Oxygen-enriched side blowing smelting converter

An oxygen-enriched, converter technology, applied in the manufacture of converters, etc., can solve the problems of no self-contained rotating device, low oxidation efficiency of molten steel, and potential safety hazards, and achieve good oxidation effects, convenient operation, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

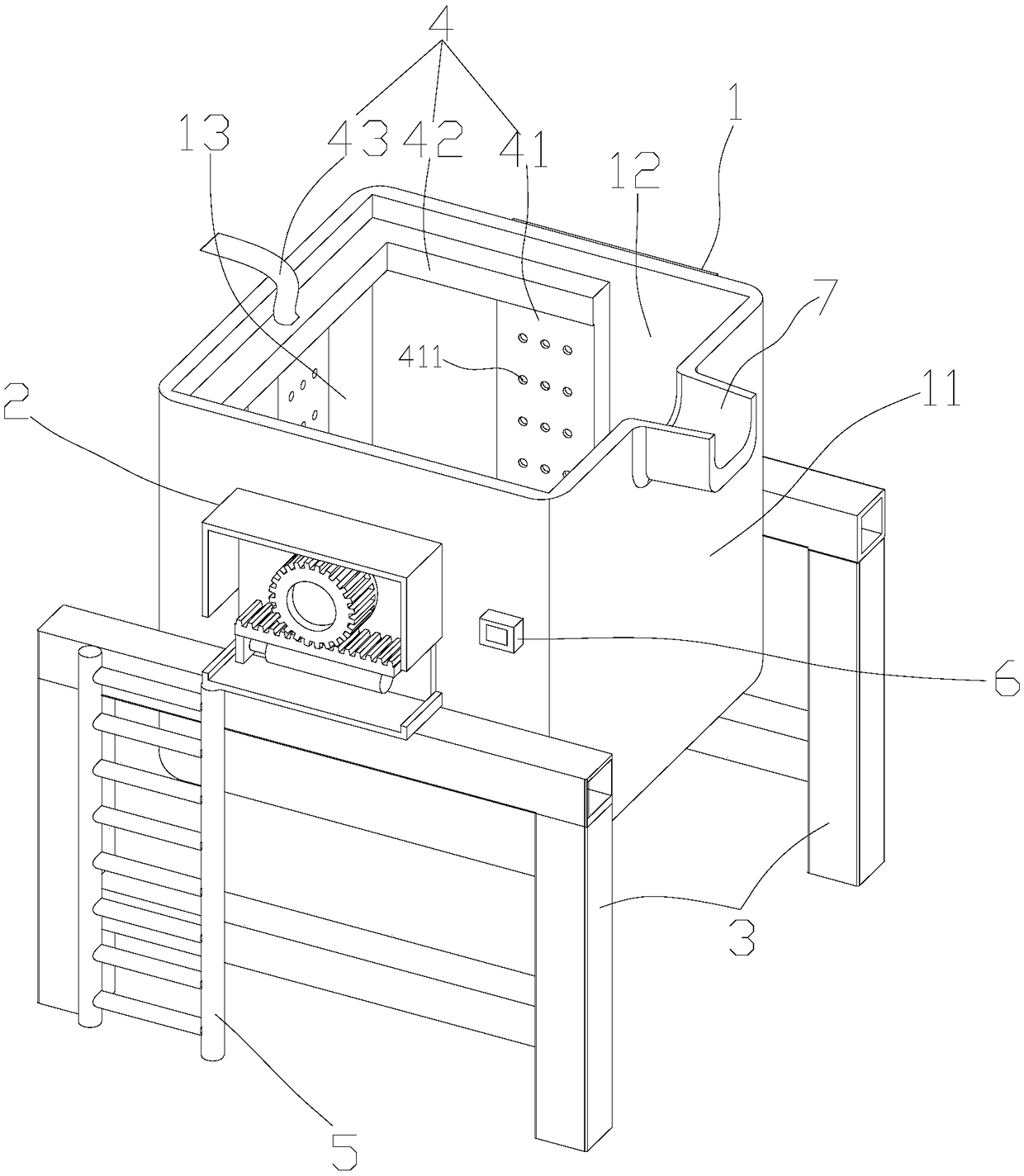

[0052] figure 1 It exemplarily shows a schematic structural view of an oxygen-enriched side-blown smelting converter provided by the present invention;

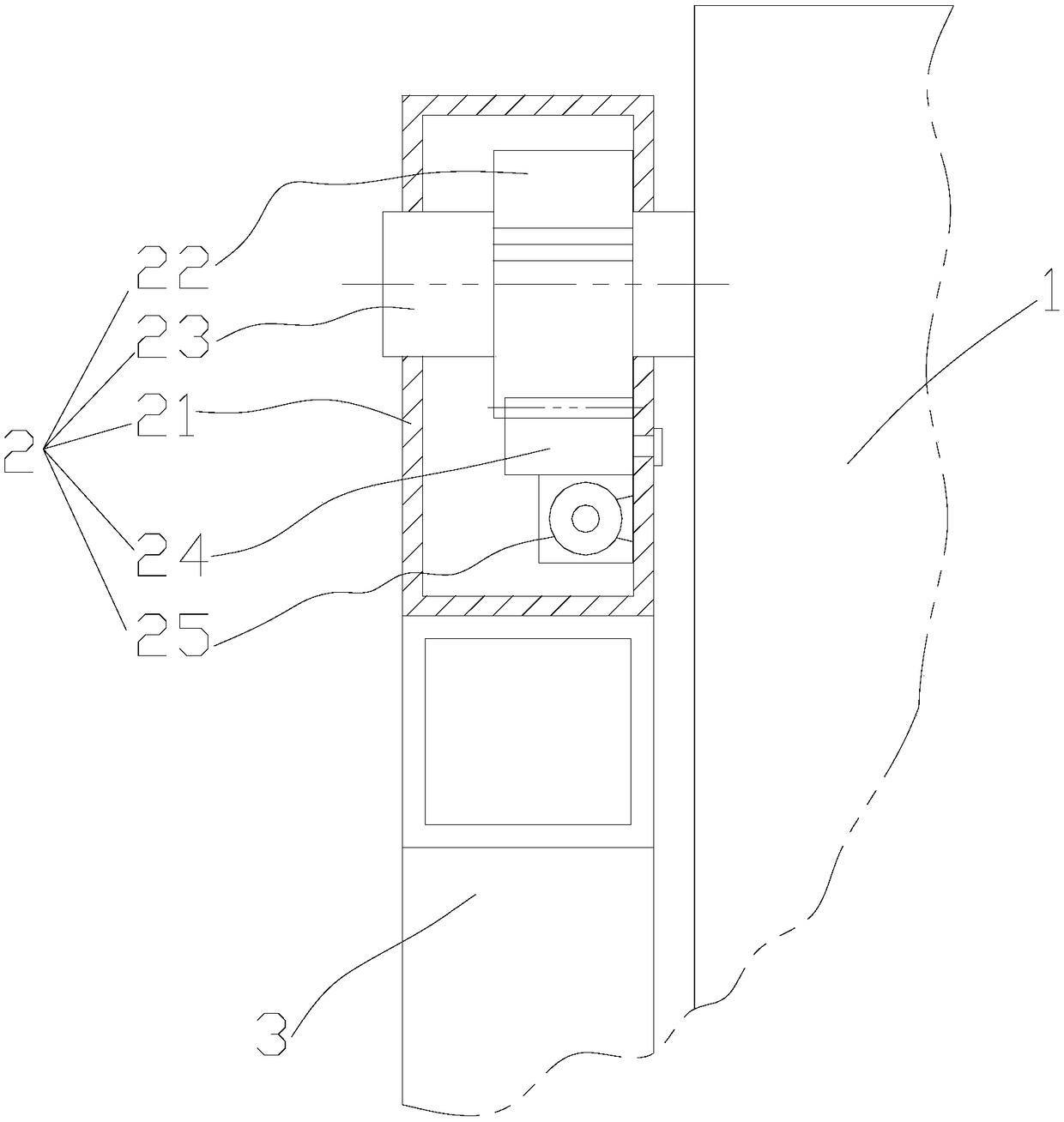

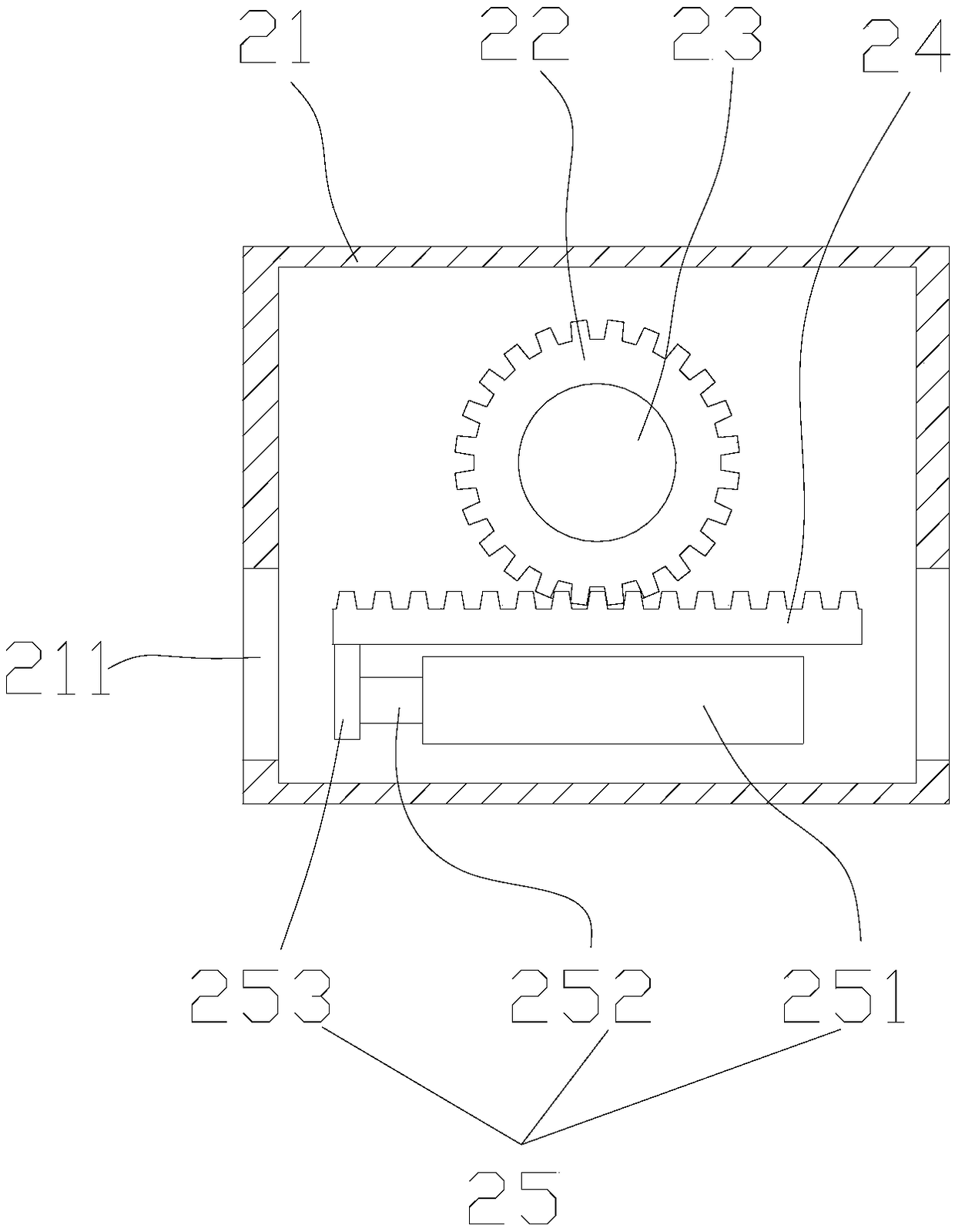

[0053] figure 2 It exemplarily shows a partial enlarged view of an oxygen-enriched side-blowing smelting converter provided by the present invention; image 3 It exemplarily shows a schematic structural diagram of a rotating device of an oxygen-enriched side-blowing smelting converter provided by the present invention; Figure 4 A schematic structural view of the main furnace body of an oxygen-enriched side-blown smelting converter provided by the present invention is exemplarily shown, as figure 1 , 2, shown in 3, 4, a kind of oxygen-enriched side-blowing smelting converter, comprises main furnace body 1, is characterized in that: also compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com