A production device for core-spun yarn

A production device and core-spun yarn technology, which is applied in the field of core-spun yarn production, can solve problems such as poor hand feel, poor comfort, and hard yarn, and achieve the effects of easy use, quality improvement, and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

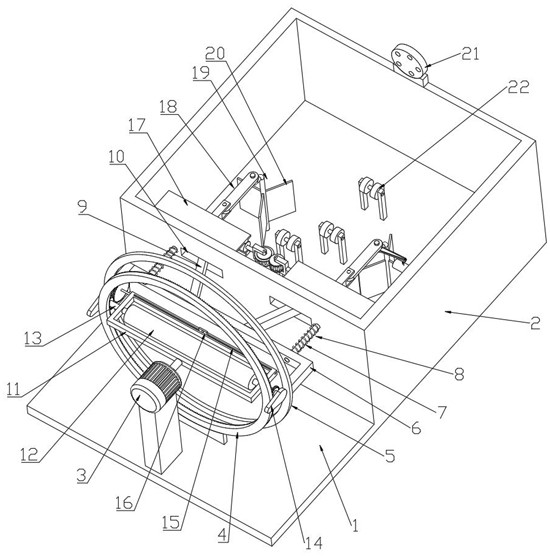

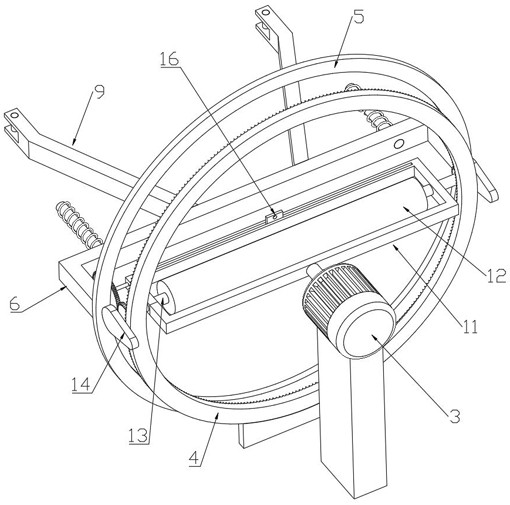

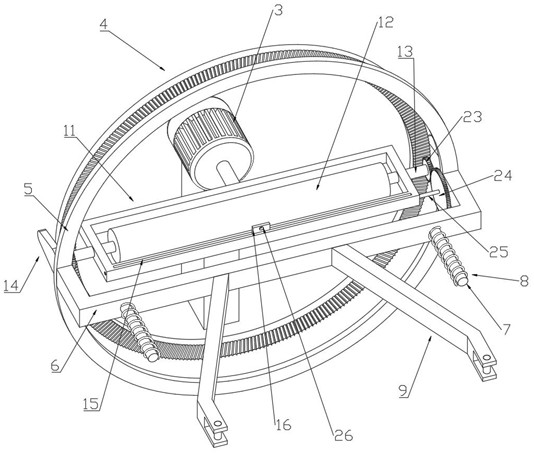

[0034] see Figures 1 to 4 , the present invention provides a technical solution: a production device for core-spun yarn, comprising a base plate 1, a wire take-up device is arranged on the base plate 1, the wire take-up device includes a motor 3, the motor 3 is fixedly connected to the upper end of the base plate 1, and the base plate The upper end of 1 is fixedly connected with the gear ring 4, the output shaft of the motor 3 is fixedly connected with the turret 11, the turret 11 is rotatably connected with the rotating shaft 13, and the end of the rotating shaft 13 located inside the turret 11 is fixedly connected with the bobbin 12, the rotating shaft 13 One end away from bobbin tube 12 is fixedly connected with gear one 23, and gear one 23 meshes with gear ring 4. The take-up device includes a wiring device, and the wiring device includes a chute 15. The chute 15 is opened on the turret 11, and the turret 11 The moving block 16 is slidably connected by the chute 15, the m...

Embodiment 2

[0042] Embodiment 2: A production device for core-spun yarn, comprising a base plate 1, characterized in that: the base plate 1 is provided with a wire take-up device, the wire take-up device includes a motor 3, the motor 3 is fixedly connected to the upper end of the base plate 1, and the base plate 1 The upper end of the motor 3 is fixedly connected with the gear ring 4, the output shaft of the motor 3 is fixedly connected with the turret 11, the turret 11 is rotatably connected with the rotating shaft 13, and the end of the rotating shaft 13 located inside the turret 11 is fixedly connected with the bobbin 12, and the rotating shaft 13 is away from the One end of bobbin tube 12 is fixedly connected with gear one 23, and gear one 23 meshes with gear ring 4, and the wire take-up device includes a wiring device, and the wiring device includes a chute 15, and the chute 15 is opened on the turret 11, and the turret 11 passes through The chute 15 is slidably connected to the movin...

Embodiment 3

[0053] A production device for core-spun yarn, comprising a base plate 1, characterized in that: the base plate 1 is provided with a wire take-up device, the wire take-up device includes a motor 3, the motor 3 is fixedly connected to the upper end of the base plate 1, and the upper end of the base plate 1 is fixedly connected to There is a gear ring 4, the output shaft of the motor 3 is fixedly connected with a turret 11, and the turret 11 is rotatably connected with a rotating shaft 13, and one end of the rotating shaft 13 located inside the turret 11 is fixedly connected with a bobbin 12, and the rotating shaft 13 is far away from the bobbin 12. One end is fixedly connected with a gear one 23, the gear one 23 meshes with the gear ring 4, the wire take-up device includes a wiring device, the wiring device includes a chute 15, the chute 15 is set on the turret 11, and the turret 11 slides through the chute 15 Connect the moving block 16, the moving block 16 is provided with a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com