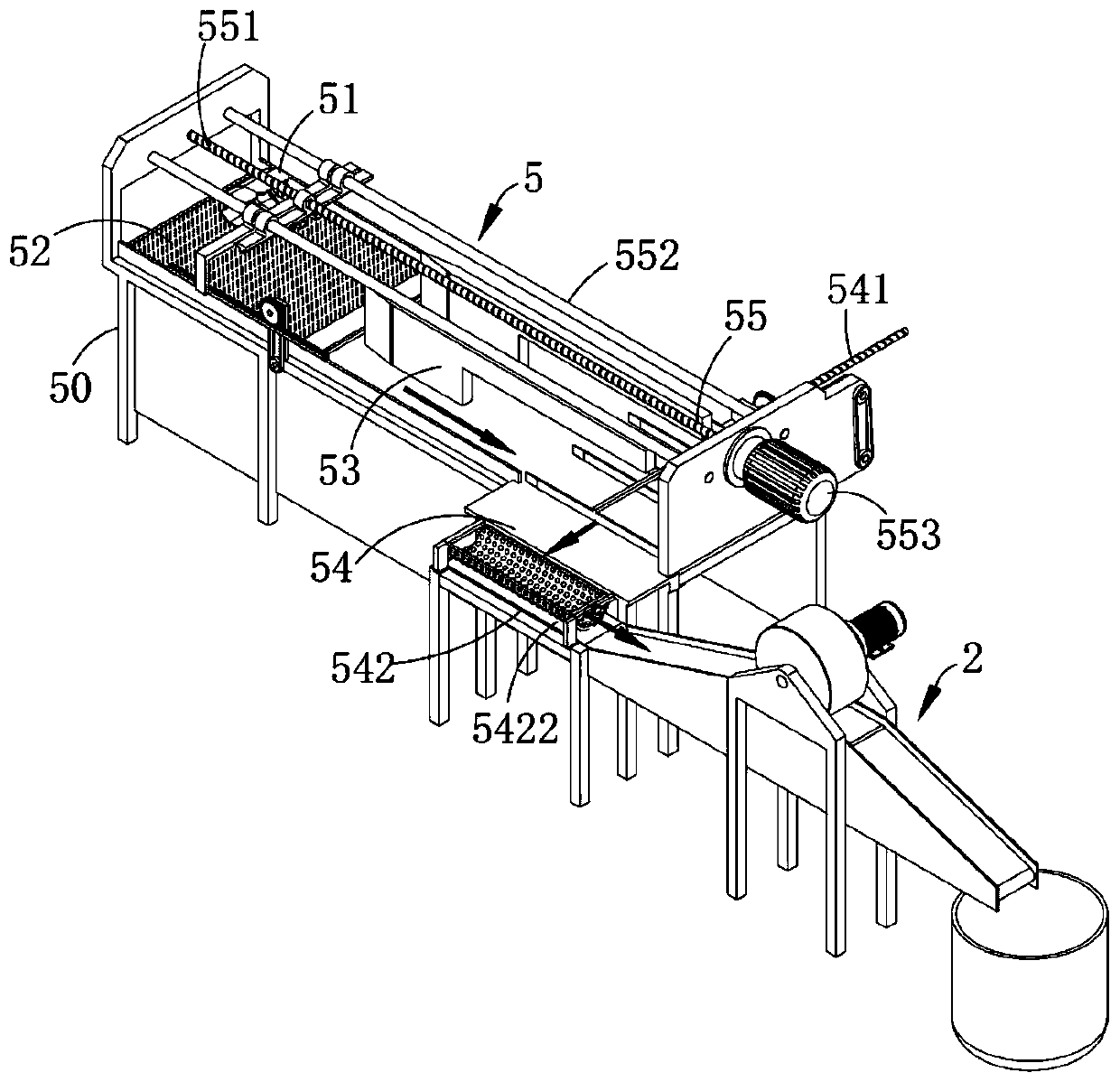

Automatic material increasing device for linen yarn production

The invention relates to the technical field of linen yarn production, in particular to an automatic material increasing device for linen yarn production. The automatic material increasing device comprises a rack, a traction mechanism, a bundle dividing mechanism, a material increasing mechanism and a transferring mechanism, wherein the traction mechanism comprises clamping assemblies and a propping assembly; the bundle dividing mechanism is used for dividing a long fiber into a plurality of fiber bundles; and the material increasing mechanism comprises a pushing assembly and an output assembly. Through the output assembly, the fiber bundles are mutually twined after being overlapped end to end; through the transferring mechanism and the output assembly, the fiber bundles are outputted; when the long fiber is directionally transferred through the traction mechanism, the removal of a short fiber from the long fiber and the division into the fiber bundles are performed through the cooperation with a carding mechanism and the bundle dividing mechanism correspondingly; by combination with the transmission connection properties of an overlapping mechanism and a driving mechanism, the fiber bundles are automatically twined when being overlapped end to end; the high-quality automatic production for linen bundle dividing and overlapping is achieved; and the technical problem that in the prior art, the yarn quality is unstable due to the non-uniform manual bundle dividing process is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

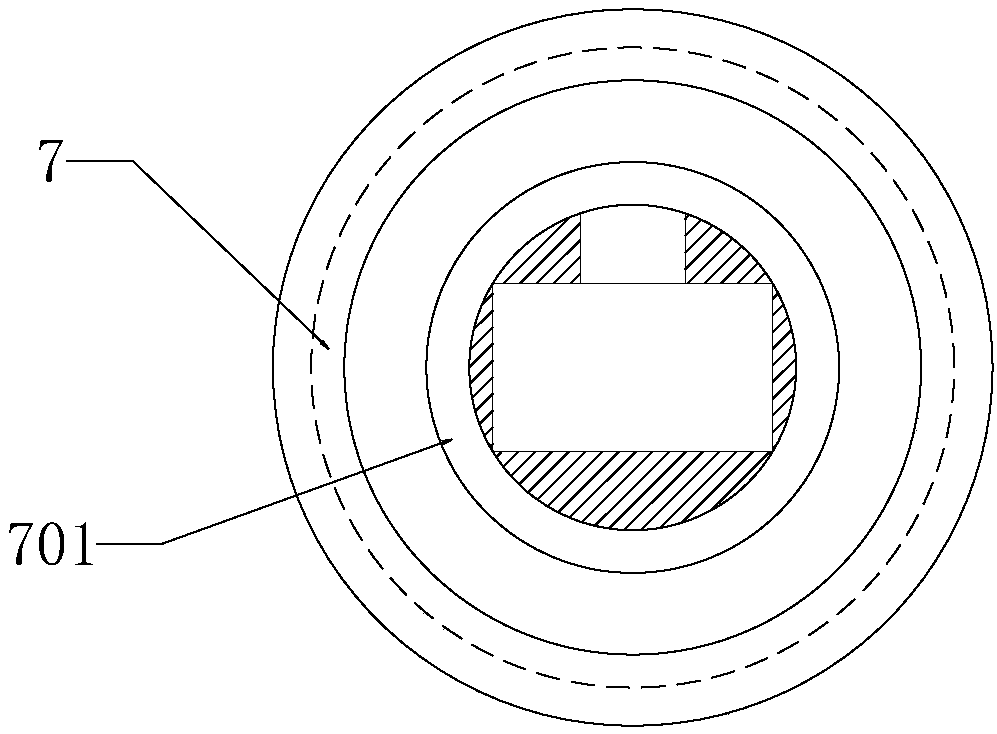

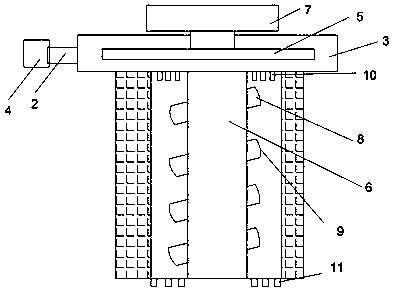

Air jet vortex spinning twister

InactiveCN107904709AAchieve circular flowImprove twisting effectContinuous wound-up machinesOpen-end spinning machinesYarnMechanics

The invention discloses an air jet vortex spinning twister. The air jet vortex spinning twister comprises a twister body, a first annular pipe and a second annular pipe. The twister body is of a cylindrical structure and forms a hollow vortex chamber inside. The first annular pipe is arranged at the upper part of the twister body and the second annular pipe is arranged at the lower part of the twister body. The first annular pipe is connected to the twister body through at least one inlet pipe; the second annular pipe is connected to the twister body through at least one air outlet pipe; the first annular pipe and the first annular pipe are connected by at least one spiral pipe; the spiral pipe is spirally disposed around the twister body. The air jet vortex spinning twister has a reasonable structure, achieves the circulation flow of the air flow inside and outside the vortex chamber, and greatly reduces the energy consumption; at the same time, the air flow field generated by the inner high-speed swirling inside the vortex chamber is more stable, thereby helping to increase the twisting effect of yarns and improve the quality of the yarns.

Owner:SUZHOU CITY XINGJINGZE FIBER TECH CO LTD

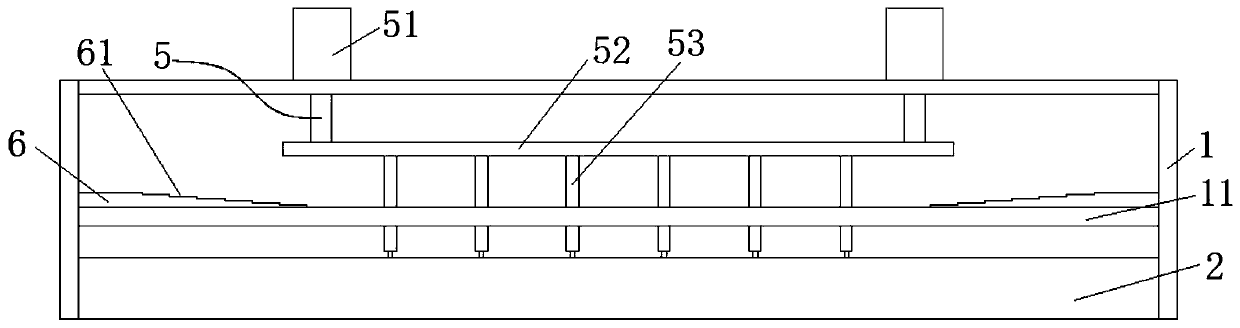

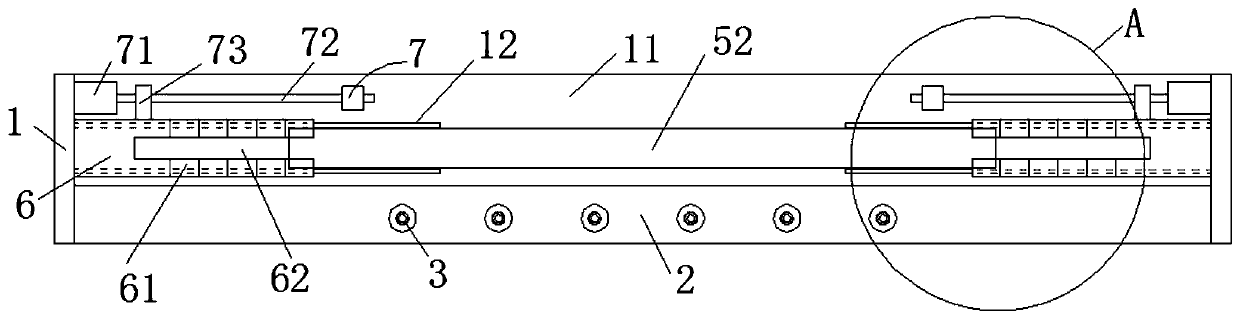

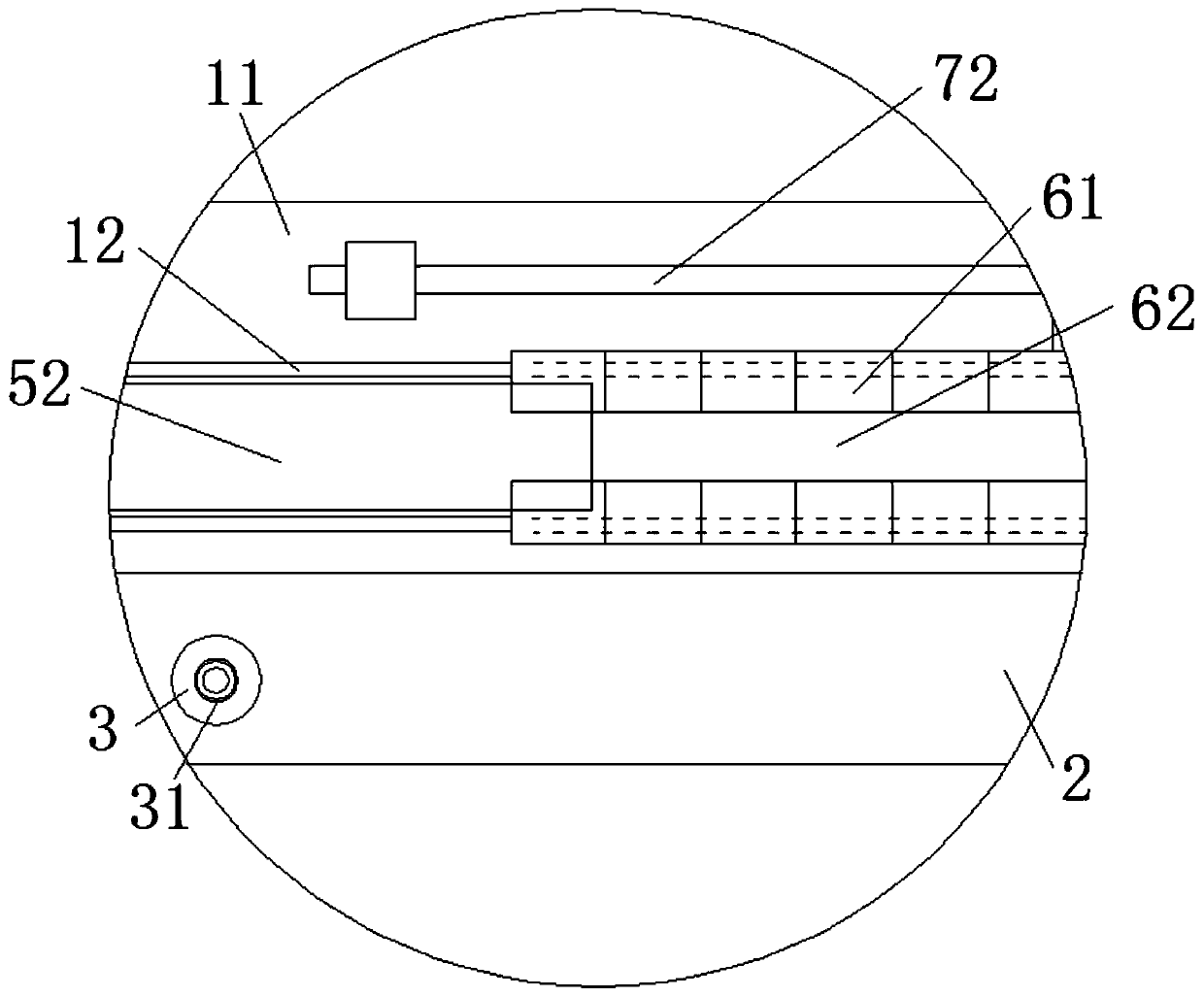

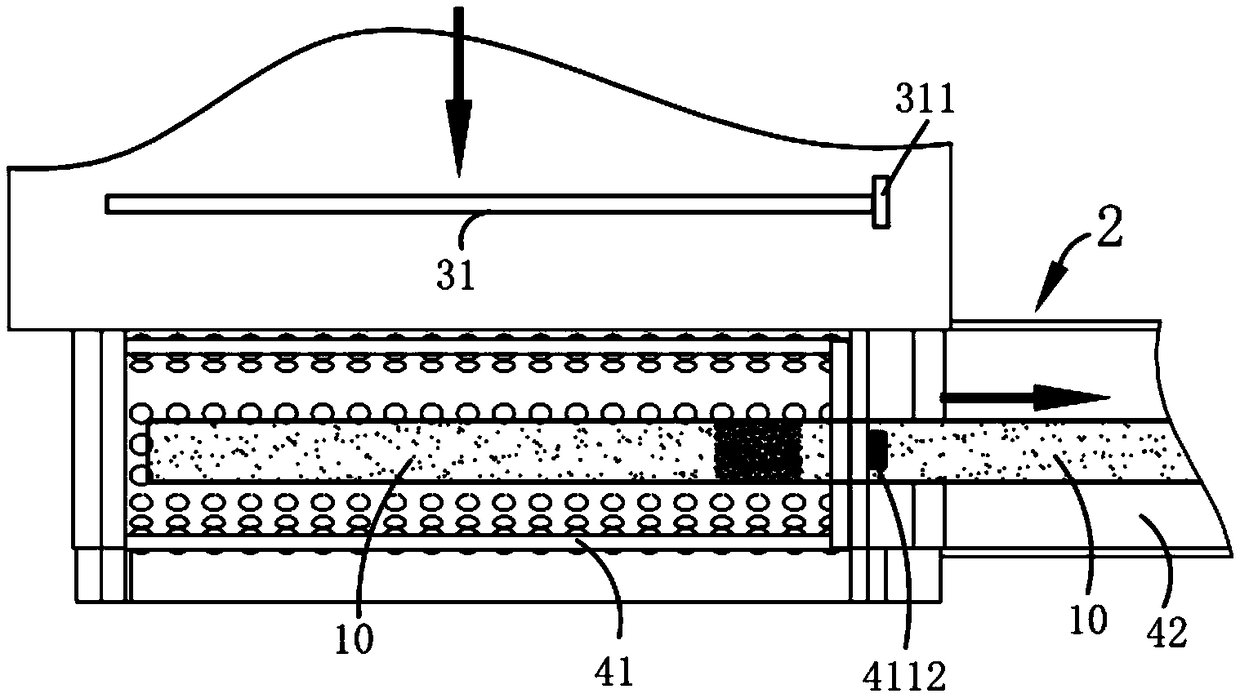

A kind of preparation device and method of long fiber reinforced thermoplastic resin composite material

The invention discloses a preparation device and method of long-fiber-reinforced thermoplastic resin composite material.The preparation device comprises a base and two conveying belt mechanisms arranged on the base.Each conveying belt mechanism comprises a conveying belt which is arranged between a drive wheel and a driven wheel in a sleeved manner and tensioned by the two, and a conveying face is formed on the surface of the conveying belt.The two conveying belt mechanisms are identical in structure, the conveying face of one conveying belt mechanism is stacked above the conveying face of the other conveying belt mechanism, and the gap and the included angle between the upper conveying face and the lower conveying face are adjustable.The preparation device has the advantages that the device is simple and practicable in structure and process and high in production efficiency; the thermal history of resin melt strips and fibers during the forming process is short, and damage to the length and mechanical strength of the fibers is small; the included angle between the two conveying belts allows the conveying belts to twist the resin melt strips and the fibers during traction, and the combination performance of the fibers and the resin melt strips is increased.

Owner:SOUTH CHINA UNIV OF TECH

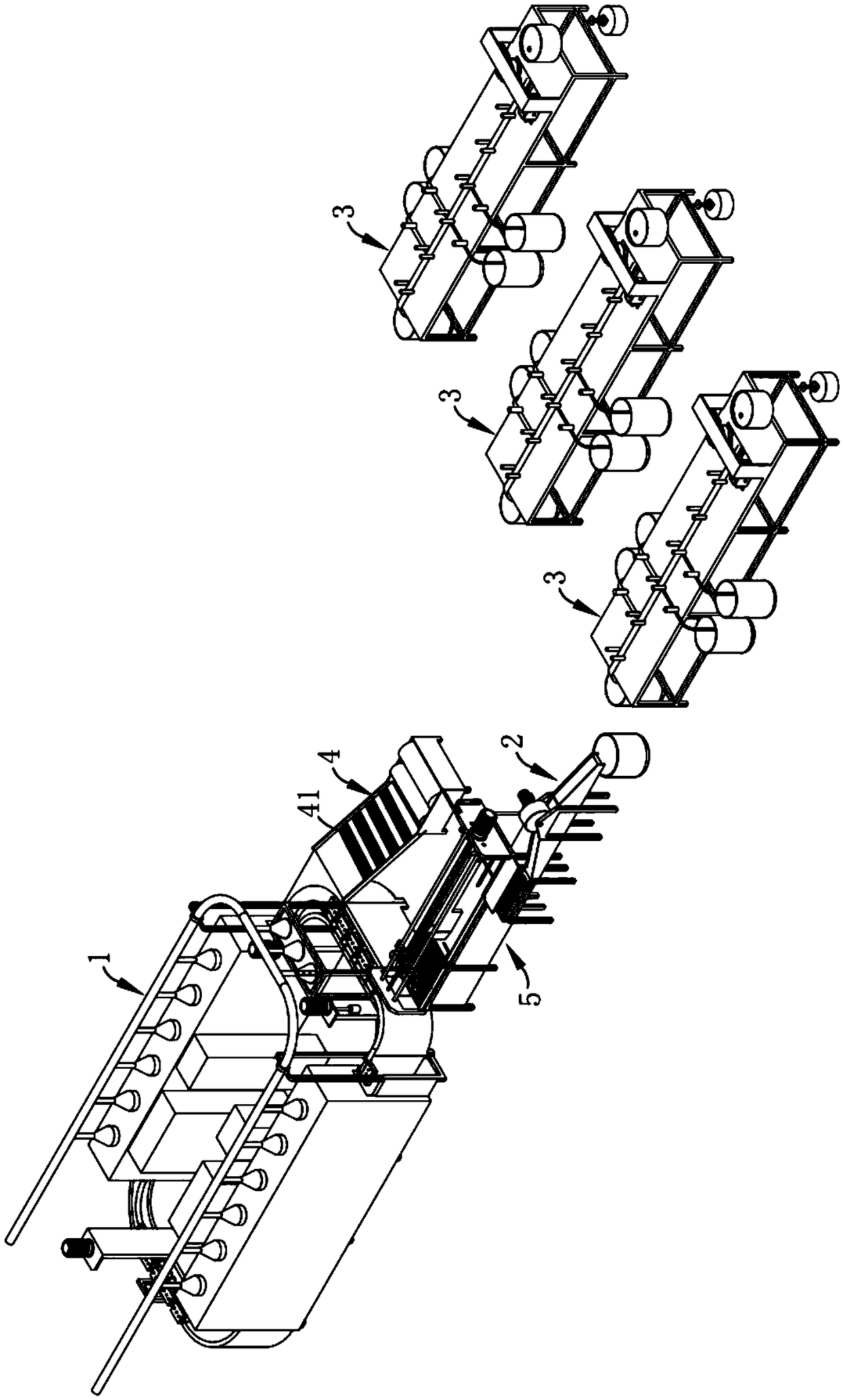

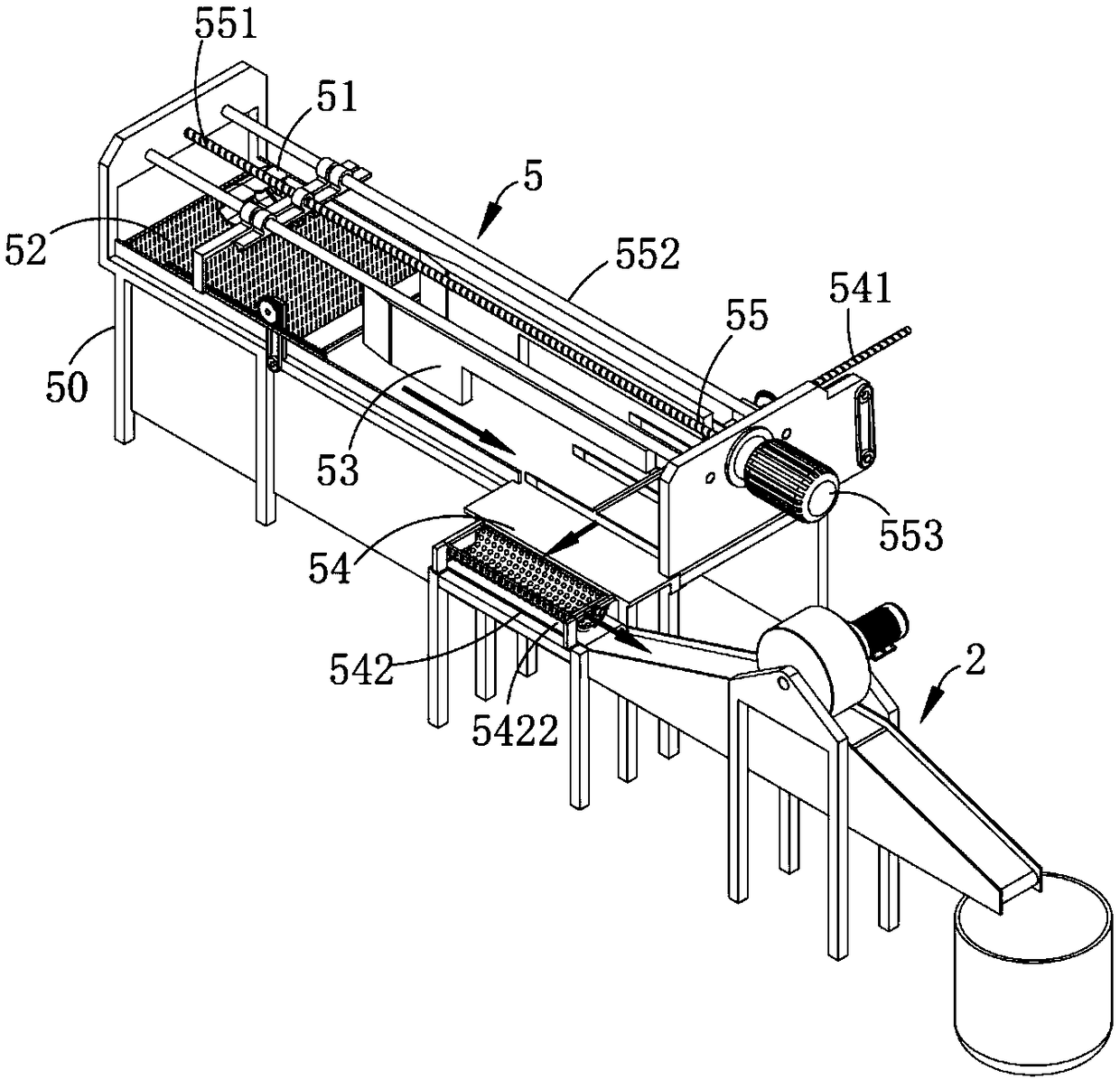

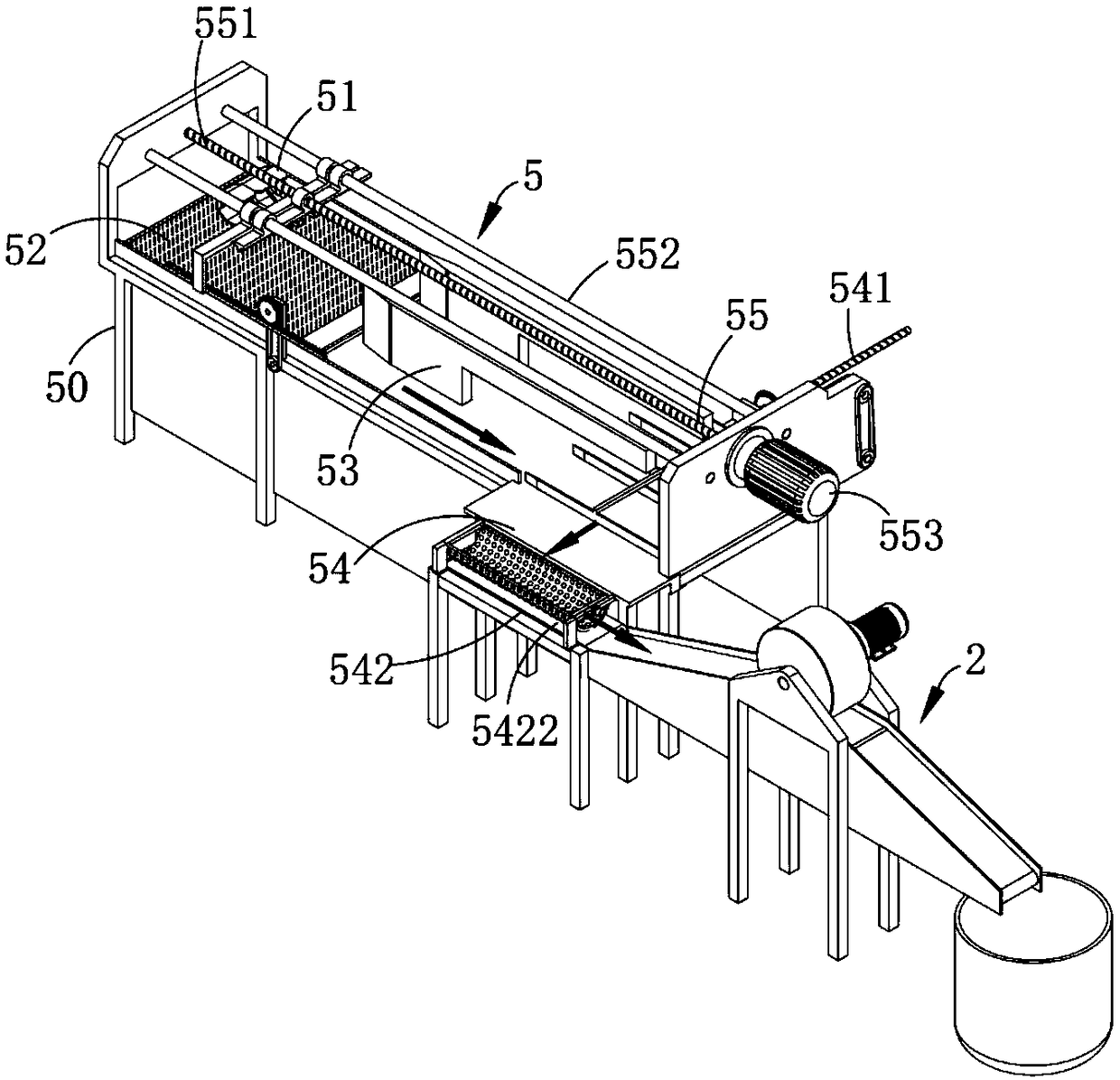

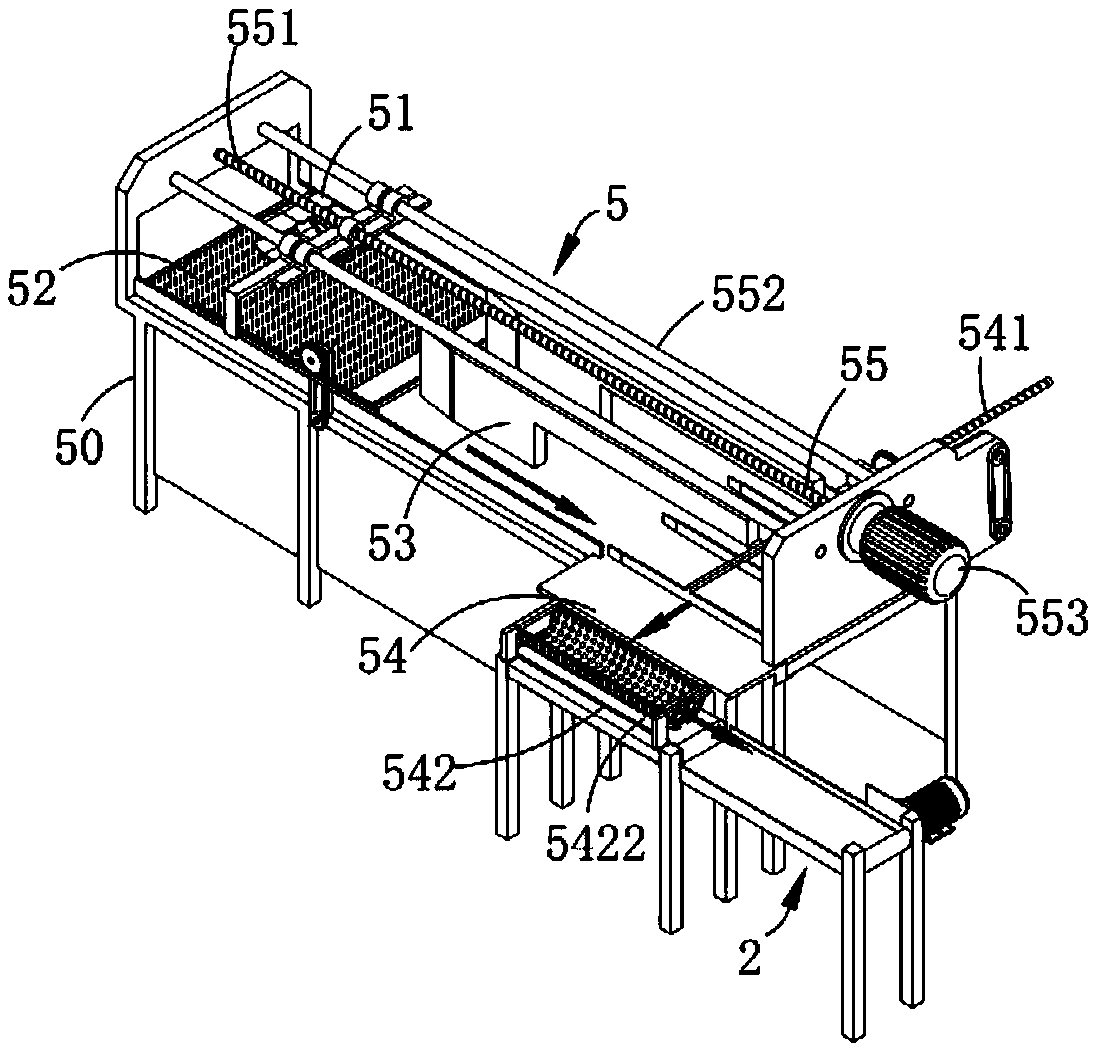

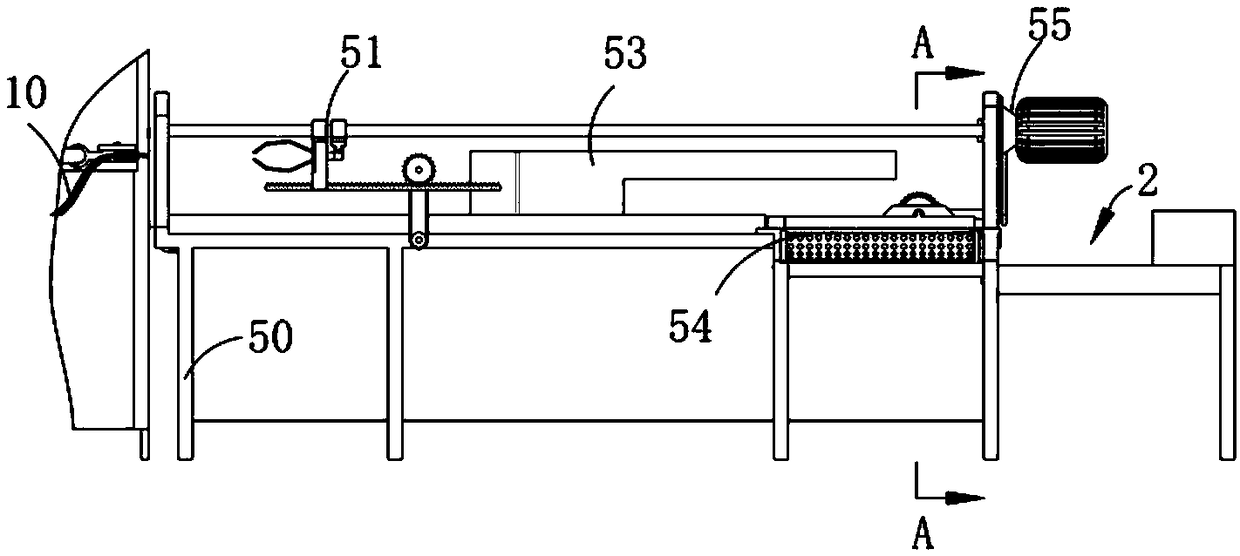

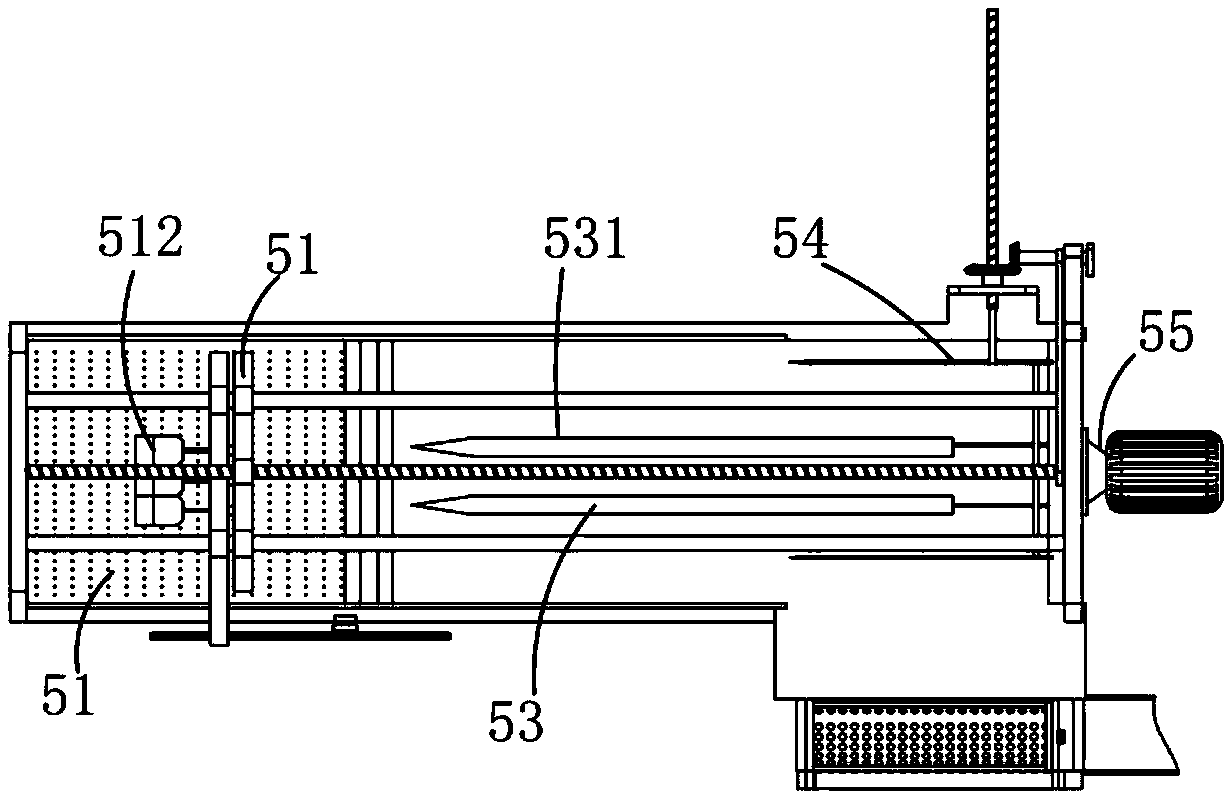

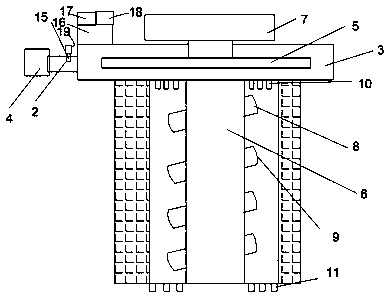

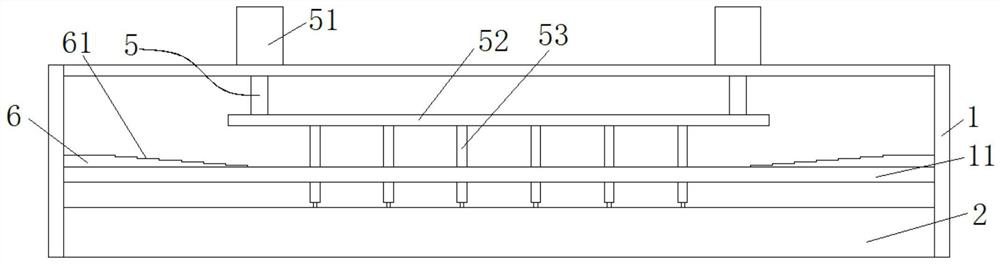

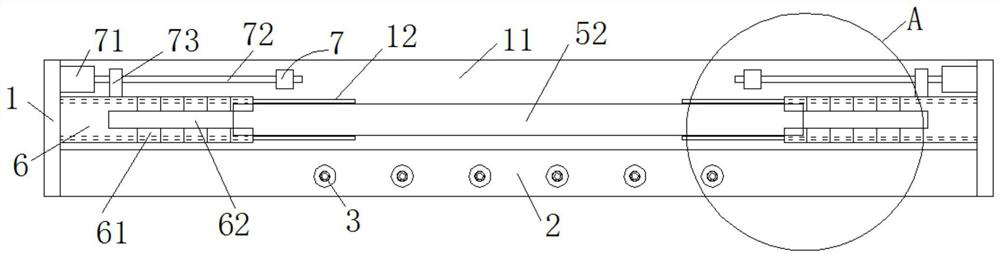

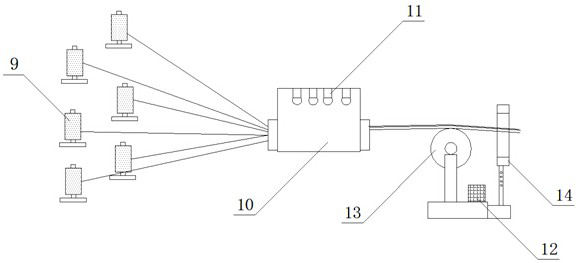

Automatic long flax feeding device for flax yarn production

InactiveCN108950758AImprove twisting effectAvoid breakingContinuous wound-up machinesYarnFiber bundle

The invention relates to the technical field of flax yarn production, in particular to an automatic long flex feeding device for flax yarn production. The device comprises a rack, a placing table, a pushing mechanism and a supplying mechanism; the pushing mechanism is arranged above the placing table and comprises pushing parts and storing areas; the supplying mechanism comprises a winding assembly and an outputting assembly, the pushing parts drive the winding assembly to swing when pushing fiber bundles into the winding assembly in sequence, thus, when being outputted, a former group of fiber bundles in the winding assembly are twined with a latter group of fiber bundles after end-to-end overlapping in the winding assembly, and the overlapped and twined fiber bundles are transferred andoutput through cooperation of the outputting assembly and the winding assembly; when multiple groups of fiber bundles are transferred into the supplying mechanism in sequence through the pushing mechanism, every two adjacent groups of fiber bundles in the winding assembly are twined crosswise through the winding assembly after automatic end-to-end overlapping, and then closely connected fiber bundles are formed. The technical problem that in the fiber bundle transferring process in the prior art, breakage occurs easily is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

Preparation device and method of long-fiber-reinforced thermoplastic resin composite material

The invention discloses a preparation device and method of long-fiber-reinforced thermoplastic resin composite material.The preparation device comprises a base and two conveying belt mechanisms arranged on the base.Each conveying belt mechanism comprises a conveying belt which is arranged between a drive wheel and a driven wheel in a sleeved manner and tensioned by the two, and a conveying face is formed on the surface of the conveying belt.The two conveying belt mechanisms are identical in structure, the conveying face of one conveying belt mechanism is stacked above the conveying face of the other conveying belt mechanism, and the gap and the included angle between the upper conveying face and the lower conveying face are adjustable.The preparation device has the advantages that the device is simple and practicable in structure and process and high in production efficiency; the thermal history of resin melt strips and fibers during the forming process is short, and damage to the length and mechanical strength of the fibers is small; the included angle between the two conveying belts allows the conveying belts to twist the resin melt strips and the fibers during traction, and the combination performance of the fibers and the resin melt strips is increased.

Owner:SOUTH CHINA UNIV OF TECH

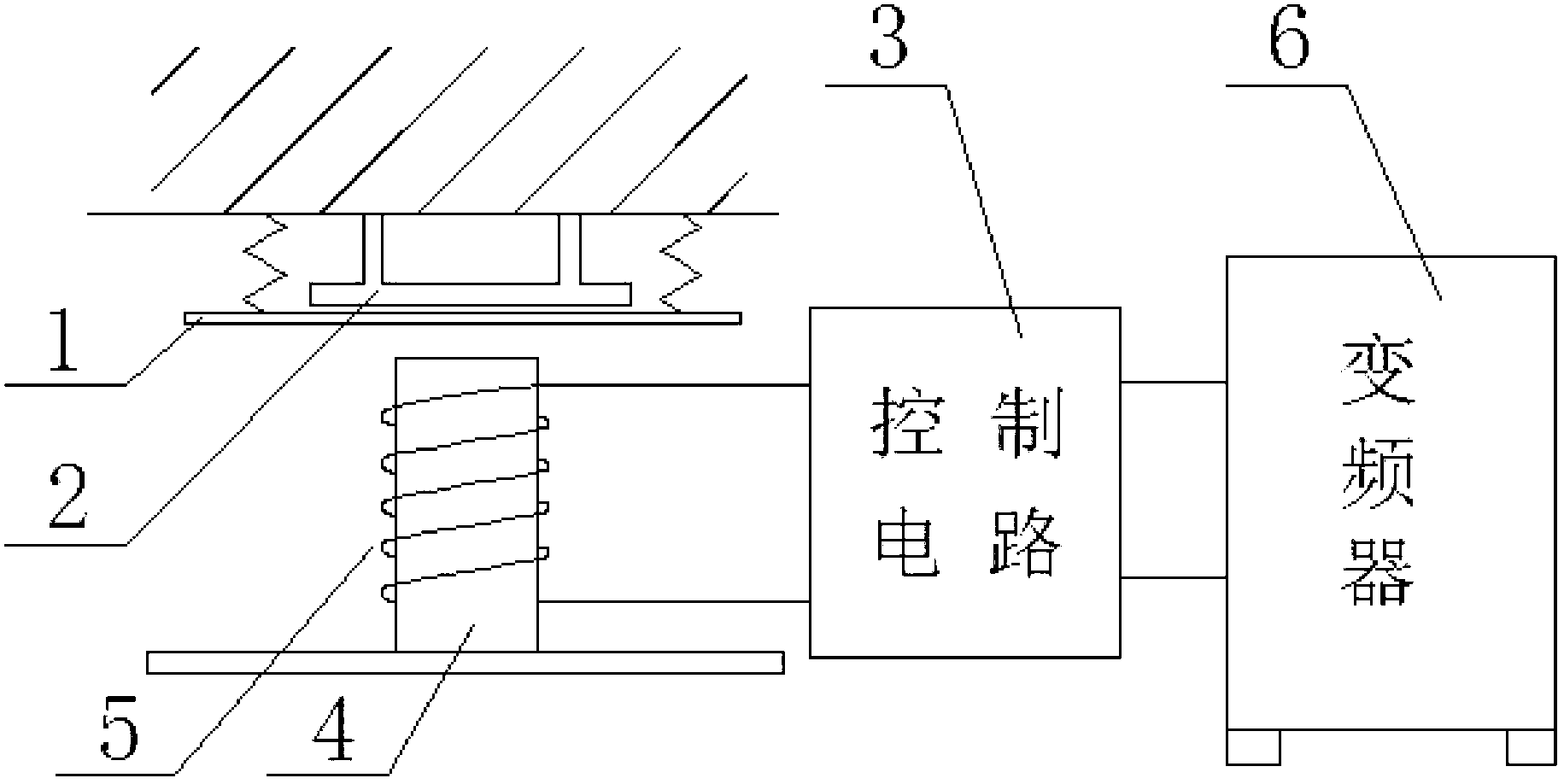

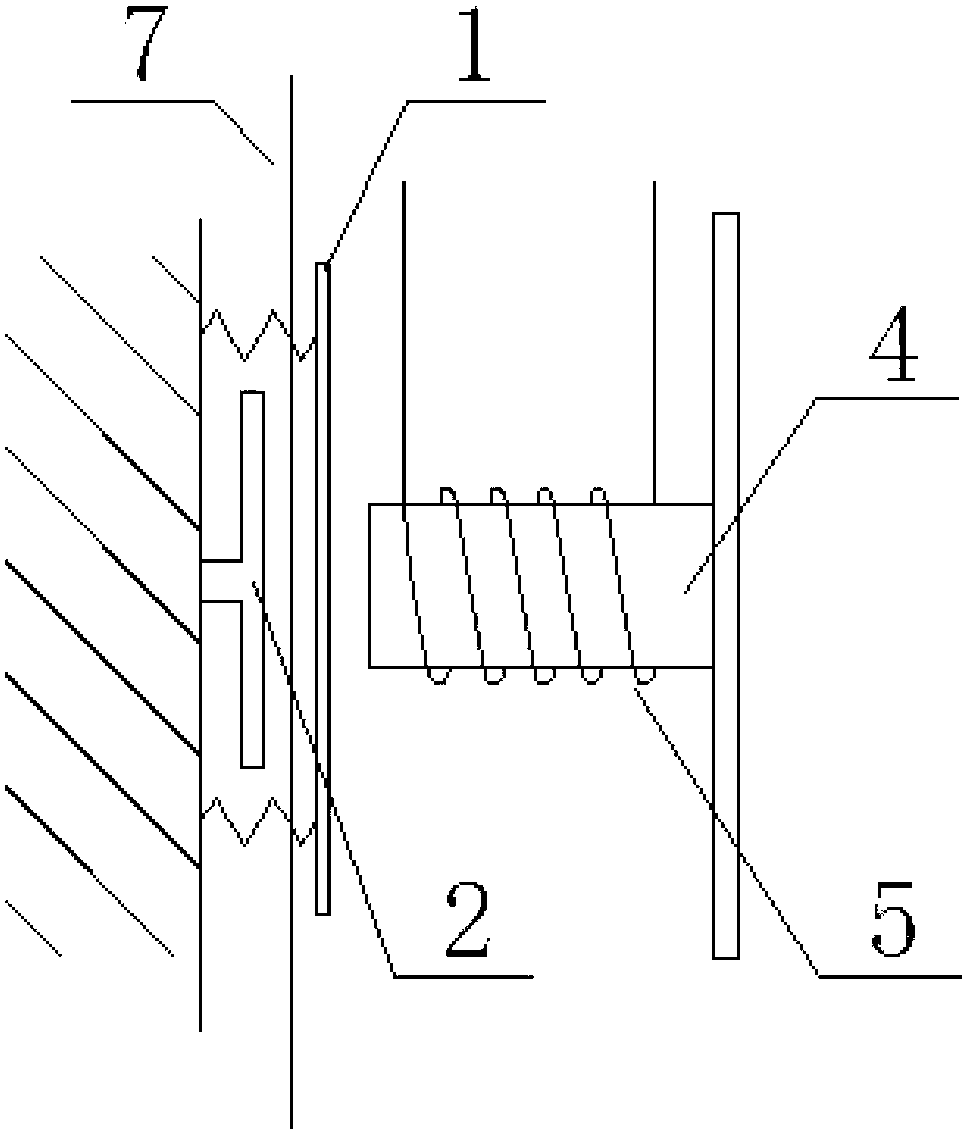

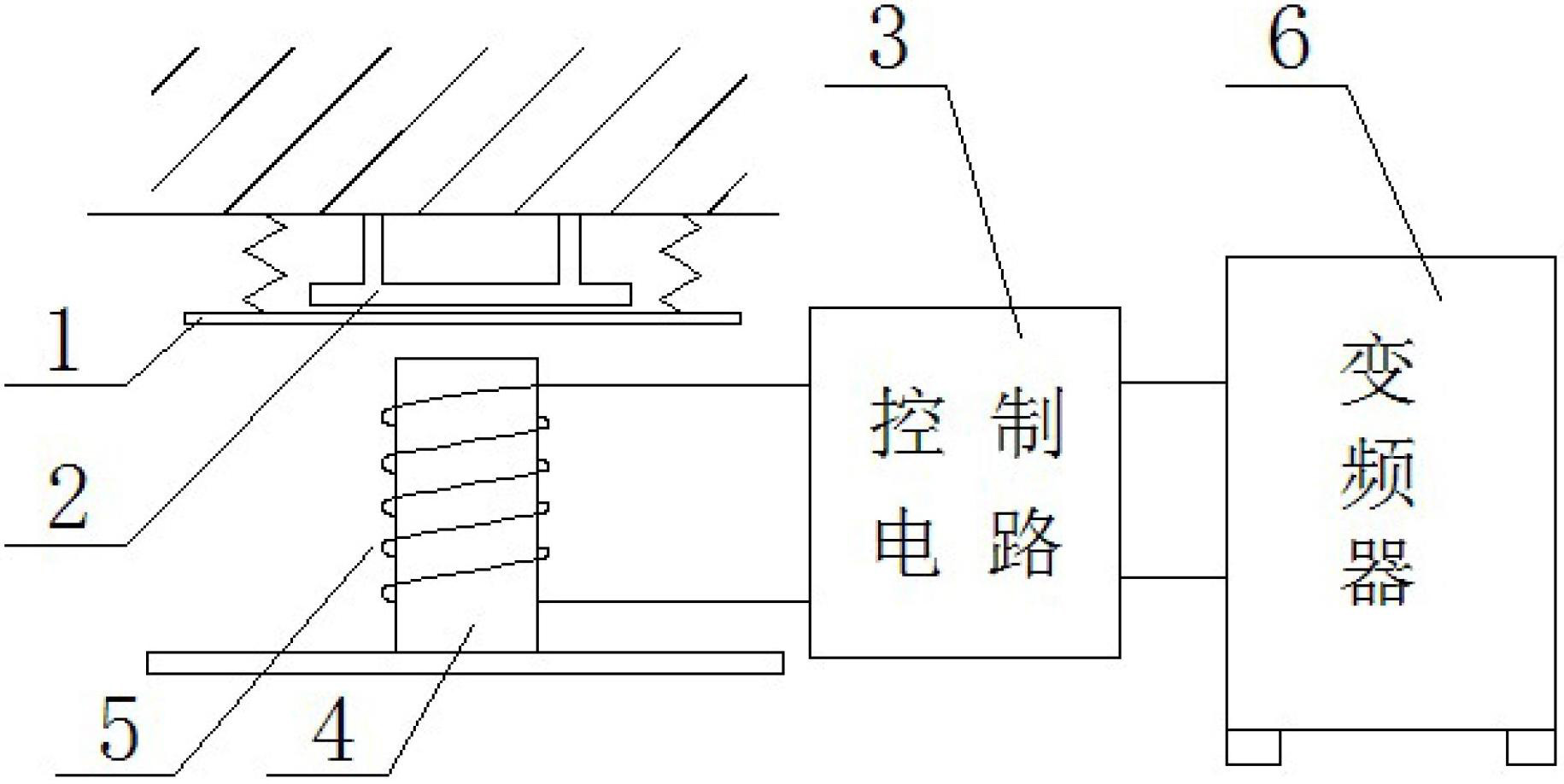

Electromagnetic relay used for dragon dance yarns

InactiveCN102709122AVariations in twistRich varietyContinuous wound-up machinesElectromagnetic relay detailsYarnFrequency changer

The invention discloses an electromagnet relay used for dragon dance yarns, which comprises a first metal plate, a second metal plate, a control circuit, an iron core and a coil, wherein the control circuit controls the coil to power on and power off, a magnetic field is generated discontinuously by the iron core, the first metal plate and the second metal plate are adhered together when no magnetic field is generated by the iron core, the first metal plate is separated from the second metal plate and is adhered to the iron core when the magnetic field is generated by the iron core, the control circuit can be connected with a frequency converter together, and the frequency of power-on and power-off of the coil is controlled by the frequency converter. The dragon dance yarns pass through a crack between the first metal plate and the second metal plate, the twist of the dragon dance yarns is controlled by the tightening and loosening of the two metal plates, so that the production efficiency is higher, the twisting effect is better, and twist changes of the dragon dance yarns are more if the frequency converter is used for controlling, therefore, the varieties of the dragon dance yarns are enriched.

Owner:SUZHOU DONGDI TEXTILE

Weeding unit for woolen card

ActiveCN103757758BIncrease contact areaPromote sheddingCarding machinesEngineeringMechanical engineering

The invention discloses a weeding device of a woolen combing machine. The weeding device comprises an upper weed pressing roller and a lower weed pressing roller, the upper weed pressing roller is arranged on a longitudinal sliding block which moves in the vertical direction of a machine frame, the lower weed pressing roller is arranged on a transverse sliding block which moves in the front-and-back direction of the machine frame, a first adjusting component is arranged below the longitudinal sliding block, a second adjusting component is arranged in front of or behind a horizontal sliding block, the first adjusting component adjusts the vertical spaced distance between the upper weed pressing roller and the lower weed pressing roller, and the second adjusting component adjusts the horizontal deviation distance between the vertical axial through face of the upper weed pressing roller and the vertical axial through face of the lower weed pressing roller. The horizontal deviation distance between the vertical axial through face of the upper weed pressing roller and the vertical axial through face of the lower weed pressing roller is adjusted, therefore, the contact area of wool is increased when the wool passes through the upper weed pressing roller and the lower weed pressing roller, the upper weed pressing roller and a lower weed pressing roller are pressed in a rubbing mode to enable weeds mixed in the wool to easily fall off, and in addition, due to the fact that the rotating speed of the upper weed pressing roller is smaller than that of the lower weed pressing roller, the twisting effect of the upper weed pressing roller and the lower weed pressing roller on the weed impurities is enhanced.

Owner:青岛东佳纺机(集团)有限公司

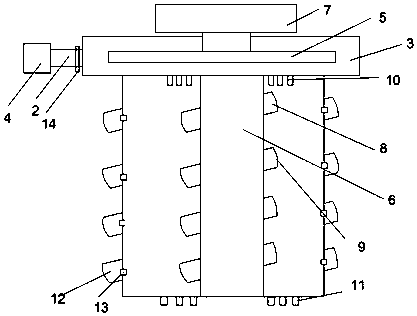

Jet vortex spinning twister and operation method thereof

PendingCN109322015AImprove twisting effectIncrease twisting strengthContinuous wound-up machinesOpen-end spinning machinesConductive materialsAerospace engineering

The invention discloses a jet vortex spinning twister. The jet vortex spinning twister comprises a twister body, the upper portion of the twister body is provided with an air path circulation chamberwith an air inlet pipe on one side, the air inlet pipe is connected with a heater for heating air, a motor is arranged above the air path circulation chamber, an output shaft of the motor extends intothe air path circulation chamber and is provided with a circulation fan, a fixing column is arranged in the twister body, and air path guiding rods are spirally distributed on the fixing column; theends of the air path guiding rods are inclined arc-shaped curves, the two sides of the junction between the air path circulation chamber and the twister body are both provided with one or more small air inlet holes, the lower portion of the twister body is provided with one or more small air outlet holes relative to the two sides of the fixing column, and the twister body is made of a heat conductive material. The invention also discloses an operation method of the jet vortex spinning twister. The twisting effect is improved.

Owner:苏州璟珮新材料科技有限公司

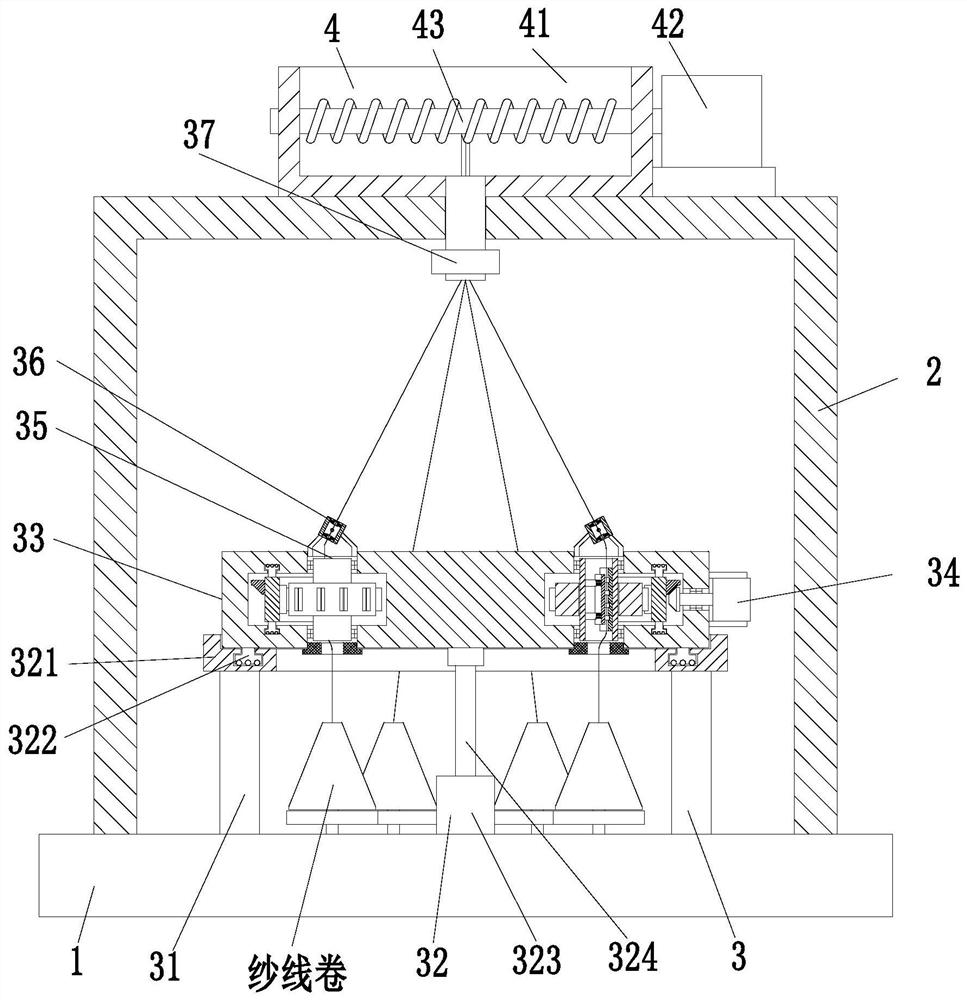

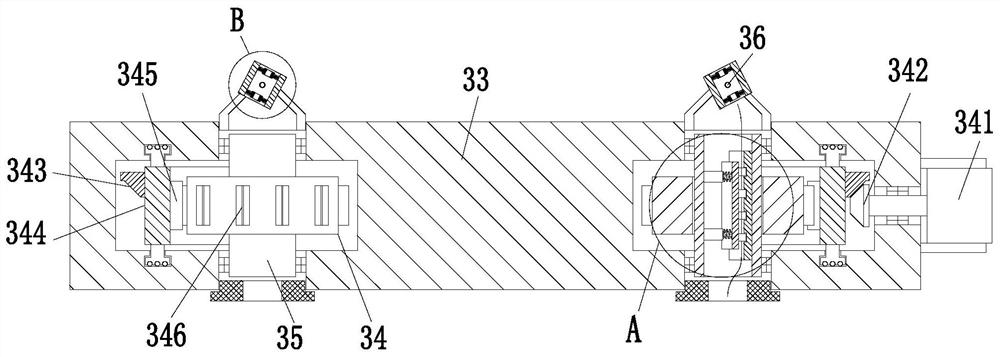

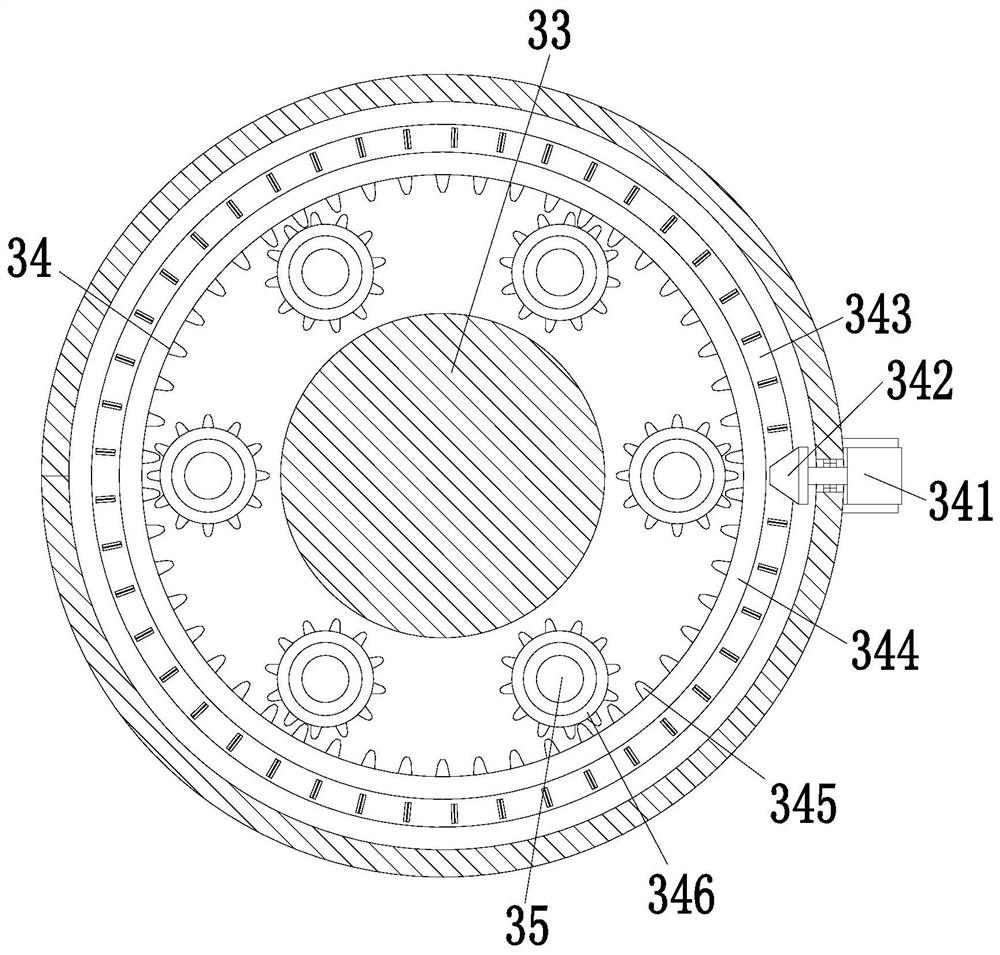

A production device for core-spun yarn

ActiveCN113638084BQuality improvementAchieve self-rotationLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsYarnBobbin

The invention discloses a core-spun yarn production device, which comprises a bottom plate, on which a wire take-up device is arranged, and the wire take-up device includes a motor, the motor is fixedly connected to the upper end of the bottom plate, and the upper end of the bottom plate is fixedly connected to a gear ring, and the motor The output shaft is fixedly connected with a turret, the turret is rotatably connected with a rotating shaft, and one end of the rotating shaft located inside the turret is fixedly connected with a bobbin, the gear one meshes with the gear ring, the wire take-up device includes a wiring device, and the wiring device includes a chute, The chute is set on the turret, and the turret slides to connect the moving block through the chute. There are wire holes on the moving block. The gear two meshes with the first gear. The upper end is provided with a water tank, the end of the water tank close to the motor is provided with a slot, and the wire take-up device also includes a water squeezing device. Compared with the traditional device, the present invention has a better twisting effect on the yarn and can make the yarn softer at the same time.

Owner:南通凌通纺织机械制造有限公司

A kind of production process of regenerated dori slub silk

The invention discloses a production process of regenerated dori slub silk, which comprises the following steps: compounding the regenerated semi-dull MOY introduced through the original silk rack and zero roller and the regenerated semi-dull FDY introduced through the original silk rack through a roller, Then the compounded tow is sent into the deformation heat box for heat treatment, and then cooled by the cooling plate, and then input into the false twister for twisting, and the twisted tow passes through the second roller, the network nozzle, the auxiliary roller, and the shaping heat box , the third roller, and then oiled by the oiling system, and finally wound to form the Duoli slub DTY. The production process of the process is stable and the production efficiency is high, and the color of the finished dori slub silk produced by the process is more natural and beautiful, and the performance is better.

Owner:浙江佳人新材料有限公司

A continuous automatic production method of flax yarn

The invention relates to the linen yarn production technology field and especially relates to the continuous automatic production method of a linen yarn. A front processing portion, a heckling portion, a beam splitting portion, a twisting portion, a drawing portion and a blended yarn portion are included. After a linen raw material is split into a plurality of raw material bundles, a hackling machine carries out carding on the raw material bundles so as to obtain long fibers and short fibers. When the long fibers are transferred, the long fibers are split into bundles and the fiber bundles aresequentially pushed into an output component. Through the output component, the previous group of fiber bundles and the next group of fiber bundles in the output component are overlapped in an end-to-end mode, and during an output process, the fiber bundles are staggered and intertwined. A bundle splitting mechanism is used to split the long fibers in a directional transfer process through a guiding splitting mode, and then, the two adjacent groups of fiber bundles are directionally output in an end-to-end overlapping manner, and at the same time automatic winding is performed so as to realize the high-quality automatic production of linen splitting and lap joint. The technical problem of unstable yarn quality due to uneven artificial bundle splitting existing in the prior art is solved.

Owner:湖北蜀峰线业发展有限公司

An adjustable yarn doubling device and its adjusting doubling method

ActiveCN111349987BPrevent slippingConducive to subsequent twisting processingContinuous wound-up machinesYarnEngineering

The invention relates to an adjustable yarn doubling and twisting device and an adjusting, doubling and twisting method thereof. The adjustable yarn doubling and twisting device comprises a bottom plate, a support frame, a doubling and twisting device and a winding device, wherein the support frame is arranged at the upper end of the bottom plate; the cross section of the support frame is of a U-shaped structure; the doubling and twisting device is arranged in the support frame and is arranged on the bottom plate; and the winding device is arranged in the middle of the upper end of the supportframe. According to the adjustable yarn doubling and twisting device, the problem that yarns are poor in winding effect and prone to loosening due to the fact that single yarn cannot be accurately driven to rotate when twirled by existing equipment, and easily slips, and the problem that the existing equipment is poor in pressing effect and inconvenient to adjust while pressing the doubled and twisted yarns and can only press the yarns with the same diameter to affect the processing efficiency of the yarns can be solved.

Owner:南县生辉纺织有限公司

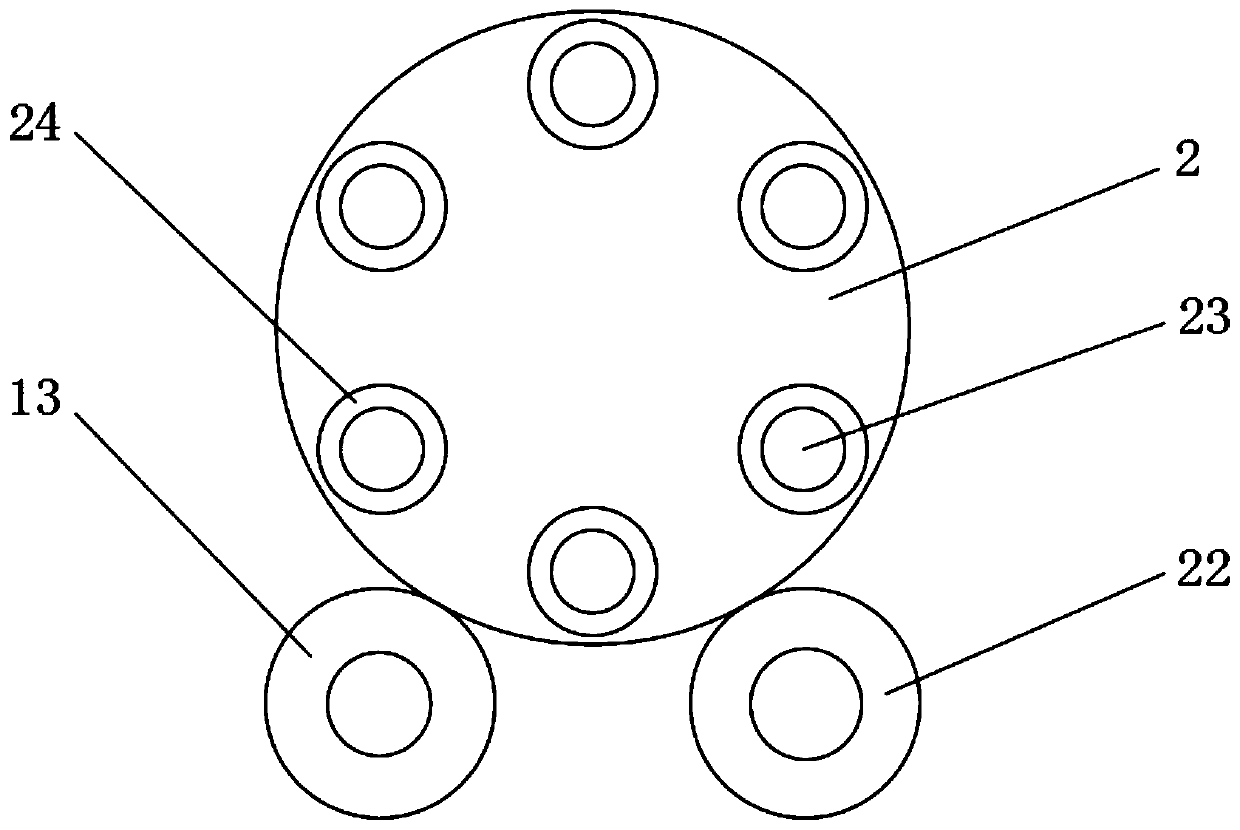

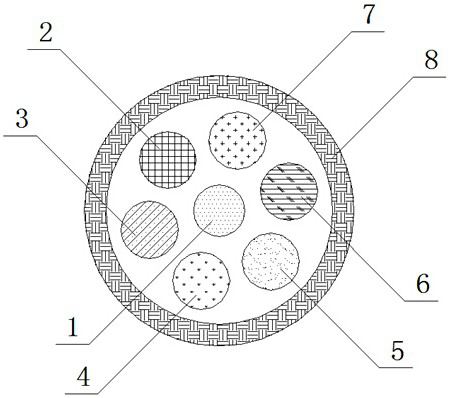

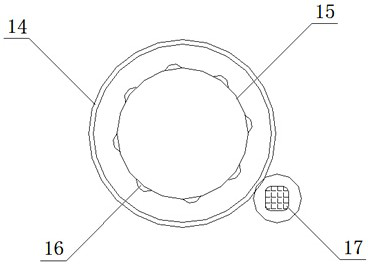

A flame-retardant and antistatic composite yarn and its processing method and opening and twisting device

ActiveCN106435889BImprove flame retardant performanceImprove anti-static performanceYarnPolymer scienceCellulose fiber

The invention relates to flame-retardant and antistatic composite yarn, a processing method and an opening and twisting device. The flame-retardant and antistatic composite yarn is characterized by comprising center fiber, the center fiber is characterized in that the center fiber is conductive cellosilk (1), and combed cotton fiber (2), polyester filament yarn (3), flame-retardant acrylic fiber (4), polysulfonamide fiber (5), nylon fiber (6) and natural cellulose fiber (7) are woven and wound around the outer surface of the conductive cellosilk (1). On the cross section of the composite yarn, fireproof flame retardance and antistatic property of the composite yarn are greatly improved, good characteristics of multiple kinds of fiber are effectively integrated, the composite yarn is suitable for high-speed sewing, good in twisting effect, high in sewing processing efficiency and breathability, and special clothes made of the composite yarn are high in wearing comfort.

Owner:JIHUA 3506 TEXTILE & APPL

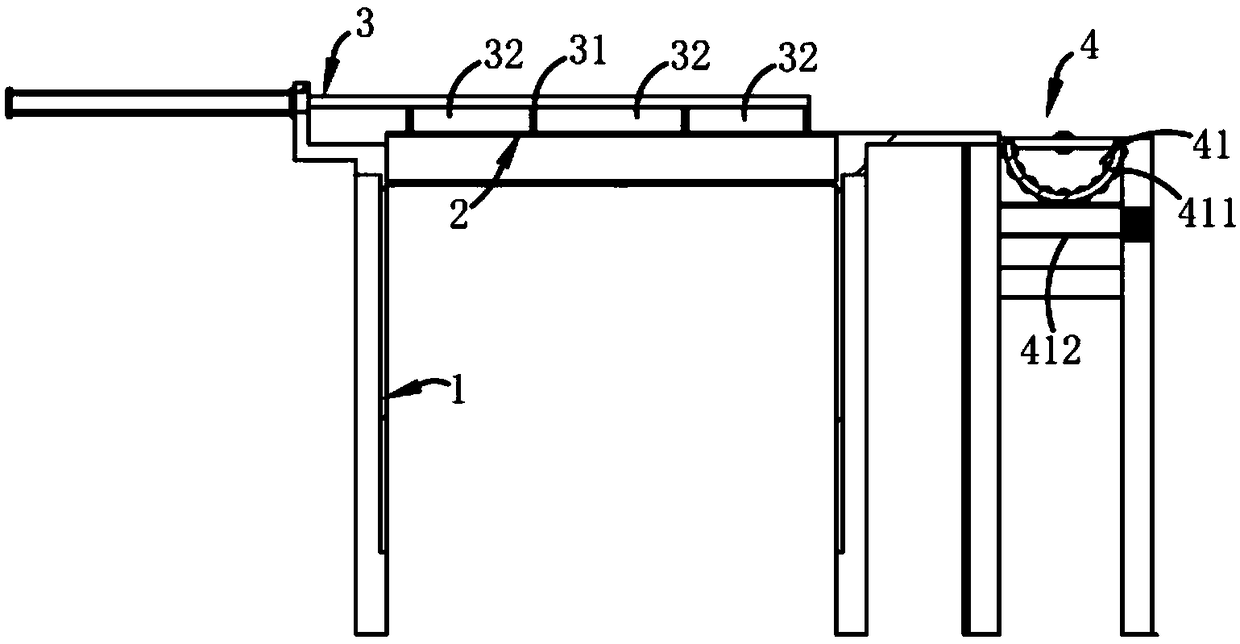

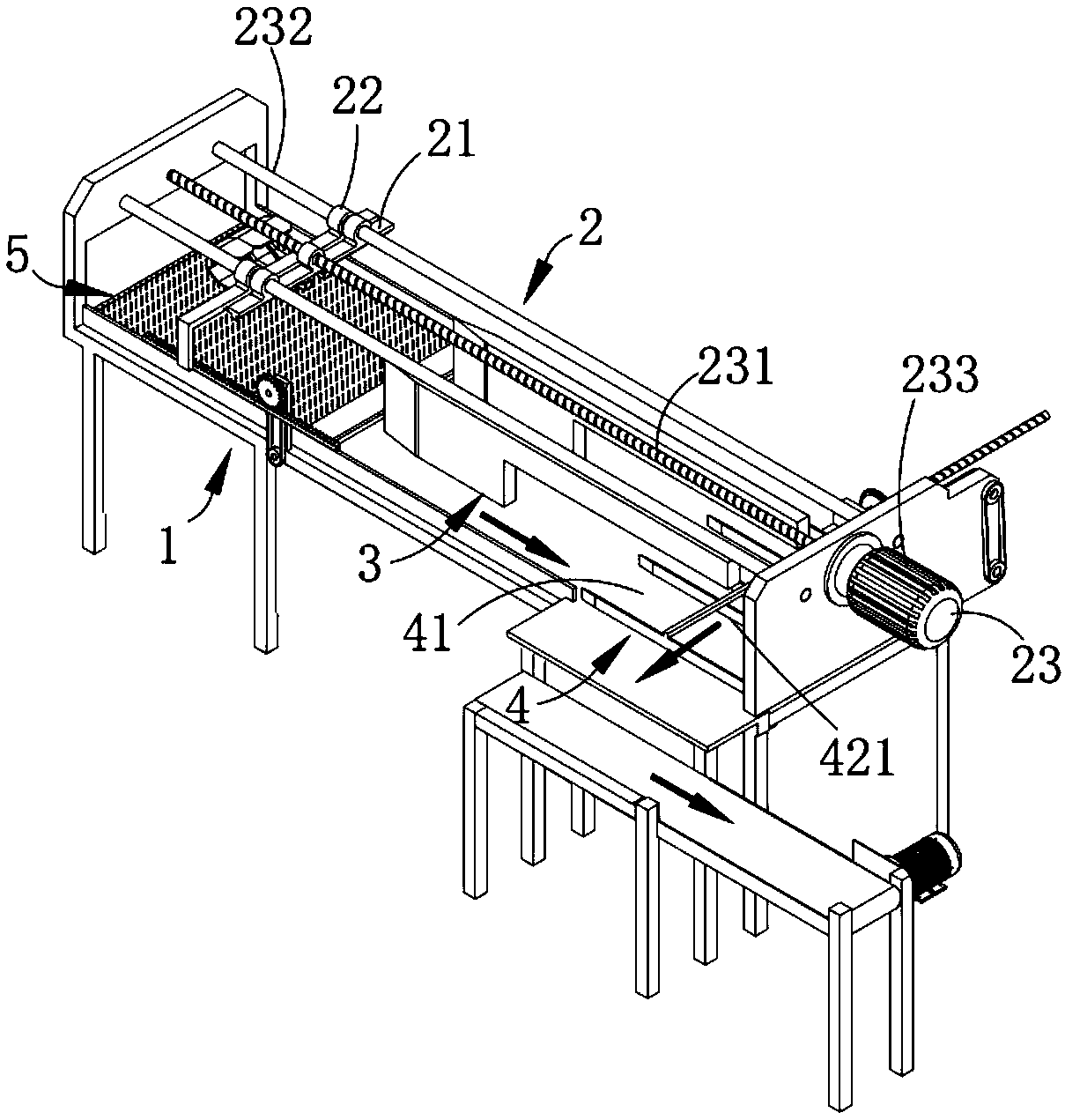

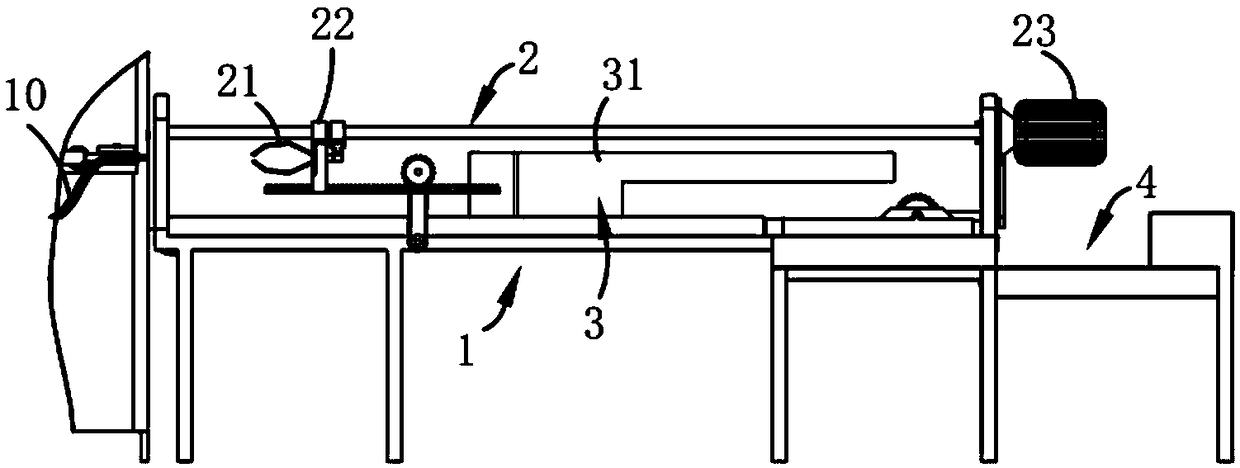

Automatic beam splitting equipment for linen yarn production

InactiveCN109023542ARealize fully automatic workSolve the technical problems of low production efficiency in manual operationHackling machinesYarnFiber bundle

The invention relates to the technical field of linen yarn production, in particular to automatic beam splitting equipment for linen yarn production. The equipment comprises a rack, a traction mechanism, a beam splitting mechanism and an output mechanism, wherein the traction mechanism comprises clamping assemblies, a fastening assembly and a driving assembly, and continuous fibers carded by a heckling machine are transferred through the clamping mechanisms; two adjacent clamping mechanisms are separated through the beam splitting mechanism to form fiber bundles; the output mechanism is arranged at the rear section of the beam splitting mechanism, and driven by the driving assembly to output the fiber bundles formed after beam splitting; automatic beam splitting and automatic output are performed on the long fibers through the traction mechanism when the long fibers are indirectly transferred, and the arrangement of a special mechanism of a carding mechanism is combined, so that automatic removing and output are performed on short fibers before beam splitting is performed on the long fibers, the automatic production of beam splitting the long fibers is achieved, and the technical problem of low production efficiency of manual operation in the prior art is solved.

Owner:CHANGXING HAIPU MACHINERY TECH CO LTD

A twisting mechanism for spinning machine

The present invention relates to the field of spinning machines, in particular to a twisting mechanism for spinning machines, which includes a turntable, on which there are several chutes, slidingly connected to sliders in the chutes, and a slider on the top of the sliders. Groove, a fixed block is connected in the groove, a vertical bar is fixedly connected to the top of the fixed block, a swivel is connected above the center of the turntable through a connecting rod, a thrust spring is provided on the end of the slider close to the swivel, and the two ends of the thrust spring are respectively connected with the The inner wall of the chute is fixedly connected with the slider; the side wall of the chute near the swivel and the side wall away from the swivel are equipped with switches; the center of the vertical bar is vertically slid and connected with a top slide bar, and the bottom of the top slide bar rotates An upper slide is connected, a lower slide is provided under the upper slide, an airbag is provided between the upper slide and the lower slide, side panels are provided on both sides of the airbag, and the upper slide and the lower slide are slidably connected to the side panels; both ends of the airbag are provided with The friction block runs through the side wall of the vertical bar and is slidably connected with the side wall of the vertical bar.

Owner:JIANGSU NASKA NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com