Split type high-voltage cable connector protection explosion-proof fire-extinguishing box

A technology of high-voltage cables and cable joints, which is applied in the direction of cable joints, etc., can solve the problems of moisture on the surface of the cable head, decline in insulation performance, and aging of insulation materials, and achieve the effects of long aging resistance, strong corrosion resistance, and good anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

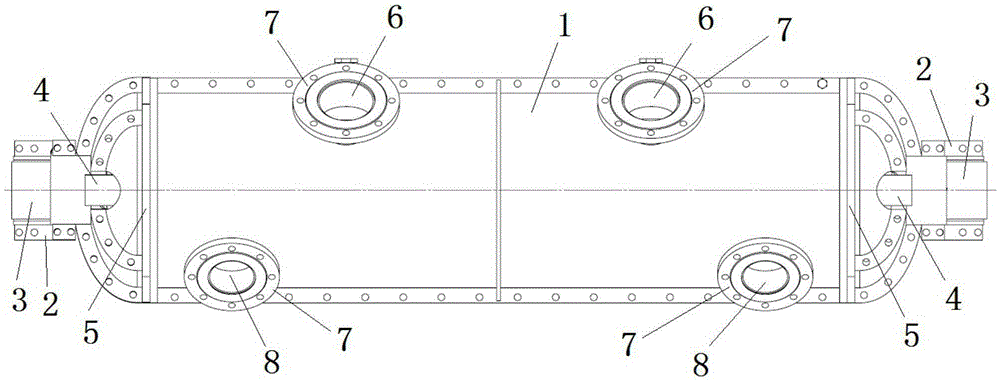

[0016] Such as figure 1 As shown, the present invention provides a split-type high-voltage cable joint protection explosion-proof fire extinguishing box, which includes a shell body 1, and the middle part of the shell body 1 is composed of two semi-cylindrical shells to form a split structure, and each half-cylindrical shell is made of stainless steel once. Sexually rolled. The two ends of the shell body 1 adopt a gradual constriction structure, and a small column 2 is formed at the constriction. An integrally formed groove-type waterproof seal is installed inside the constriction. The seal is made of high-quality silicone rubber material. To ensure the sealing performance; the small cylinders 2 at both ends are respectively provided with a main cable installation port 3 and a grounding cable installation port 4, the diameter of the main cable instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com