Patents

Literature

151 results about "Mouth structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The main structures inside the mouth are the teeth, tongue, tonsils, salivary glands and - at the back of the throat (not shown on the left). the epiglottis. See also more about teeth.

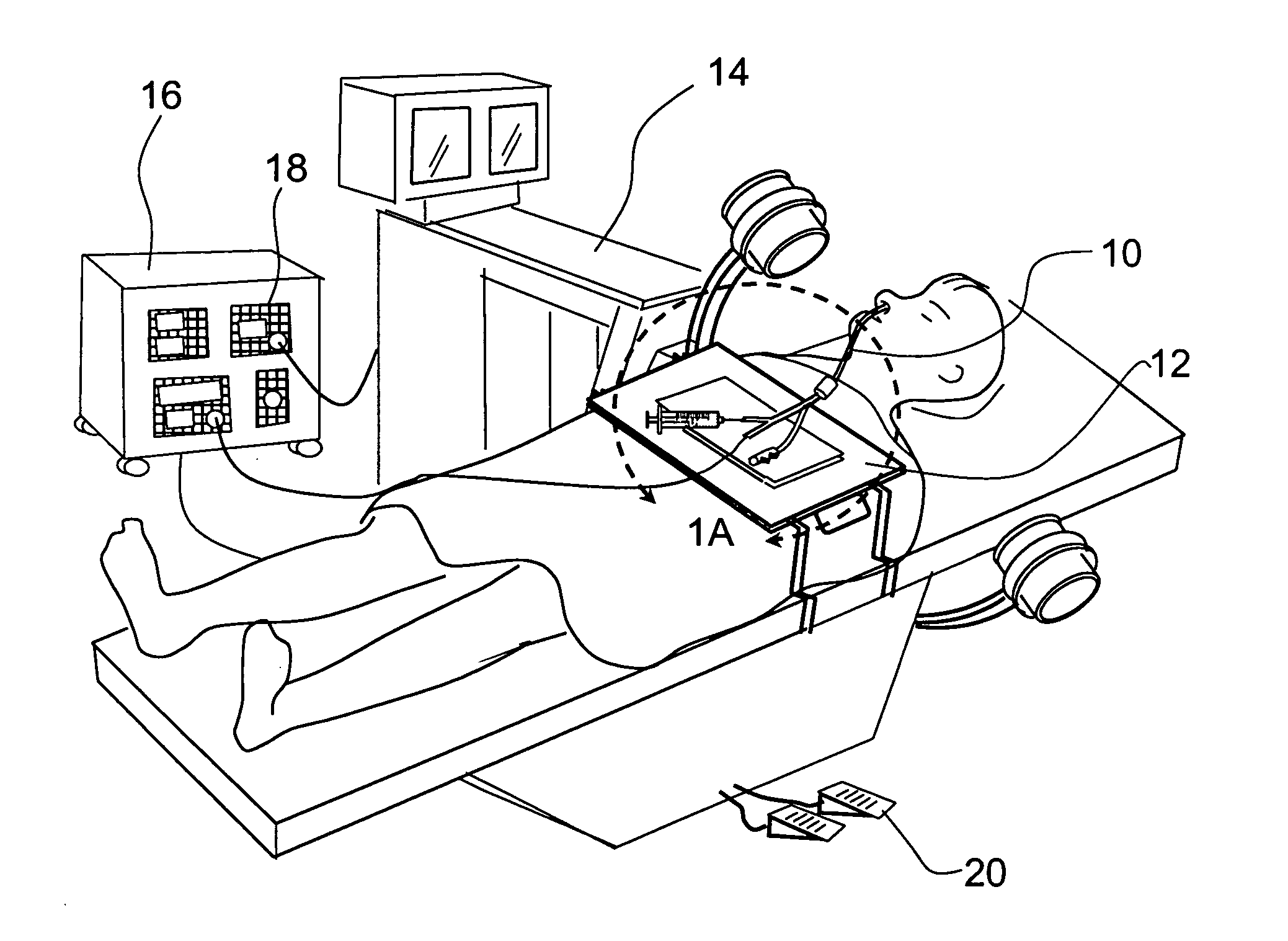

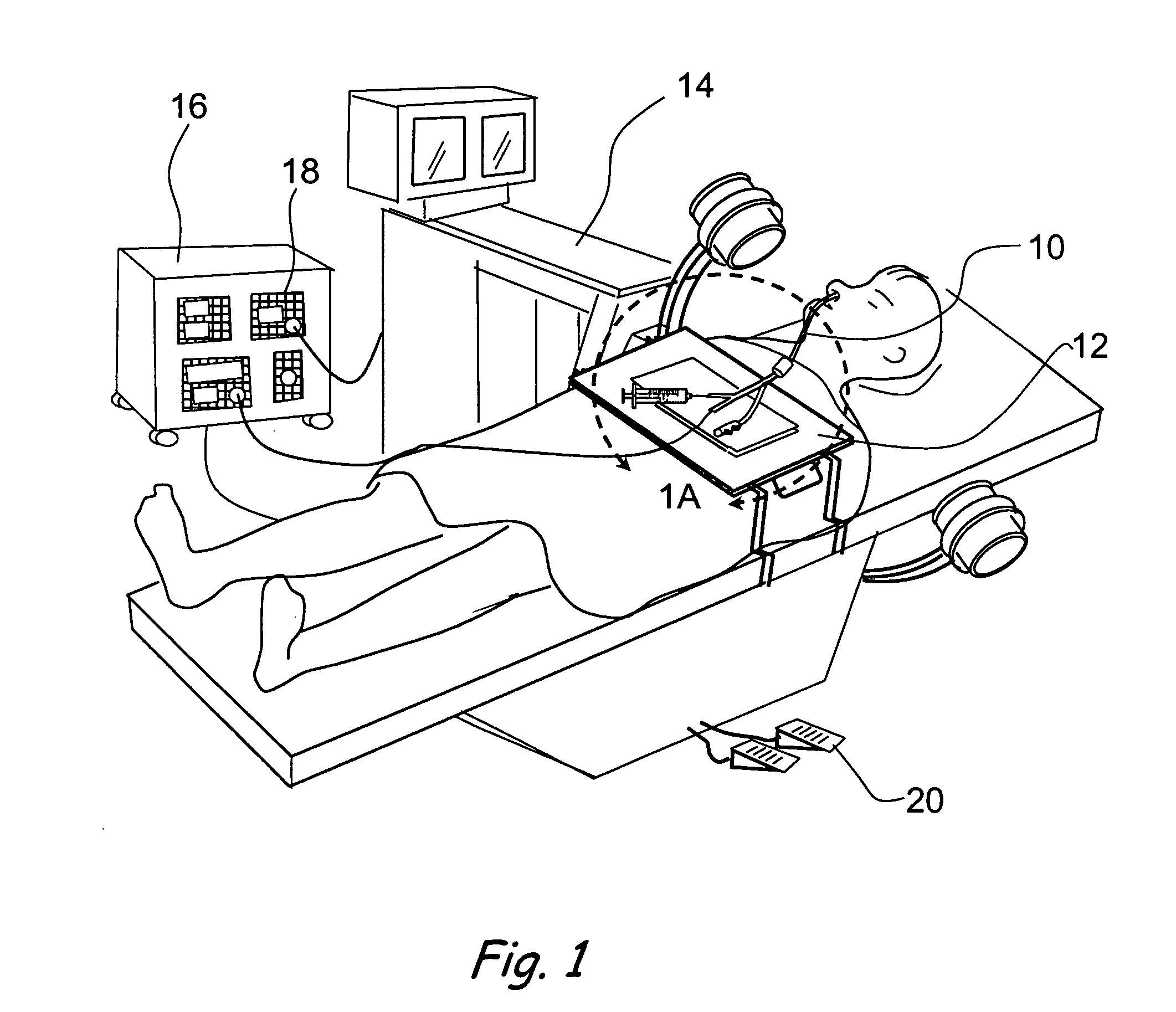

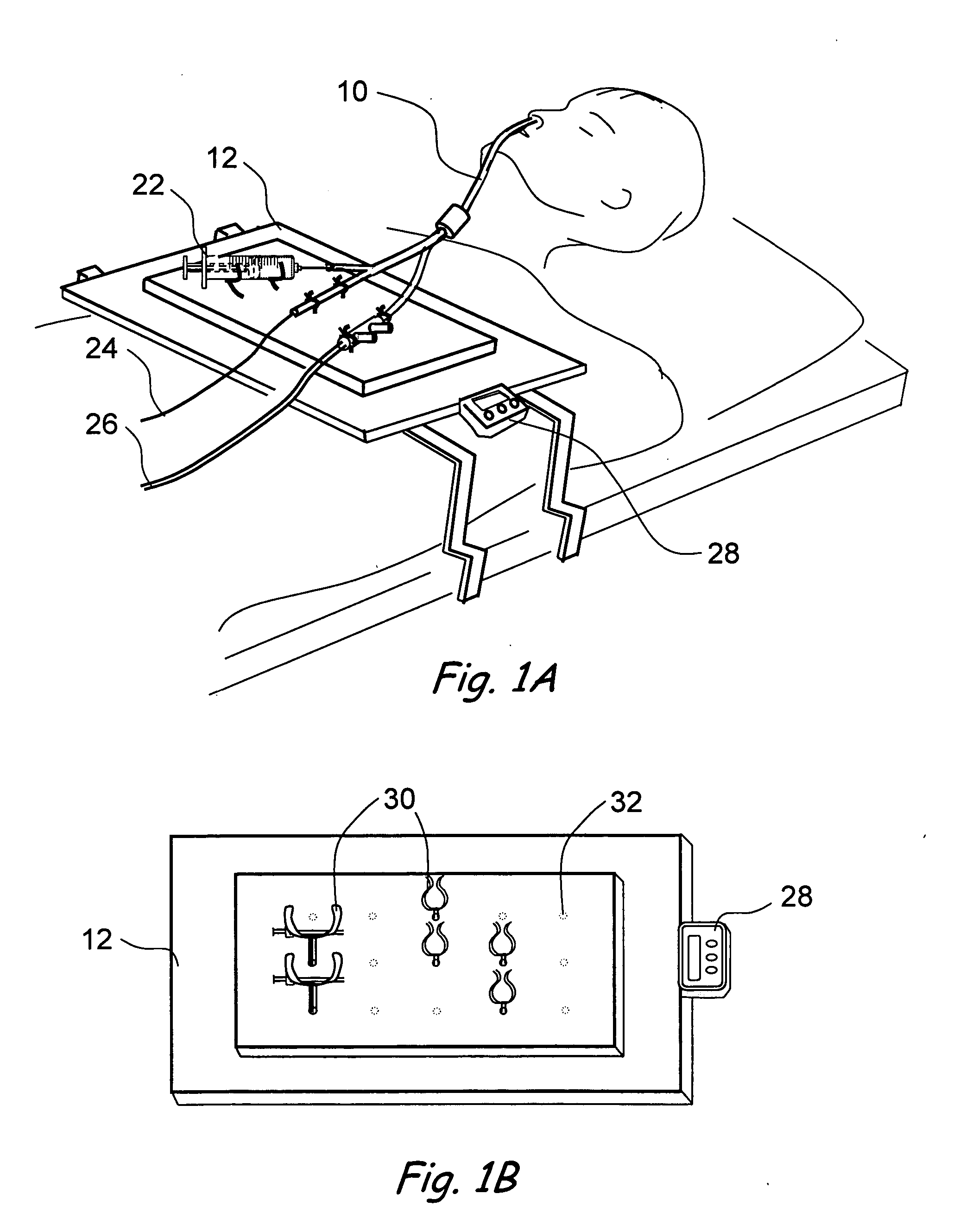

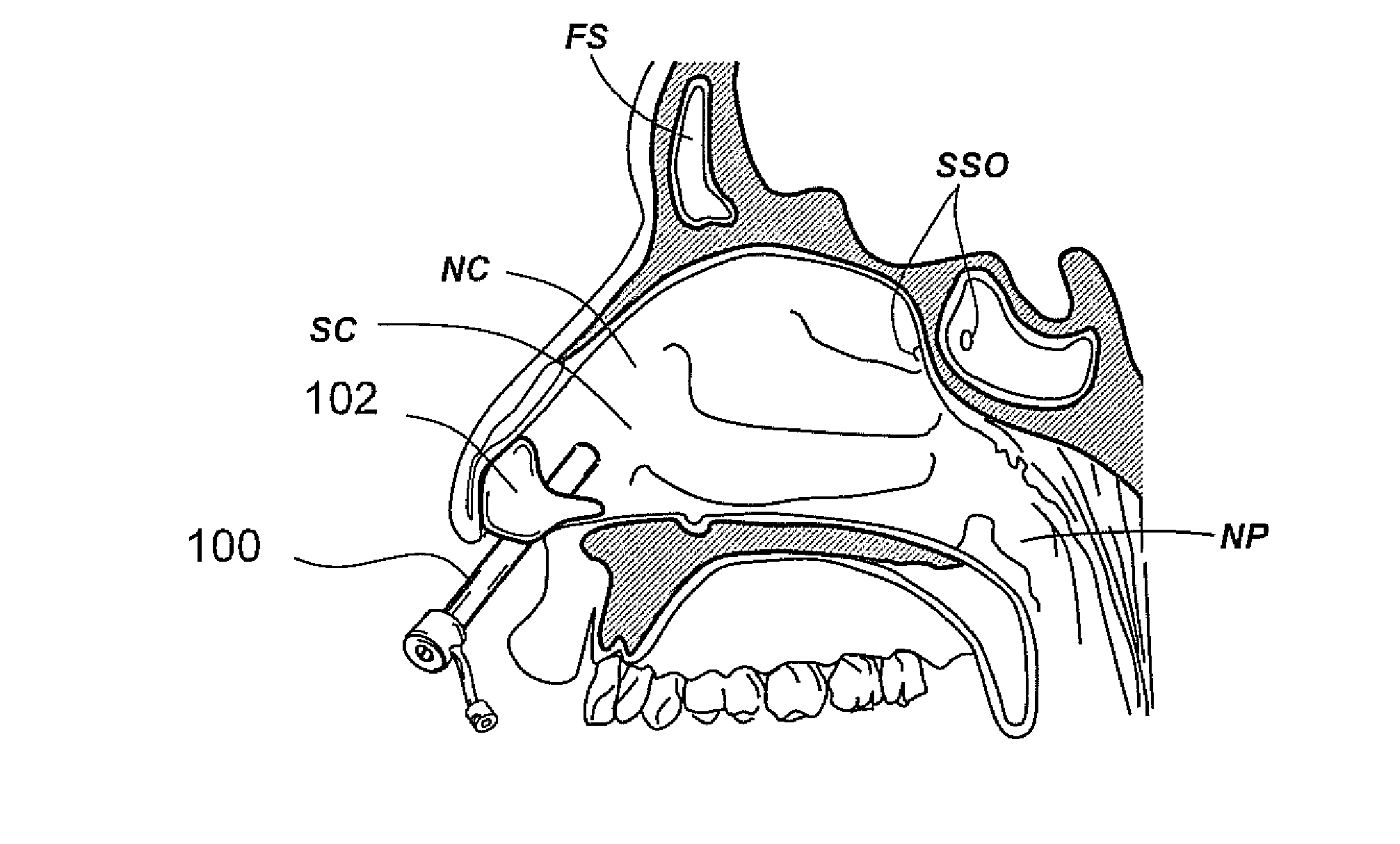

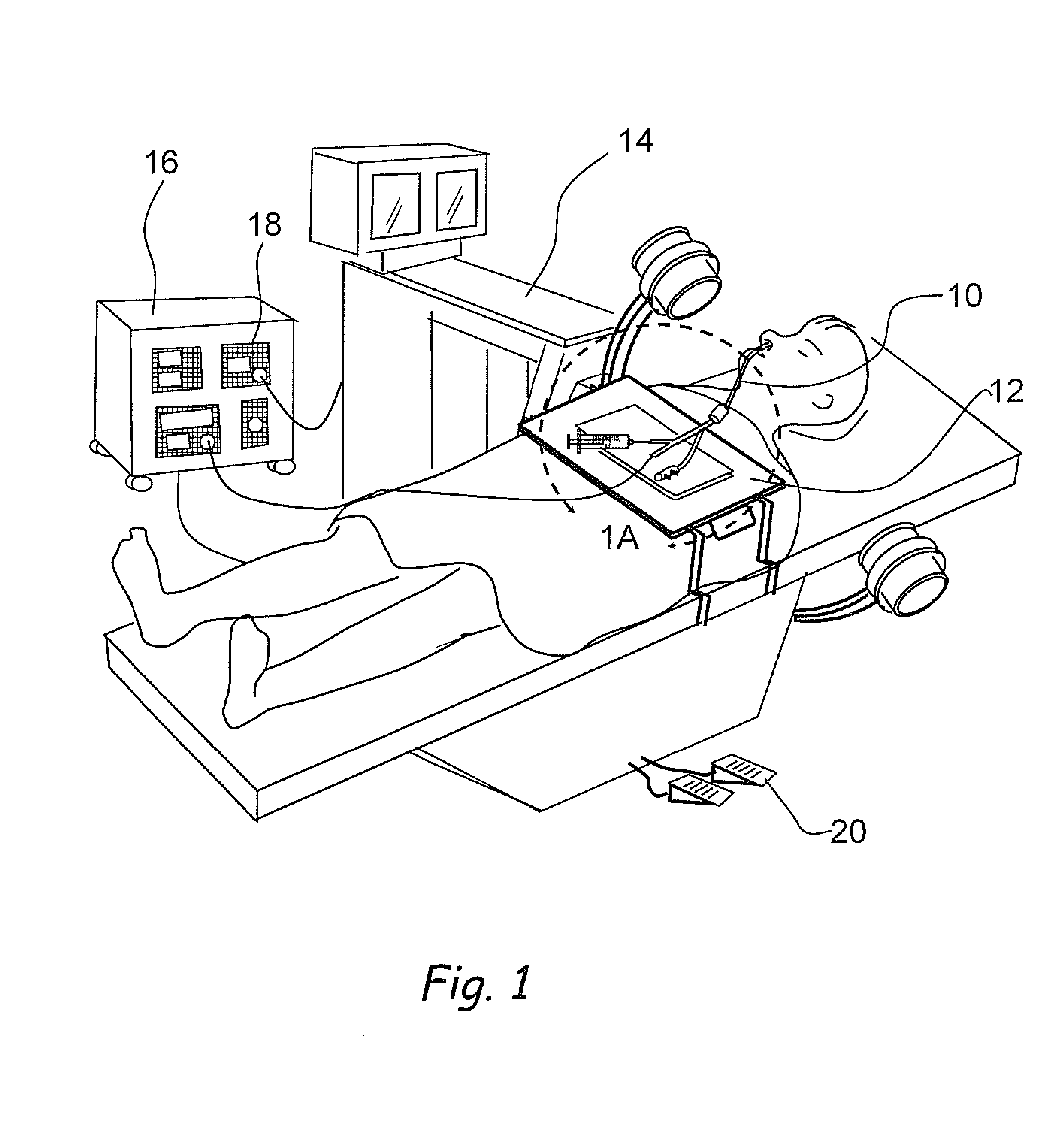

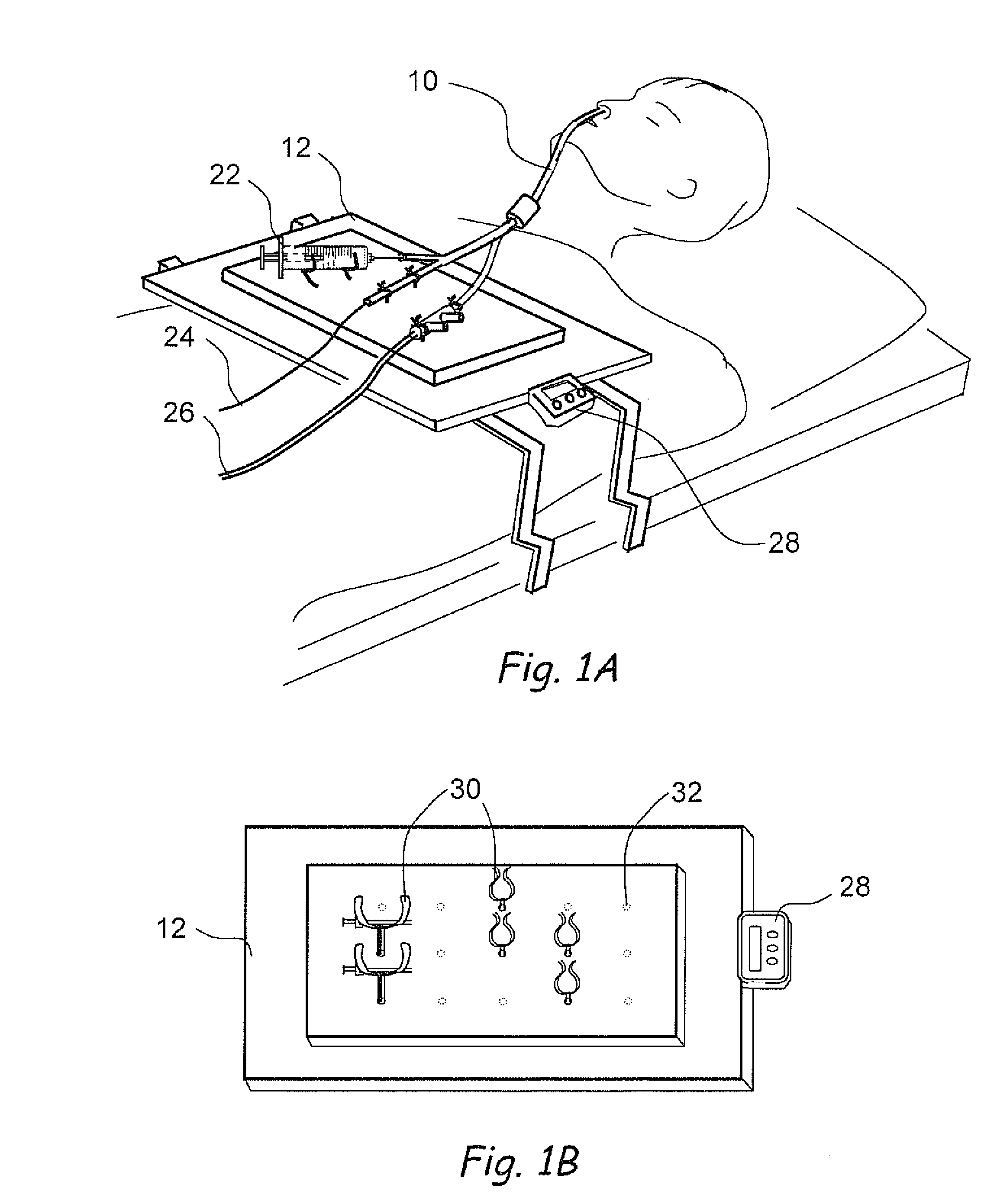

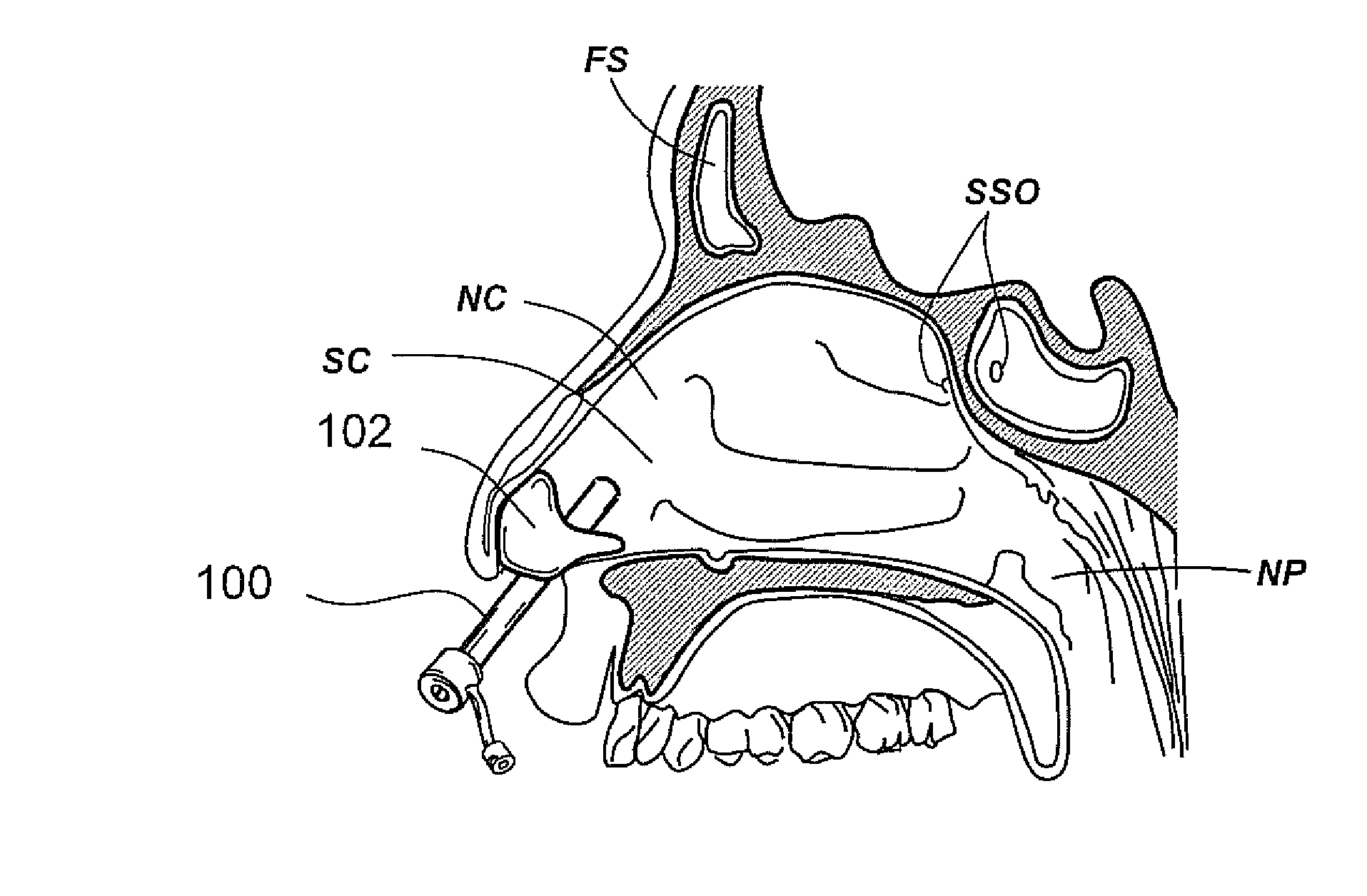

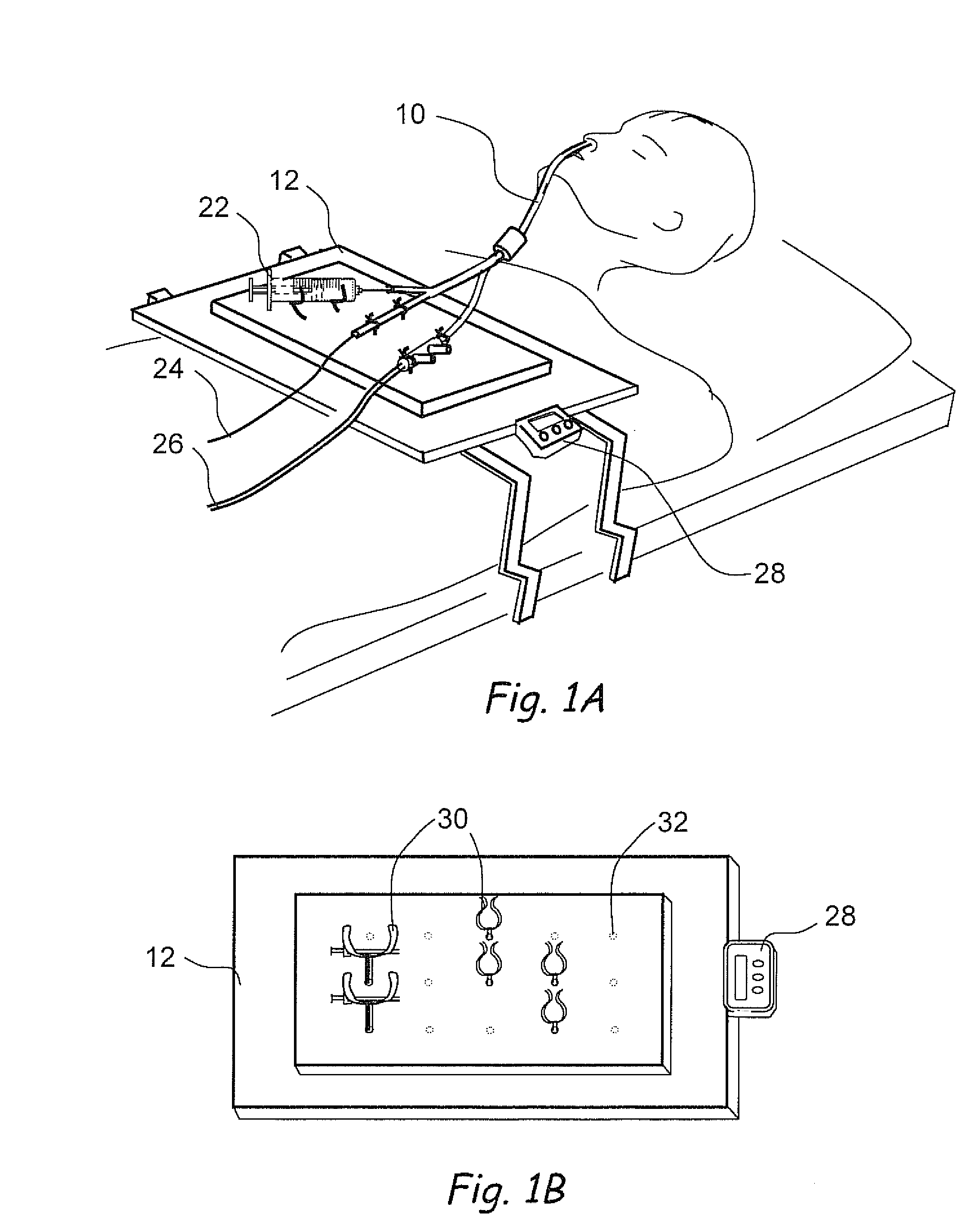

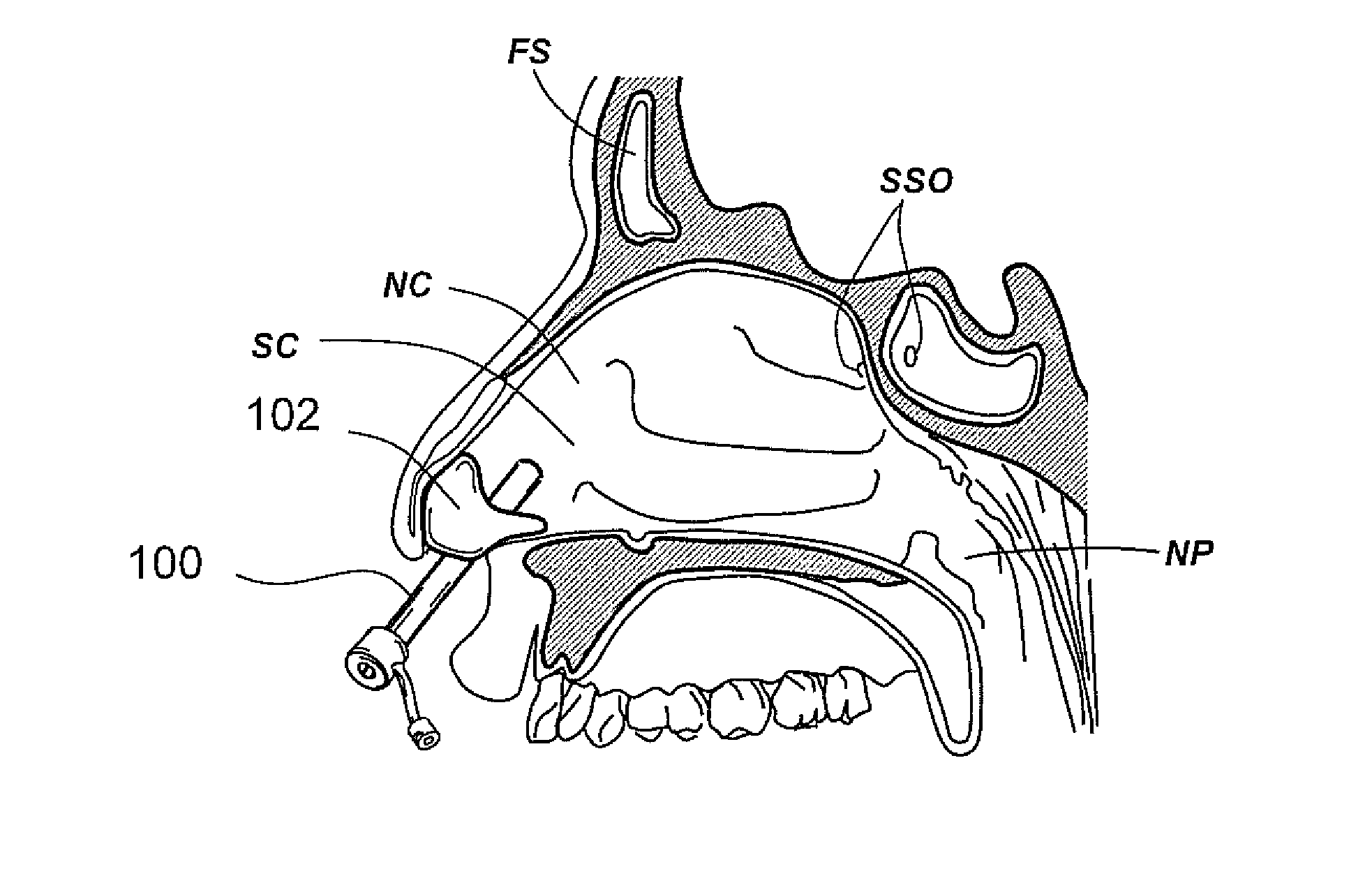

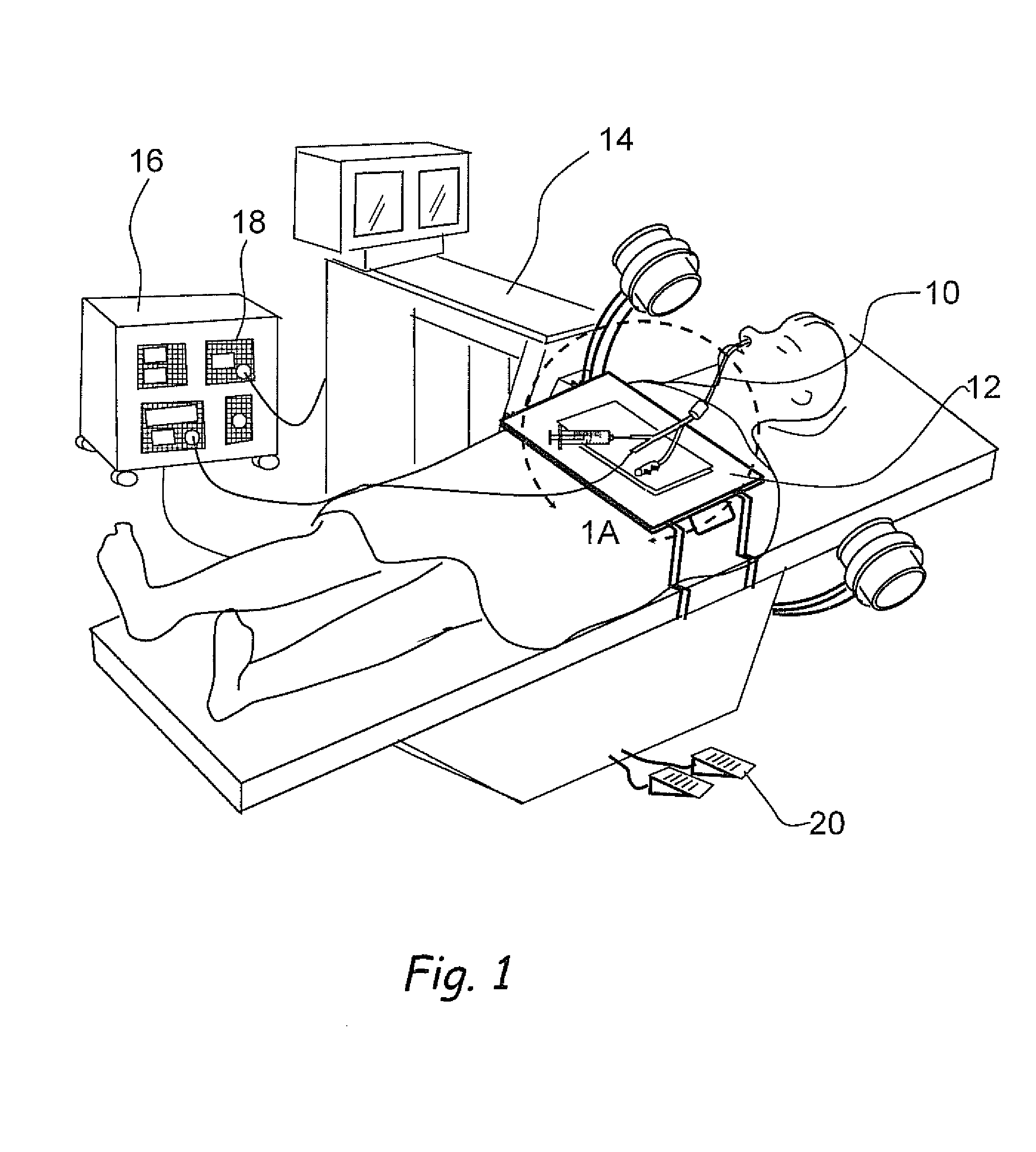

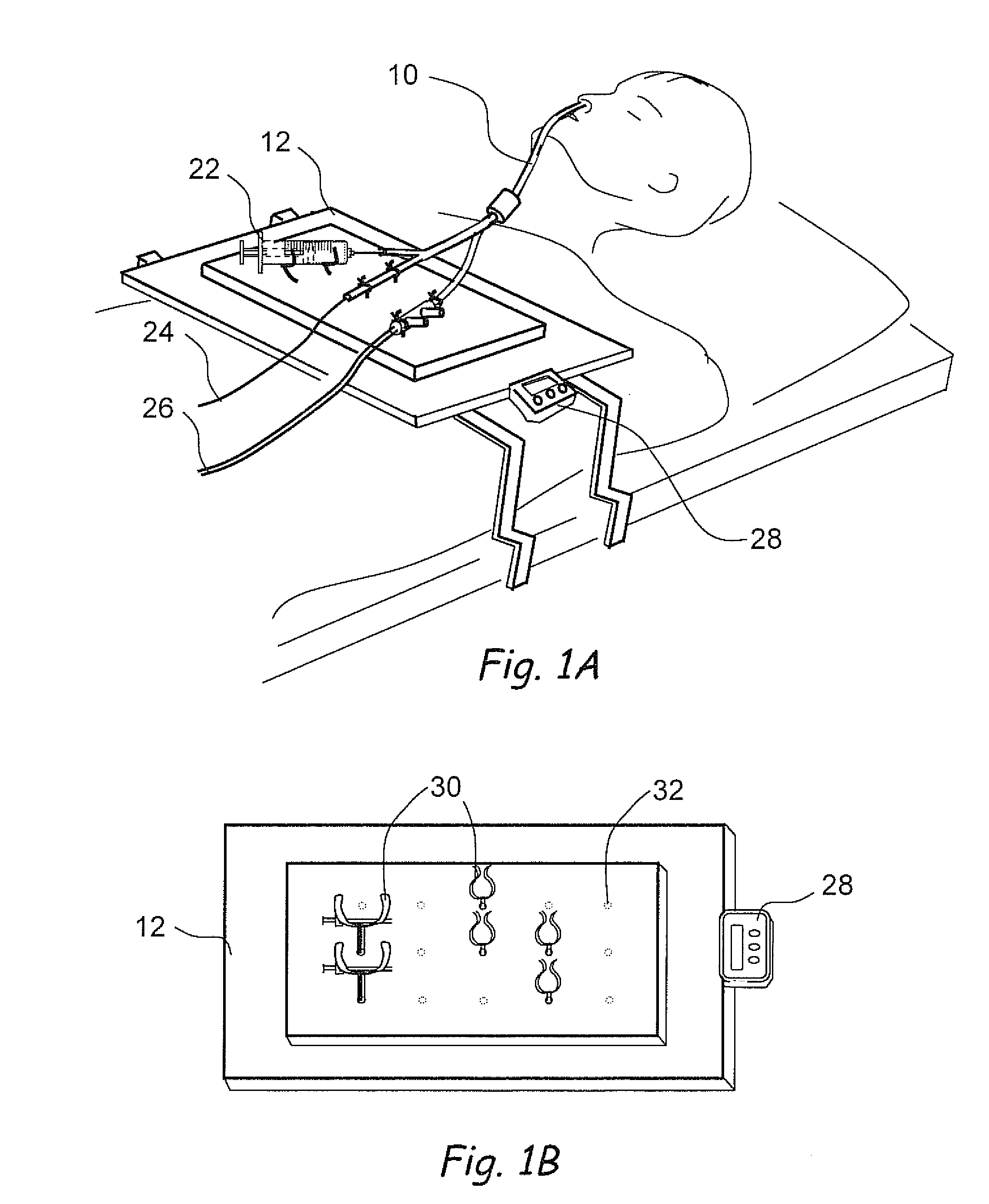

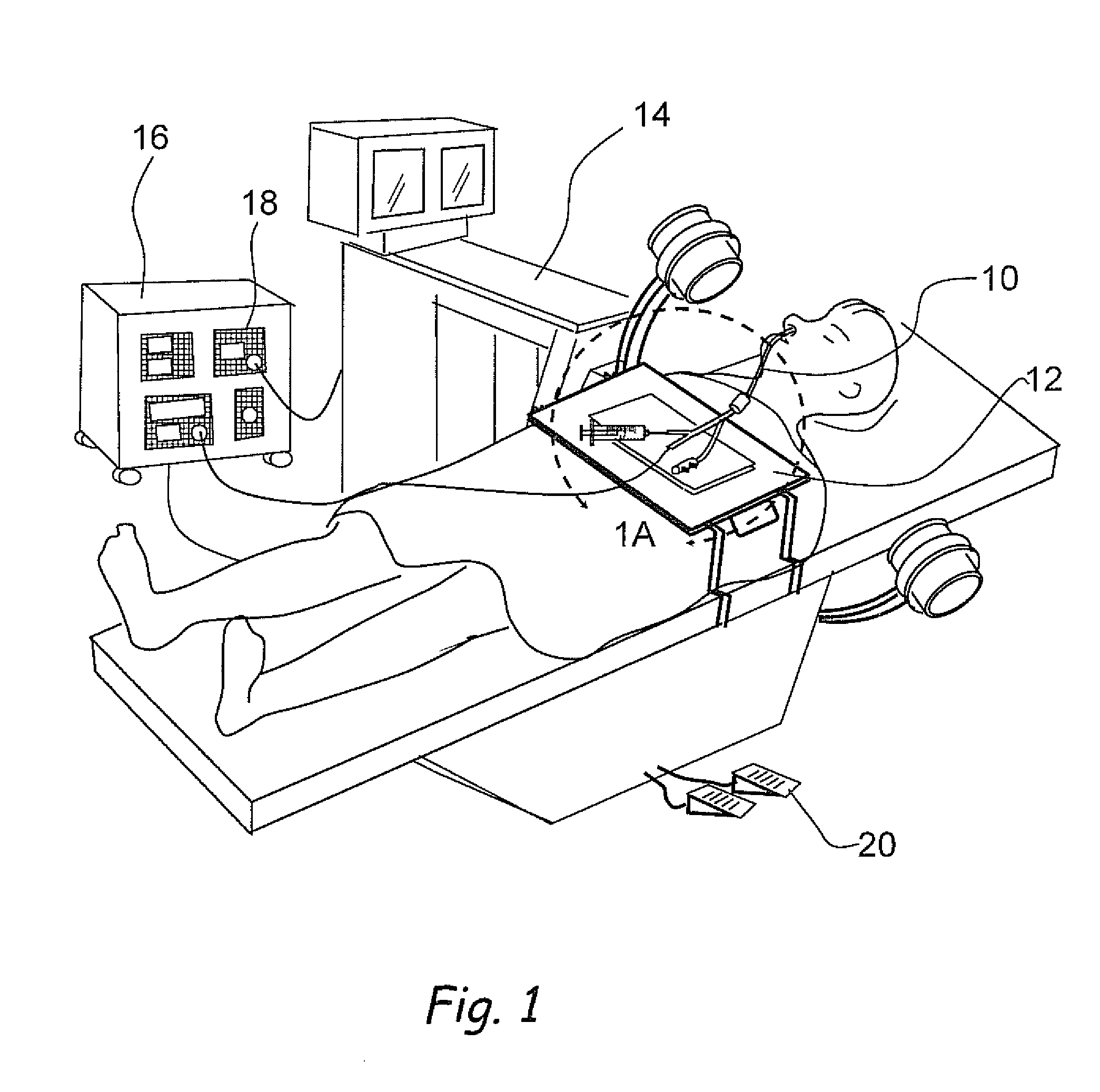

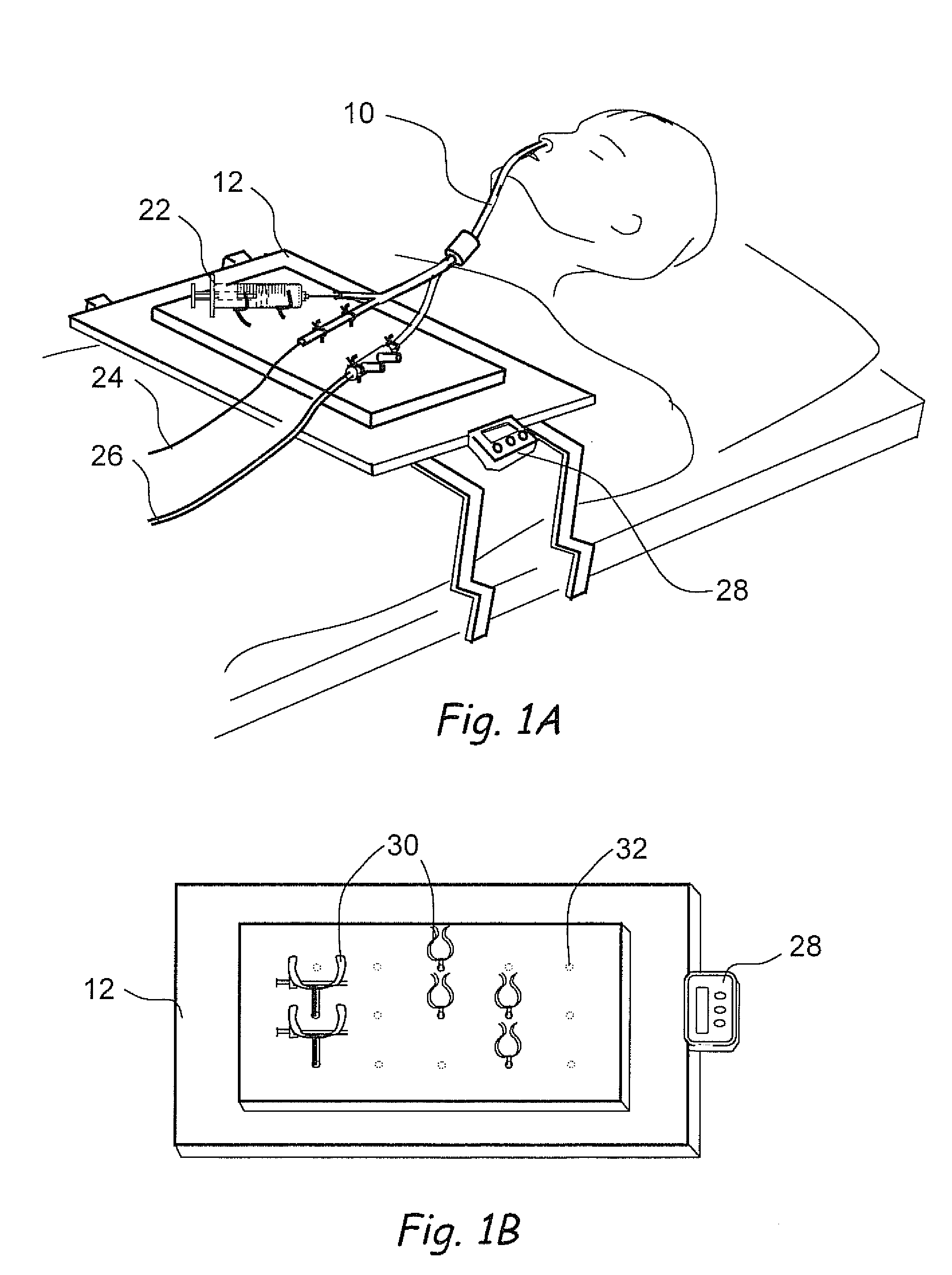

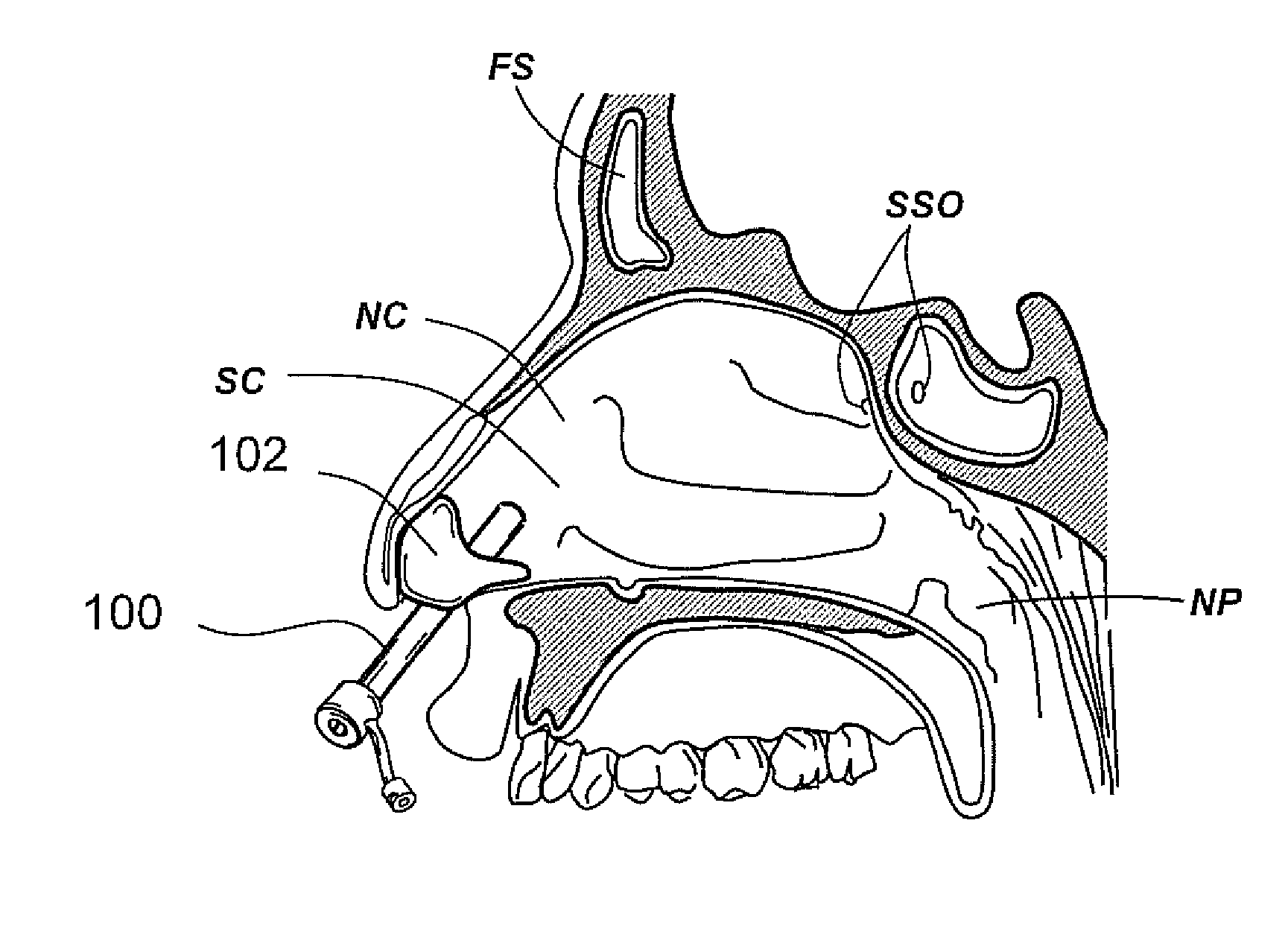

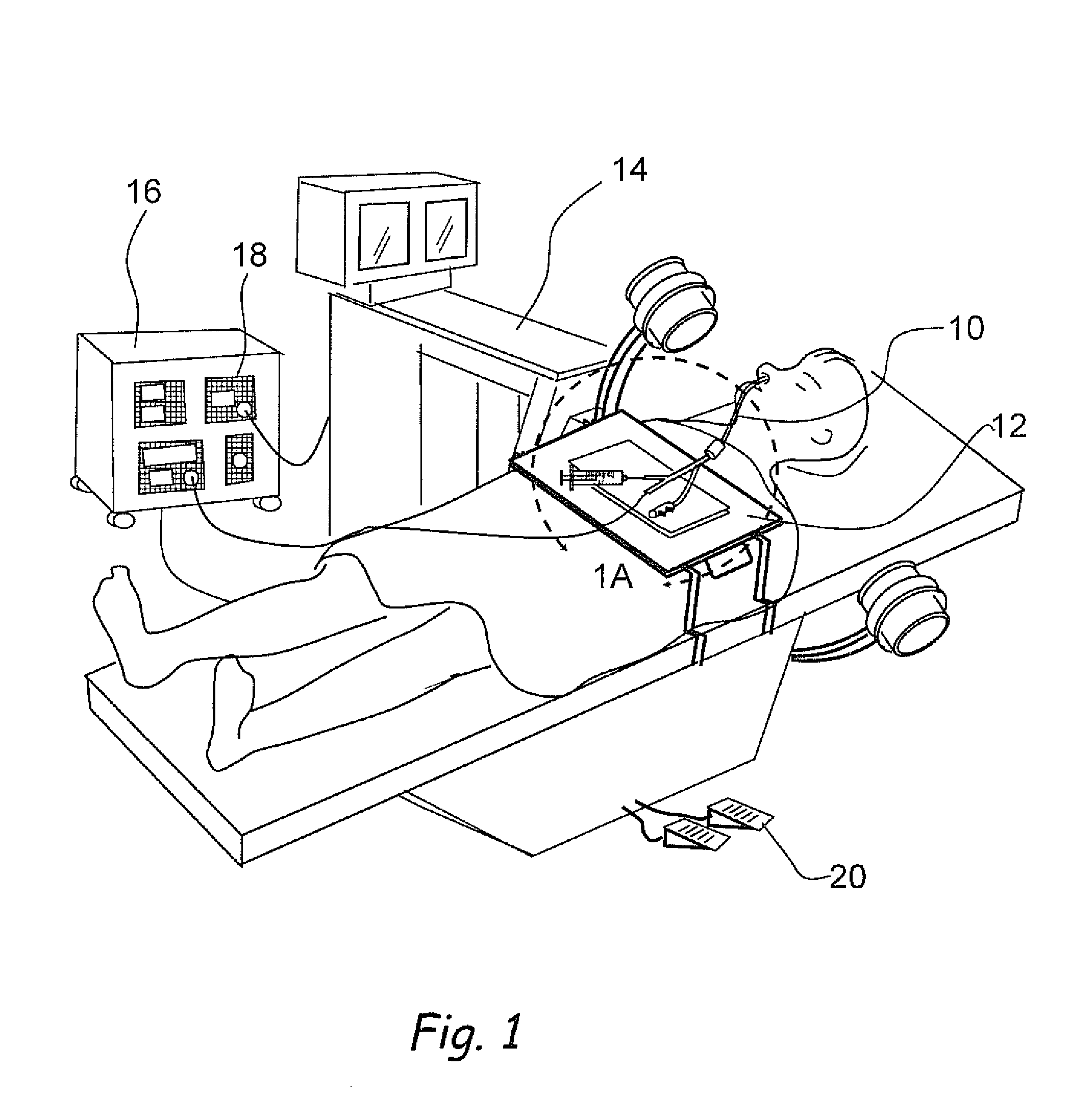

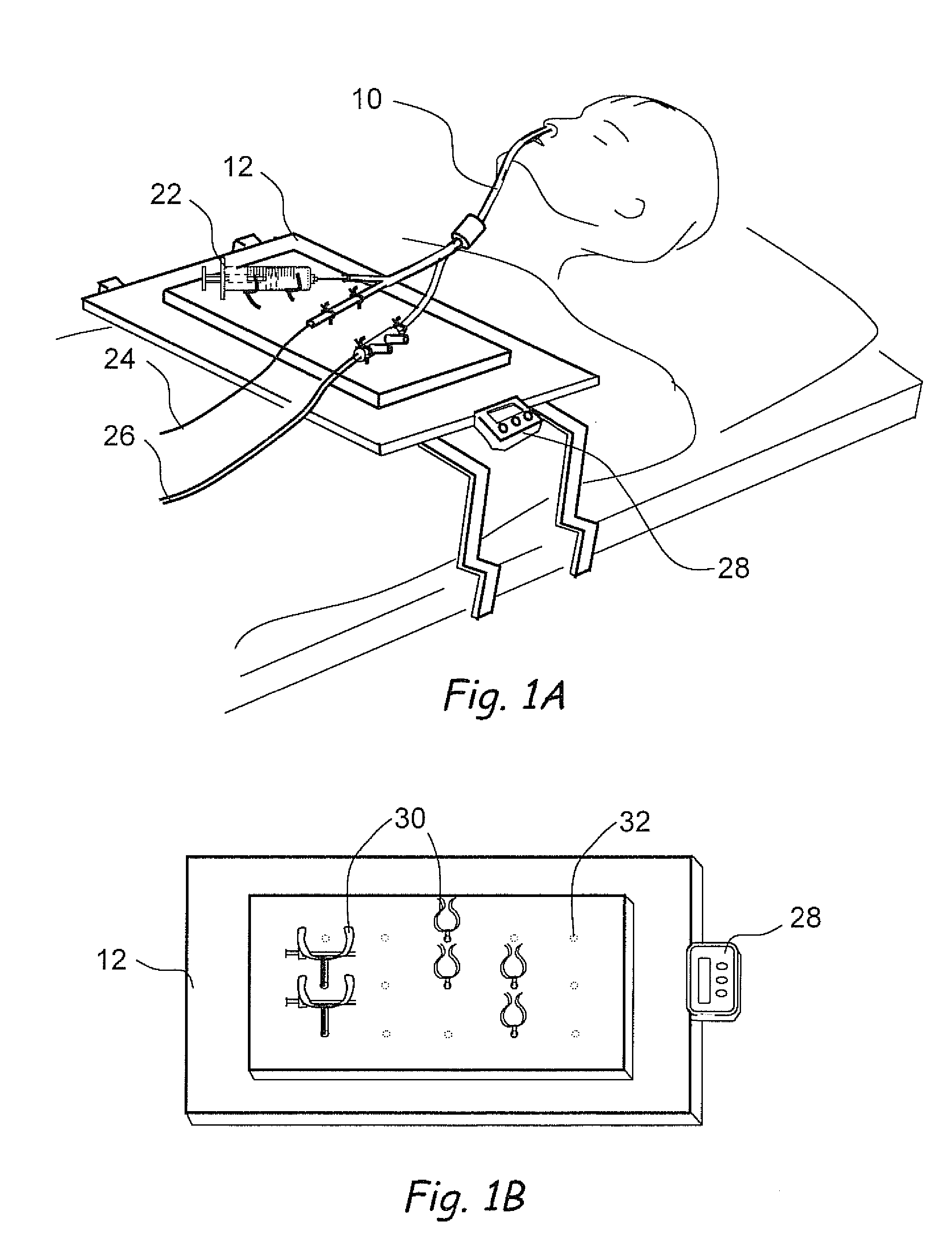

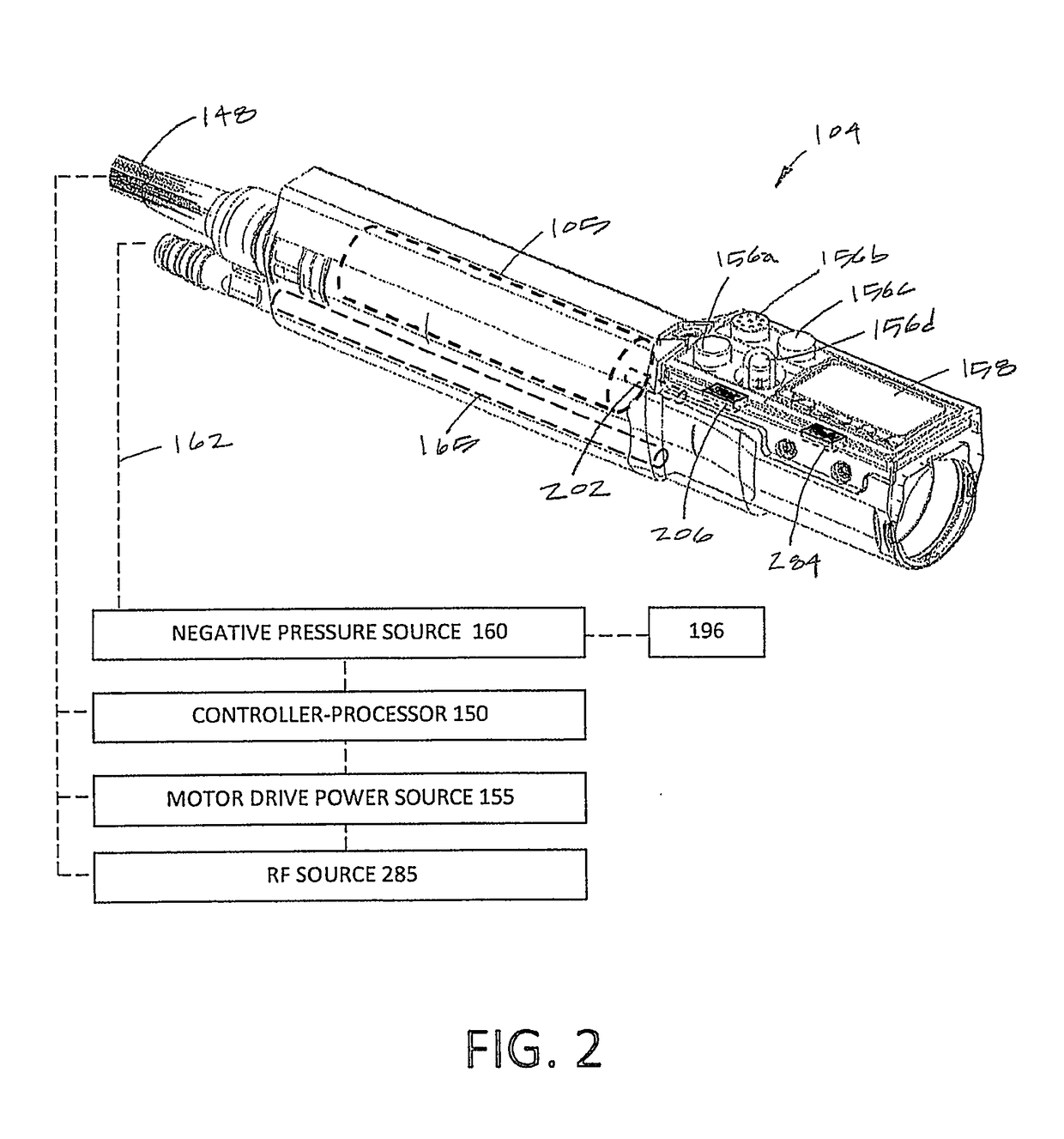

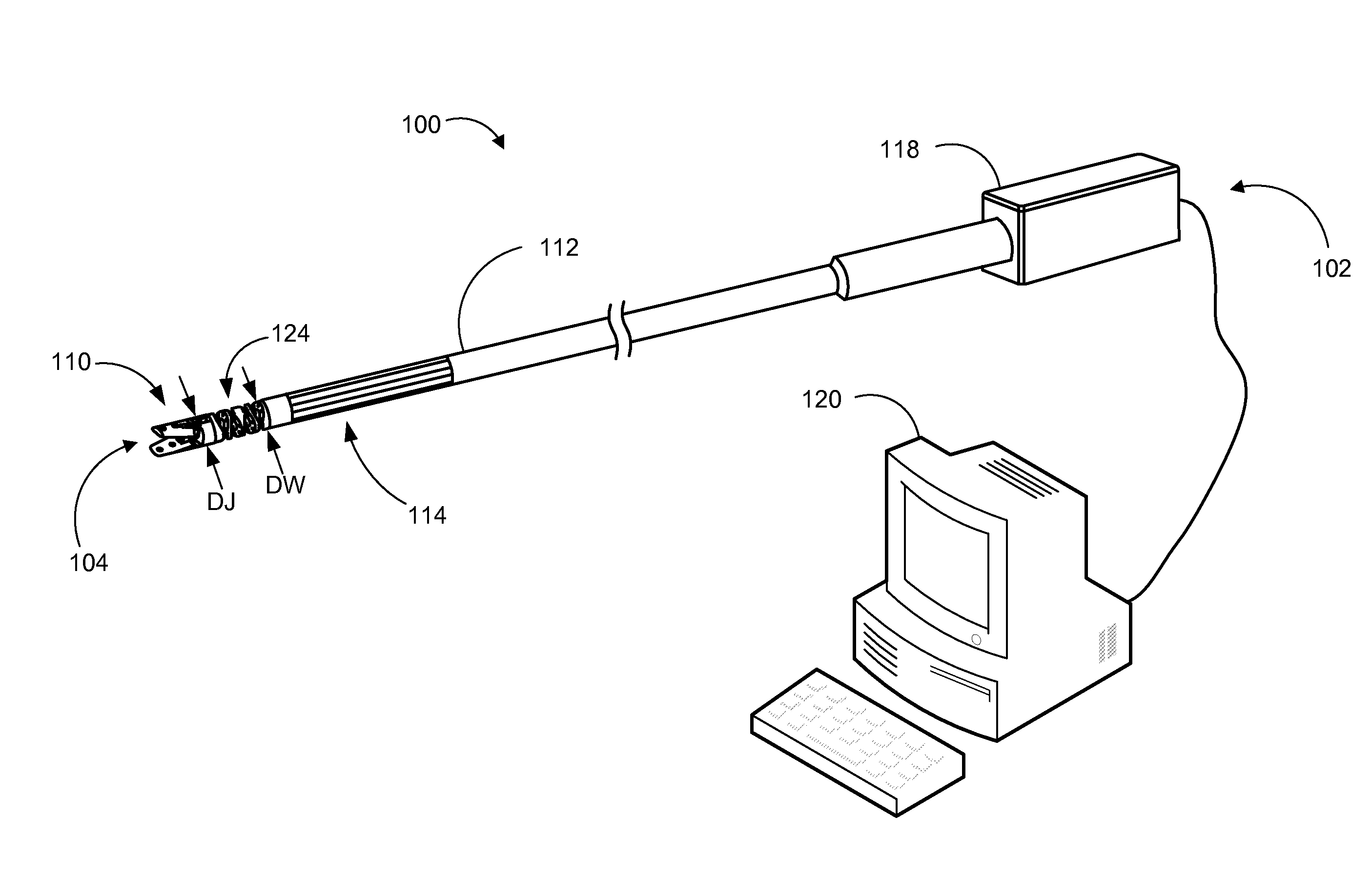

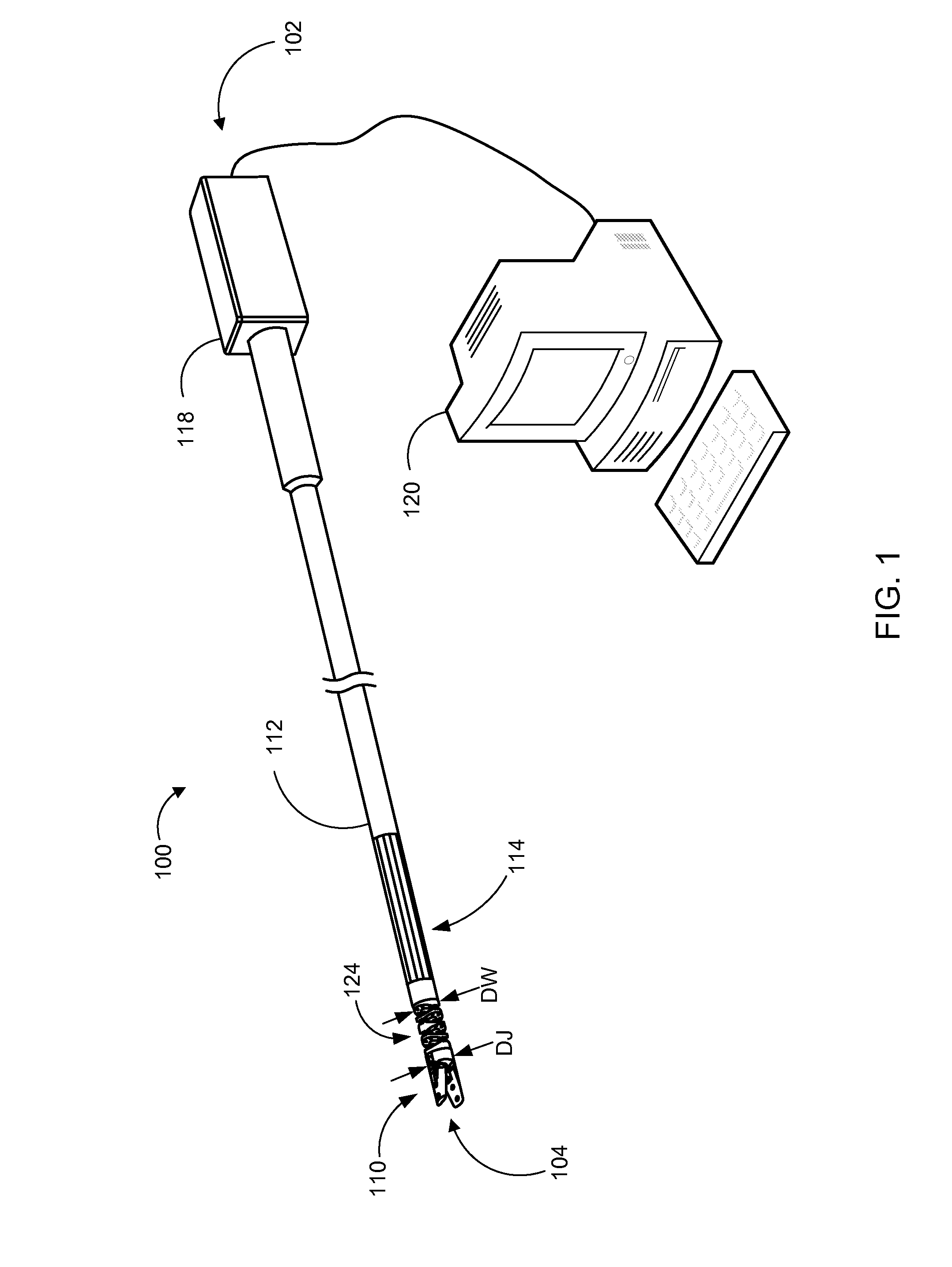

Devices, systems and methods for treating disorders of the ear, nose and throat

Sinusitis, mucocysts, tumors, infections, hearing disorders, choanal atresia, fractures and other disorders of the paranasal sinuses, Eustachian tubes, Lachrymal ducts and other ear, nose, throat and mouth structures are diagnosed and / or treated using minimally invasive approaches and, in many cases, flexible catheters as opposed to instruments having rigid shafts. Various diagnostic procedures and devices are used to perform imaging studies, mucus flow studies, air / gas flow studies, anatomic dimension studies and endoscopic studies. Access and occluding devices may be used to facilitate insertion of working devices such asendoscopes, wires, probes, needles, catheters, balloon catheters, dilation catheters, dilators, balloons, tissue cutting or remodeling devices, suction or irrigation devices, imaging devices, sizing devices, biopsy devices, image-guided devices containing sensors or transmitters, electrosurgical devices, energy emitting devices, devices for injecting diagnostic or therapeutic agents, devices for implanting devices such as stents, substance eluting or delivering devices and implants, etc.

Owner:ACCLARENT INC

Devices, Systems and Methods for Treating Disorders of the Ear, Nose and Throat

Sinusitis, mucocysts, tumors, infections, hearing disorders, choanal atresia, fractures and other disorders of the paranasal sinuses, Eustachian tubes, Lachrymal ducts and other ear, nose, throat and mouth structures are diagnosed and / or treated using minimally invasive approaches and, in many cases, flexible catheters as opposed to instruments having rigid shafts. Various diagnostic procedures and devices are used to perform imaging studies, mucus flow studies, air / gas flow studies, anatomic dimension studies and endoscopic studies. Access and occluding devices may be used to facilitate insertion of working devices such asendoscopes, wires, probes, needles, catheters, balloon catheters, dilation catheters, dilators, balloons, tissue cutting or remodeling devices, suction or irrigation devices, imaging devices, sizing devices, biopsy devices, image-guided devices containing sensors or transmitters, electrosurgical devices, energy emitting devices, devices for injecting diagnostic or therapeutic agents, devices for implanting devices such as stents, substance eluting or delivering devices and implants, etc.

Owner:ACCLARENT INC

Devices, Systems and Methods for Treating Disorders of the Ear, Nose and Throat

Sinusitis, mucocysts, tumors, infections, hearing disorders, choanal atresia, fractures and other disorders of the paranasal sinuses, Eustachian tubes, Lachrymal ducts and other ear, nose, throat and mouth structures are diagnosed and / or treated using minimally invasive approaches and, in many cases, flexible catheters as opposed to instruments having rigid shafts. Various diagnostic procedures and devices are used to perform imaging studies, mucus flow studies, air / gas flow studies, anatomic dimension studies and endoscopic studies. Access and occluding devices may be used to facilitate insertion of working devices such asendoscopes, wires, probes, needles, catheters, balloon catheters, dilation catheters, dilators, balloons, tissue cutting or remodeling devices, suction or irrigation devices, imaging devices, sizing devices, biopsy devices, image-guided devices containing sensors or transmitters, electrosurgical devices, energy emitting devices, devices for injecting diagnostic or therapeutic agents, devices for implanting devices such as stents, substance eluting or delivering devices and implants, etc.

Owner:ACCLARENT INC

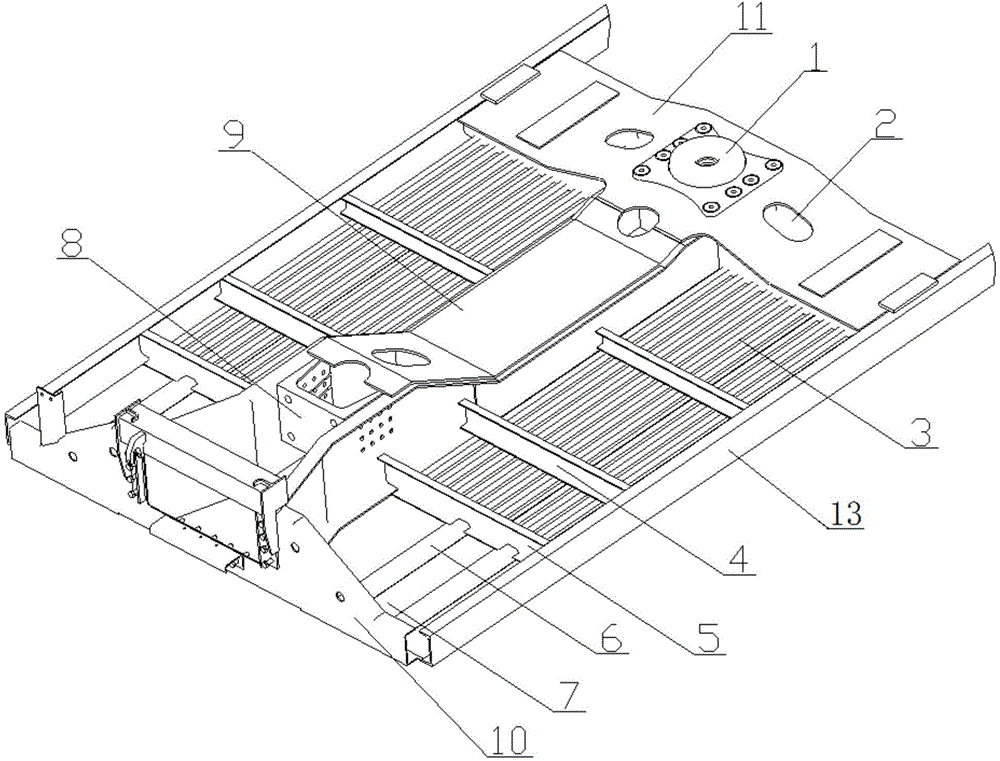

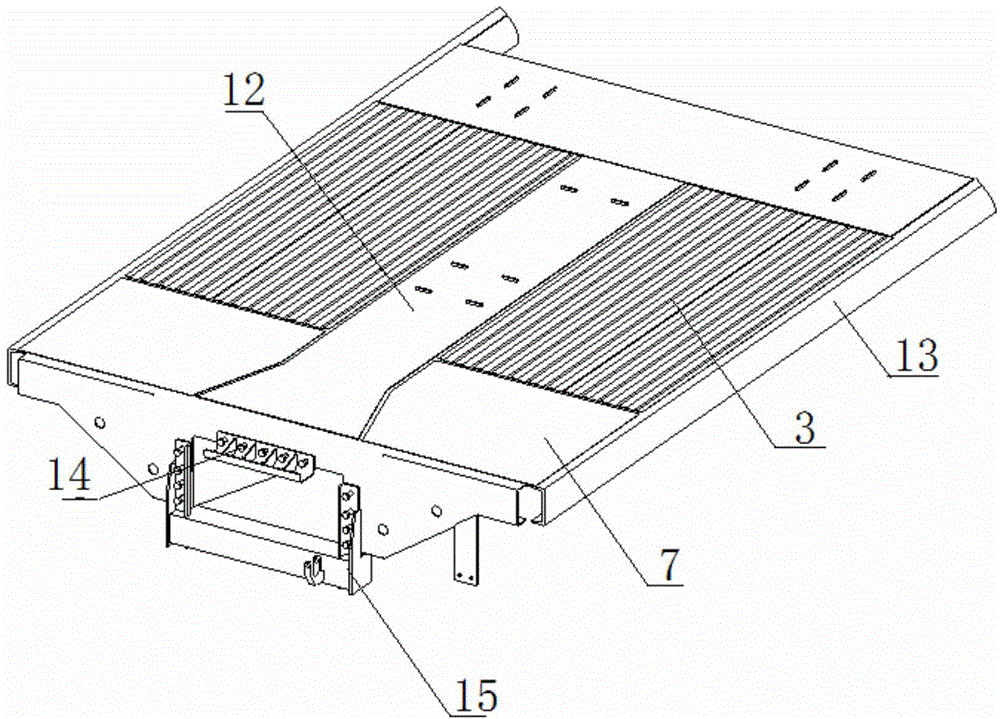

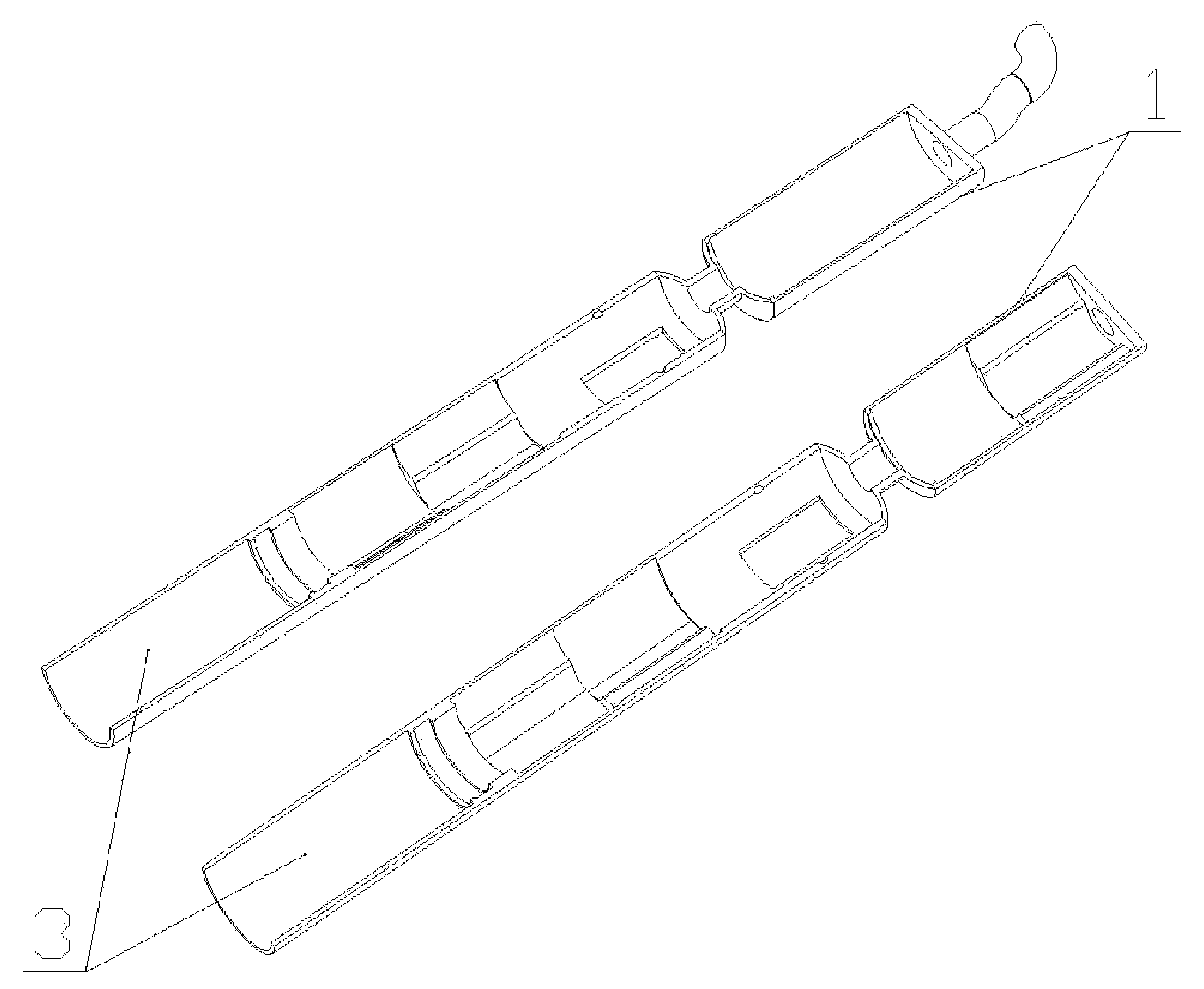

Railway vehicle outside-sleeper structure

The invention discloses a railway vehicle outside-sleeper structure. A center filler is fixed to a lower cover plate of a sleeper beam through a bolt, the back end of a traction beam and the sleeper beam are welded and fixed, a connector of a bogie is arranged between two webs of the sleeper beam, and the lower cover plate on the parts, on the two sides of the center filler, of the sleeper beam is provided with installing holes. The front section of the traction beam is provided with a vehicle hook installing base, a large beam is transversely arranged between the traction beam and side beams, the large beam is located near the vehicle hook installing base, a corrugated floor is laid between the large beam and the sleeper beam, a flat floor is laid between the large beam and an end beam, a panel is laid on the upper surface of the traction beam, and the front end of the traction beam is of a horn mouth structure. According to the outside-sleeper structure, a high load is achieved through a series of improvements and design, the maintaining frequency is low, manufacturing is easy, and the railway vehicle outside-sleeper structure can well adapt to the operation characteristics of meter-gauge rail intercity passenger trains due to the small curve radius.

Owner:CRRC NANJING PUZHEN CO LTD

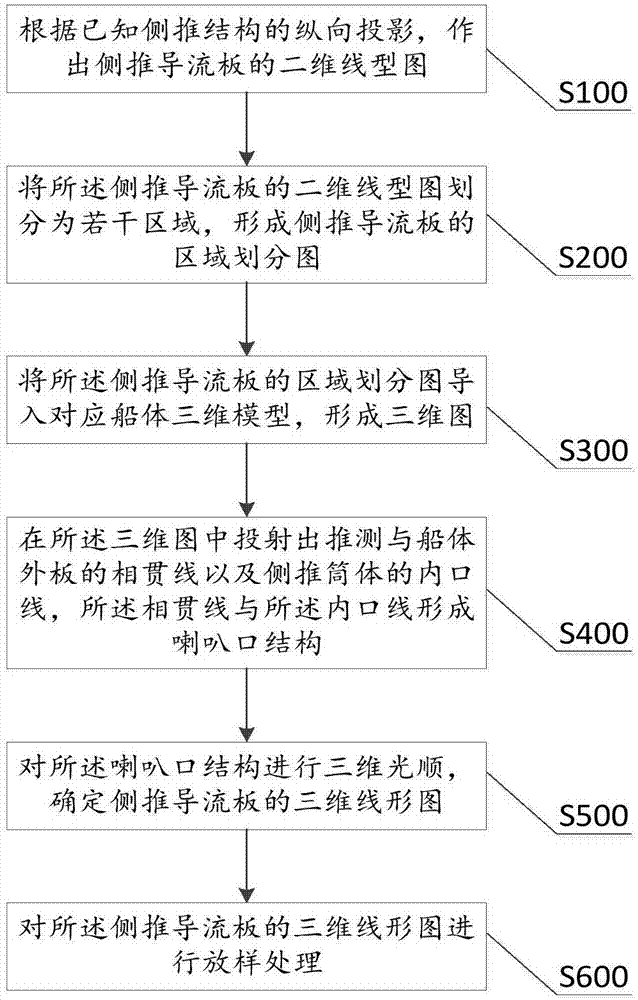

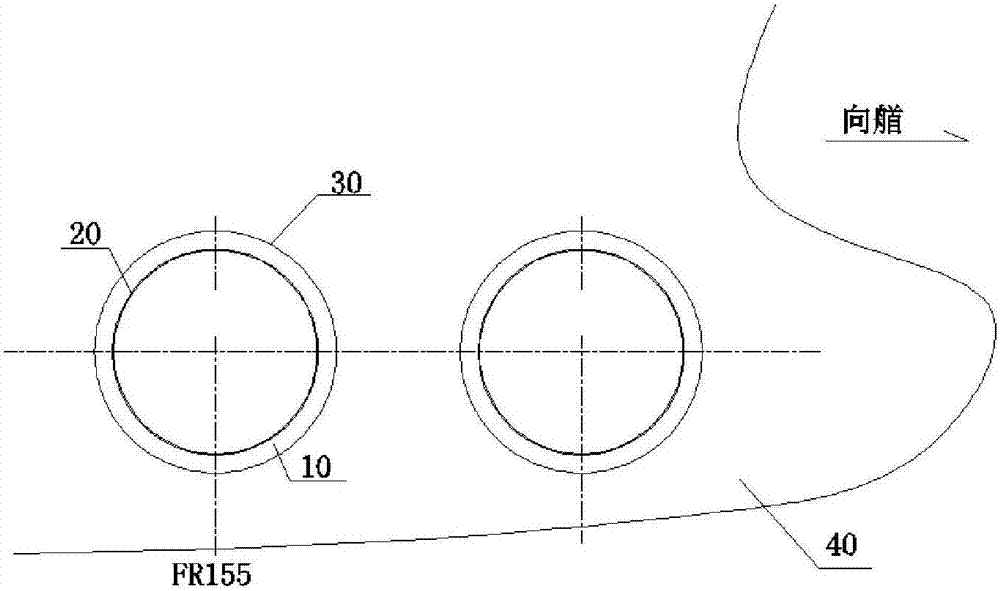

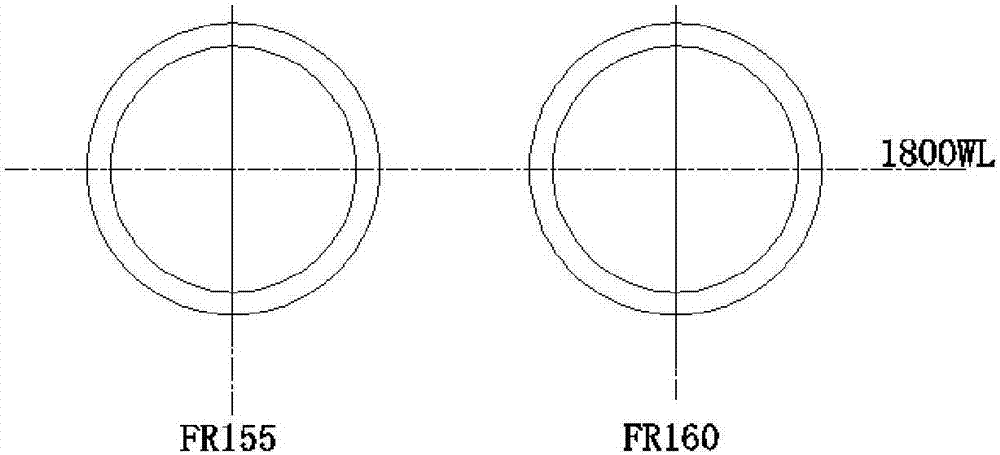

Three-dimensional modeling method of side-pushing structure

ActiveCN107391798AGuaranteed performanceGuaranteed aestheticsGeometric CADDesign optimisation/simulationDimensional modelingComputer science

The invention relates to a three-dimensional modeling method of a side-pushing structure. The method comprises the following steps: A, making a two-dimensional line graph of a side-pushing flow guide plate along projection of a shaft line direction in the side-pushing structure according to a three-dimensional model of the known side-pushing structure; B, dividing the two-dimensional line graph of the side-pushing flow guide plate into a plurality of regions to form a region division graph of the side-pushing flow guide plate; C, importing the region division graph of the side-pushing flow guide plate to a corresponding three-dimensional hull model to form a three-dimensional graph; D, projecting an intersecting line of the side-pushing structure and an outer plate of a hull and an inner mouth line of a side-pushing cylinder in the three-dimensional graph, wherein the intersecting line and the inner mouth line forms a horn mouth structure; E, carrying out three-dimensional fairing on the horn mouth structure, and determining a three-dimensional line graph of the side-pushing flow guide plate; and F, carrying out lofting processing on the three-dimensional line graph of the side-pushing flow guide plate. According to the method provided by the invention, jointing transition of the side-pushing structure and the outer plate can be intuitively adjusted, fairing connection of the side-pushing structure and the outer plate of the hull is ensured, and the performance and the beauty of the side-pushing structure are ensured.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

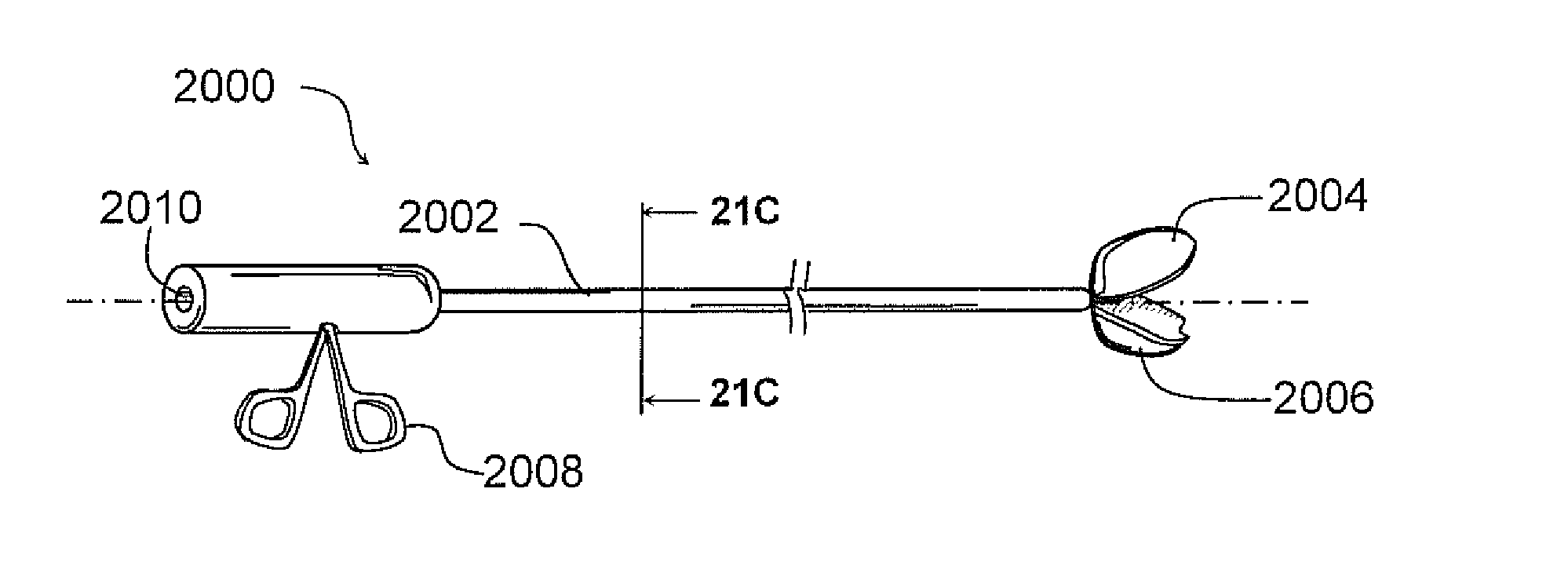

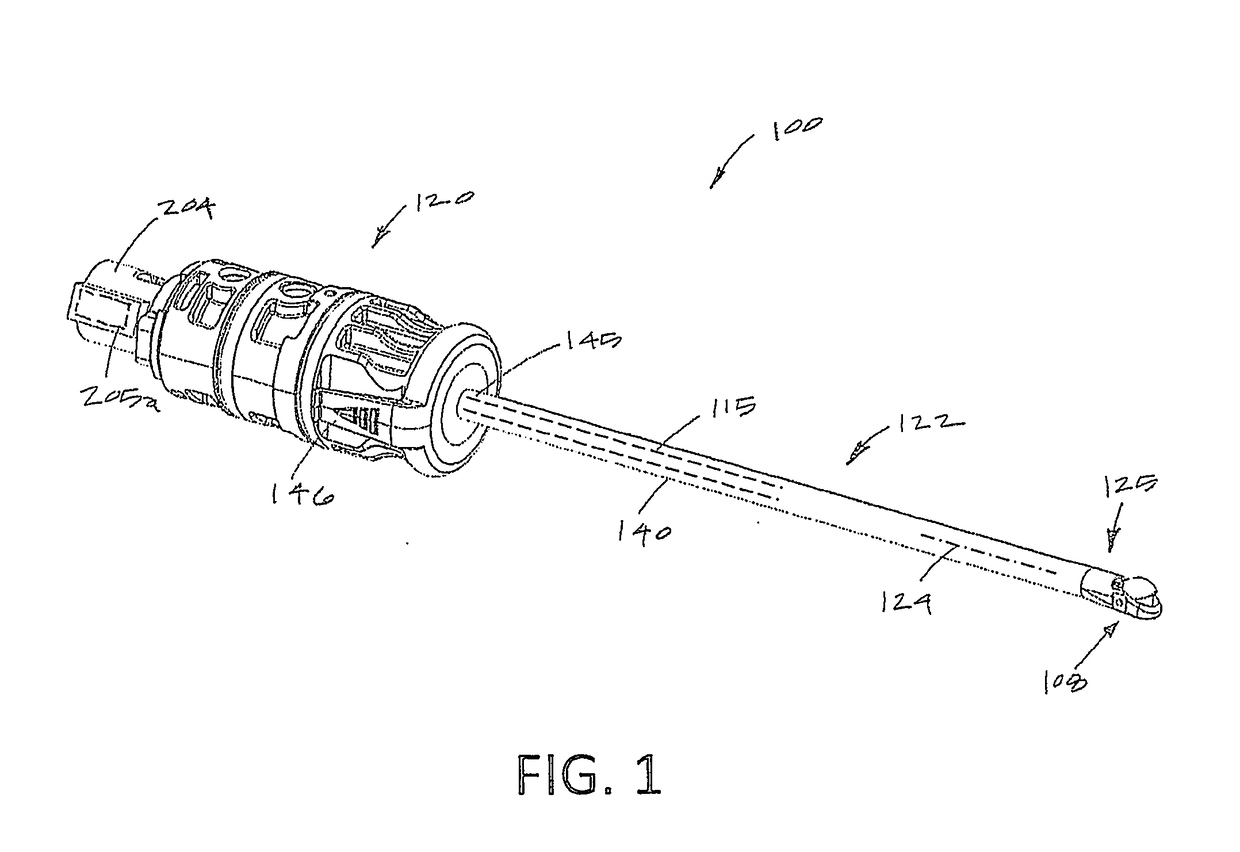

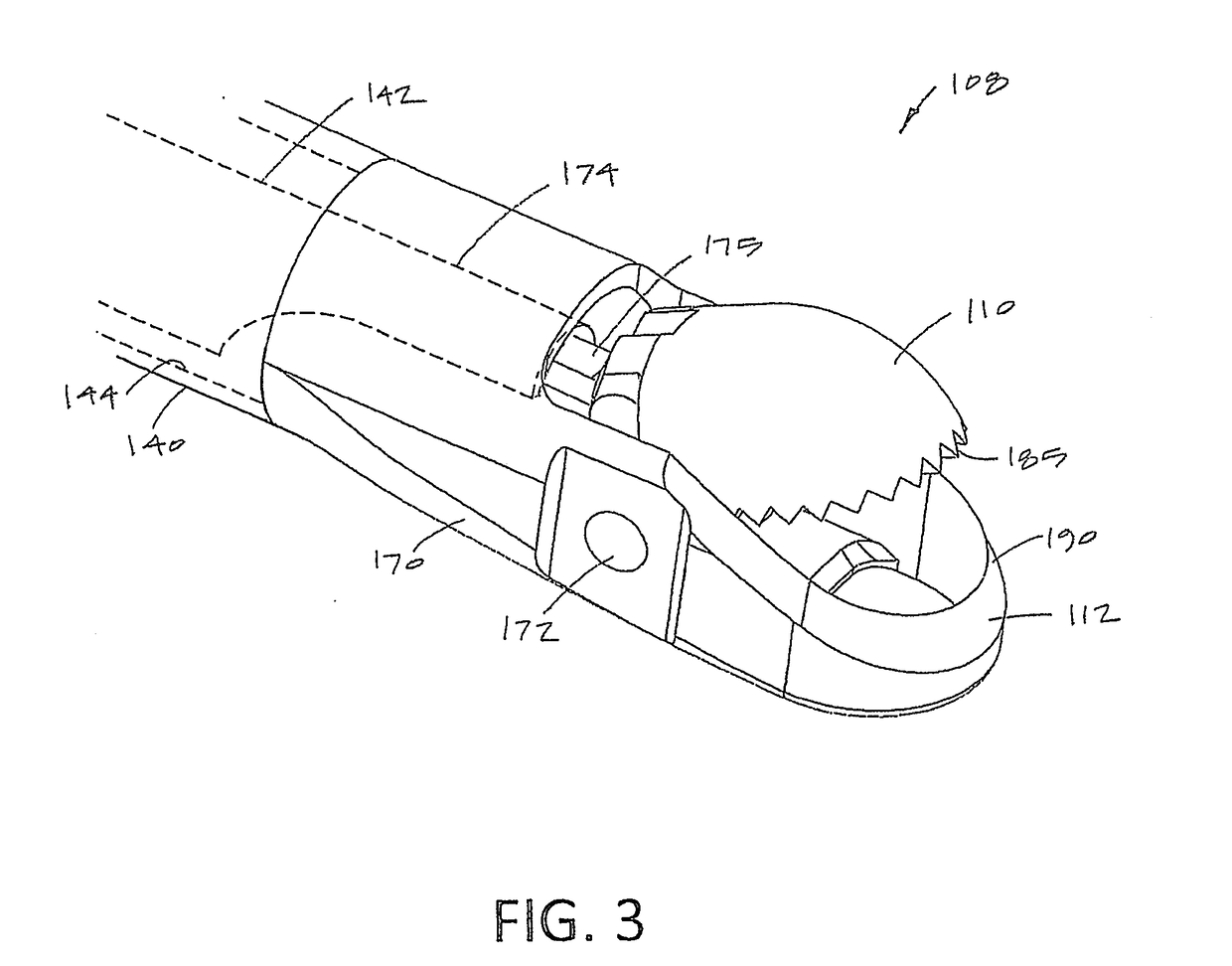

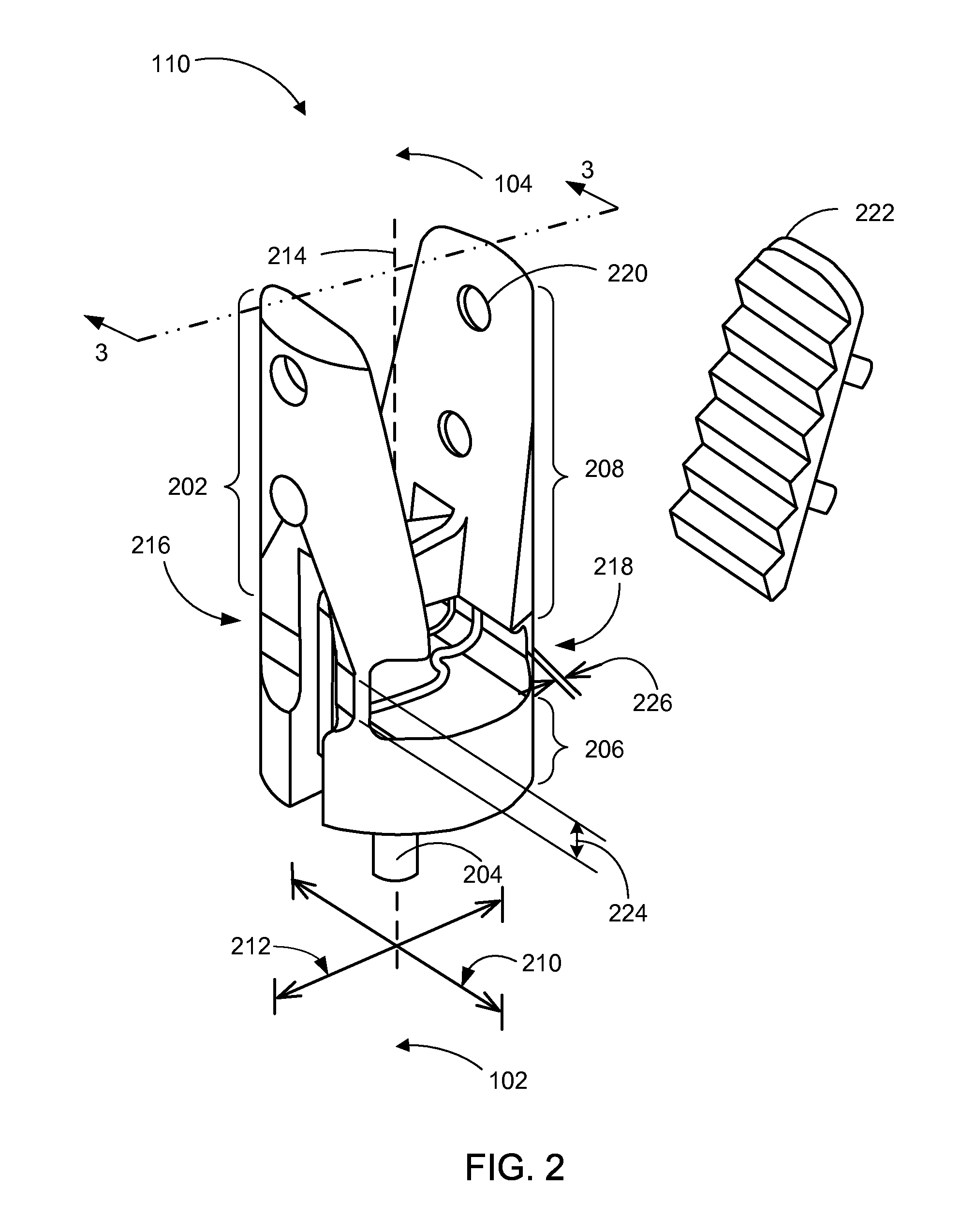

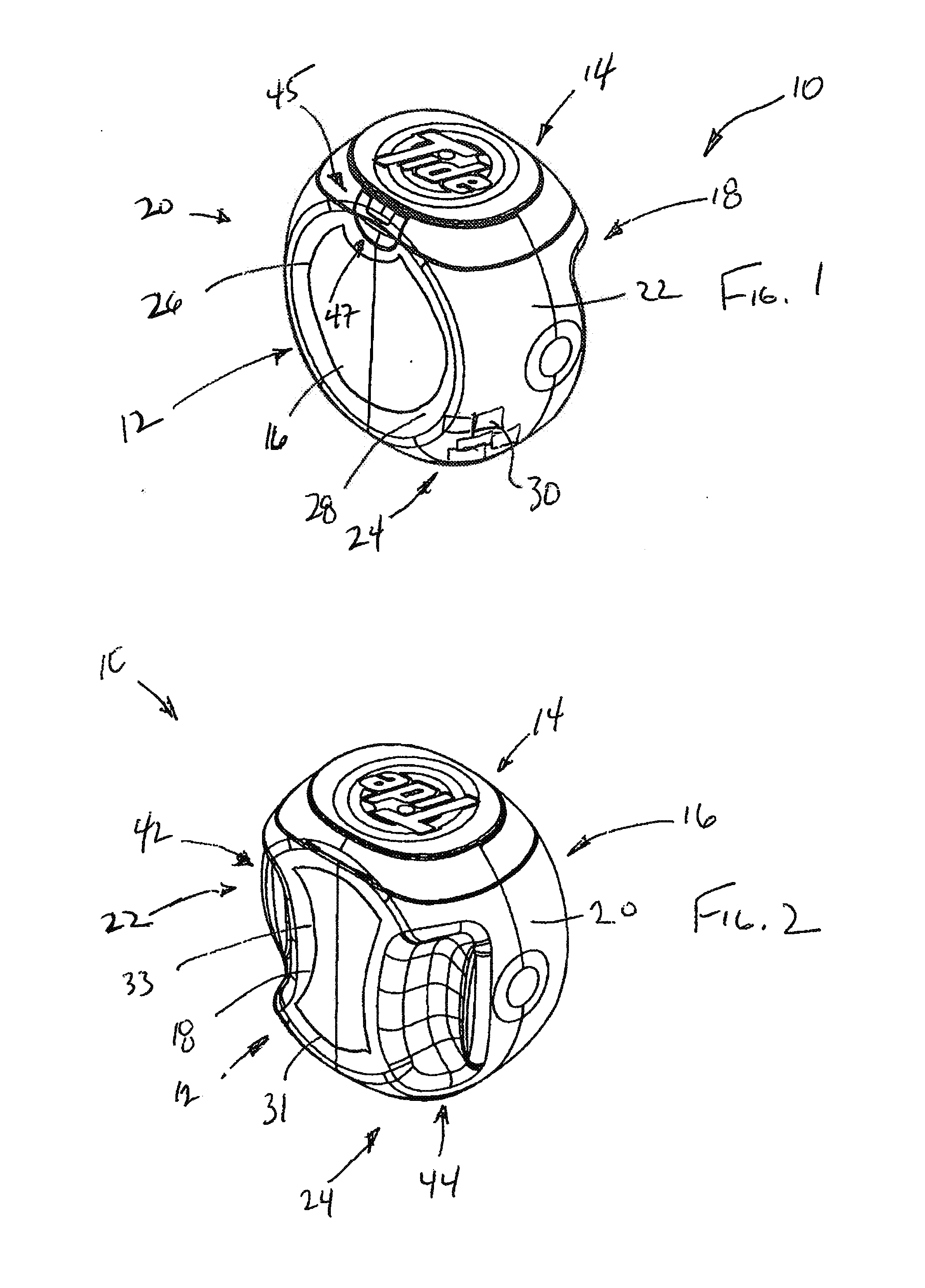

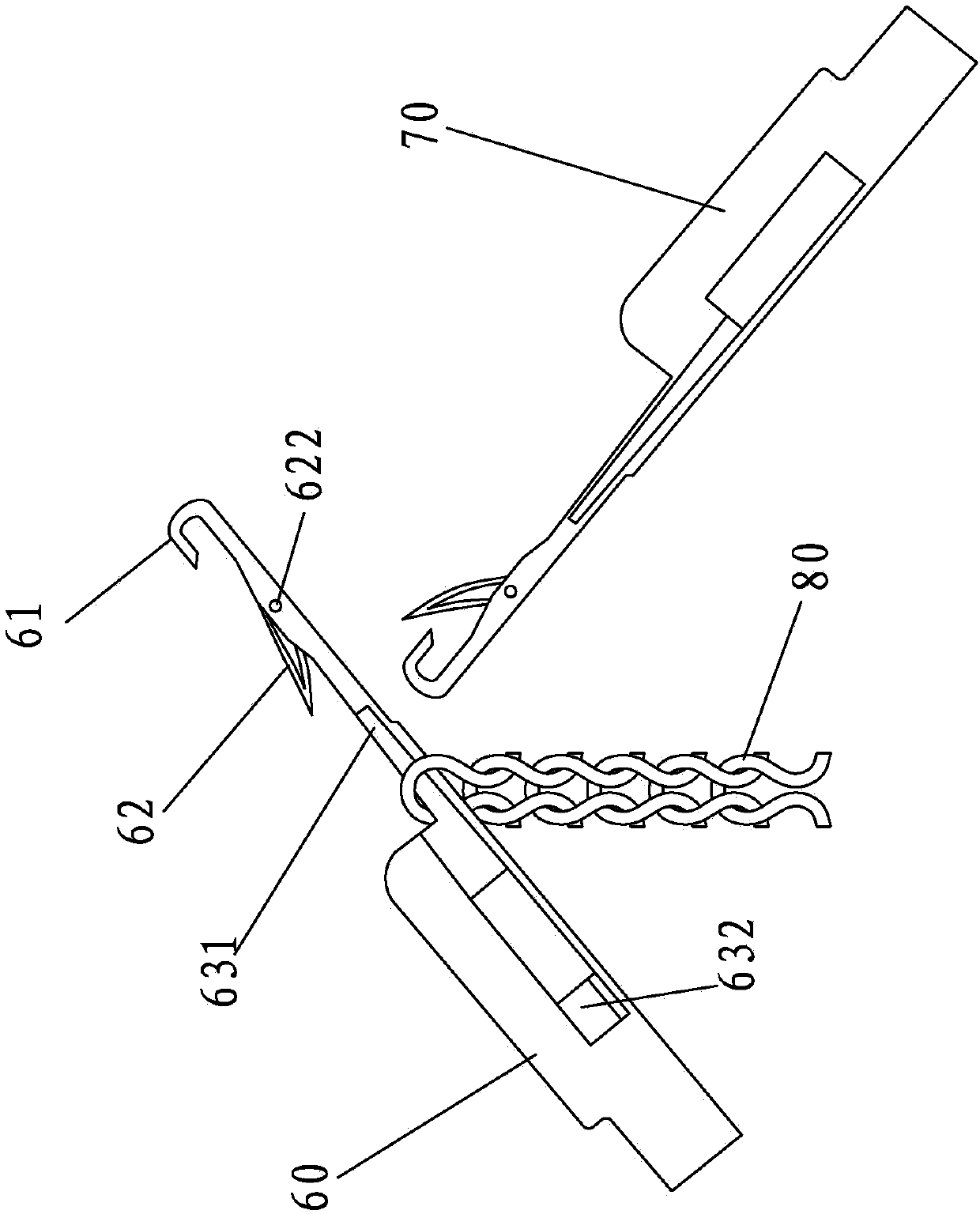

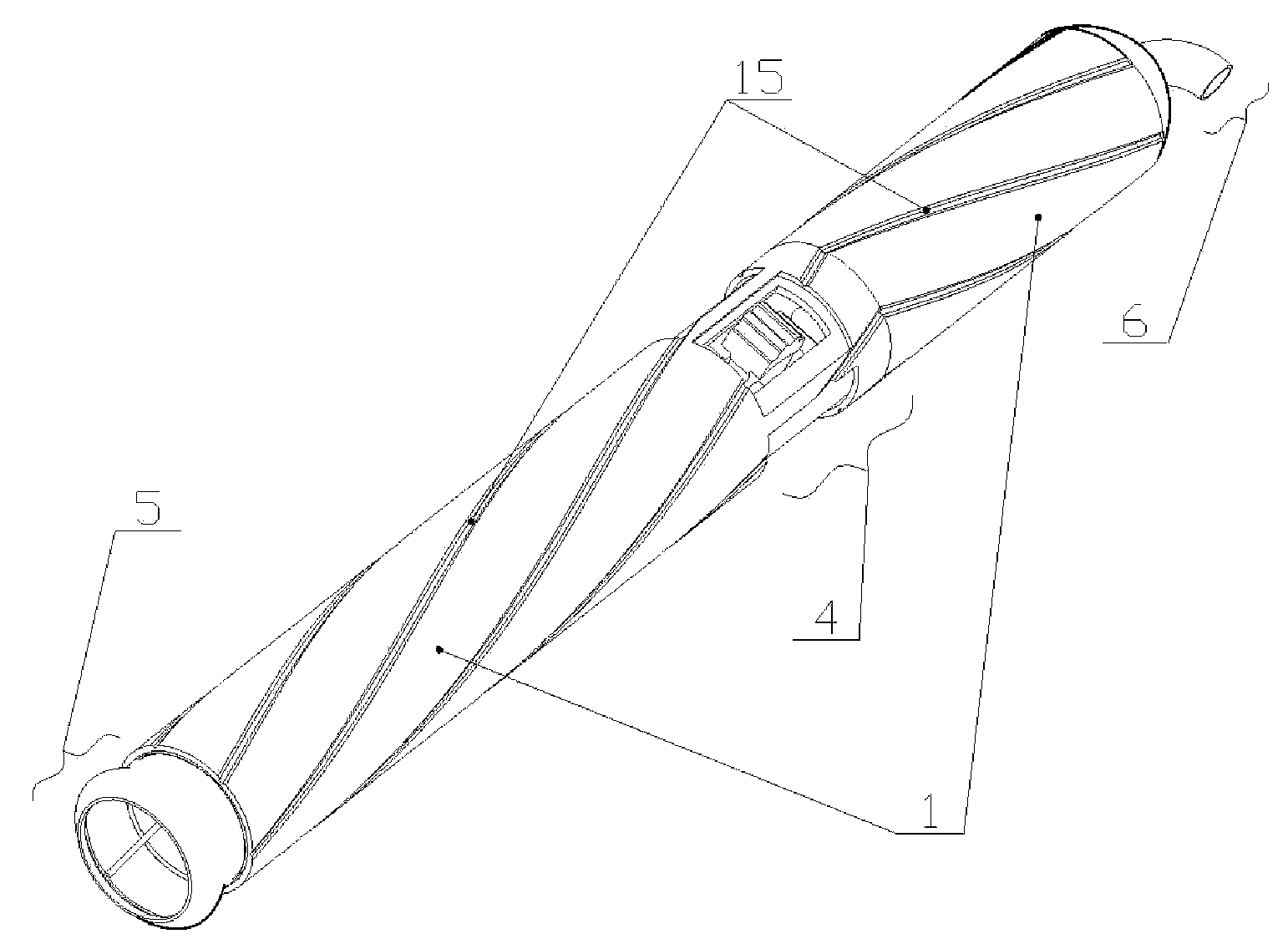

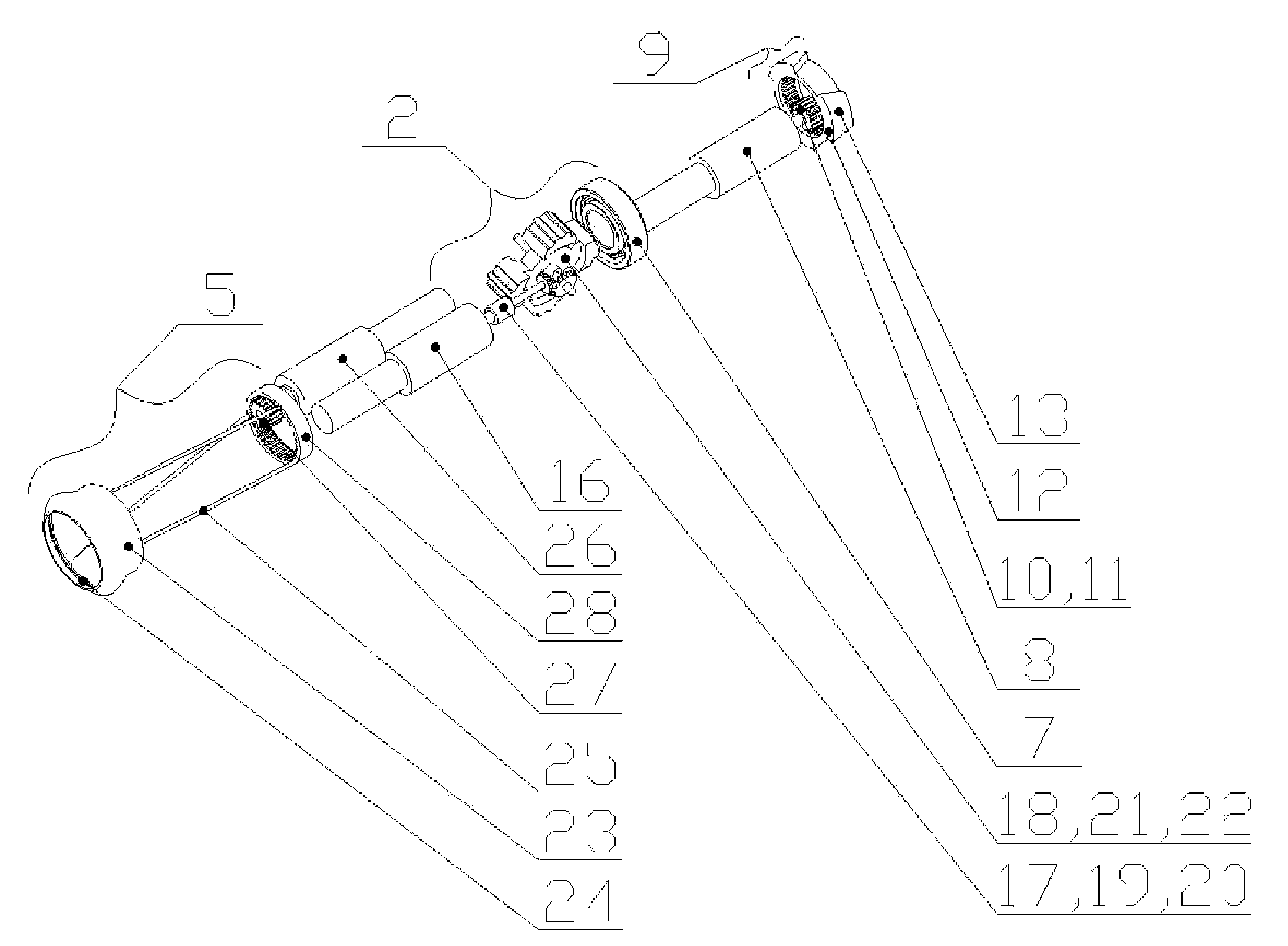

Artroscopic devices and methods

ActiveUS20190008541A1High strengthInhibition of translationSurgical instrument detailsEndoscopic cutting instrumentsDrive shaftEngineering

An arthroscopic device is used with a hand piece having a motor drive with a rotating drive shaft. An elongate probe extending along a longitudinal axis and includes a proximal hub on a proximal end. The proximal hub detachably couples to the hand piece, and an openable-closeable jaw structure is disposed on a distal end of the elongate probe. A conversion mechanism carried by the hub converts a rotational motion of the motor drive shaft to a longitudinal motion of an actuator member. The actuator member drives the jaw structure between jaw-open and jaw-closed positions to resect bone and other hard tissues.

Owner:RELIGN CORP

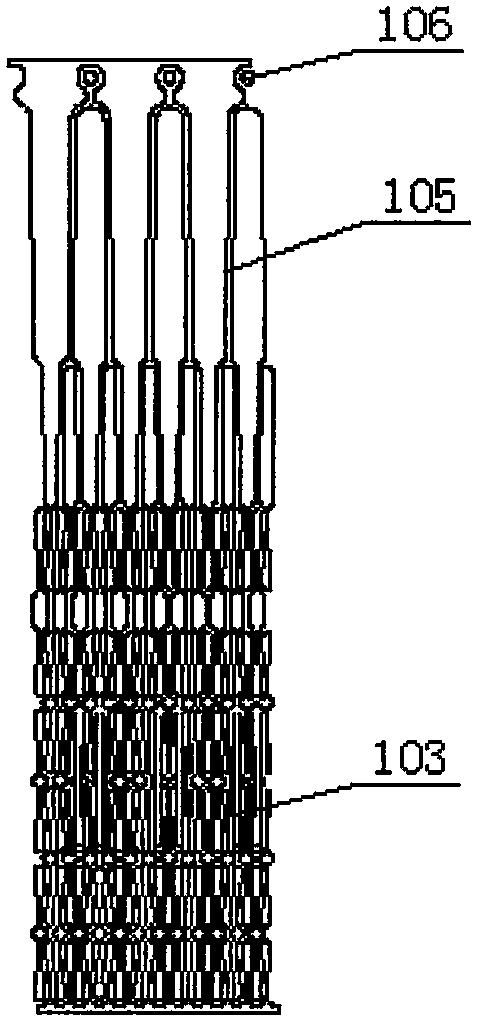

Pile, pole interface positioning device and construction method

InactiveCN101294384AOvercome the disadvantage of easy displacementGuaranteed bottom positioningBulkheads/pilesSteel barMouth structure

The invention discloses a pile / post interface positioning device as well as the construction method thereof. After a pile hole is drilled, a steel reinforcement cage and a steel casing are hung into the pile hole, concrete is poured into the pile hole until exceeding the height mark on the top surface of the pile foundation, then the concrete laitance at the pile head is chiseled off to expose a pre-buried anchoring foundation, and the pile / post interface positioning device is arranged in the steel casing and is permanently connected with the pre-buried anchoring foundation through bolts, and then anchoring concrete is poured; when a steel pipe column is laid, the root part thereof is sleeved at the periphery of the pile / post interface positioning device, and the concrete is poured into a cup-mouth structure, then the concrete is poured into the steel pipe column, and then backfilling sand is filled in until reaching the ground surface; finally, the steel casing is pulled out in a way that the lowermost end of the steel casing is left. The delivering plate of the pile / post interface positioning device is a cross-shaped standing plate, the cross-section of the cross-shaped standing plate presents a cross shape, the diameter of the cross-shaped standing plate gradually diminishes from the middle lower part to the top part, a positioning bottom plate is welded with a ground anchor reinforcing steel bar on the lower surface, and long circular positioning holes which are radially distributed are formed on the positioning bottom plate. The invention solves the problem that the steel pipe column and the foundation pile are not fast and precisely positioned.

Owner:北京住总集团有限责任公司 +1

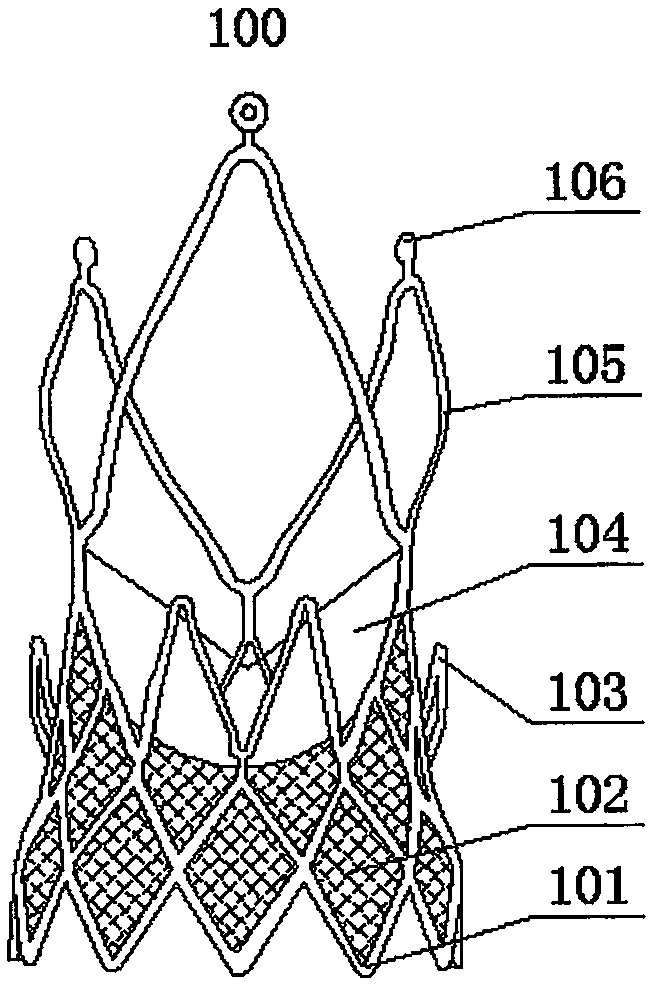

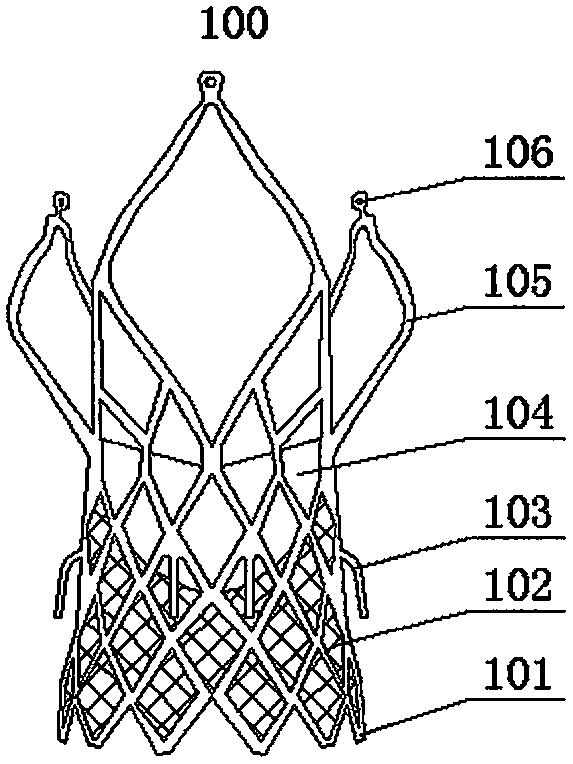

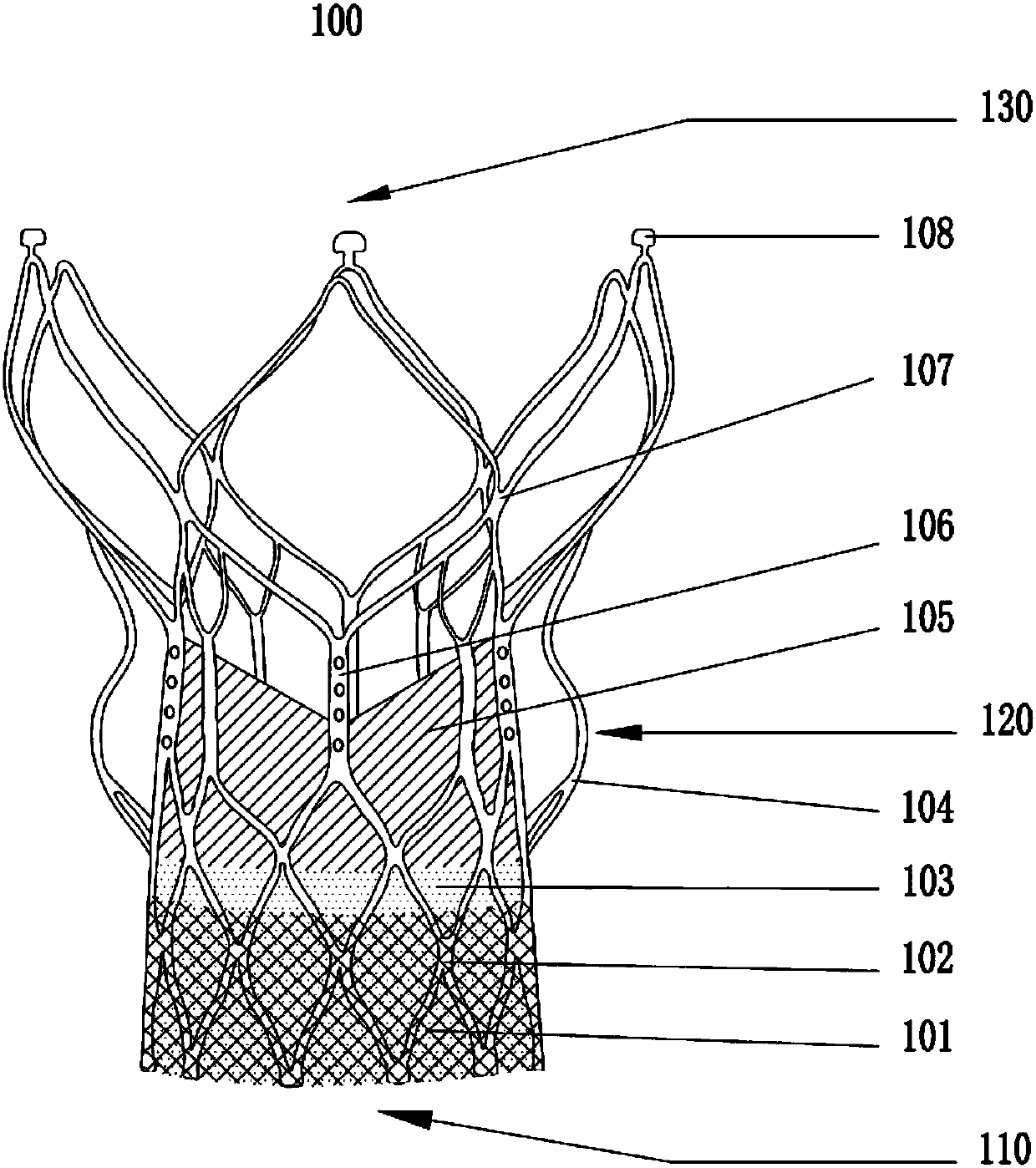

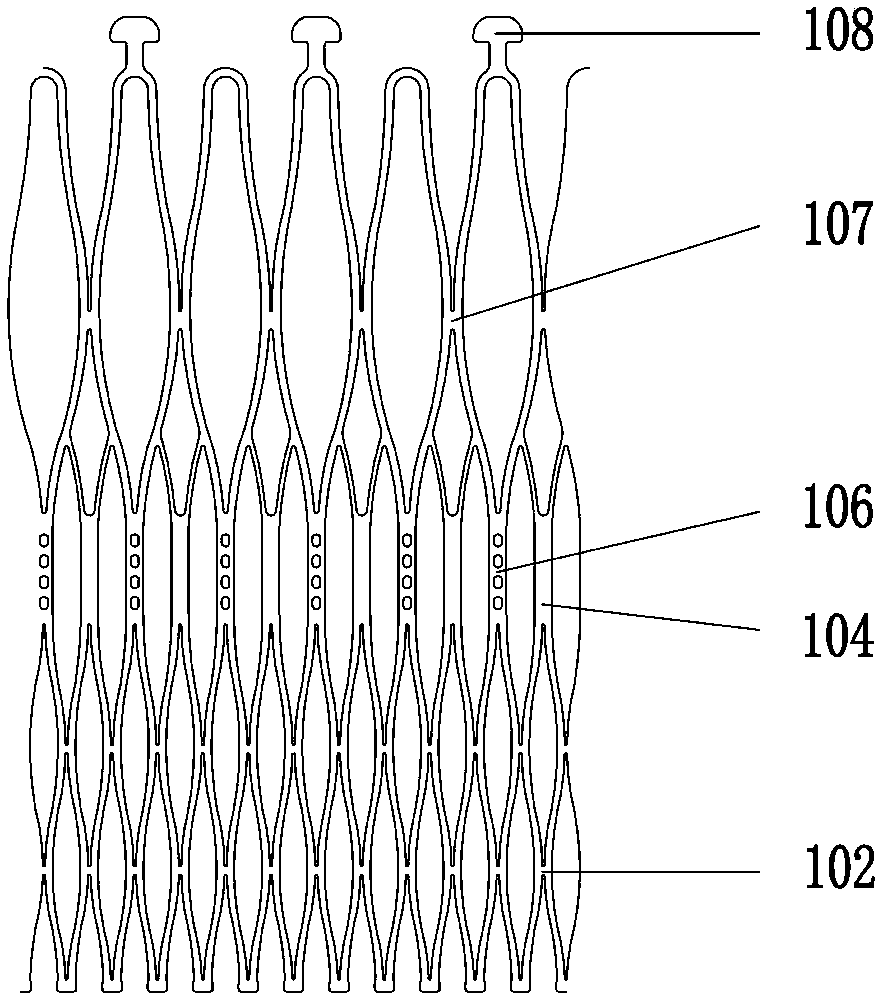

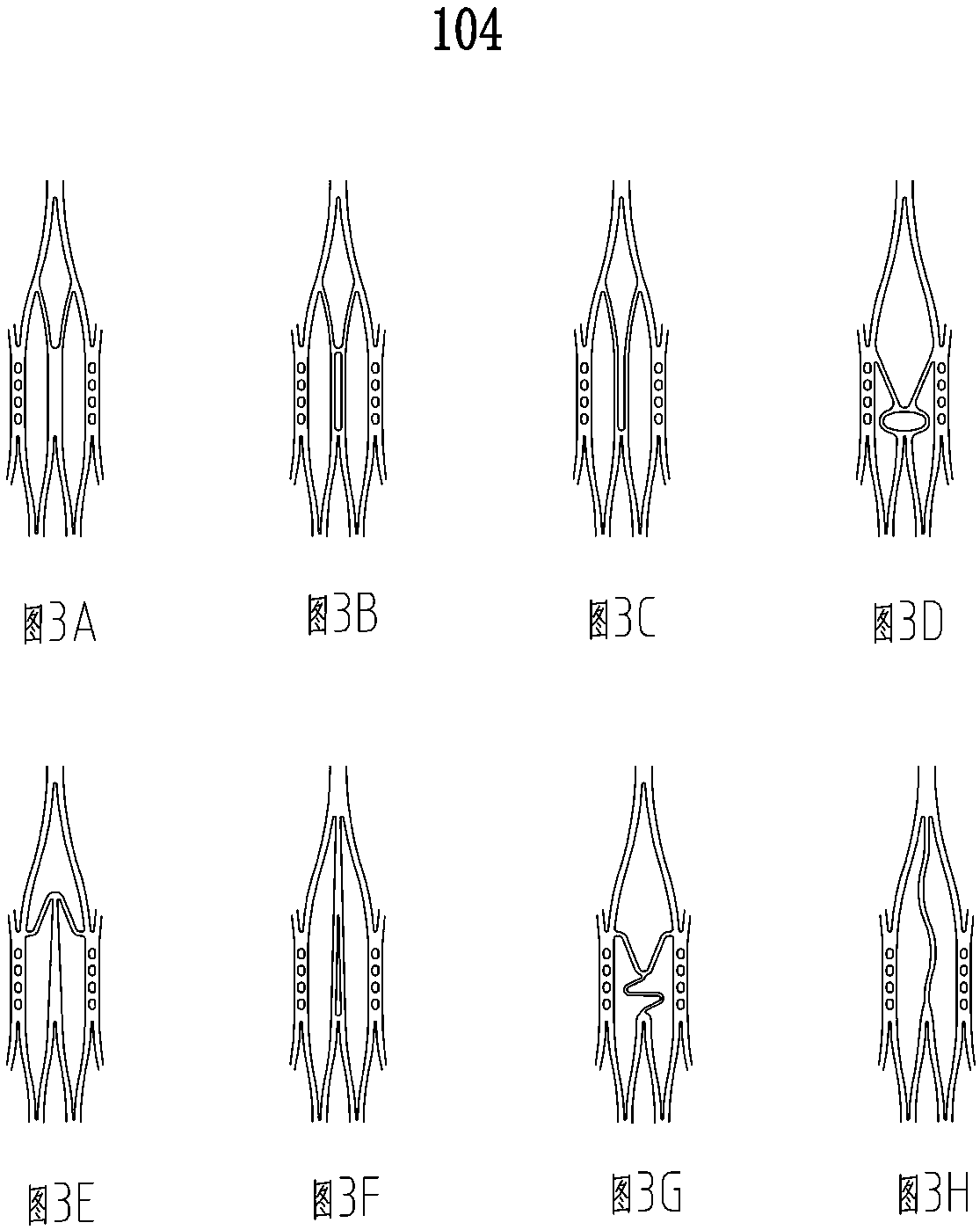

Aortic valve device conveyed by catheter

InactiveCN105476731AAchieve precise positioningReduce weekly leakageHeart valvesAortic valve diseaseNeoaortic valve

The invention discloses an aortic valve device conveyed by a catheter. The aortic valve device comprises a supporting frame, valve leaflets fixed to the inner side of the middle part of the supporting frame, and skirt rims which are fixed along the periphery of the inner side of the supporting frame and fixed to the valve leaflets. An upper horn mouth structure in a three-valve form is formed at the upper end of the supporting frame. Three round connecting claws used for loading the supporting frame are arranged at the tail end of the upper horn mouth structure. A tentacle structure expanding outwards and assisting location by clamping a valve ring is arranged at the outer side of the middle part of the supporting frame. A lower horn mouth structure used for reducing pervalvular leakage and expanding outwards is arranged at the bottom end of the supporting frame.

Owner:BEIJING MED ZENITH MEDICAL SCI CORP LTD

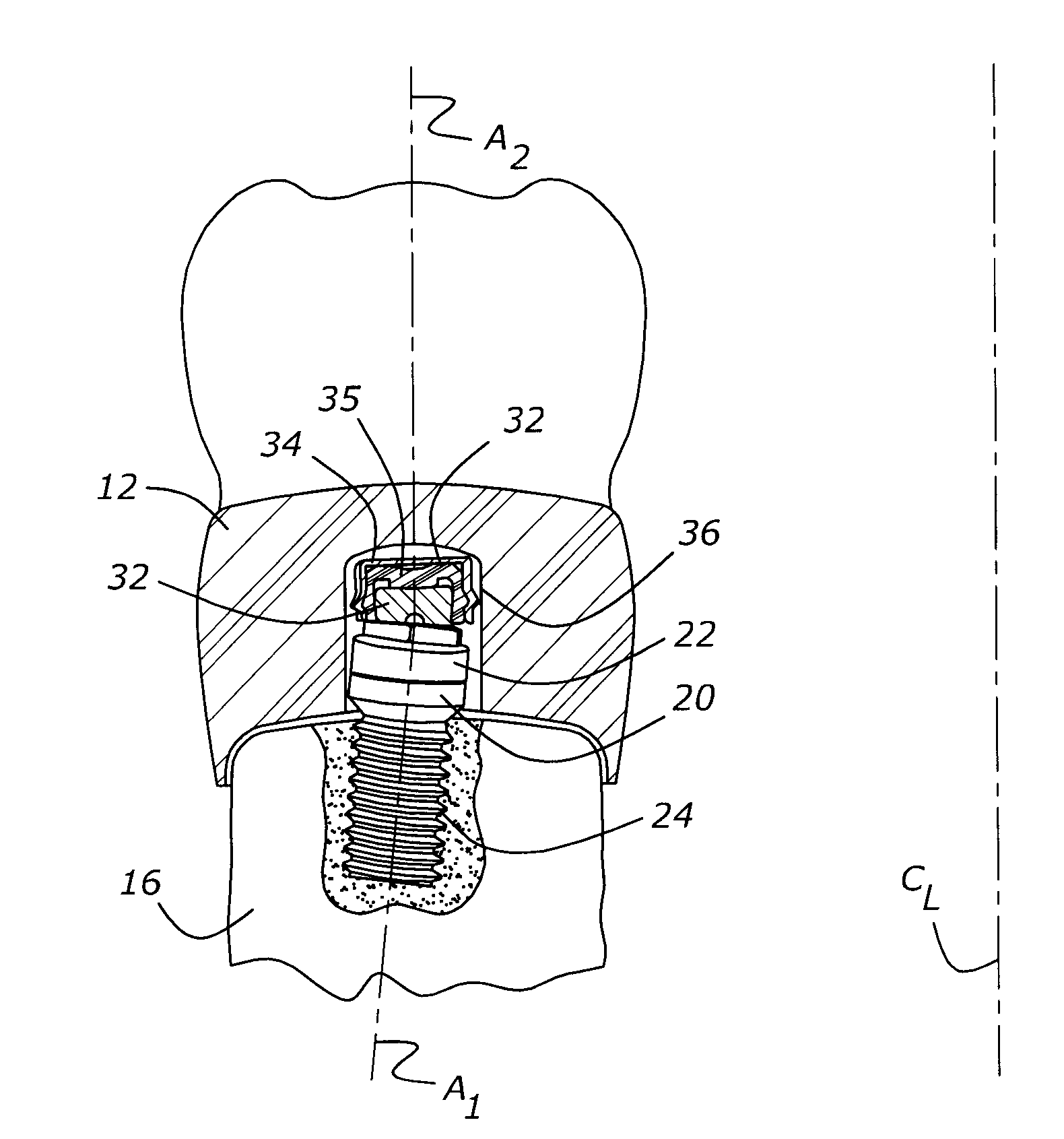

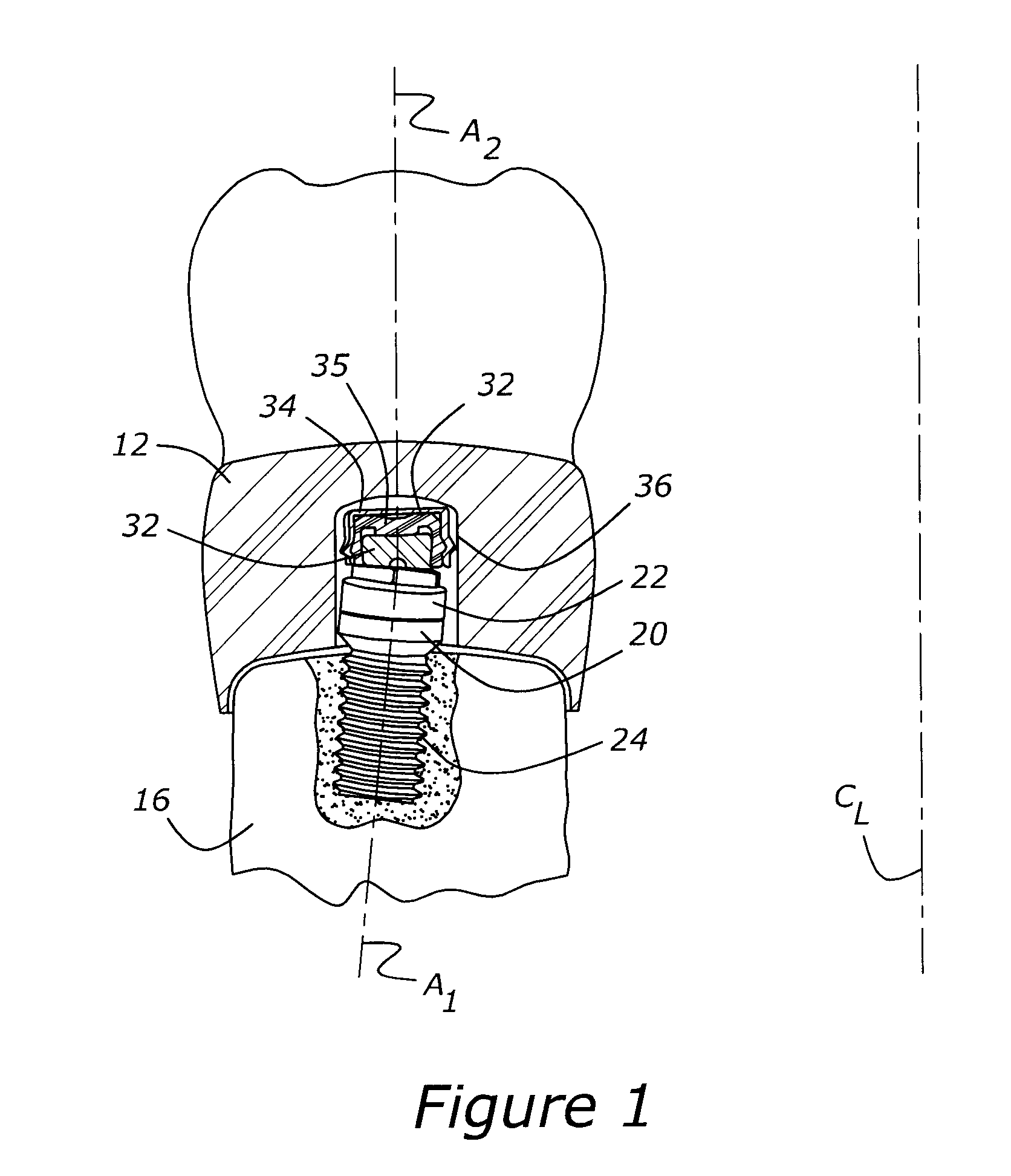

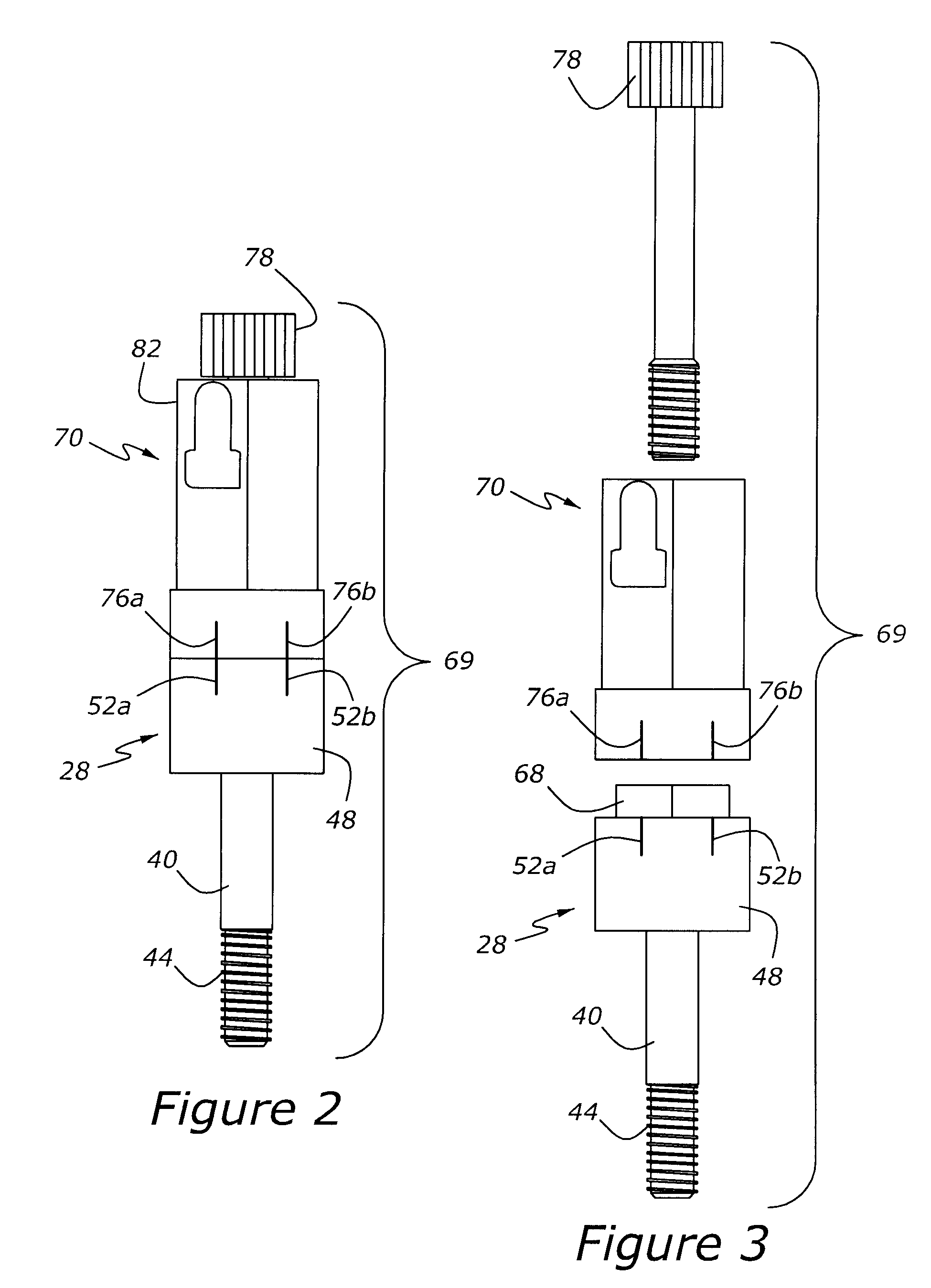

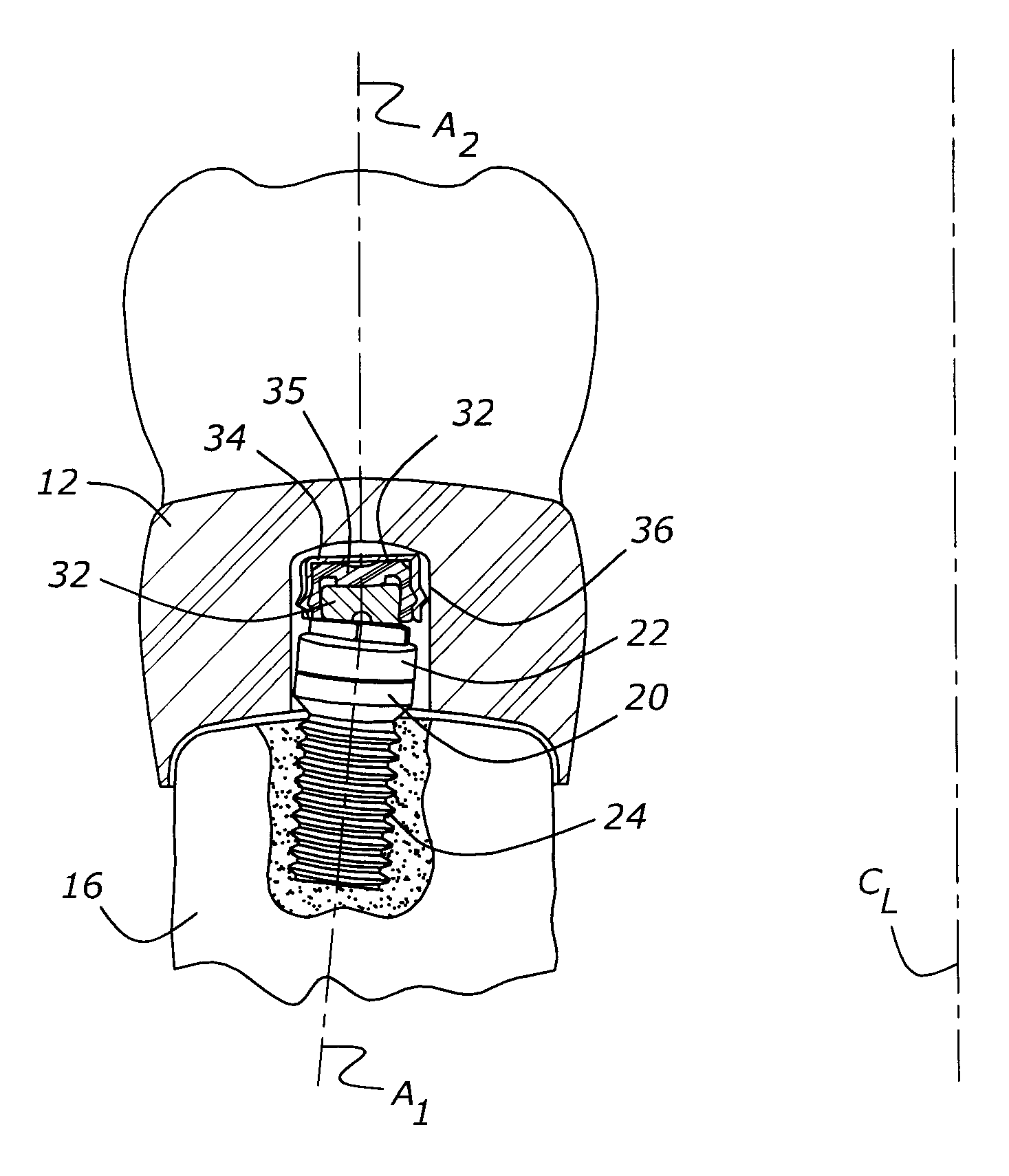

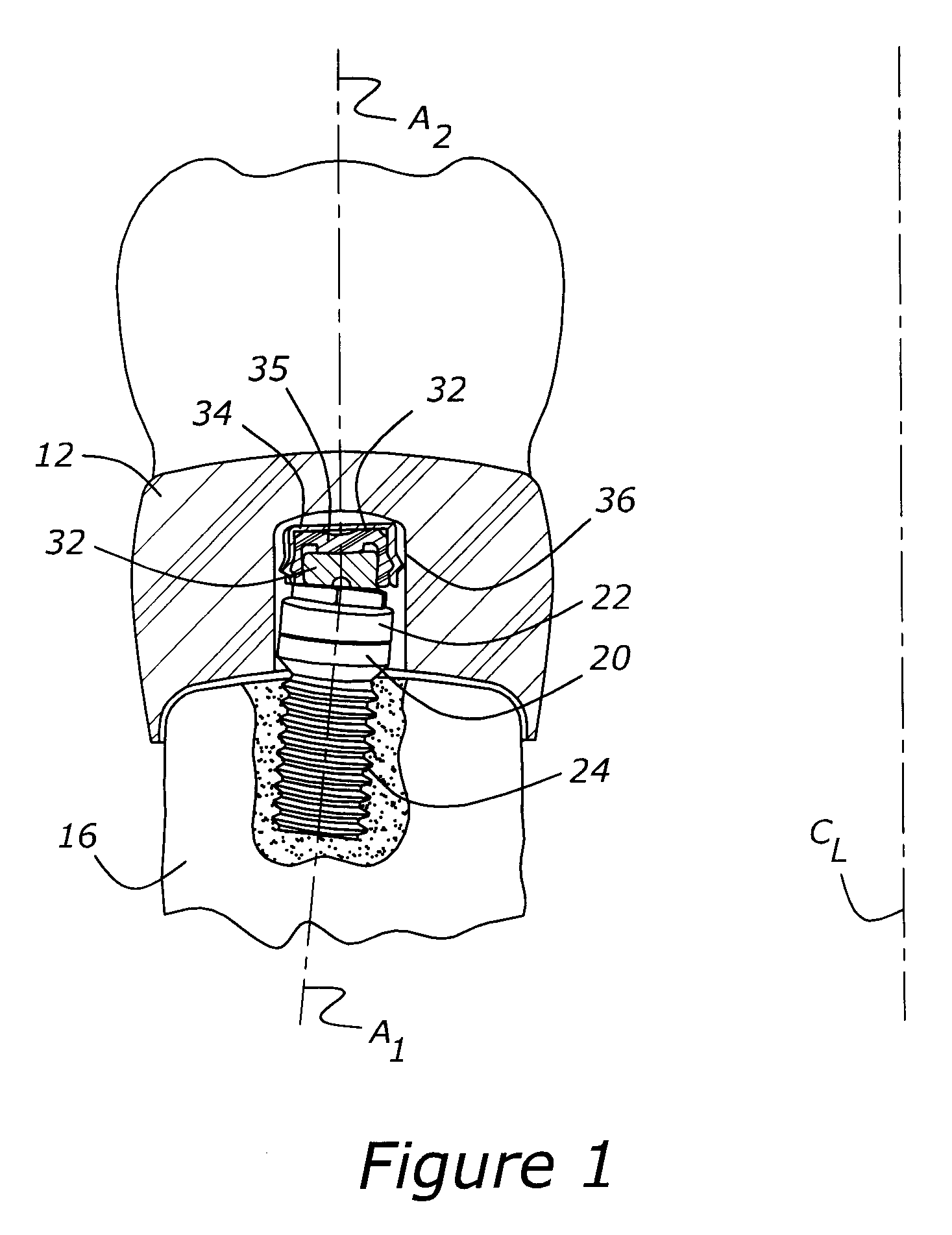

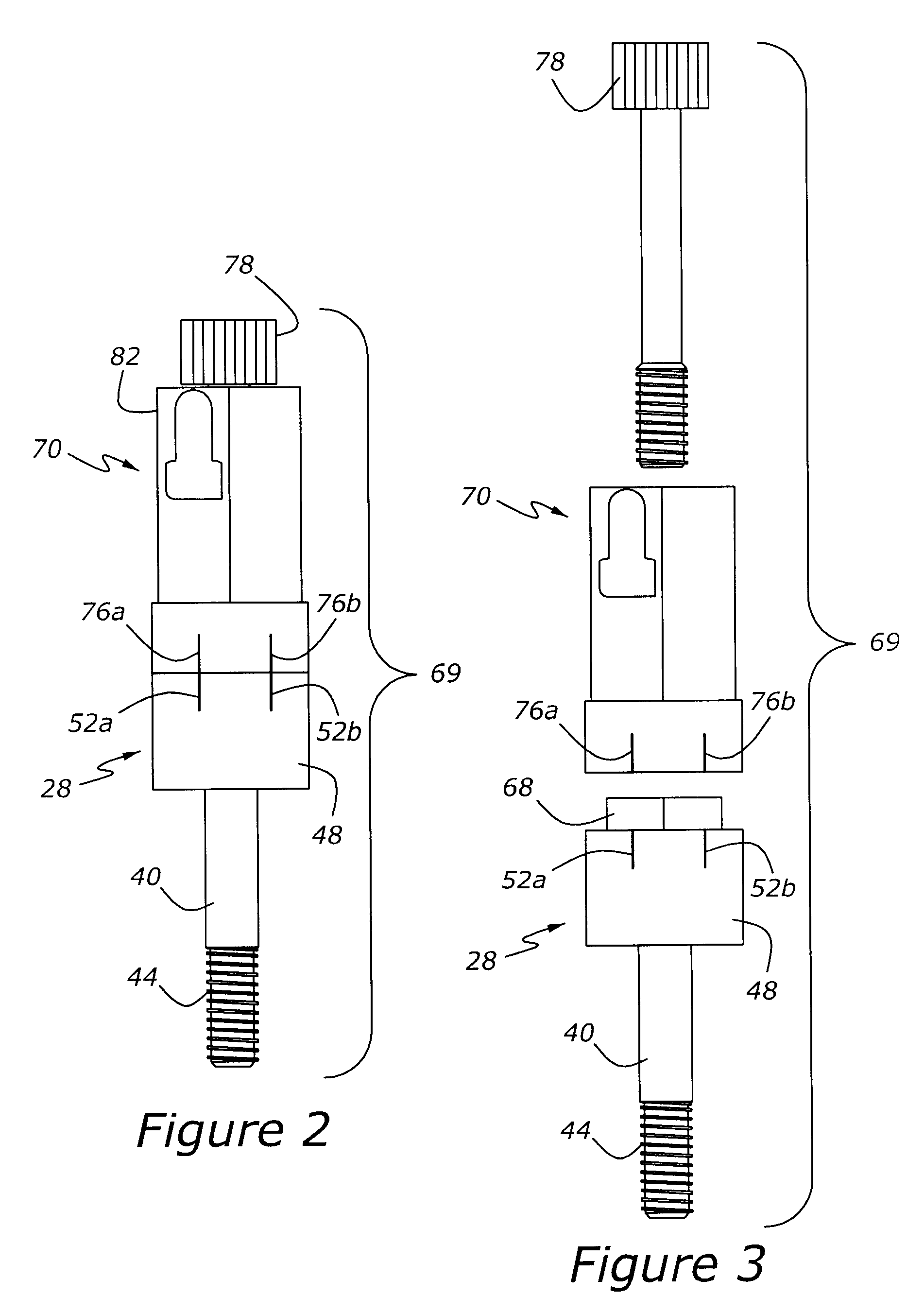

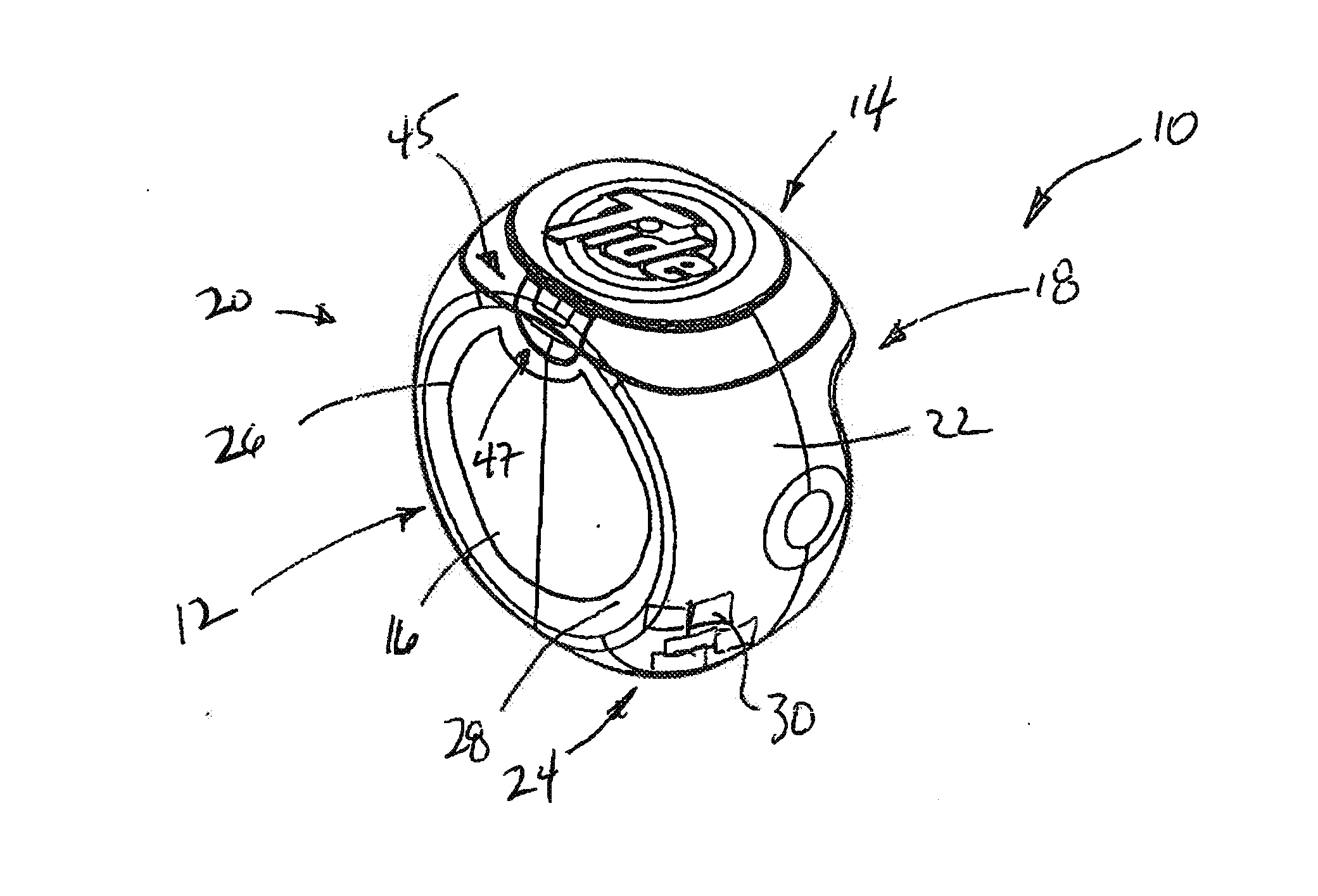

Method for fabricating an implanted dental restoration

InactiveUS20100112527A1Save time in doctor visitsCost controlDental implantsTooth crownsDental implantLaboratory facility

A method for fabricating an implant-based dental restoration includes attaching an abutment analog to a dental implant contained in a patient's mouth in an angularly indexed fashion. After an impression is made, an implant analog will be attached to the abutment analog, which is contained within the impression, and the assembled impression, including the abutment analog, including an impression coping and abutment base, will be employed along with the implant analog to make a model of a patient's mouth structure, including thread-timed implant analogs, to permit fabrication of an angle-corrected dental restoration device in a laboratory.

Owner:CHAPEL TIMOTHY DOW

Aortic valve device conveyed by catheter

The invention discloses an aortic valve device conveyed by a catheter. The aortic valve device comprises a supporting frame, wave leaflets and a skirt. The valve leaflets are fixed to the inner side of the middle of the supporting frame. The skirt is fixed along the periphery of the inner side of the supporting frame and fixed to the valve leaflets. An upper horn mouth structure in a three-valve form is formed by the upper end of the supporting frame. Three circular connection jaws used for loads of the supporting frame are arranged at the tail end of the horn mouth structure. Thorn-shaped positioning rods extending towards the bottom end of the supporting frame to be exposed are arranged on the outer side of the middle of the supporting frame. A lower horn mouth structure used for reducing outward expanding of perivalvular leakage is arranged at the bottom end of the supporting frame.

Owner:BEIJING MED ZENITH MEDICAL SCI CORP LTD

Dental abutment analog for implant-secured restoration

InactiveUS20100112521A1Save time in doctor visitsCost controlDental implantsTooth crownsDental restorationLaboratory facility

An abutment analog for fabricating an implant-based dental restoration includes an abutment base which is fixed within a patient's mouth in an angularly indexed fashion. After an impression is made, an implant analog will be attached to the abutment analog, and the combined abutment analog and implant analog will be replaced within the impression. The resulting impression, including the abutment analog and attached implant analog, will be used to make a model of a patient's mouth structure, to permit fabrication of a dental restoration device in a laboratory.

Owner:CHAPEL TIMOTHY DOW

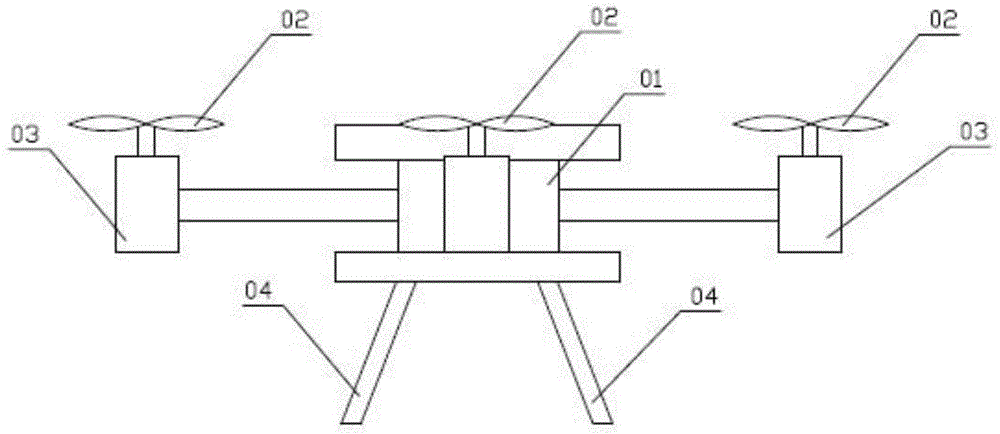

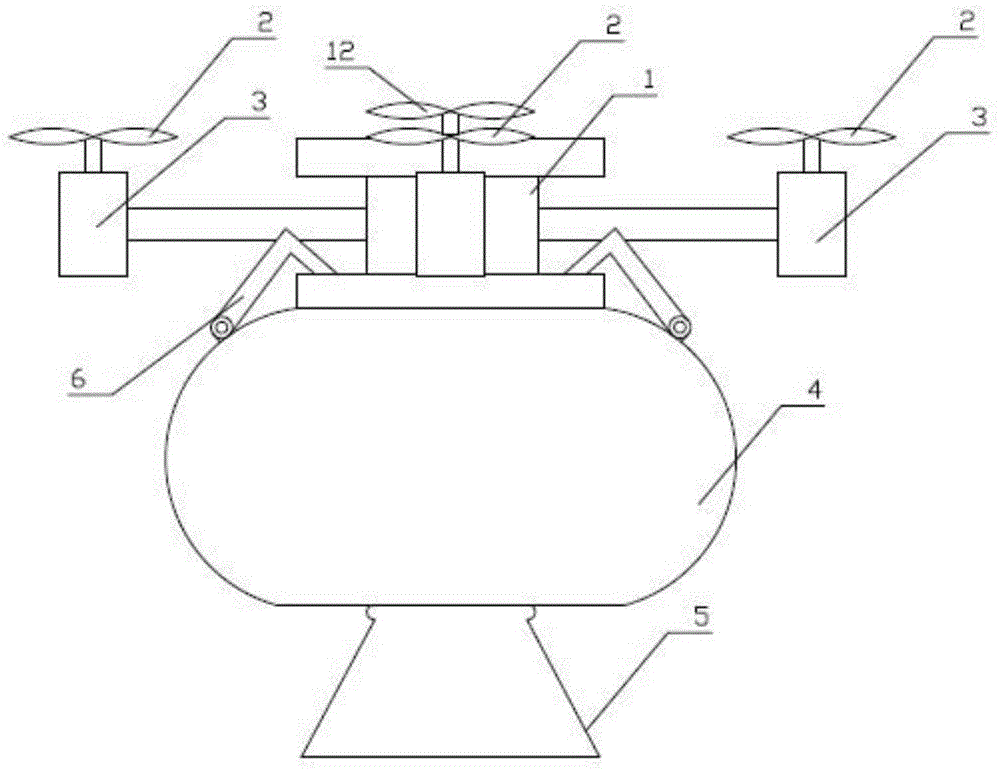

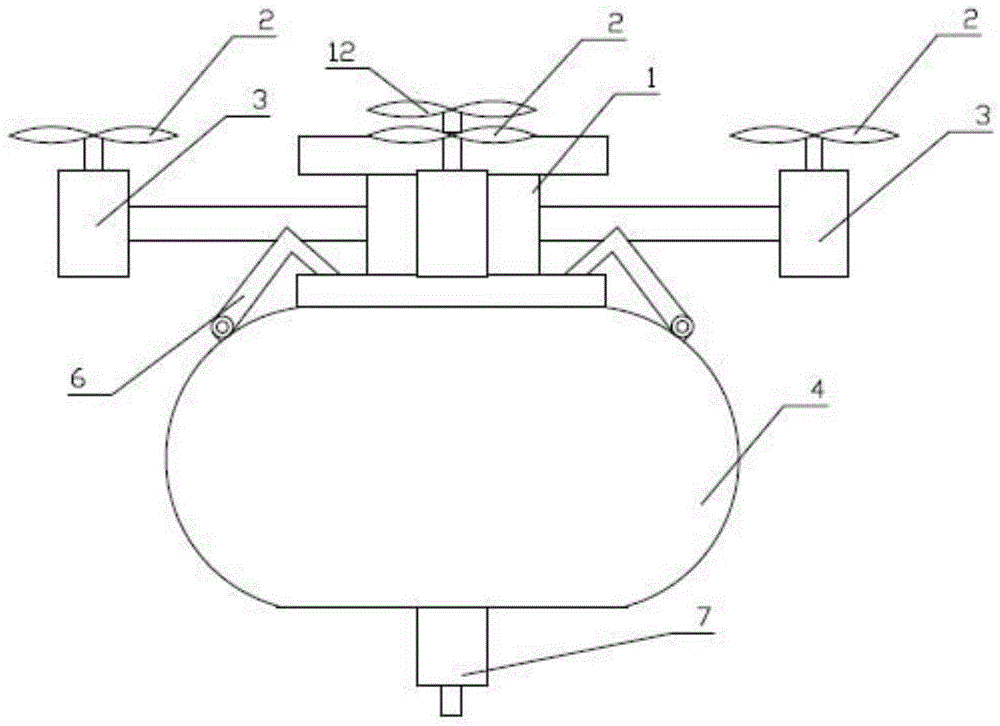

Agricultural spraying multi-rotor wing unmanned aerial vehicle

ActiveCN104354866AImprove connection stabilityImprove stabilityAircraft componentsLaunching weaponsElectricityCoupling

The invention provides an unmanned aerial vehicle capable of being applied to small scattered farmlands in the south to carry out pesticide spraying. The unmanned aerial vehicle comprises a rack, rotor wings and a rotor wing motor. The unmanned aerial vehicle is characterized in that a medical tank is also arranged below the rack; the upper part of the medical tank is clamped with the rack through a plurality of claws; support legs and electric nozzles are arranged below the medical tank; the support legs are of a horn mouth structure which gradually expands downwards; the electric nozzles are arranged in the support legs, and are electrically connected with an information processor; a stirring device is also arranged on the medical tank, and comprises a stirring cage, a stirring shaft, a coupler and a stirring motor; the stirring shaft is inserted into the medical tank; the stirring cage is fixed on the stirring shaft; the stirring motor is arranged on the rack and is electrically connected with the information processor; the stirring motor is a two-axis motor; the lower end of the stirring motor is connected with the coupler; the upper end of the stirring motor is also connected with an expanding rotor wing; the motor of the electric nozzles is a motor which can be switched between forward and backward rotation; a liquid level sensor and a temperature sensor are arranged in the medical tank.

Owner:宁波达鹏无人机科技有限公司

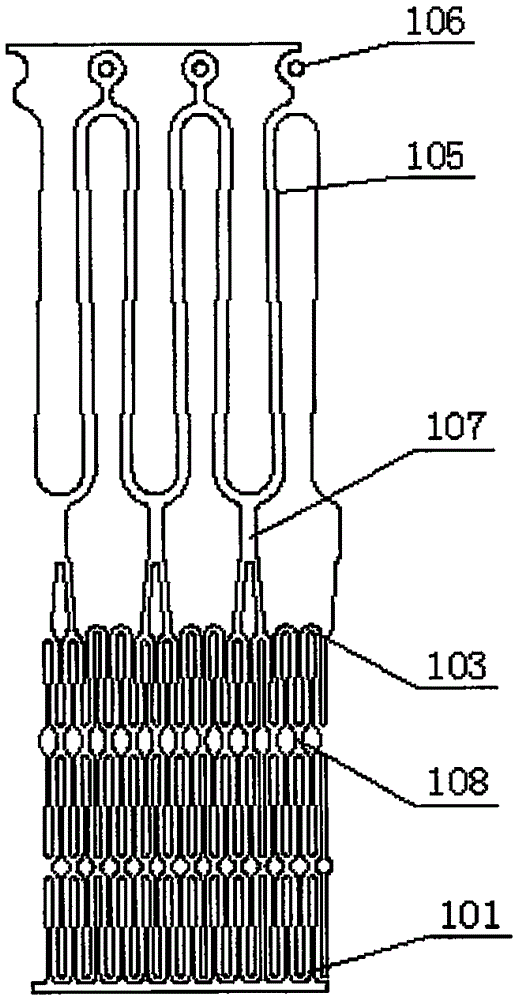

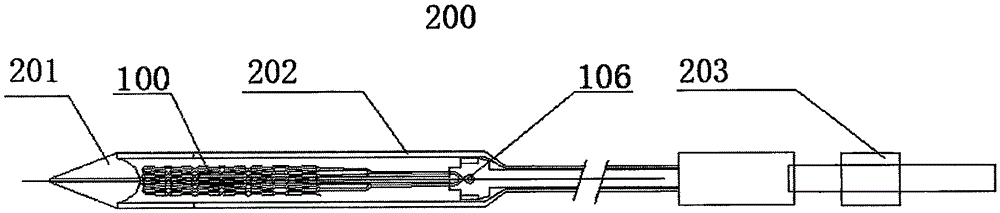

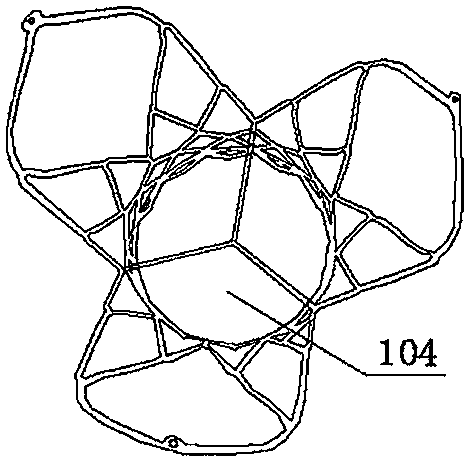

Device capable of locating and recycling transcatheter implantable aortic valve

The invention relates to a device capable of locating and recycling a transcatheter implantable aortic valve. The device provided by the invention comprises a valve stent, a valve leaflet, an inner skirt and an outer skirt, wherein the valve stent comprises three grids; an influx end structure, a middle section structure and an outflow end structure are sequentially combined to form a whole; the middle section structure is formed by combining a straight connecting rod structure and a locating rod structure expanding and raising outward; the influx end structure is of a first horn mouth structure composed of multiple rhombic-shaped grid structures; the outflow end structure is of a second horn mouth structure composed of multiple rhombic-shaped grid structures; a connecting claw used for loading the valve stent is arranged at the tail end of the second horn mouth structure; the valve leaflet is fixed at the inner side of the middle section structure of the valve stent; the inner skirt is fixed at the inner side of the influx end structure of the valve stent and is fixedly connected with the valve leaflet; and the outer skirt is fixed at the outer side of the outflow end structure ofthe valve stent.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

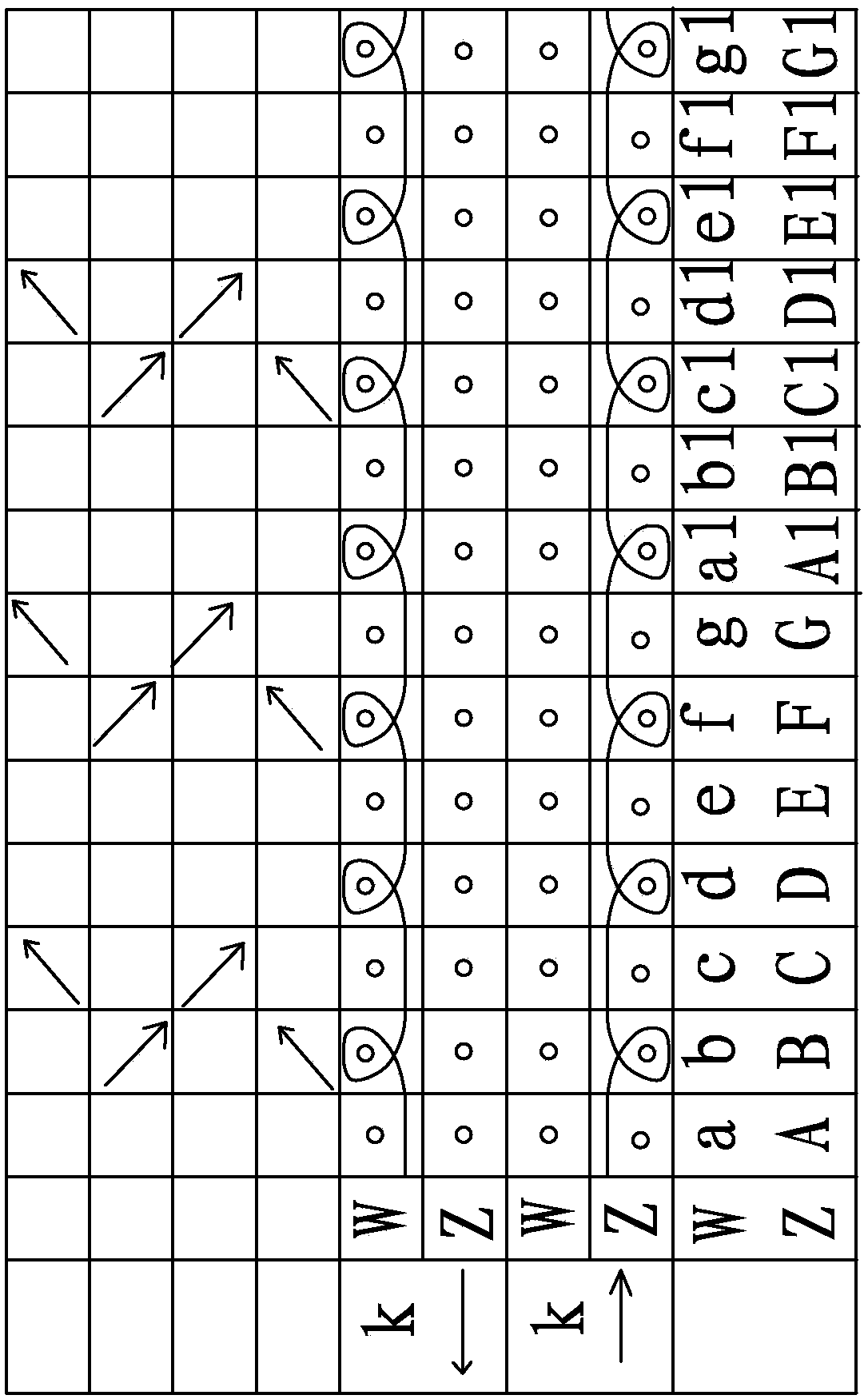

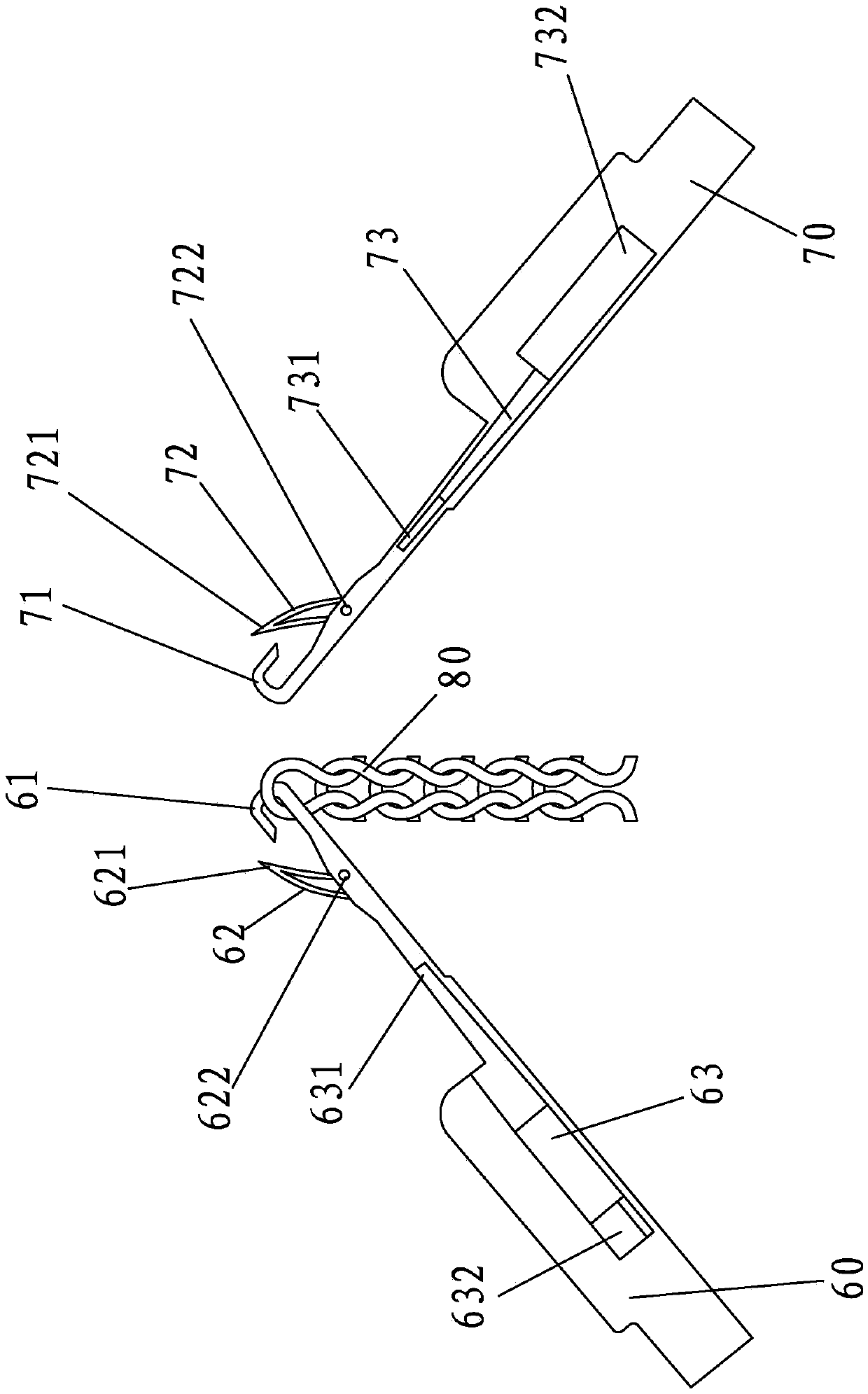

Medical instrument with flexible jaw mechanism

A medical instrument includes a unitary jaw structure having: a connector portion, a first jaw portion flexibly integral with the connector portion, a first arm portion integral with the first jaw portion, and an actuator portion flexibly integral with the first arm portion for causing rotating motion of the first jaw portion upon linear motion of the actuator portion.

Owner:INTUITIVE SURGICAL OPERATIONS INC

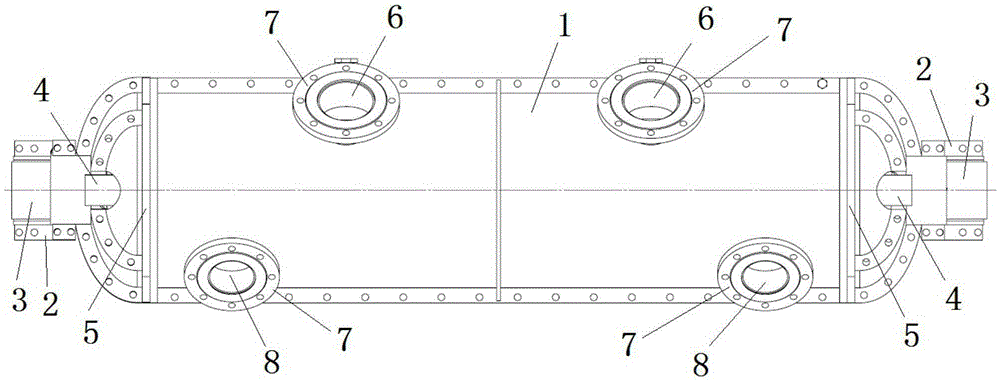

Split type high-voltage cable connector protection explosion-proof fire-extinguishing box

The invention relates to a split type high-voltage cable connector protection explosion-proof fire-extinguishing box comprising a shell body. A split structure composed of two semi-cylindrical shells is formed in the middle part of the shell body. Each semi-cylindrical shell is made of stainless steel material through one-time rolling. The external part of the shell body is circumferentially provided with multiple reinforcing ribs. The two ends of the shell body use a gradient tightening mouth structure, and a cylinder is formed at the tightening mouth. The internal part of the tightening mouth is provided with a groove type waterproof sealing member which is integrally formed. The cylinders of the two ends are internally provided with a main cable installing port and a grounding cable installing port respectively. The aperture of the main cable installing port is greater than that of the grounding cable installing port. The two cylinders are respectively provided with an elastic explosion-proof heat-insulating protection plate and a temperature sensing automatic fire-extinguishing device. The middle part of the semi-cylindrical shell arranged at the upper part is provided with two energy discharge holes which are arranged in a spacing way. The two energy discharge holes are respectively provided with an extruding type silicone rubber sealing gasket and a sealing flange. The two sides of the semi-cylindrical shell arranged at the lower part are respectively provided with a material feeding hole. The two material feeding holes are respectively provided with a sealing flange.

Owner:STATE GRID CORP OF CHINA +3

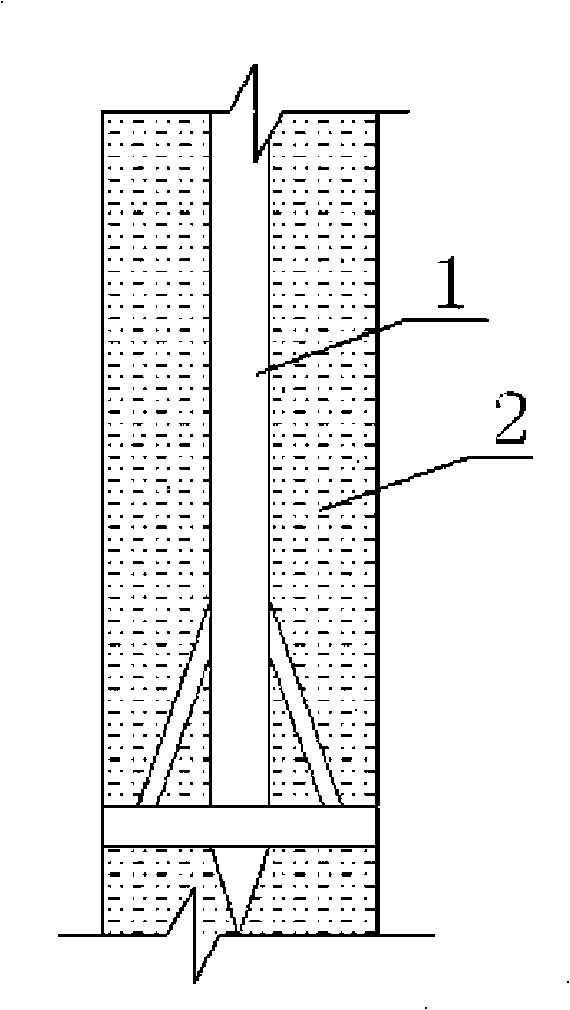

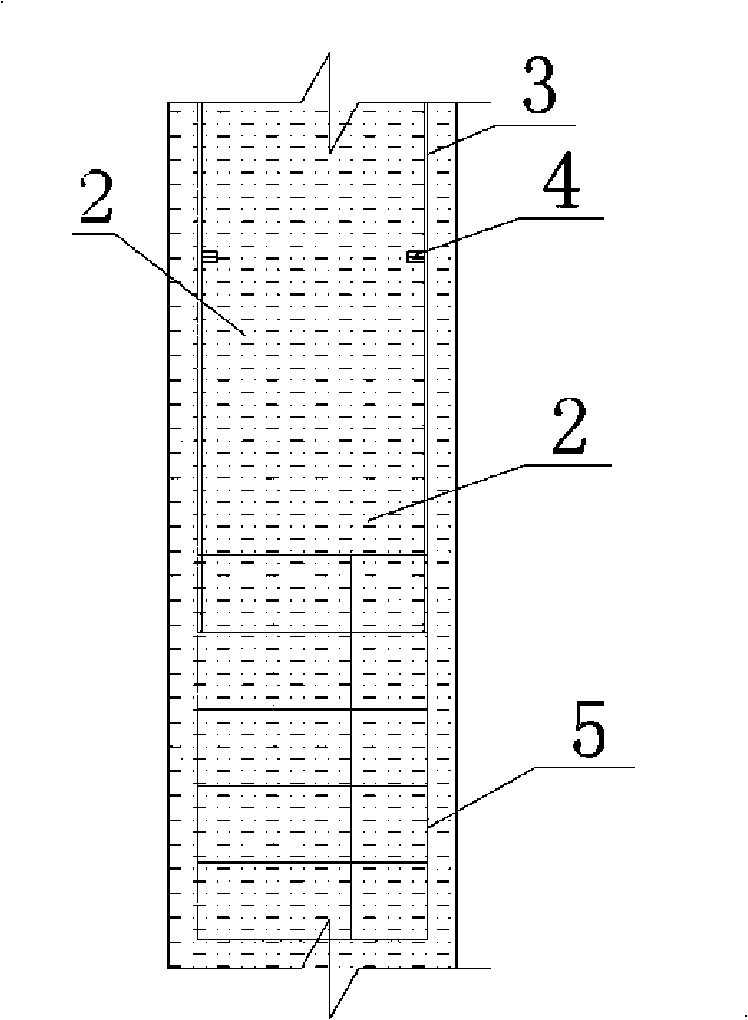

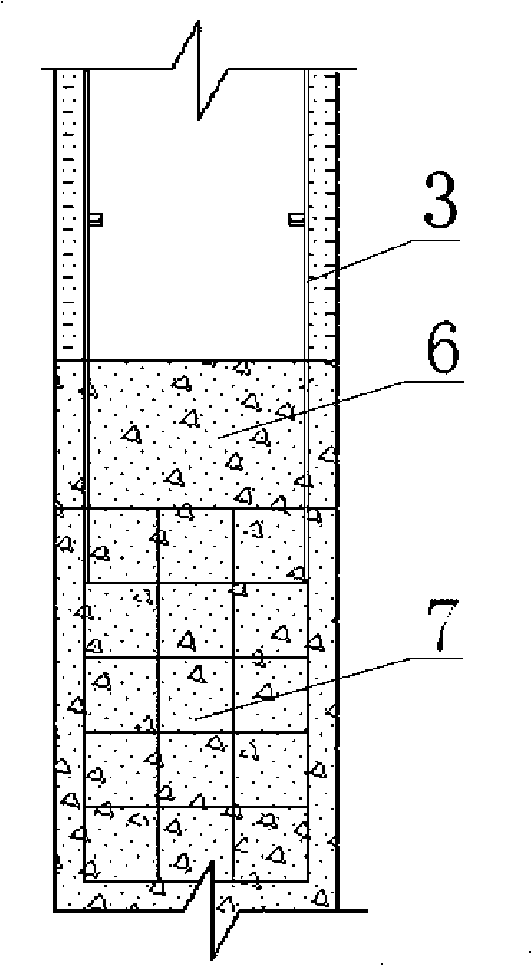

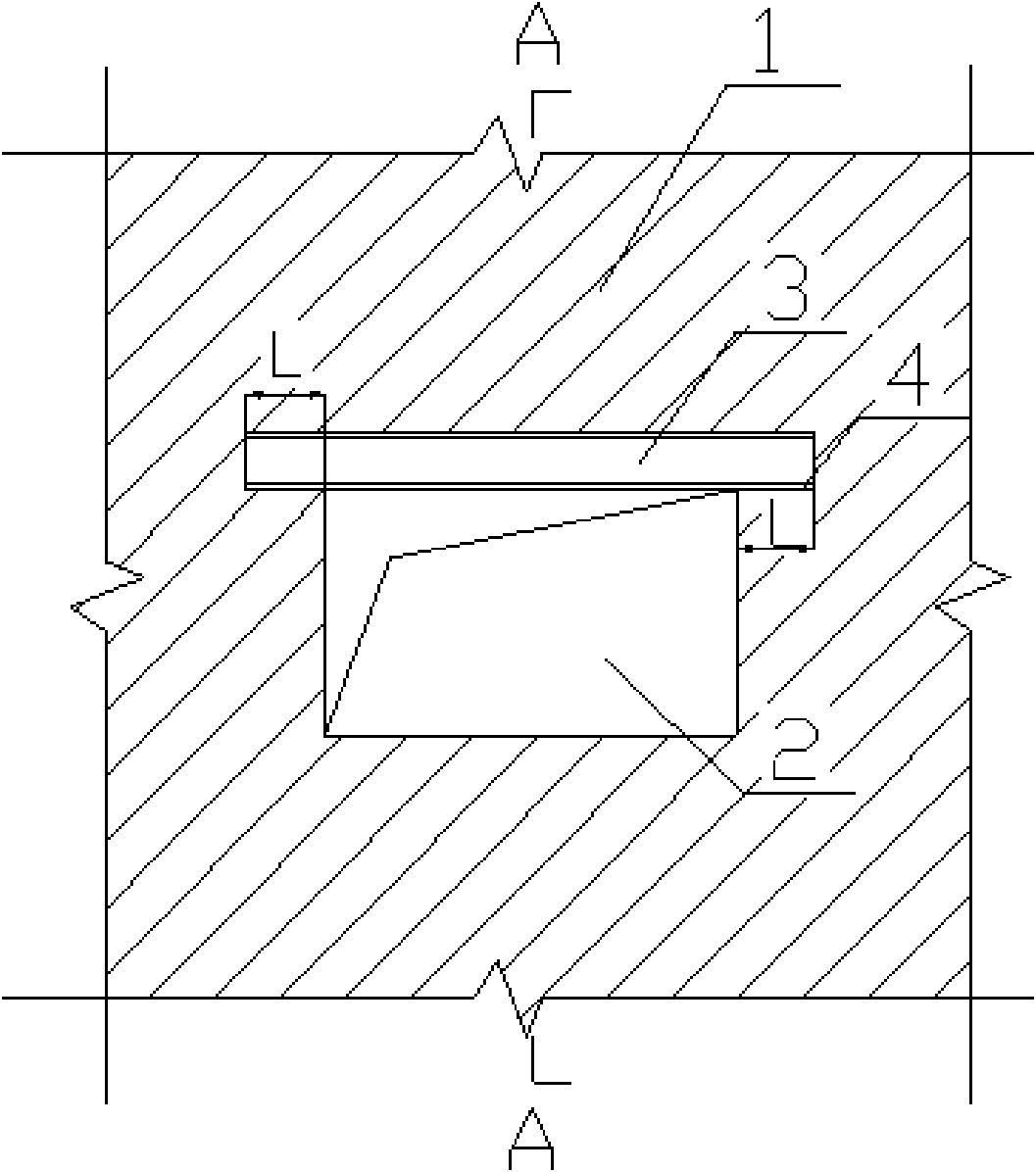

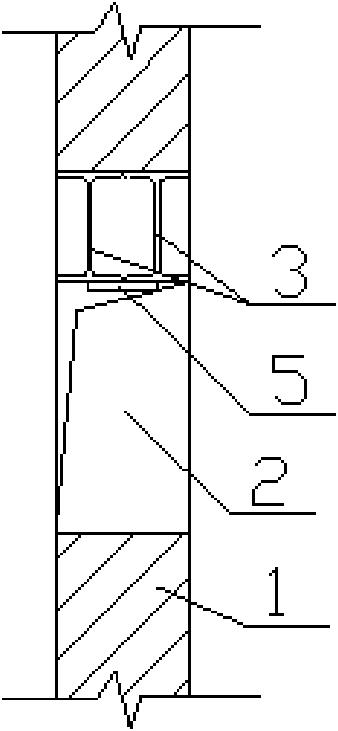

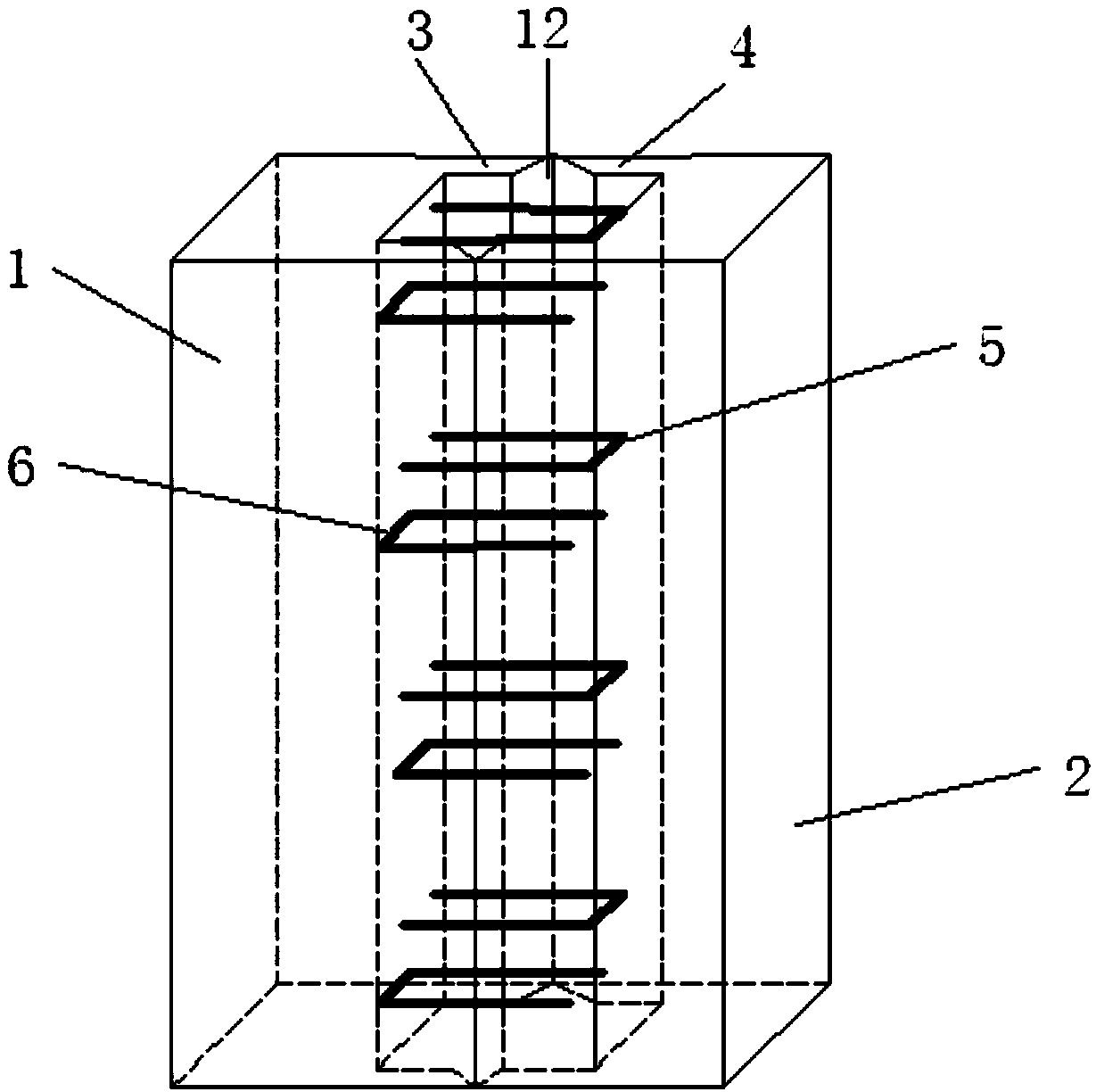

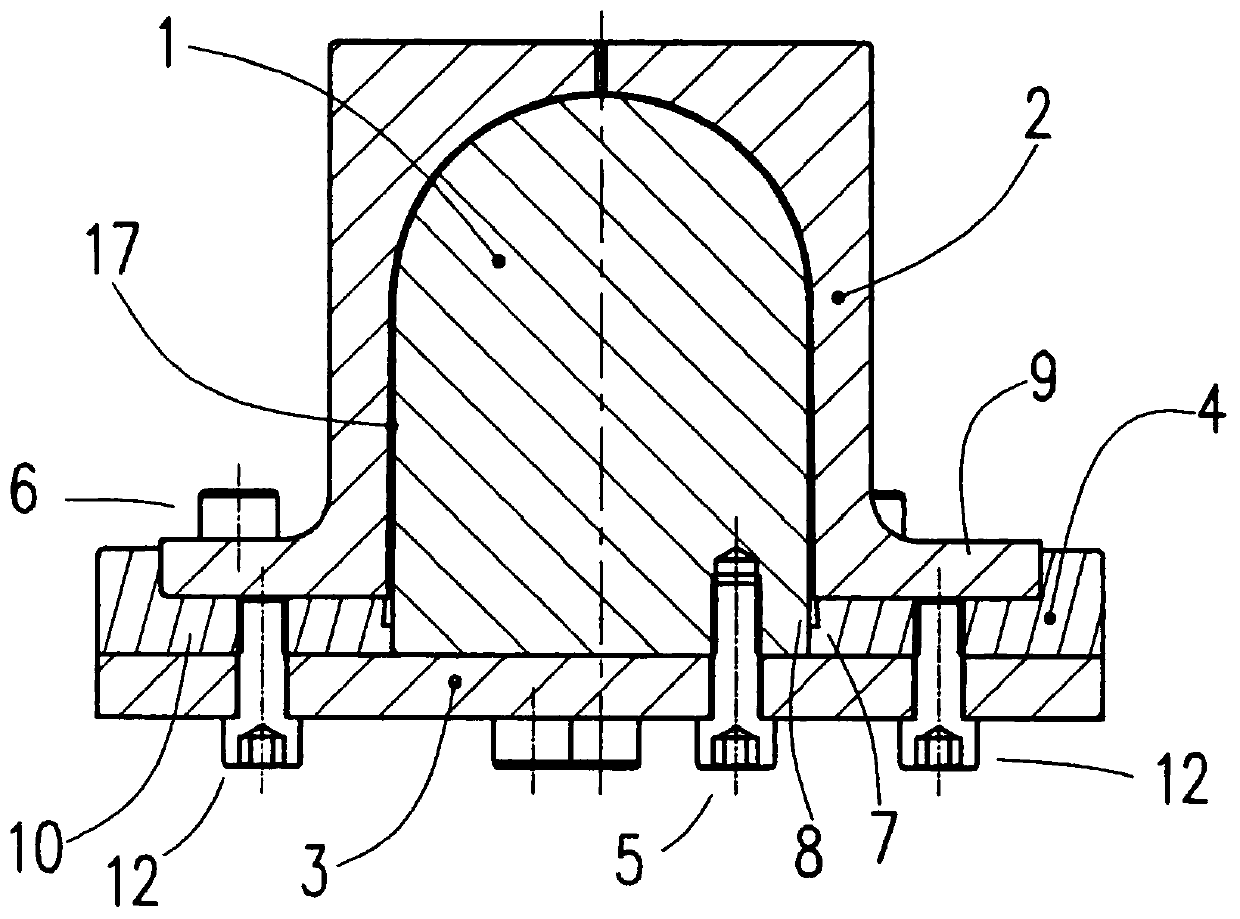

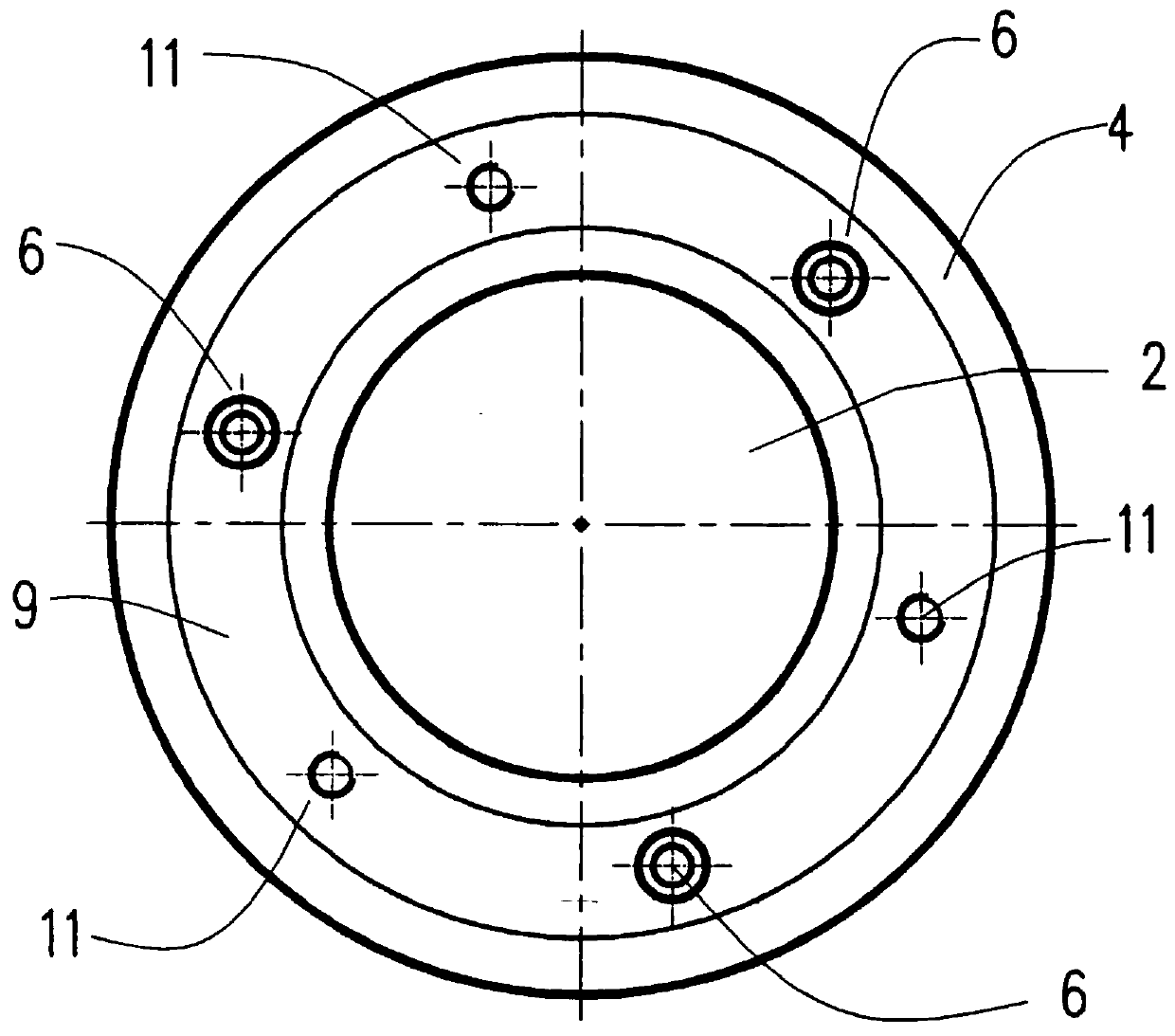

Cave mouth structure on bearing wall and method for forming cave mouth thereon

InactiveCN101638920AIntensity is not affectedStability is not affectedWallsBuilding repairsStructural engineeringCave

The invention discloses a cave mouth structure on a bearing wall and a method for forming the cave mouth thereon. The structure comprises a bearing wall body (1) and a cave mouth (2) formed on the bearing wall body (1), wherein a steel member (3) is arranged on the bearing wall body (1) above the cave mouth (2), and both ends of the steel member (3) are respectively positioned in bearing slots (4)on both ends of the upper part of the cave mouth (2). The invention adopts the structure that the steel member is arranged above the cave mouth which needs to be formed, both ends of the steel memberare supported on the bearing wall on both ends of the upper edge of the cave mouth, and therefore a larger cave mouth can be formed on the wall body without demolishing the wall body or unloading load on the wall; and the strength and the stability of the wall can be prevented from being influenced.

Owner:GUIYANG AL-MG DESIGN & RES INST

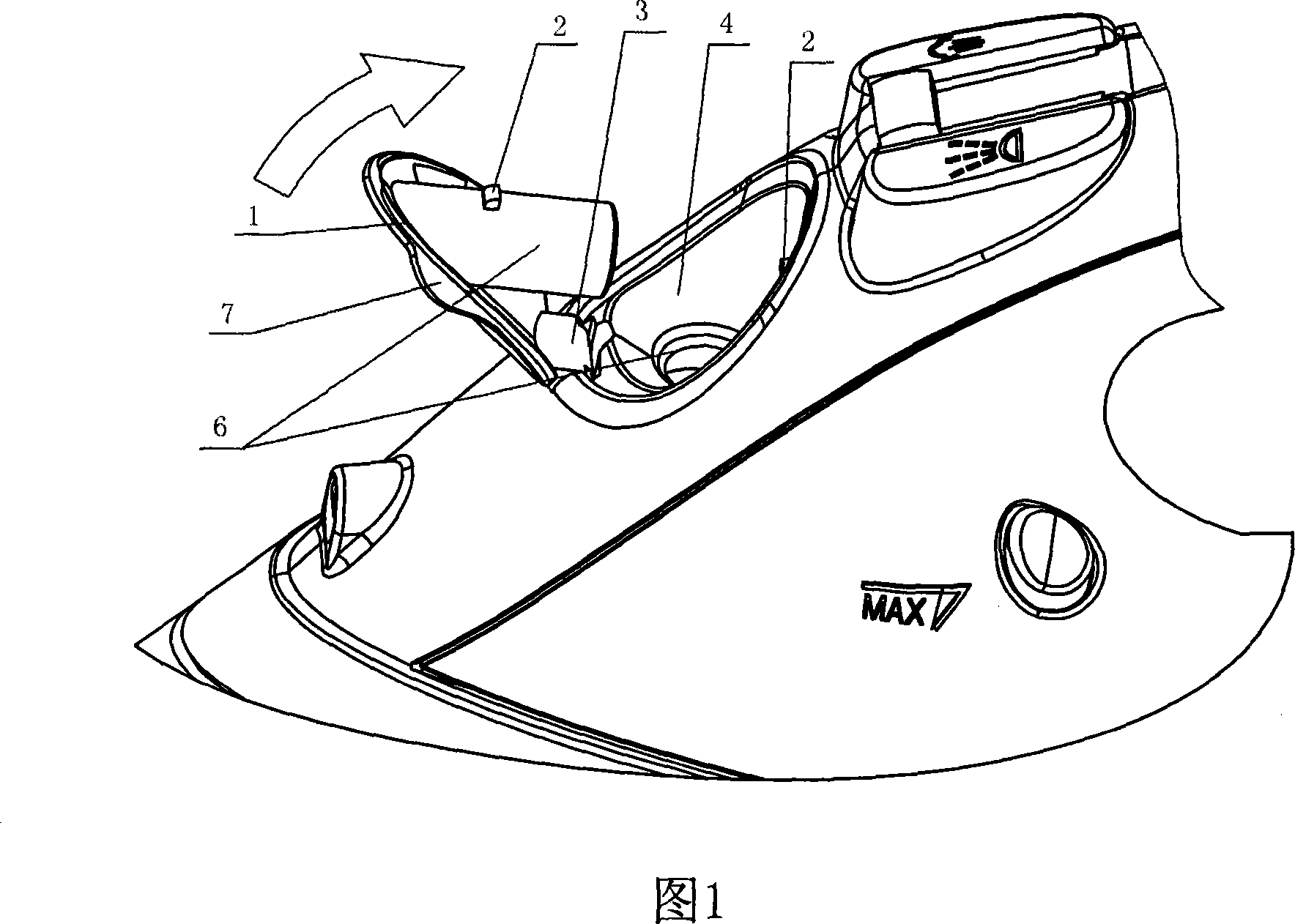

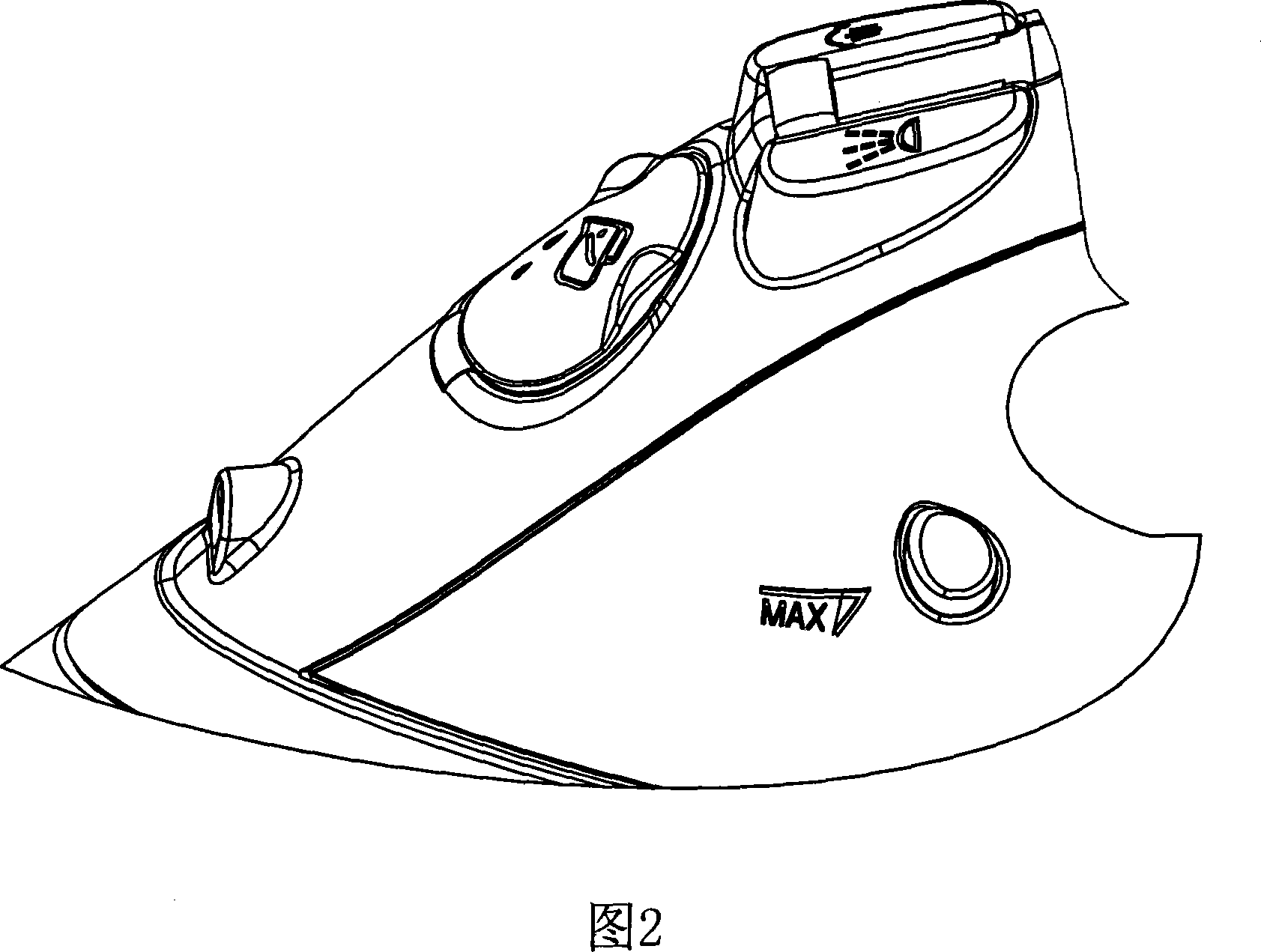

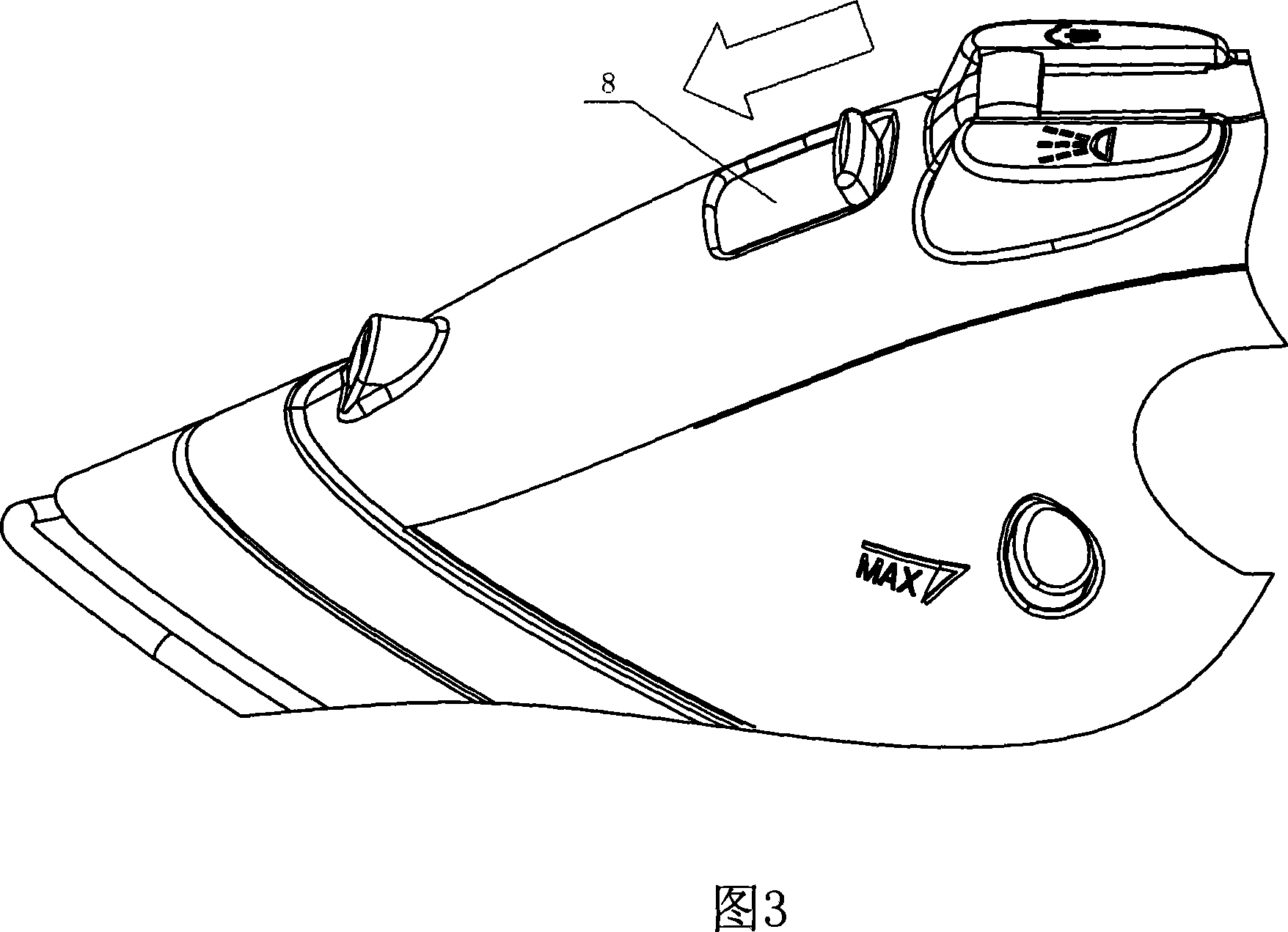

Steam electric iron

The present invention involves a steam electric iron. It includes shell, the water inlet mouth opened on the shell and connected with water tank, retaining cap installed on said water inlet mouth, and it is characterized by it is also equipped with a rotating device used for opening or closing said retaining cap. The structure changes the operating methods of pushing, pulling, carrying and pressing of retaining cap in prior steam electric iron into rotating operation. The Structure has good stability and easy operation. And also because rotational movement is delivered to water inlet mouth retaining parts through rotating device, the holding parts of rotational movement need not installed near water inlet mouth necessarily, so the water inlet mouth structure and size can be not considered but it is designed proper size and form according need causally, it has strong practicability.

Owner:严杰波

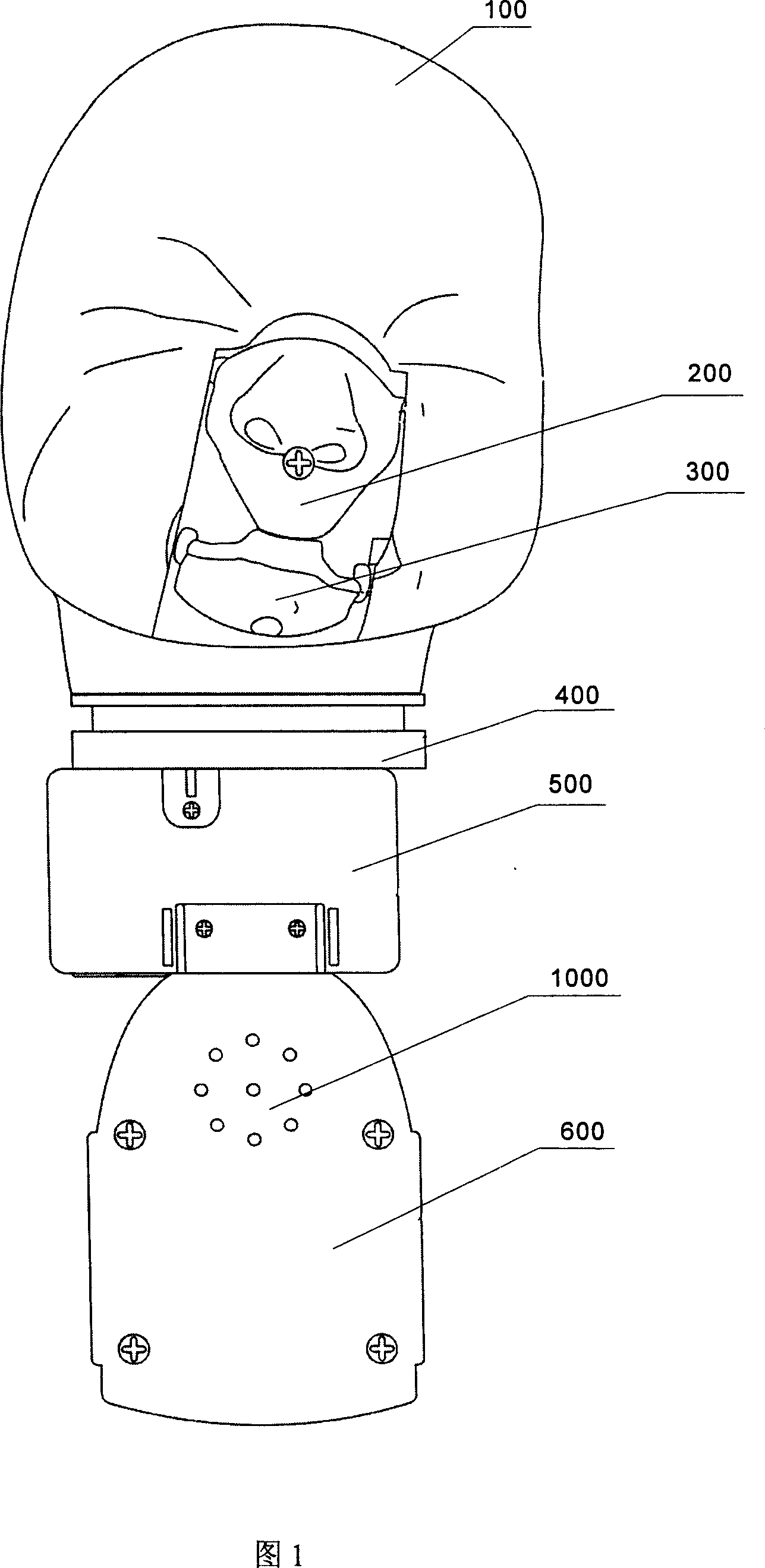

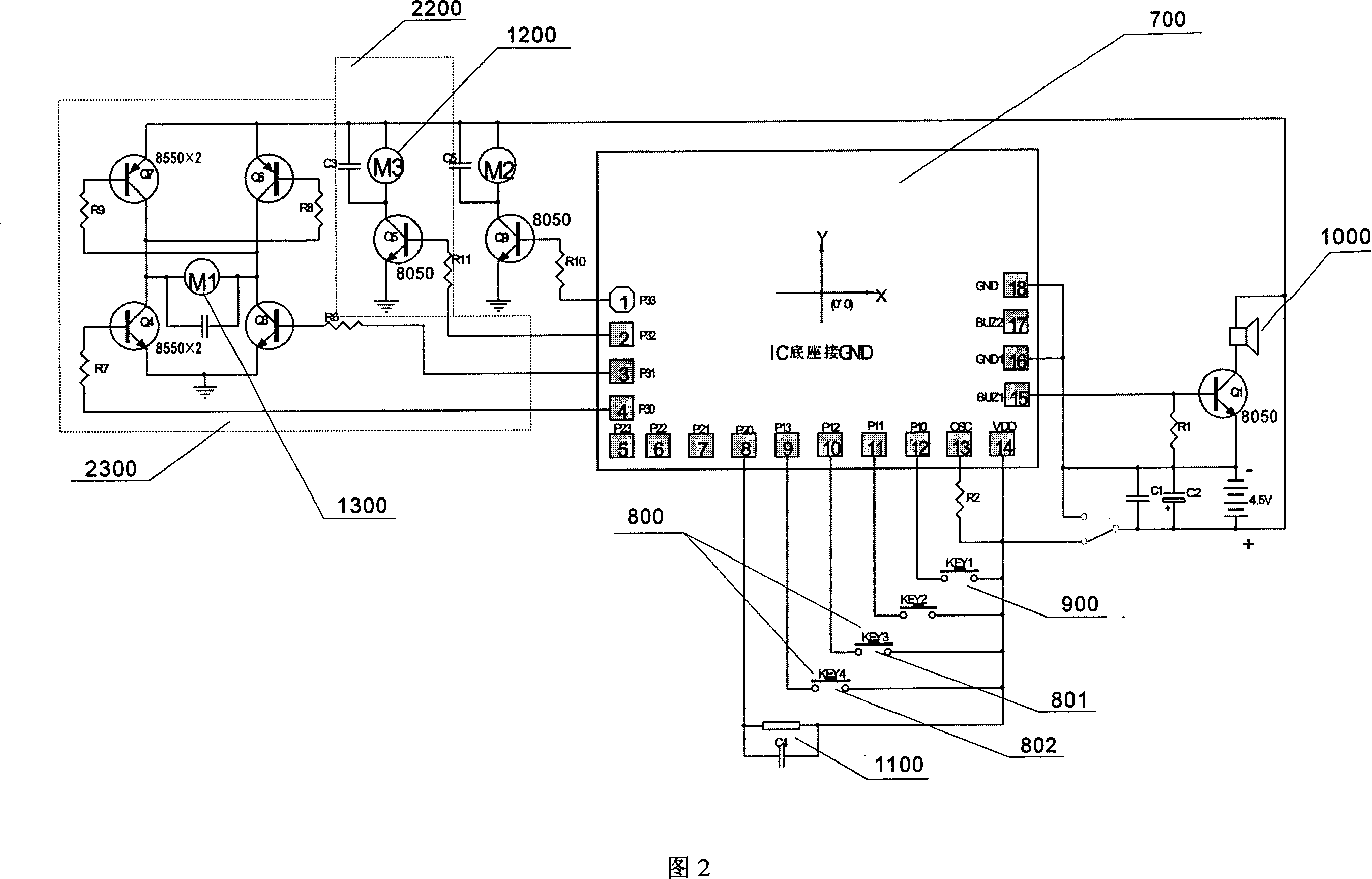

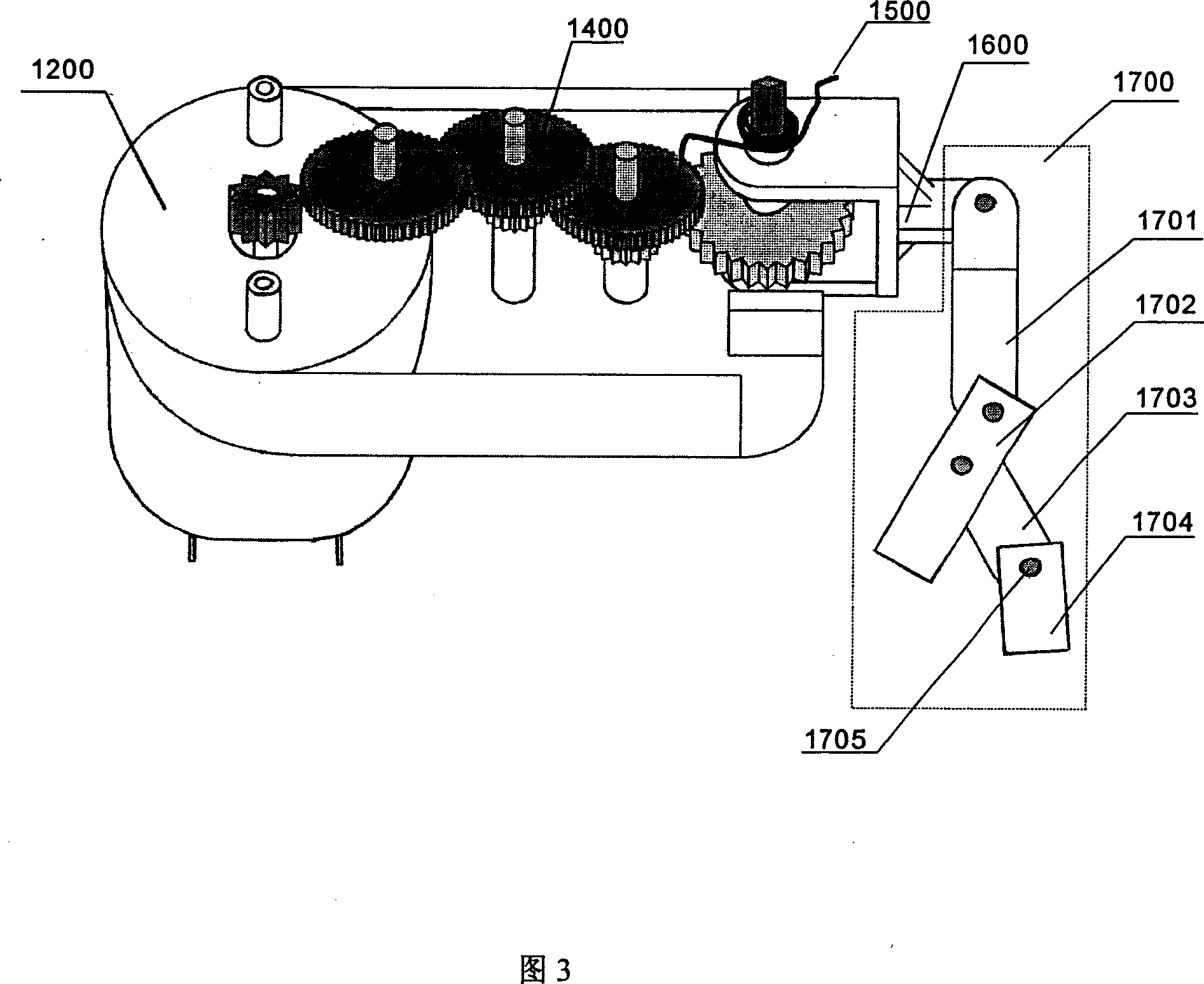

Simulating electronic doll

The simulating electronic doll can simulate crying, laugh and other actions of baby or animal and has improved mouth structure and raised simulating degree. The simulating electronic doll includes casing, circuit inside the casing, and movable parts, such as mouth, driven with the transmission mechanism. It is vivid and interesting.

Owner:陈 国梁

Container systems with lids for unit dose detergent compositions

InactiveUS20160229599A1Easy to handleSufficient sealing function against moistureLidsNon-removalbe lids/coversEngineeringMouth structure

A container system includes a tub including a front wall, a back wall opposite the front wall and side walls extending between the front wall and the back wall. A bottom extends between the front wall, back wall and side walls. A mouth structure includes a fastening feature configured for connecting to a lid. The mouth structure has an opening therethrough that provides access to a containing volume of the tub. A shoulder extends inwardly from the side walls to the mouth structure. A plurality of unitized doses of a detergent composition is located within the containing volume of the tub. A lid is connected to tub using the fastening feature. The lid has an open position for allowing user access to the containing volume and a closed position for preventing user access to the containing volume. A flexible membrane may be connected to the underside of the lid

Owner:THE PROCTER & GAMBLE COMPANY

Shoe-upper mouth structure of integrated knitted shoe upper and knitting process of shoe-upper mouth structure

PendingCN107299453AHigh tensile strengthImprove stabilityWeft knittingUpperEngineeringMouth structure

The invention relates to a shoe-upper mouth structure of an integrated knitted shoe upper. The structure includes a cylinder-shaped shoe-upper mouth body, the end, in the axial direction, of the shoe-upper mouth body is the connection end which is connected with a shoe upper body, and the other end of the shoe-upper mouth body is the free end. The structure further includes a plurality of first raised parts arranged on the inner side face of the shoe-upper mouth body, the first raised parts are arranged in a protruding mode in the axial direction of the shoe-upper mouth body, and a ventilation channels are formed between each two adjacent first raised parts. According to the shoe-upper mouth structure, ventilation channels are formed between each two adjacent first raised parts, heat in the shoe upper body can be dissipated through the ventilation channels, the ventilation effect of the integrated knitted shoe upper is improved, at the same time, the first raised parts have functions of reinforcing ribs, and the tensile strength and stability of the shoe-upper mouth can be further improved. The invention further provides a knitting process of the shoe-upper mouth structure of the integrated knitted shoe upper, by means of the knitting process of the shoe-upper mouth structure, the first raised parts and second raised parts are integrally knitted on the shoe-upper mouth body, and the processing efficiency of the integrated knitted shoe upper can be improved.

Owner:SINCETECH FUJIAN TECH CO LTD

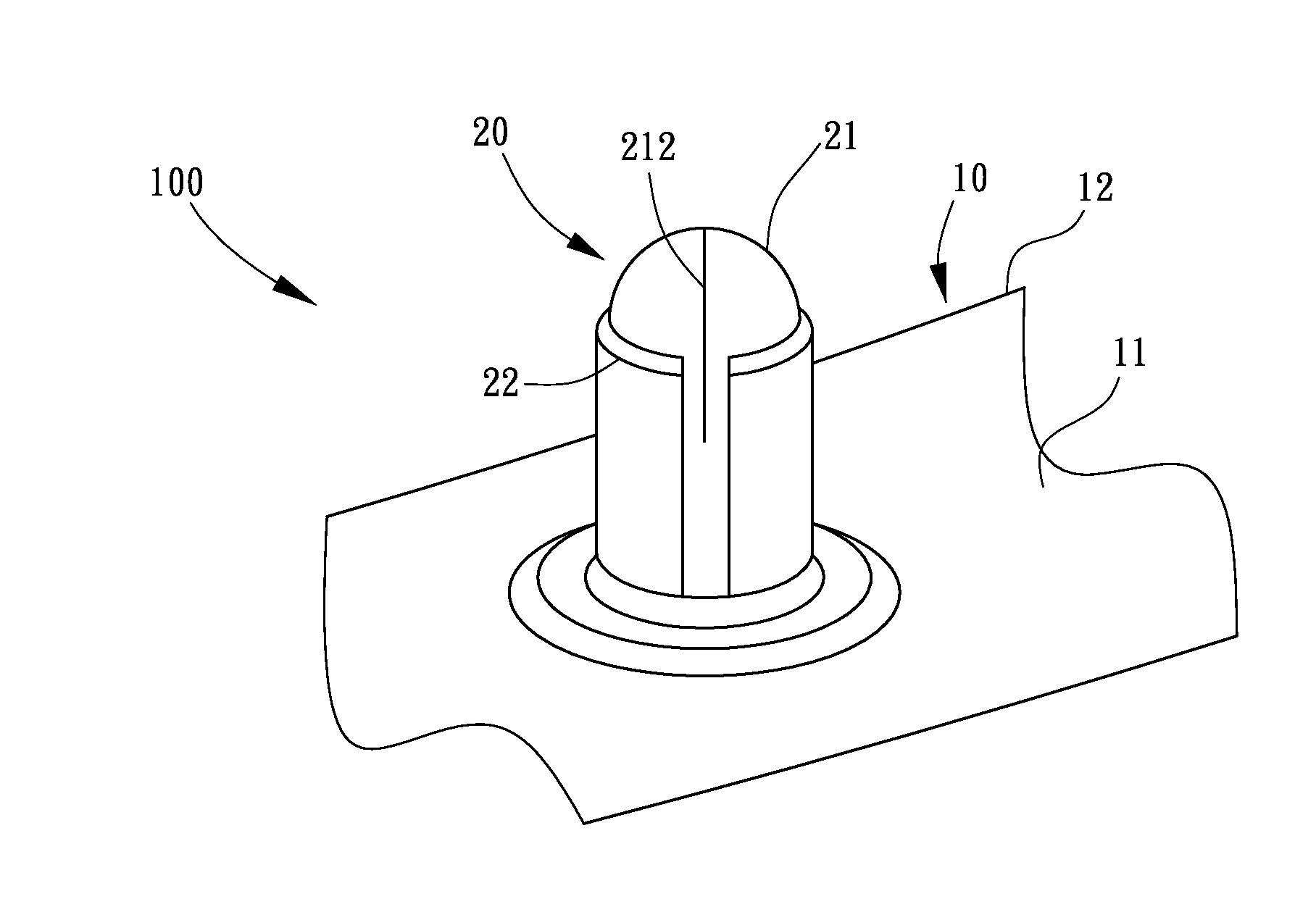

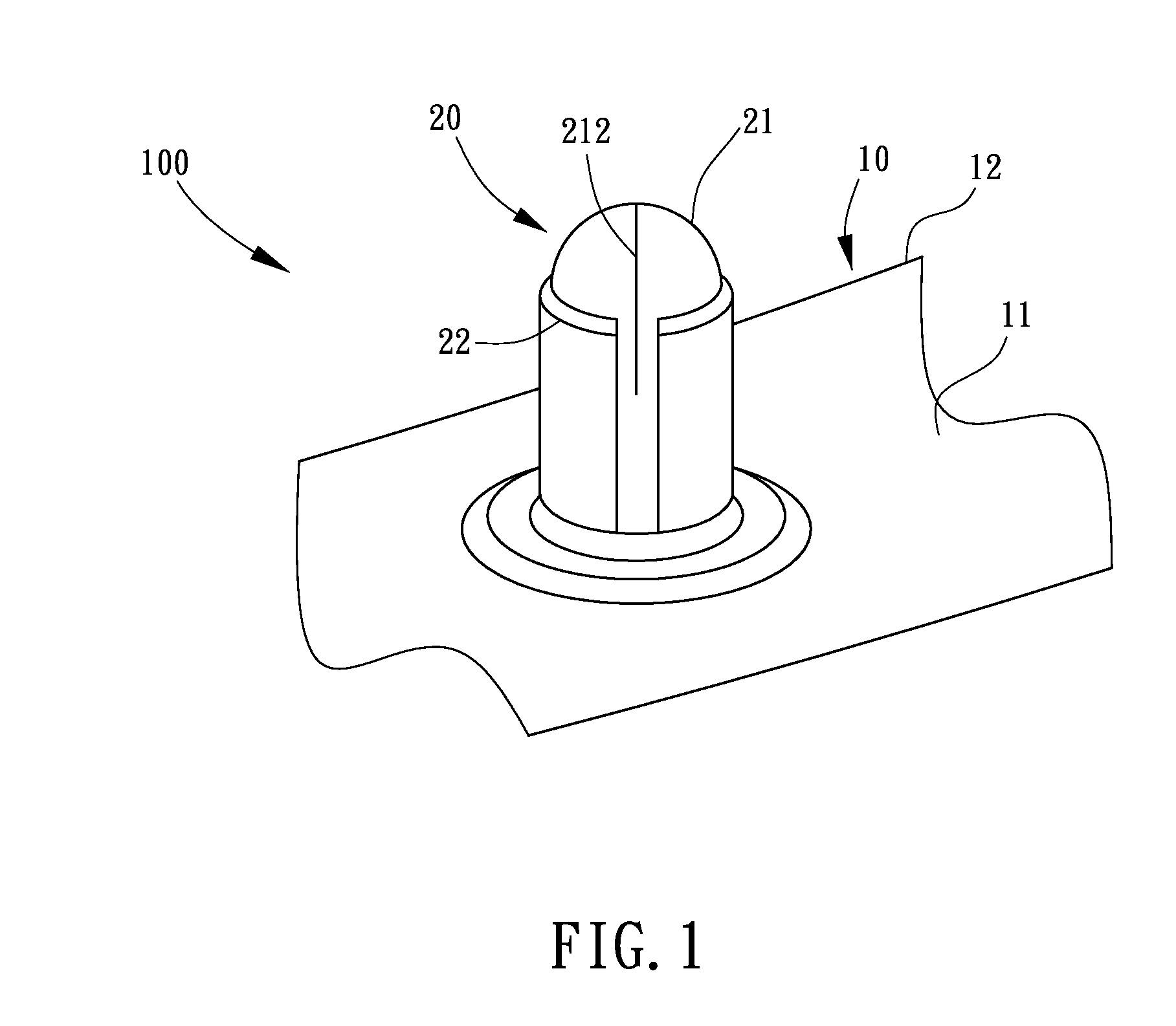

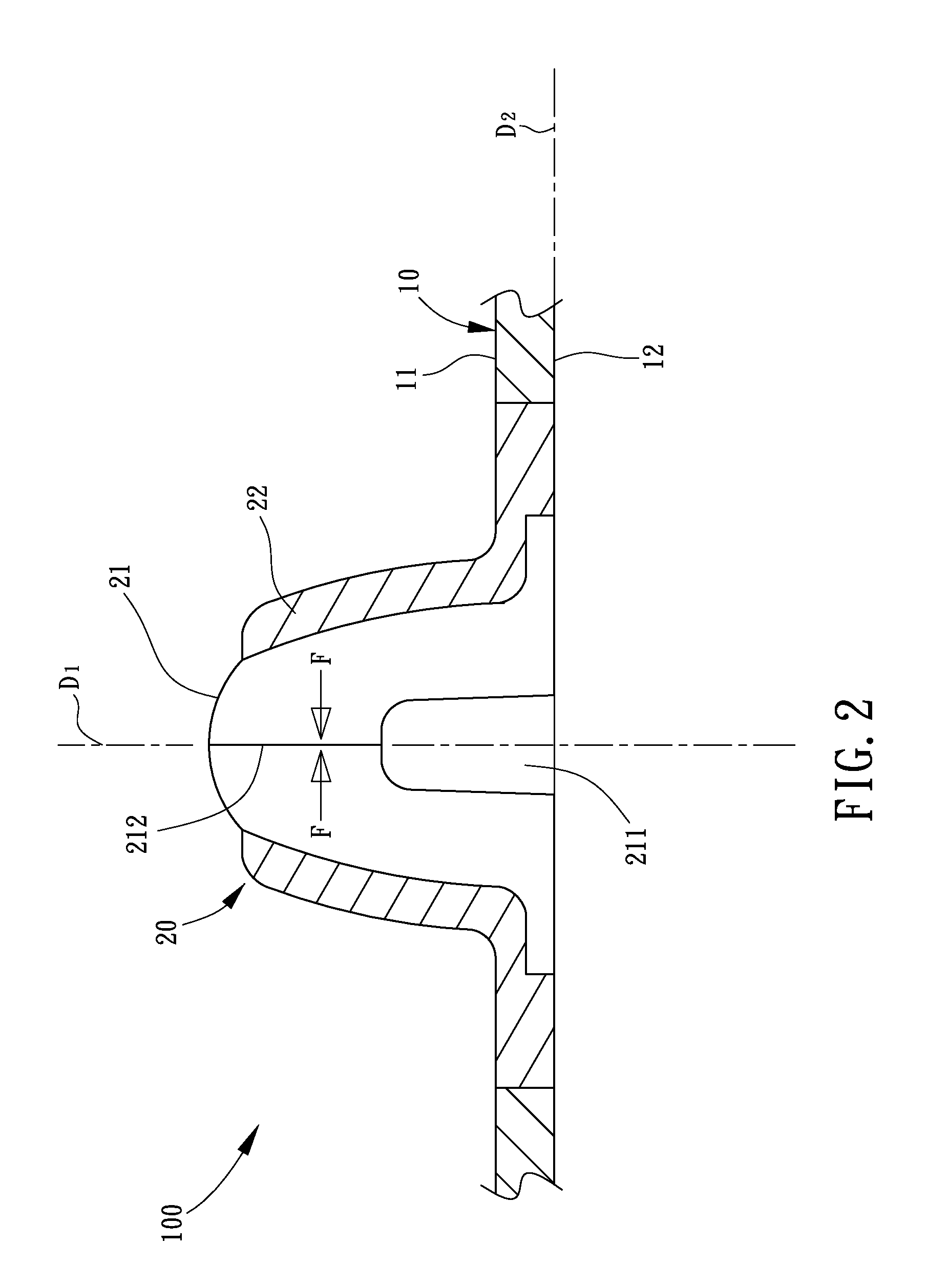

Plastic formed inflation mouth structure

InactiveUS20120085958A1Low production costImprove air tightnessCheck valvesValve housingsPlastic injection moldingEngineering

A plastic formed inflation mouth structure comprises a plastic formed body which is integrally formed with an inflation mouth by plastic injection molding. The inflation mouth includes an inflation apparatus passage and a restoration unit that are integrally formed. The inflation apparatus passage unit is formed with a notch for passage of an inflation apparatus to perform the inflation or deflation. The restoration unit applies an elastic restoration force onto the notch to make the notch assuredly enclose the inflation apparatus during the inflation and ensure a high airtightness when inflation is stopped.

Owner:YANG TENG JEN

Operational robot for minimally invasive celiac surgery

InactiveCN101721253ASmall woundShorten operation timeDiagnosticsSurgical robotsHuman bodyAbdominal cavity

The invention provides an operational robot for minimally invasive celiac surgery, which belongs to the technical field of surgical robots and comprises a casing, a rotational structure, an endoconch, a translational structure, a bionic mouth structure and an incoming line structure, wherein the endoconch is arranged inside of the casing; the rotation structure is fixedly arranged at the inner side of the casing and is contacted with the endoconch to drive the casing to rotate corresponding to the endoconch; the translation structure is fixedly arranged in the middle of the outer side of the casing; and the bionic mouth structure is fixedly arranged inside of the endoconch. Comparatively complicated operation is realized in the enterocoelia of a human body by the operational robot for minimally invasive celiac surgery in the invention, the method that the operational part bionic mouth structure of the robot is used for collecting and carting post-operation remnants from the human body is proposed by the invention in a groundbreaking manner. Compared with the traditional method that remnants are clipped out after the belly is punched, the method in the invention reduces the wound greatly, shortens the surgery time containing anesthesia, and can take out all remnants in the belly in a single operation.

Owner:SHANGHAI JIAO TONG UNIV

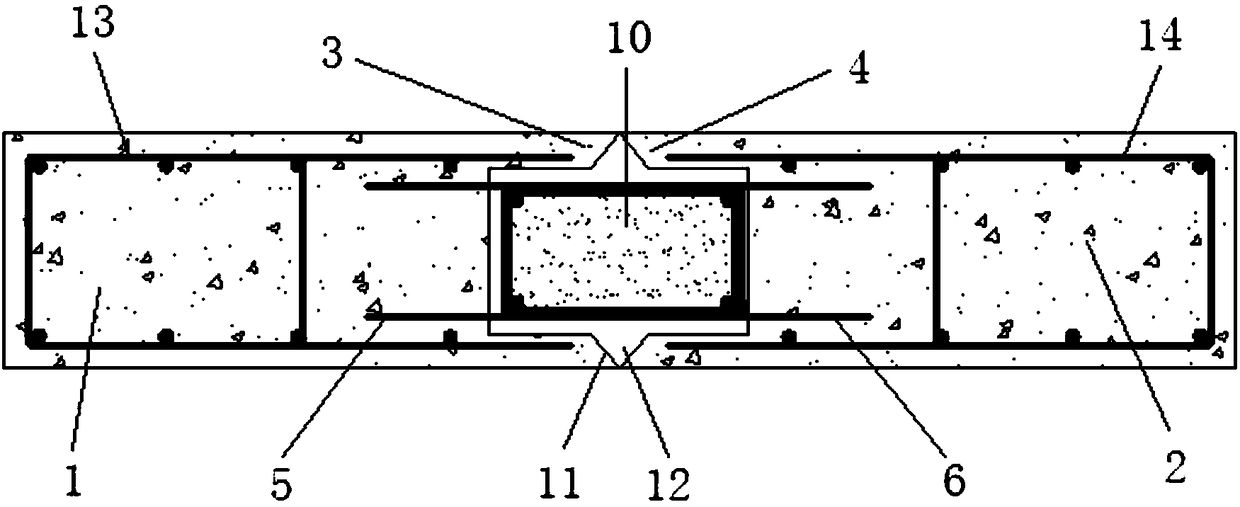

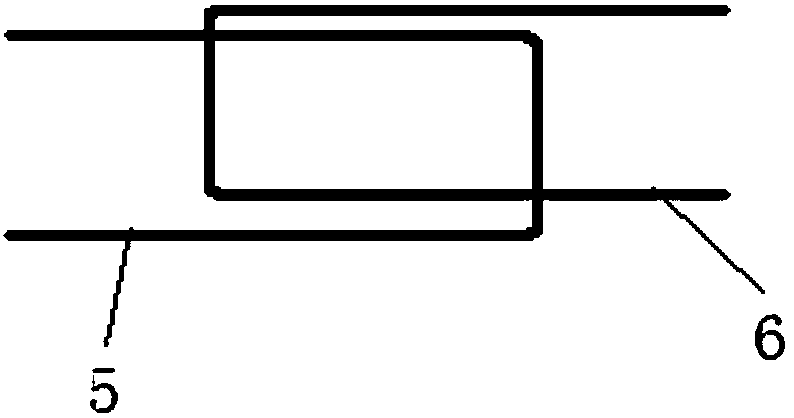

Prefabricated shear wall groove grouting anchor horizontal connection structure

The invention provides a prefabricated shear wall groove grouting anchor horizontal connection structure. The prefabricated shear wall groove grouting anchor horizontal connection structure comprisesa first shear wall and a second shear wall which are laterally arranged side by side, and a first convex plate and a second convex plate are separately disposed on the end faces, facing each other, ofthe first shear wall and the second shear wall. First U-shaped stirrups and second U-shaped stirrups are disposed in a cavity structure in a staggered mode in the vertical direction, wherein the cavity structure is formed by the first and second shear walls and the first and second convex plates in a surrounding mode. Mouth structures formed by overlapping portions of the first and second U-shaped stirrups are provided with reinforcement cages in an inserted mode, and concrete is poured in the cavity structure. Manpower is saved, on-site operation time is reduced and construction is more simple and convenient, the staggered first and second U-shaped stirrups reduce the use of steel bars, and cost is saved; the reinforcement cages inserted in the stirrups improve the shear capacity of theshear walls, the first and second U-shaped stirrups transmit force to the reinforcement cages, and the transmission force is clear, the integrity is improved, and the shear performance is good; and when an earthquake occurs, the reinforcement cages form an embedded column in the shear walls to prevent the shear walls from collapsing.

Owner:SHENYANG JIANZHU UNIVERSITY

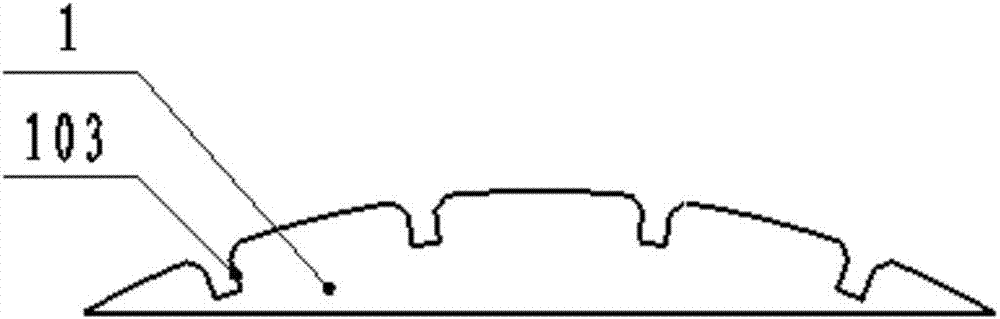

Deceleration strip with fluorescent display strips

InactiveCN103614979ANot easy to fall offAvoid breakingTraffic signalsRoad signsFluorescenceRare earth

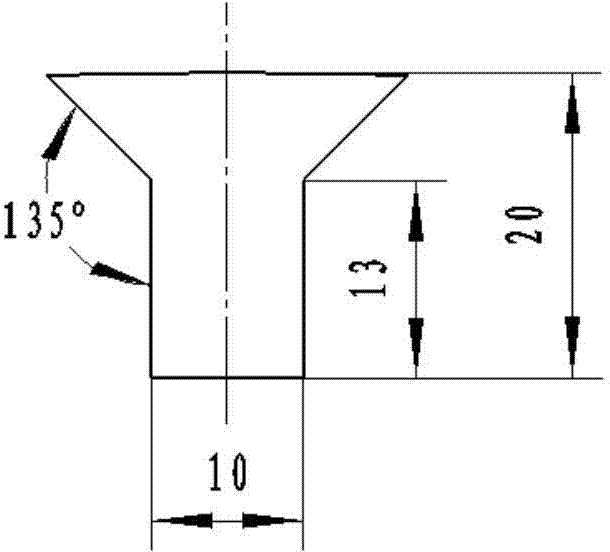

The invention discloses a deceleration strip with fluorescent display strips, and belongs to the field of public facilities. The deceleration strip is composed of a deceleration strip rubber body and the fluorescent display strips capable of being embedded in the deceleration strip rubber body. Rubber body installation holes are formed in the rubber body, the cross section is of an arc-shaped structure of a traditional rubber deceleration strip, grooves where the fluorescent display strips are installed are formed in the deceleration strip rubber body, the number of the grooves, where the fluorescent display strips are installed, in the deceleration strip rubber body is four, the grooves are symmetrically and evenly distributed with respect to the center line of the cross section of the deceleration strip cross section, the cross section of each fluorescent display strip is in a T shape, the size of the shape of the cross section of each fluorescent display strip is optimized to be 20mm in total height, 10mm in lower portion width and 13mm in lower portion height, and the upper portions of the fluorescent display strips are of horn mouth structures with 90-degree central angles. Fluorescent powder used in the fluorescent display strips are photoinduced energy-stored type rare earth aluminate type fluorescent powder. Thedeceleration strip has the advantages that thedeceleration strips installed on the deceleration lamp can emit light at night, and traffic accidents, caused by the fact that lamplight does not exist, to pedestrians by the deceleration strip are avoided.

Owner:张小轩

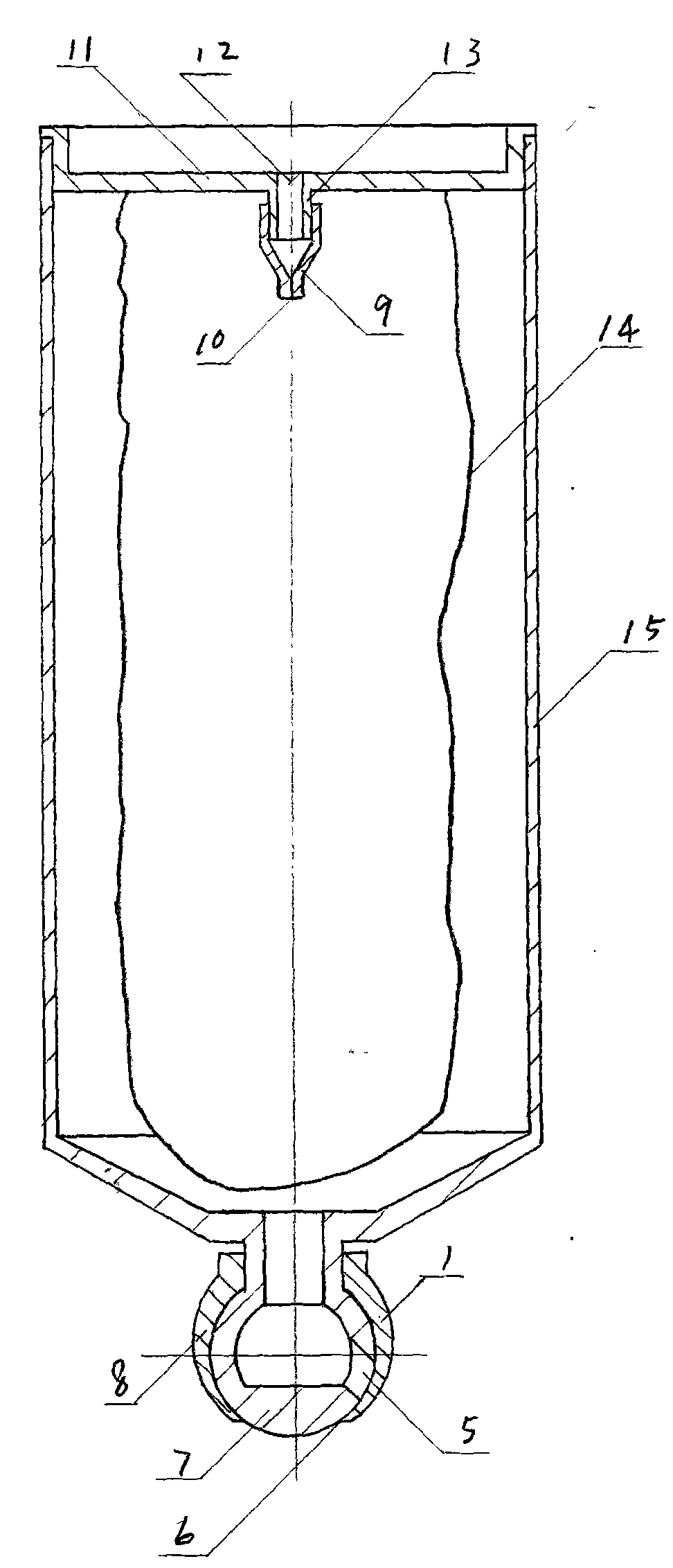

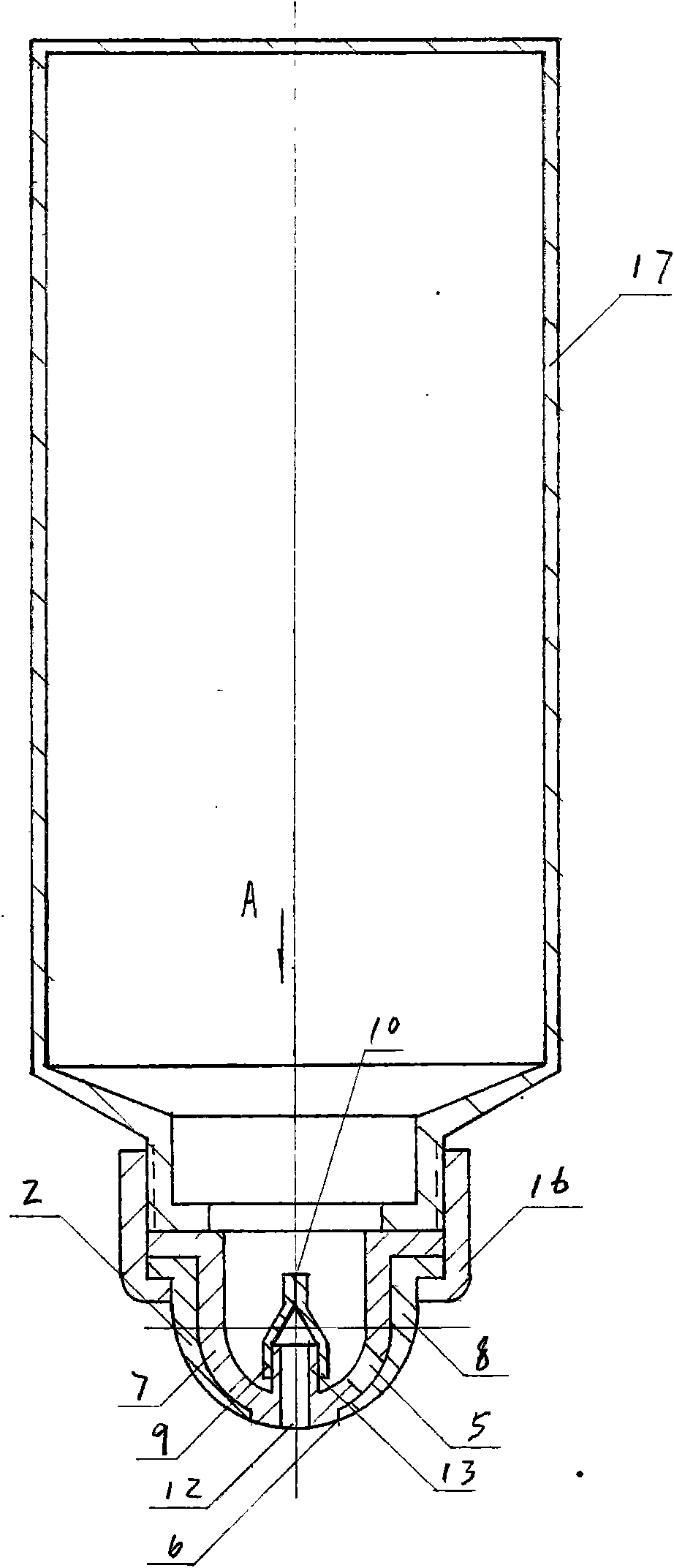

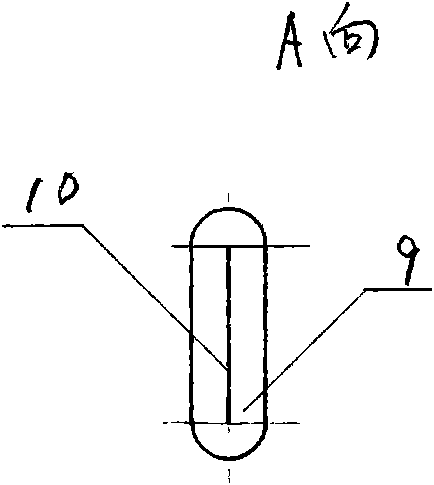

Flexible packing pipe and flexible plastic bottle

InactiveCN102233987AEasy extrusionAutomatic drip preventionDispensing apparatusRigid containersAtmospheric pressureAirbag deployment

The invention discloses a flexible packing pipe and a flexible plastic bottle which are formed by squeezing with air pressure. The tail end of the flexible packing pipe is provided with a flexible air admission structure capable of admitting air, the front end of the flexible packing pipe is provided with a bolt plug bottle mouth structure consisting of a bolt plug and a flexible lip bushing and being capable of preventing leakage; the flexible pipe and the flexible bottle are internally provided with an air sac communicated with an air intake or a partition ring transversely arranged between paste and air. According to the invention, the paste is prevented from being polluted by the air entering the flexible pipe.

Owner:彭加桂

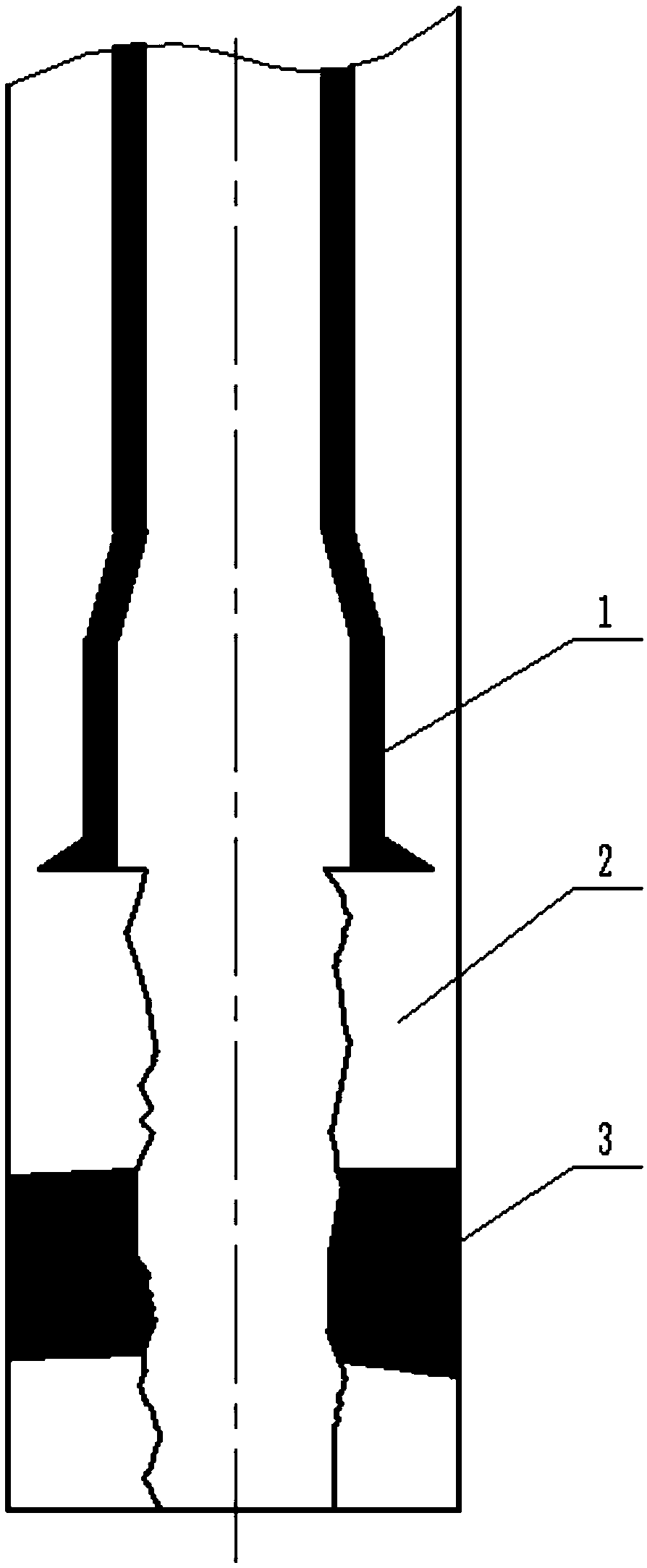

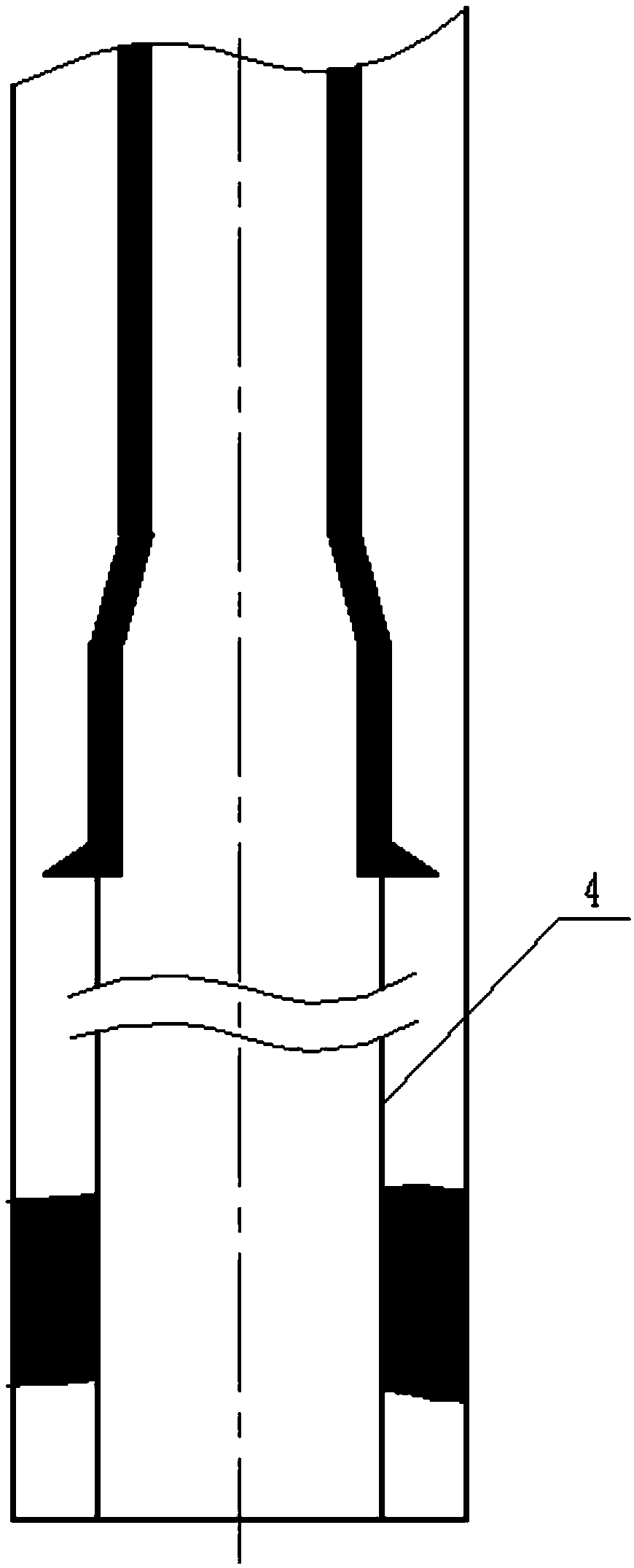

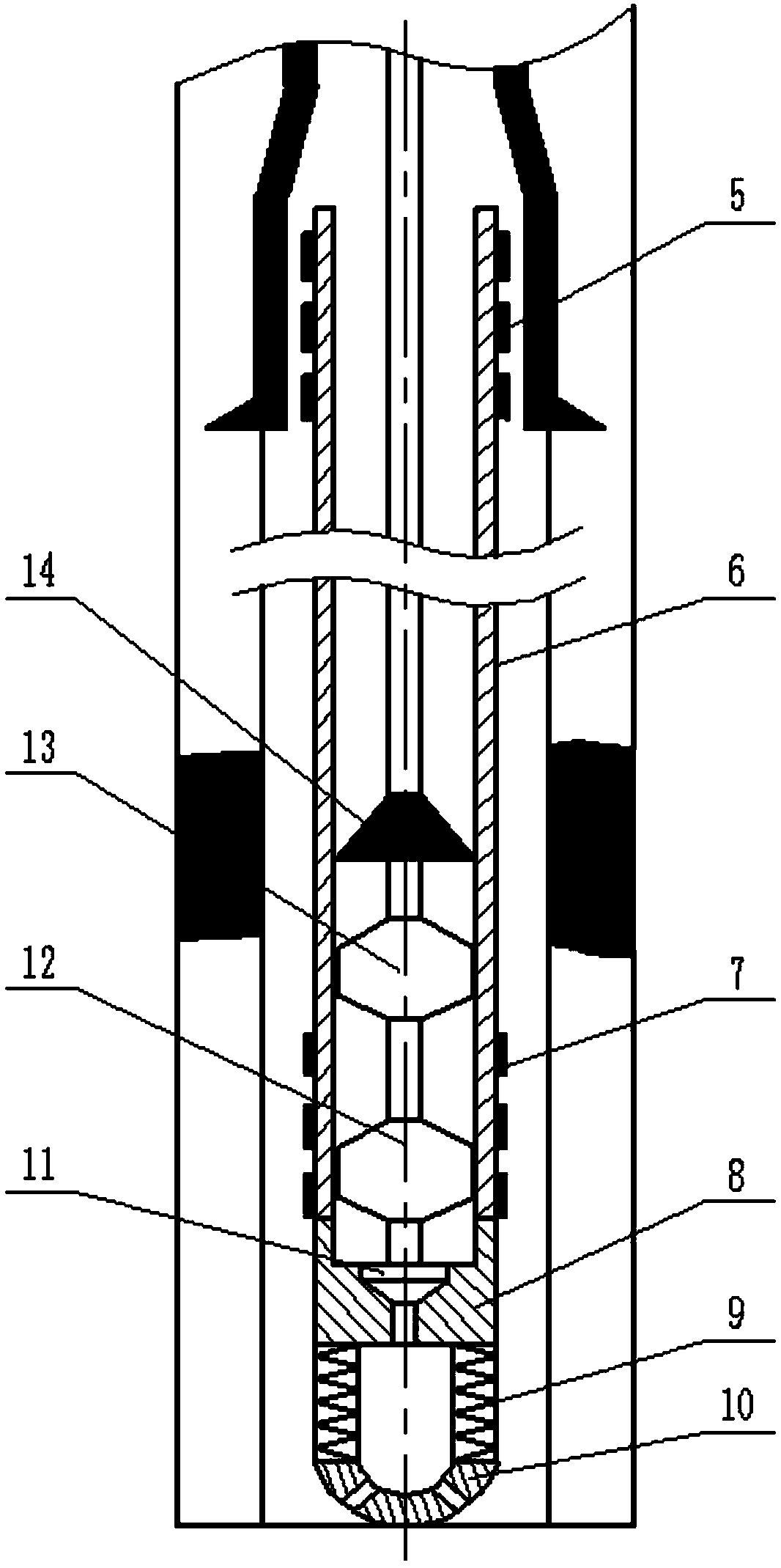

Isobaric expansion casing leakage stopping method

InactiveCN109267963ANo loss of sizeIntegrity guaranteedSealing/packingDrilling machines and methodsPressure systemWell drilling

The invention relates to the technical field of leakage stopping operation for multi-pressure-system strata and malignant leaking strata, in particular to an isobaric expansion casing leakage stoppingmethod. The method comprises the following steps that 1, when an upper-layer casing body is put down into a designed position, casing shoes of a horn-mouth structure follow the upper-layer casing body to be put down into the design position in advance, and after well cementation is conducted according to construction design, a lower drill drills the casing shoes to form a first lap-joint horn mouth, wherein the inner diameter of the horn-mouth structure of the lower ends of the casing shoes is larger than the inner diameter of the upper-layer casing body; 2, after a complex stratum has well leaking during drilling, a reaming tool is put down into a well for fixed-diameter reaming on a to-be-drilled section. According to the method, the borehole size is not damaged, the well depth structure is not changed, the integrity of a well shaft is guaranteed, the leaking risk is avoided, the drilling speed is effectively increased, and the drilling period is shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

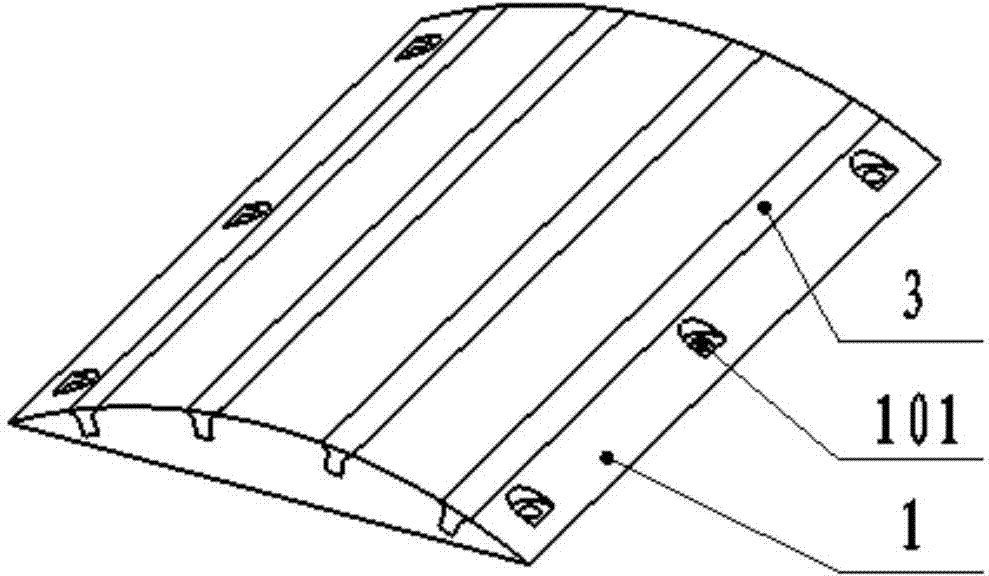

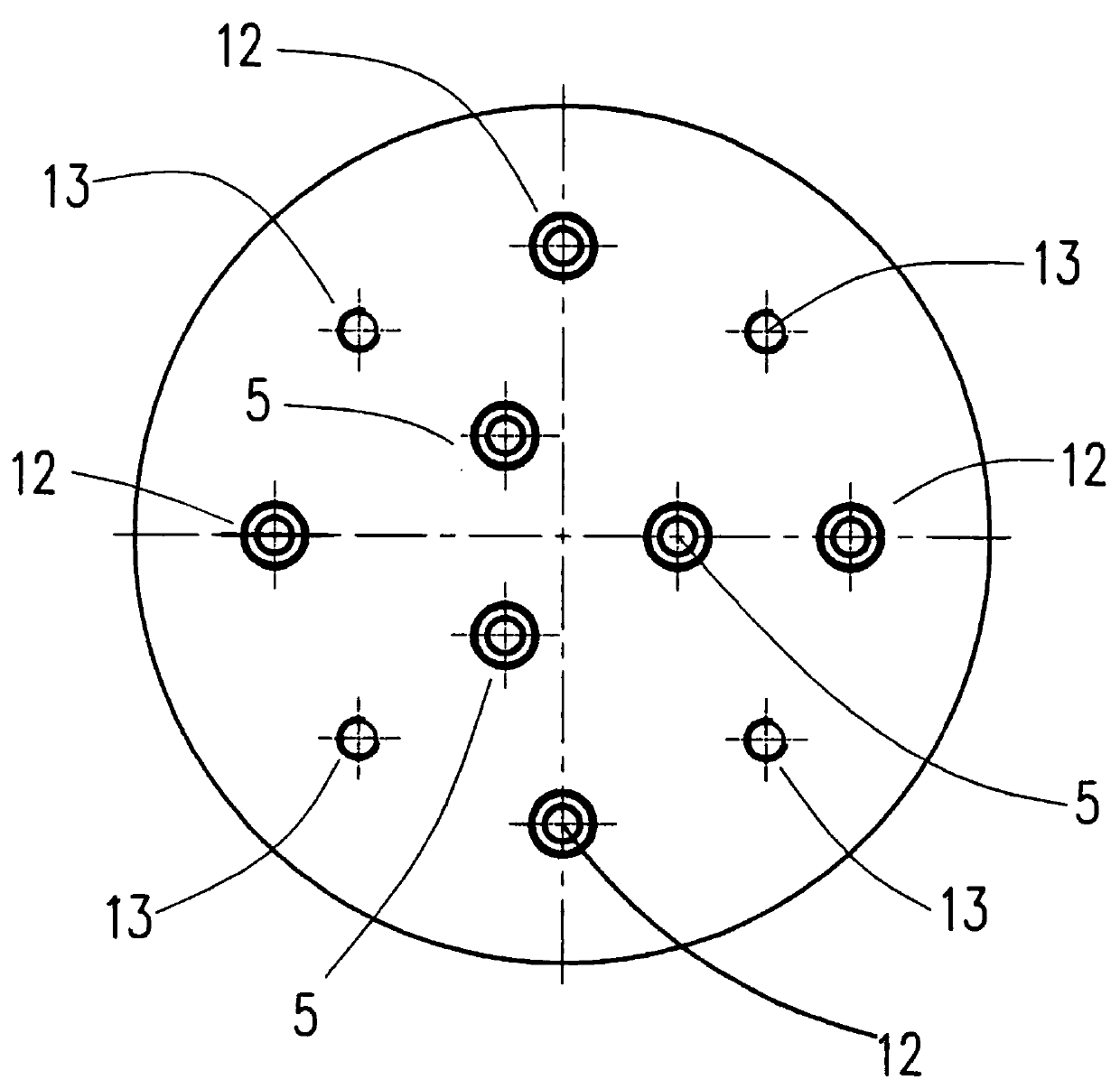

Molding die of resin-based composite radome

The invention relates to a molding die of a resin-based composite radome. The molding die comprises a male die, a female die, a bottom plate and a demolding ring; an inner circle edge opening of the demolding ring is matched with an outer circle edge opening of the male die in shape and size; the lower end of the female die is provided with a positioning ring piece, the upper end surface of the demolding ring is provided with a ring-shaped groove seat matched with the positioning ring piece in shape and size, and the female die can be clamped into the ring-shaped groove seat through the positioning ring piece; and the positioning ring piece is provided with a first demolding screw matched with a first demolding screw hole, the bottom plate is provided with a second demolding screw matched with a second demolding screw hole, the inner circle edge opening is a stepped hole, the stepped hole includes an upper hole opening and a lower hole opening, and the upper hole opening is of a horn mouth structure small in top and larger in bottom. The molding die has the following advantages that 1, the structure is simple, and demolding operation is convenient and quick; 2, a stress part of the demoulding process is designed reasonably, and protection of a main body part of a radome product is facilitated; 3, and the product yield rate is above 98%.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com