Degradable resin-starch-kenaf extruded plastic master batch

A technology of plastic masterbatch and kenaf, which is applied in the field of polymer materials, can solve the problems of unsatisfactory material properties, poor compatibility between polyethylene and kenaf, etc., and achieve the effect of good processing performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

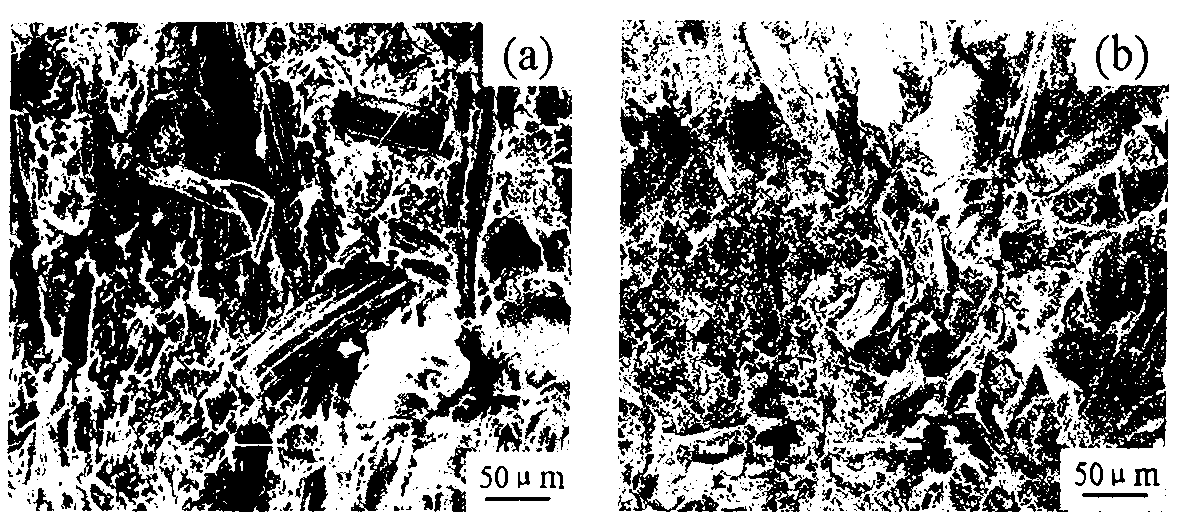

Image

Examples

Embodiment 1

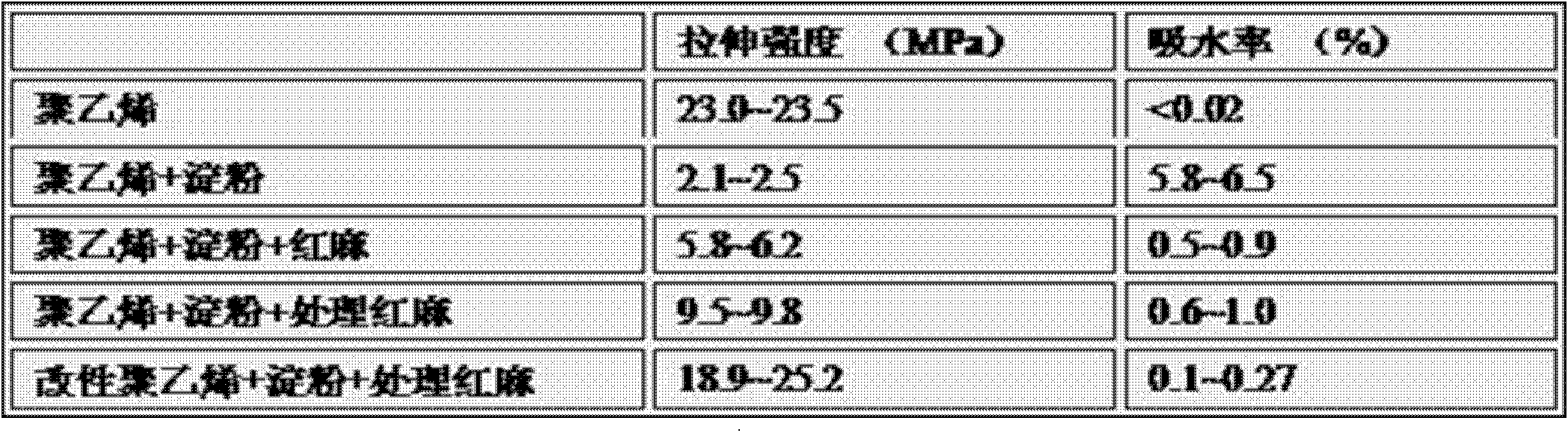

[0020] A kind of degradable resin-starch-kenaf extruded plastic masterbatch, its components are low-density polyethylene 15%, maleic anhydride graft modified low-density polyethylene 15%, starch 45% and kenaf 25%, the kenaf is soaked in hydrochloric acid with a mass fraction of 1% for 10 hours, the tensile strength of the blended material is 20.7MPa, the water absorption is 0.27%, and the biodegradation rate reaches 70% in the presence of aerobic organisms. %.

Embodiment 2

[0022] A kind of degradable resin-starch-kenaf extruded plastic masterbatch, its components are low-density polyethylene 8%, maleic anhydride graft modified low-density polyethylene 40%, starch 20% and kenaf 32%, the kenaf is soaked in acetic acid with a mass fraction of 10% for 5 hours, the tensile strength of the material after blending is 22.2MPa, the water absorption rate is 0.10%, and the biodegradation rate reaches 50% under the condition that aerobic organisms exist. %.

Embodiment 3

[0024] A kind of degradable resin-starch-kenaf extruded plastic masterbatch, its components are low-density polyethylene 20%, maleic anhydride graft modified low-density polyethylene 20%, starch 50% and kenaf 10%, the kenaf is soaked in caustic soda with a mass fraction of 15% for 3 hours, the tensile strength of the material after blending is 18.9MPa, the water absorption rate is 0.19%, and the biodegradation rate reaches 60% under the condition that aerobic organisms exist. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com