Isobaric expansion casing leakage stopping method

A technology of expanding casing and plugging method, applied in drilling equipment and methods, drilling equipment, earth-moving drilling, etc., can solve the problems of leakage and inability to ensure the integrity of the wellbore, so as to improve the drilling speed, avoid the risk of leakage, Effectiveness without loss of wellbore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A method for leak plugging with an expansion casing of equal diameter, the steps of the method are as follows:

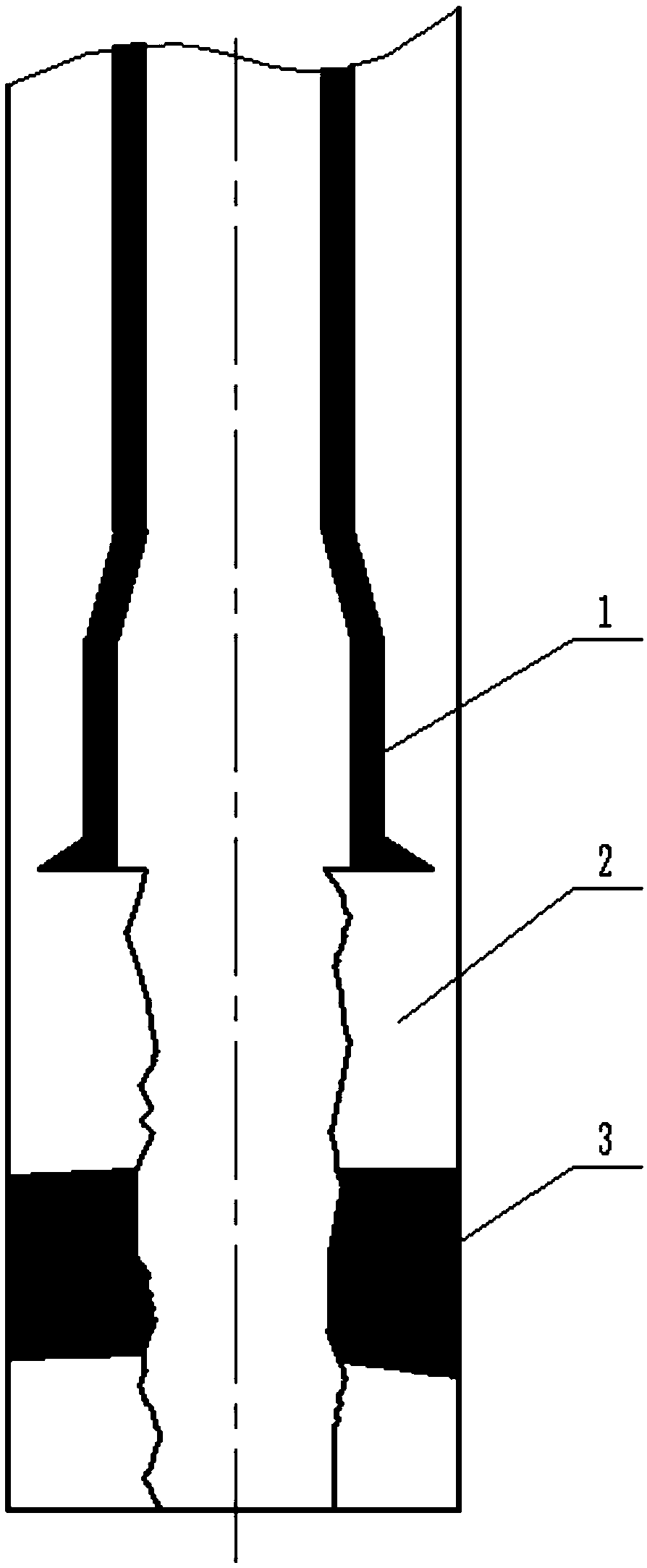

[0031] 1. When lowering the upper casing, the casing shoe with bell-mouth structure is lowered to the design position along with the upper casing in advance. The inner diameter of the bell-mouth structure at the lower end of the casing shoe is larger than the inner diameter of the upper casing. After the well, the drill bit is drilled through the casing shoe to form the overlapping bell mouth I1, such as figure 1 shown;

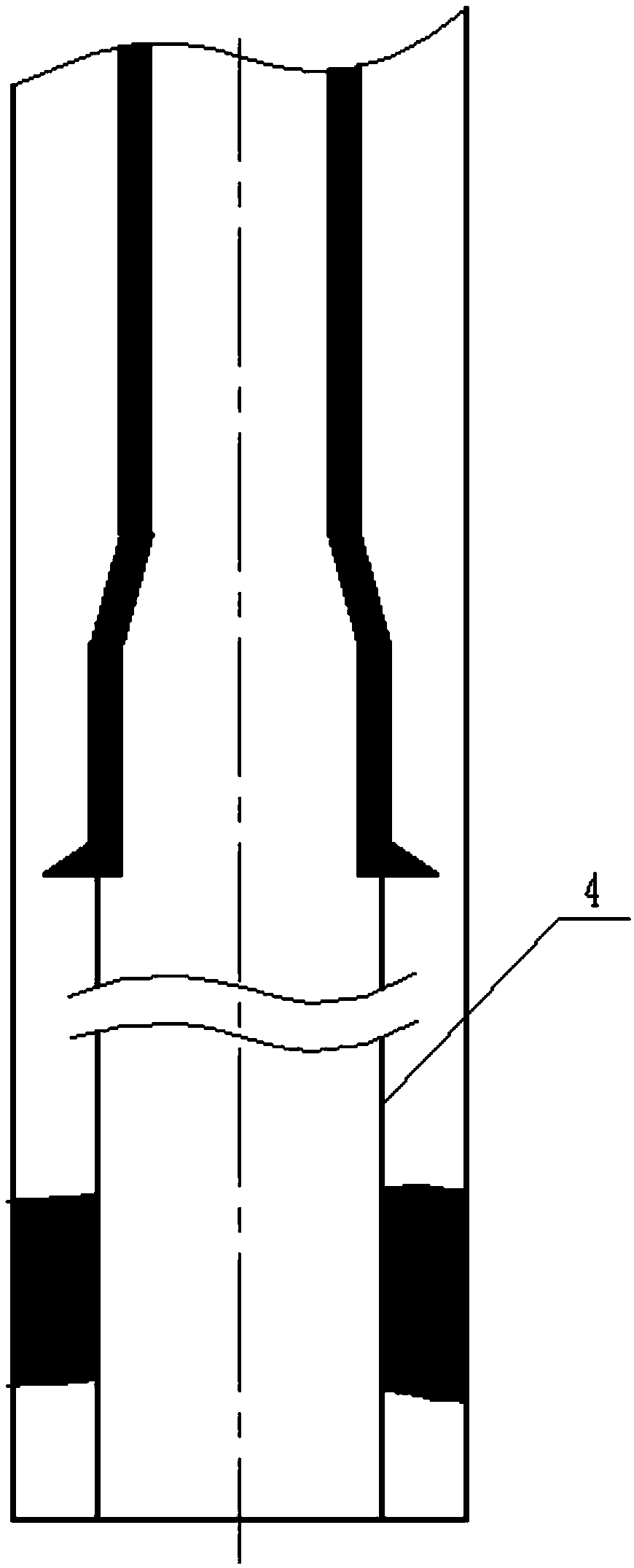

[0032] 2. After lost circulation occurs when drilling in complex formations, run the reaming tool to perform sizing and reaming on the unreamed formation 2 in the drilled section, such as figure 2 shown;

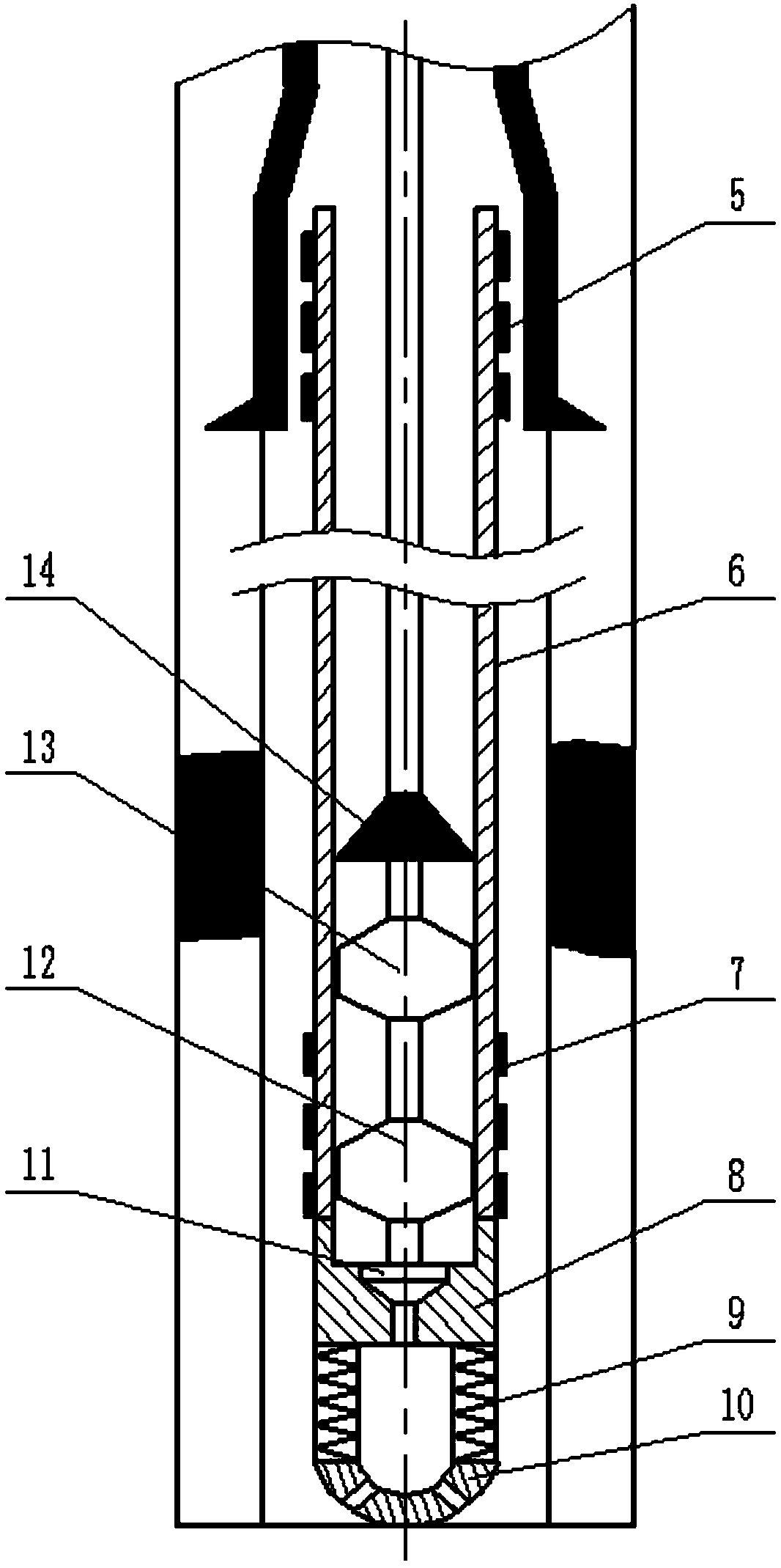

[0033] 3. Run the expansion casing of the outer string and the expansion tool of the inner string, and send them to the bottom of the open hole section, such as image 3 shown;

[0034] The expansion casing of the outer pipe string in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com