Multifunctional vertical combined machining lathe

A combined processing and multi-functional technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome processing of valve body parts, unfavorable large-scale production of enterprises, and restriction of market competitiveness of enterprises. Achieve the effect of reducing labor intensity of workers, significant economic effect and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

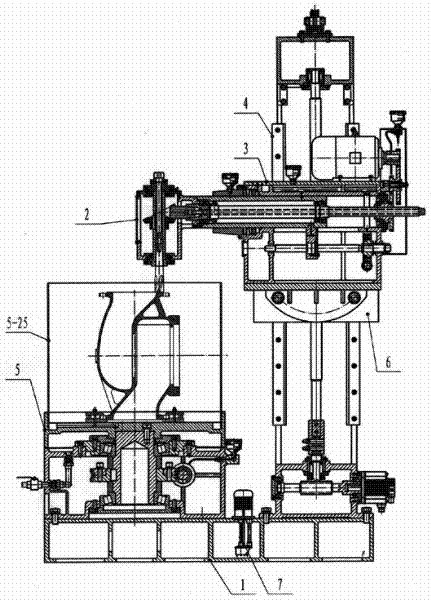

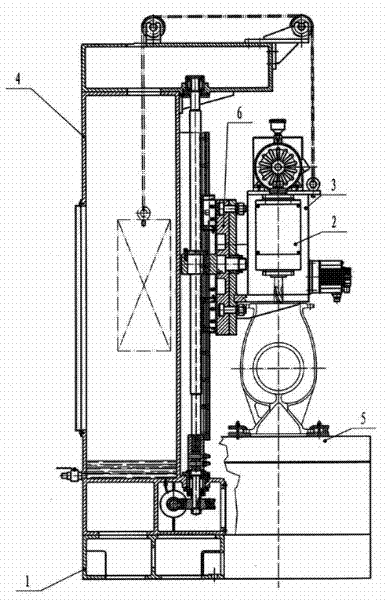

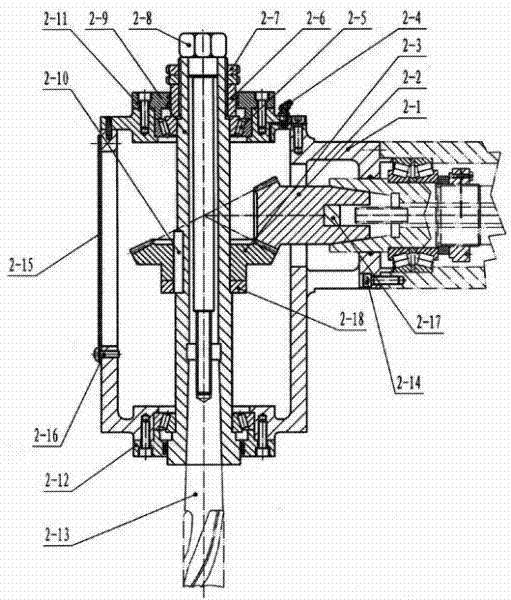

[0036] see figure 1 and figure 2: The present invention includes a bed 1, a tool rest mechanism 2, a spindle box 3, a column mechanism 4 and a control system, wherein the bed 1 is fixed with a rotary table 5, which corresponds to the upper tool rest mechanism 2, and the bed 1 is reserved with cooling lubricating fluid, which is used for cooling and lubricating the processed parts and tools through the cooling pump 7 and the pipeline, the column mechanism 4 is fixed on the bed 1, and the headstock 3 is assembled on the column mechanism through the supporting plate mechanism 6 4, the tool rest mechanism 2 is connected on the spindle box 3, and the control system is an existing disclosed PLC control system of numerical control and electric control. The tool holder mechanism 2 of the present invention is any one of an angle milling head, a grinding head and a turning tool holder (the tool holder mechanism of the present embodiment takes the angle milling head as an example, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com