Patents

Literature

150results about How to "Elastic foot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

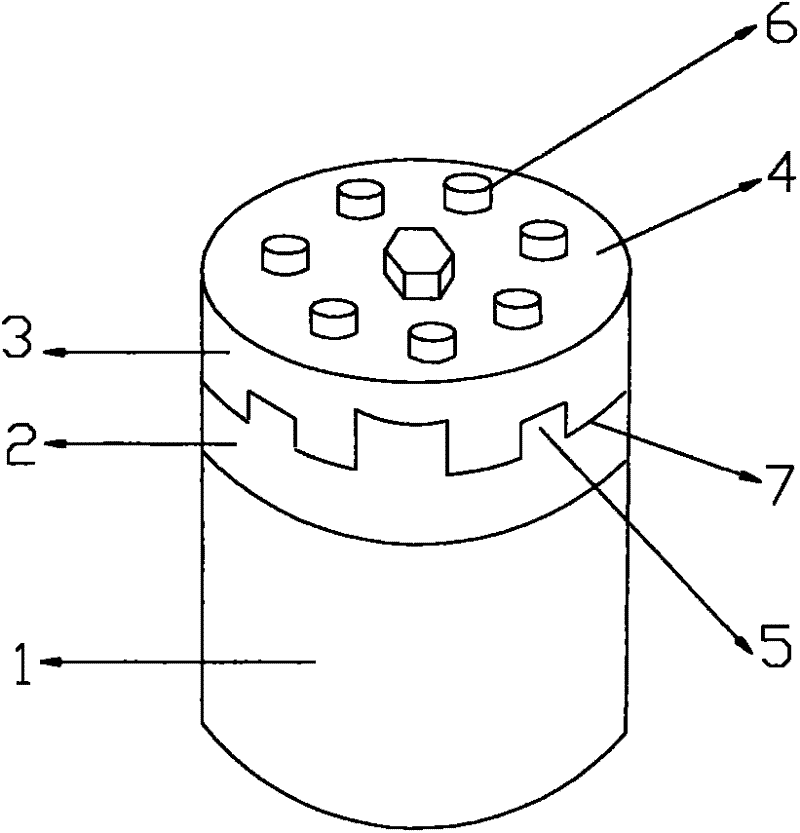

Pitted-surface metal and rubber composite conductive particle

The invention provides a pitted-surface metal and rubber composite conductive particle, which is formed by adhering a metal surface layer to a rubber basic body or slitting after adhesion, wherein the metal surface layer is a pitted surface and has pits or bumps or both the pits and the bumps; the pits or the bumps are formed on an external surface of the metal surface layer or an internal surface or both the external surface and the internal surface; the depths of the pits are smaller than the thickness of the metal surface layer; the heights of the bumps are greater than or equal to one tenth of the thickness of the metal surface layer; the metal surface layer is made of metal or alloy; gold, silver, copper or nickel can be coated on the external surface of the metal surface layer; the rubber basic body is made of silicon rubber or polyurethane rubber; an adhesion layer can be arranged between the metal surface layer and the rubber basic body; the adhesion layer is made of a heat vulcanization adhesive, a prime coating agent or a material which is the same as that of the rubber basic body; and aids such as a coupling agent can be coated on the internal surface of the metal surface layer. The metal surface layer is high in strength, stable in conductivity, high in strength of the adhesion layer and high in elasticity of the rubber basic body; and the pitted-surface metal and rubber composite conductive particles can serve as conductive parts of various kinds of keys of a mobile phone, an automobile and the like, and the cost can be controlled.

Owner:NANTONG MEMTECH TECH

Medicated diet sea cucumber can and processing method of medicated diet sea cucumber can

InactiveCN104000233AFull of nutritionExtended shelf lifeNatural extract food ingredientsMeat/fish preservation using chemicalsMonosodium glutamateFlavor

The invention relates to a medicated diet sea cucumber can and a processing method of the medicated diet sea cucumber can. The processing method comprises the steps of cooking sea cucumber, cooling, cutting off sea cucumber tendons of the sea cucumber or sea cucumber pieces, and soaking the sea cucumber or sea cucumber pieces at low temperature; desalting by soaking to obtain kelp pieces; adding the sea cucumber or the sea cucumber pieces, the kelp pieces, traditional Chinese medicine extracting solution prepared by taking radix astragali, angelica sinensis, Chinese yam, barbary wolfberry fruit, grape seeds, fructus amomi, poria cocos, prepared rehmannia root and radix paeoniae alba as raw materials, and seasoning liquid prepared by taking table salt, sugar, monosodium glutamate, ginger, green onion, cooking wine and water as raw materials into a can, exhausting, sealing, sterilizing and cooling to obtain the medicated diet sea cucumber can; the medicated diet sea cucumber can comprises the following components by weight percent: 40-50% of sea cucumber or sea cucumber pieces, 5-15% of kelp pieces, 5-15% of traditional Chinese medicine extracting solution and 30-40% of seasoning liquid. The medicated diet sea cucumber can is unique in flavor, delicious in taste, rich in nutrition, tender and elastic in mouth feel and chewable, and has the nourishing and health care effects of tonifying qi, nourishing blood, enhancing immunity, resisting fatigue, etc. According to the preparation method, the technology is reasonable and the operation is simple.

Owner:RONGCHENG CITY HAOJIAHAO AQUATIC FOOD CO LTD

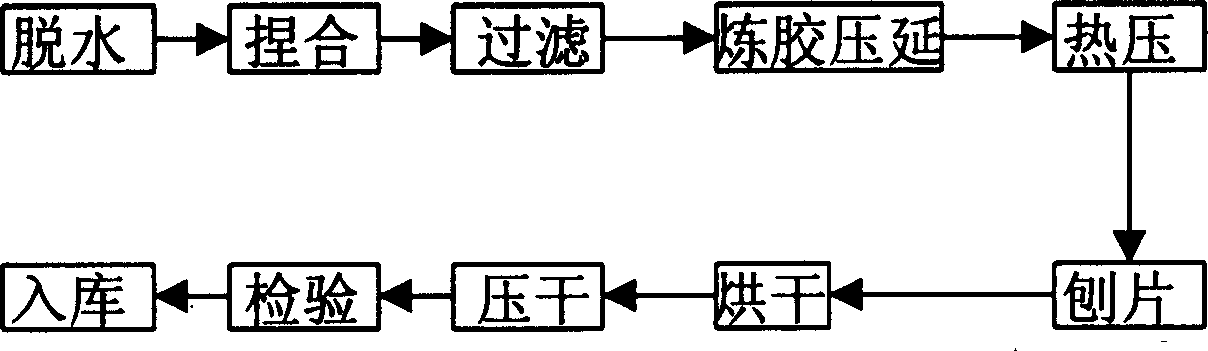

Cellutloid sheet material for producing ping-pong ball

The celluloid sheet is produced with dewatered nitrified cellulose as main material and through adding acetone and alcohol as solvent, zinc oxide as stuffing, camphor as plasticizer, ethyl acetate astoughener, pigment and other assistant, heating and kneading, filtering, mixing, rolling, shaving, stoving, drying and flattening. Replacing traditional titania white powder with zinc oxide powder as stuffing makes the table tennis produced with the sheet possess high strength, high toughness, stable gravity center, high elasticity and good table tennis feeling.

Owner:江阴华士道勃尔体育用品有限公司

Convenient additive-free five-cereal nutritional noodles and processing method thereof

ActiveCN104256361AElastic footIncrease elasticityFood ingredient functionsFood preparationNutritive valuesQuality optimization

The invention relates to convenient additive-free five-cereal nutritional noodles and a processing method thereof, and belongs to the field of food processing. The processing method comprises the following steps: performing quality optimization treatment on corns and black beans, grinding together with wheat, polished round-grained rice and yellow millets, blending, and performing curing forming to obtain the convenient five-cereal nutritional noodles. The obtained five-cereal nutritional noodles give full play to complementary nutrition advantages of rice, flour and beans, are endowed with relatively high nutritional value, are good in elasticity, toughness and reconstitution properties, do not need to be digested, can be eaten after being soaked with boiling water, and are convenient and quick; the process conditions are mild, no chemical and biosynthetic technologies are adopted, no pollution, waste residue, waste steam, waste water or harmful substance is generated, green production is realized, no gluten fortifier, thickening colloid, enzyme preparation or preservative is added, and no chemical reagent is used, so that the noodles are safe to eat.

Owner:吉林省正源食品有限责任公司

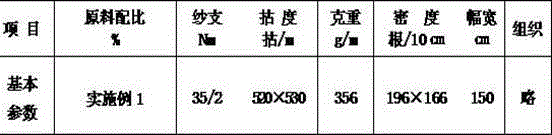

Production technology for T/R/H multielement functional fiber high textual quality yarn

The invention discloses a production technology for T / R / H multielement functional fiber high textual quality yarn. Heterotype cross-section Dacron, functional modified mucilage glue and Han jute fiber are selected as the raw materials or microporous modified dacron, functional modified mucilage glue and Han jute fiber are selected as the raw materials; the raw materials are prepared into clean, neat, puffy, soft, parallel and straight short fiber strands after going through opening and scutching, carding and edulcoration, combing and setting; then drawing decrement is carried out on the Heterotype cross-section dacron short fiber strands or microporous dacron short fiber strands; afterwards the drawing hybrid yarn principle is employed to enable the short fiber strands to be drawn with the functional modified mucilage glue and Han jute fiber; repeated drawing and gilling are performed to realize uniform blending of 3 functional fibers; the fiber strands after being blended and carded is processed into single yarn or plied yarn finished product yarn after going through processes of roving, spun yearn, spooling, doubling and wire twisting.The product of the invention features excellent conformality, bacterial resistance and moisture absorption and perspiration property, thus being an ideal new material of bionic function yarn.

Owner:SHAOXING UNIVERSITY

Method for processing hot-stewed airing rabbit

InactiveCN102429250AChange the processing technologySuitable for mass productionFood preparationFermentationChemistry

The invention relates to a method for processing a hot-stewed airing rabbit. The method comprises the following steps of: inoculating auxiliary materials to an integral rabbit which is cooled and subjected to acid discharge, rolling and kneading under vacuum, salting and fermenting at low temperature, hanging, airing and fermenting in the shade, performing halogen cooking, drying, finishing, packaging, sterilizing, keeping temperature and inspecting, wherein the auxiliary materials consist of the following components in part by weight: 3 to 5 parts of fermentation agents, 3 to 4 parts of halogen materials and 4 to 5 parts of flavorings. In the method, the convention salting process is changed by utilizing a vacuum rolling and kneading technology, and the fermentation agents such as a probiotics growth promoter, a proenzyme activator and the like are added by utilizing a microbial fermentation technology; the integral rabbit is fermented twice and is flavored and subjected to the halogen cooking, a modernization processing process and the conventional sauce halogen process are combined, the conventional process for processing airing products is changed, the production period of the products is shortened, the integral production process is finished only for 22 to 26 hours, and the integral processing process can be programmed and standardized; and thus, method is suitable for large-scale batch production of factories.

Owner:青岛康大食品有限公司

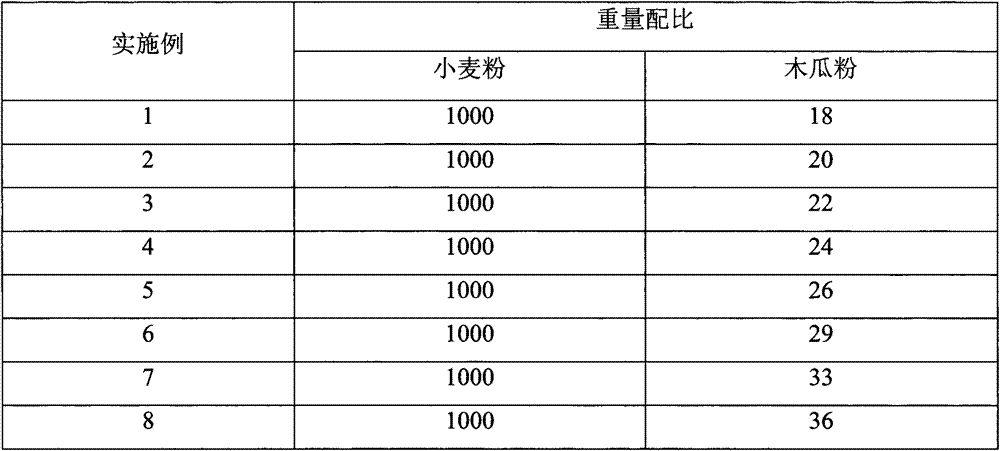

Papaya flour

InactiveCN103109890AIncrease meridian activationEnhance nutrition and health careDough treatmentDrugMarket potential

The invention relates to papaya flour which is made from, by weight, 1000 parts of wheat flour and 18-36 parts of papaya powder by well mixing. The papaya flour can be made into various flour products such as mantou, steamed twisted roll, noodles, steamed buns and dumplings. The papaya flour has the advantages that the flour with the papaya powder has the additional nutrition and health functions of regulating channels and activating collaterals and removing dampness to restore normal functioning of the stomach; complex procedures of decocting papaya and drugs and the like are omitted, and accordingly dietetic invigoration is facilitated; harmful effects of pharmaceutical excipients on human body are avoided; eating the papaya flour often is beneficial to people's physical health, and the papaya flour has great market potential in nowadays with increasing focus on dietetic invigoration.

Owner:苏州天南星生物科技有限公司

Production method of whole oat flour product and fresh-keeping whole oat flour product

The invention relates to a production method of a whole oat flour product and a fresh-keeping whole oat flour product. The method comprises the following steps of pretreating raw materials, performing dough making, fermenting the obtained dough, performing extruding to obtain strips, performing quick-freezing, performing ageing, performing unfreezing, performing soaking, performing sterilizing, performing ageing for the second time, performing sterilizing for the second time, and the like, so that a dried product and a fresh-keeping product of the whole oat flour product are produced. The prepared whole oat flour product is unique in flavor, chewy in mouth feel, elastic, and resistant to cook, and does not swell after absorbing water. The prepared fresh-keeping flour product greatly reserves the characteristics of the quality and the mouth feel of fresh wet flour products, can be stored under normal atmospheric temperature for 12 months, and can be eaten after being soaked with boiling water and rehydrated.

Owner:无锡新禾创工食品科技有限公司

High-fiber additive-free pure-corn noodle and environment-friendly production method thereof

ActiveCN103549282AImprove sensory qualityImprove bindingMulti-step food processesFood ingredient functionsFiberExtensibility

The invention relates to high-fiber additive-free pure-corn noodle and an environment-friendly production method thereof, belonging to a food processing technology. The preparation method of the high-fiber additive-pure pure-corn noodle comprises the steps of after impurities are removed through screening ripen corn kernels, melting and expanding through high-pressure steam, crushing, improving textures, carrying out fine-crushing, blending, forming and the like to produce the high-fiber additive-free pure-corn noodle. The high-fiber additive-free pure-corn noodle produced by adopting the invention has the advantages of being good in binding force, proper in extensibility and flexibility, good in boiling fastness, and pure in corn flavor, improving the digestibility of the corn foods, and developing the main food function and the nutrition health care function of the corn. The production method is mild in conditions in a production process, does not adopt any chemical and biological synthesis technologies, is free of pollution, waste residue, waste steam and harmful substances, and realizes the environment-friendly production; no non-corn grain raw materials and products are added, thus the pure flavor of the corn is ensured; no gluten fortifier, thickening colloid, enzyme preparation or preservative is added, no chemical reagents are used, thus the eating safety is ensured.

Owner:吉林省正源食品有限责任公司

Health-caring and freshness-retaining bean curd containing squillid head and squillid shell and preparation method thereof

InactiveCN104187443AIncrease profitGood nutrition and health careCheese manufactureNatural extract food ingredientsDiseaseCaryopteris incana

The invention relates to a health-caring and freshness-retaining bean curd containing squillid heads and squillid shells and a preparation method thereof. Raw materials of the beverage includes, by weight, 55-75% of soybean, 15-25% of cyperus esculentus, 2-5% of a squillid fermentation liquid, 3-6% of glucosamine hydrochloride and 5-9% of caryopteris incana juice. The bean curd is prepared from above raw materials in different processing methods, is high in production rate, is good in elasticity, is strong in toughness, is not liable to break, is fine in texture and is delicious in taste. Not only are problems that the squillid enzymolysis protein liquid is thick in bitter and fishy smell and cannot be used as a food base material solved, but also the bean curd is better in health-caring value and meanwhile is more unique in flavor, is long in preservation time and shelf life and is high in edible safety. The bean curd, when being eaten often, can enhance human body immunity, can improve physiological functions, can reduce glucose and fat, has an anti-microbial effect and an anti-inflammation effect, has an anti-cancer and anti-aging function, can prolong life, can alleviate osteoporosis, can prevent diseases in heart and cerebral vessels and alimentary canals and the like, allows waste materials to be comprehensively reused, and has huge social, ecological, environmental and economic benefits.

Owner:陆思烨

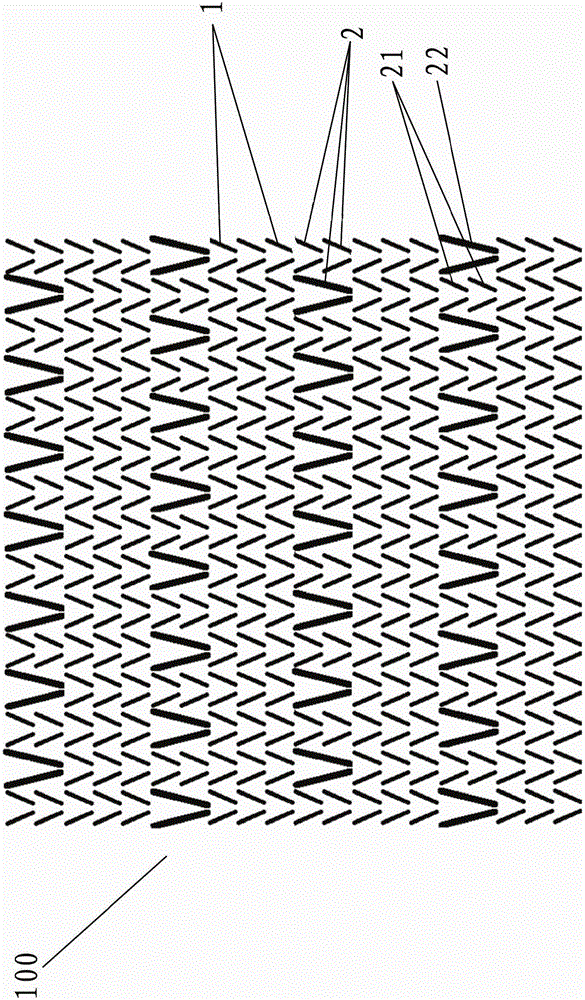

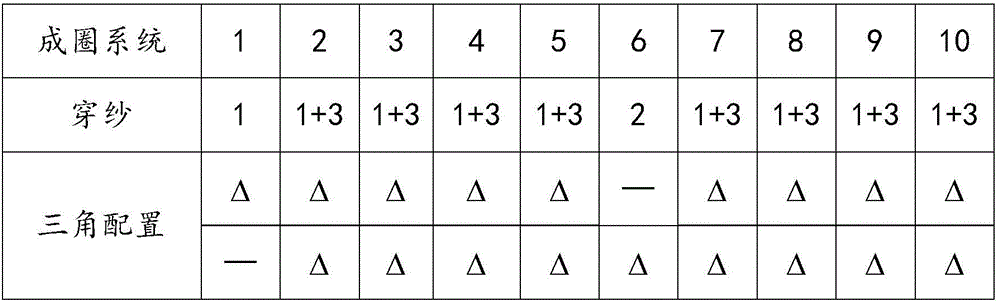

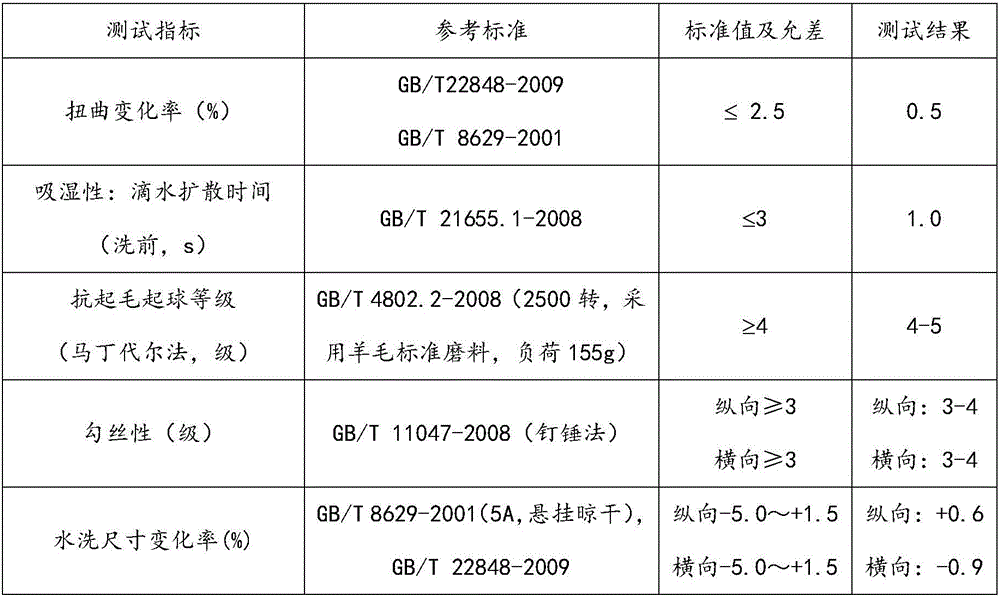

Single-sided weft-knitted fabric with cross-stripe effect and production method of single-sided weft-knitted fabric

ActiveCN106480589AGood bar effectRich fabric surfaceWeft knittingHeating/cooling textile fabricsPolyesterEngineering

The invention provides single-sided weft-knitted fabric with the cross-stripe effect. The single-sided weft-knitted fabric comprises a fabric body with the cross-stripe structure, the cross-stripe structure is formed by first coil rows and second coil rows, the first coil rows and the second coil rows are longitudinally and alternatively arranged, each second coil row behind each first coil row performs 1-stitch displacement, the first coil rows are composed of coils by knitting of three continuous cross-row looped coils protruding the front side of the fabric body, the second coil rows are formed by alternative knitting of looped coils of two cross-row coils protruding the front side of the fabric body and one longitudinal floating-thread stretched coil, the first coil rows are woven by cationic polyester filament and spandex in a doubling manner, and the second coil rows are knitted by half-matting polyester filament. Compared with the prior art, the single-sided weft-knitted fabric has the advantages of remarkable stripe experience, good cross elasticity and extension, good resistance to pilling and the like. The invention further provides a production method of the single-sided weft-knitted fabric with the cross-stripe effect.

Owner:QUANZHOU HAITIAN MATERIAL TECH CORP

Suede towel and preparation thereof

The invention relates to a suede towel and a preparation method thereof. The suede towel is formed by evenly mixing dissolved polyvinyl alcohol with starch, and then filling the mixture in fiber pores of polyester wadding. The invention also discloses steps of the preparation method. The suede towel has the advantages of strong hygroscopicity, light weight and softness, strong toughness, and good cleaning effect.

Owner:HUIZHOU QIANGLI DAILY NECESSITIES

Preparation method of corn noodles

The invention discloses a preparation method of corn noodles. The corn noodles are prepared with a method including smashing or soaking and smashing, mixing, ultrasonic treatment, puffing curing, pressing, drying or ageing and the like, the obtained corn noodles have pure corn flavor and do not contain any gluten fortifier, thickening colloid, enzymic preparations or preservative, no chemical reagents are used, the edible safety of the product is guaranteed, and the production process is simple, convenient to operate and applicable to large-scale industrial production.

Owner:延边阿拉里机械设备制造有限公司

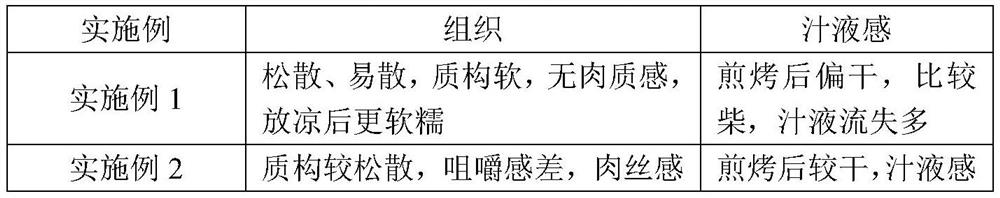

Gel plant meat and preparation method thereof

InactiveCN114287513AImprove soft waxy phenomenonIncrease elasticityProteins working-up by texturisingVegetable proteins working-upBiotechnologyCellulose

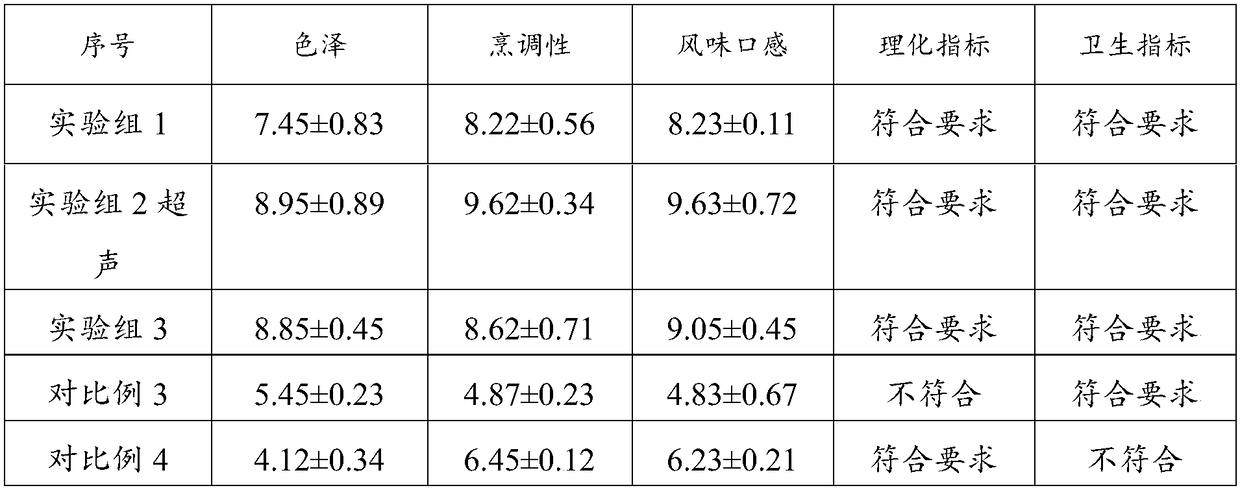

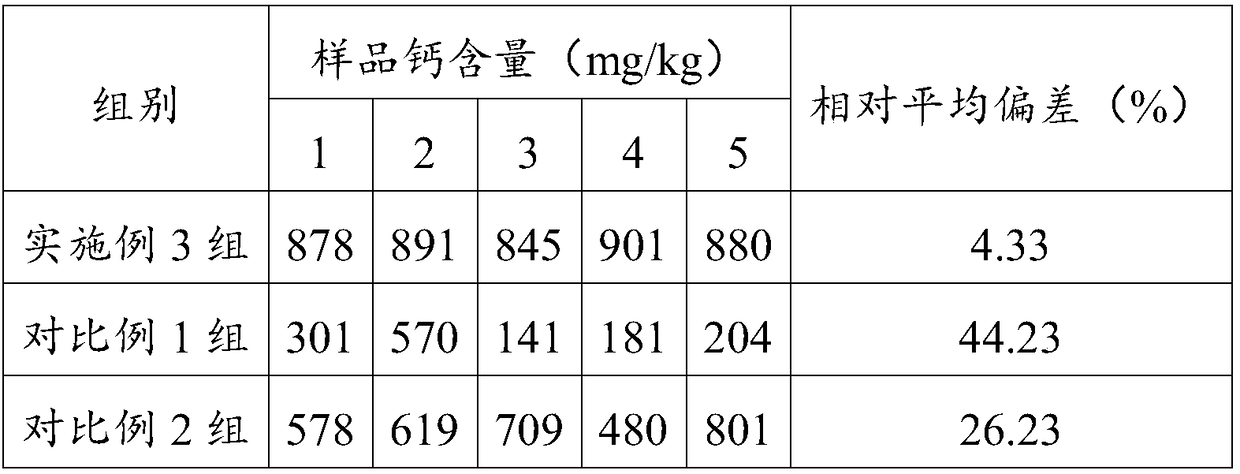

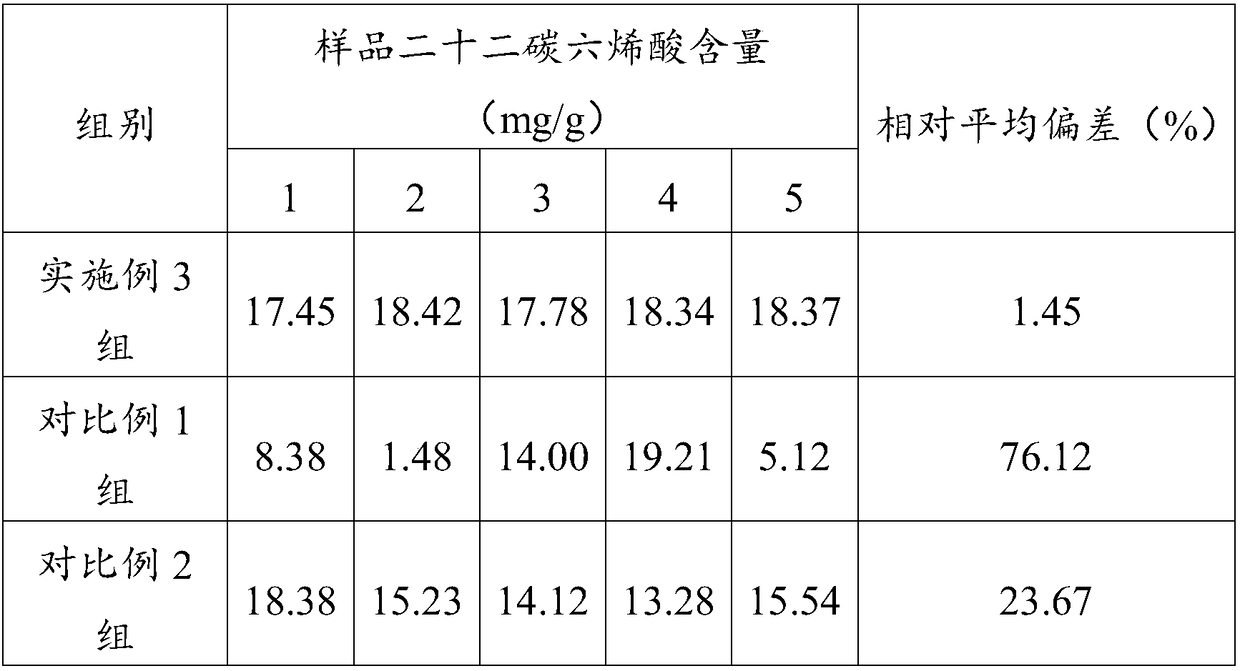

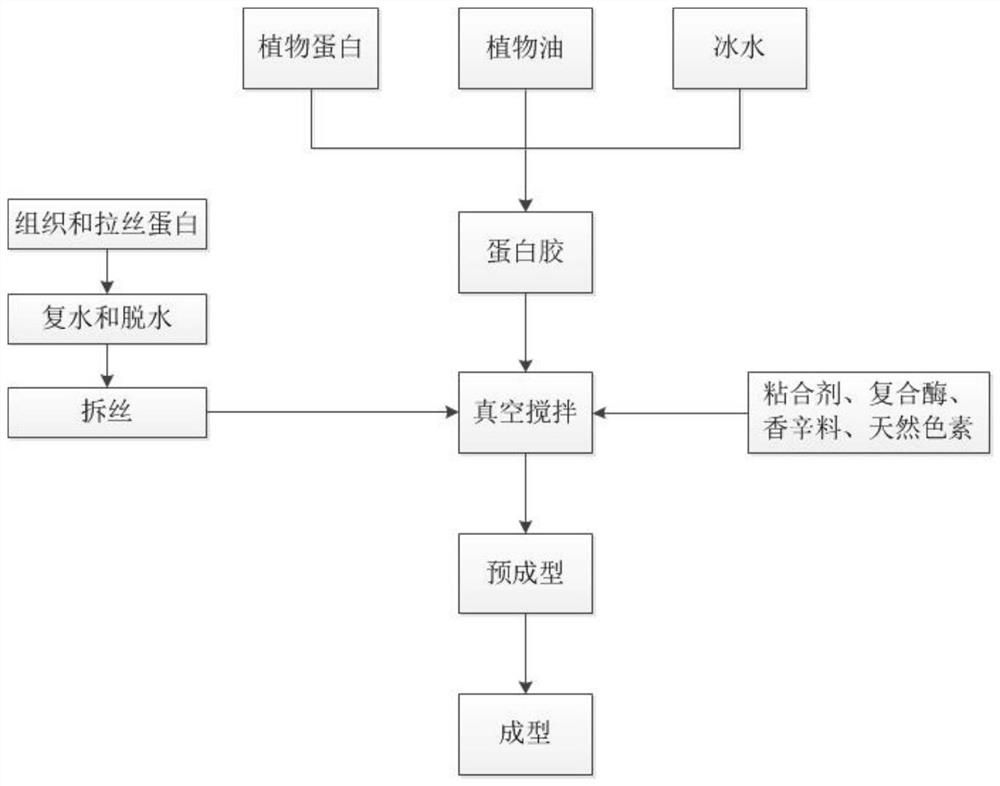

The invention provides gelled plant meat and a preparation method thereof, and the gelled plant meat is prepared from the following raw materials in parts by weight: 3-20 parts of plant protein, 15-65 parts of tissue and drawing protein, 2-20 parts of vegetable oil, 10-40 parts of ice water, 1.8-10 parts of an adhesive, 0.2-5 parts of compound enzyme, 2-15 parts of spice and 0.1-1 part of natural pigment. The adhesive comprises curdlan, methyl cellulose, konjac glucomannan, carrageenan and modified starch, different gel characteristics of several gelling agents are combined, when the gelling agents are matched according to different proportions, formation of a protein colloid system can be promoted, and particularly, the konjac glucomannan and the carrageenan can cooperate to form thermal reversible gel with good elasticity; besides, the compound enzyme comprises sylvite, TG enzyme and laccase, potassium ions can improve the gel property of the thermal reversible gel after being combined with the plant protein, so that the colloid of the cooled plant meat is sufficient in elasticity and good in toughness, and the soft and glutinous phenomenon of the cooled plant meat can be improved.

Owner:陕西未来植膳健康科技有限公司

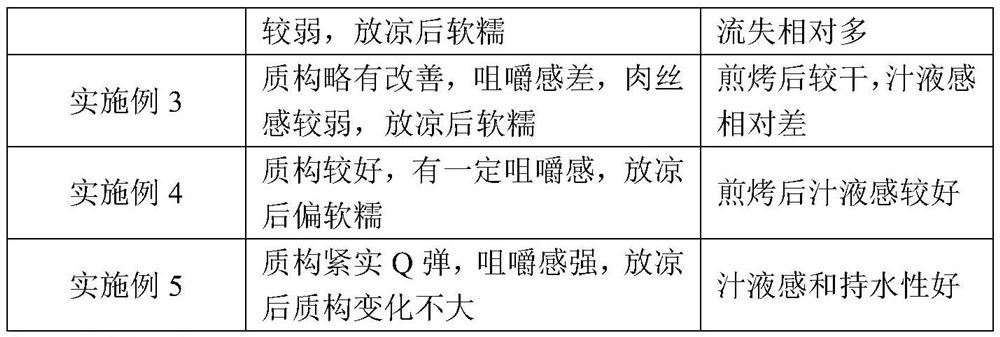

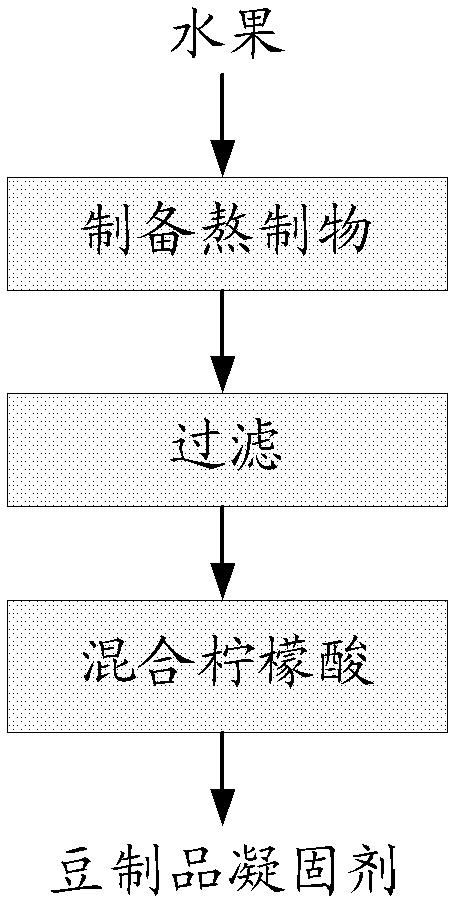

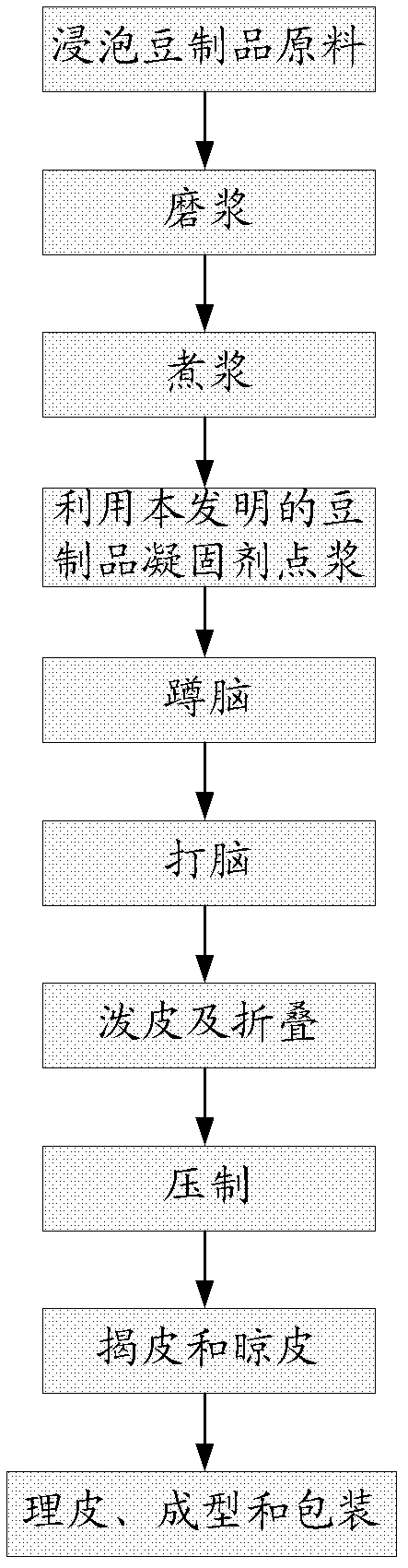

Coagulant and method for preparing bean products by same

InactiveCN102550701AImprove water holding capacityNo residual odorCheese manufactureFood scienceCitric acidStandardization

The invention provides a bean product coagulant and an application thereof. The bean product coagulant is prepared by adopting the following steps: mixing fruit with 360-400 parts by weight of water and decocting at a high temperature to obtain a decocted substance, wherein the fruit comprises 10-15 parts by weight of red fruits, 8-10 parts by weight of apples, 8-12 parts by weight of pineapples and 5-15 parts by weight of lemons; filtering the decocted substance to obtain the filtrate; and mixing and coagulating the filtrate and 4-8 parts by weight of citric acid to obtain the coagulant. Thebean product coagulant and the method for preparing bean products have the advantages that the bean products can be prepared conveniently and effectively; the operation is easy, standardization and industrialization can be realized easily, the cost is low, and the product yield is high; the prepared bean products have a good water-keeping capacity and a good mouthfeel; the inherent fragrance of raw materials of the bean products can be retained; and no peculiar taste is left.

Owner:刘峰松

Livestock blood wine soaked cooking sausage and processing method thereof

ActiveCN103815428AImprove food safetyHigh nutritional valueSugar food ingredientsAlcoholic food ingredientsBiotechnologyHeme

The invention relates to a livestock blood wine soaked cooking sausage and a processing method thereof, and solves the problem that the existing livestock blood is difficult to apply in food processing due to the fact that a blood smell is greater, heme iron is easy to oxidize and becomes brown, and the livestock blood is poor in palatability. On the other hand, the invention provides a sausage without an artificial color and with high safety. A red color of the livestock blood wine soaked cooking sausage is the livestock blood, and the addition of the blood accounts for 12-20% of the total raw material mass of the sausage. In order to prevent ferrous iron from being oxidized into ferric iron, the livestock blood wine soaked cooking sausage also comprises at least 0.01% of a reducer to cover the blood smell, and comprises 8-10% of Sanhua Liquor and 0.2-0.4% of beta-cyclodextrin, and can further comprise 2-3% of soy isolate protein according to the total raw material mass of the sausage. The natural color of the blood serves as the color of the sausage, and the edible safety of the sausage is improved. An appropriate amount of the reducer is added into the sausage and can effectively prevent Fe<2+> in heme from being oxidized into Fe<3+>, and the sausage becomes important food for supplementing available Fe.

Owner:GUANGXI UNIV

Nutrient mixed flour and preparation method thereof

The present invention relates to a flour, particularly to a nutrition compound flour and a preparing method thereof. The nutrition compound flour of the invention is prepared by mixing special dumpling flour, black scented rice powder, amino acid powder, spinage powder, pumpkin powder, triticale powder and modified starch, has high nutrition value, eliminates the harm to human body caused by excess acidic materials in normal flour, promotes the positive cycle of absorbent system in human body and brings a new black nutrition food to the market. The food prepared by the flour has good taste, color and elasticity, clear texture and freeze resistance, has multiple health care functions to human body and has certain effects on protecting kidney and liver, expelling toxin and beautifying face, tonifying yin and invigorating yang, stabilizing blood sugar, blackening hair, tonifying qi and engendering blood.

Owner:李敏

Multi-component easy-care fabric

The invention discloses multi-component easy-care fabric. The multi-component easy-care fabric is formed by interweaving warp yarn and weft yarn, wherein the warp yarn is formed by blending 80 counts of australasian wool, 1.5D polyester fiber and silk, the specification is 92 counts / 2, and the degree of Z-twist is 900 twists / m; the weft yarn is formed by 80 counts of australasian wool, 1.5D polyester fiber, silk and Lycra, firstly, 54 counts / 1 of single yarn is prepared by the 80 counts australasian wool, the 1.5D polyester fiber and the silk, then 30D Lycra is added to prepare Lycra core spun yarn, the specification of the weft yarn is 48 counts / 1, and the degree of Z-twist is 1,050 twists / m. The multi-component easy-care fabric has bright color, cool hand feeling, sufficient elasticity, high stereoscopic effect, good breathability and superior performance, has the characteristics of fashion and practicality simultaneously, and is comfortable, aesthetic and suitable for manufacture of men's casual clothing.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

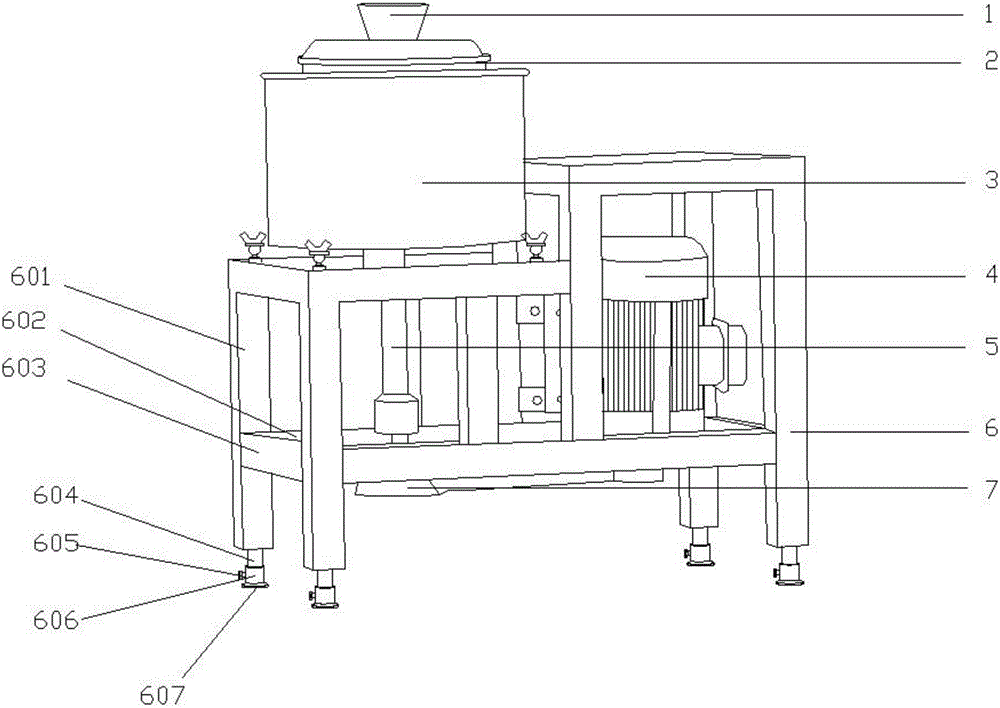

Meatball beater with easily levelled frame

InactiveCN105994568AImprove the level ofGood colorMeat processingDrive shaftArchitectural engineering

The invention discloses a meatball beating machine with an easy-to-level frame. The inner barrel is fixedly connected, the beating inner barrel is fixedly installed on the cooling outer barrel, the cooling outer barrel is fixedly installed on the frame, the cooling outer barrel is fixedly connected to the transmission shaft, and the transmission shaft is fixedly connected to the pulley. The belt pulley is fixedly connected with the motor, and the motor is fixedly installed on the frame. The frame is composed of a vertical bar, a support plate, a horizontal bar, a lifting column, a lifting shaft, an outer column, and a base. The vertical bar and the horizontal bar are fixed. connection, the horizontal bar is fixedly connected with the support plate, the bottom of the vertical bar is fixedly connected with the lifting column, the lifting column is movably connected with the outer column, the outer column is fixedly equipped with a lifting shaft, and the base of the outer column is fixed connection, the invention facilitates the leveling of the supporting feet of the equipment, and ensures the normal operation of the equipment.

Owner:李清雪

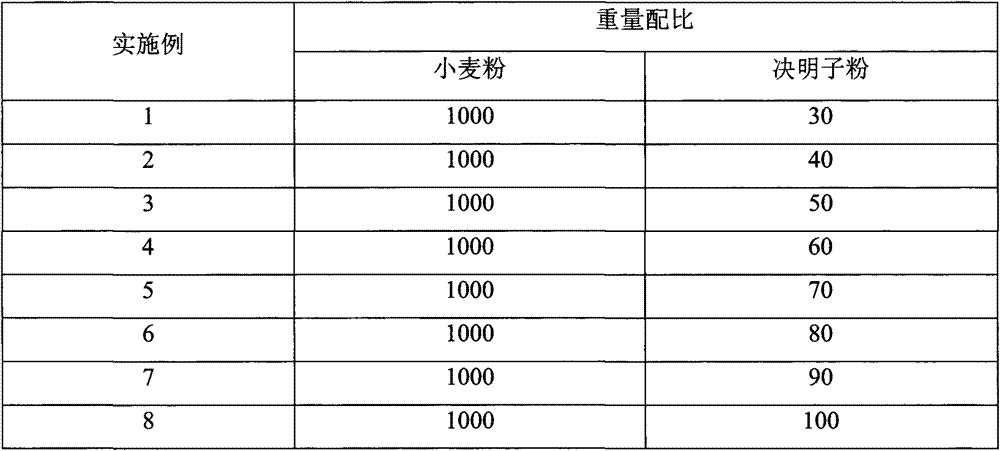

Application of cassia seed in edible flour

InactiveCN103109892AEnhance liver clearing and eyesightIncrease Suppressing Liver and Potential YangDough treatmentMarket potentialCassia mimosoides

The invention relates to application of cassia seed in edible flour. 1000 parts of wheat flour and 30-100 parts of cassia seed powder are evenly mixed into mixture by weight. The mixture can be made into various four products such as mantou, steamed twisted roll, noodles, steamed buns and dumplings. The application of cassis seed in edible flour has the advantages that the flour with the cassia seed powder has the additional nutrition and health functions of removing liver-fire for improving eyesight, calming liver and suppressing yang, relaxing bowels and the like; complex procedures of decocting cassia seed and the like are omitted, and dietetic invigoration is facilitated; harmful effects of pharmaceutical excipients on human body are avoided. Eating the products often is beneficial to people's physical health. The application is of large market potential in nowadays with increasing focus on dietetic invigoration.

Owner:苏州天南星生物科技有限公司

Bitter gourd cake and making method thereof

InactiveCN103609643AHigh nutritional valueHeat-clearing and detoxifyingDough treatmentBakery productsNutritive valuesFlavor

The invention discloses a bitter gourd cake and a making method thereof. The bitter gourd cake comprises bitter gourd, eggs, white granulated sugar, citric acid, flour, salad oil, cream, malt syrup, peanut oil and blend oil. The making method of the bitter gourd cake comprises the steps of preparation of bitter gourd juice, stirring, mixing, injection molding, baking, oiling and demolding. The bitter gourd cake has the advantages that the taste is soft, fine and smooth, the cake tastes sweet, slightly bitter, tasty, and refreshing, the elasticity is good, the rough sense is avoided, the cake does not stick to teeth, the fragrance is strong and pure, and the flavor is special; the cake can clear away heat and toxic materials, relieve summer heat, nourish the kidney and the spleen, improve the immunity, and reduce blood fat, the nutritive value is high, and the cake is a high-grade product which is suitable for both the old and children; the cake is instant dietetic food and can meet requirements of different special populations, and the market of bitter gourd is developed.

Owner:陈思远

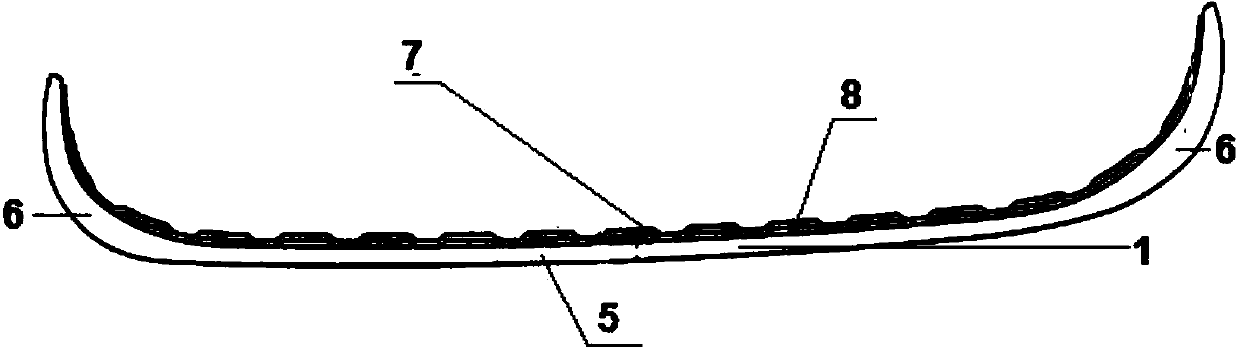

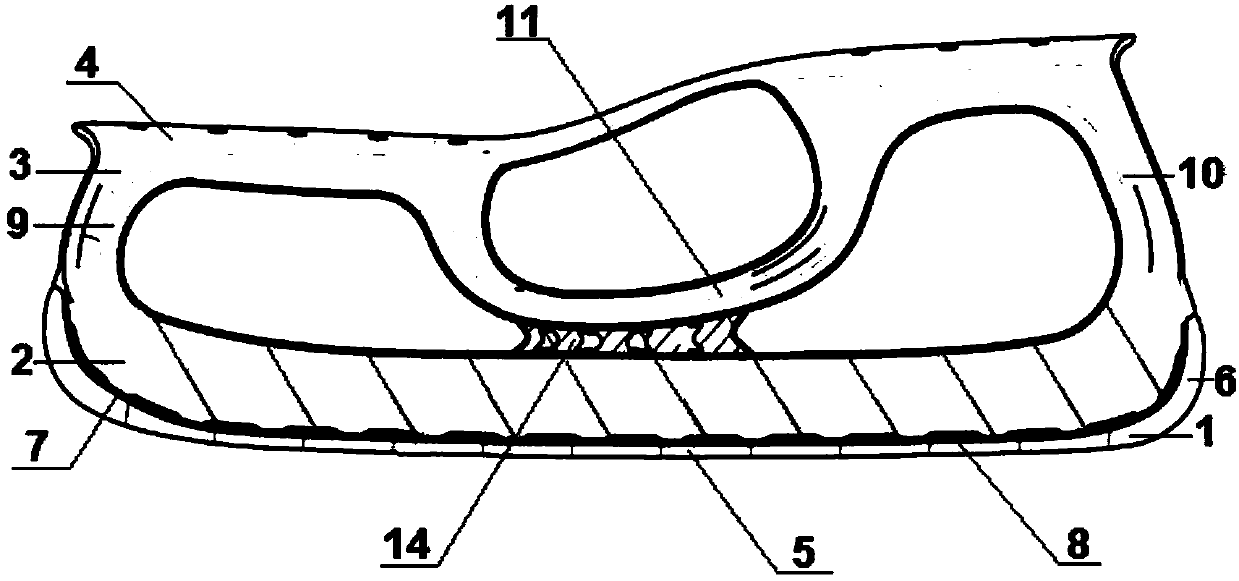

Skate frame and manufacturing method thereof

The invention discloses a skate frame and a manufacturing method thereof. The skate frame comprises a blade, a vertical connection plate arranged on the blade and a support arranged on the vertical connection plate. The support comprises a skate bottom fixing plate, a front support pillar and a rear support pillar, the front support pillar and the rear support pillar are arranged between the skate bottom fixing plate and the vertical connection plate, the skate bottom fixing plate between the front support pillar and the rear support pillar is provided with a curved solid tube hunching downward, and a connection strip is arranged between the curved solid tube and the vertical connection plate. The skate frame has light weight, good flexibility, small motion resistance, good stability, good durability, high-intensity instant impact force resistance, and strong carrying capacity. In skating, the skate frame is conducive to force application and ice grasping of the skate blade. The skate frame has good flexibility and enough elasticity, produces a fast rate in skating and has a long service life.

Owner:包爾曲棍球有限公司

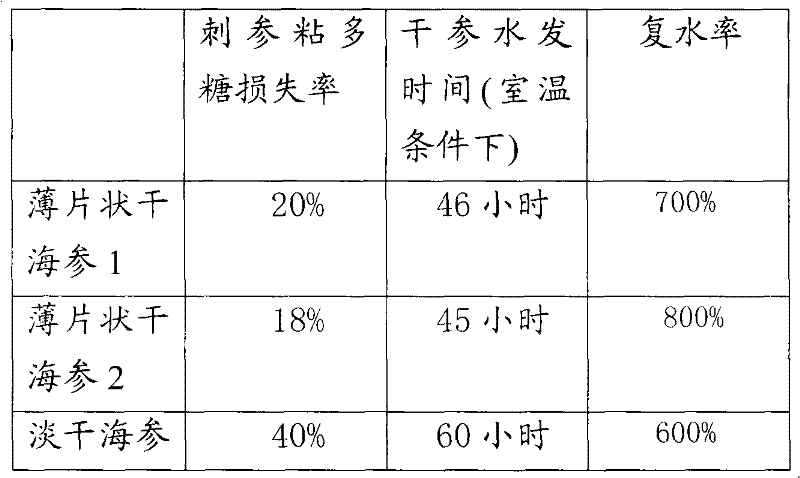

Sliced dry sea cucumber, preparation method thereof, drugs and health care products containing sliced dry sea cucumber and application thereof

InactiveCN102342546AElastic footAvoid lostEchinodermata material medical ingredientsFood preparationTrace elementWater soluble

The invention provides a preparation method of sliced dry sea cucumber, comprising the following steps of: firstly, soaking sea cucumber; secondly, stretching the soaked sea cucumber; and thirdly, tiling, fixing and drying the stretched sea cucumber. By adopting the preparation method, great loss of acidic mucopolysaccharide Apostichopus japonicas, vitamins, trace elements and water soluble components can be avoided; less collagen of the sea cucumber is damaged, and water risen sea cucumber has enough elasticity and large toughness. In addition, by adopting the preparation method to prepare dried sea cucumber, the preparation period is remarkably shortened, and the entire period can be shortened within 10h.

Owner:OCEAN UNIV OF CHINA

Fish ball and preparation method thereof

InactiveCN105341766ASolve problems such as dark color, weakened elasticity, and poor tasteKeep proteinFood scienceSodium bicarbonateFresh fish

The present invention discloses a fish ball and a preparation method thereof. The fish ball is prepared from the following raw materials in weight percentage: 85-95% of fish flesh, 2.5%-7.5% of eggs, 1.5%-4.5% of flour, 0.5%-1.5% of refine salt, 0.25%-0.75% of disodium dihydrogen pyrophosphate, 0.15%-0.45% of sodium bicarbonate and 0.1%-0.3 % of calcium carbonate. The present invention also discloses a preparation method of the fish balls, which solves the problems that the fish balls are dark in color after being placed or froze, less in elasticity, bad in taste, etc., keeps the proteins in the fresh fish, and enables the fish balls to be easy for cooking. The fish balls are not high in equipment requires and strong in maneuverability, can effectively solve the existing problems of color and luster, elasticity, etc., in the surimi products, and are suitable for a large-scale industrial production of fish balls and other surimi products. Similarly, the fish balls can also be prepared into a H-shape to enable the diet to be diversified.

Owner:邓其青

Health food containing bergamots

InactiveCN103416756AIncrease soothing the liver and regulating qiEnhance nutrition and health careFood preparationMedicinal herbsMarket potential

The invention relates to a health food containing bergamots. The health food is prepared from, by weight, 1000 parts of wheat flour and 170 parts of bergamot power, wherein the wheat flour and the bergamot power and evenly stirred and mixed. The health food containing the bergamots has the advantages that after the bergamot powder is added into the flour, the nutritious and healt-care functions of reliving the liver to sooth qi, regulating the middle warmer and reducing phlegm; the complex processes such as decocting and cooking bergamot medical materials are eliminated and the health food has huge market potential.

Owner:苏州天南星生物科技有限公司

Method for preparing fabric having deodorizing effect

The invention discloses a method for preparing a fabric having a deodorizing effect. The method comprises a superfine powder active carbon preparing process, a dyeing and deodorizing process, a spinning process, a weaving process and post-treatment processes. By employing the method, the particle size of active carbon can be decreased, so that the active carbon can permeate the interior of a fiber and be absorbed onto the inner surface of the fiber more easily. According to the method, purchased powder active carbon, hyper-dispersants and antifoaming agents are mixed based on a certain mass ratio and then are repeatedly ball-milled in a planetary ball mill, and finally the superfine powder active carbon with the particle size being less than 10 [mu]m can be obtained. By employing the method, the particle size of the powder active carbon is greatly decreased, so that the powder active carbon can permeate the interior of the fiber and be absorbed onto the inner surface of the fiber more easily by the aid of the permeation effect of a penetrant JFC during a wool boiling dyeing expansion process. The fabric has soft, smooth, skin-friendly and nutritive characteristics which the wool also has, the fabric is high in elasticity, the fabric is close-fitted and a user does not feel tight, and the fabric is processed through the powder active carbon serving as a deodorizing agent, so that the fabric has health-care, deodorizing, environmental-friendly and antistatic functions.

Owner:JIANGSU JIANLU WOOLEN

Wicker softening and sterilizing treatment method

InactiveCN106042115AGood flexibilityImprove resistance to yieldingWood treatment detailsReed/straw treatmentMedicineDistilled water

The invention provides a wicker softening and sterilizing treatment method. The wicker softening and sterilizing treatment method comprises the following steps that firstly, deionized water is sprayed onto wicker to be harvested, and the temperature of the water is 25-30 DEG C; secondly, two hours later, the wicker sprayed with the deionized water is cut and harvested, leaves are removed, and the wicker skin of the portion from a cut opening to the position 5 cm above the cut opening is scraped; thirdly, the wicker is placed in a bucket containing sterilization liquid with the cut opening facing downwards, the wicker is taken out of the bucket after softening treatment is conducted on the wicker for 1-2 hours, the wicker is dried till the water content of the wicker is not higher than 3%, then the wicker is placed in softening liquid to be subjected to softening treatment for 2-4 hours again, the wicker is taken out and completely washed with distilled water, and afterwards, the wicker is dried till the water content of the wicker is not higher than 5%; and fourthly, the wicker is soaked in the softening liquid for 30 minutes, then completely cleaned with clear water and placed in a burning sun environment to be dried. The wicker softening and sterilizing treatment method has an extremely good killing effect on certain harmful bacteria, moths and the like in the wicker, the tenacity and processability of the wicker are enhanced, and the treated wicker can prevent mould breeding for a long time.

Owner:GP TOPARTS MFR ANHUI

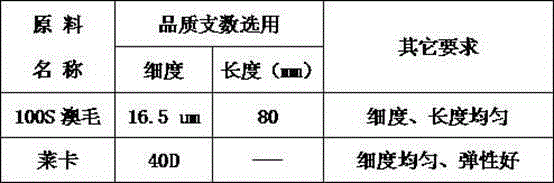

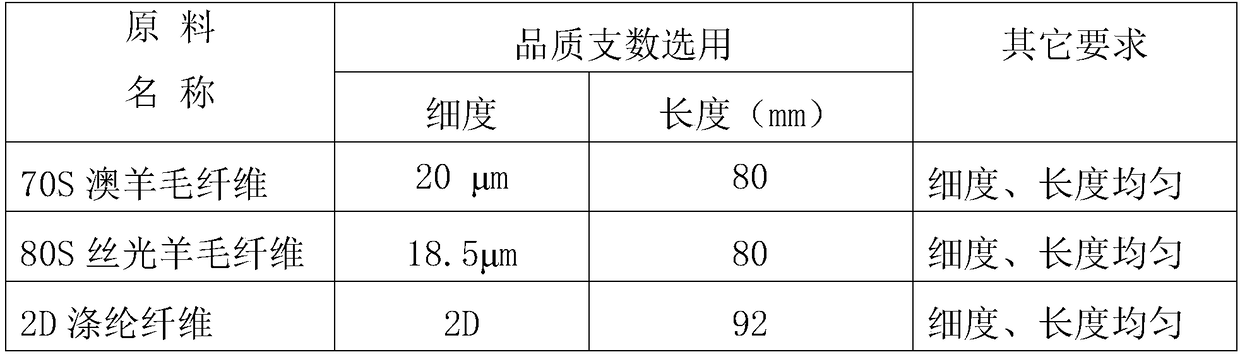

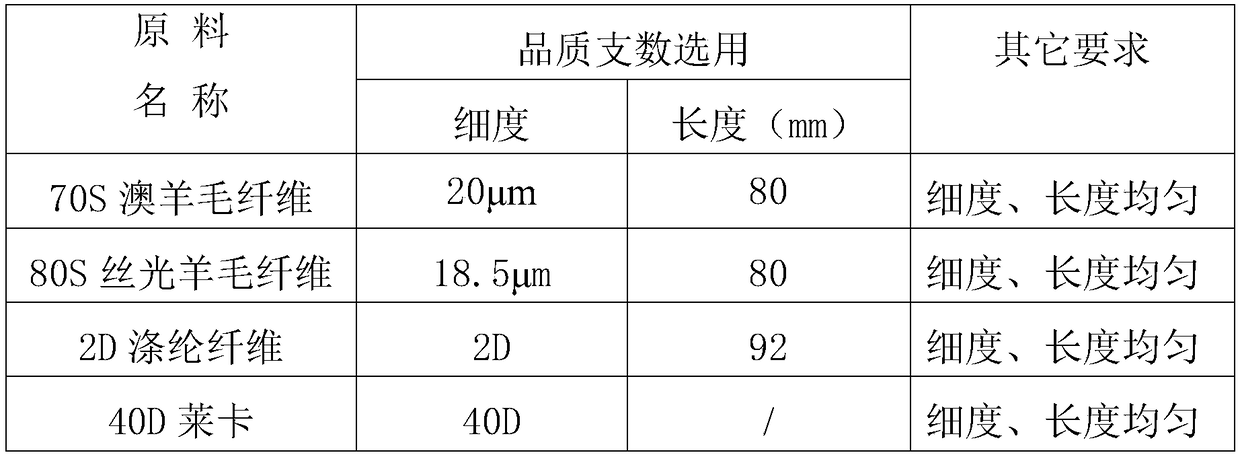

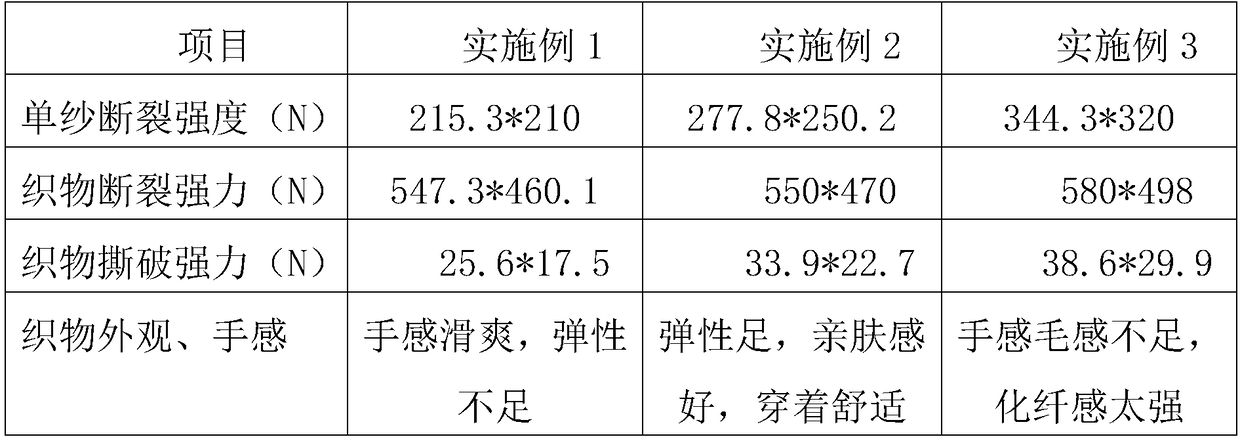

Wool polyester elastic force valetin and preparation method thereof

The invention discloses a wool polyester elastic force valetin and a preparation method thereof. The wool polyester elastic force valetin is prepared from warp yarns and weft yarns, wherein the warp yarn is prepared from the following raw materials: 31.8% of Australian wool fiber, 20% of mercerized wool fiber and 48.2% of polyester fiber, the weft yarn is prepared from the following raw materials:30.26% of Australian wool fiber, 20% of mercerized wool fiber, 46.94% of polyester fiber and 2.8% of lycra, and a finished product is prepared from the warp yarns and the weft yarns through a dyeingprocess, a spinning process, a weaving process and a finishing process. According to the invention, the warp yarn is blended by using the Australian wool fiber, the mercerized wool fiber and the polyester fiber, so that the fabric strength is obviously improved, and the problems of insufficient strength of a prior finished product after the wool fabric is woolen and the like are solved; the mercerized wool is added to endow the wool fabric with silky luster, and the hand feeling is softer; in addition, the lycra is added in the weft yarns, so that the fabric is elastic and is close to the bodywithout being tightened when being worn; and the warp yarns and the weft yarns are reasonably matched, so that the lycra is prevented from being exposed after the finished product is produced.

Owner:JIANGSU JIANLU WOOLEN

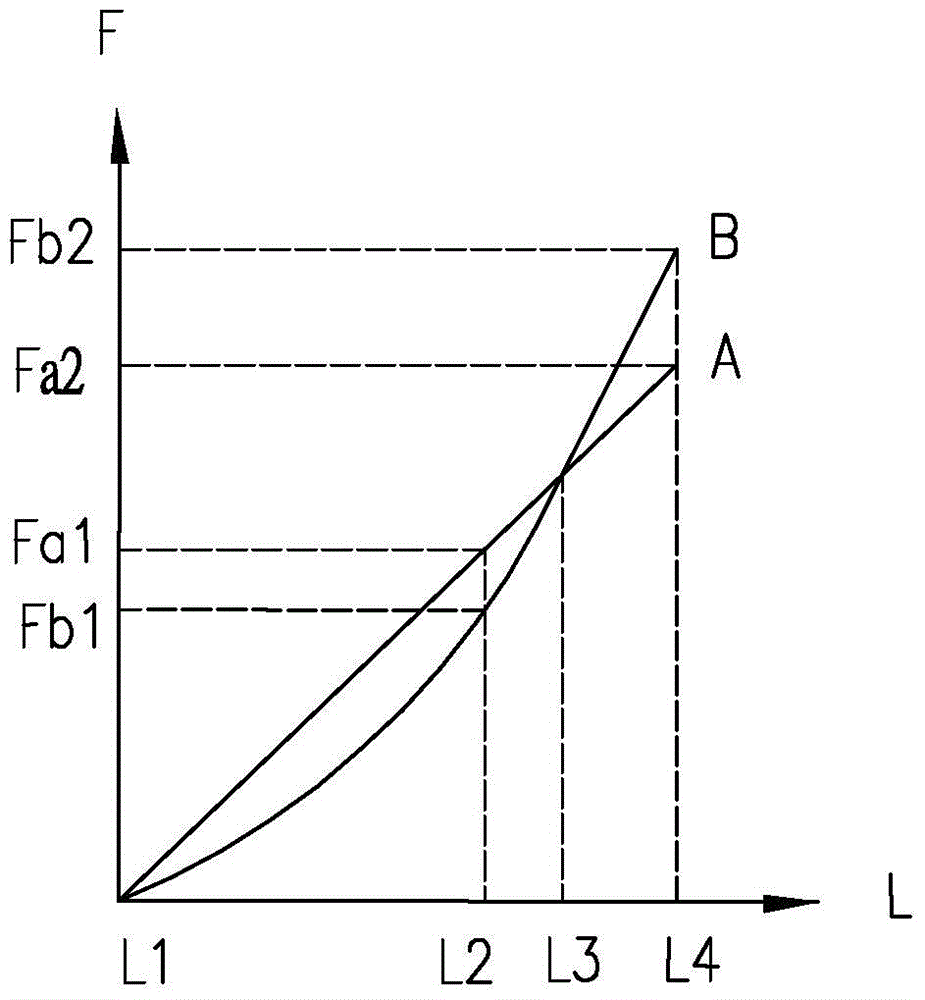

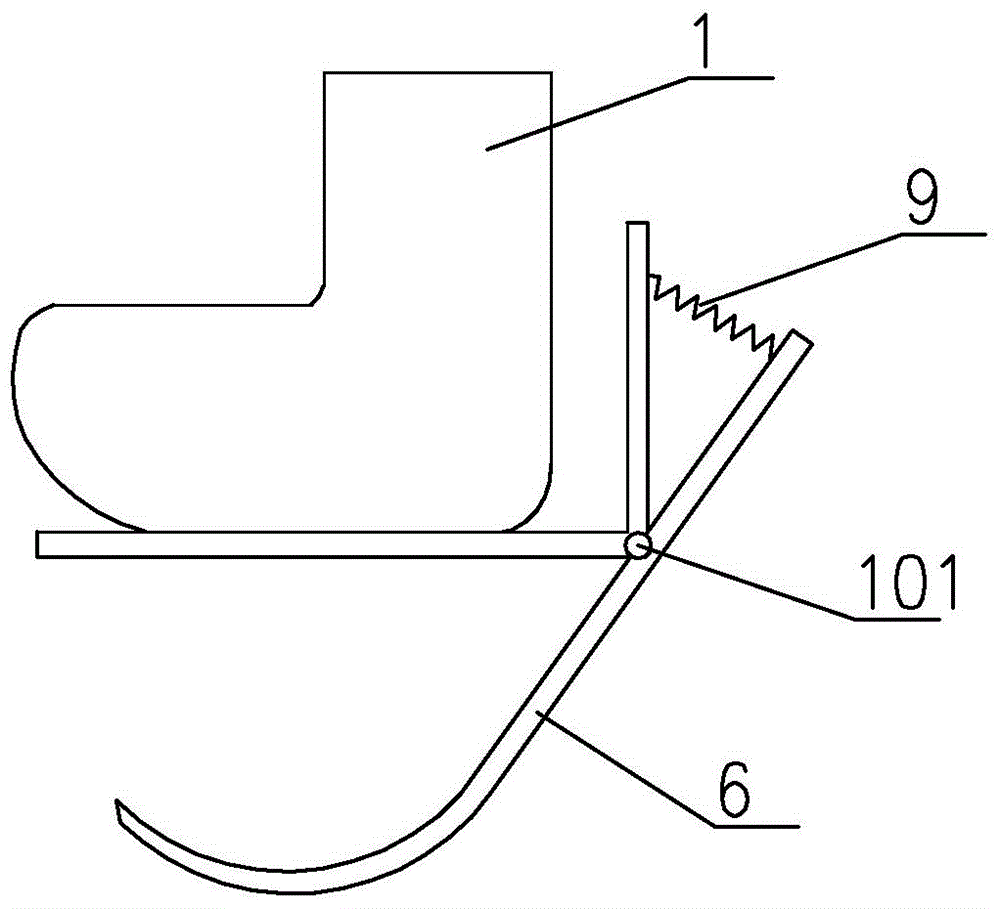

X-shape mechanism bouncing shoe

The invention discloses an X-shape mechanism bouncing shoe comprising a wearing device and an elastic device connected with the wearing device; the elastic device comprises an X-shape mechanism and an elastic piece; the X-shape mechanism mainly comprises a fixed member used for supporting a foot and a movable member making contact with the ground; the fixed member and the movable member are connected through a rotary shaft; one end of the elastic piece is connected on the fixed member, and the other end is connected on the movable member. The elastic piece of the bouncing shoe is the X-shape structure; the bouncing shoe is simple in structure, low in cost, sufficient in elasticity, good in safety, can further realize non-linear elasticity, thus enhancing the bouncing shoe landing resiliency and rebounding force from the ground.

Owner:石利平 +1

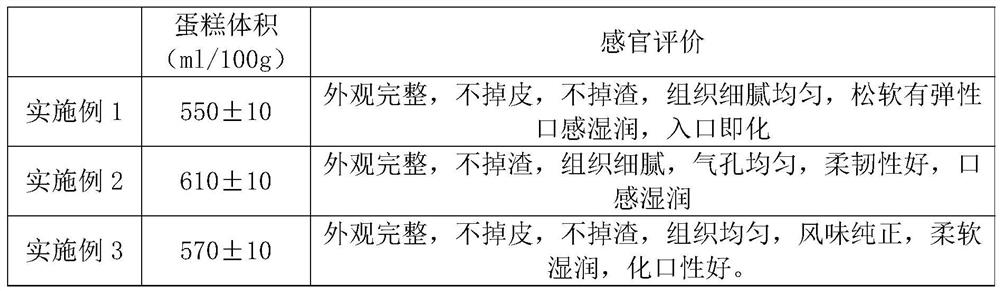

Wheat-flour-free cake and making method thereof

PendingCN113261579AReduce consistencyHigh transparencyDough treatmentDough/pre-mixesBiotechnologyCellulose

The invention relates to the technical field of food baking, in particular to a wheat-flour-free cake and a making method thereof. The formula comprises the following raw materials in parts by weight: 3-8 parts of corn flour, 30-50 parts of eggs, 8-14 parts of white granulated sugar, 6-12 parts of trehalose, 5-10 parts of refined vegetable oil, 1-5 parts of skim milk powder, 0.1-0.5 part of edible salt, 10-20 parts of hydroxyl propyl distarch phosphate, 1-3 parts of a sorbitol solution, 1-3 parts of glycerol, 1-5 parts of a compound emulsifier, 0.5-1.5 parts of a compound leavening agent, 0.1-0.5 part of citric acid, and 0.01 to 0.05 part of sodium dehydroacetate. According to the cake, the corn flour is used for replacing wheat flour, the cake is good in sensory characteristic and taste, and the problem that a wheat bran cake is aged and hardened after being placed for two or three days is solved. The cake is rich in nutrition, contains rich vitamins, trace elements, cellulose, polysaccharide and the like, is suitable for people of all ages, enriches the variety of cake products, and promotes improvement of human dietary fiber structures.

Owner:蔡小强

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com