A method for degrading polypropylene with high conversion rate driven by solar thermal-electrical coupling

A technology of solar heat and high conversion rate, applied in the direction of electrolytic components, electrolytic process, electrolytic organic production, etc., can solve the problems of high cost and low degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1), can adopt the reaction device with following structure:

[0079] The outer layer of the reaction device is a reaction kettle made of stainless steel. The reaction kettle is divided into upper and lower parts. The upper part is a stainless steel cover. The stainless steel cover and the flange of the lower part of the reaction kettle are sealed by graphite packing. Fasten with bolts and nuts. The fastened reactor can ensure that the gas generated by the reaction does not leak. There are five channels distributed on the upper part of the flange cover, one of which can be set in the center of the flange cover as a thermocouple channel through which the thermocouple can go deep into the center of the reactant to realize real-time monitoring of the reaction temperature; in addition The two channels are symmetrically distributed along the thermocouple channel. As the electrode channel, the anode electrode and the cathode electrode can be connected to the extern...

Embodiment 6

[0099] Embodiment 6 is basically the same as Embodiment 1, the difference is:

[0100] The preset temperature of the reactor is 400°C.

[0101] The preparation methods of Examples 7 to 10 are basically the same as those of Example 6, except that the current intensities are 100mA, 200mA, 300mA, and 400mA, respectively.

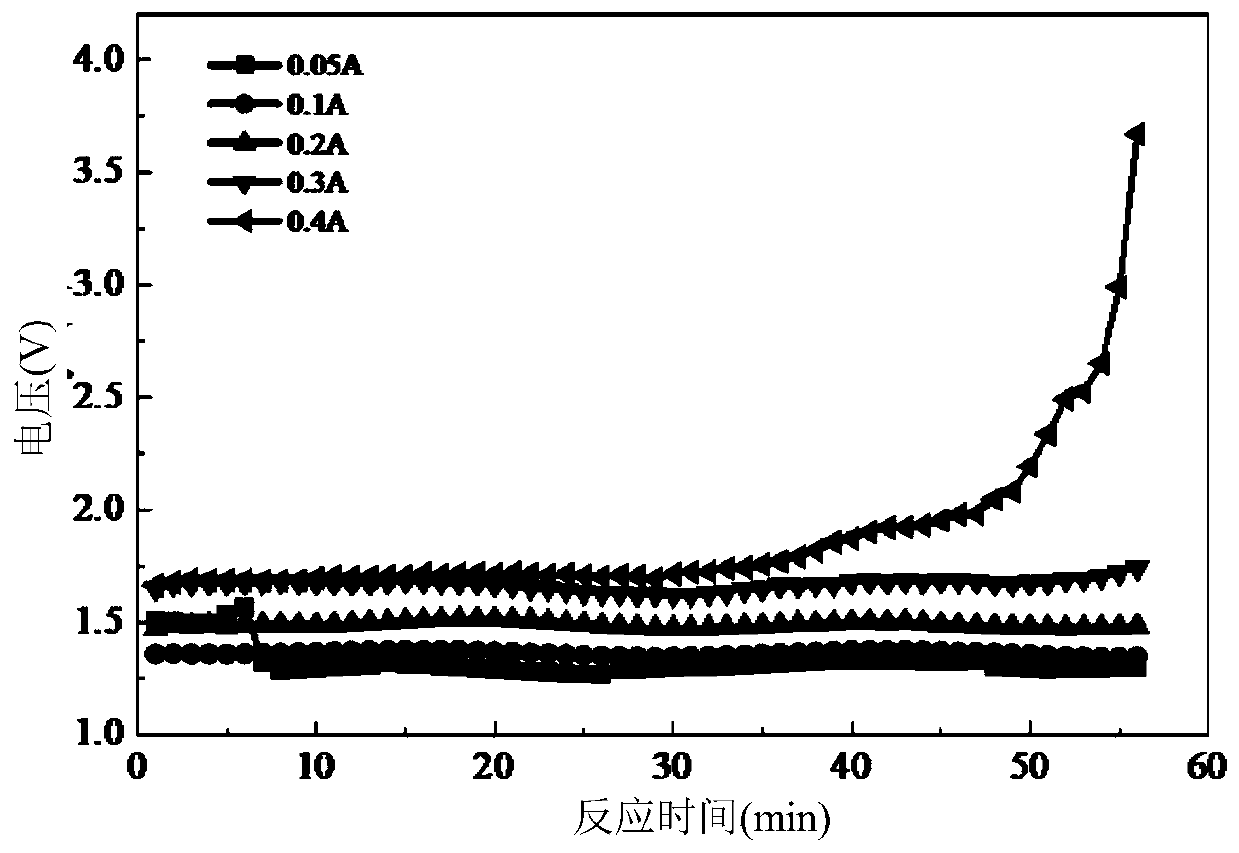

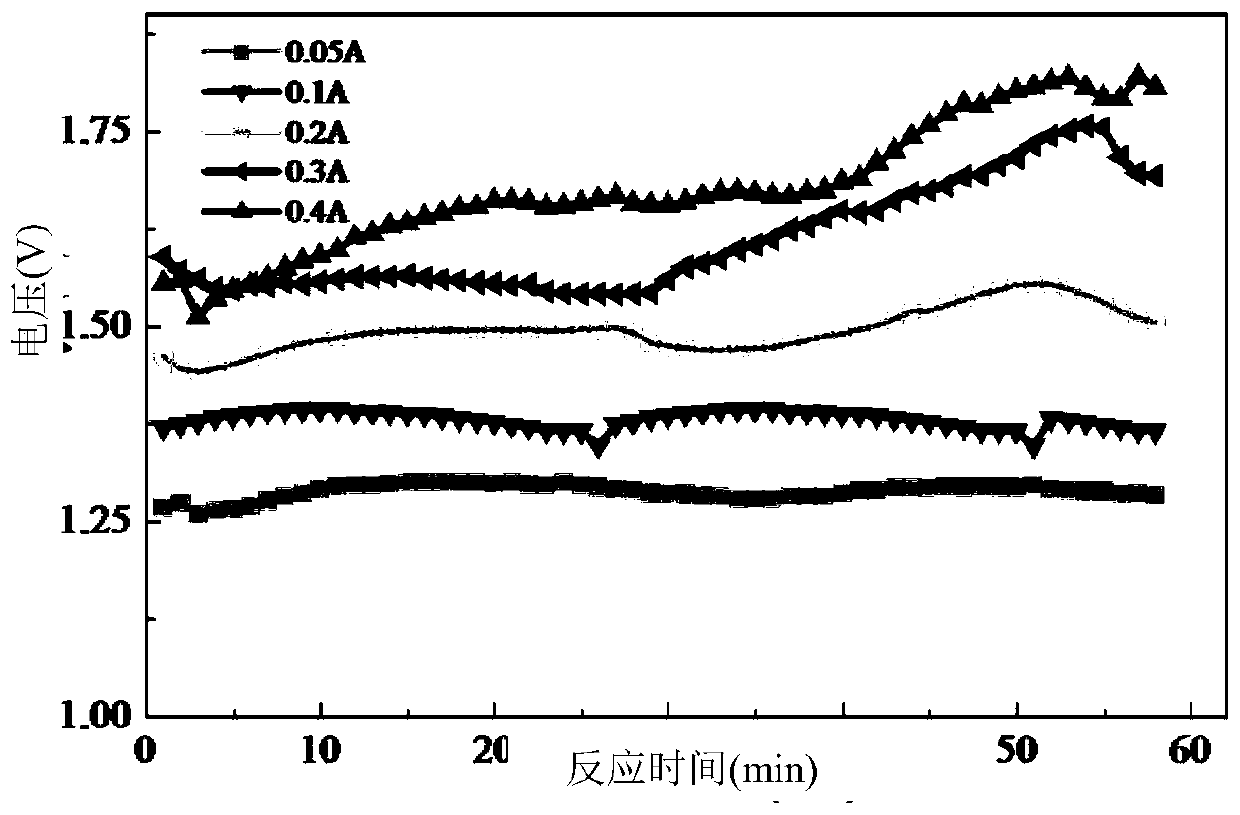

[0102] image 3 The voltage changes during the degradation process of Examples 6 to 10 are shown. At 400°C, the current changes from 50mA to 400mA, and the fluctuation range of the voltage gradually increases.

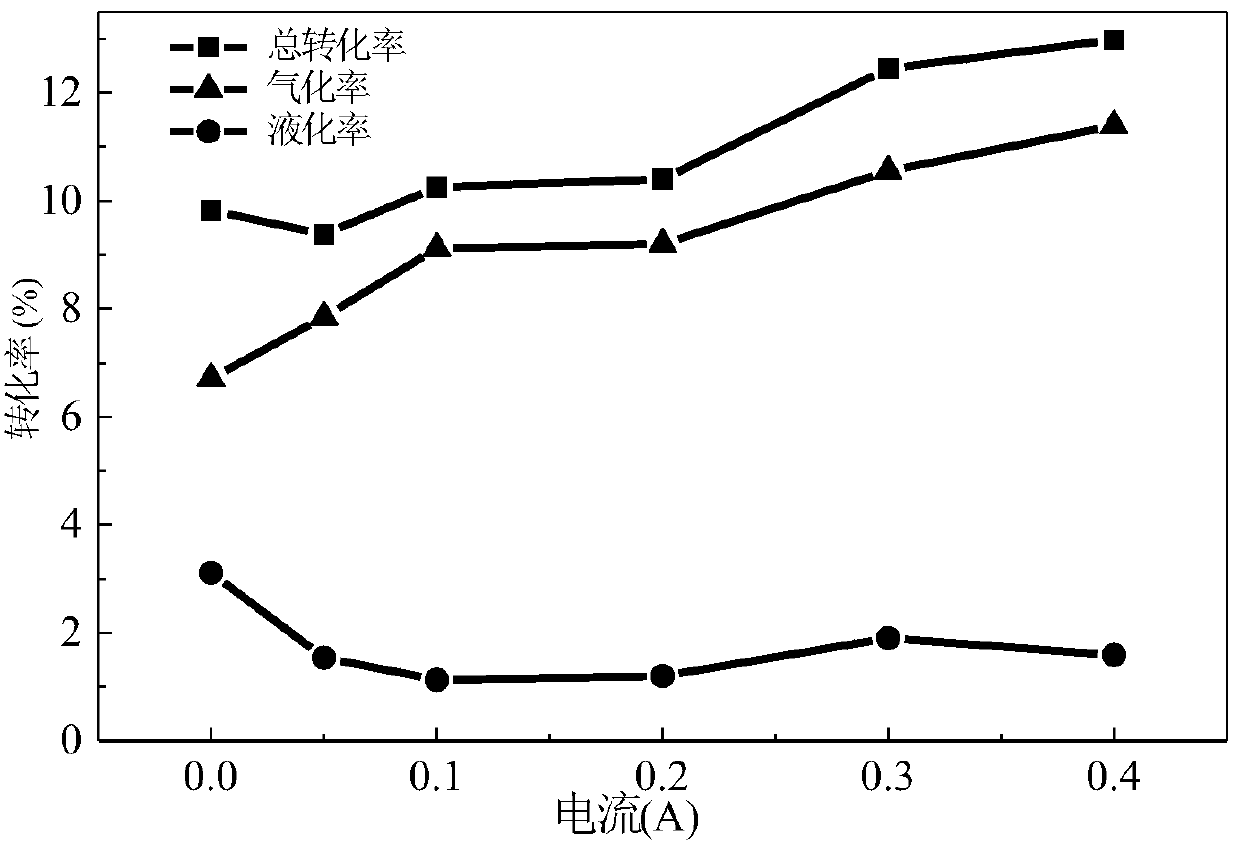

[0103] Figure 4 The polypropylene conversions for Examples 6 to 10 are shown. It can be seen that at 400 °C, the conversion rate of thermal-electrical coupling degradation polypropylene is higher; when the current is increased, the improvement of the total conversion and gasification rate of the reaction is more obvious.

Embodiment 11

[0104] Example 11 is basically the same as Example 1, except that the electrolysis is carried out at a constant voltage of 1.5V.

[0105] Embodiment 12 to Embodiment 16 are basically the same as Embodiment 11, except that the preset temperatures in the reactor are 360°C, 370°C, 380°C, 390°C, and 400°C respectively.

[0106] Figure 5 The polypropylene conversions for Examples 11 to 16 are shown. It can be seen that the total conversion rate, gasification rate and liquefaction rate of polypropylene all increase with the increase of temperature.

[0107] Embodiment 17 to Embodiment 23 are basically the same as Embodiment 11, except that the dosage of polypropylene is 0.5g, 1g, 1.5g, 2.5g, 3g, 3.5g, 4g respectively.

[0108] Figure 6 The conversion ratio comparison results of Example 11, Example 17 to Example 23 are shown. It can be seen that as the dosage of polypropylene increases, the total conversion rate, gasification rate and liquefaction rate of polypropylene decrease...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com