Middle school electrostatic dust removing and yarn winding demonstration device

An electrostatic dust removal and demonstration device technology, applied in teaching models, educational appliances, instruments, etc., can solve the problems of unimpressed students, unintuitive mechanics and processes, and difficulty in understanding students, so as to facilitate understanding, improve exploration interest and hands-on the effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

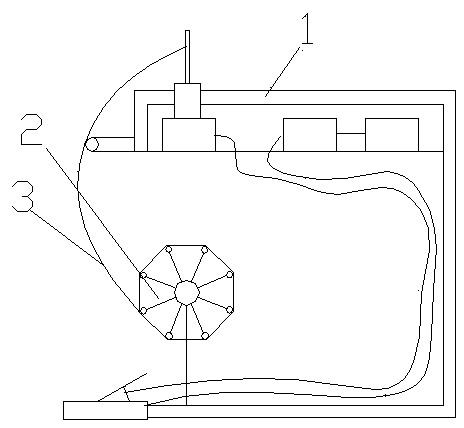

[0030] Such as figure 1 As shown, a middle school electrostatic precipitator winding demonstration device includes a frame 1, a frame platform is arranged on the frame 1, and one side of the frame is a skein frame 2 on which a yarn 3 is wound.

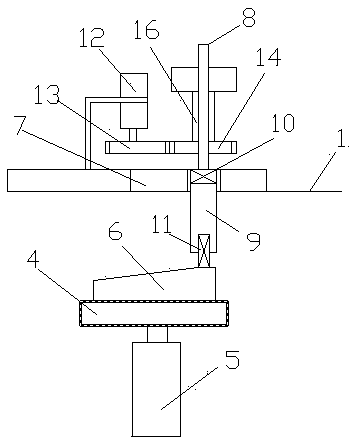

[0031] figure 2 As shown, the frame 1 platform is provided with a motor 5, the motor 5 is located below the frame 1, the motor 5 is vertically arranged, the upper end of the motor 5 is fixed with a turntable 4, and the upper end surface of the turntable 4 is an annular column 6. The distance between the upper surface of the column 6 and the upper end surface of the turntable 4 gradually decreases and then gradually increases, forming a smooth transition.

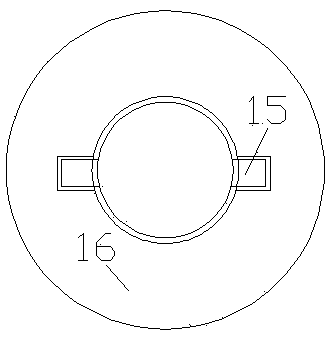

[0032] The upper end of frame 1 is provided with the base 7 that protrudes from the frame plane, and the middle part of base 7 is provided with a through hole, is provided with upper rotating shaft 8 and lower rotating shaft 9 in the through hole, is provided with a groove in the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com