Wool polyester elastic force valetin and preparation method thereof

A technology of elastic and wool-polyester, applied in the field of wool-polyester elastic vanitin and its preparation, can solve the problems of insufficient softness, insufficient elasticity, and affecting the comfort of fabrics, so as to achieve soft handfeel, reduce damage, and increase the production rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

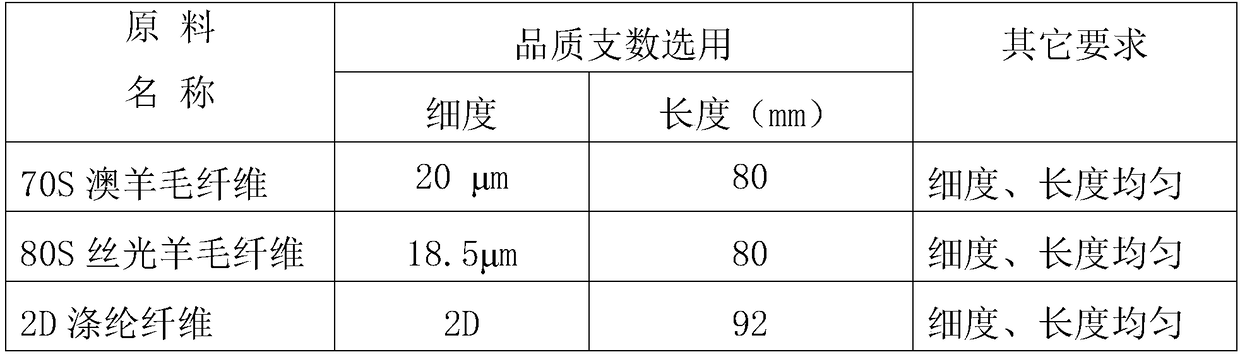

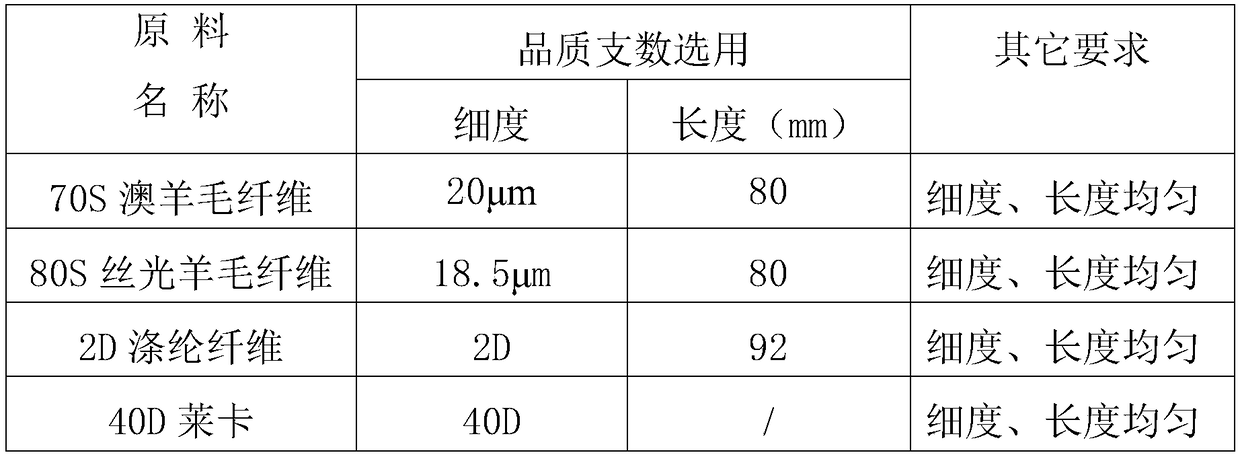

Method used

Image

Examples

Embodiment 1

[0029] Proportion of warp raw materials: Australian wool fiber 31.8%, mercerized wool fiber 20%, polyester fiber 48.2%.

[0030] Weft raw material ratio: 31.8% of Australian wool fiber, 20% of mercerized wool fiber, and 48.2% of polyester fiber.

[0031] A preparation method of wool-polyester elastane, comprising the steps of:

[0032] (1) Dyeing process

[0033] Australian wool fiber adopts the design idea of low-temperature dyeing at 90°C. The environmentally friendly imported Lanna wool is dyed with reactive dyes, and 0.5% N2 low-temperature dyeing accelerator is added. The wool dyeing temperature is reduced from 98°C to 90°C, which reduces the loss of wool Fiber damage improves the spinning rate and yarn strength, saving energy;

[0034] The mercerized wool fiber adopts environmentally friendly imported reactive dyes for wool, and the imported leveling agent Abaig B is added, the dosage is 2%, and the liquor ratio is 1:20. After the wool is stripped, the dyeing speed i...

Embodiment 2

[0045] Compared with Example 1, the preparation method of a kind of wool-polyester elastane is the same, but the ratio of raw materials is different.

[0046] Proportion of warp raw materials: Australian wool fiber 31.8%, mercerized wool fiber 20%, polyester fiber 48.2%.

[0047] Weft raw material ratio: 30.26% of Australian wool fiber, 20% of mercerized wool fiber, 46.94% of polyester fiber, and 2.8% of Lycra.

Embodiment 3

[0049] Compared with Example 1, the preparation method of a kind of wool-polyester elastane is the same, but the ratio of raw materials is different.

[0050] Proportion of warp raw materials: Australian wool fiber 22%, mercerized wool fiber 20%, polyester fiber 58%.

[0051] Weft raw material ratio: 20.2% of Australian wool fiber, 20% of mercerized wool fiber, 57% of polyester fiber, and 2.8% of Lycra.

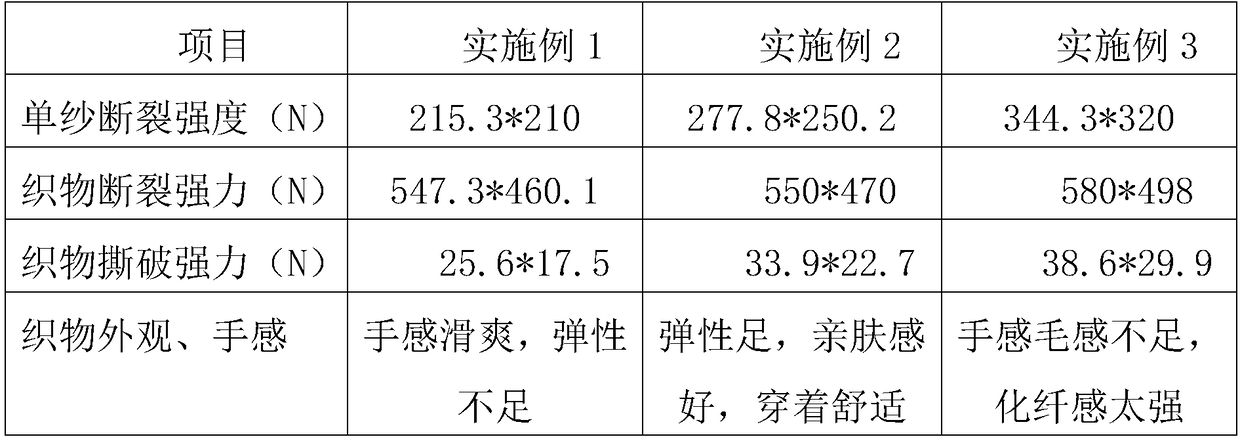

[0052] After trial production in small batches, we obtained the indicators of the three varieties, as shown in the table below:

[0053]

[0054] It can be seen from the table that after the finished product was trial-produced in Example 1, because Lycra was not added in the weft direction, it felt smooth, but the elasticity was insufficient and the comfort was slightly poor. In Example 2, Lycra was added in the weft direction, and the finished product produced It has enough elasticity, good skin-friendly feeling, and comfortable to wear. The finished product of Example 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com