Three-dimensional modeling method of side-pushing structure

A 3D modeling and 3D model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of long assembly time, difficult deployment, poor aesthetic effect, etc., to ensure performance and aesthetics, reduce Production cost, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

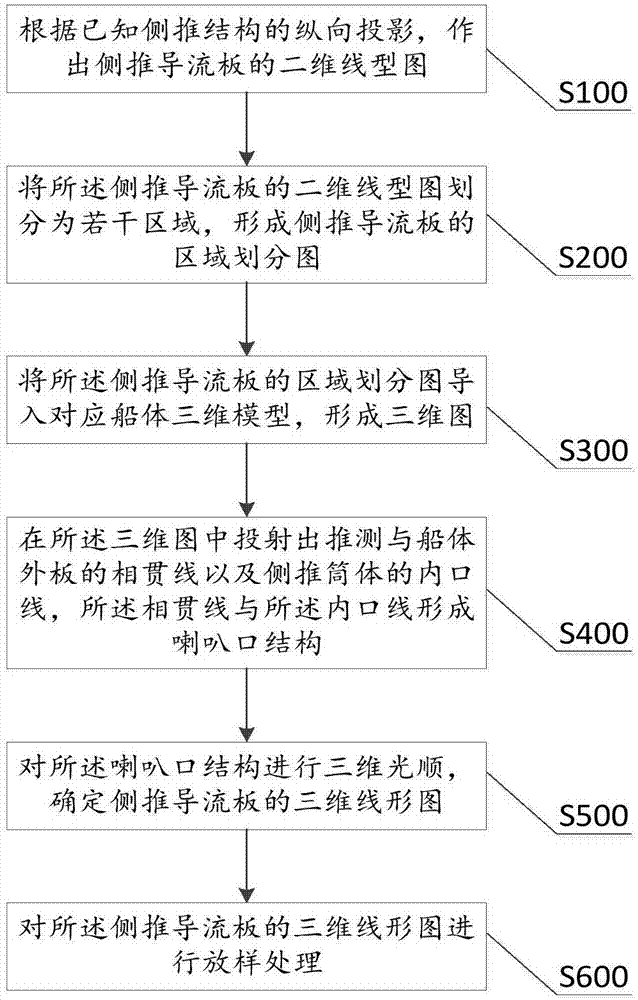

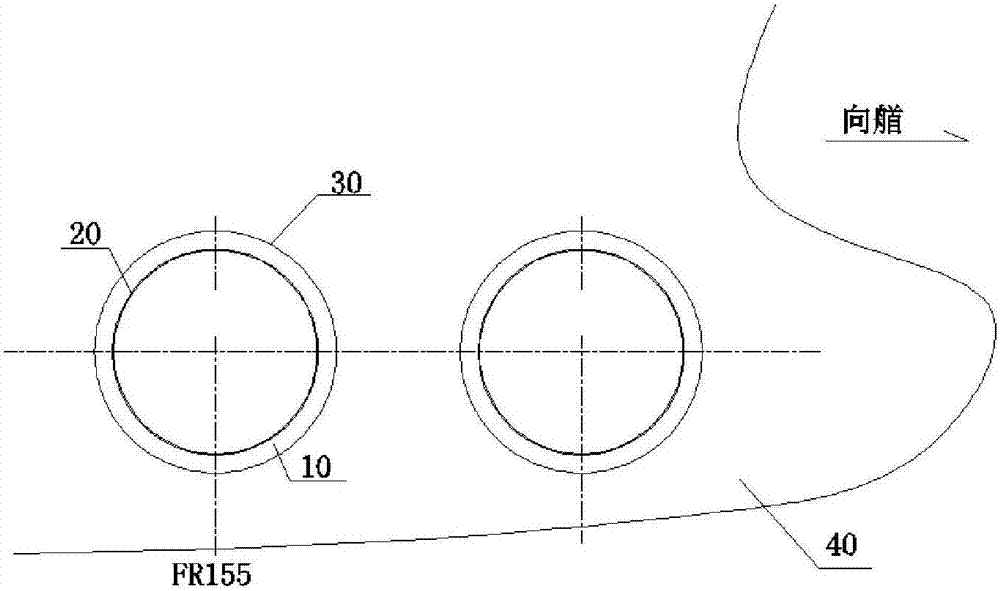

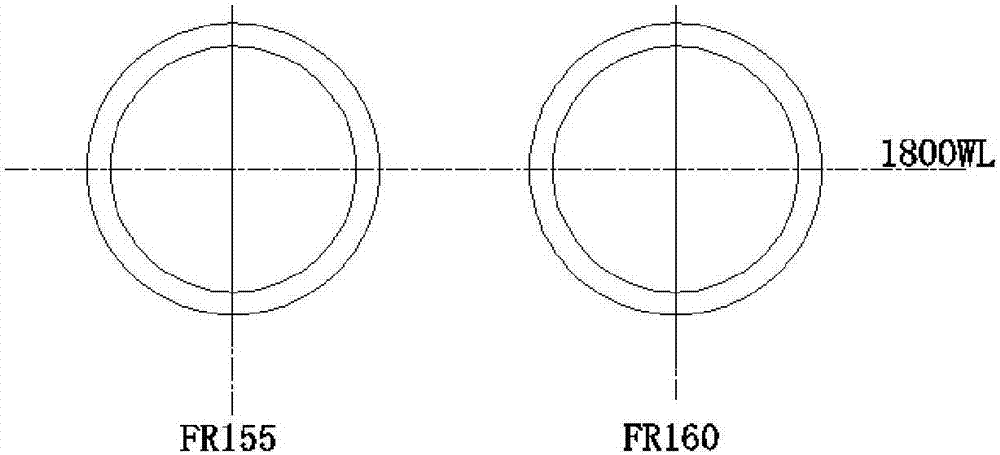

[0030] Such as figure 2 Shown is the design requirement diagram of the hull side thrust structure, which is represented by figure 2 It can be seen that the transition between the side thruster structure and the outer plate of the hull is an irregular curved surface, and those skilled in the art call the transition surface formed by the side thruster structure and the outer plate of the hull a side thruster deflector 10 . For the processing and manufacturing of the side thrust deflector 10 , it is necessary to carry out lofting and unfolding for dimension measurement. At present, the lofting and unfolding of the side thrust deflector 10 mainly relies on traditional manua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com