Patents

Literature

71results about How to "Achieve self-rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

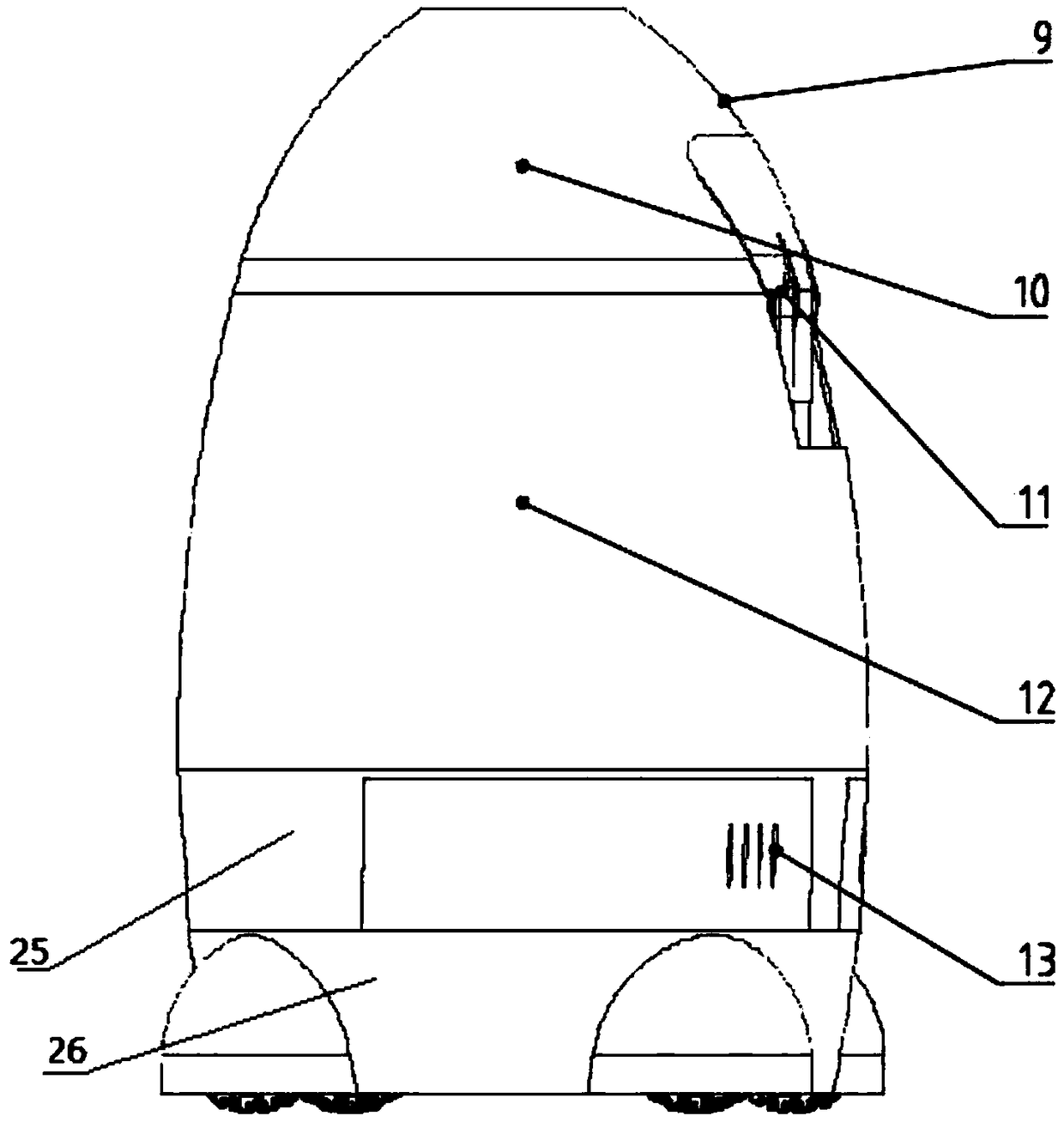

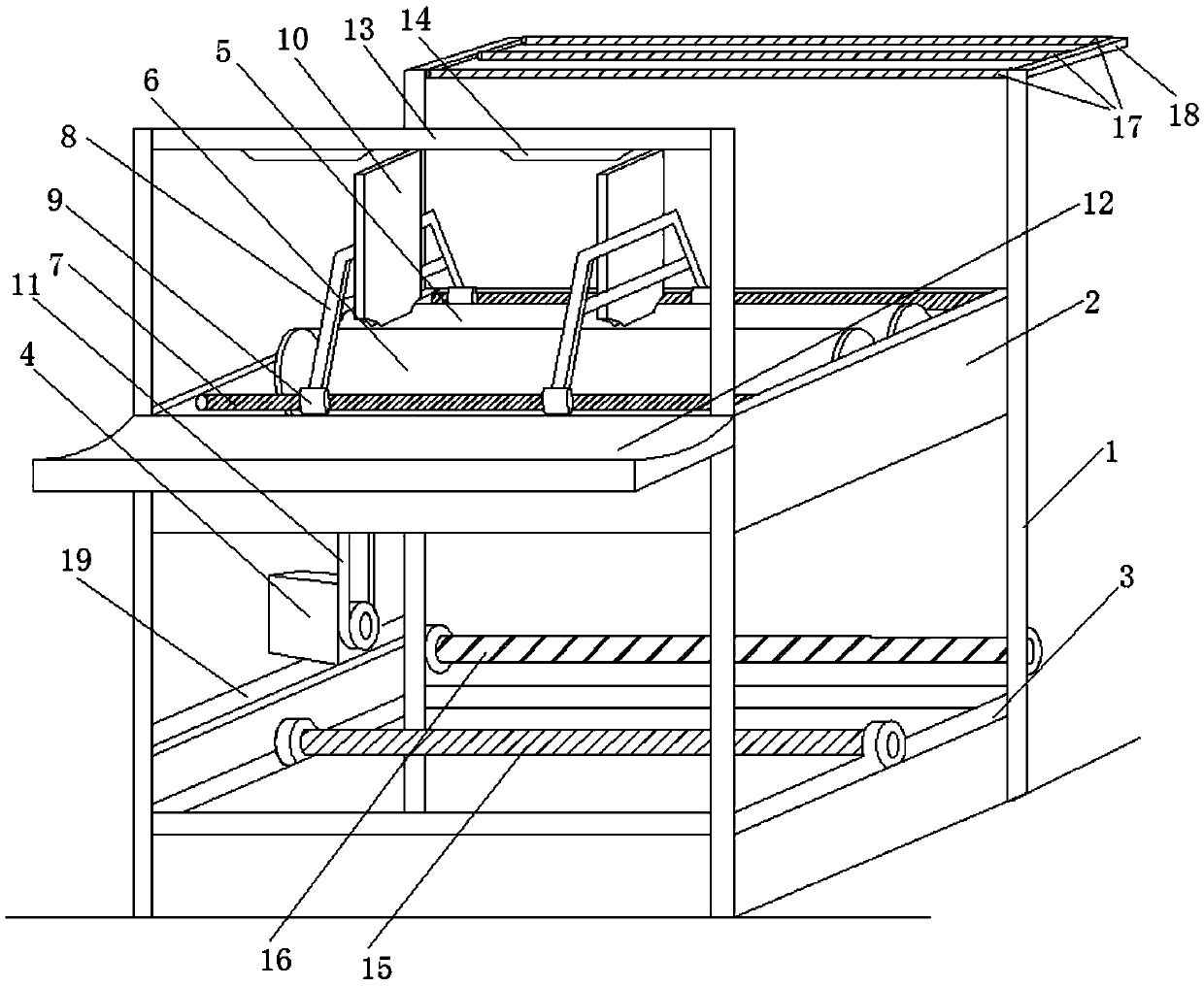

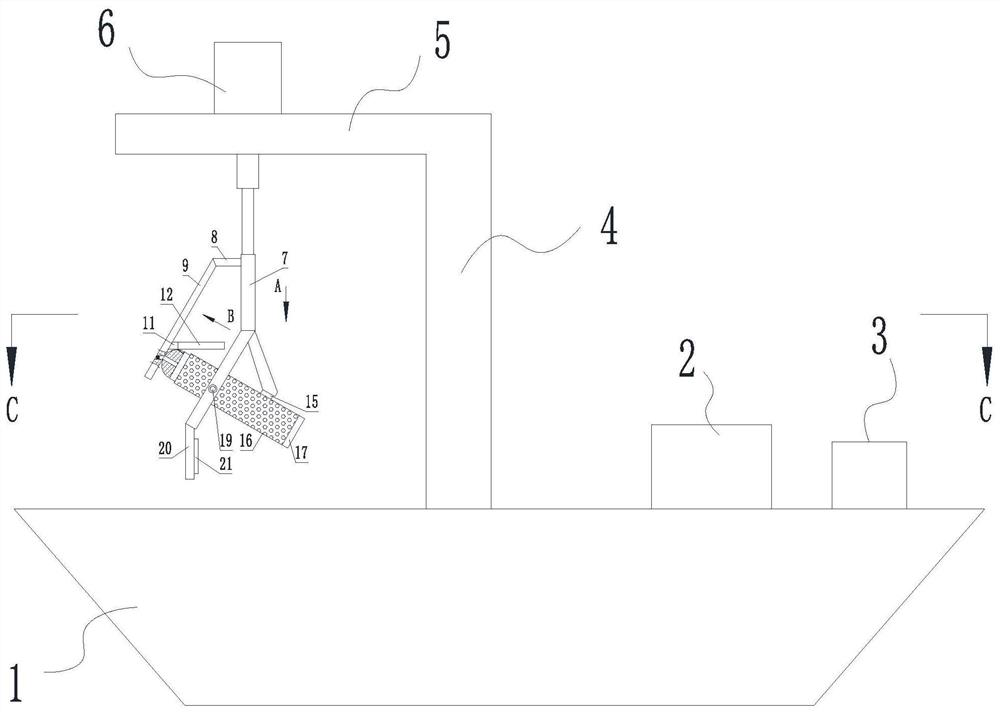

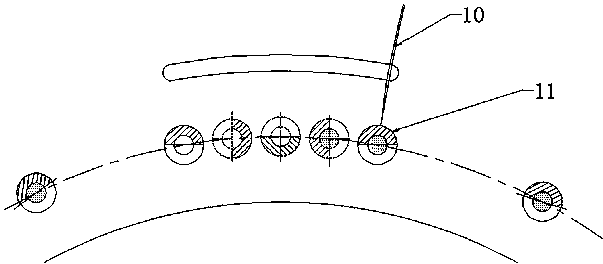

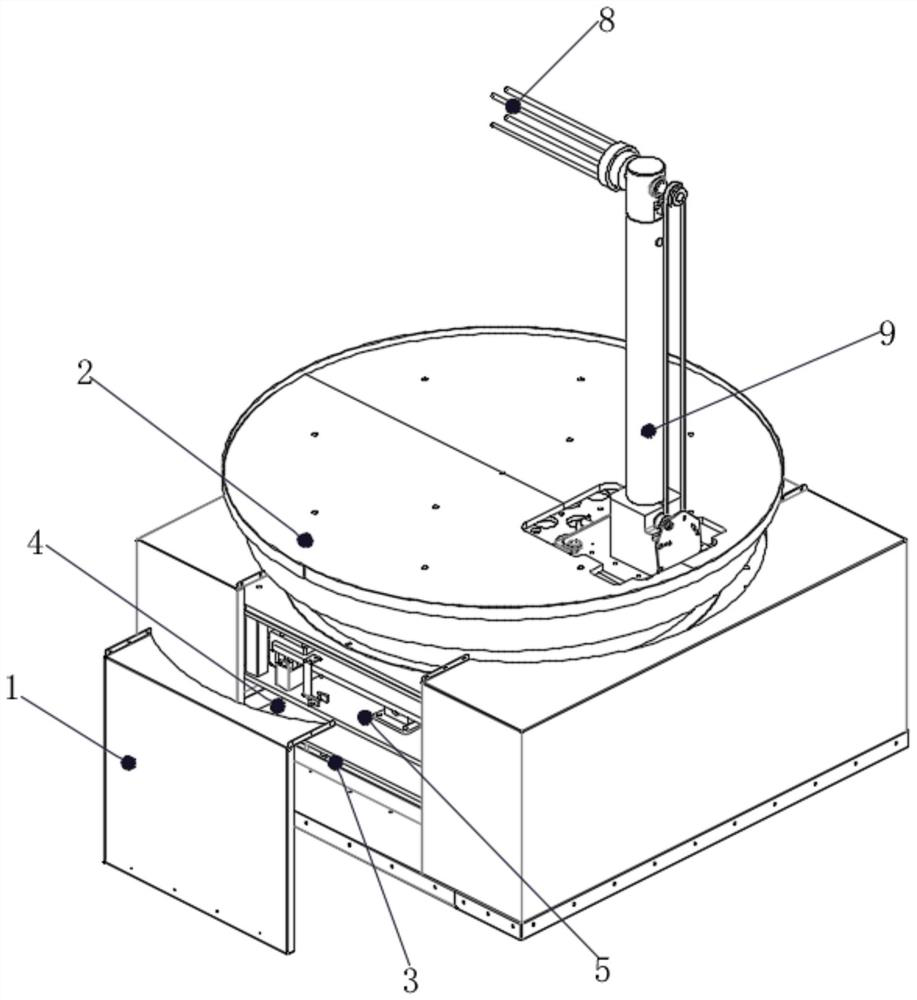

A tableware collection, cleaning and sorting robot system

ActiveCN109199292ARealize self-cleaningImprove battery lifeTableware washing/rinsing machine detailsCarpet cleanersRobotic systemsEngineering

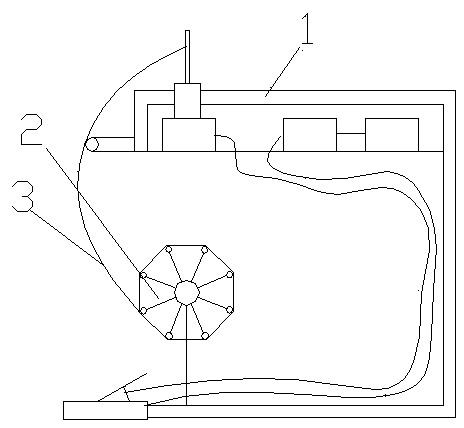

The invention discloses a tableware collection, cleaning and sorting robot system, which relates to the technical field of intelligent food and beverage, comprising a fixed table and a mobile robot. The fixed table comprises a table body and a cleaning device installed on both sides of the table body. The middle of the table body is a central panel that can incline downward. The bottom of the central panel is provided with a signal emitter. The bottom of the mobile robot is provided with a moving chassis. The inside of the mobile robot is a cavity structure, and a central cylinder which playsa supporting role is arranged at the middle of the cavity structure, and a washing layer, a separation layer and a collection layer are arranged sequentially from top to bottom along the central cylinder. The robot system has reasonable structure design, which can collect tableware, clean tableware, separate tableware and tidy table and is easy to use and flexible to move.

Owner:XI AN JIAOTONG UNIV

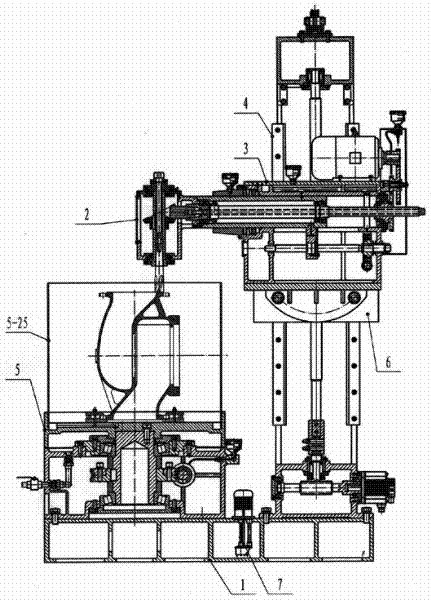

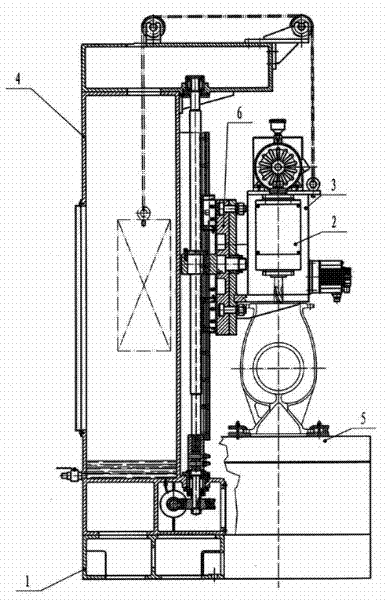

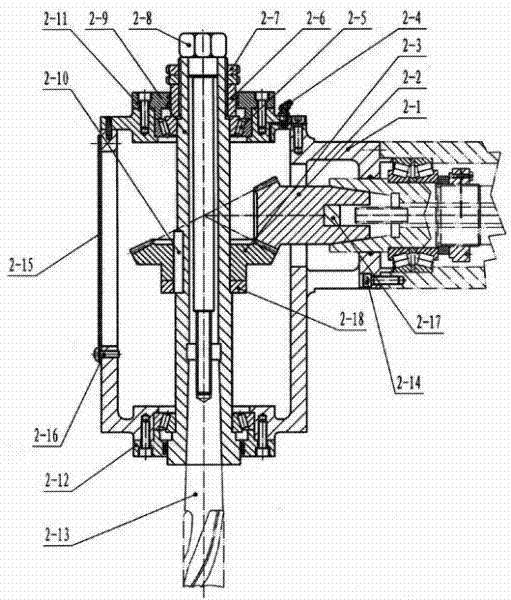

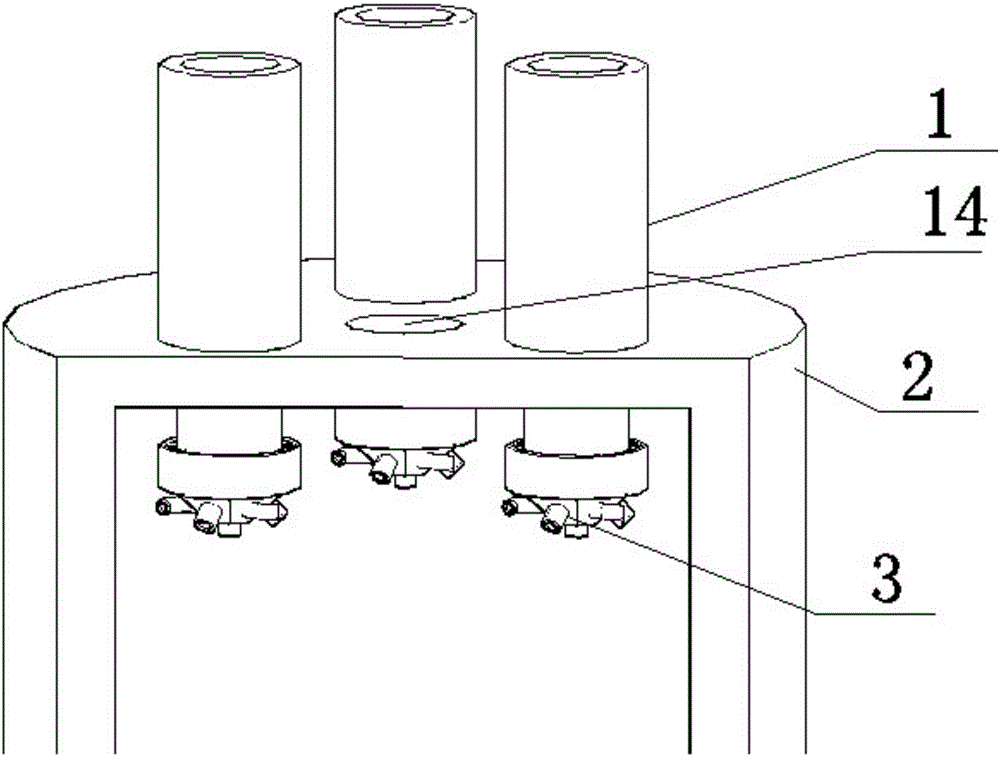

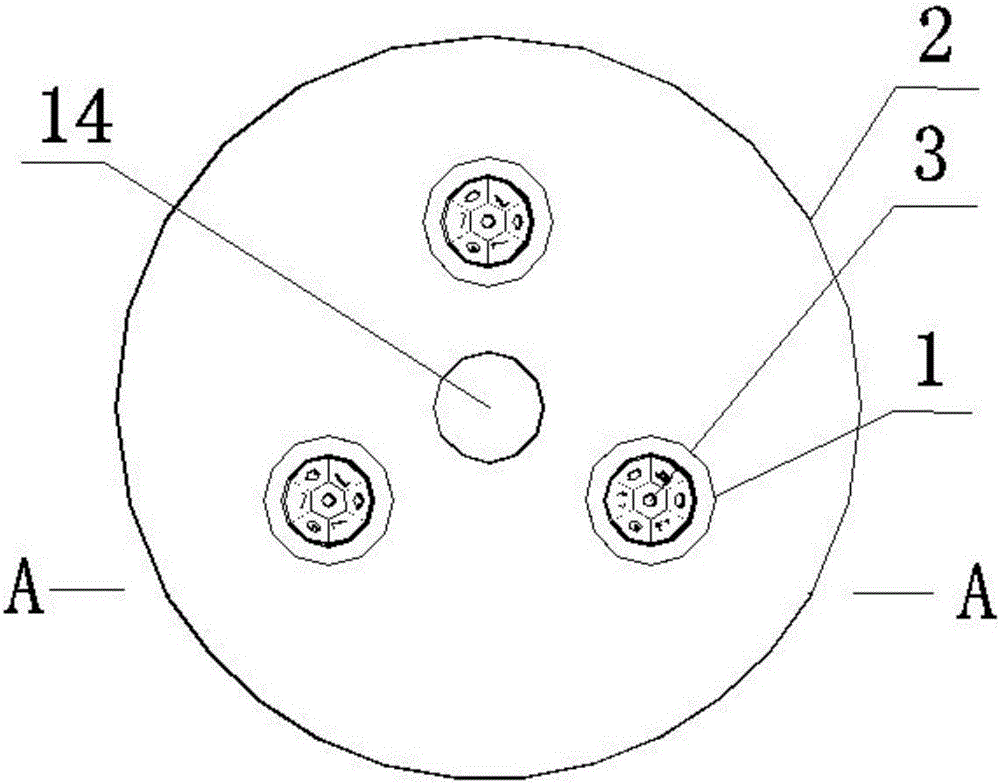

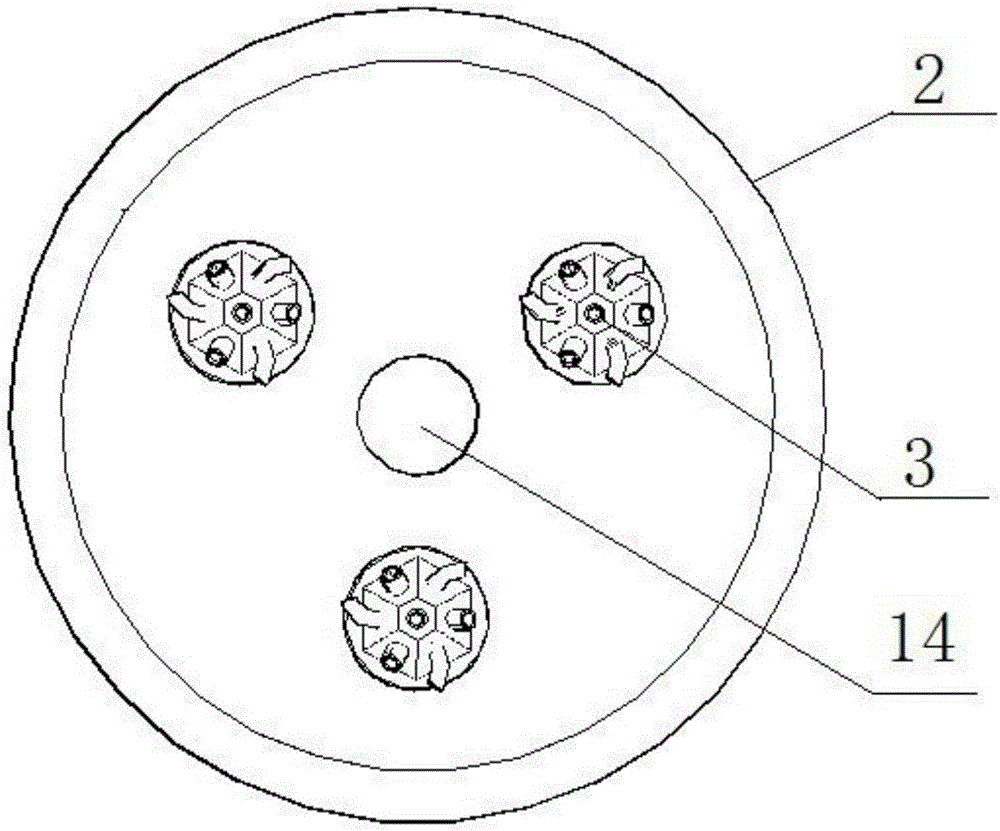

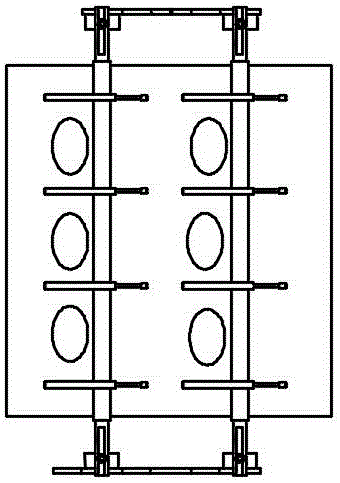

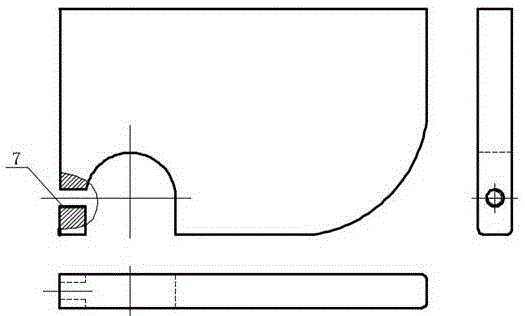

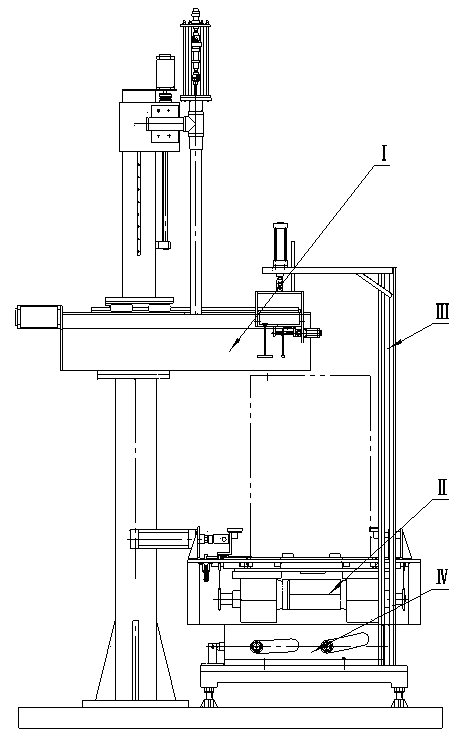

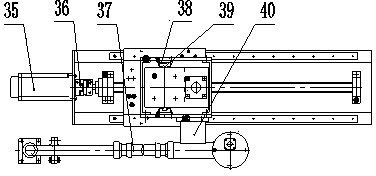

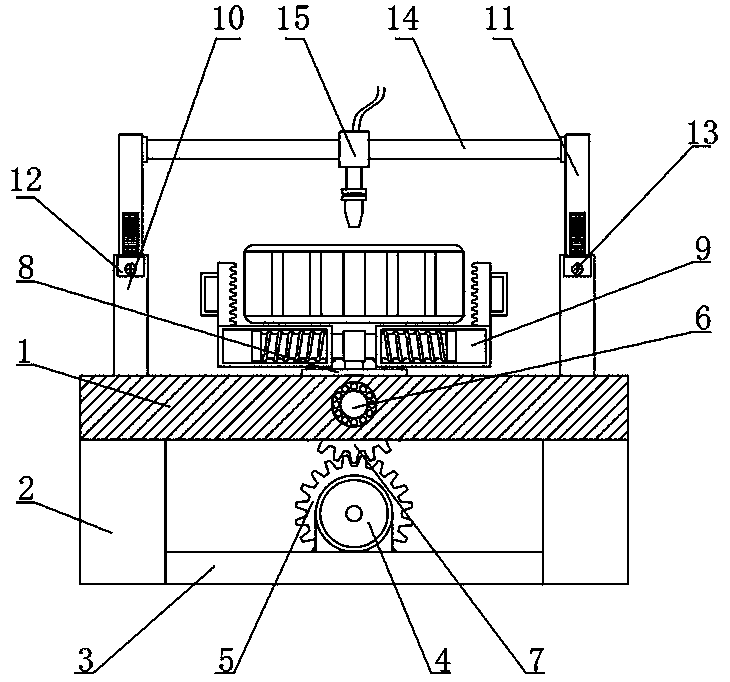

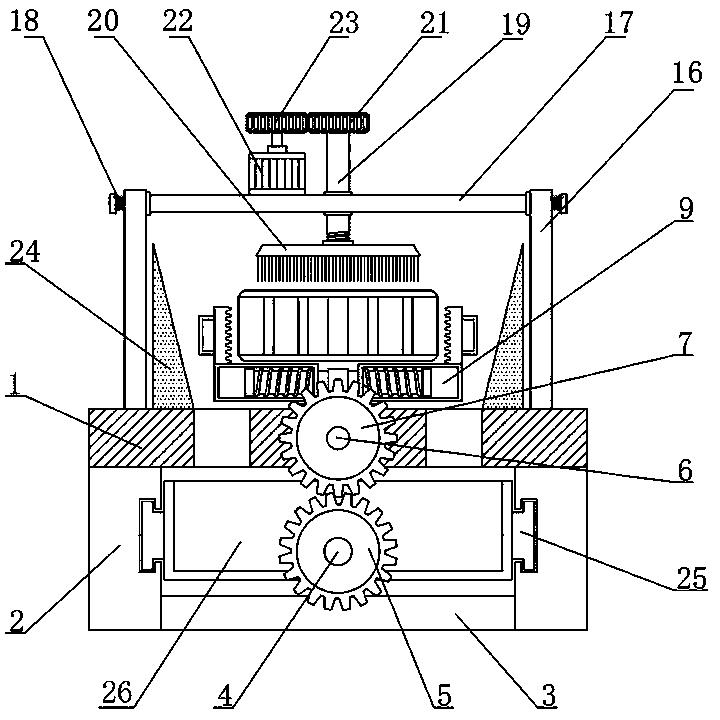

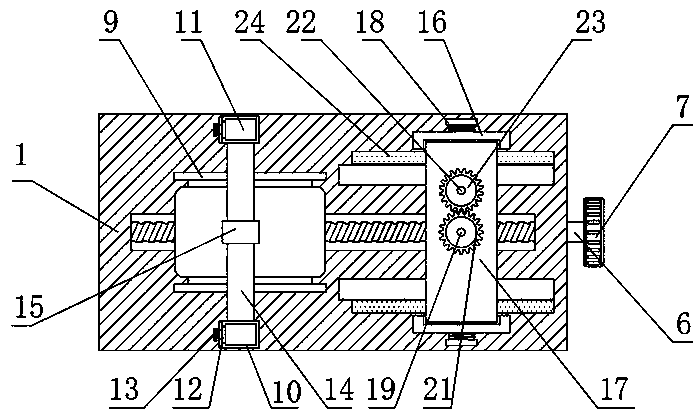

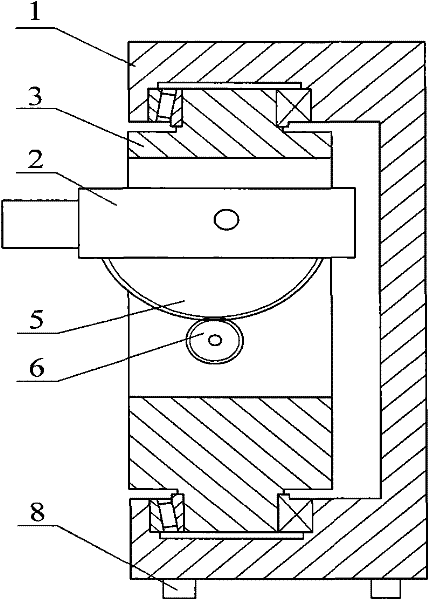

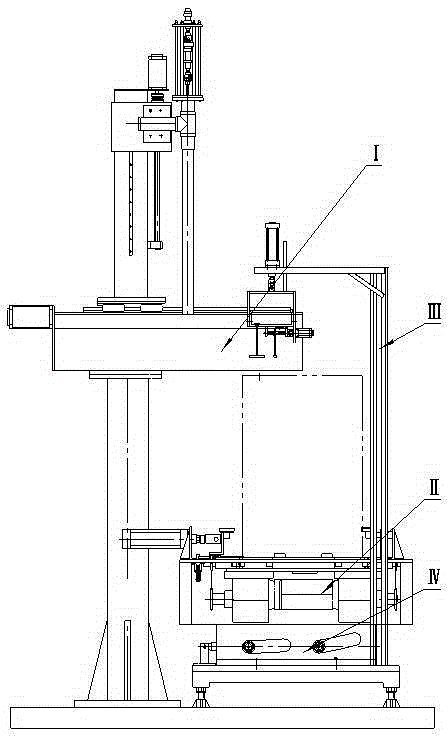

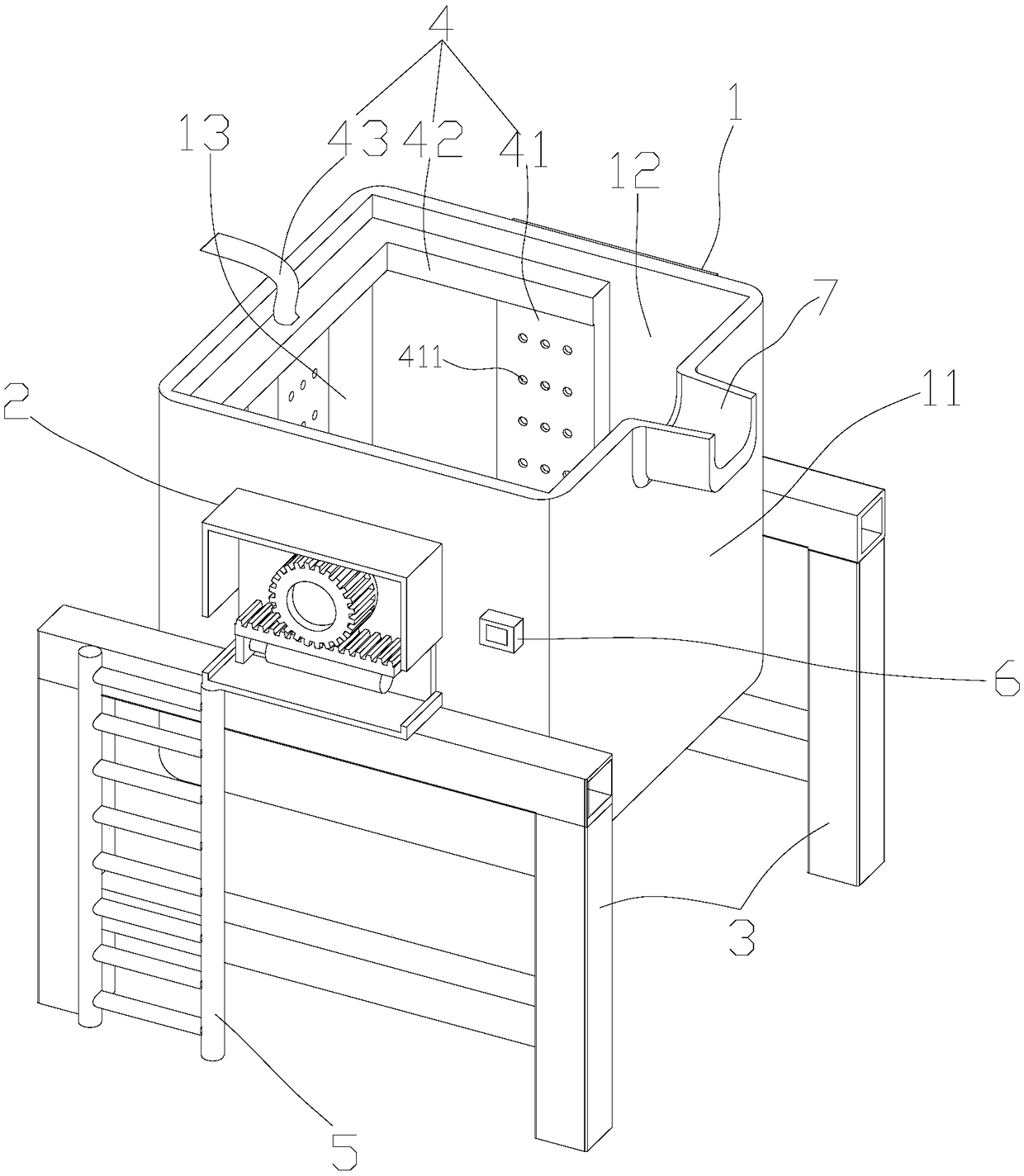

Multifunctional vertical combined machining lathe

InactiveCN102357799AEasy to replaceAdd processing functionOther manufacturing equipments/toolsLarge fixed membersEngineeringKnife holder

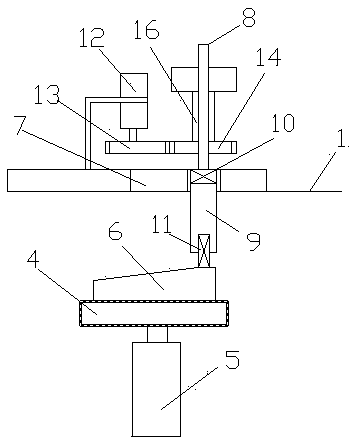

The invention provides a multifunctional vertical combined machining lathe. The multifunctional vertical combined machining lathe comprises a lathe body, a knife rest mechanism, a spindle box, an upright column mechanism and a control system, wherein, the upright column mechanism is fixed on the lathe body; the spindle box is assembled on the upright column mechanism; the knife rest mechanism is connected on the spindle box; a rotary worktable is fixed on the lathe body and is mainly composed of a rotating platform, a spindle, a frame and a servo motor; the rotating platform is equipped with a fixture for fixing parts and is fixed on the spindle; the spindle extends into the frame and is arranged on the frame through bearings at journals of upper and lower ends, and a sleeve and a worm wheel are arranged on the spindle between the bearings on the two ends; the frame is fixed on the lathe body and is equipped with a worm shaft meshed with the worm wheel on the spindle; and the servo motor is fixed on the frame and is used for driving the worm shaft. The multifunctional vertical combined machining lathe has the functions of ensuring the machining precision, realizing automatic rotation and transposition of the rotary worktable, facilitating the replacement of the machining cutters, and increasing the machining functions of the lathe, thus achieving higher practicability and obvious economic effect.

Owner:UNICIMA VALVE MFG CHENGDU

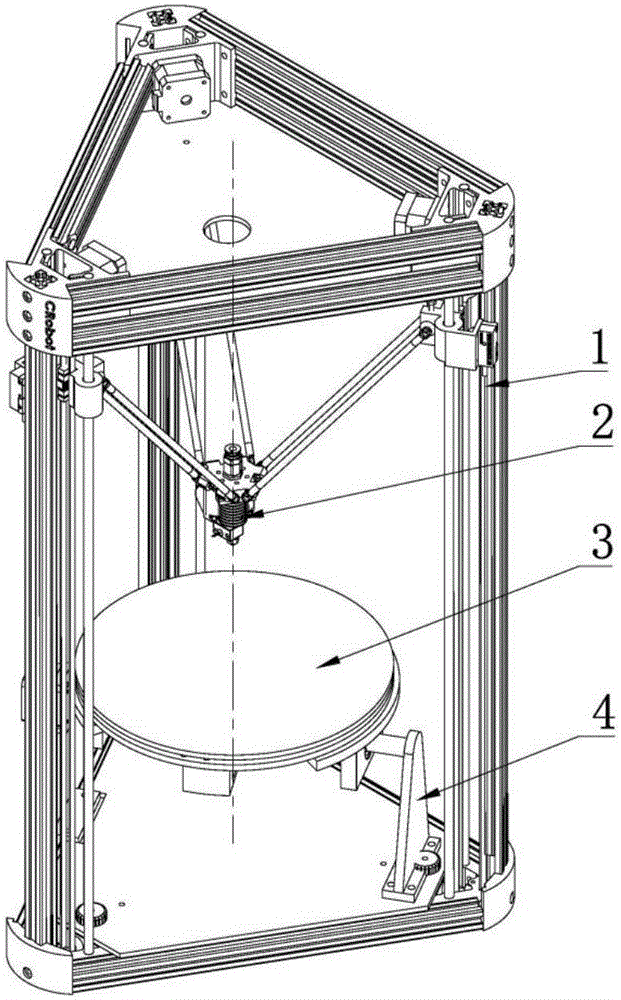

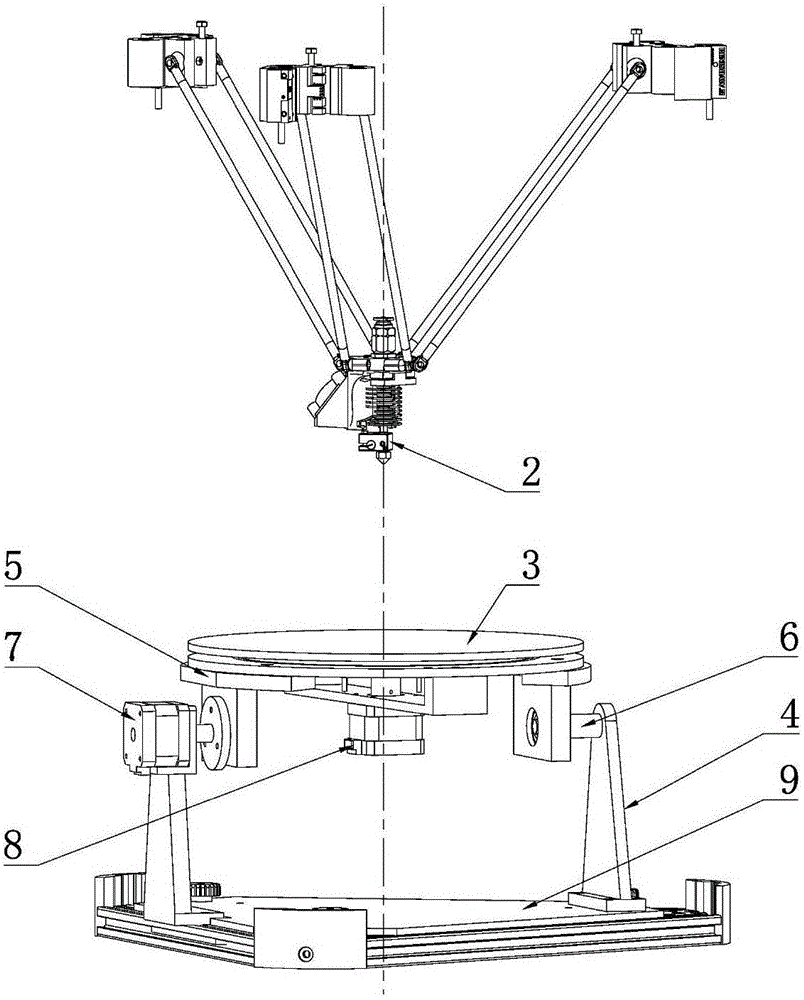

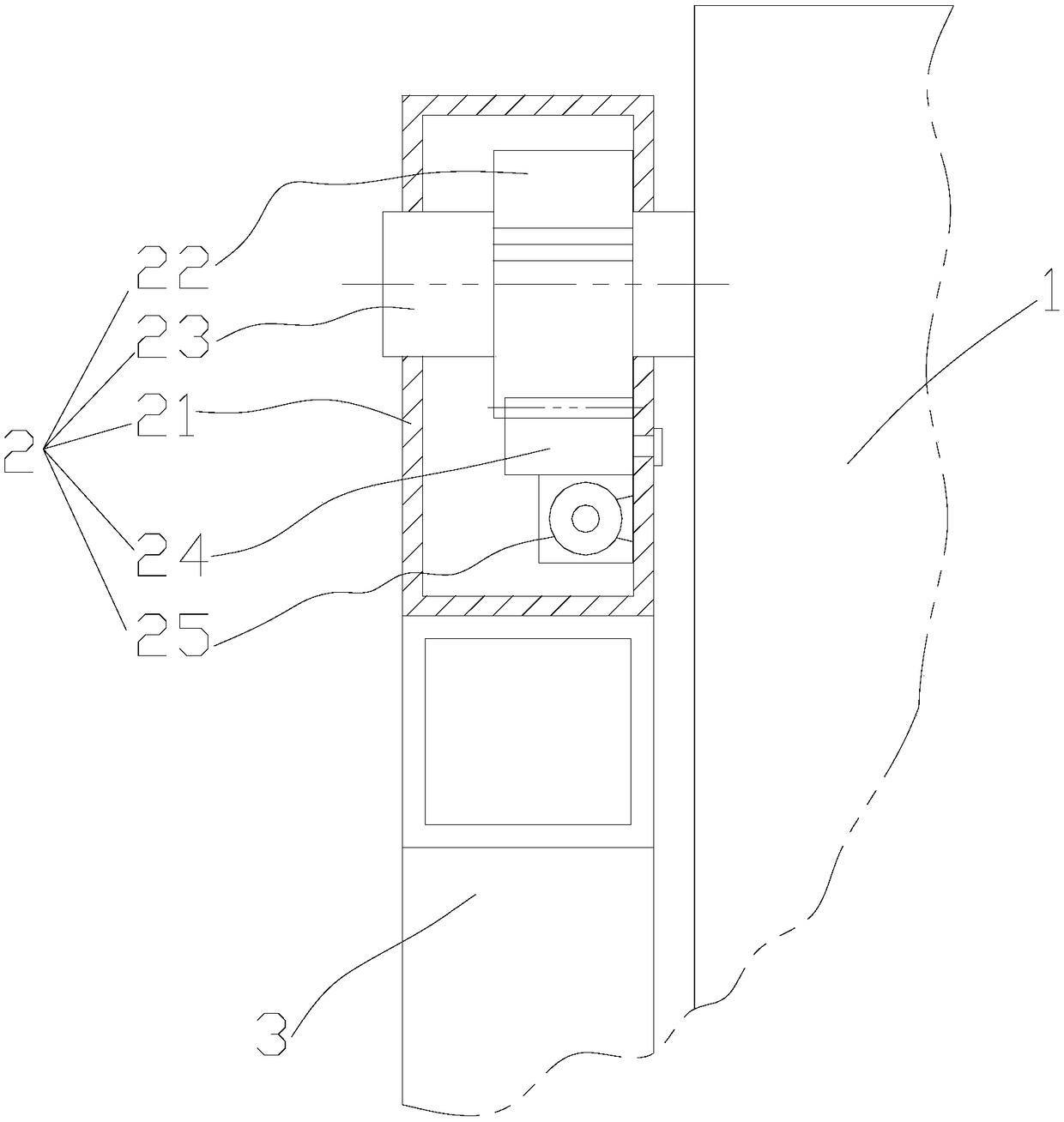

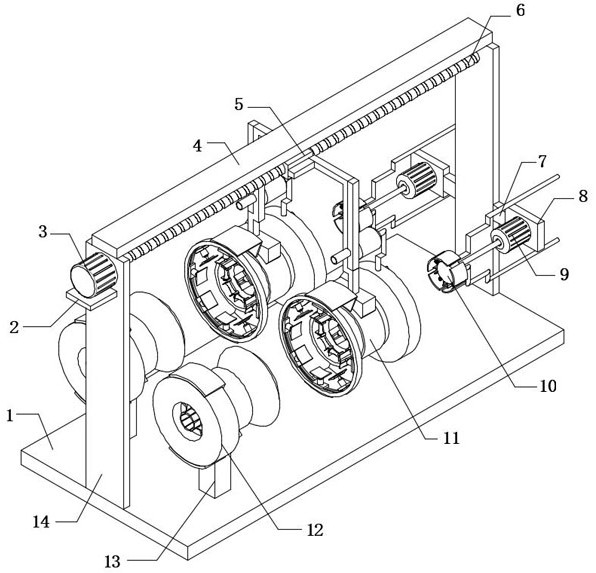

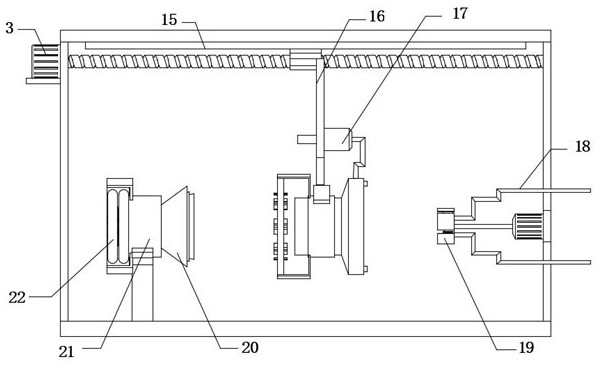

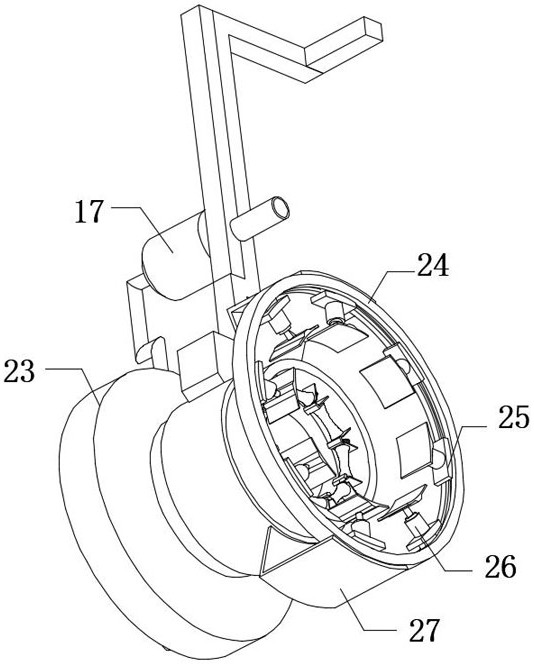

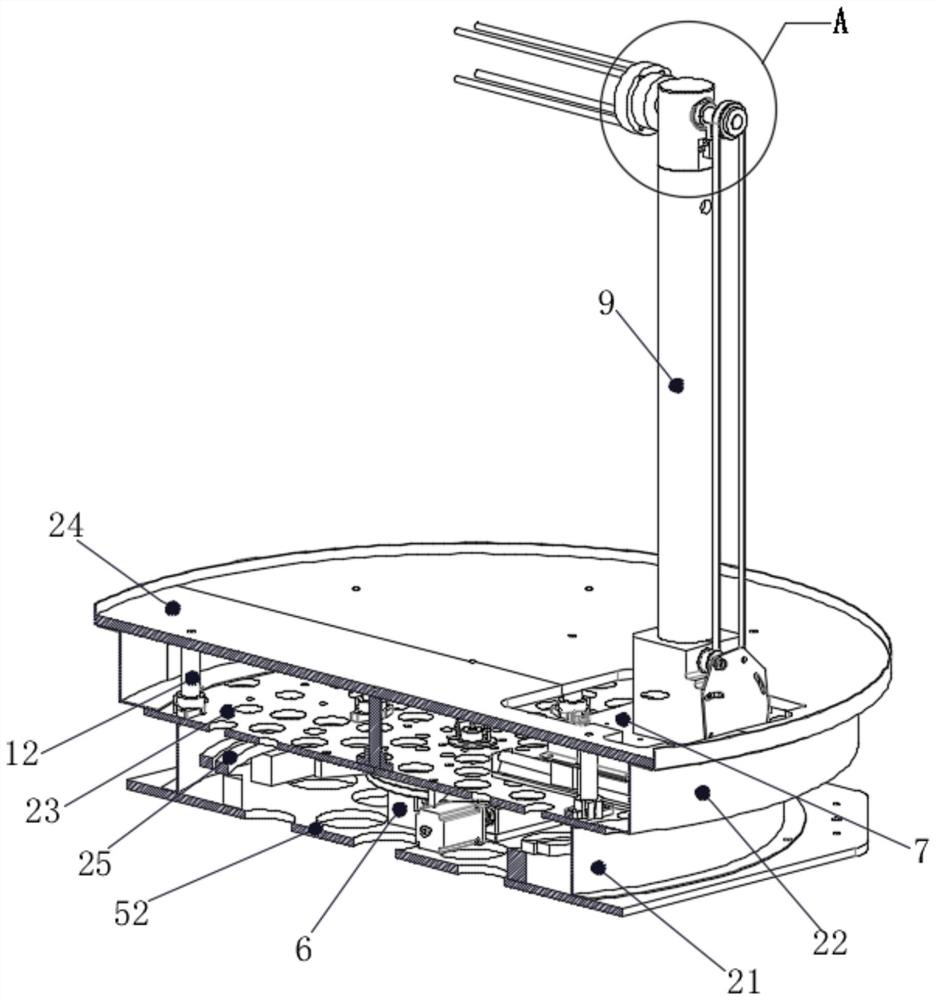

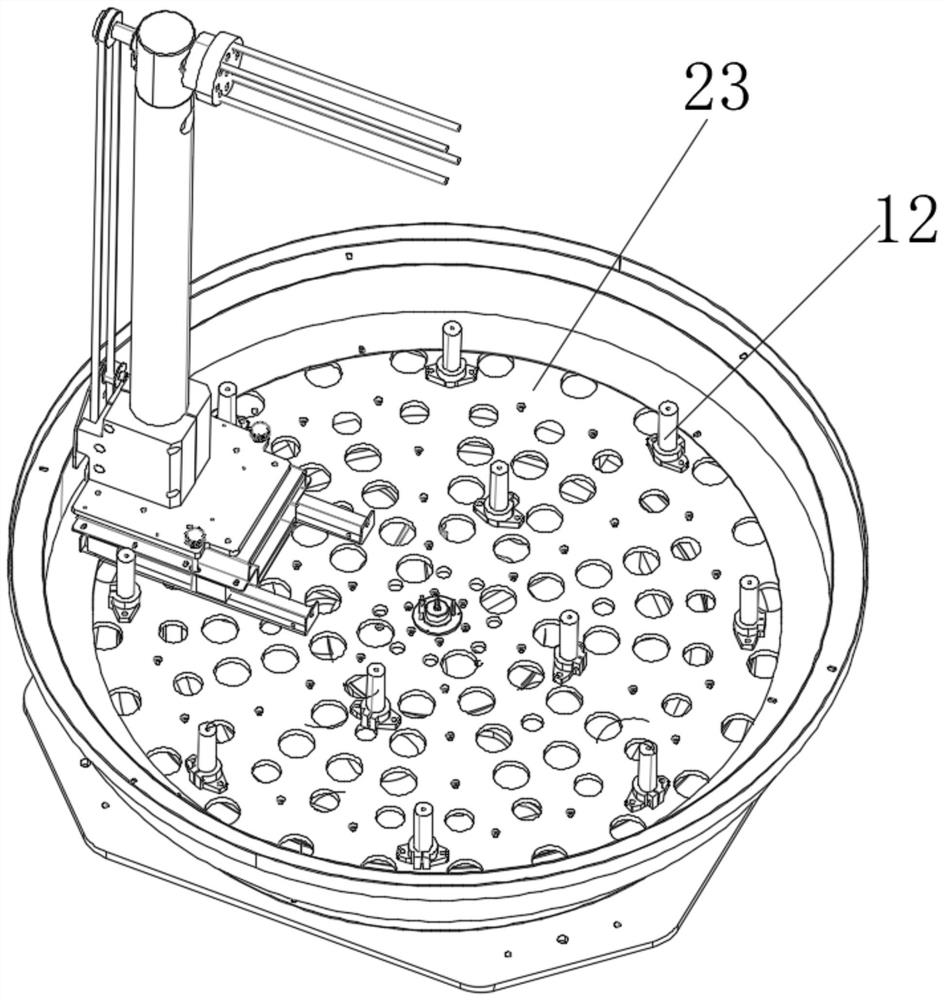

Double-rotating-shaft composite 3D printer based on Delta structure

PendingCN106738919AAchieve self-rotationImplement the flipping actionManufacturing platforms/substratesManufacturing driving meansEngineering3D printing

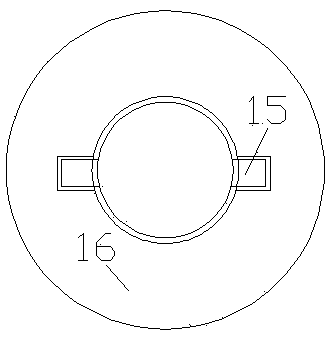

The invention discloses a double-rotating-shaft composite 3D printer based on a Delta structure. A double-rotating-shaft 3D printing platform is arranged. The double-rotating-shaft 3D printing platform is arranged on a 3D printer base, is located under a printing head of a 3D printer and can do self-rotation and turnover actions. By means of the double-rotating-shaft composite 3D printer, the self-rotation and turnover actions of the platform can be achieved, expandability is high, and the double-rotating-shaft composite 3D printer can meet requirements of different printing product sizes and is compact in structure, convenient and fast to install and high in practicability.

Owner:武汉古工道科技有限公司

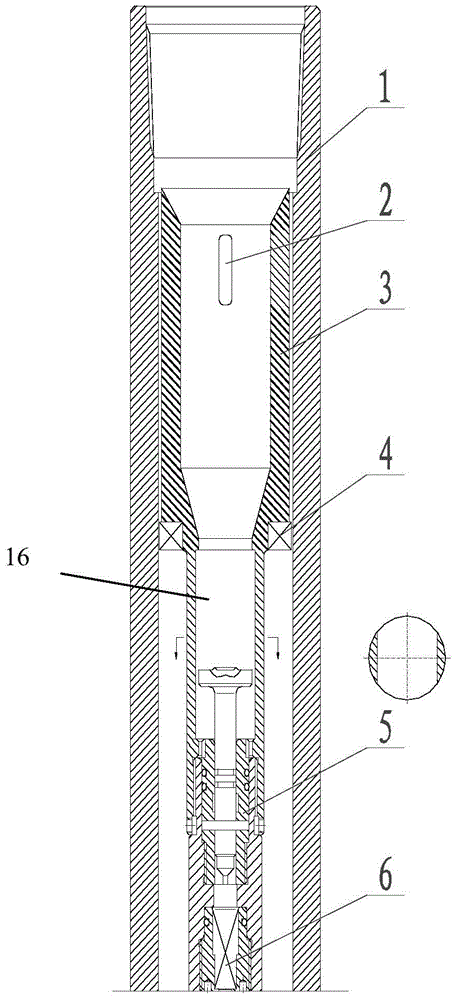

Suction anchor capable of downwards penetrating to position below sea bottom surface and mounting method thereof

InactiveCN105926627AAchieve self-rotationIncrease impact rangeArtificial islandsFoundation engineeringFree rotationSpray nozzle

The invention discloses a suction anchor capable of downwards penetrating to the position below the sea bottom surface. The suction anchor comprises an anchor bucket with a downward opening; a drainage hole is formed in the top end of the anchor bucket, and a plurality of opening conduits which communicate with the inside and outside of the anchor bucket are arranged at the top end of the anchor bucket; the upper portion of the drainage hole is connected with a submerged pump; the lower end of each opening conduit is connected with a spray nozzle communicating with the corresponding opening conduit through a bearing; the upper portion of each spray nozzle is in a hollow round tube shape and connected with the outer ring of the corresponding bearing, and the lower portion of each spray nozzle is an inverted regular hexagon prismoid; a bottom conduit used for vertically impacting on a sea bottom surface soil body is disposed on the lower bottom surface of each inverted regular hexagon prismoid; every three inclined conduits and every three horizontal conduits are alternately arranged on the corresponding six side surfaces; the angle between the center lines of every three inclined conduits and the center axis of the anchor bucket is 30 to 60 degrees; every three horizontal conduits are located in the same horizontal plane, and the tail ends of all the horizontal conduits are bent by a certain radian along the same circumference and in the same direction; and self-rotation of the spray nozzles is achieved through free rotation of the outer rings of the bearings. The invention further discloses a mounting method of the suction anchor at the same time.

Owner:OCEAN UNIV OF CHINA

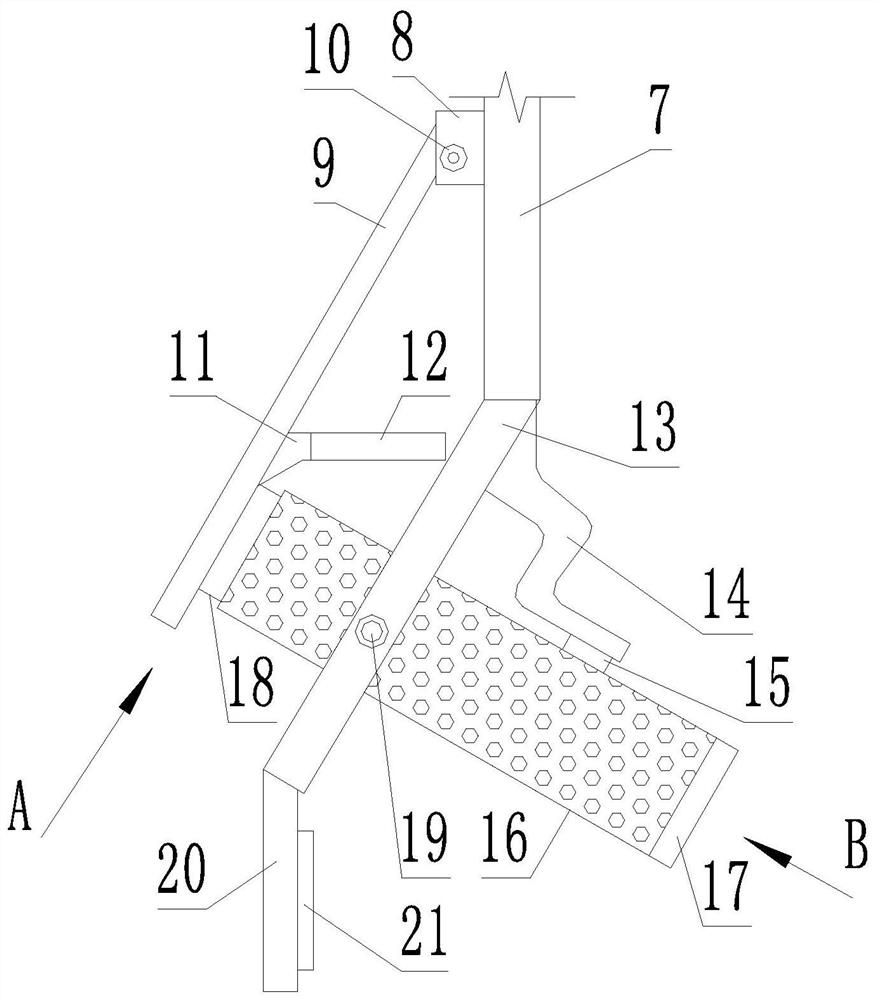

Red date conveying and turnover device

ActiveCN106269550AAchieve single columnizationAchieve self-rotationSortingEngineeringMechanical engineering

Owner:SHIHEZI UNIVERSITY

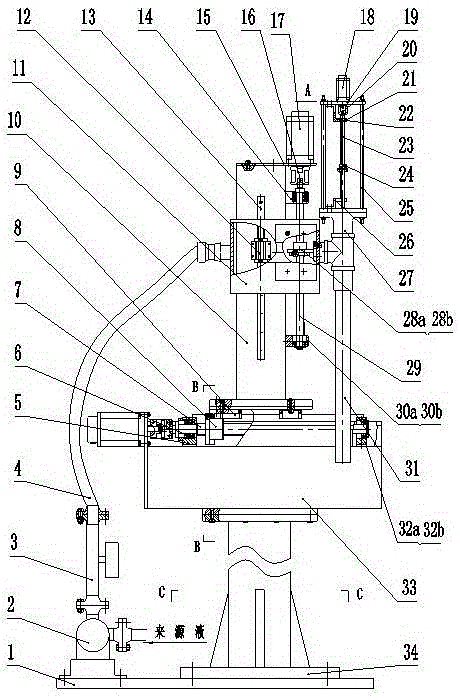

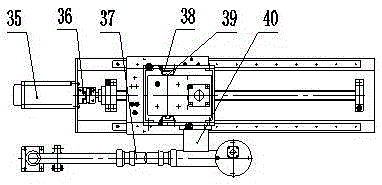

Automatic filling extraction system

InactiveCN104192781AGuaranteed to cleanWon't interfereBarrels/casks fillingMechanical engineeringEngineering

The invention discloses an automatic filling extraction system which is formed by connecting a filling extraction device, a barrel rotating device, an opening finding device, a barrel tilting device and a detection control part. According to the system, the operations of automatic opening finding, automatic barrel rotating, automatic barrel tilting, automatic filling and automatic extraction can be realized.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

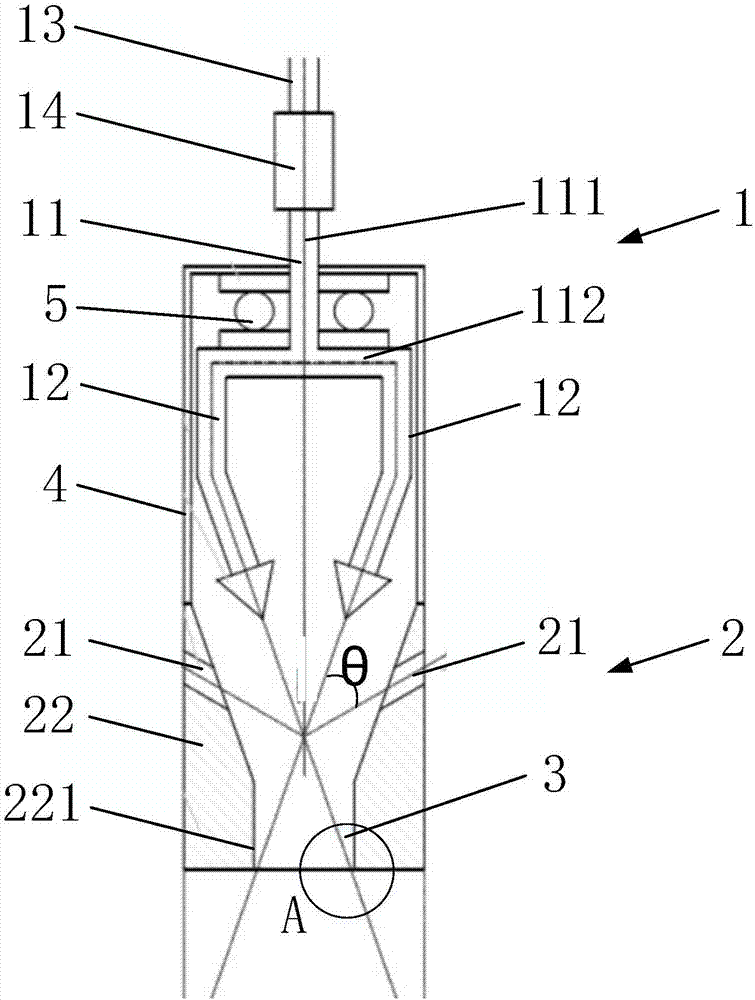

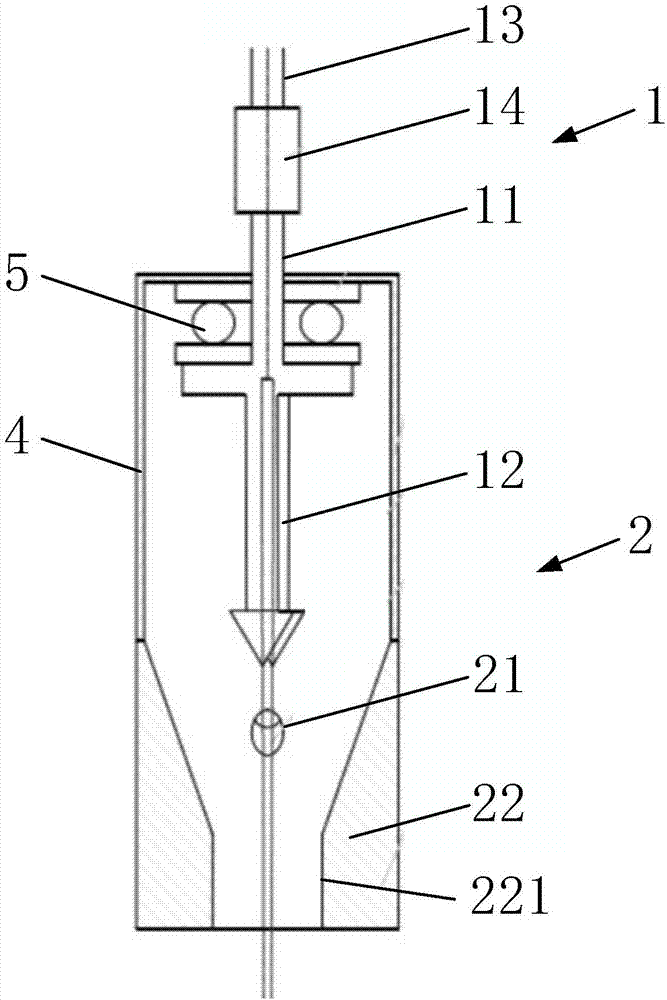

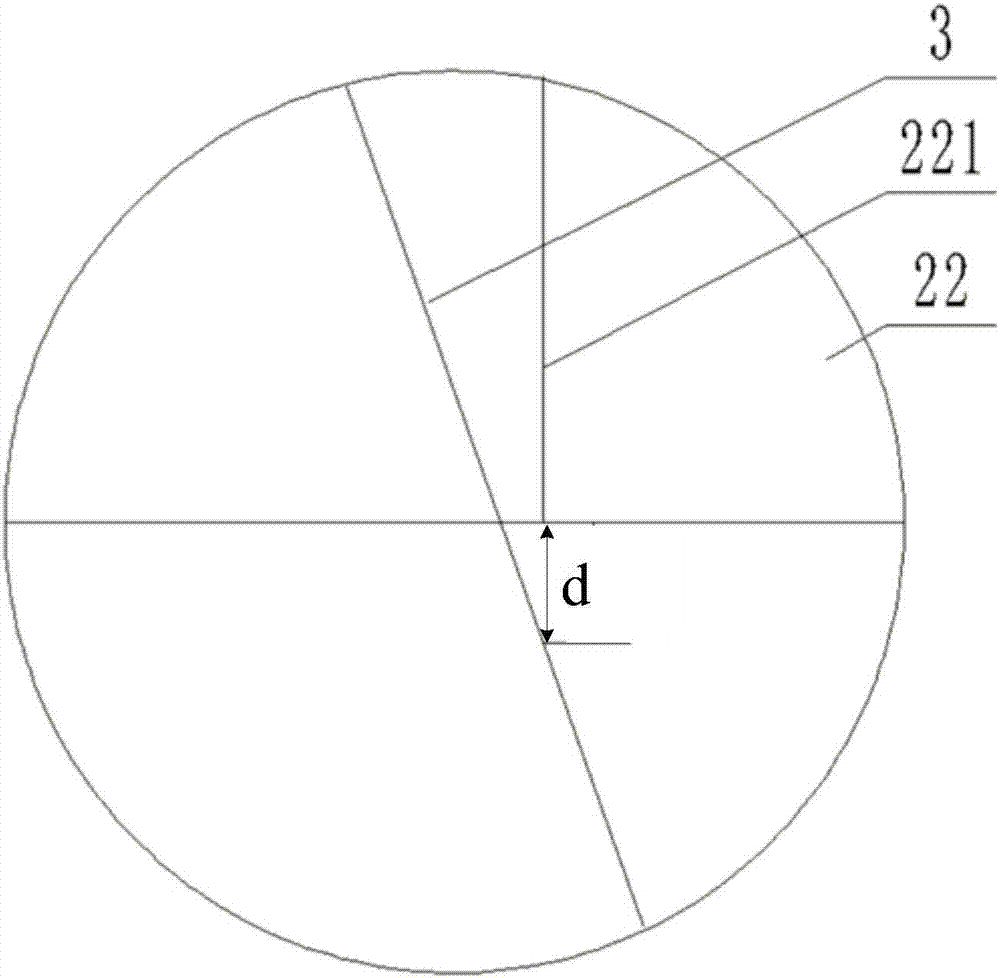

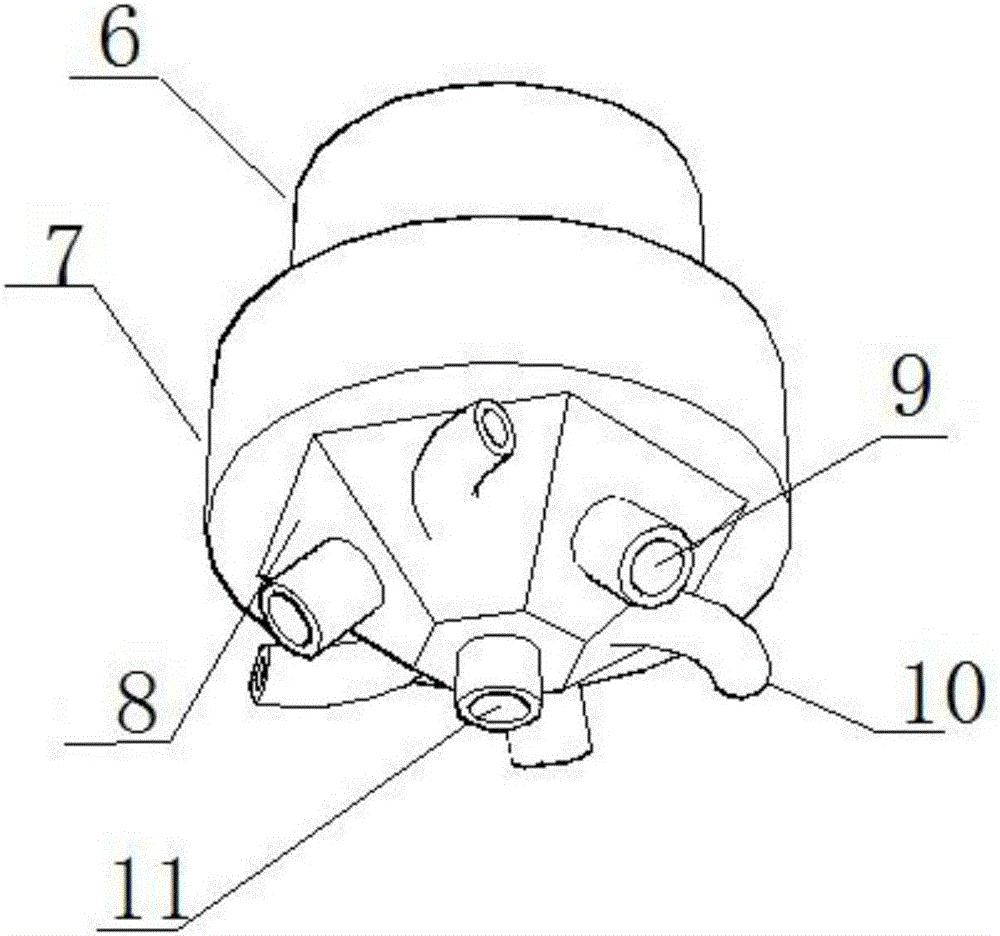

Abrasive material water jet flow spray head

ActiveCN107116481AAvoid wear and tearAvoid stickingBlast gunsAbrasive feedersEnvironmental engineeringHigh pressure water

The invention provides an abrasive material water jet flow spray head. The abrasive material water jet flow spray head comprises a water inlet assembly and a material inlet assembly, wherein the water inlet assembly conveys high pressure water, and the material inlet assembly conveys abrasive materials. The water inlet assembly comprises a rotary water pipe and two or more water spray nozzles. The multiple water spray nozzles are arranged in the circumferential direction of the rotary water pipe, and the central lines of the water spray nozzles intersect. The material inlet assembly comprises abrasive material inlets arranged below the water spray nozzles. The central lines of the abrasive material inlets intersect with the intersection point of the water spray nozzles. The abrasive material water jet flow spray head has the beneficial effect that the requirement for crushing hard barriers and a large-area soil layer is met.

Owner:CHINA RAILWAY CONSTR HEAVY IND

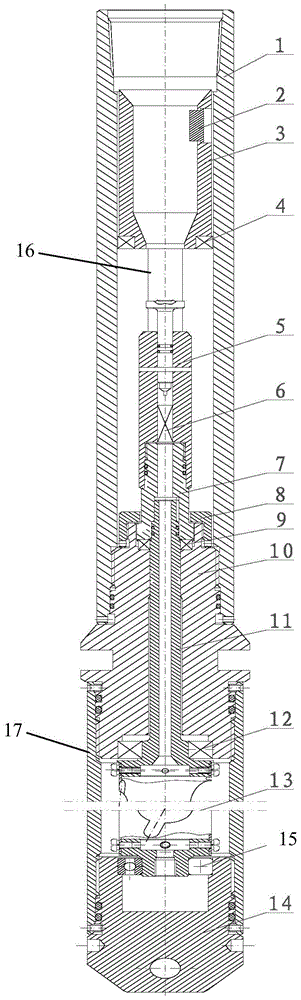

Internal Directional Spin-rotation Impact Detonation Device for Completion of Oil and Gas Wells

ActiveCN104314529BSolving Perforation Measurement ProblemsImprove accuracySurveyFluid removalDetonatorEngineering

The invention relates to an internal directional self-rotating impact initiation device used for oil and gas well completion. The guide sleeve is a part of the upper end of the impact initiation device. The azimuth key is fixed on the guide sleeve through welding. Connection, the detonator is placed inside the lower end of the impact detonating device, the directional connecting pipe is connected to the gun joint through the connecting union, the positioning plate is fixed inside the directional connecting pipe, and is connected with the directional connecting pipe and the orientation key on the guide sleeve through the positioning key Keeping the same axial direction, the above assembly components are placed inside the outer cylinder and supported by each bearing. The detonating device realizes the measurement of the perforation azimuth from the upper end of the detonating part of the perforating gun string, and effectively improves the accuracy of the inner directional positioning perforation. Based on the directional measurement method of the detonating device, the problem of internal directional and azimuth perforation measurement is solved.

Owner:WUHUA ENERGY TECH CO LTD

Negative pressure bucket applicable to ocean wind power and capable of downwards penetrating to position below sea bottom surface, and installation method

InactiveCN105926664AAchieve self-rotationIncrease impact rangeArtificial islandsFoundation engineeringSurface oceanSpray nozzle

The invention discloses a negative pressure bucket applicable to ocean wind power and capable of downwards penetrating to the position below the sea bottom surface. The negative pressure bucket comprises a bucket body with a downward opening; a stand barrel is disposed in the center of the upper end face of the bucket body; a drainage hole and a plurality of uniformly distributed water inlet holes which communicate with the inside of the bucket body are formed in the positions, on one side of the stand barrel, of the upper end face of the bucket body; and a self-rotating spray nozzle is connected with the lower end of each water inlet hole inside the bucket body. The invention further discloses an installation method for the negative pressure bucket at the same time. The downwards penetrating depth of the negative pressure bucket is freely controlled within a certain range through alternate starting and stopping of an injection pump and a water suction pump. Meanwhile, when the end of the negative pressure bucket downwards penetrates to the position below the sea bottom surface, a sea bottom soil body gradually buries the end due to washing of sea bottom underflow action, so that the end is effectively utilized, and the ultimate up-lift bearing capacity and overturning resistance of the negative pressure bucket are greatly improved. According to the negative pressure bucket, the counter acting force of high-pressure water is fully utilized so as to achieve self-rotation of the spray nozzles, the range of impact of the high-pressure water on the sea bottom surface soil body is greatly widened, and local impact is effectively avoided.

Owner:OCEAN UNIV OF CHINA

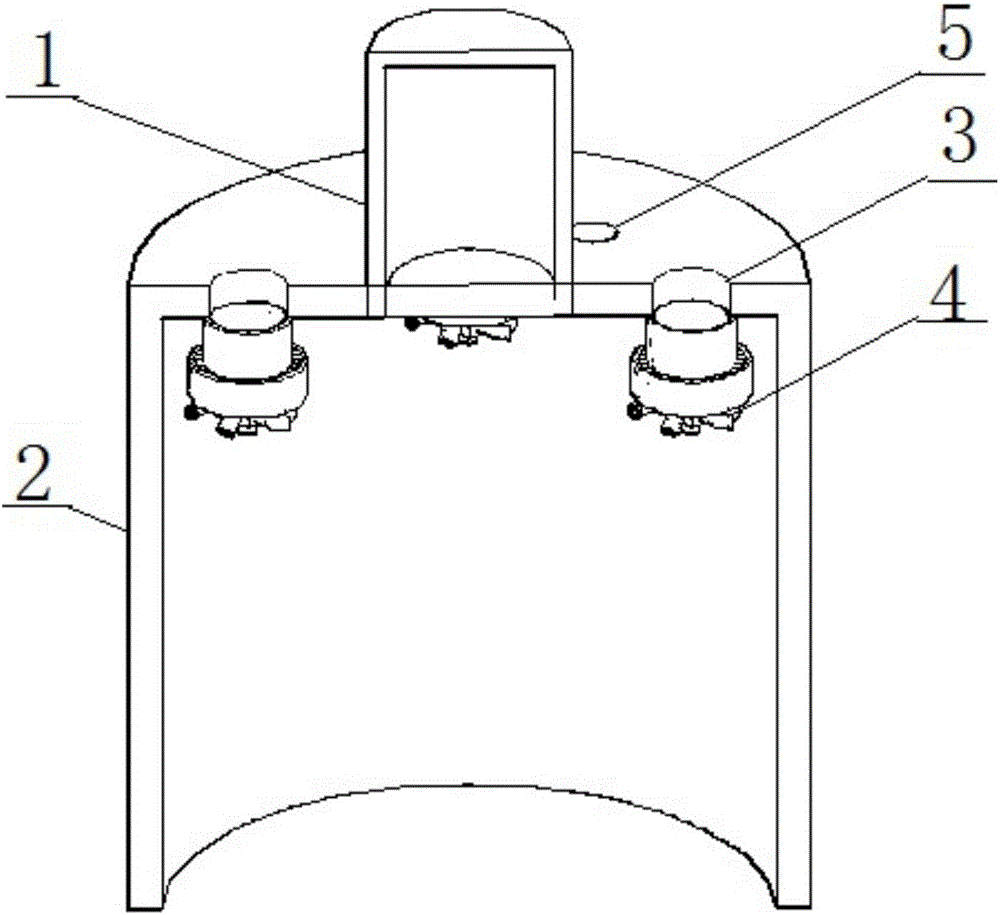

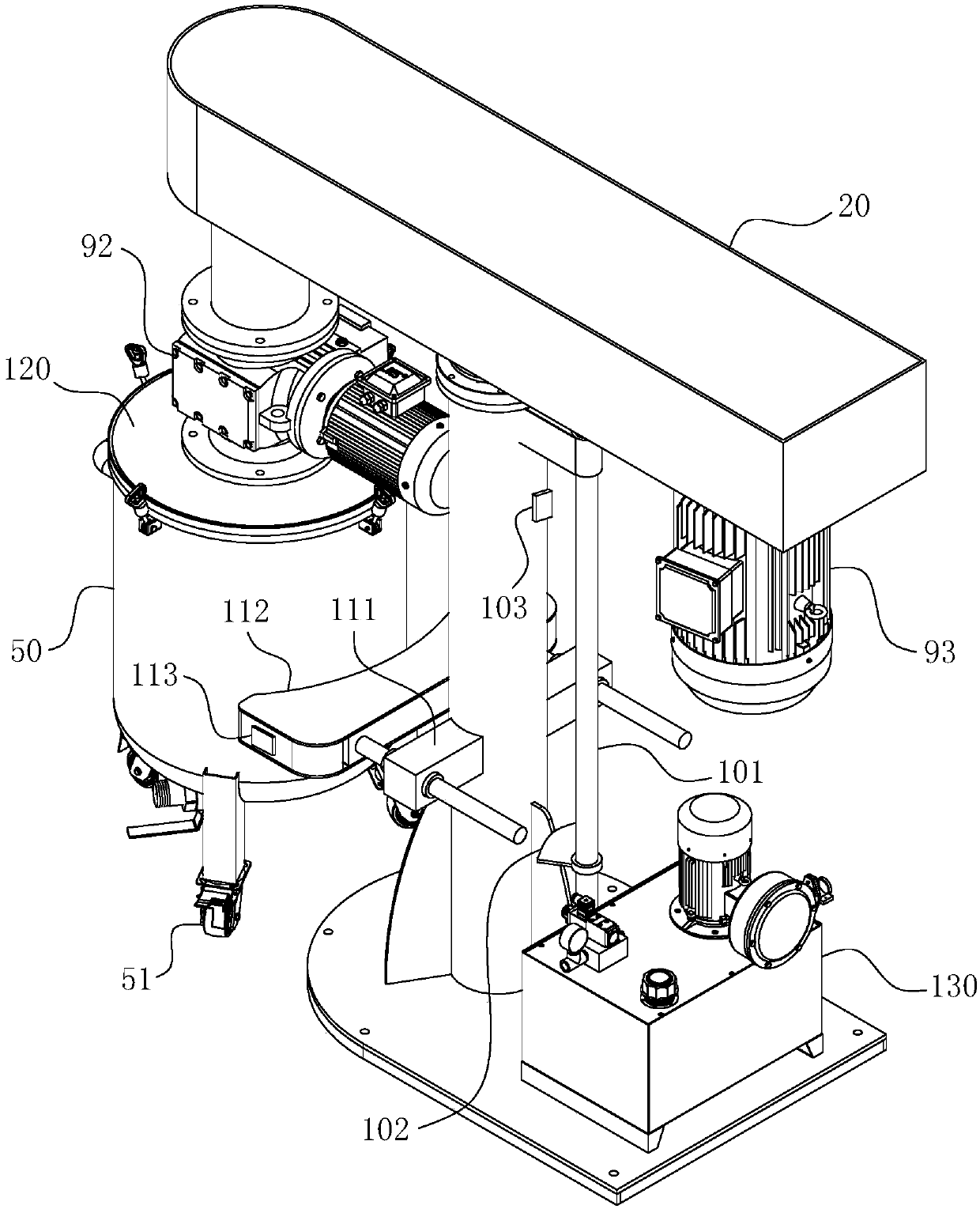

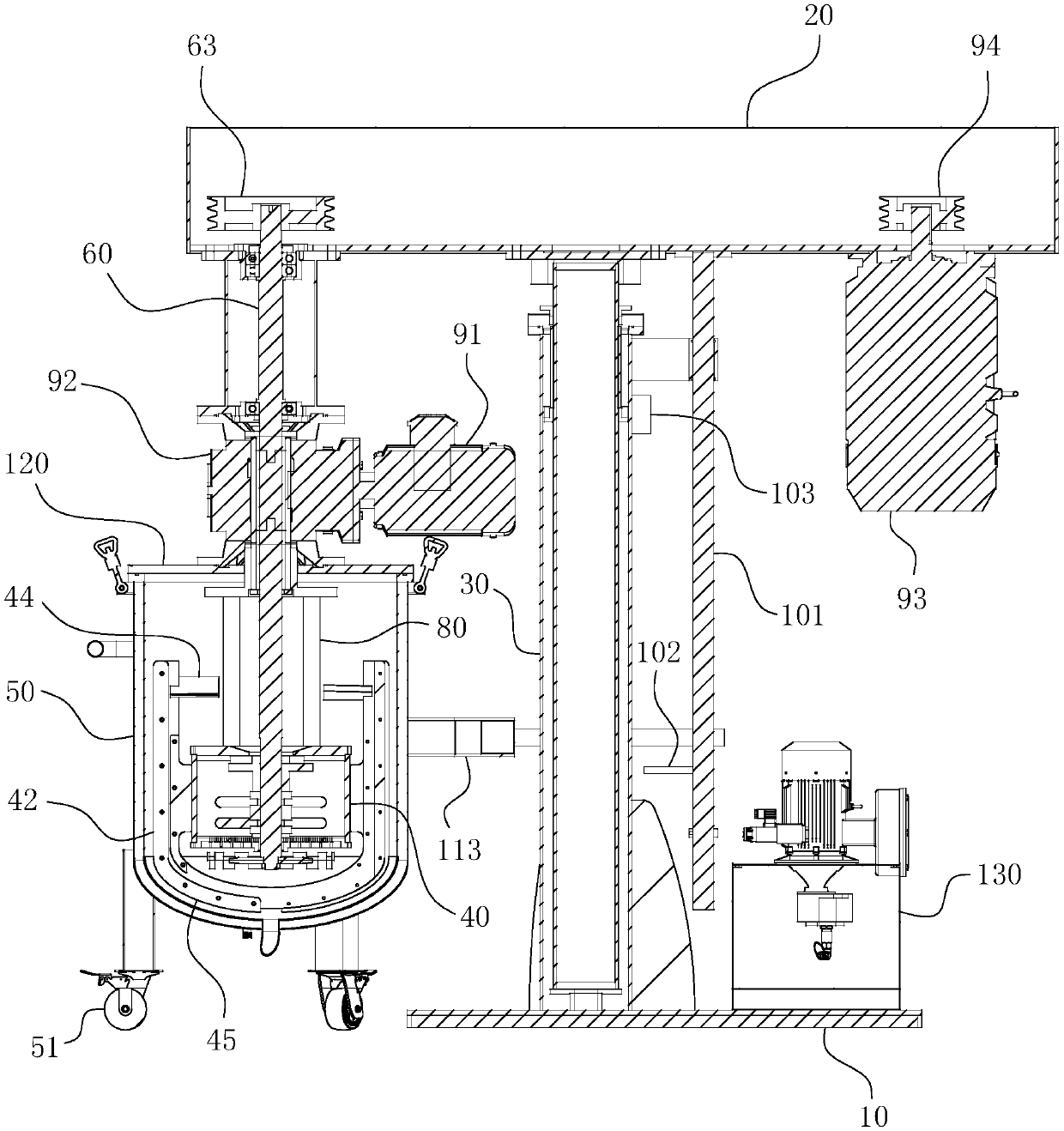

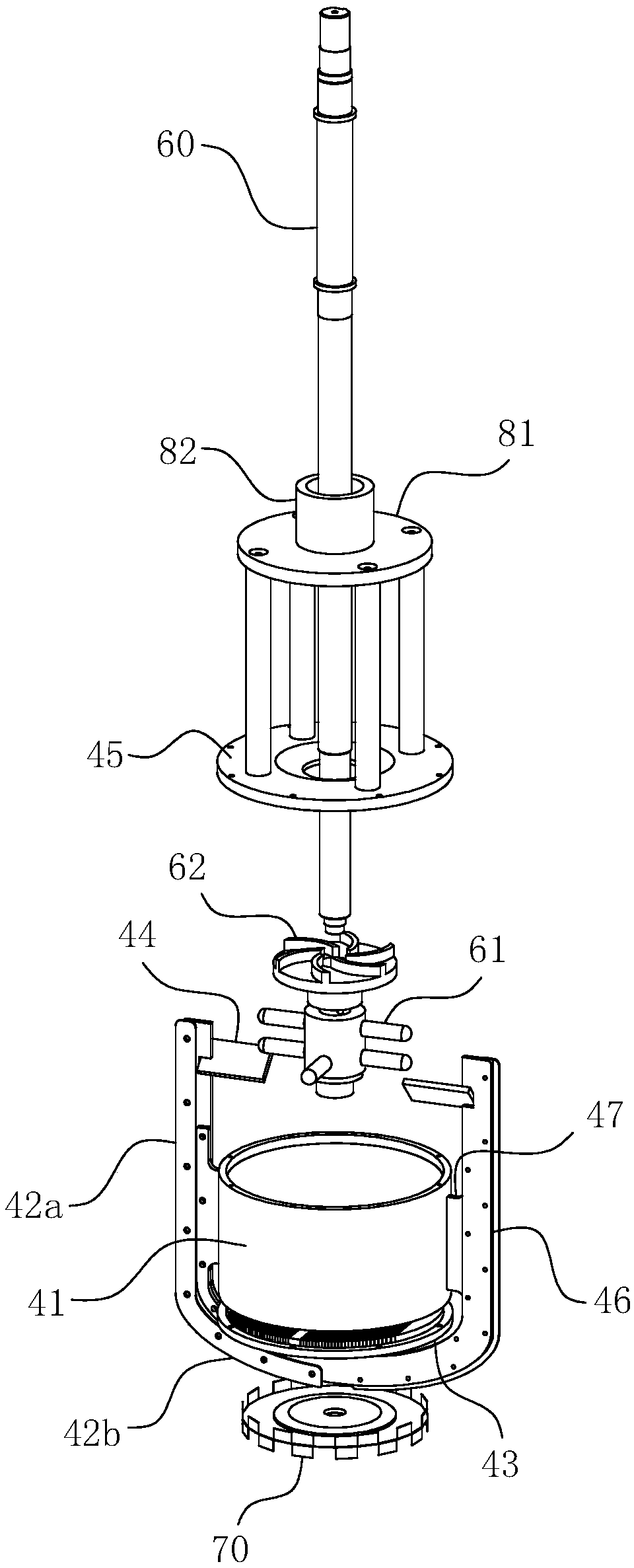

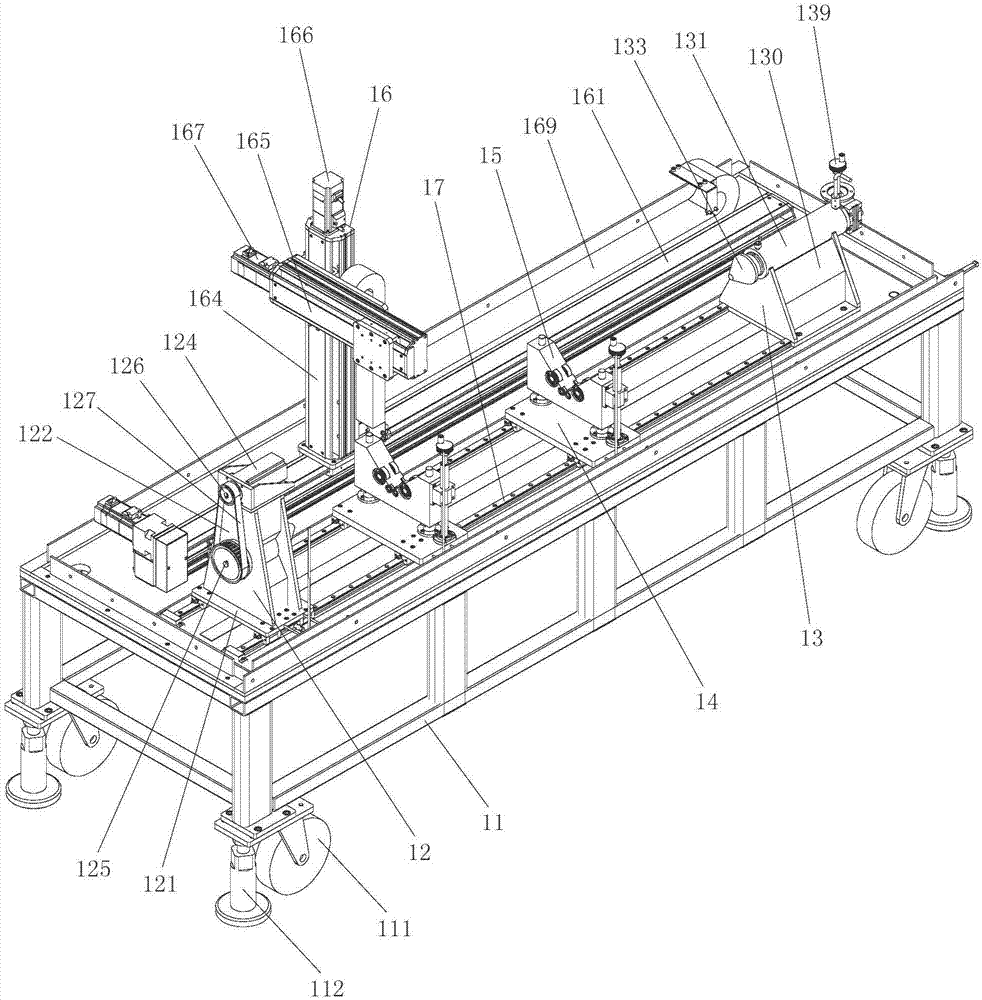

Concentric double-axis vacuum hydraulic basket grinding machine

ActiveCN109590078AEfficient mixingEfficient grindingGrain treatmentsCantileverMechanical engineering

The invention belongs to the field of grinding equipment, in particular to a concentric double-axis vacuum hydraulic basket grinding machine. The grinding machine comprises a base, a frame, a liftingassembly, a grinding basket and a cylinder. The grinding basket comprises a cylinder body, an end cap and a filter plate. The end cap and the filter plate are vertically coaxially penetrated by a stirring shaft and the stirring shaft is respectively rotatably matched with the end cap and the filter plate. A basket support is coaxially arranged with the stirring shaft but dose not interfere the stirring shaft. The top end of the basket support is matched with the output end of a second power source, and the bottom end of the basket support is coaxially fixed at the end cap for driving the grinding basket to produce a coaxial rotating action opposite to the turning direction of the stirring shaft. A cantilever extends radially outwardly at the outer wall of the grinding basket, and the extending end of the cantilever arm is fixedly connected with a scraper for scraping the attachment at the wall of a cylinder chamber. The invention has the advantages of high grinding efficiency, good stirring effect, good product fineness, convenient and reliable operation.

Owner:费曹民

Roll-dividing machine

The invention discloses a roll-dividing machine which comprises a machine frame, a driving device, a clamping device, a lighting device and a tensioning device. A whole cloth roll is placed on a first roller and a second roller of the driving device, the cloth is limited and compressed through compressing plates of the clamping device, one end of the cloth penetrates through a gap between the first roller and the second roller, and the cloth bypasses a tensioning roller and a redirection roller to be upwards lifted, is wound in an S-shaped mode through three pressing rods and is then pulled out. The roll-dividing machine is small in occupied area, automatic rotation of the cloth can be achieved, roll dividing can be rapidly conducted only with one operator, and labor is saved; in addition, the roll-dividing machine is simple in structure, low in manufacturing cost, high in working efficiency and capable of being widely applied to roll-dividing work, cost pressure can not be brought to an enterprise, and the cloth can not be damaged in the roll-dividing process.

Owner:安徽锦绣经纬编有限公司

New-energy automobile lithium battery welding equipment with welding slag recovery device

InactiveCN111360436AAchieve self-rotationAvoid the risk of easy handsWelding/cutting auxillary devicesDirt cleaningSlag (welding)New energy

The invention relates to the technical field of lithium battery production, and discloses new-energy automobile lithium battery welding equipment with a welding slag recovery device. The equipment comprises a machine frame, wherein a supporting block is arranged on each of the two sides of the bottom of the machine frame, and a connecting plate is arranged on the portion, on the inner sides of thesupporting blocks, of the bottom of the machine frame; a positive-negative motor is arranged at the top of the connecting plate, and a first transmission gear is arranged at one end of an output shaft of the positive-negative motor; and a threaded rod is arranged in the middle of the front surface of the machine frame, a driven gear is arranged at one end of the threaded rod, and an internal threaded sleeve is arranged in the middle of the threaded rod. According to the new-energy automobile lithium battery welding equipment with the welding slag recovery device, through mutual cooperation ofa rotating rod, a slag removing block, a driving motor and a second transmission gear, the slag removing block can rotate automatically, so that welding slag on the surface of a lithium battery doesnot need to be cleaned manually, the situation that certain danger to the hands during manual cleaning of the welding slag on the surface of the lithium battery is prone to occur is avoided, and the safety of workers is improved.

Owner:柳州永安行汽车科技有限公司

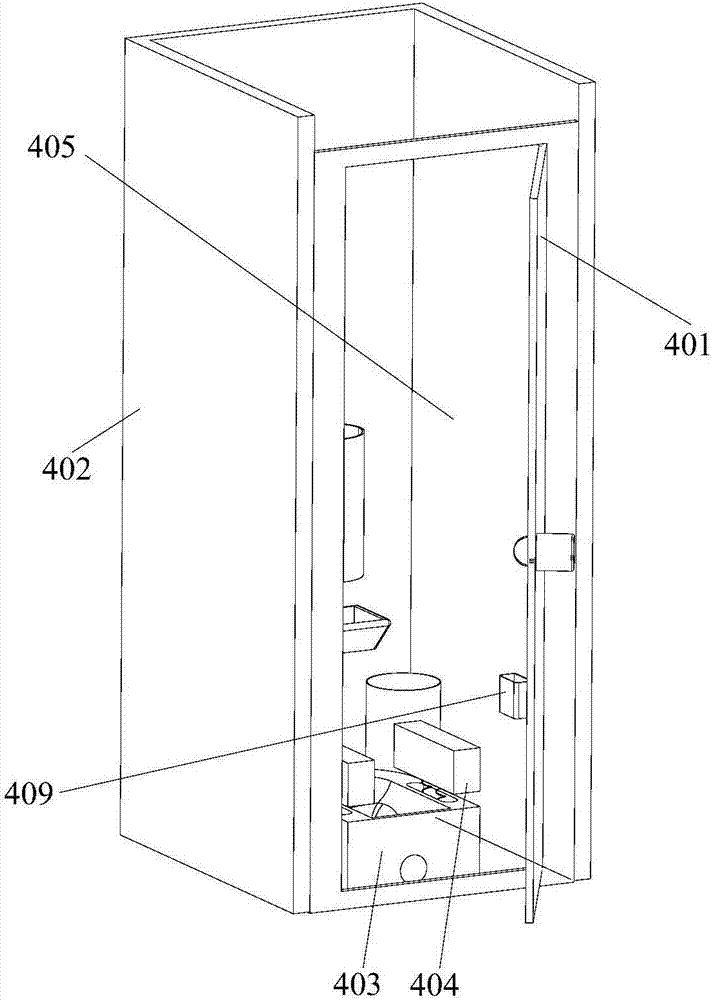

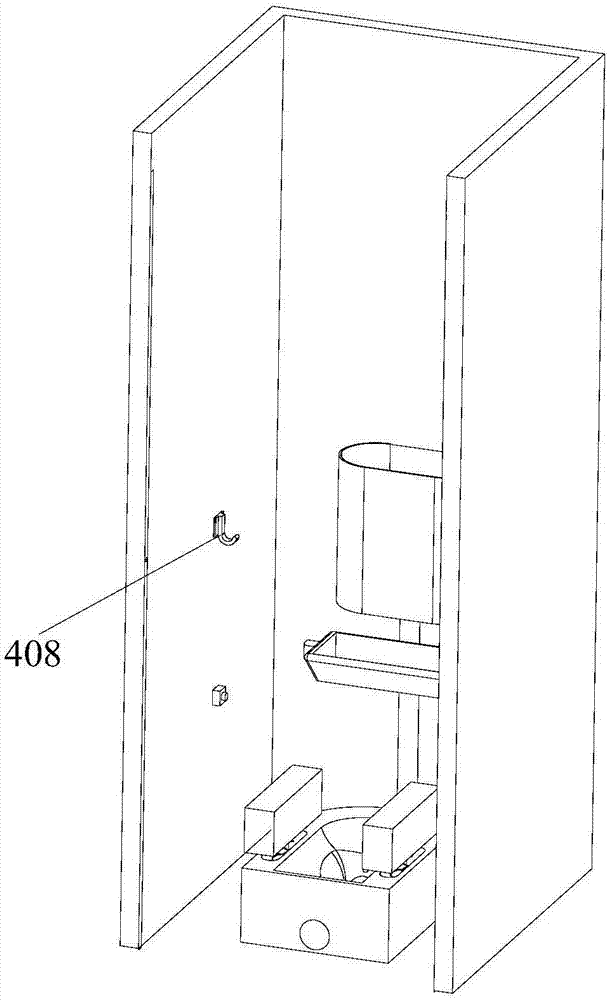

Toilet room structure suitable for public toilet

ActiveCN107152175AHumanized designDesign intelligenceWater closetsNon-mechanical controlsEngineeringLatrine

The invention discloses a toilet room structure suitable for a public toilet. The toilet room structure comprises a toilet room body provided with an entrance or an exit for passing of users who use the toilet, a squatting pan arranged in the toilet room body, a toilet room door rotatably connected with the toilet room body and used for controlling opening and closing of the entrance or the exit, and a door lock arranged on the toilet room door, wherein the door lock comprises a lock pin movably arranged on the toilet room door and an electromagnet used for controlling the lock pin to do linear movement in the horizontal direction; a locking hole, through which the lock pin can penetrate, is formed in the toilet room body. The toilet room structure suitable for the public toilet is more humanized and more intelligentized in design and has sounder functions.

Owner:YANGXIN XINRUI DYEING & WEAVING

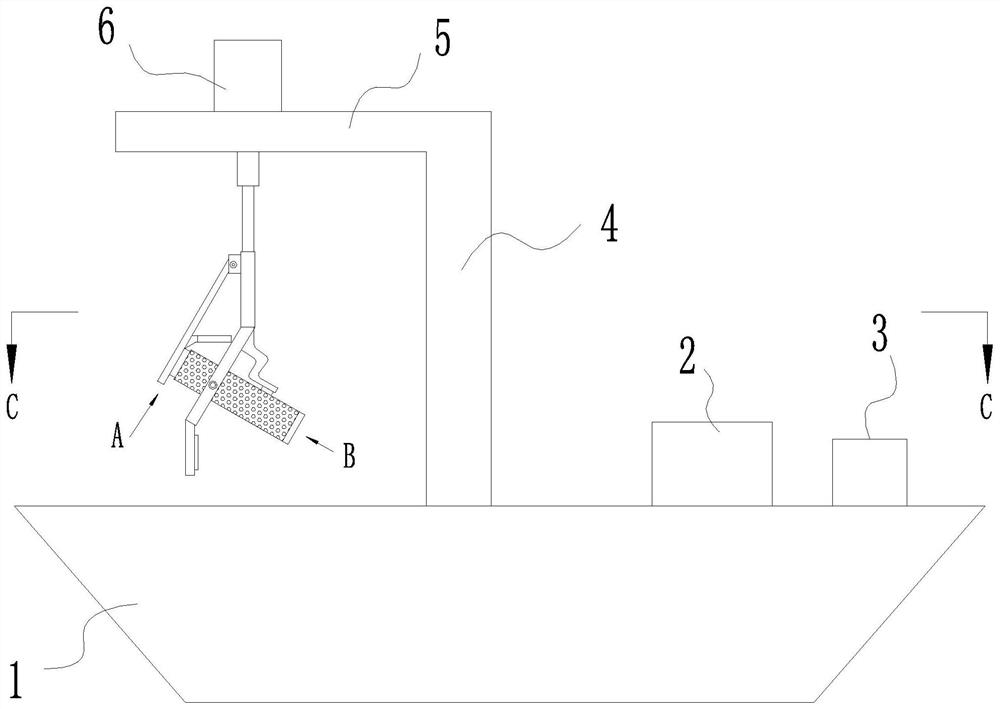

Eccentric self-rotating plugging type water sample collection device and method

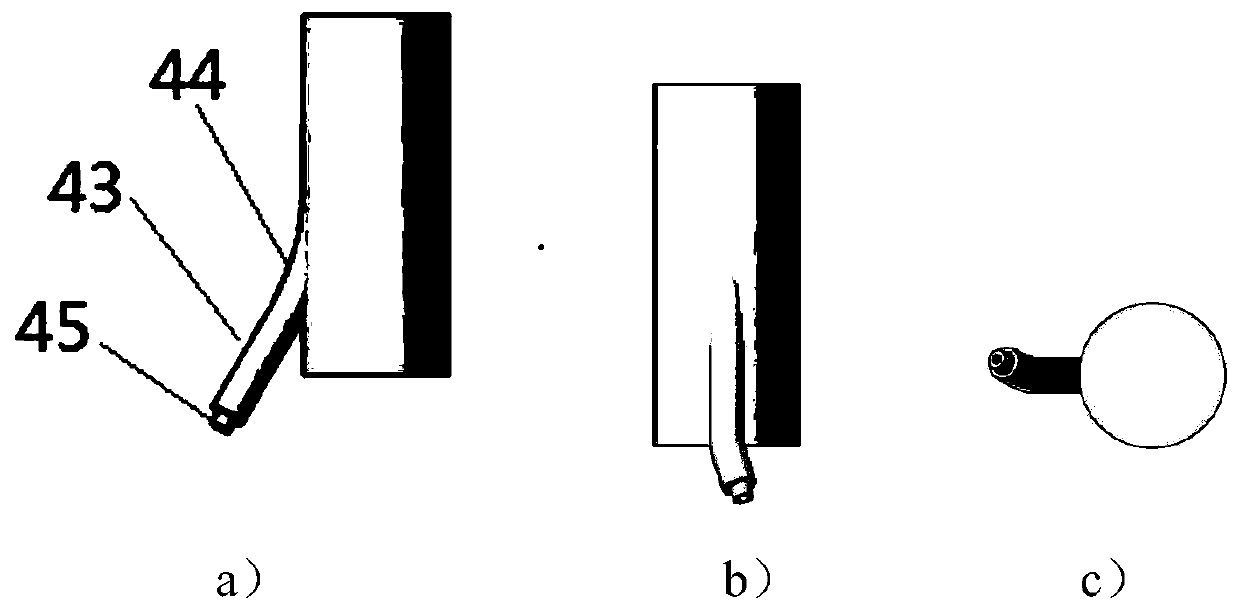

PendingCN113567191AMeet the needs of useSimple structureWaterborne vesselsWithdrawing sample devicesRemote controlEngineering

The invention discloses an eccentric self-rotating plugging type water sample collection device and method. The device comprises an unmanned ship, an electric cylinder is installed on the unmanned ship, the bottom end of a piston rod of the electric cylinder is connected with a sampler, the sampler comprises a support plate, and the bottom of the support plate is connected with an inclined U-shaped frame. A protection cylinder is hinged to the U-shaped frame through a pin shaft. A sampling pipe is mounted in the protection cylinder in a sleeving manner, a first magnet sheet is connected to one side of the U-shaped frame, and when the protection cylinder is adsorbed on the surface of the first magnet sheet, the protection cylinder is inclined; the U-shaped frame is connected with a second magnet piece, and when the protection cylinder is attracted to the surface of the second magnet sheet, the protection cylinder is in a vertical shape. The device further comprises a rotating plate, and the top of the rotating plate is hinged to the supporting plate through a rotating shaft. A torsional spring is arranged on the rotating shaft; and a plugging plate is slidably connected to the surface of one side of the rotating plate, and when the protection cylinder is in a vertical shape, the plugging plate is pressed at the pipe opening, so that plugging of the pipe opening is achieved. The whole sampling process is simple to operate, efficient, intelligent and convenient for remote control.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

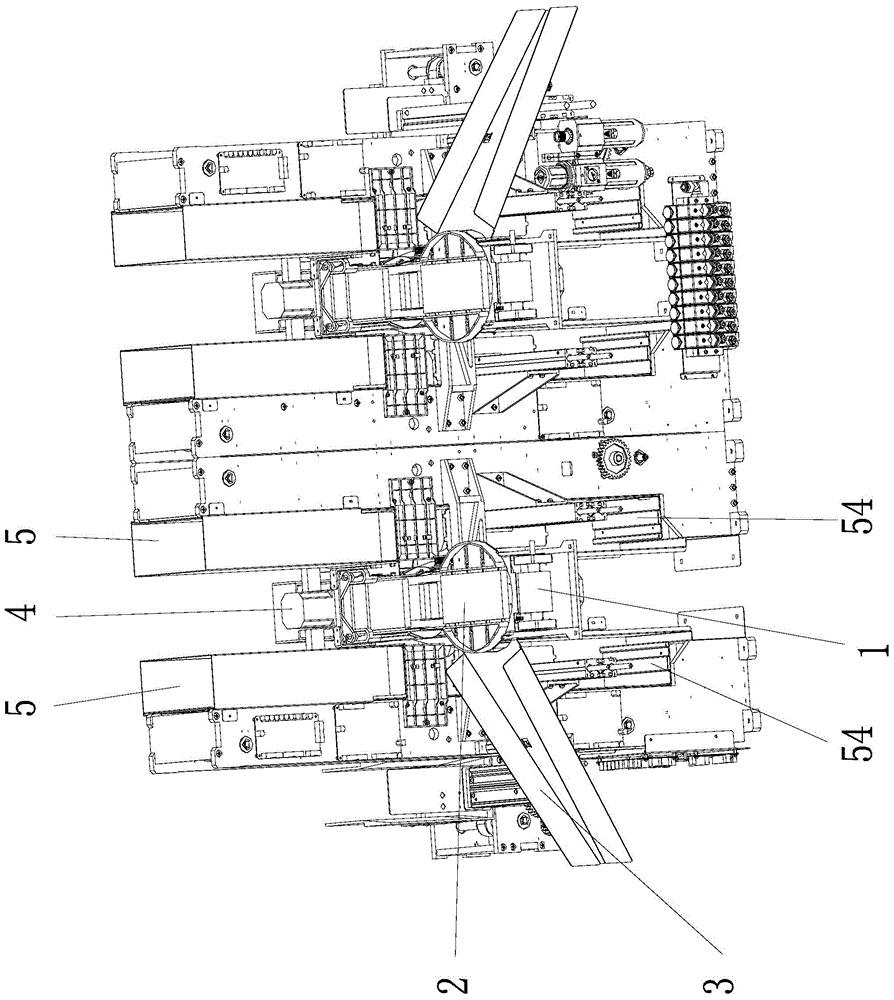

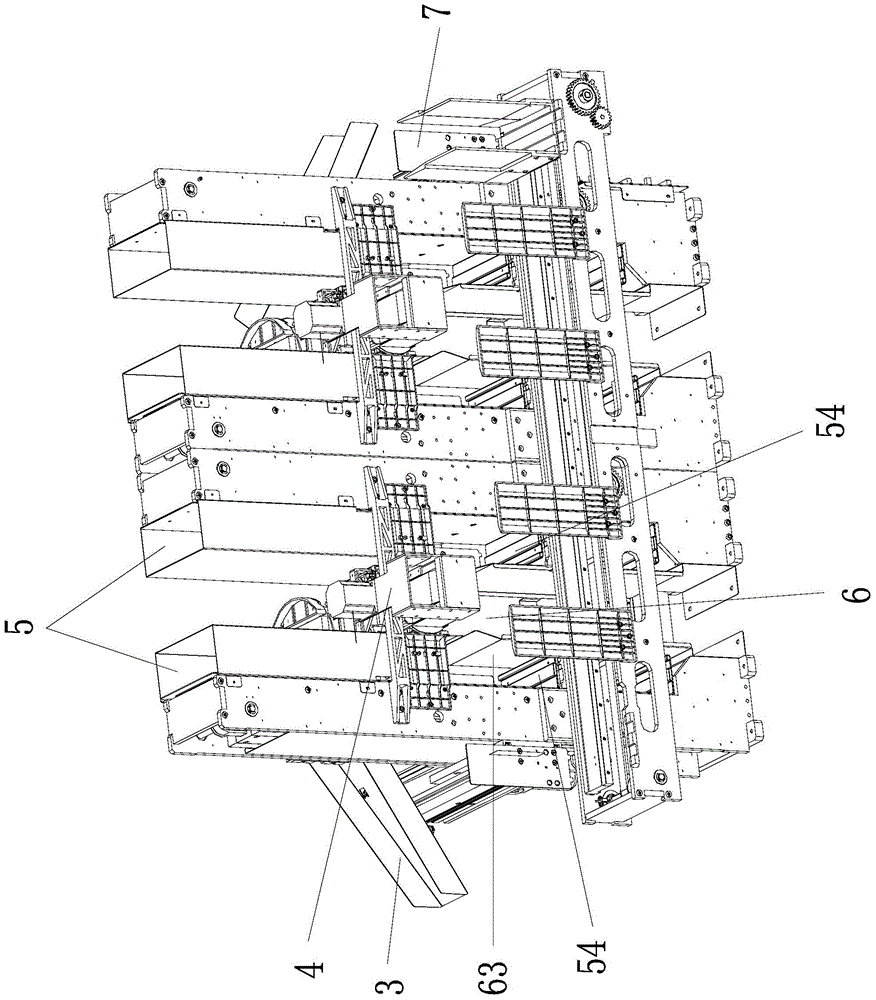

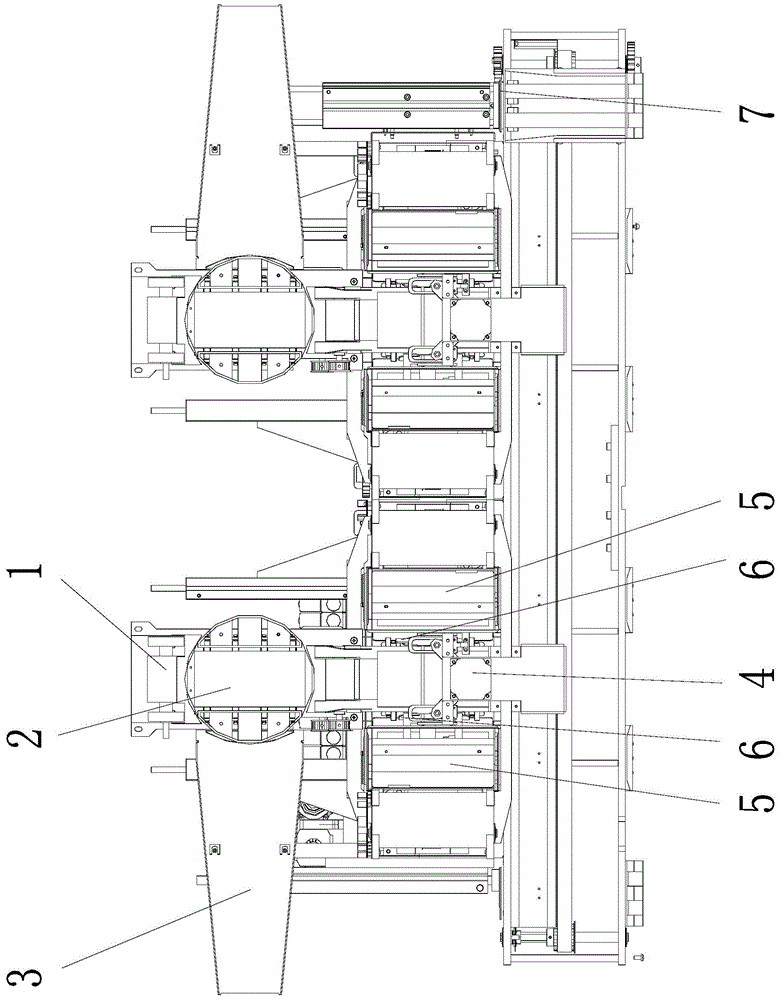

Paper money classifying flow line

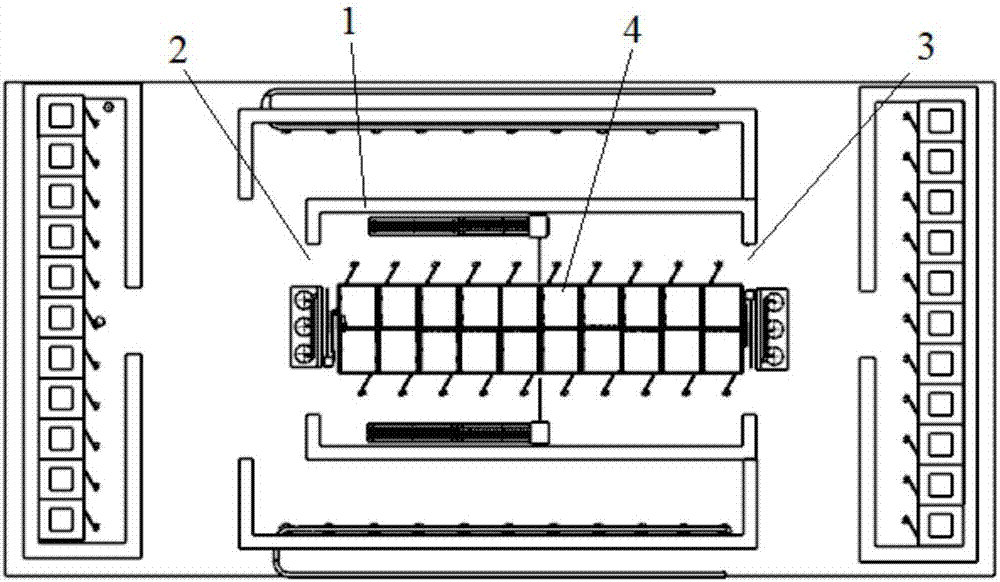

ActiveCN104627442AImplement classification processingRealize transmissionPaper article packagingPackaging automatic controlEngineeringPulp and paper industry

The invention discloses a paper money classifying flow line. The paper money classifying flow line comprises a conveying belt, a steering distributing mechanism, a driving plate mechanism, two lifting mechanisms, an arranging mechanism and two paper money out push plates, wherein the steering distributing mechanism is located at the upper end of the conveying belt; the driving plate mechanism is located at the upper end of the conveying belt and located on the back portion of the steering distributing mechanism, and the paper money is pushed to the two sides of the conveying belt through the driving plate mechanism; the lifting mechanisms are used for containing the paper money and provided with lifting platforms which move in the Z-shaft direction, and the lifting mechanisms are located on the two sides of the conveying belt; the arranging mechanism is provided with two push plates and located at the lower end of the conveying belt, and the two push plates are located between the lifting mechanisms and the conveying belt; each paper money out push plate is movably located at the lower end of each lifting mechanism in the X-shaft direction, and the paper money which falls to the lowest end of each lifting mechanism is pushed outwards. According to the paper money classifying flow line, the classification processing on the denomination and currency sort of the paper money can be effectively achieved.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

Tennis trainer

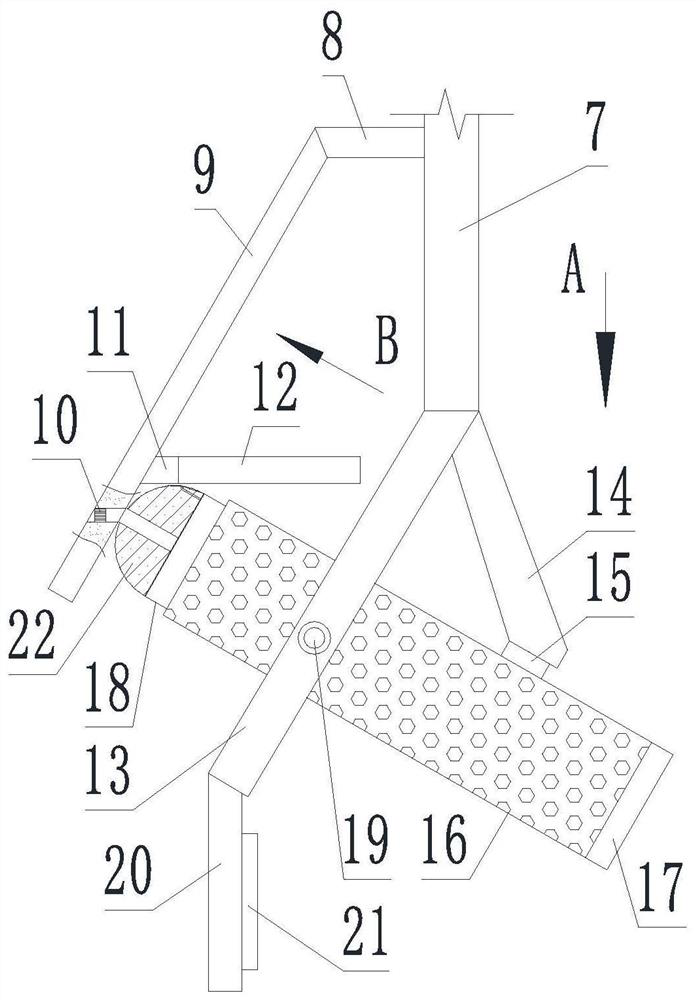

InactiveCN101898032BAir pressure requirements are not highAchieve self-rotationSport apparatusAtmospheric pressureTennis ball

The invention aims at providing a tennis trainer which comprises a trainer rack, a launching mechanism and a horizontally-rotating mechanism. The tennis trainer is characterized in that the launching mechanism is fixed in the horizontally-rotating mechanism, and the trainer rack is positioned outside the horizontally-rotating mechanism and is connected with the horizontally-rotating mechanism. The tennis trainer has the characteristics of undemanding air pressure for tennis launching and high launching accuracy, and can realize the self rotation of the tennis and vividly simulation on playingtennis by human. Besides, the tennis trainer has the advantages of simple structure, lighter weight, high safety performance and lower overall cost.

Owner:HARBIN ENG UNIV

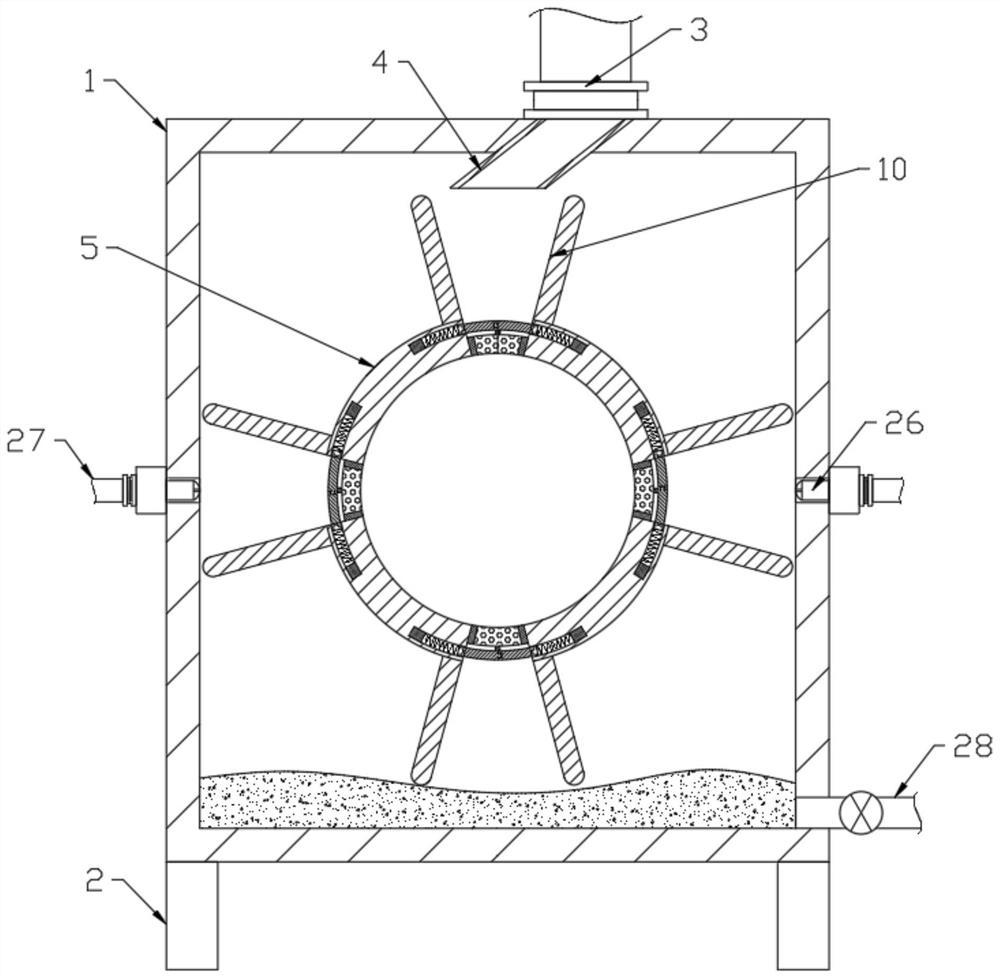

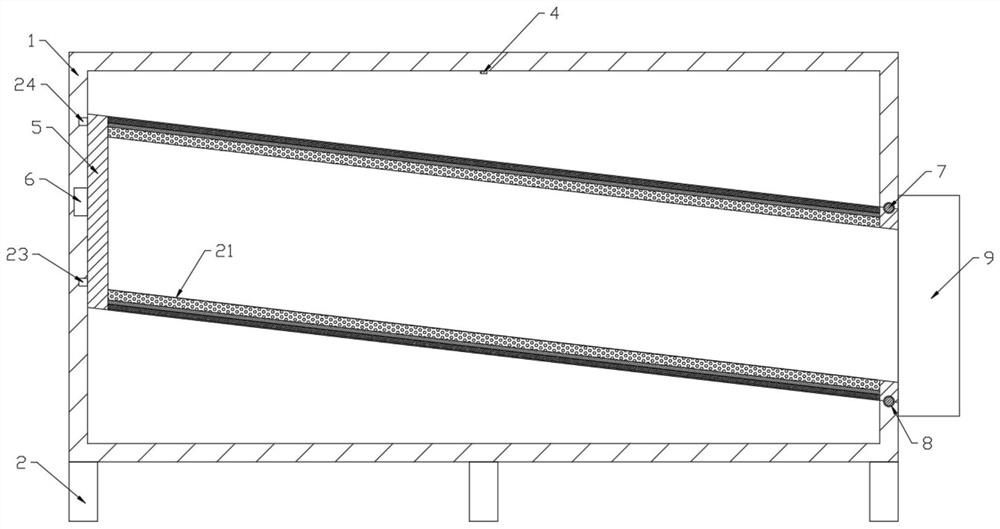

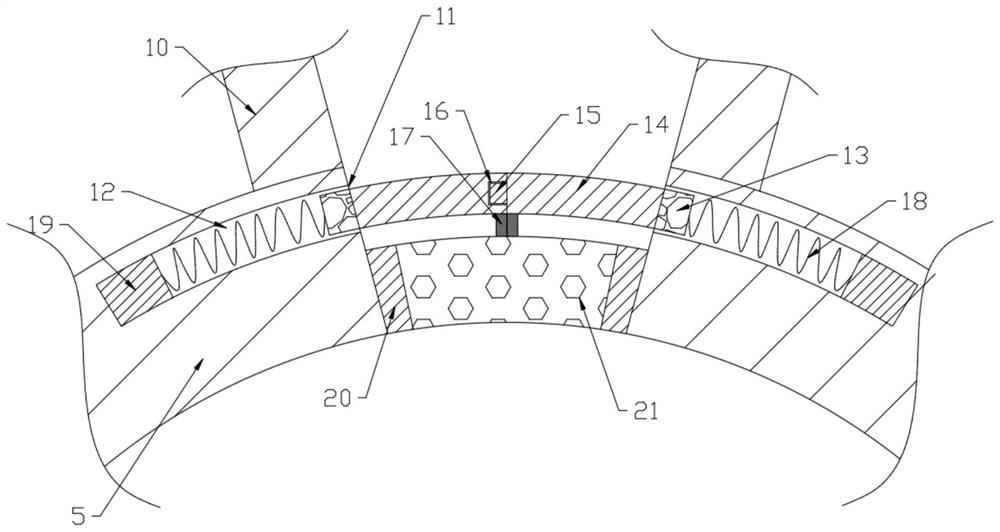

Sewage treatment filtering device

InactiveCN111871044AAchieve self-rotationSmooth rotationMoving filtering element filtersSewage treatmentSewage

The invention discloses a sewage treatment filtering device, which comprises a box body and a plurality of supporting columns arranged at the lower end of the box body, wherein a water inlet connectoris formed in the upper end of the box body and communicated with a water inlet pipe, a rotary drum is rotatably connected into the box body, and a water outlet pipe communicated with the rotary drumis arranged at the side end of the box body; a partition plate, a through groove, a filtering assembly and a sealing plate are arranged on the rotary drum; and a driving assembly for driving the sealing plate to perform sealing work is arranged on the rotary drum, and a cleaning assembly for cleaning the filtering assembly is arranged on the box body. The rotating drum rotates to enable the contact on the rotating drum to be in periodic contact with the contact block and the empty groove on the box body, so that the energized magnet is periodically energized or not, the energized magnet periodically generates magnetism, the permanent magnet drives the sealing plate to move in the sliding groove, and the through groove can be opened and closed; and then the sewage is filtered through the filter screen on the through groove, and the filtered sewage falls into the rotary drum and then is discharged out of the box body through the water outlet pipe due to the fact that the rotary drum is obliquely arranged in the box body.

Owner:张长敏

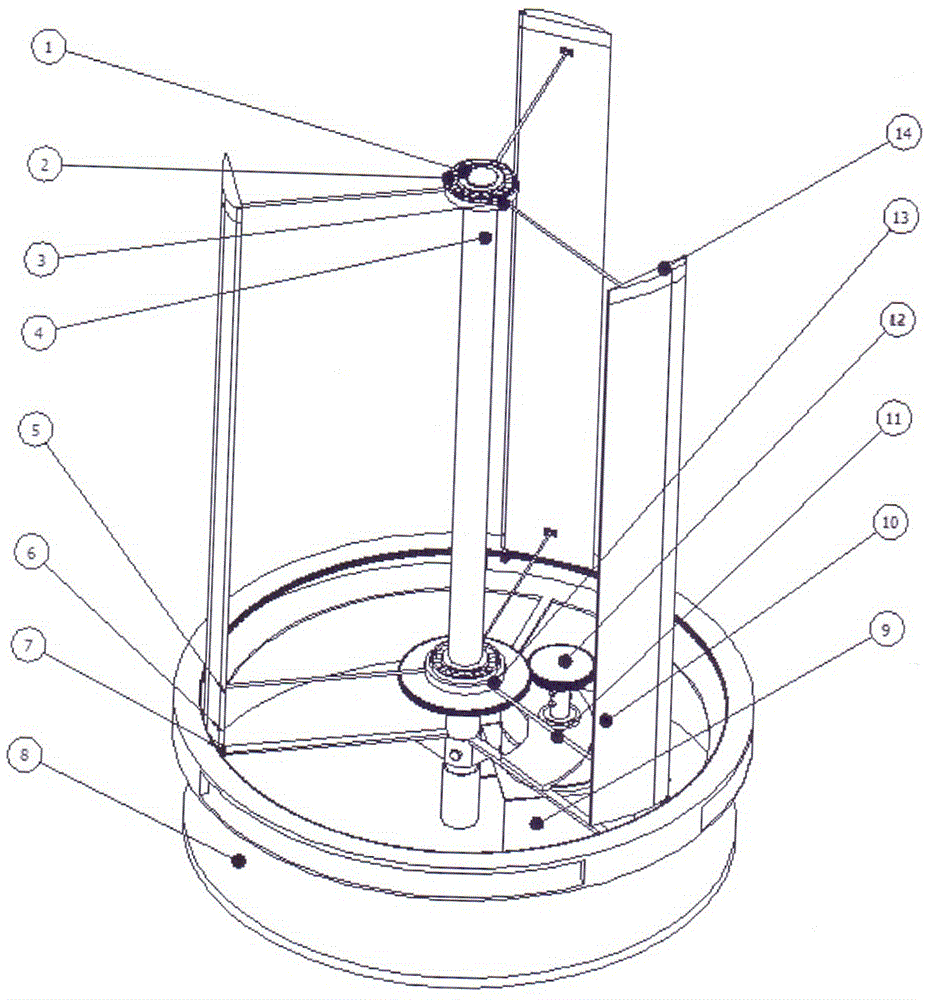

Vertical axis wind turbine with rotating cylinders on front edge

ActiveCN105545602AChange the airflowEasy to separateEngine fuctionsWind motor supports/mountsWork performanceFront edge

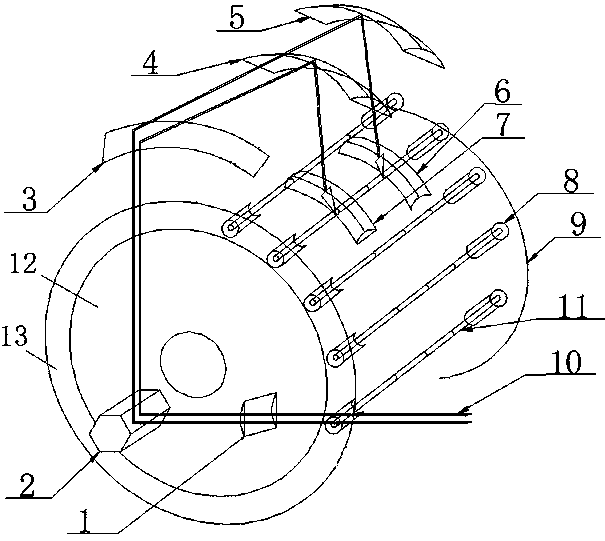

The invention discloses a vertical axis wind turbine with rotating cylinders on the front edge. A hollow stand column is welded on the center of a chassis vertically. An upper thrust bearing and a lower thrust bearing are mounted on the hollow stand column. Loop bars sleeve the thrust bearings, and are connected with supporting rods. The supporting rods are welded with blades. The blades of the wind turbine are vertically arranged and are connected together with the supporting rods. The blades are circumferentially and uniformly distributed along the hollow stand column to form a wind wheel. A gear is mounted at the excircle of the lower thrust bearing, and is welded together with a gear of a generator to form a gear pair. The generator is fixed in a box body on the chassis. An arc slab is fixed on the box body, and is welded together with an internal gear. The blades and the rotating cylinders on the front edge are clamped together through clamping groove parts at the upper ends and the lower ends of the blades. The rotating cylinders on the front edge are supported and fixed through thrust bearings, and the thrust bearings are sleeved by grooves of the clamping groove parts in an interference fit manner. External gears are mounted at the lower ends of the rotating cylinders on the front edge. The external gears are meshed with the internal gear outside the rotating cylinders. The vertical axis wind turbine is reasonable in structure, and high in working performance.

Owner:江苏天能海洋重工有限公司

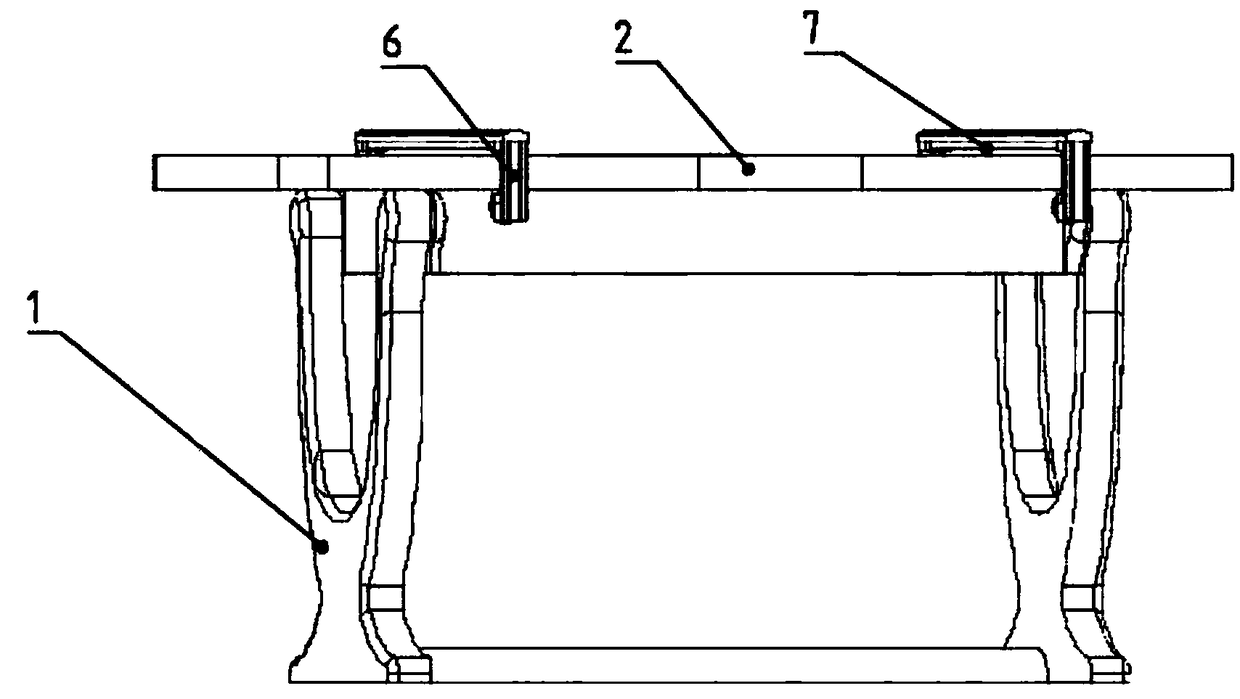

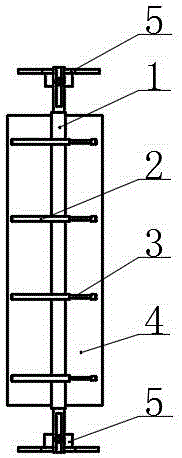

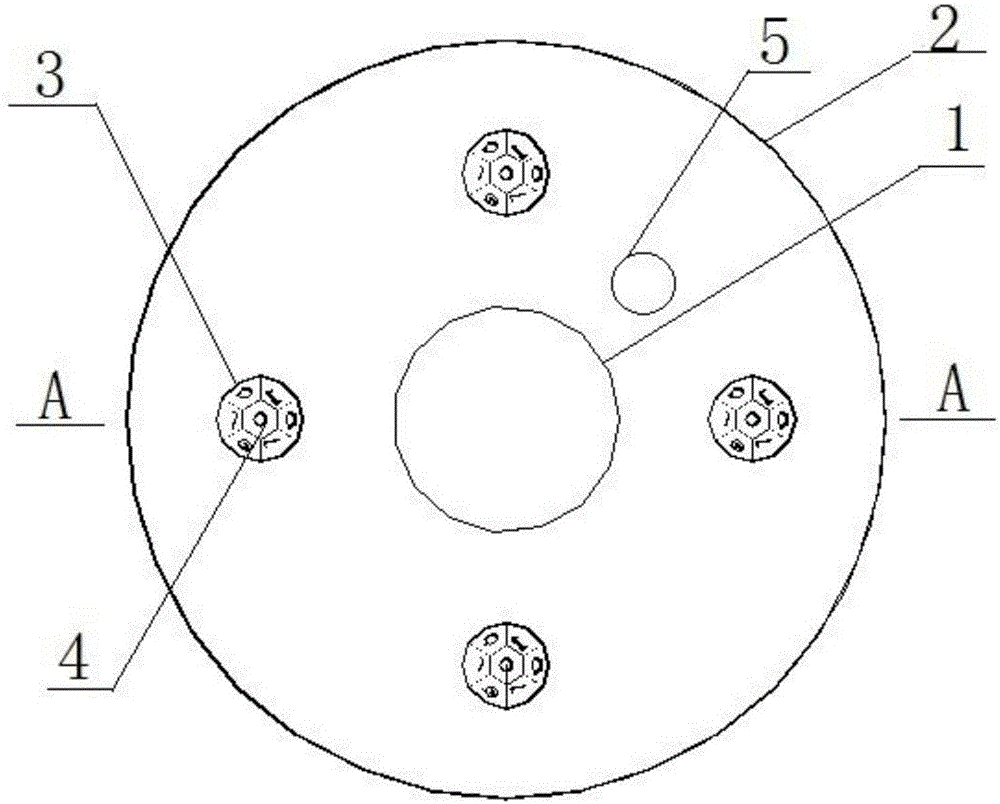

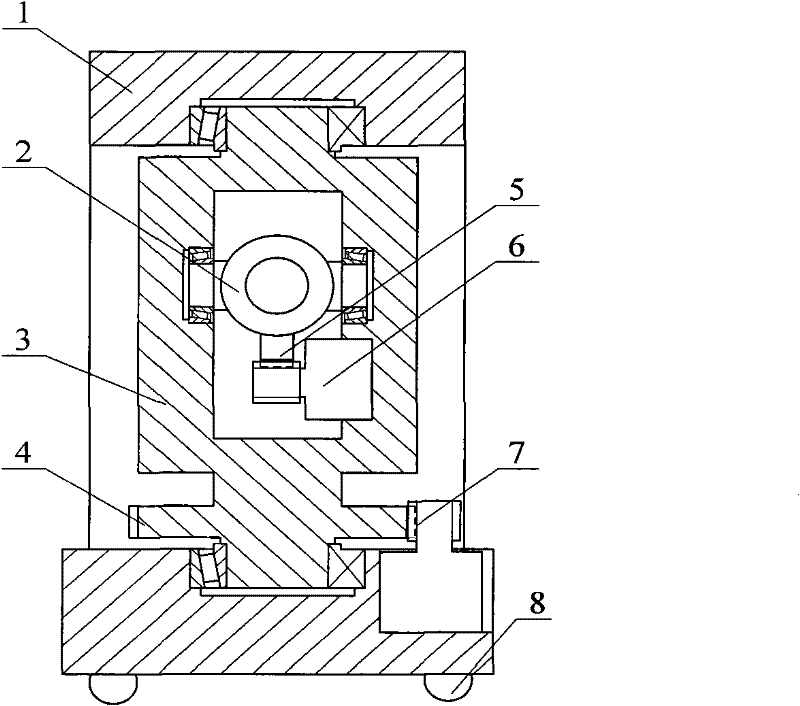

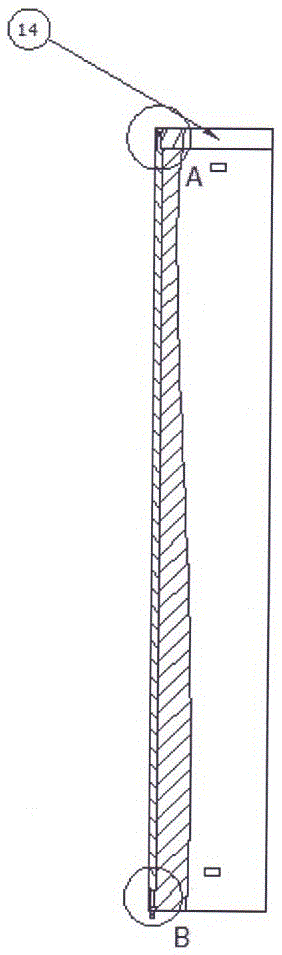

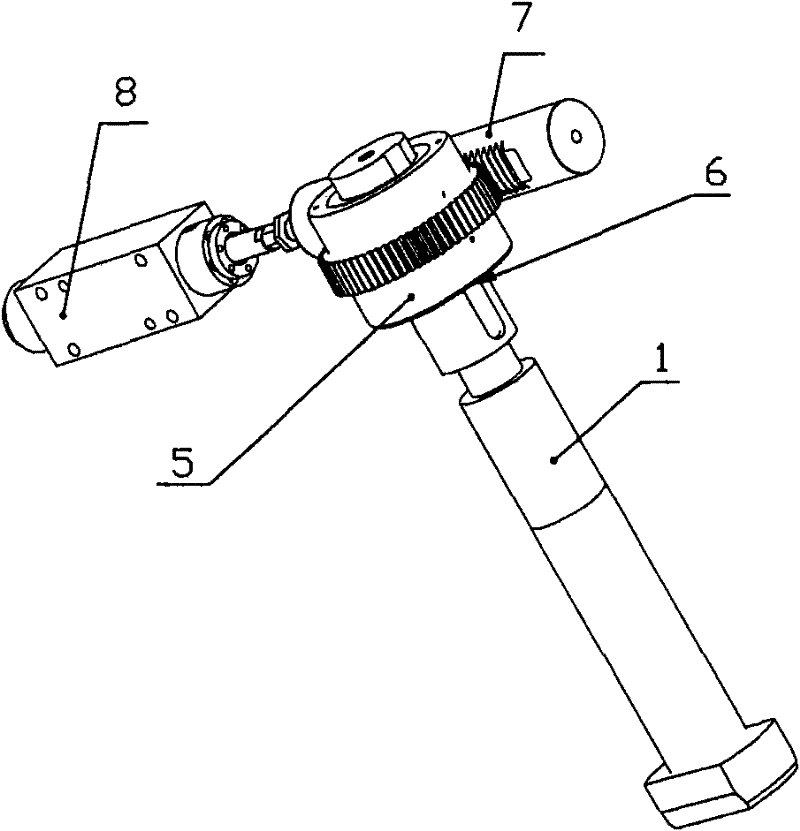

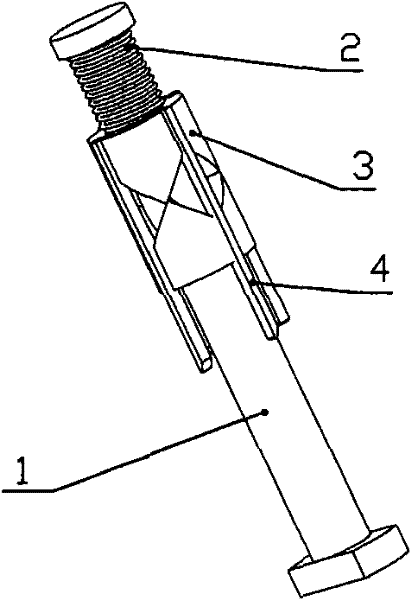

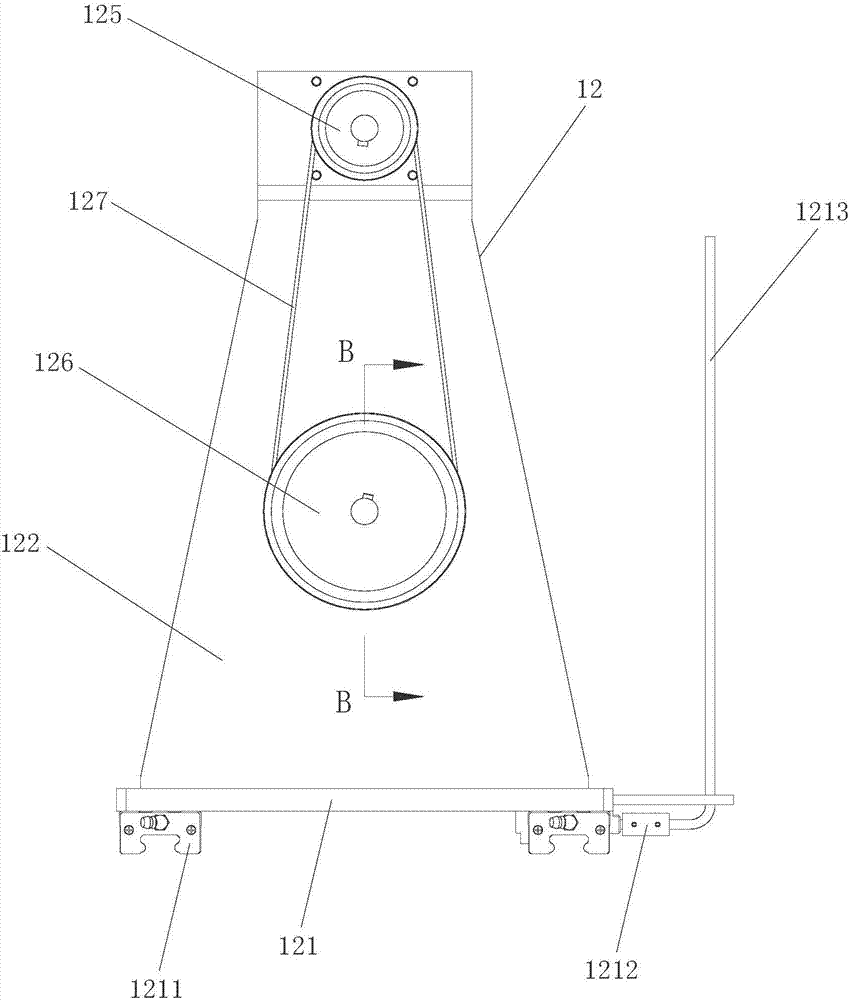

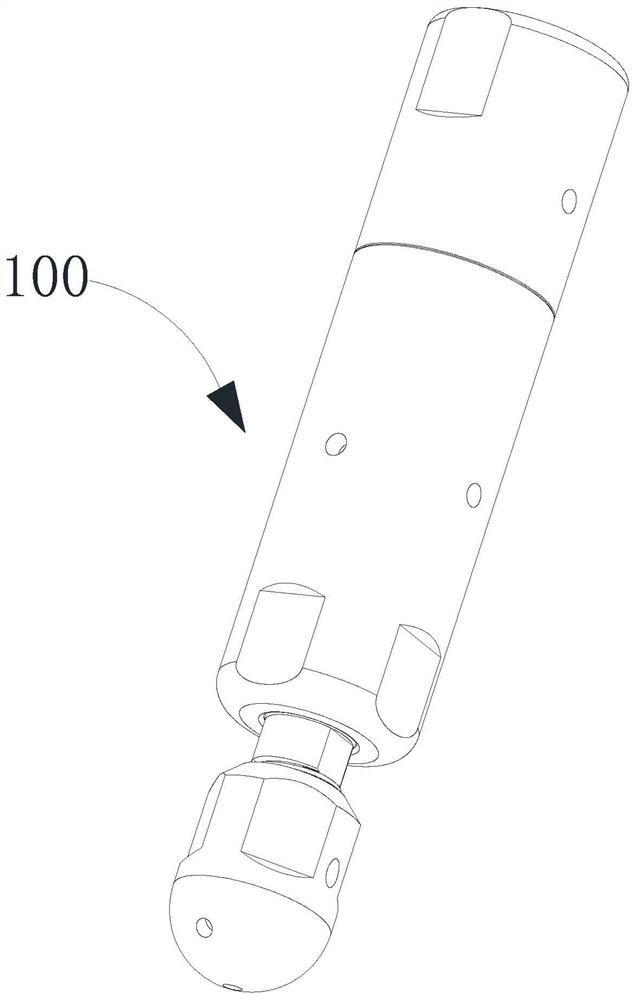

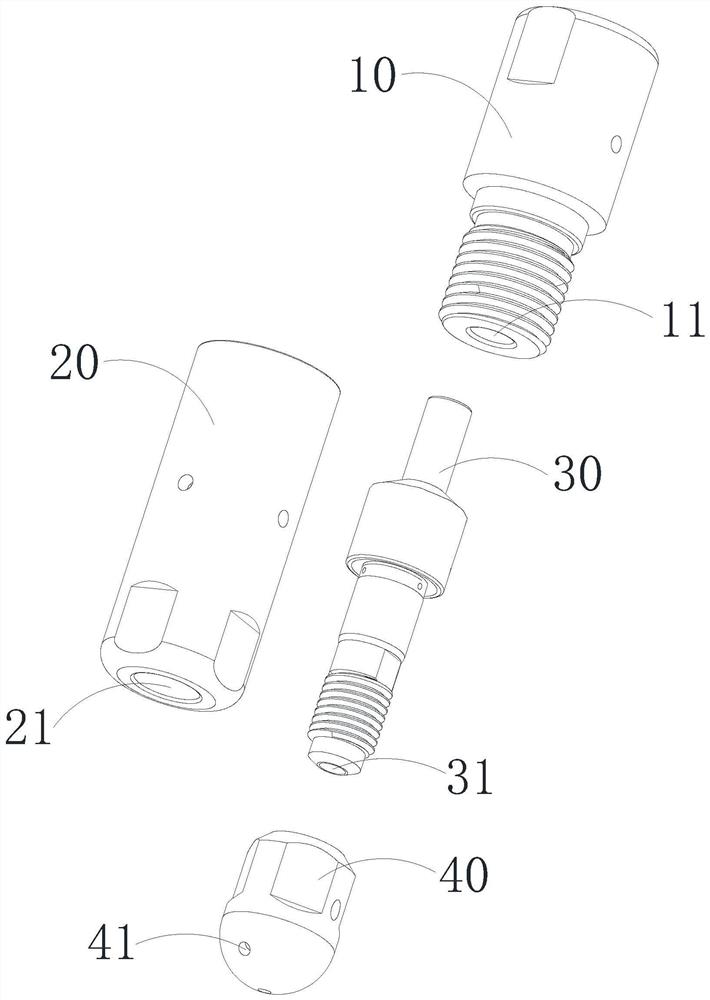

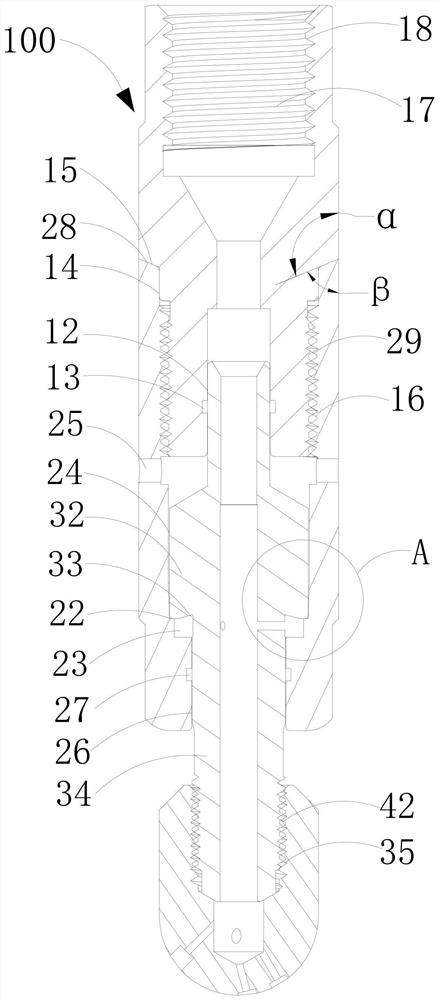

Self-rotating clamping device used for rapidly changing upper anvil for forging press

ActiveCN101797620BSmooth movementForce balanceForging/hammering/pressing machinesMechanical engineeringEngineering

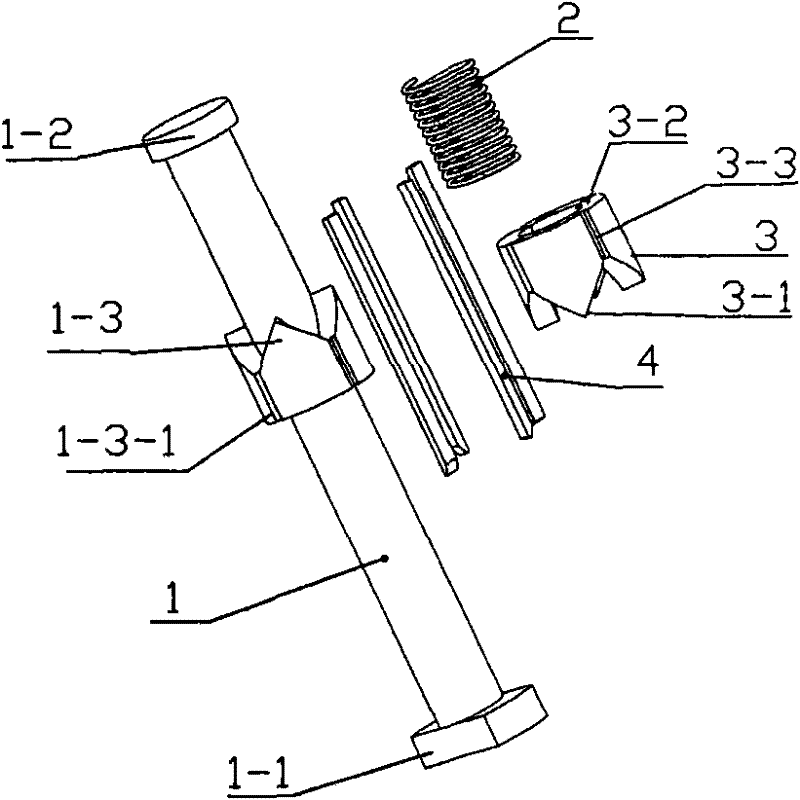

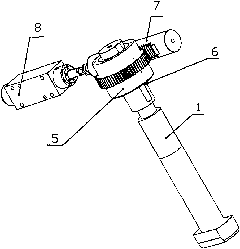

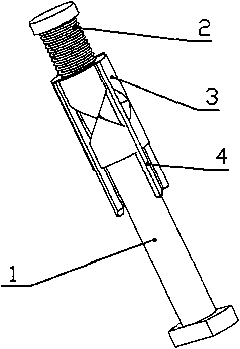

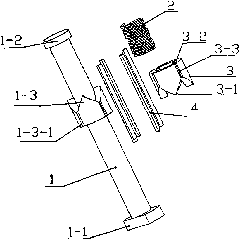

The invention relates to a self-rotating clamping device used for rapidly changing an anvil for a forging press, which relates to an auxiliary tool of the forging press. The invention solves the problems of complicated structure, unbalanced stress of a clamping shaft and low anvil changing speed in the prior art. The invention is characterized in that the top end of the clamping shaft 1 is provided with a convex shoulder 1-2, and the middle part thereof is provided with a tooth 1-3 meshed with a moving sleeve 3; the upper end of the moving sleeve 3 is a plane 3-2, and the lower end thereof isa tooth 3-1; the moving sleeve 3 is sleeved above the tooth 1-3 of the clamping shaft 1; a compression spring 2 is arranged between the upper plane 3-2 of the moving sleeve 3 and the convex shoulder 1-2 of the top end of the clamping shaft 1; the surface of the moving sleeve 3 is symmetrically provided with four moving sleeve sliding slots 3-3; the surface of the tooth 1-3 of the clamping shaft is provided with four clamping shaft sliding slots 1-3-1 which correspond to the moving sleeve sliding slots 3-3; and four glidingly matched guiding edges 4 are respectively arranged in the moving sleeve sliding slots 3-3 and the clamping shaft sliding slots 1-3-1.

Owner:TAIYUAN HEAVY IND

Self-rotating clamping device used for rapidly changing upper anvil for forging press

ActiveCN101797620ASmooth movementForce balanceForging/hammering/pressing machinesEngineeringMechanical engineering

The invention relates to a self-rotating clamping device used for rapidly changing an anvil for a forging press, which relates to an auxiliary tool of the forging press. The invention solves the problems of complicated structure, unbalanced stress of a clamping shaft and low anvil changing speed in the prior art. The invention is characterized in that the top end of the clamping shaft 1 is provided with a convex shoulder 1-2, and the middle part thereof is provided with a tooth 1-3 meshed with a moving sleeve 3; the upper end of the moving sleeve 3 is a plane 3-2, and the lower end thereof is a tooth 3-1; the moving sleeve 3 is sleeved above the tooth 1-3 of the clamping shaft 1; a compression spring 2 is arranged between the upper plane 3-2 of the moving sleeve 3 and the convex shoulder 1-2 of the top end of the clamping shaft 1; the surface of the moving sleeve 3 is symmetrically provided with four moving sleeve sliding slots 3-3; the surface of the tooth 1-3 of the clamping shaft is provided with four clamping shaft sliding slots 1-3-1 which correspond to the moving sleeve sliding slots 3-3; and four glidingly matched guiding edges 4 are respectively arranged in the moving sleeve sliding slots 3-3 and the clamping shaft sliding slots 1-3-1.

Owner:TAIYUAN HEAVY IND

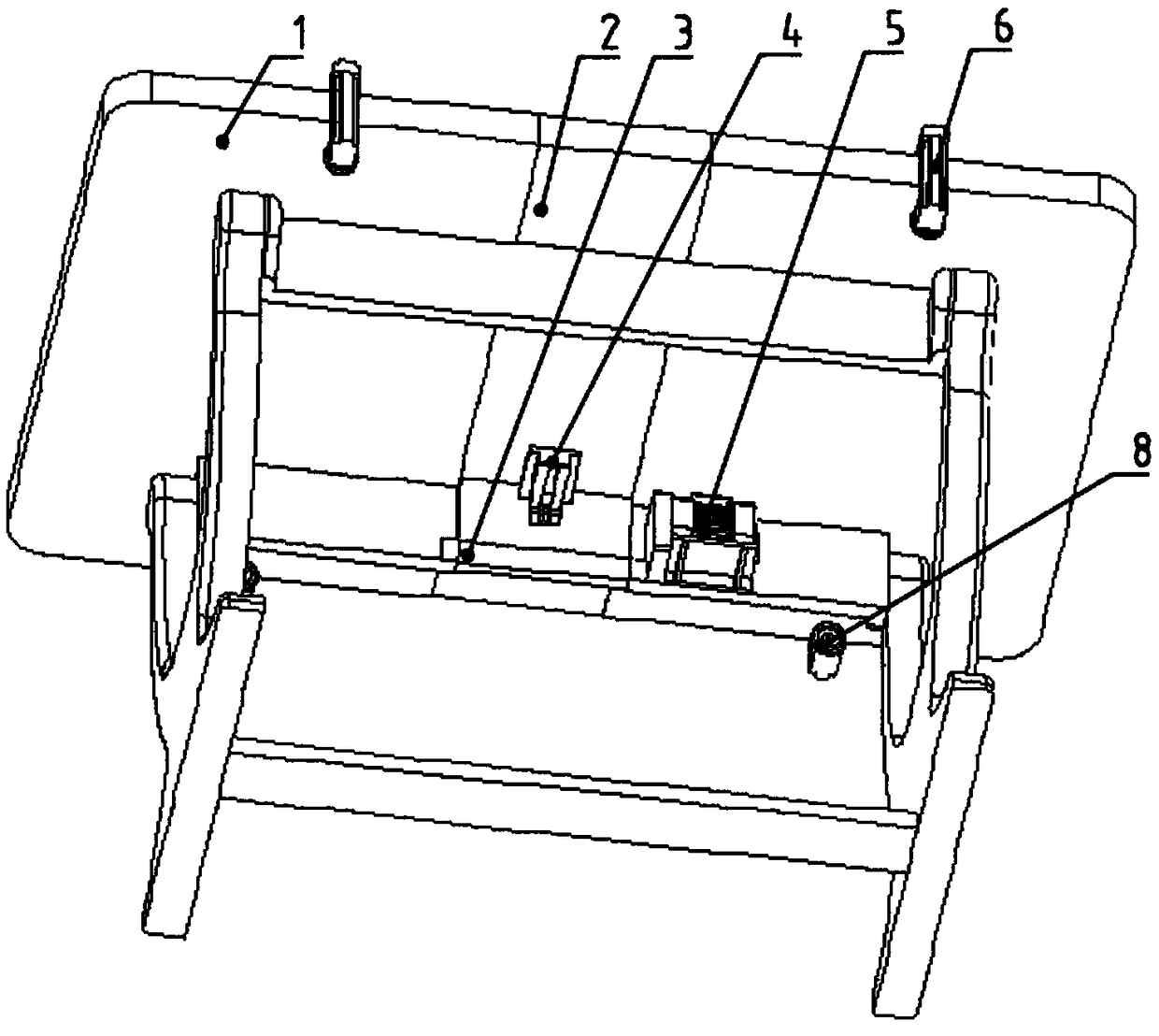

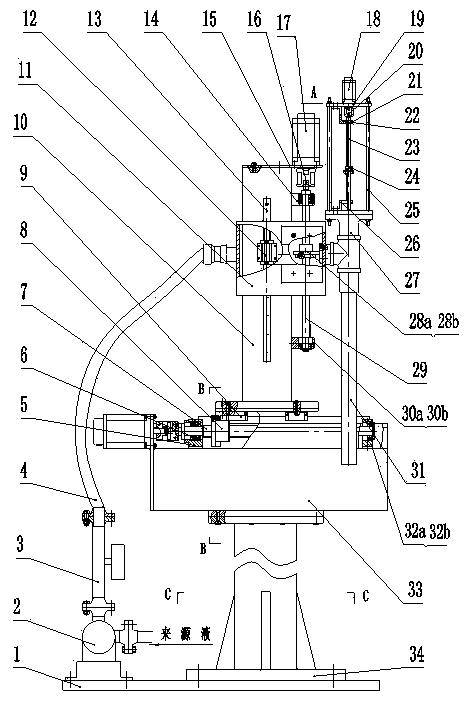

Automatic filling and extraction system

InactiveCN104192781BAchieve traceabilityAchieve self-rotationBarrels/casks fillingEngineeringMechanical engineering

An automatic filling and extracting system is composed of a filling and extracting device, a barrel rotating device, a mouth-finding device, a barrel tilting device and a detection control part. It can realize automatic mouth finding, automatic barrel rotation, automatic barrel tilting, automatic filling and automatic extraction.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

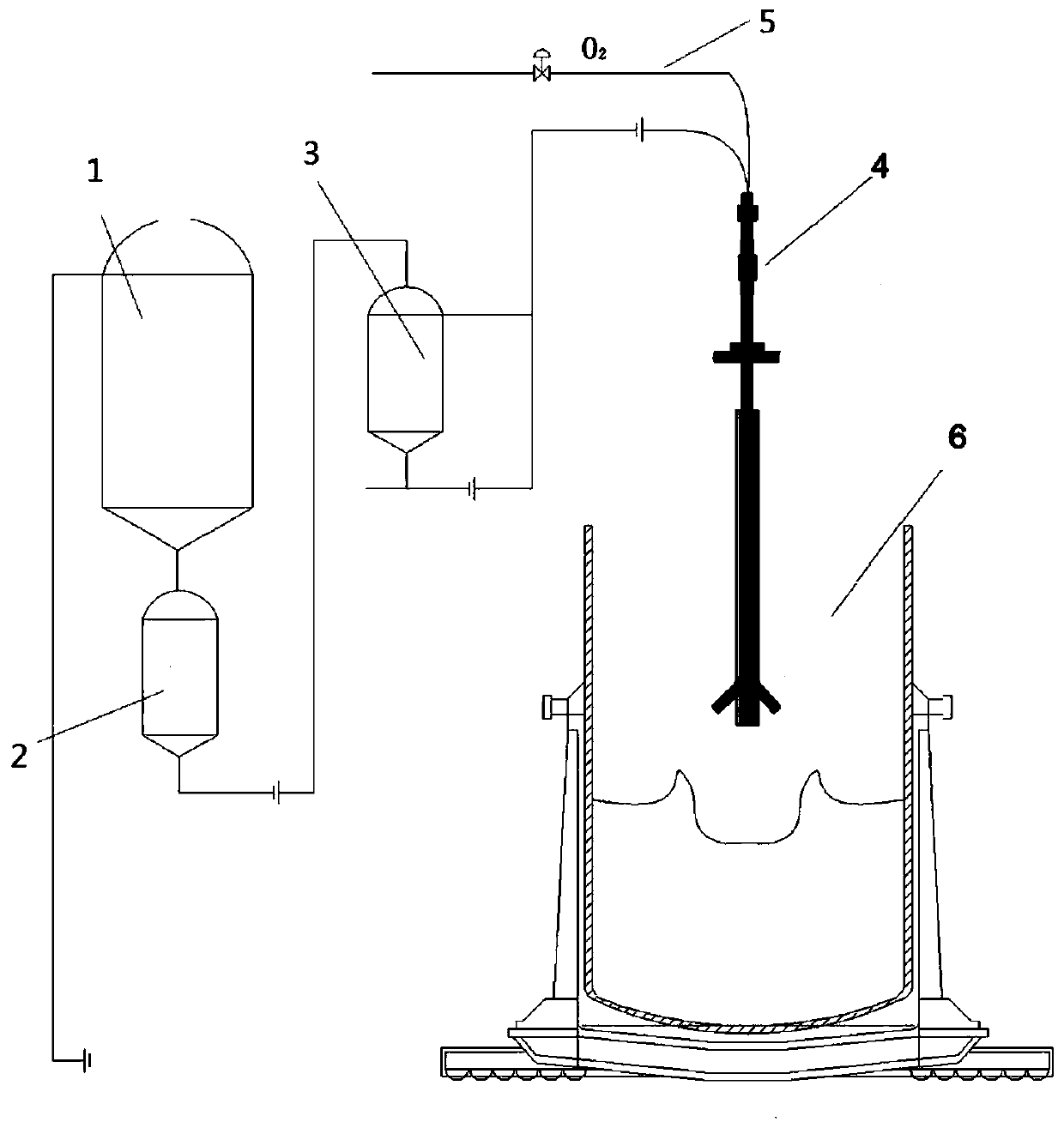

Molten iron dephosphorization device and dephosphorization method for smelting stainless steel

The invention relates to a molten iron dephosphorization device and dephosphorization method for smelting stainless steel, belongs to the technical field of ferrous metallurgy, and solves the problemsthat an existing dephosphorization device is large in occupied space, large in powder loss and low in smelting efficiency. The molten iron dephosphorization device comprises a storage tank, a conveying tank, a blowing tank, a spray gun, a ventilation pipe and a steel ladle, wherein the storage tank is connected with the blowing tank through the conveying tank, and the blowing tank and the ventilation pipe are connected with the spray gun; the spray gun comprises a first pipe and a second pipe, the first pipe is provided with a supporting bearing or the first pipe consists of flexible connecting pipes, and the first pipe is telescopically arranged in the second pipe; and the second pipe is provided with N spray gun outlets. The dephosphorization method comprises the following steps that desiliconization treatment is carried out on molten iron, desiliconized slag is removed, the molten iron is sprayed with oxygen and slagging materials, and molten slag is formed on the surface of the molten iron; and the steel ladle is sprayed with oxygen and slagging materials for dephosphorization treatment, wherein the oxygen spraying flow is 0.9 Nm<3> / t.min-1.2 Nm<3> / t.min, and the oxygen supply pressure is not less than 0.6 Mpa, so that the self-rotation of the spray gun is guaranteed. The device and the method can be used for molten iron dephosphorization for smelting the stainless steel.

Owner:CENT IRON & STEEL RES INST

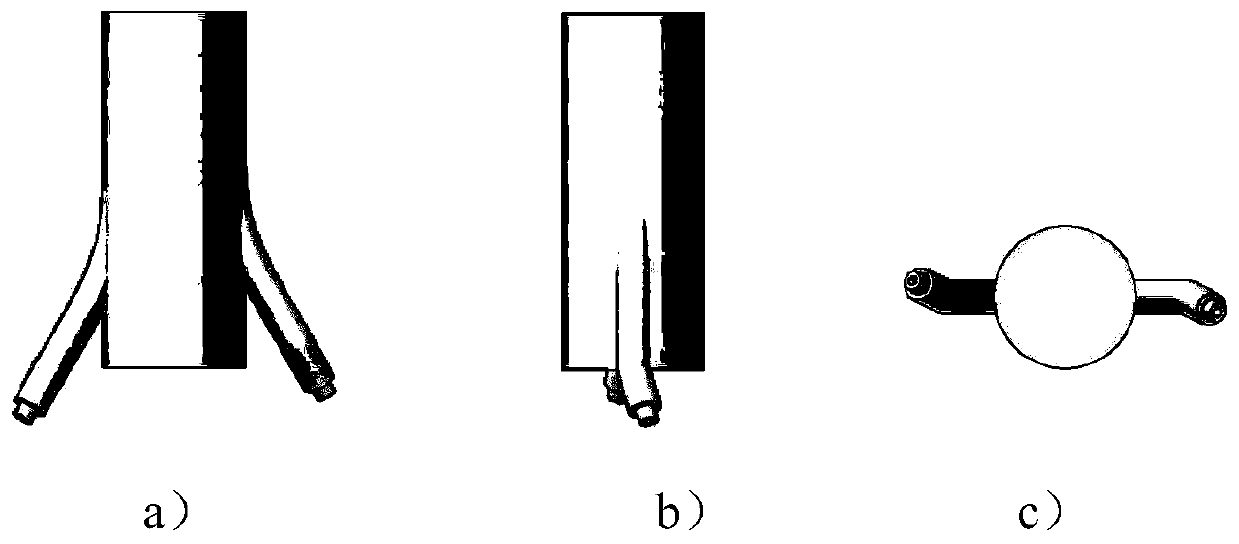

Water body sampling device based on unmanned ship and use method of water body sampling device

PendingCN113567190ASimple structureLow costWaterborne vesselsWithdrawing sample devicesStructural engineeringMarine engineering

The invention discloses a water body sampling device based on an unmanned ship and a use method thereof. The water body sampling device comprises the unmanned ship, an electric cylinder is installed on the unmanned ship, the bottom end of a piston rod of the electric cylinder is connected with a sampler, the sampler comprises a supporting plate, and the bottom of the supporting plate is connected with an obliquely-arranged U-shaped frame. A protection cylinder is hinged to the U-shaped frame through a pin shaft. A sampling pipe is mounted in the protective cylinder in a sleeving manner, a cushion block is connected to one side of the U-shaped frame, and when the protective cylinder is attached to the surface of the cushion block, the protective cylinder is inclined; the U-shaped frame is connected with a magnet piece, and when the protection barrel is attracted to the surface of the magnet piece, the protection barrel is in a vertical shape. The device also includes a baffle plate. The top of the baffle plate is connected with the supporting plate; a blocking plate is slidably connected to the surface of one side of the baffle plate, and when the protection barrel is in a vertical shape, the blocking plate is pressed at the center hole, so that blocking of the center hole is achieved. The whole sampling process is easy to operate, efficient and intelligent, the sampling pipe can automatically rotate and seal, manual control is not needed, the structural design is ingenious and reasonable, and use is very convenient.

Owner:WATER RESOURCES RES INST OF SHANDONG PROVINCE

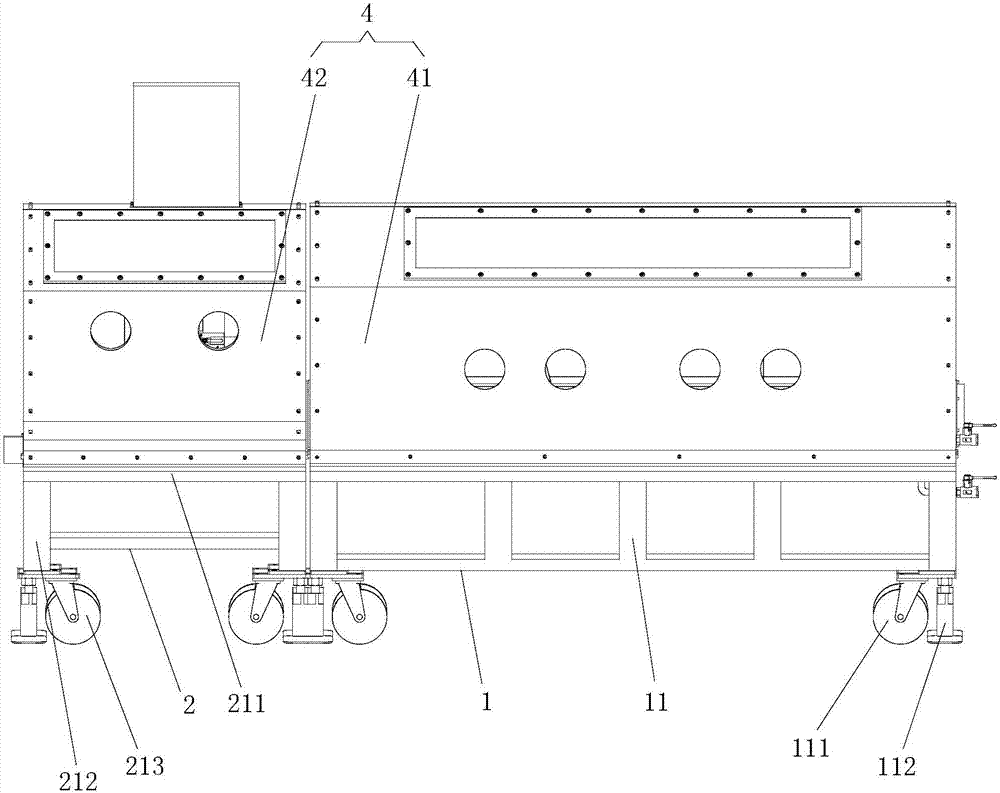

Radiating product cutting equipment

PendingCN107160073AReasonable structural designEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesWaste recoveryControl system

The invention relates to radiating product cutting equipment. The radiating product cutting equipment comprises a movable clamping system, a movable automatic cutting device, a waste recovery device, a shielding shell system, a control system and a control cabinet. The movable clamping system comprises an operating stand main body, a movable tailstock, a fixed tailstock, a triangular support connecting plate, a triangular supporting frame and a three-dimensional auxiliary moving mechanism. The movable automatic cutting device is arranged on one side of a movable split type operating stand in a matched mode. The waste recovery device is arranged on the bottom side of the movable automatic cutting device in a matched mode. The shielding shell system comprises an operating stand shielding case mounted on the operating stand main body in a matched mode and a cutting shielding case mounted outside the movable automatic cutting device in a matched mode. The control system achieves remote and fixed control over the equipment through an operation interface of the control system and is mounted in the control cabinet. The radiating product cutting equipment is reasonable and compact in structural design, convenient to operate and use, high in workpiece cutting efficiency, good in effect and wide in application range.

Owner:四川同人精工科技有限公司

Middle school electrostatic dust removing and yarn winding demonstration device

InactiveCN105374270AEasy to understandIncrease interest in explorationEducational modelsYarnEngineering

The invention discloses a middle school electrostatic dust removing and yarn winding demonstration device. The middle school electrostatic dust removing and yarn winding demonstration device is characterized in that the middle school electrostatic dust removing and yarn winding demonstration device comprises a rack; a rack platform is arranged on the rack; a yarn stranding frame is arranged to one side of the rack; the yarn stranding frame is wound with yarns; the front side of the rack is provided with a front guide device; the guide device includes two parallel guide rollers which are arranged sequentially along a vertical direction; a groove extending along the peripheral wall of the guide roller is formed at the middle of the guide roller; the yarns can pass through a space between the two grooves; two end portions of the guide roller are provided with pressing covers; the pressing covers at the two ends of the same guide roller are symmetrically arranged; the pressing cover is of an ring-shaped horn mouth structure; the outer peripheries of the pressing covers of the upper guide roller are of bent structures; the pressing covers of the lower guide roller are inserted at the pressing covers of the upper guide roller; and the rear end of the front guide device is provide with a spray device and a drying device sequentially. With the middle school electrostatic dust removing and yarn winding demonstration device provided by the technical schemes of the invention adopted, existing theories in books can be utilized. The middle school electrostatic dust removing and yarn winding demonstration device has the advantages of high intuitive performance and simple structure.

Owner:吕畅宇

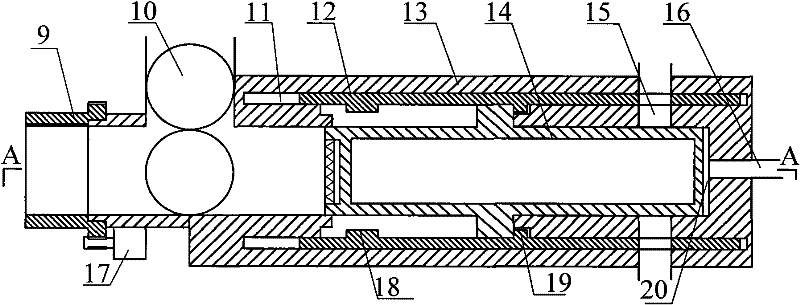

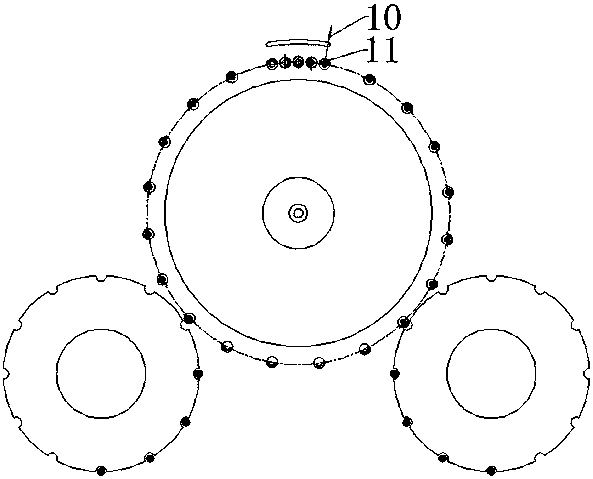

Laser perforating device with wide scanning focus

The invention discloses a laser perforating device with wide scanning focus. The laser perforating device includes a floating rotation conveying device and a laser perforating device body; the floating rotation conveying device includes a rotating disc rotating axially, and a plurality of rotating negative pressure sucking grooves are formed in the circumference of the rotating disc; the laser perforating device body includes a rotating prism, arc-shaped cylindrical lenses and a plurality of reflectors, the rotating prism is arranged at the end of the rotating disc and is coaxially arranged with the rotating disc; the arc-shaped cylindrical lenses are arranged on the outer ring of the rotating disc in the circumferential direction of the rotating disc; and pulse laser received by the rotating prism is transmitted to the arc-shaped cylindrical lenses through the reflectors, focuses on filter tips of cigarettes adsorbed by the negative pressure sucking grooves, and circumferential perforating is completed along with the rotation of the negative pressure sucking grooves. According to the laser perforating device, the defect that traditional laser perforating can only focus on the plane is overcome, laser is scanning and perforating while the cigarettes rotate, and the cigarettes are always perforated on the focal plane without damage. The perforating accuracy is high, the moldingeffect is good, the distance is uniform, the size is consistent, the operation is convenient, the adjustment is easy, and the practicability and wide applicability are high.

Owner:HOHAI UNIV +1

Oxygen-enriched side blowing smelting converter

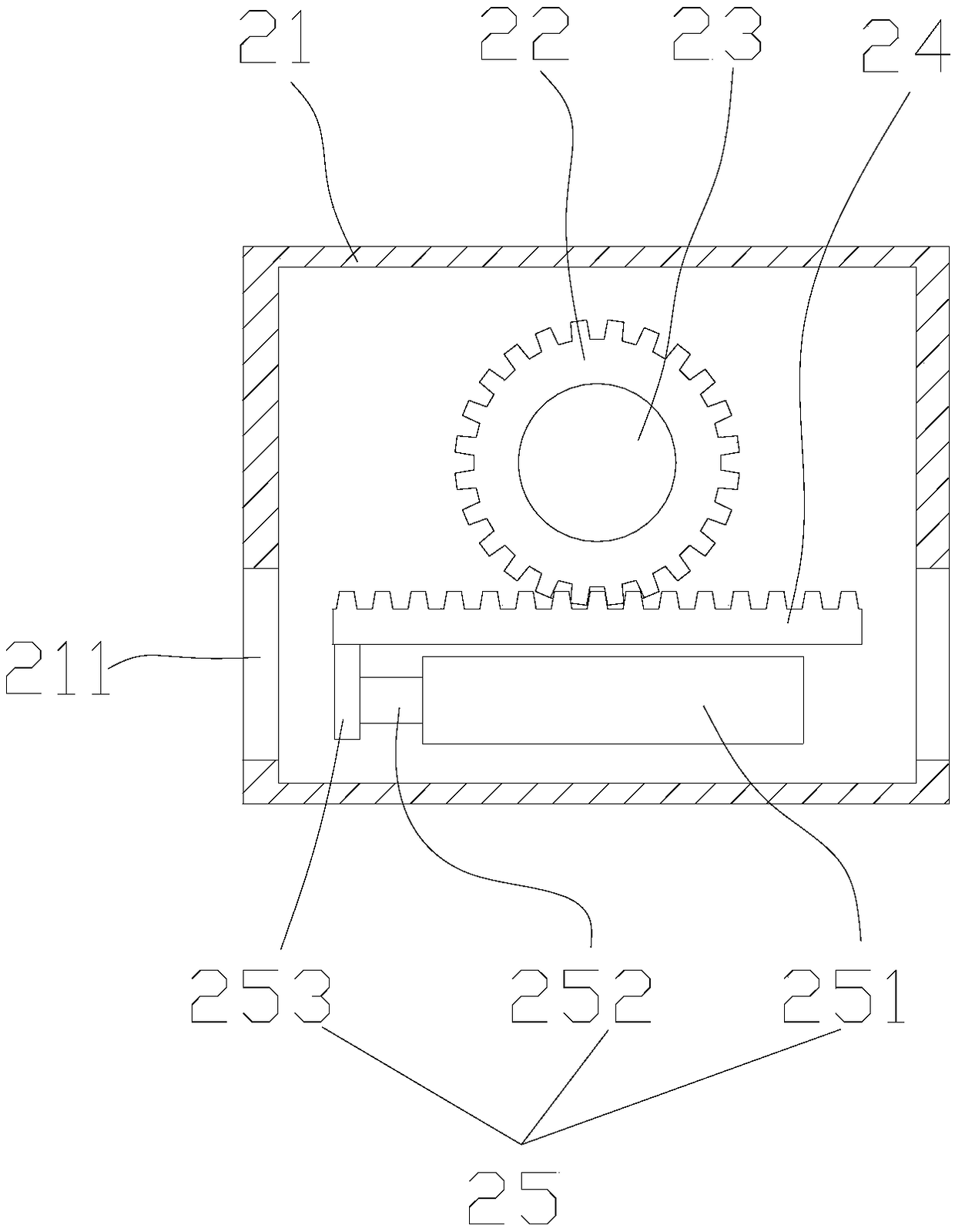

ActiveCN109355458AAchieve self-rotationFully oxidizedManufacturing convertersHydraulic cylinderEngineering

The invention discloses an oxygen-enriched side blowing smelting converter, and belongs to the field of smelter equipment. The oxygen-enriched side blowing smelting converter comprises a main converter body, a rotating device, supports and a side blowing device; the rotating device comprises a box, a gear, a rotating shaft, a rack and a hydraulic cylinder; and the side blowing device comprises three side blowing plates, a gas inlet passage and a gas inlet pipe, wherein the gas inlet passage is arranged at the top parts of the side blowing plates. According to the oxygen-enriched side blowing smelting converter disclosed by the invention, by installing the rotating device, the main converter body can rotate without using lifting equipment, and use safety is enhanced; by installing the sideblowing device, oxygen high in concentration is blown into the side part of molten steel, so that the molten steel located in the main converter body can be fully oxidized; and therefore, the oxygen-enriched side blowing smelting converter is capable of realizing rotation of the main converter body, is convenient to operate and high in safety, and has a good oxidation effect on the molten steel.

Owner:大余明发矿业有限公司

Cold drawing equipment for stainless steel product machining

The invention belongs to the technical field of stainless steel product machining, and particularly relates to cold drawing equipment for stainless steel product machining. According to the scheme, the cold drawing equipment comprises an operation table and a fixing rod, and a pre-cold-drawing mold is fixedly connected to the outer wall of the bottom of the fixing rod. According to the cold drawing equipment for stainless steel product machining, through the arrangement of a molding cover, sliding blocks, hydraulic cylinders and molding plates, a guide groove is formed in the inner wall of the molding cover, in the pre-cold-drawing process of a stainless steel product, the hydraulic cylinders are adjusted to drive the molding plates to make contact with the outer wall of the stainless steel product, in the process of sliding on the outer wall of the stainless steel product along with the pre-cold-drawing mold, the molding plates extrude the stainless steel product, the cold-drawn stainless steel product is easy to deform, the outer wall of the stainless steel product is polished and molded through the molding plates, the situation that the outer wall of the stainless steel product is uneven is prevented, and in the process that the molding plates and the stainless steel product are mutually extruded, the sliding blocks slide in the guide groove, so that the molding plates realize self-rotation, and the molding effect on the stainless steel product is improved.

Owner:南通飞神金属制品有限公司

Ultrahigh-pressure water jet cleaning spray head

PendingCN112090607AAchieve self-rotationImprove output efficiencyMovable spraying apparatusRotational axisUltra high pressure

The invention relates to the technical field of cleaning equipment, and provides an ultrahigh-pressure water jet cleaning spray head. The cleaning spray head comprises a fixing base with a first through hole, a shell with a cavity, a rotating shaft with a second through hole and a spray head with a spray hole, wherein the spray hole is formed in a deflection mode, one end of the fixing base is connected with a water inlet high-pressure pipe, the other end of the fixing base is connected with the shell, the rotating shaft is arranged in the cavity and is in clearance fit with the inner wall ofthe cavity, one end extends out of the shell and is connected with the spray head, the other end is in clearance fit with the inner wall of the first through hole, the first through hole communicateswith the second through hole, a step is arranged in the cavity, a supporting part is arranged on the rotating shaft, the supporting part is matched with the step to limit and install the rotating shaft in the cavity, a rebound cavity is formed, a rebound hole is formed in the rotating shaft, the rebound hole communicates with the second through hole and the rebound cavity, and a centripetal conical groove is formed in the side, close to the step, of the supporting part and used for reducing centrifugal force deflection generated in the rotating process of the rotating shaft, improving the stability of axial rotation and prolonging the service life.

Owner:LASTING TECH SHENZHEN CO LTD

Millimeter wave single-user performance system test turntable

PendingCN112285391ARealize moving up and downAchieve rotationMeasurement instrument housingVertical planeClassical mechanics

The invention innovatively provides a millimeter wave single-user performance system test turntable which comprises a shell and a bearing table; the shell internally comprises a first moving mechanism, a second moving mechanism and a lifting mechanism from bottom to top in sequence, and the first moving mechanism gives a first thrust to the second moving mechanism so as to enable the bearing tableto move in the horizontal direction; the second moving mechanism provides a second pushing force for the lifting mechanism to enable the bearing table to move in the horizontal direction, the liftingmechanism provides a third pushing force for the bearing table to enable the bearing table to move in the vertical direction, and the bearing table internally comprises a first rotating mechanism anda second rotating mechanism. The first rotating mechanism gives a first rotating force to the bearing table to enable the bearing table to rotate on a horizontal plane, a test fixture is horizontallyarranged on the bearing table, and the second rotating mechanism gives a second rotating force to the test fixture to enable to-be-tested equipment to rotate on a vertical plane. The test turntable has the beneficial effects that the test turntable can achieve the testing position adjustment and angle adjustment of the to-be-tested equipment.

Owner:杭州永谐科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com