Device and method for receiving pulverized coal by utilizing negative pressure

A pulverized coal and negative pressure technology, which is applied in the field of coal injection in ironmaking blast furnaces, can solve the problems of pulverized coal leakage, large footprint, and high cost, and achieve the effects of improving work efficiency, avoiding pulverized coal leakage, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

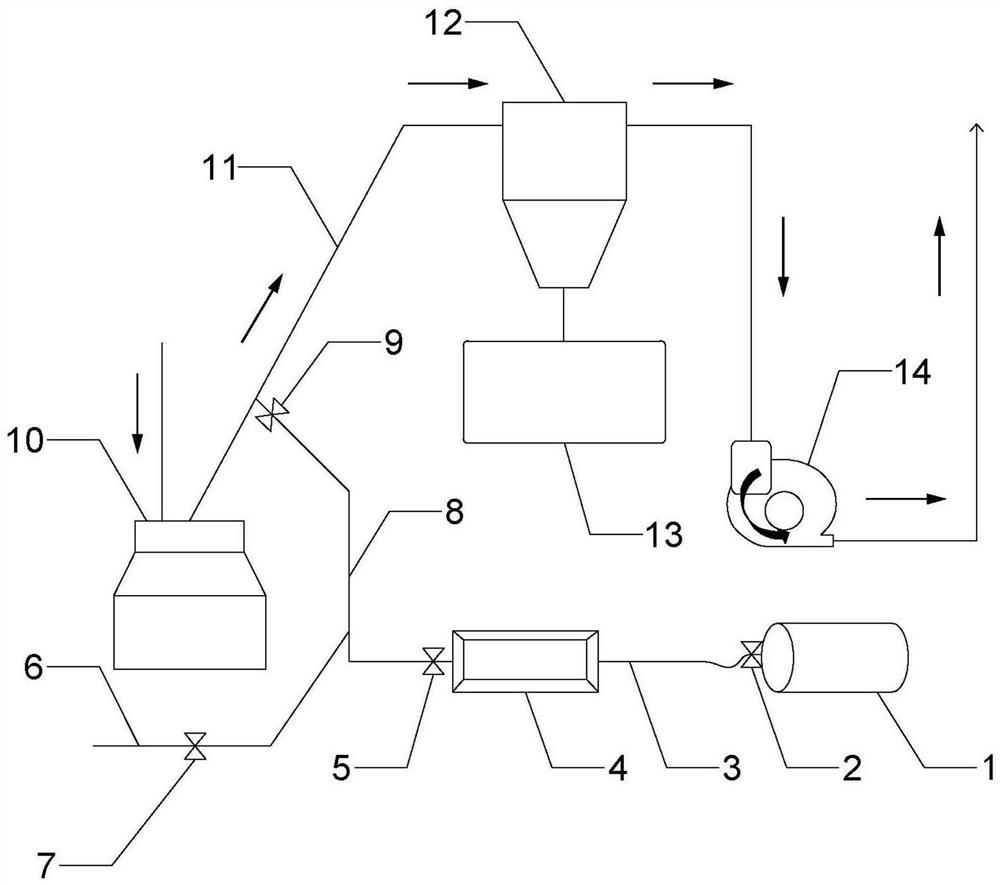

[0037] Such as figure 1 As shown, a device for pulverized coal pulverized by negative pressure includes a pneumatic tank car 1, a pulverized coal filter 4, a coal mill 10 and a pulverized coal bag collector 12, and a coal lowering valve 2 is installed on the pneumatic tank car 1. The powder filter 4 is connected with the first powder receiving pipeline 3, and the other end of the first powder receiving pipeline 3 is provided with a quick joint, which is connected with the lower coal valve 2 of the pneumatic tanker 1, and the coal powder filter 4 is also connected with a second powder receiving pipeline. Pipeline 8, the first gate valve 5 and the second gate valve 9 are installed on the second powder receiving pipeline 8, the booster pipeline 6 is connected to the second powder receiving pipeline 8, the booster valve 7 is installed on the booster pipeline 6, and the coal mill 10 It is connected with the pulverized coal bag collector 12 through a powder outlet pipeline 11 , and ...

Embodiment 2

[0043] On the basis of embodiment 1, a kind of method utilizing negative pressure to carry out pulverized coal pulverization comprises the steps:

[0044] Step S1: Pneumatic tanker 1 transports the purchased coal powder to the pulverized operation point;

[0045] Step S2: pressurize the purchased pulverized coal in the pneumatic tanker 1;

[0046] Step S3: Connect the coal lowering valve 2 of the pneumatic tanker 1 to the quick connector of the pulverized pipeline;

[0047] Step S4: After the pressure of the pneumatic tanker 1 reaches the specified value, close the pressurization valve, and open the first gate valve 5, the second gate valve 9 and the booster valve 7 in sequence;

[0048] Step S5: Open the lower coal valve 2, and the purchased coal powder enters the coal powder filter 4 through the first pulverized pipeline 3;

[0049] Step S6: The purchased pulverized coal is filtered by the pulverized coal filter 4 and enters the pulverized coal outlet pipeline 11 through the...

Embodiment 3

[0054] On the basis of the above embodiments, the boosting medium in the boosting pipeline 6 is heated nitrogen, and the temperature of the heated nitrogen is 80-120°C.

[0055] During the transportation of the purchased pulverized coal, the temperature of the pulverized coal gradually drops. When it reaches the second pulverized pipeline 8DN150, the temperature of the pulverized coal is 35°C to 50°C, resulting in the pulverized coal being in a state of low-temperature condensation and poor fluidity. In order to prevent pulverized coal from being pulverized The phenomenon of pulverized coal blocking the pipeline occurs in the pipeline, and the booster medium uses heated nitrogen, which can be heated to 120°C, which can not only preheat the pulverized coal, but also reduce the condensation of pulverized coal, which is conducive to improving the flow of pulverized coal In the vertical section of the second pulverized pipeline 8, pulverized coal can pass through quickly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com