Radiating product cutting equipment

A technology of cutting equipment and products, which is applied in the direction of welding/cutting auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient operation and use, low cutting efficiency, unfavorable storage and so on, so as to achieve convenient operation and use, improve cutting Efficiency, the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

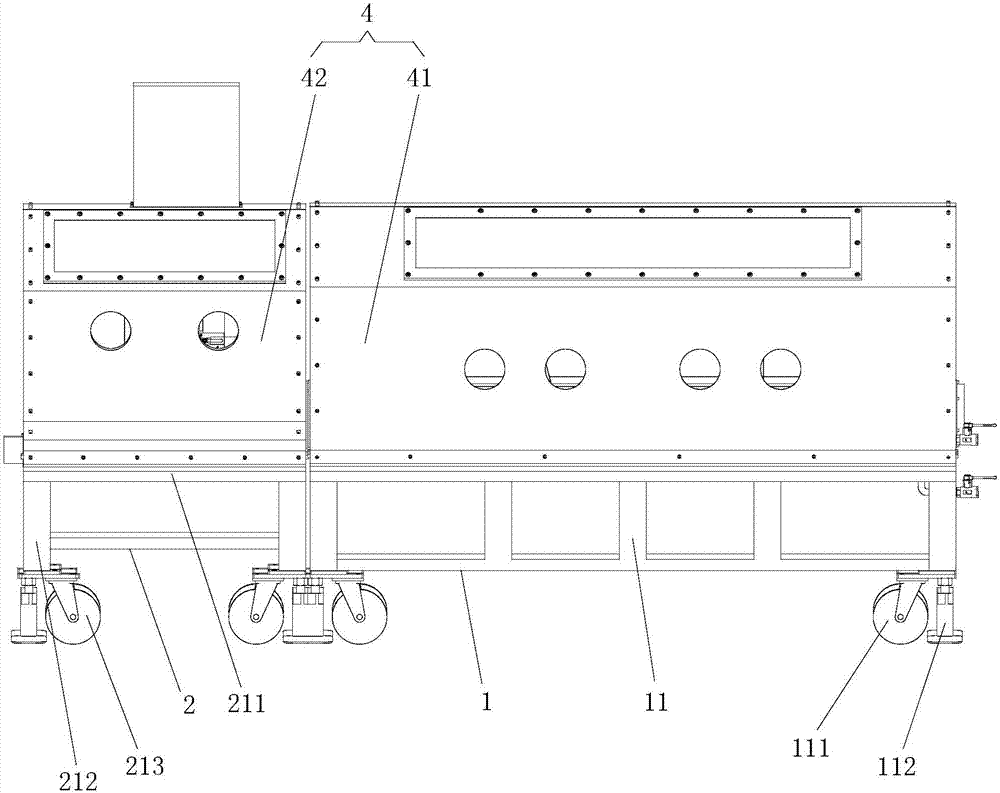

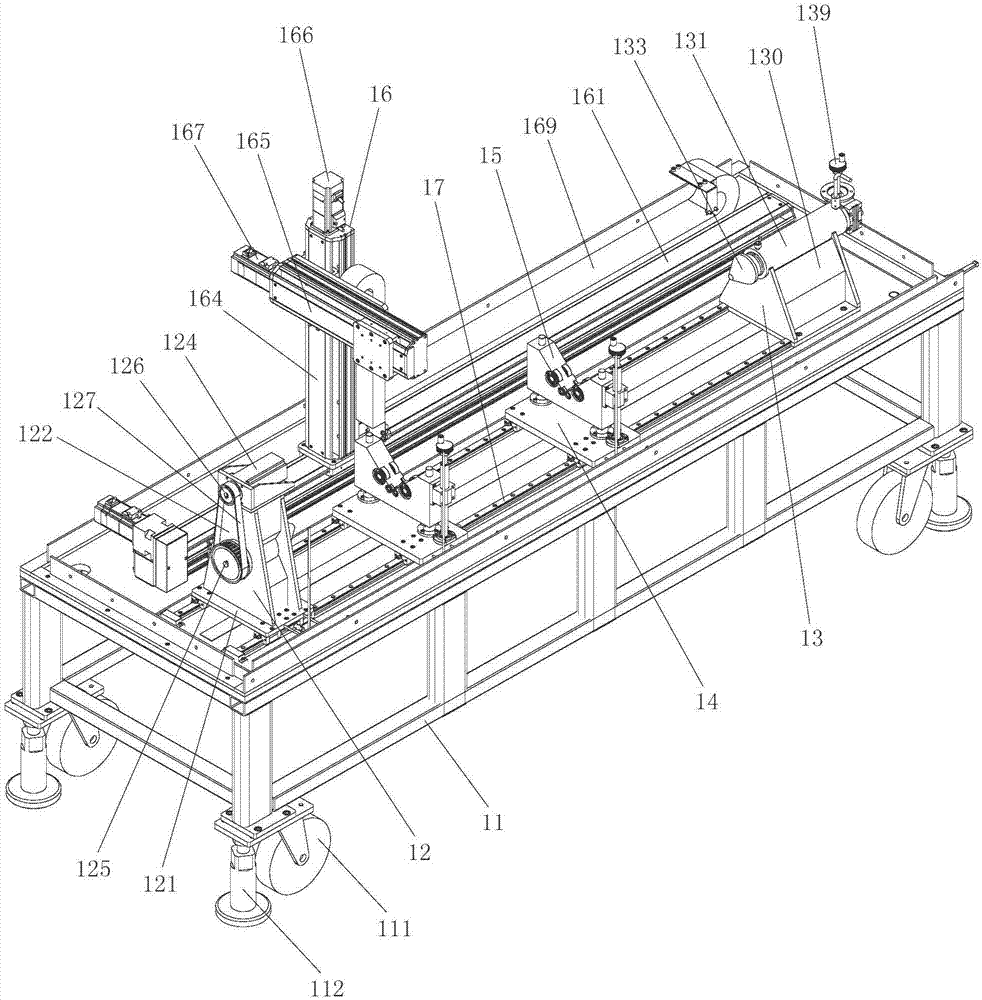

[0028] like Figures 1 to 13 As shown, the radiation product cutting equipment of the present invention includes a mobile clamping system 1, a mobile automatic cutting device 2, a waste recycling device 3, a shielding shell system 4, a control system and a control cabinet.

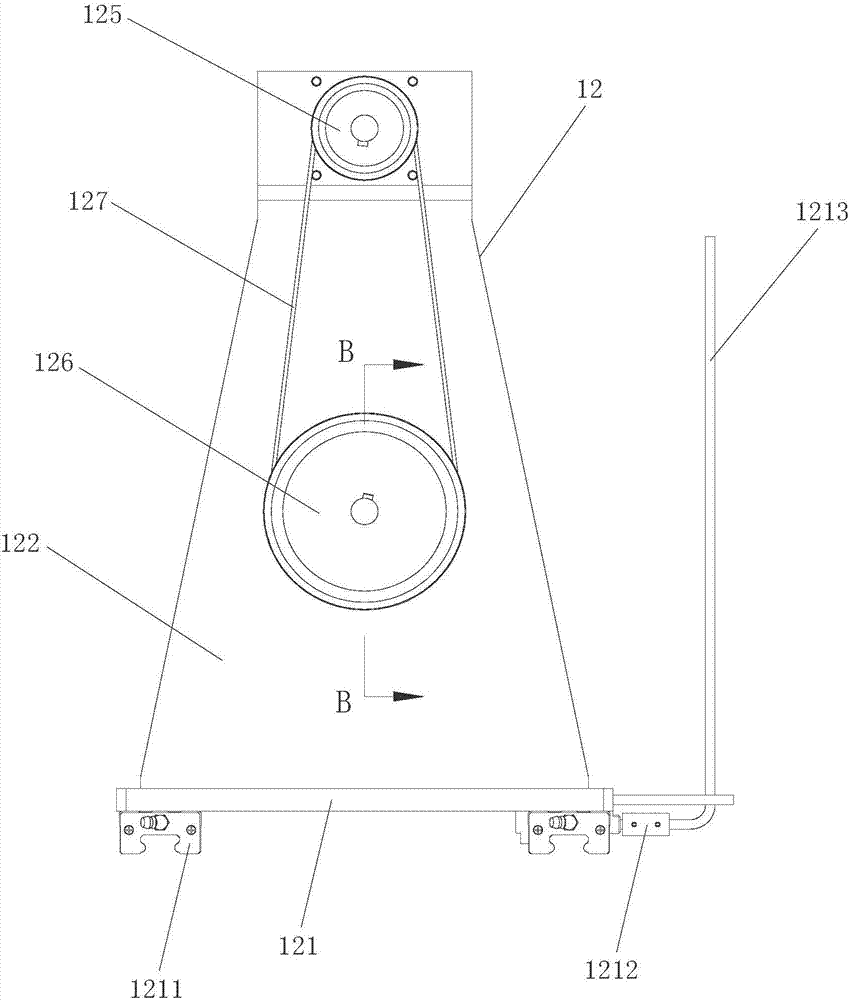

[0029] The mobile clamping system 1 includes a console main body 11 , a movable center seat 12 , a fixed center seat 13 , a tripod connecting plate 14 , a tripod support frame 15 and a three-dimensional auxiliary moving mechanism 16 .

[0030] The main material of the main body 11 of the operating table is stainless steel, and the size is length×width: 2000mm×700mm. The four corners of the bottom are symmetrically equipped with movable casters 111 and fixed tripods 112 are arranged on one side of the movable casters 111, which is convenient for fixing the system after determining the position. Position: the table top of the console main body 11 is provided with slide grooves for installing the shielding sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com