Method for preparing fabric having deodorizing effect

A technology for deodorization and fabrics, which is applied in the treatment of textile materials, dyeing methods, liquid/gas/steam textile materials treatment, etc. It can solve the problems of poor washability, low dosage, non-universal and environmental protection, etc. problems, to achieve the effect of clear lines, reduced particle size, and easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

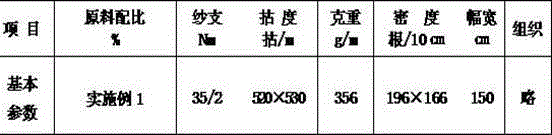

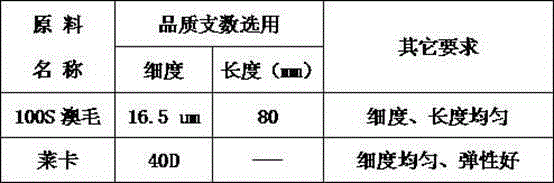

Embodiment 1

[0036] A method for preparing a fabric with deodorizing effect, which is characterized in that it comprises the following steps:

[0037] 1) Preparation of ultra-fine powder activated carbon

[0038] The powdered activated carbon, Silok7007 hyperdispersant and XPJ220 defoamer were repeatedly ball milled in a planetary ball mill at a mass ratio of 50:10:1 for 4 hours to obtain ultrafine powdered activated carbon with a particle size of less than 10μm.

[0039] 2), dyeing, deodorizing finishing process

[0040] The wool fiber is dyed with environmentally friendly Lanna free and easy dyes. Add 2% of the above-prepared ultra-fine powder activated carbon and 0.3% JFC penetrant to the dye bath for 30 minutes, and then add 0.2% acrylic water-based adhesive After the dyeing is finished, rinse out the tank,

[0041] Through dye screening and reasonable formulation of the process (40°C dyeing and heating rate 1°C / min, 80°C heat preservation for 10 minutes, heat preservation at 98°C for 60 minute...

Embodiment 2

[0054] A method for preparing a fabric with deodorizing effect, which is characterized in that it comprises the following steps:

[0055] 1) Preparation of ultra-fine powder activated carbon

[0056] The powdered activated carbon, Silok7007 hyperdispersant and XPJ220 defoamer were repeatedly ball milled in a planetary ball mill at a mass ratio of 60:20:1 for 4 hours to obtain ultrafine powdered activated carbon with a particle size of less than 10μm.

[0057] 2), dyeing, deodorizing finishing process

[0058] When dyeing wool fiber, use environmentally friendly Lanna free and easy dyes for boiling dyeing. Add 5% of the above-prepared ultra-fine powder activated carbon and 1% JFC penetrant to the dyeing bath for 30 minutes, and then add 1% acrylic water-based adhesive After the dyeing is finished, rinse out the tank,

[0059] Through dye screening and reasonable formulation of the process (40°C dyeing and heating rate 1°C / min, 80°C heat preservation for 10 minutes, heat preservation at ...

Embodiment 3

[0072] A method for preparing a fabric with deodorizing effect, which is characterized in that it comprises the following steps:

[0073] 1) Preparation of ultra-fine powder activated carbon

[0074] The powdered activated carbon, Silok7007 hyperdispersant and XPJ220 defoamer were repeatedly ball milled in a planetary ball mill at a mass ratio of 55:15:1 for 4 hours to obtain ultrafine powdered activated carbon with a particle size of less than 10μm.

[0075] 2), dyeing, deodorizing finishing process

[0076] The wool fiber is dyed with environmentally friendly Lanna free and easy dyes. Add 4% of the above-prepared ultra-fine powder activated carbon and 0.7% JFC penetrant to the dyeing bath for 30 minutes, and then add 0.6% acrylic water-based adhesive After dyeing is finished, flush out the tank,

[0077] Through dye screening and reasonable formulation of the process (40°C dyeing and heating rate 1°C / min, 80°C heat preservation for 10 minutes, heat preservation at 98°C for 60 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com