Patents

Literature

44 results about "Indirect injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Indirect injection in an internal combustion engine is fuel injection where fuel is not directly injected into the combustion chamber. In the last decade, gasoline engines equipped with indirect injection systems, wherein a fuel injector delivers the fuel at some point before the intake valve, have mostly fallen out of favor to direct injection. However, certain manufacturers such as Volkswagen and Toyota have developed a 'dual injection' system, combining direct injectors with port (indirect) injectors, combining the benefits of both types of fuel injection. Direct injection allows the fuel to be precisely metered into the combustion chamber under high pressure which can lead to greater power, fuel efficiency. The issue with direct injection is that it typically leads to greater amounts of particulate matter and with the fuel no longer contacting the intake valves, carbon can accumulate on the intake valves over time. Adding indirect injection keeps fuel spraying on the intake valves, reducing or eliminating the carbon accumulation on intake valves and in low load conditions, indirect injection allows for better fuel-air mixing. This system is mainly used in higher cost models due to the added expense and complexity.

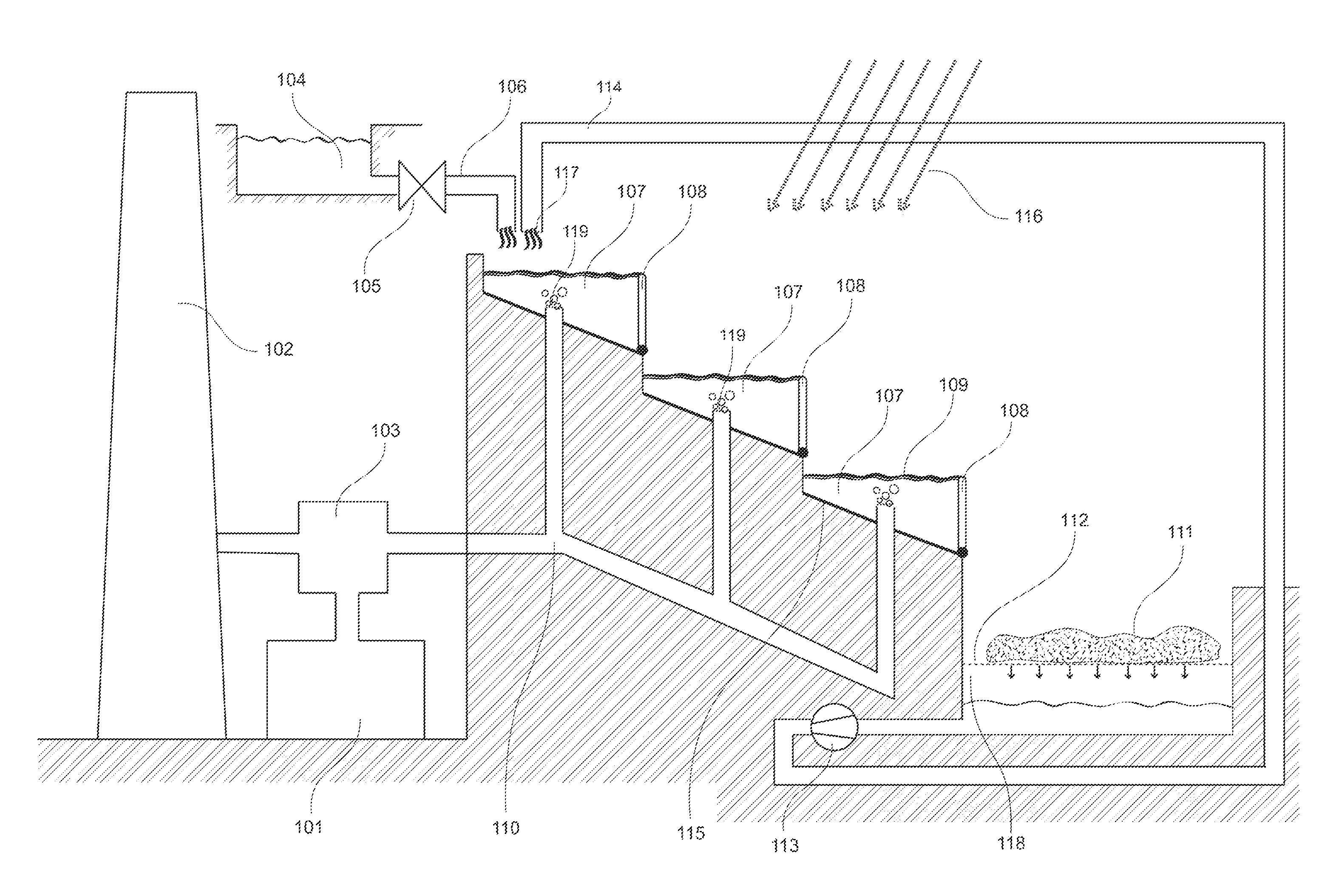

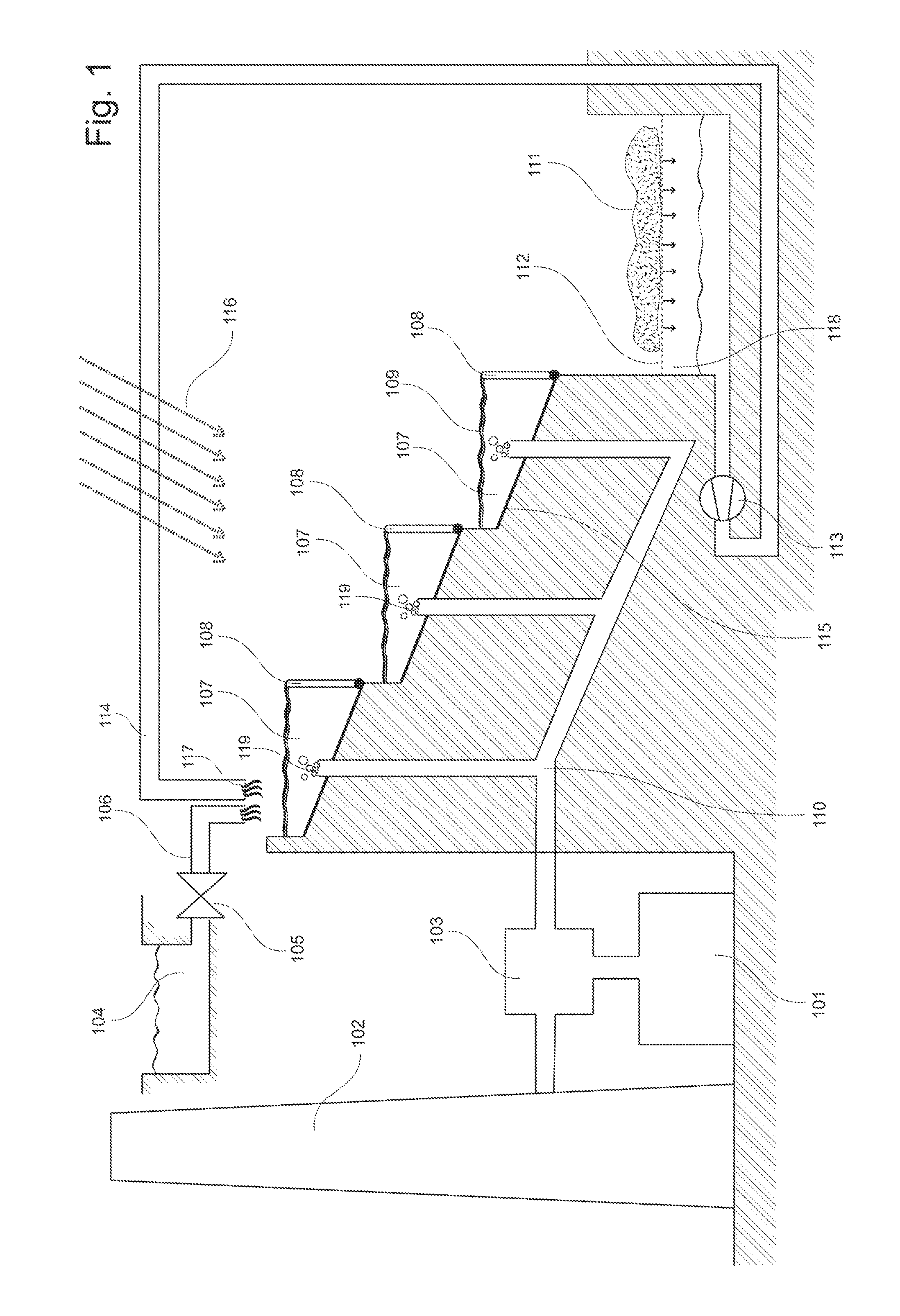

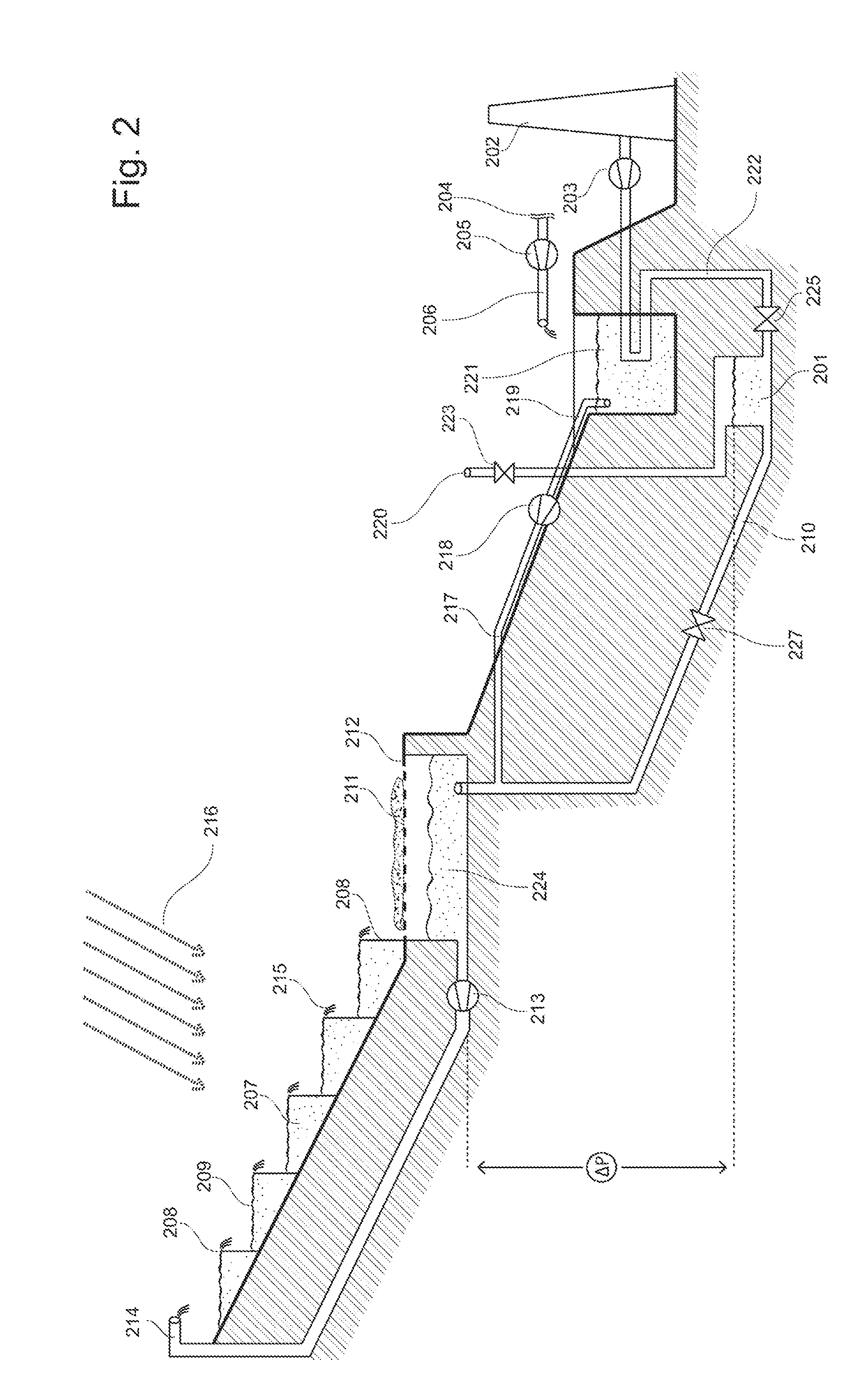

Construction material made of algae, method for cultivating algae, and algae cultivation plant

InactiveUS20110307976A1Promotes algae growthReduce carbon dioxide emissionsUnicellular algaeLayered productsAlgal growthZygnematales

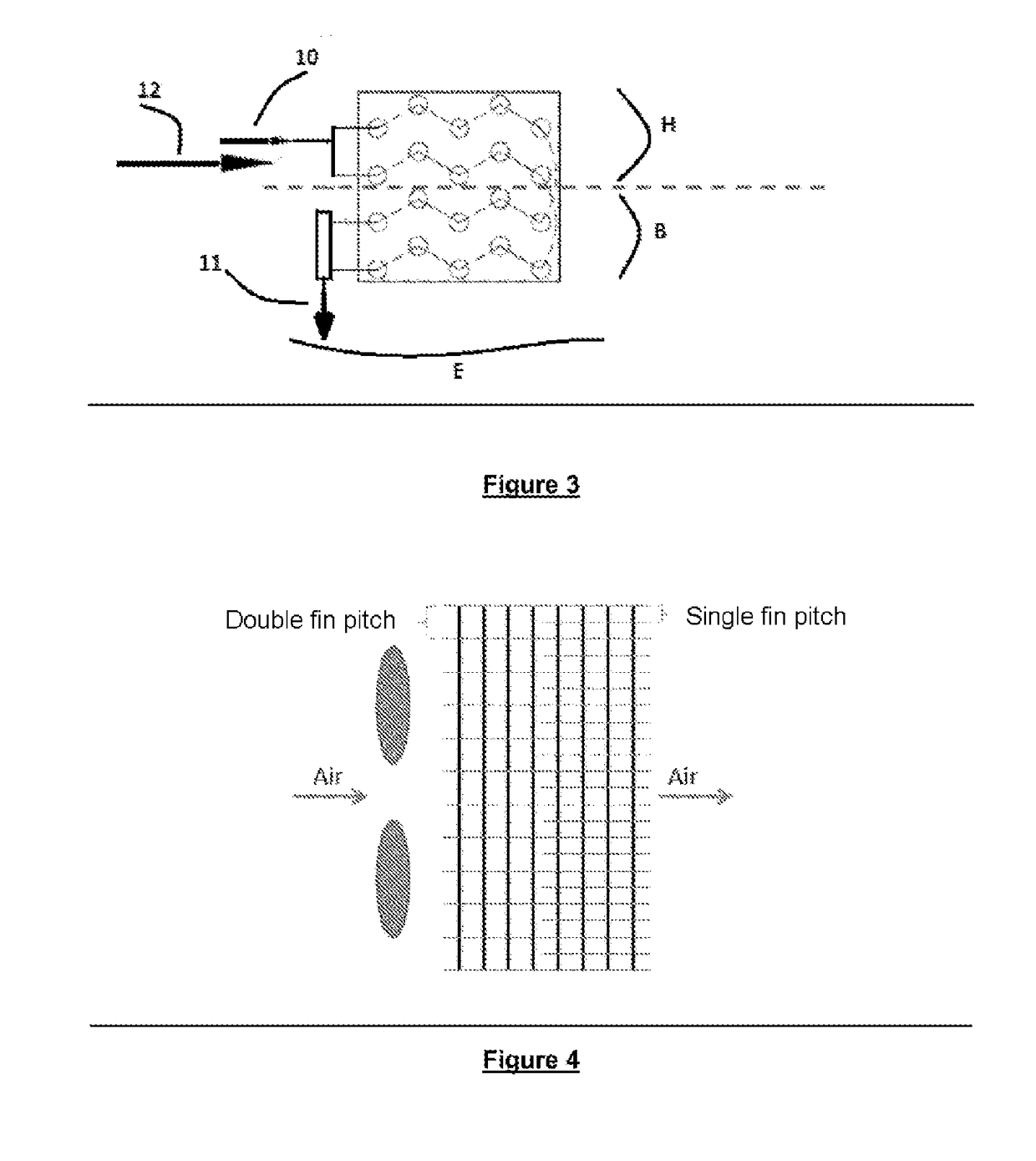

The present disclosure describes use of filamentous algae to form insulating construction materials which provide thermal and noise insulation. Algae from the order Zygnematales, the Cladophorales, or the Ulotrichales can be dried and formed for use as insulating material. Algae mass can be combined into several layers, using a binder to attach the layers to each other. A composite material of algae mass and an additive can be used and form the body of insulation panels having honeycomb-shaped chambers, which are sealed by a foil that is laminated onto the body.Various plants for cultivating algae for use in construction material are disclosed. Plants utilizing gravity harvest comprise cultivation ponds located at a slope, wherein the ponds can be opened to allow algae and water to flow downhill through a collector grill. Plants utilizing net harvest, overflow harvest or rake harvest are described. Carbon dioxide injection concepts utilizing direct and indirect injection of carbon dioxide into algae cultivation ponds are disclosed. An algae harvesting machine is disclosed. Control concepts for controlling the growth of algae in an algae cultivation plant are described.

Owner:PLOECHINGER HEINZ

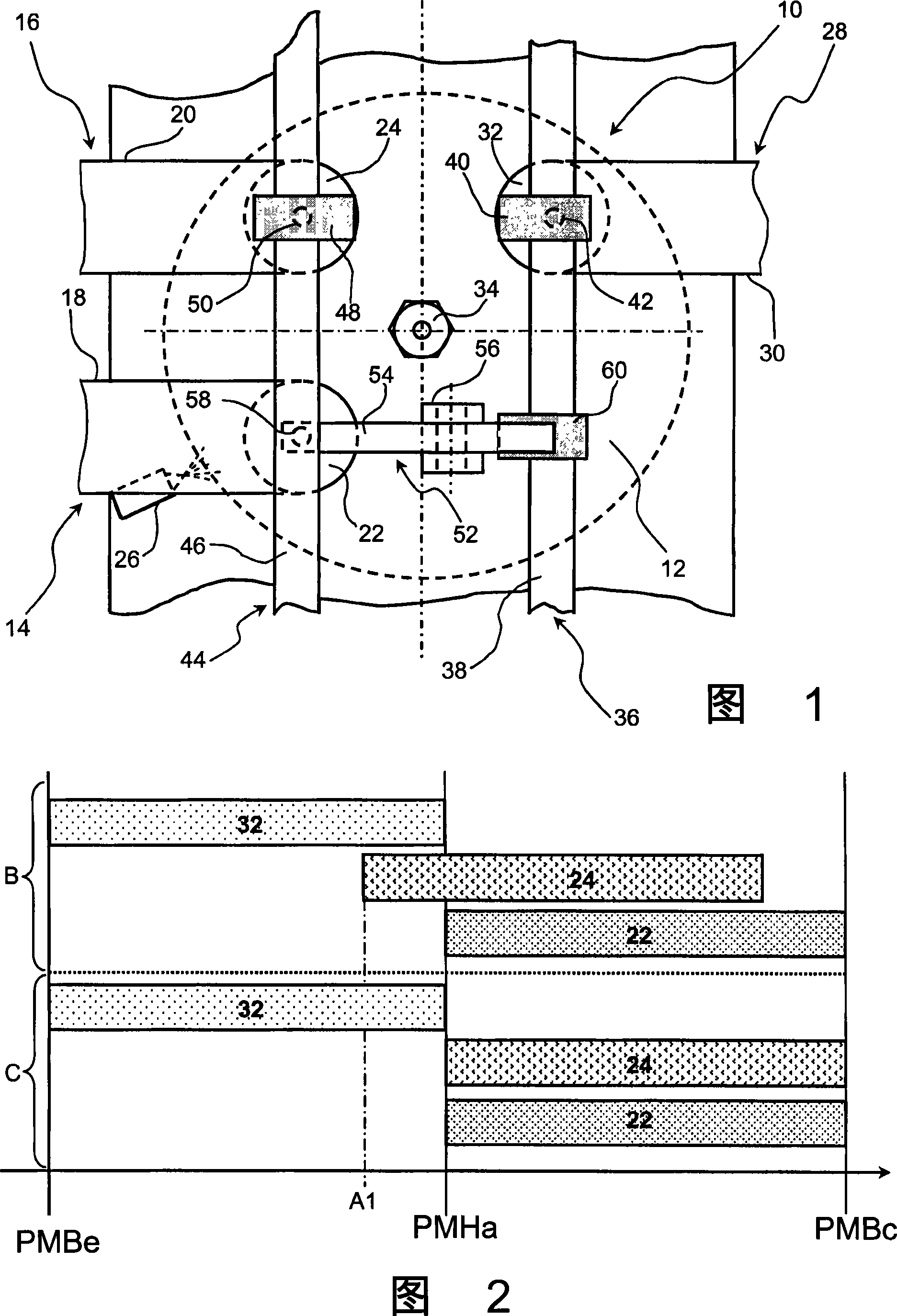

Method of controlling scavenging of the burnt gas of an indirect-injection engine, notably a supercharged engine, and engine using such a method

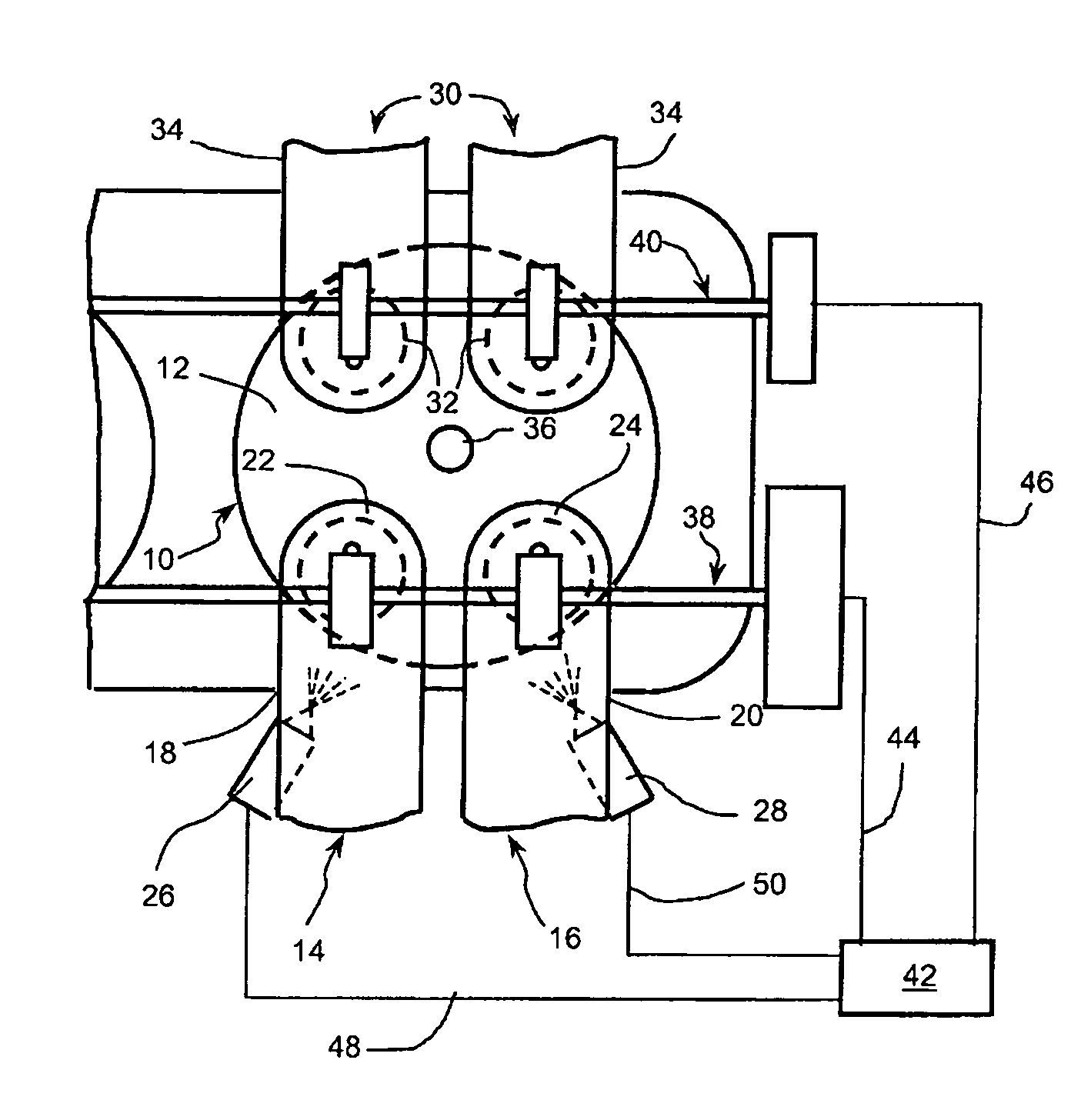

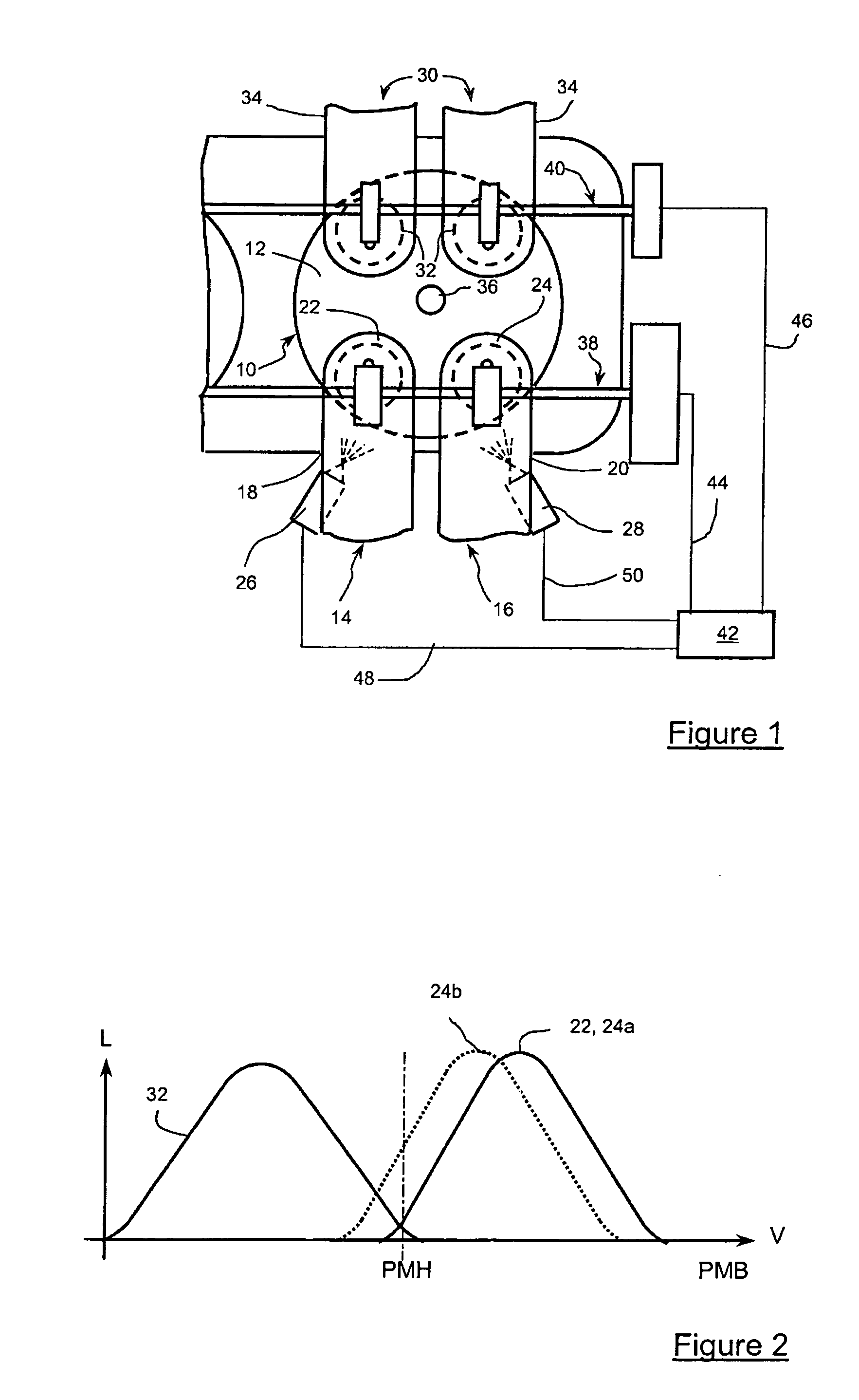

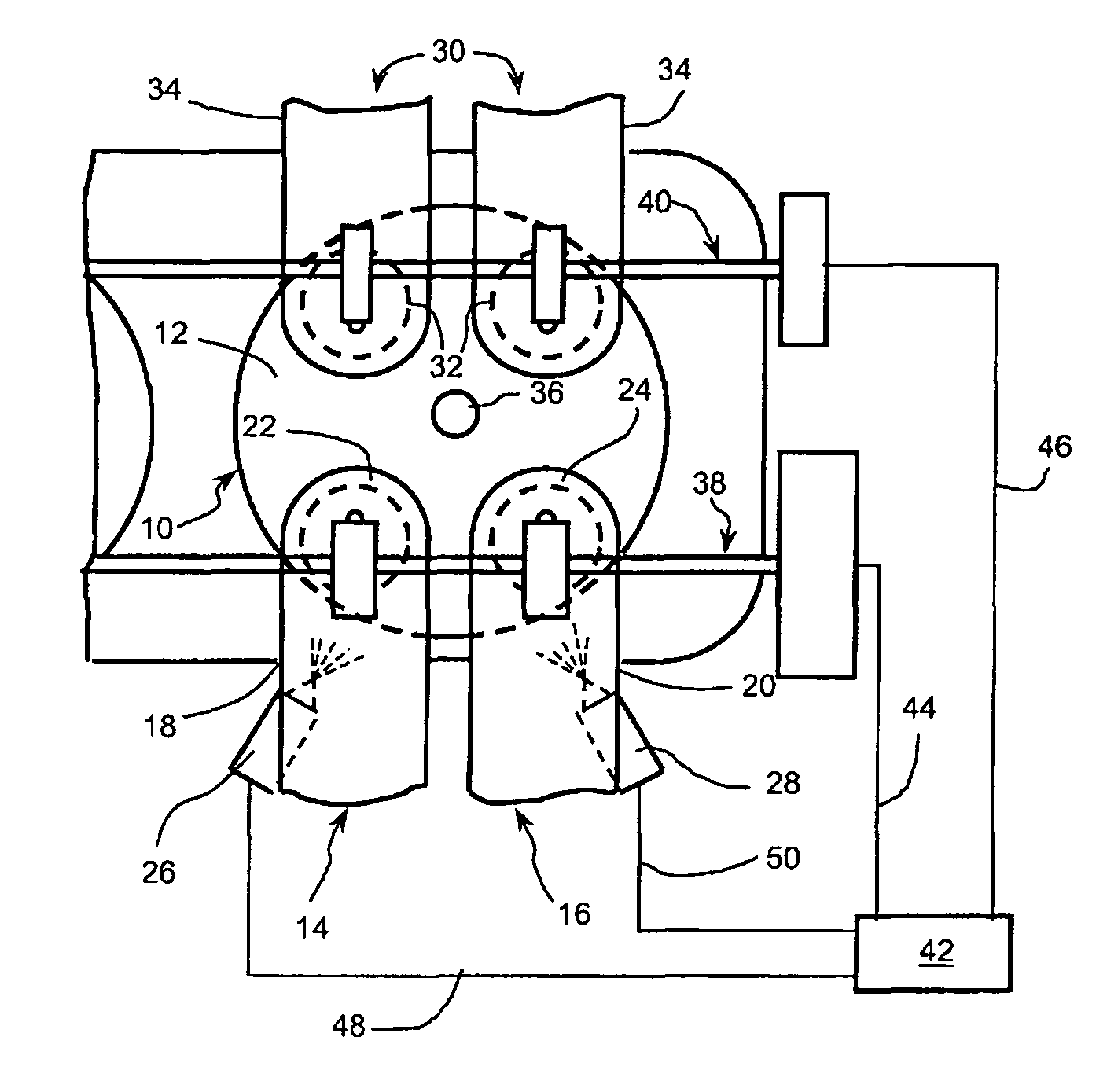

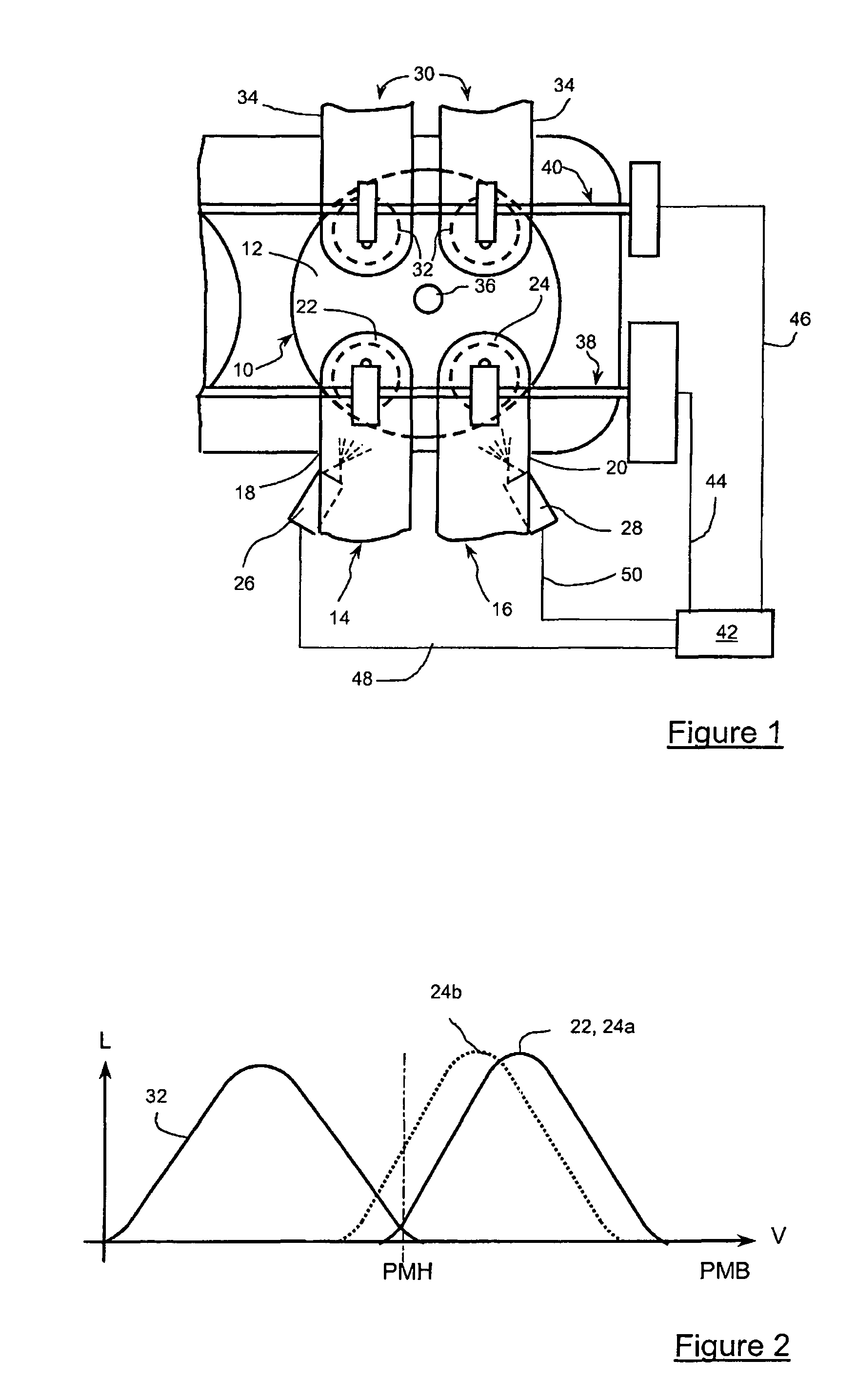

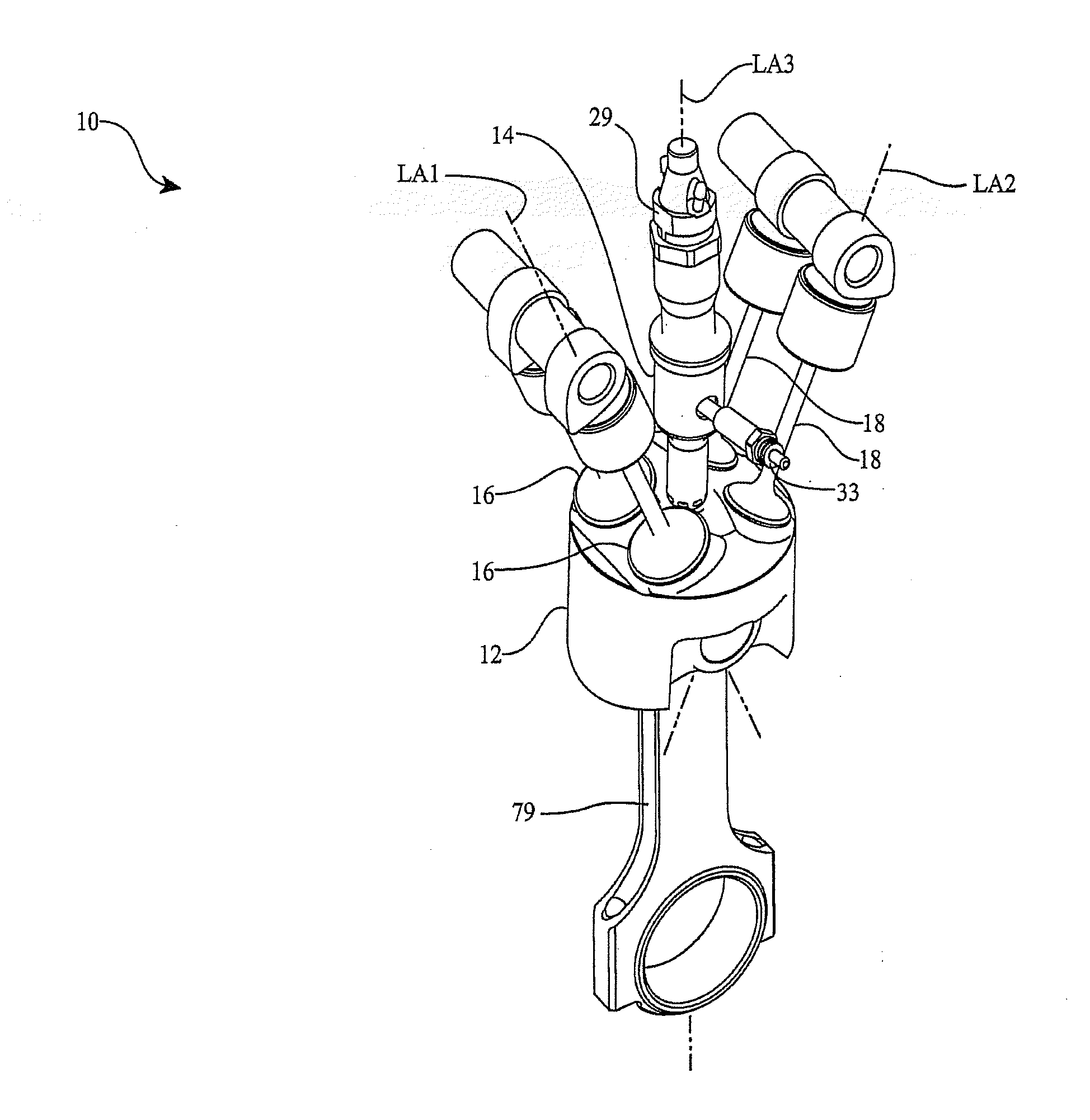

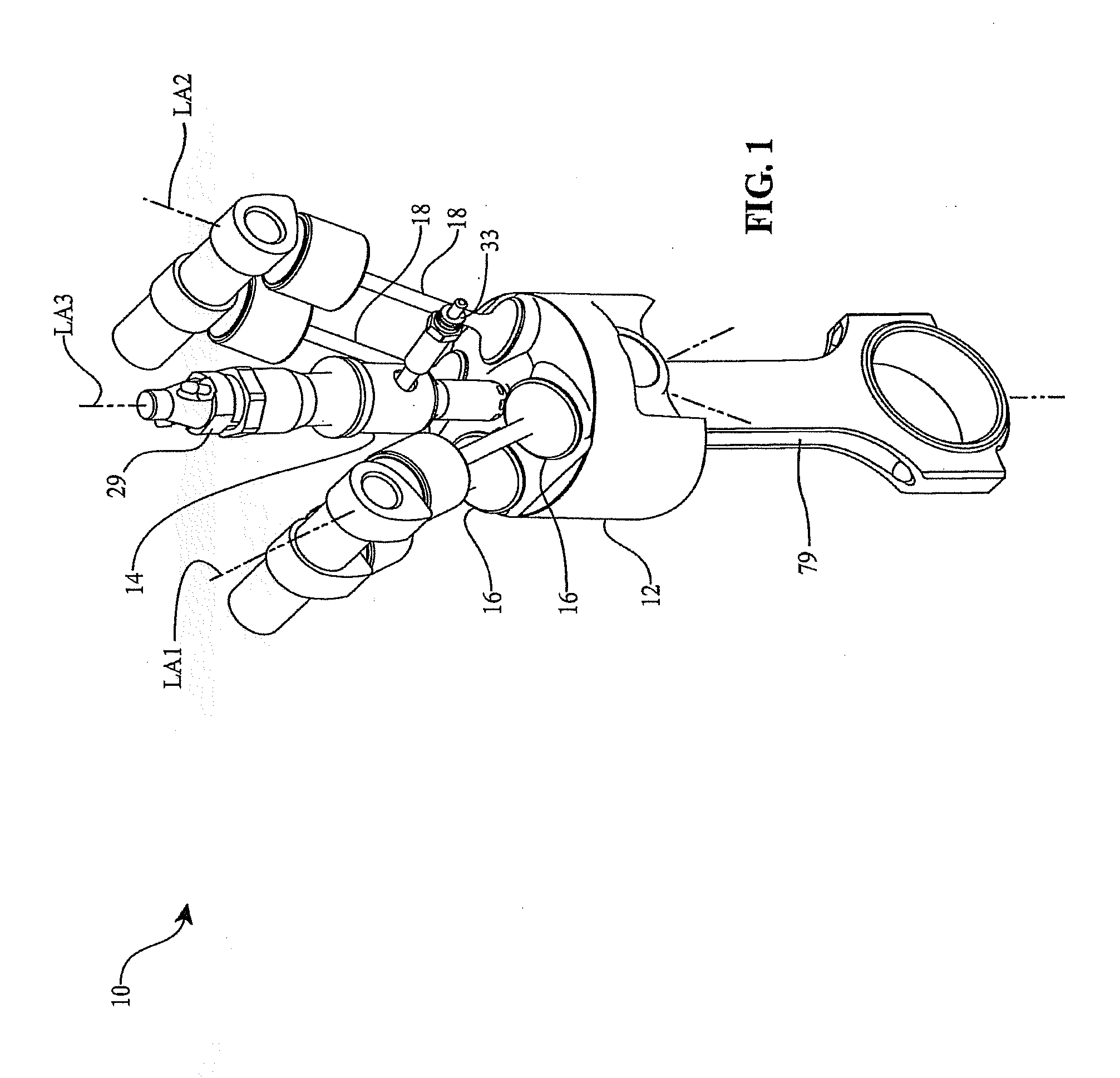

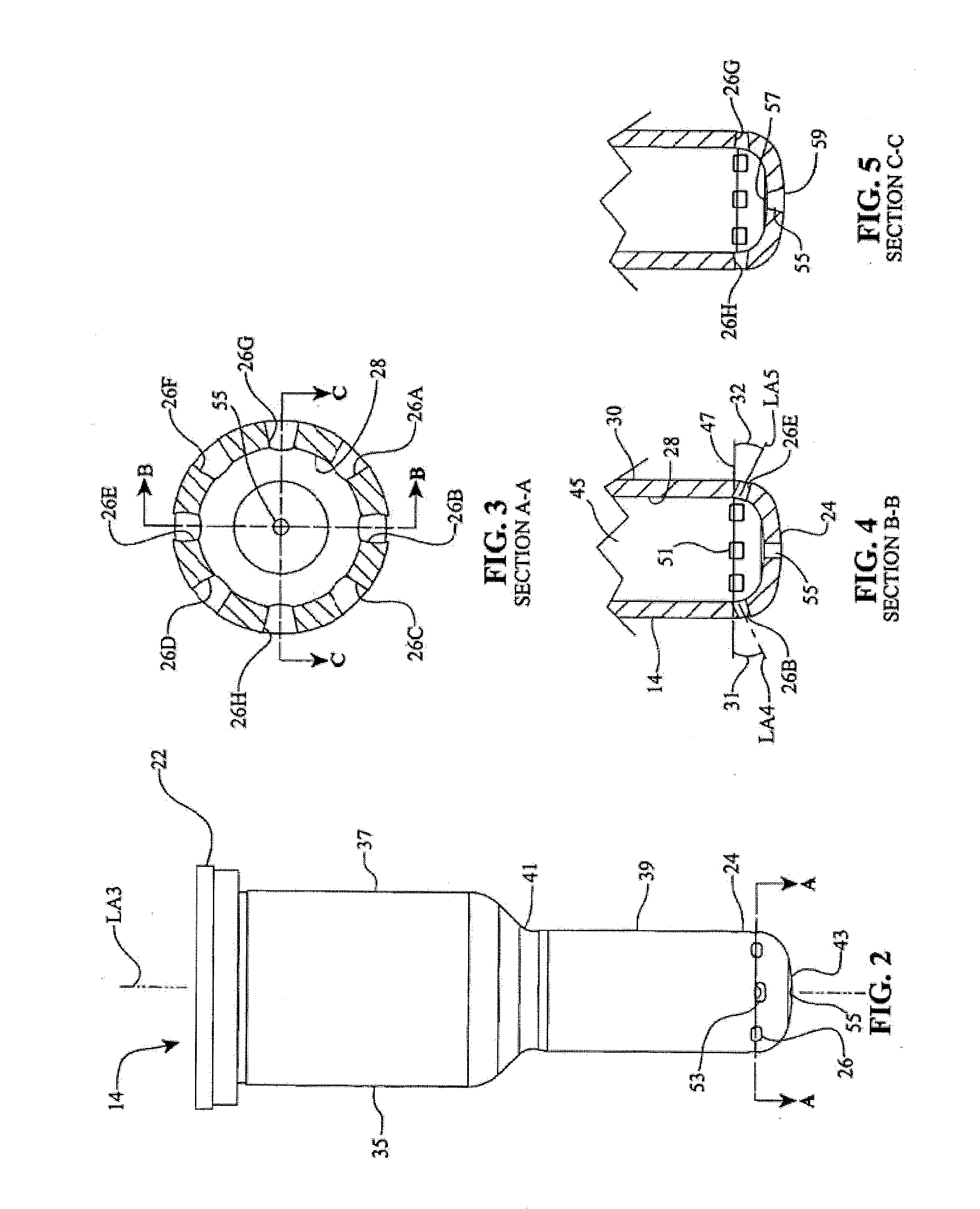

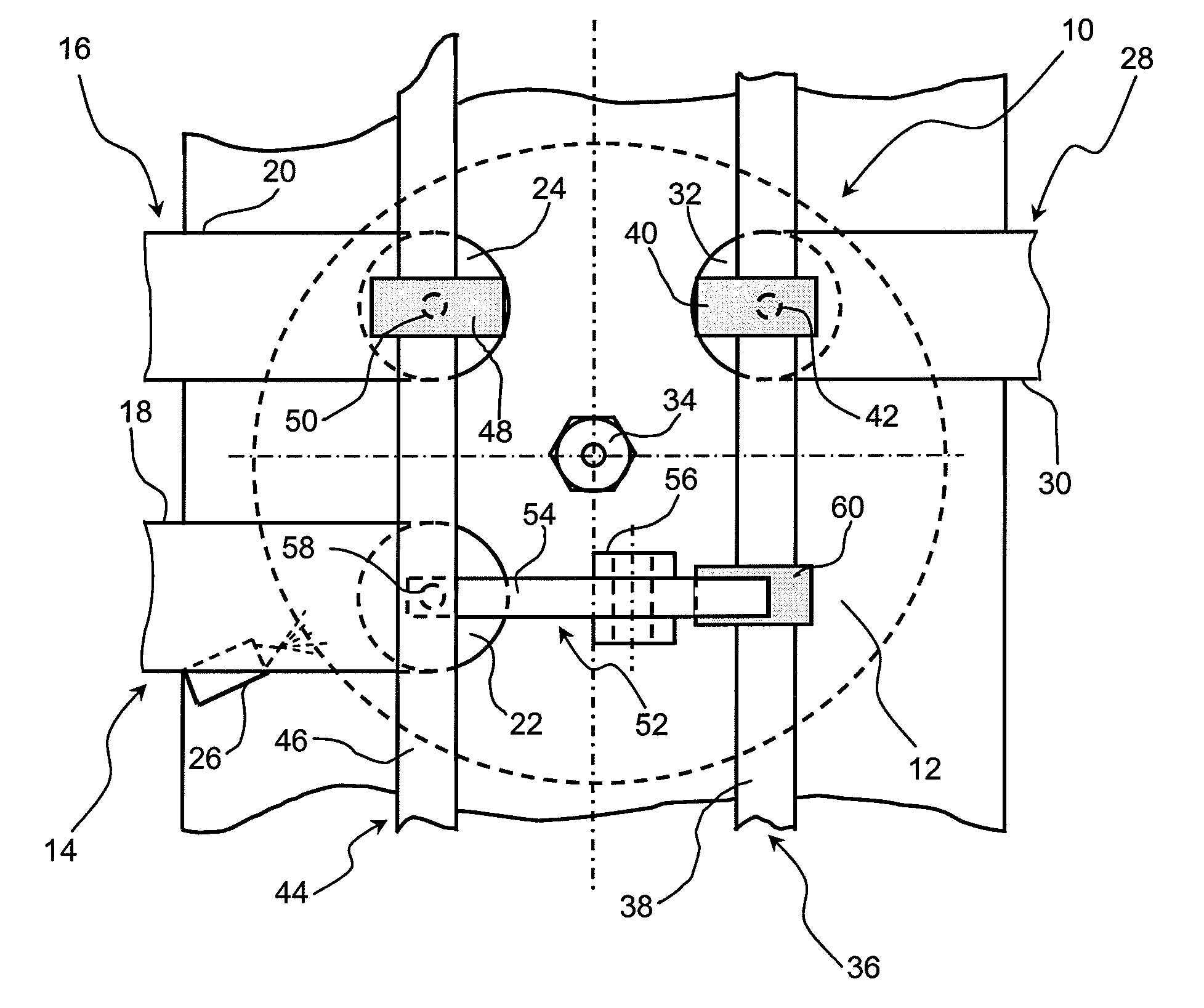

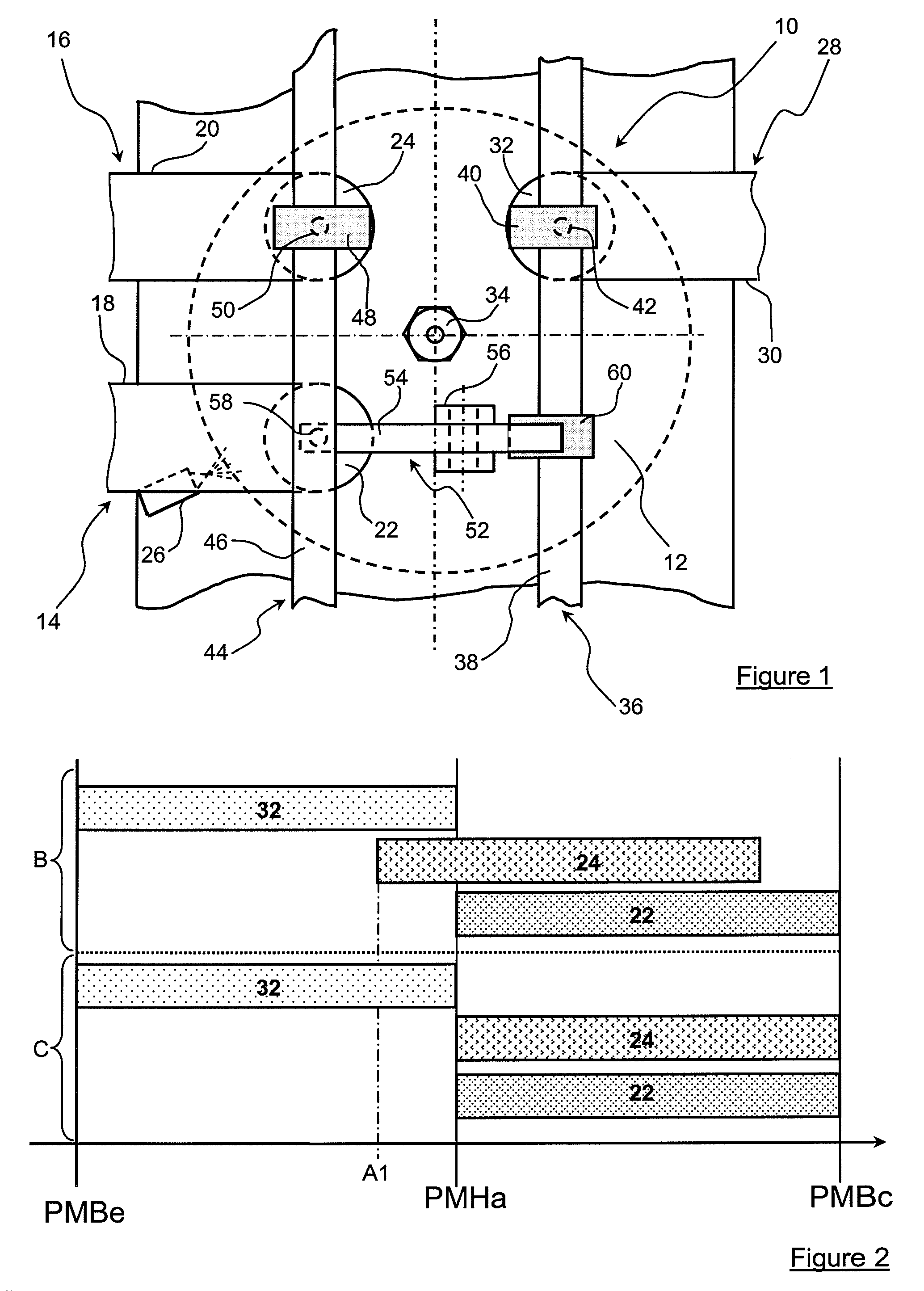

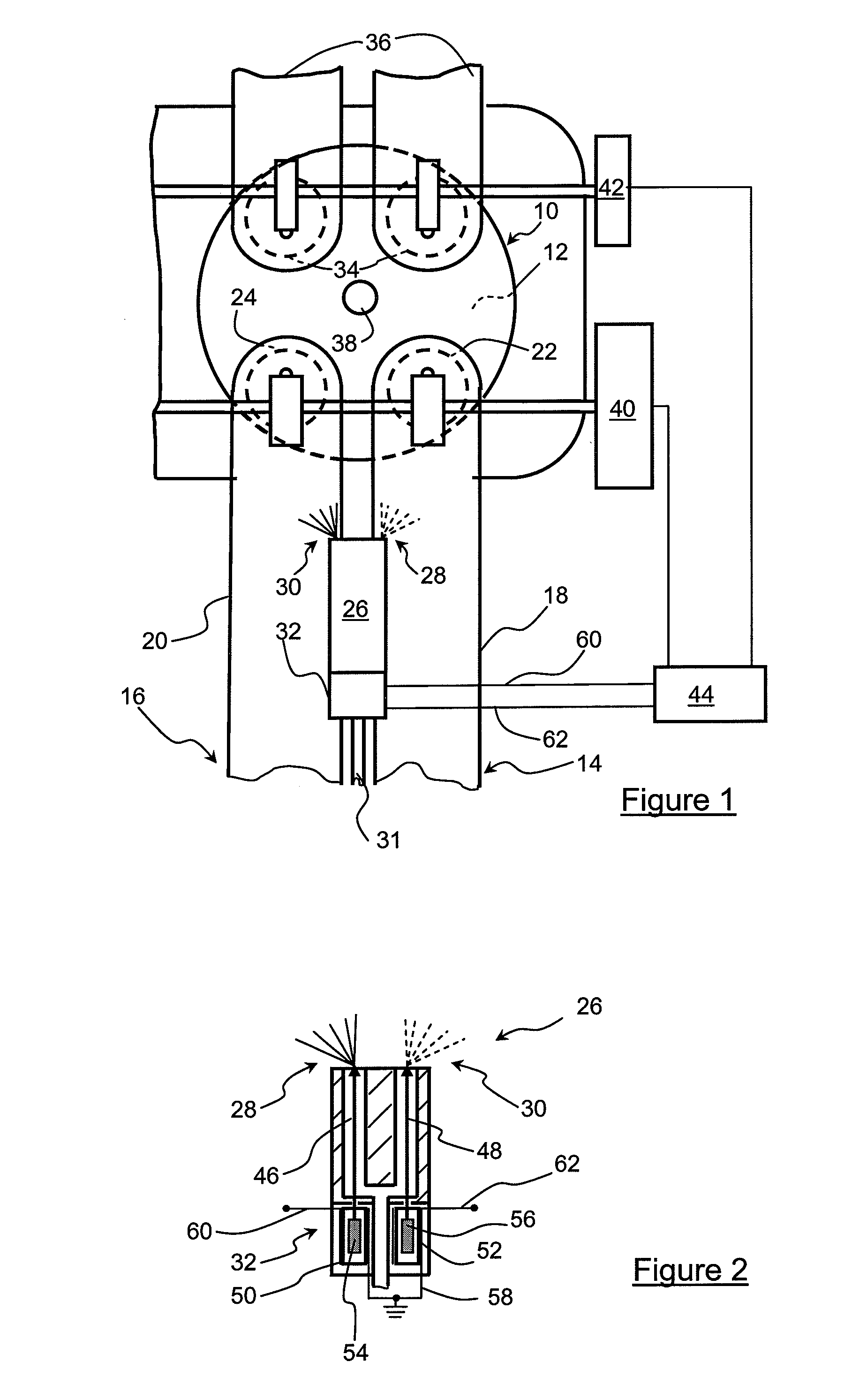

The present invention relates to a method of controlling an indirect-injection engine, notably a supercharged engine, in particular a spark-ignition engine, comprising at least one cylinder (10) including a combustion chamber (12), at least two air intake means (14, 16) comprising each a pipe (18, 20) controlled by an intake valve (22, 24), at least one fuel injection means (26, 28) associated with each intake means and at least one burnt gas exhaust means (30) with an exhaust valve (32), said engine running according to two intake modes, a mode with burnt gas scavenging and a mode without scavenging, characterized in that it consists in: supplying, in intake mode with scavenging, non-carbureted air through one (16) of the intake means then, in the vicinity of the scavenging end, in supplying carbureted air through the other (14) intake means, supplying, in intake mode without scavenging, carbureted air through the two intake means (14, 16).

Owner:INST FR DU PETROLE

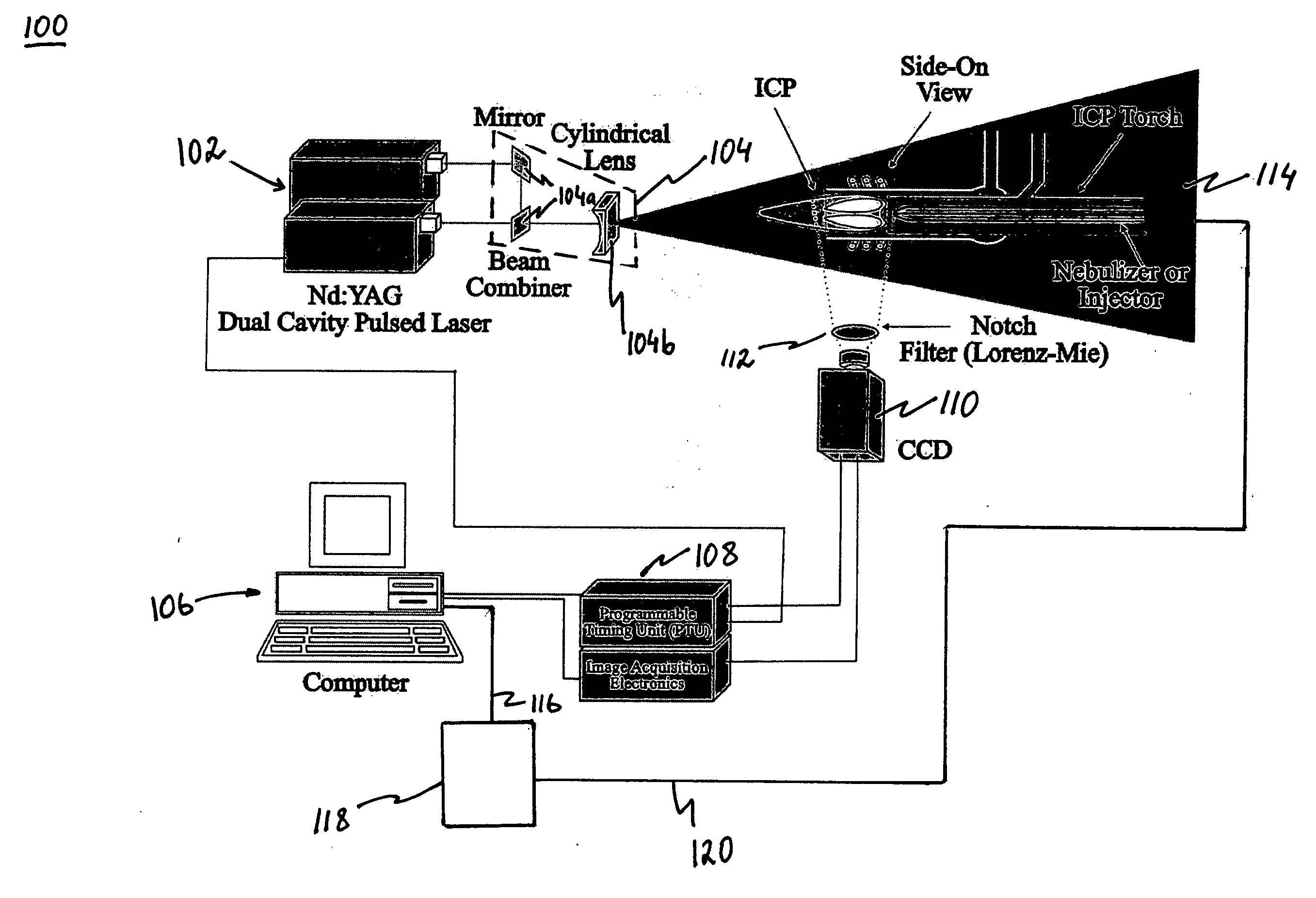

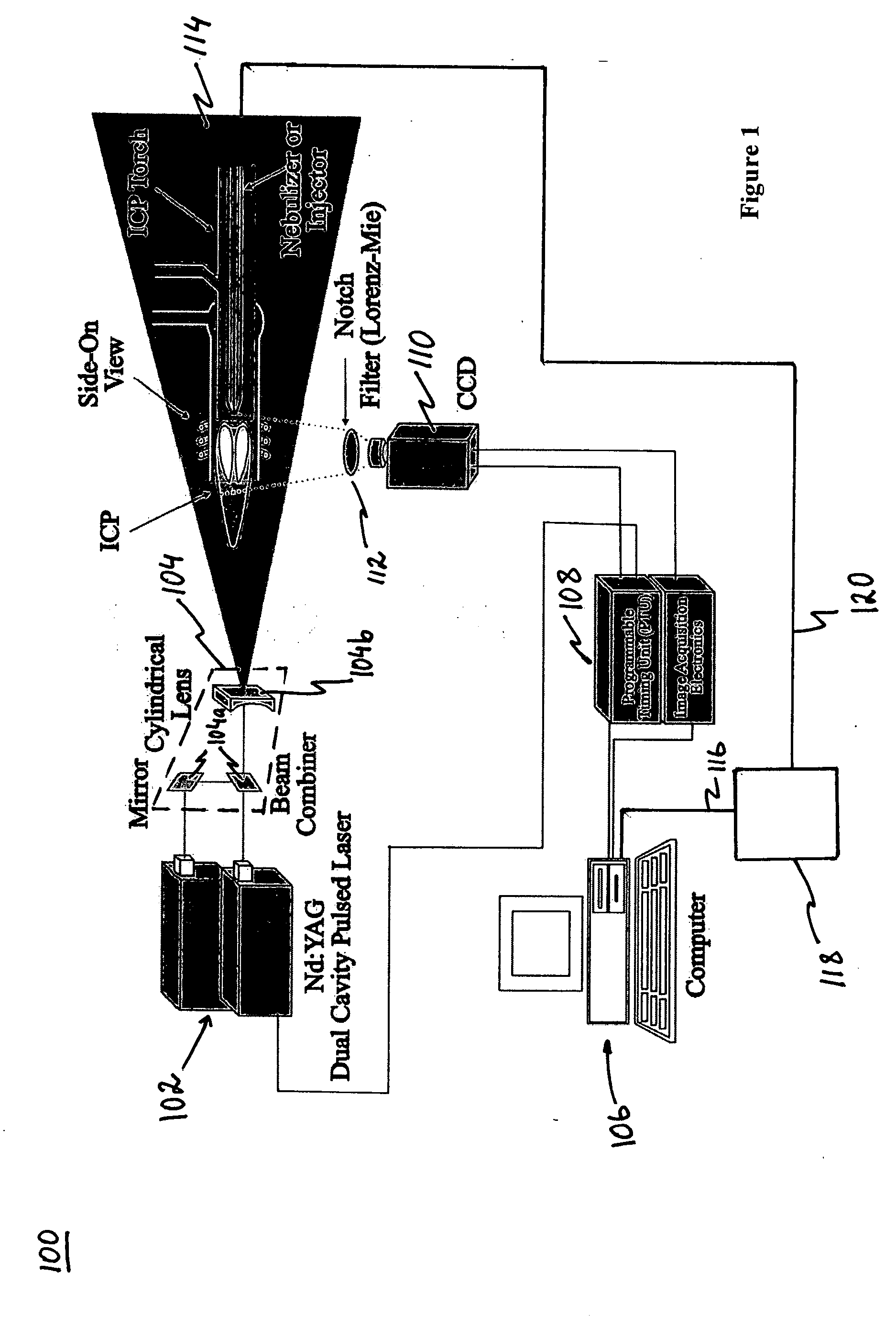

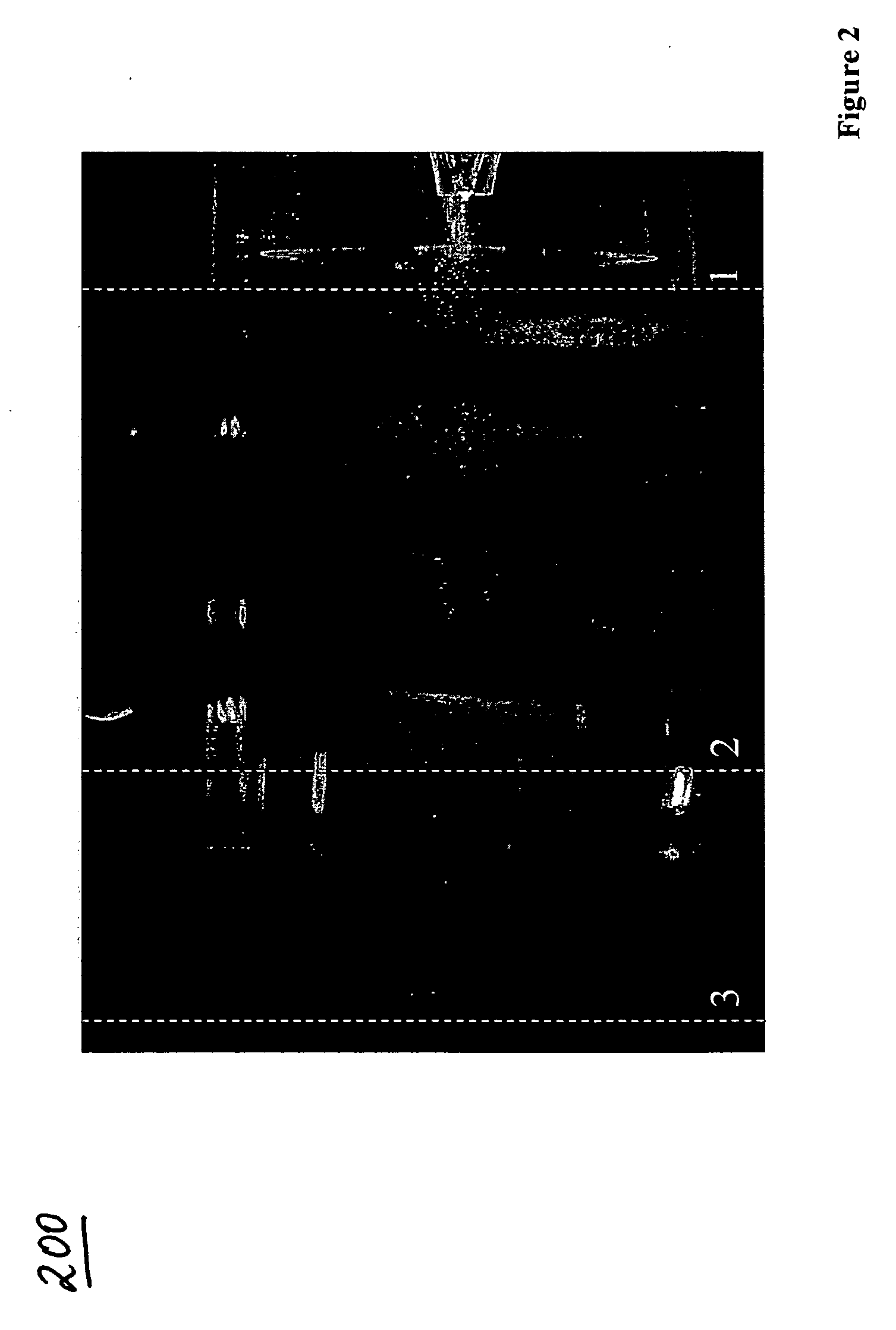

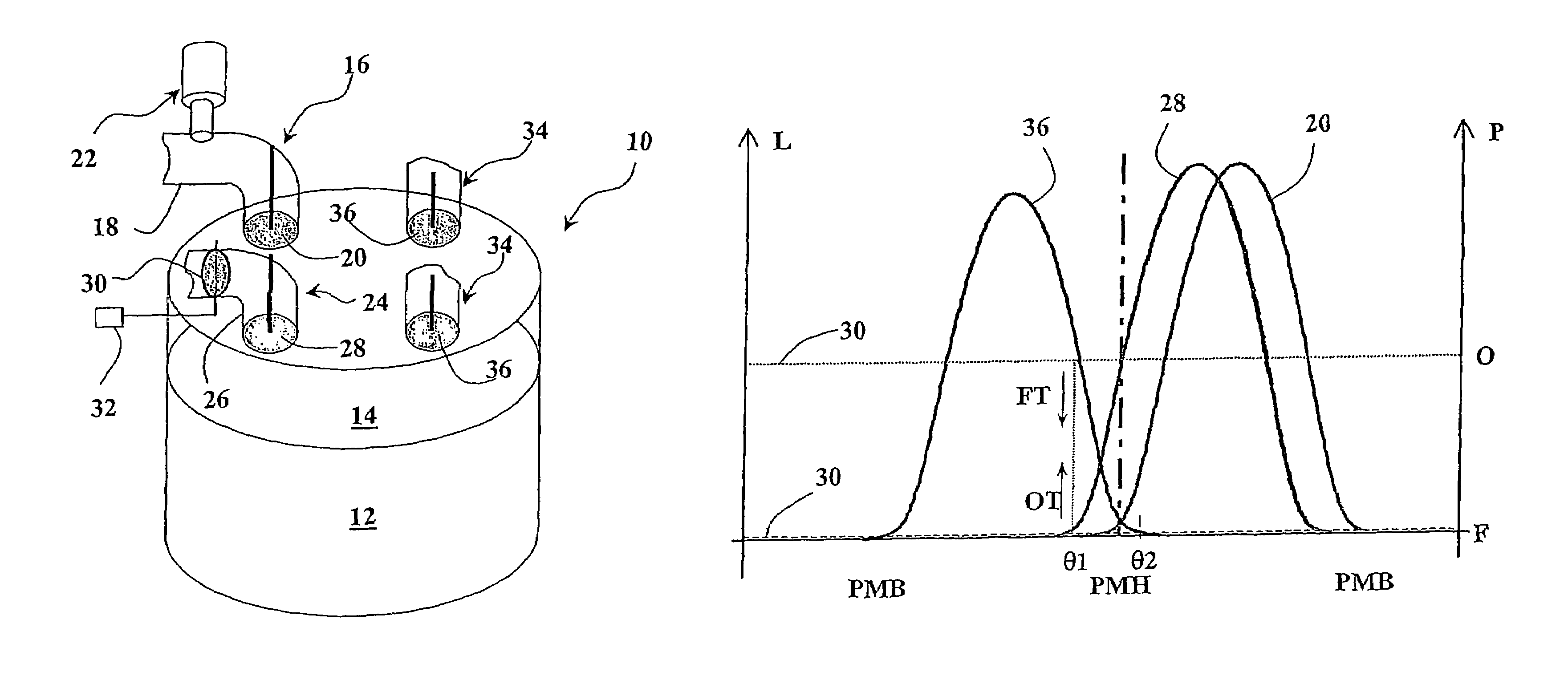

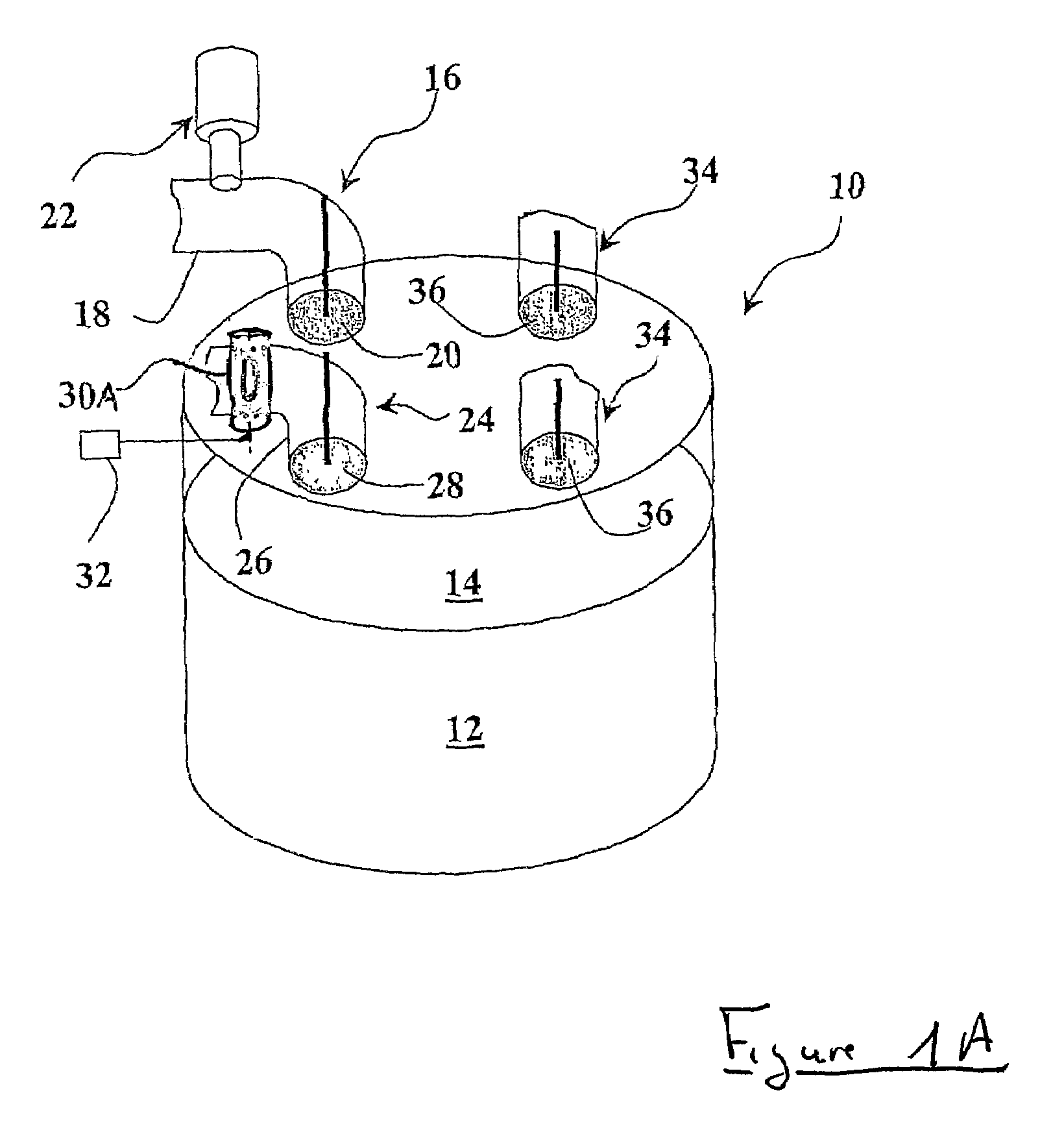

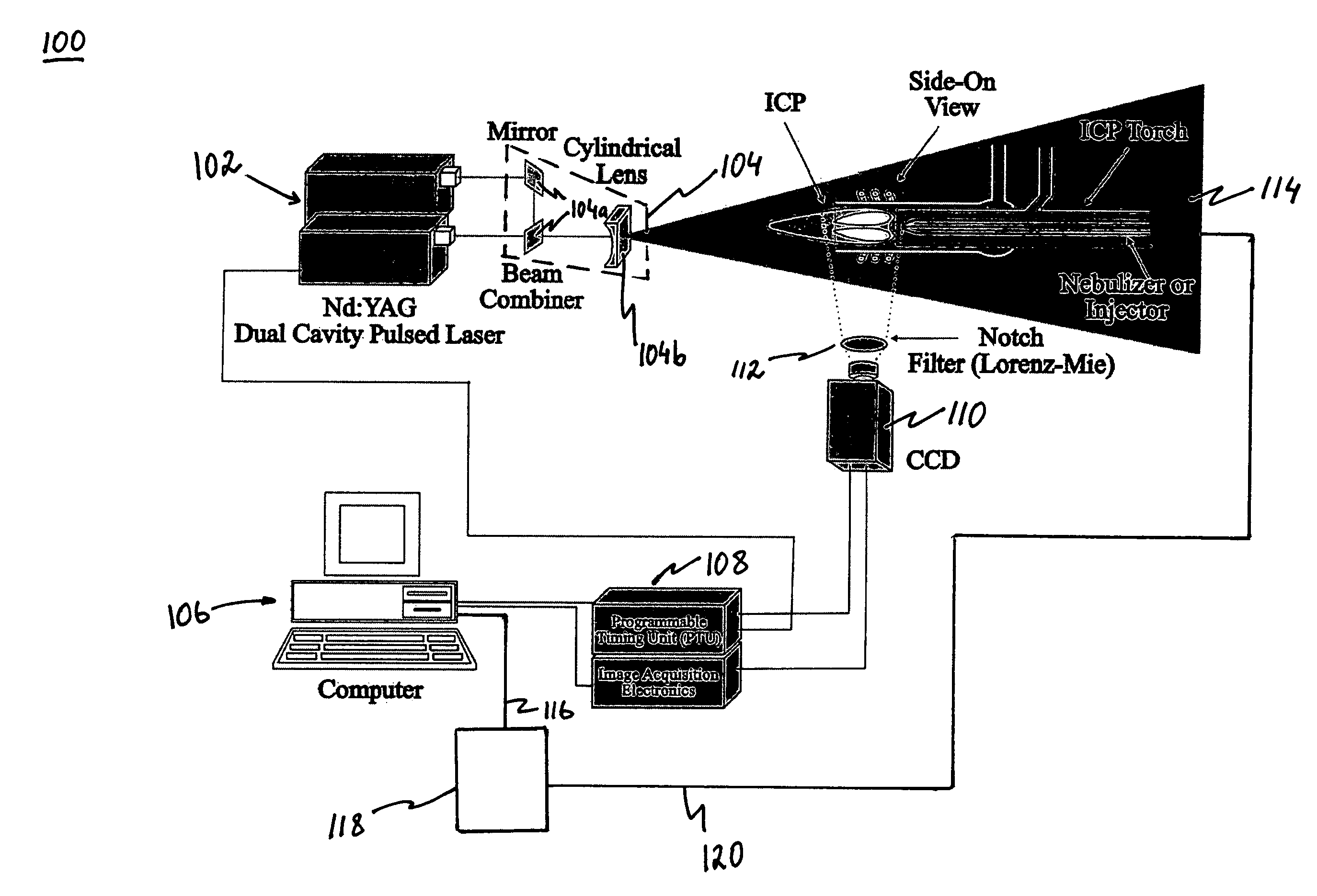

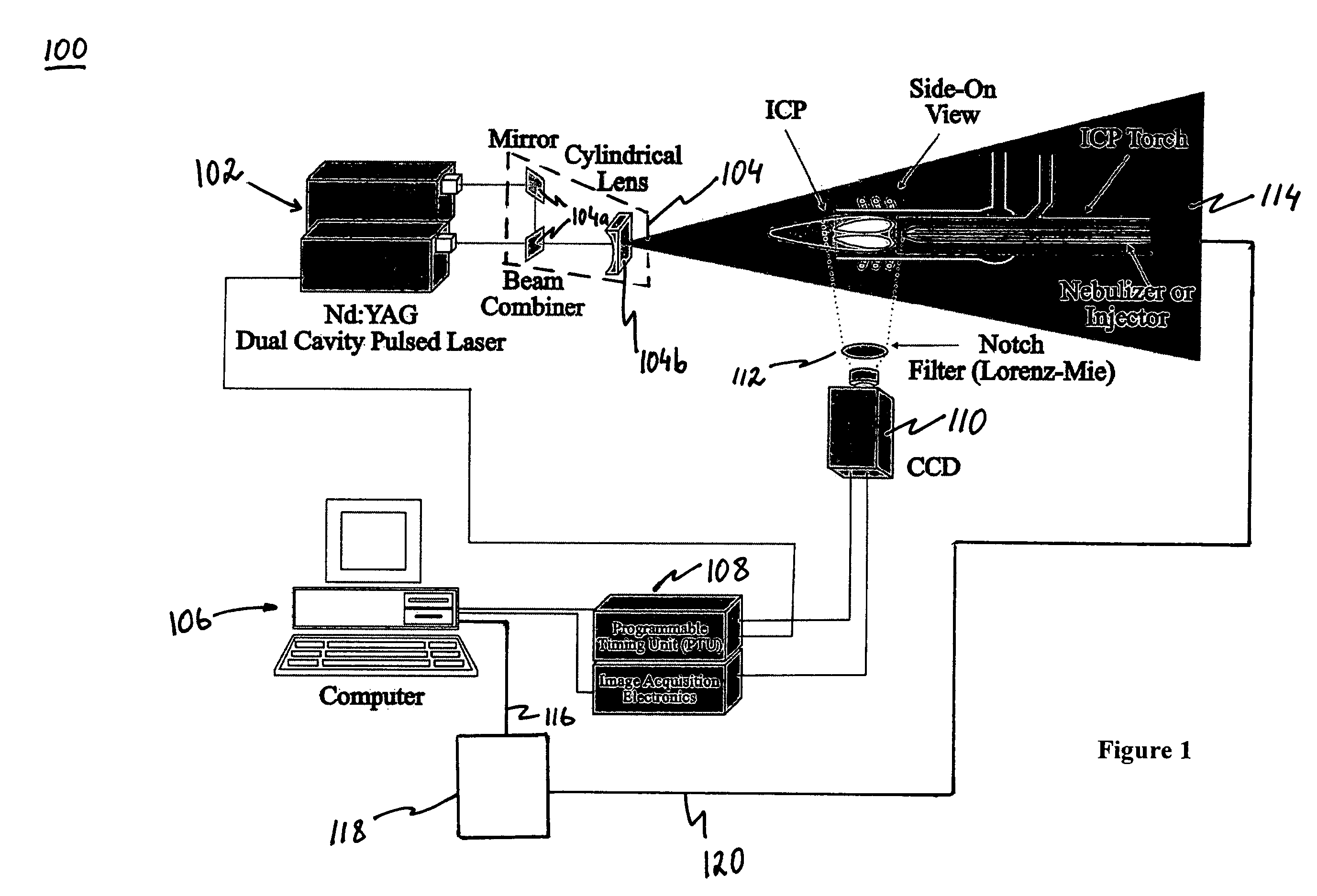

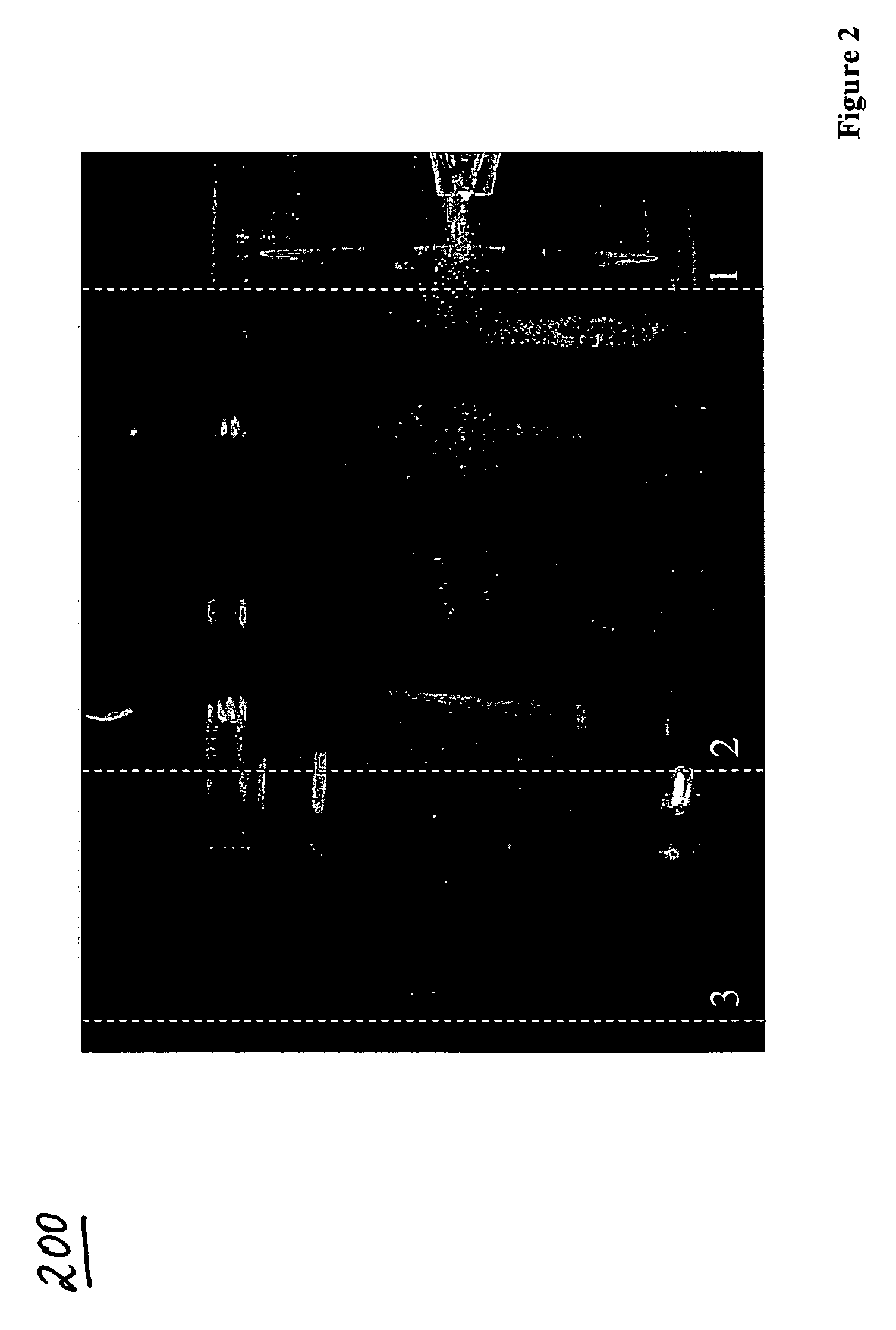

In-situ droplet monitoring for self-tuning spectrometers

ActiveUS20060087651A1Fast dropletStable analytical signalParticle separator tubesMaterial analysis by optical meansLow noiseLaser scattering

A laser scattering based imaging technique is utilized in order to visualize the aerosol droplets in an inductively coupled plasma (ICP) torch from an aerosol source to the site of analytical measurements. The resulting snapshots provide key information about the spatial distribution of the aerosol introduced by direct and indirect injection devices: 1) a direct injection high efficiency nebulizer (DIHEN); 2) a large-bore DIHEN (LB-DIHEN); and 3) a PFA microflow nebulizer with a PFA Scott-type spray chamber. Moreover, particle image velocimetry (PUV) is used to study the in-situ behavior of the aerosol before interaction with, for example, plasma, while the individual surviving droplets are explored by particle tracking velocimetry (PTV). Further, the velocity distribution of the surviving droplets demonstrates the importance of the initial droplet velocities in complete desolvation of the aerosol for optimum analytical performance in ICP spectrometries. These new observations are important in the design of the next-generation direct injection devices for lower sample consumption, higher sensitivity, lower noise levels, suppressed matrix effects, and for developing smart spectrometers. For example, a controller can be provided to control the output of the aerosol source by controlling the configuration of the source or the gas flow rate via feedback information concerning the aerosol.

Owner:GEORGE WASHINGTON UNIV THE

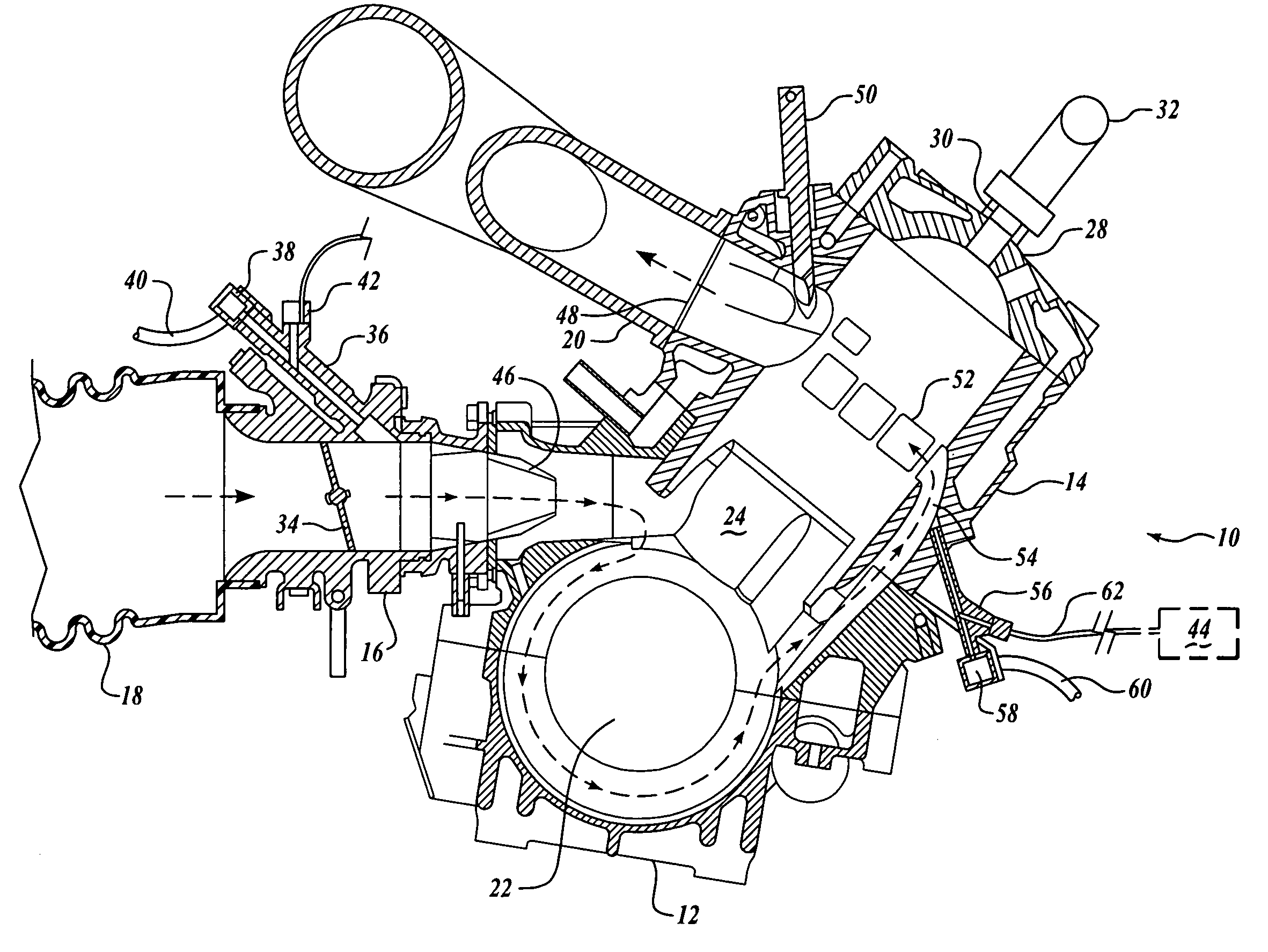

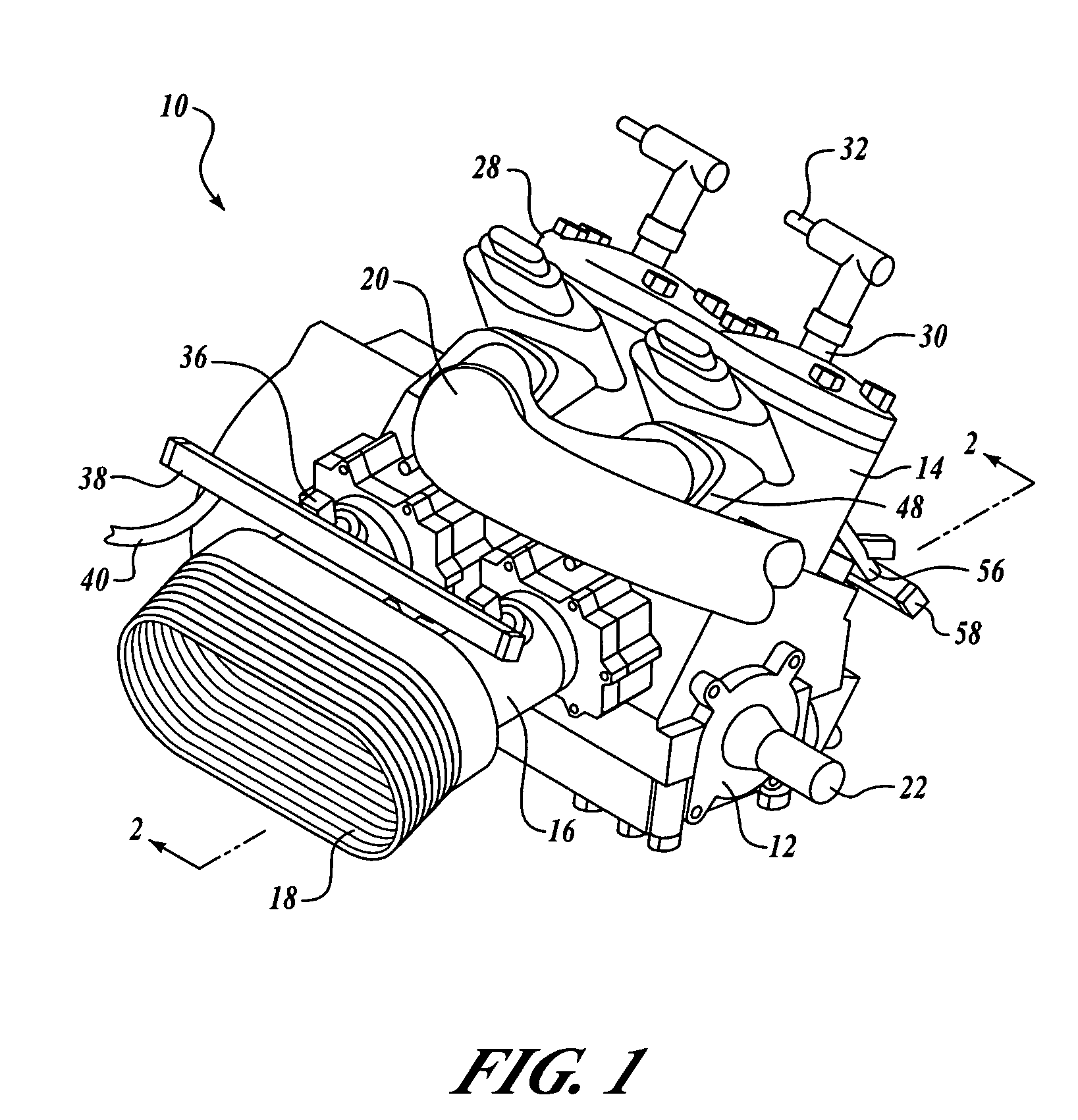

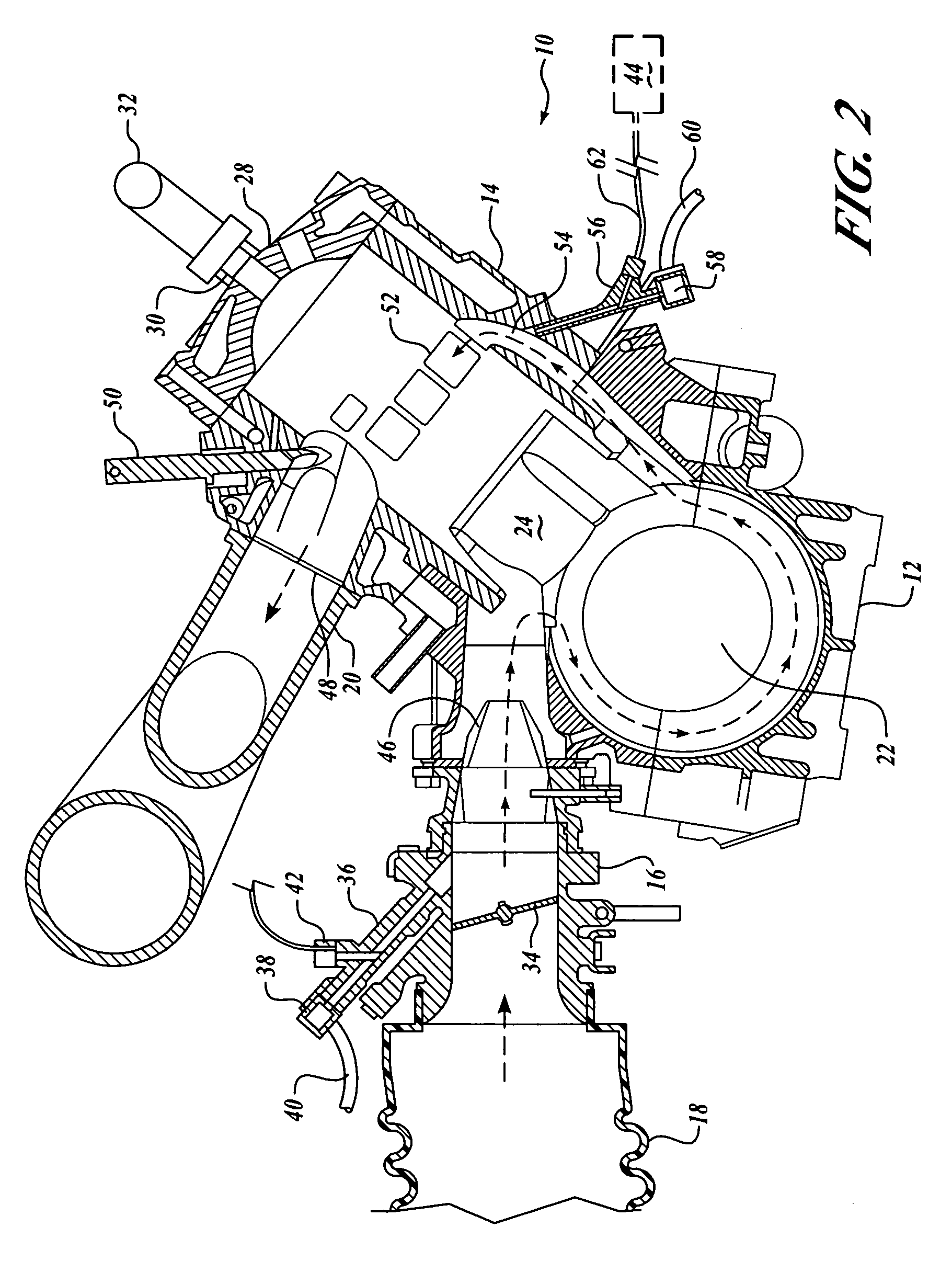

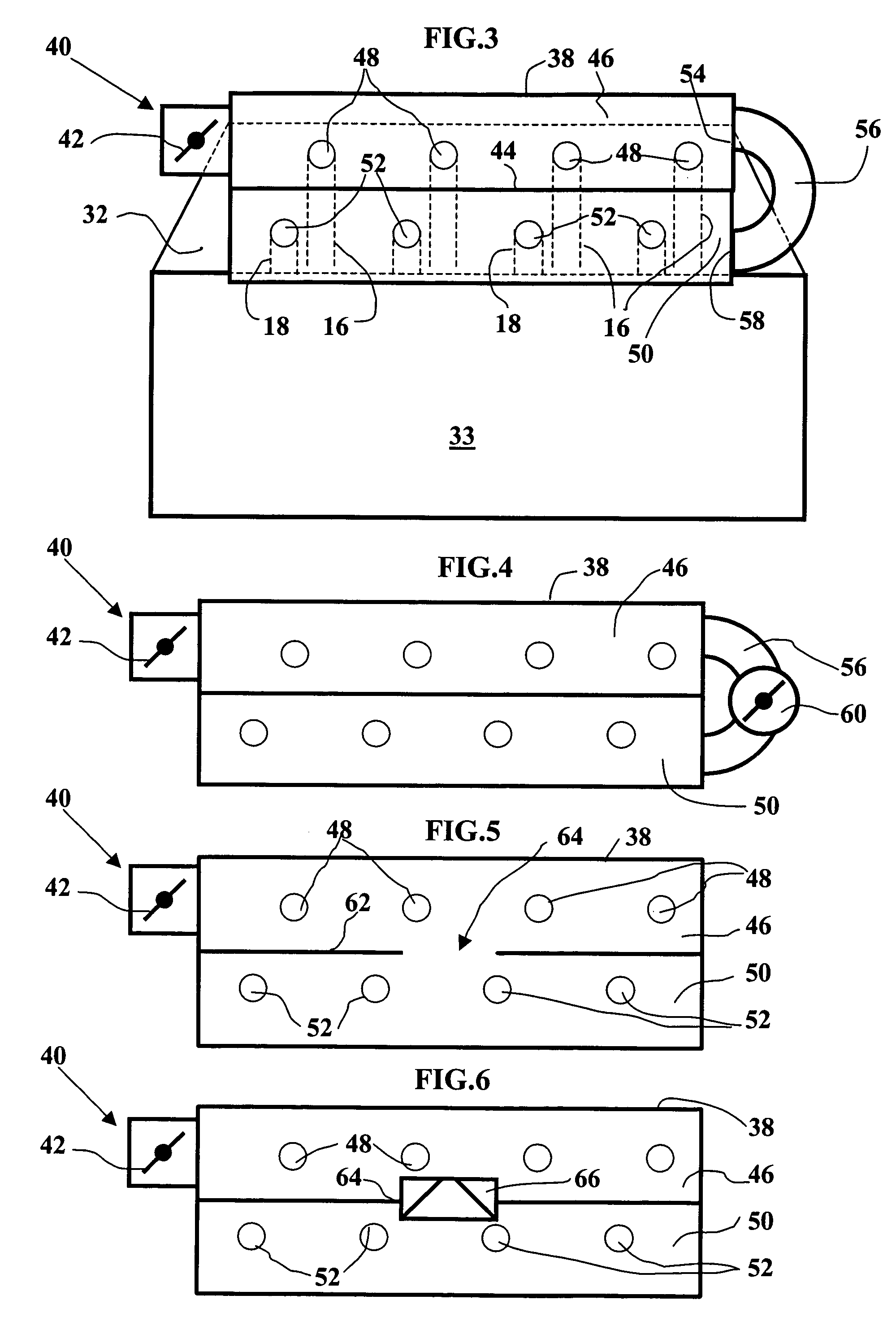

Multi-location fuel injection system

ActiveUS7168401B2Lower emission levelsSacrificing a potential peak horsepowerCombustion enginesLow pressure fuel injectionExhaust valveCrankcase

Owner:ARCTIC CAT

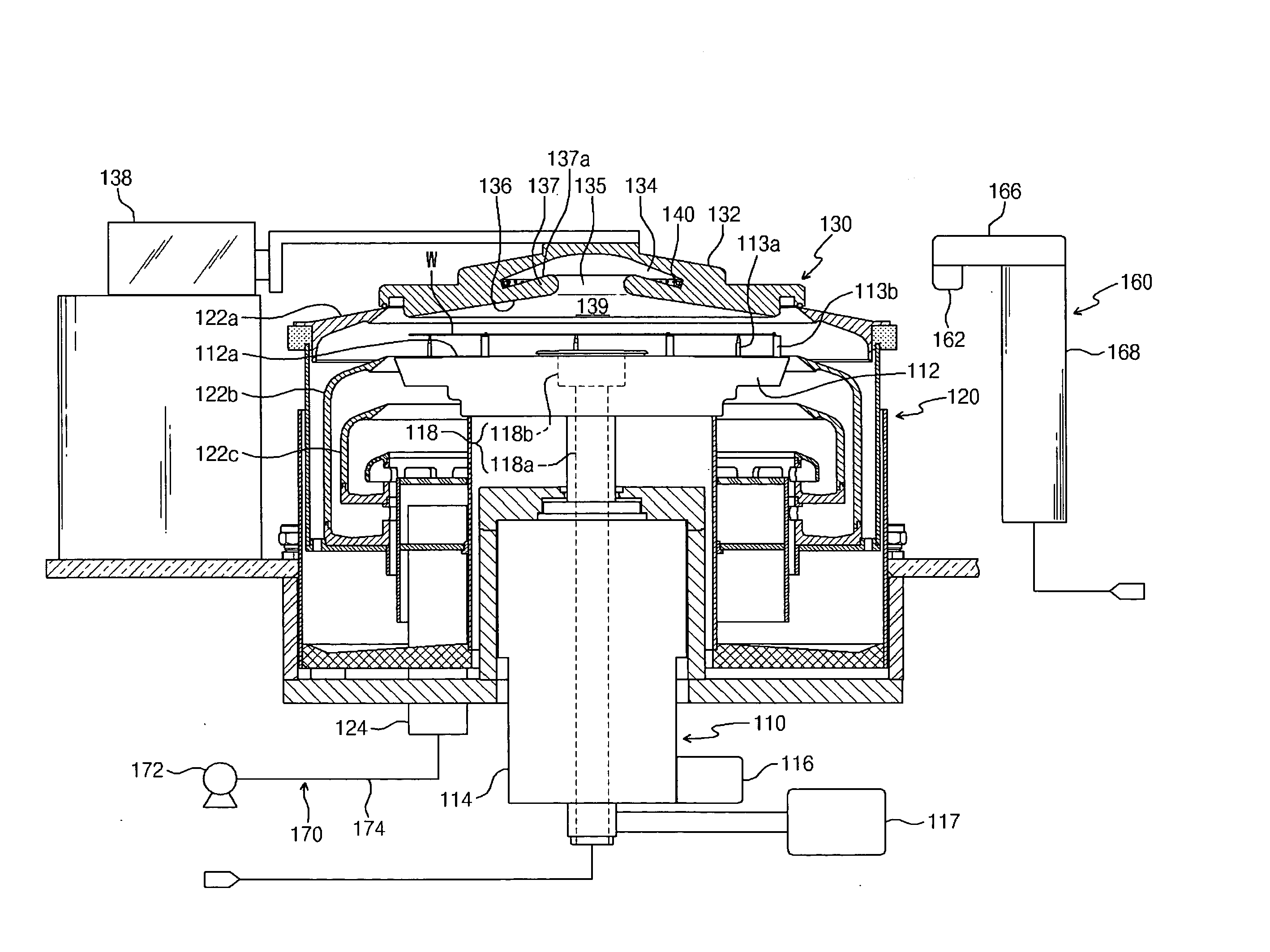

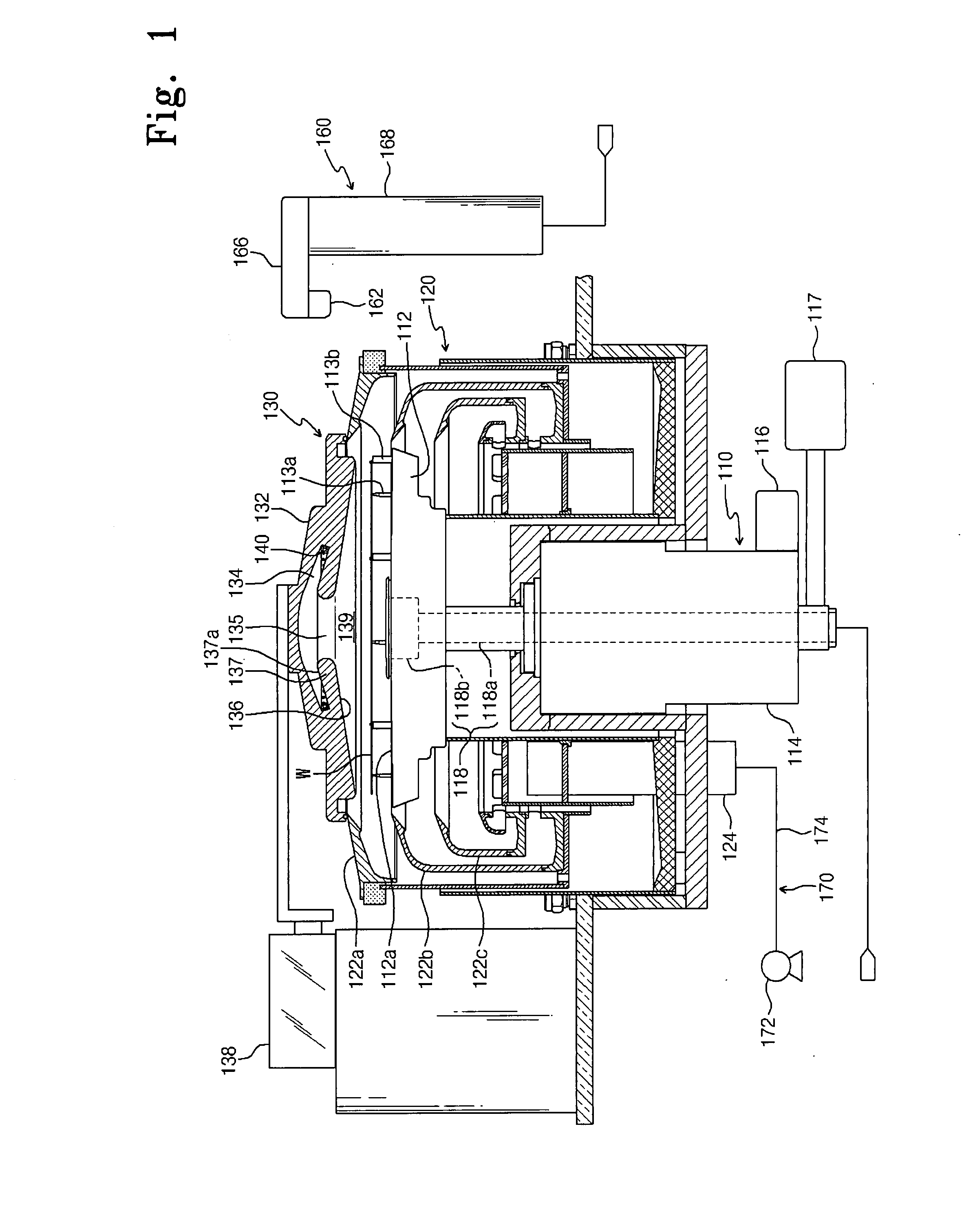

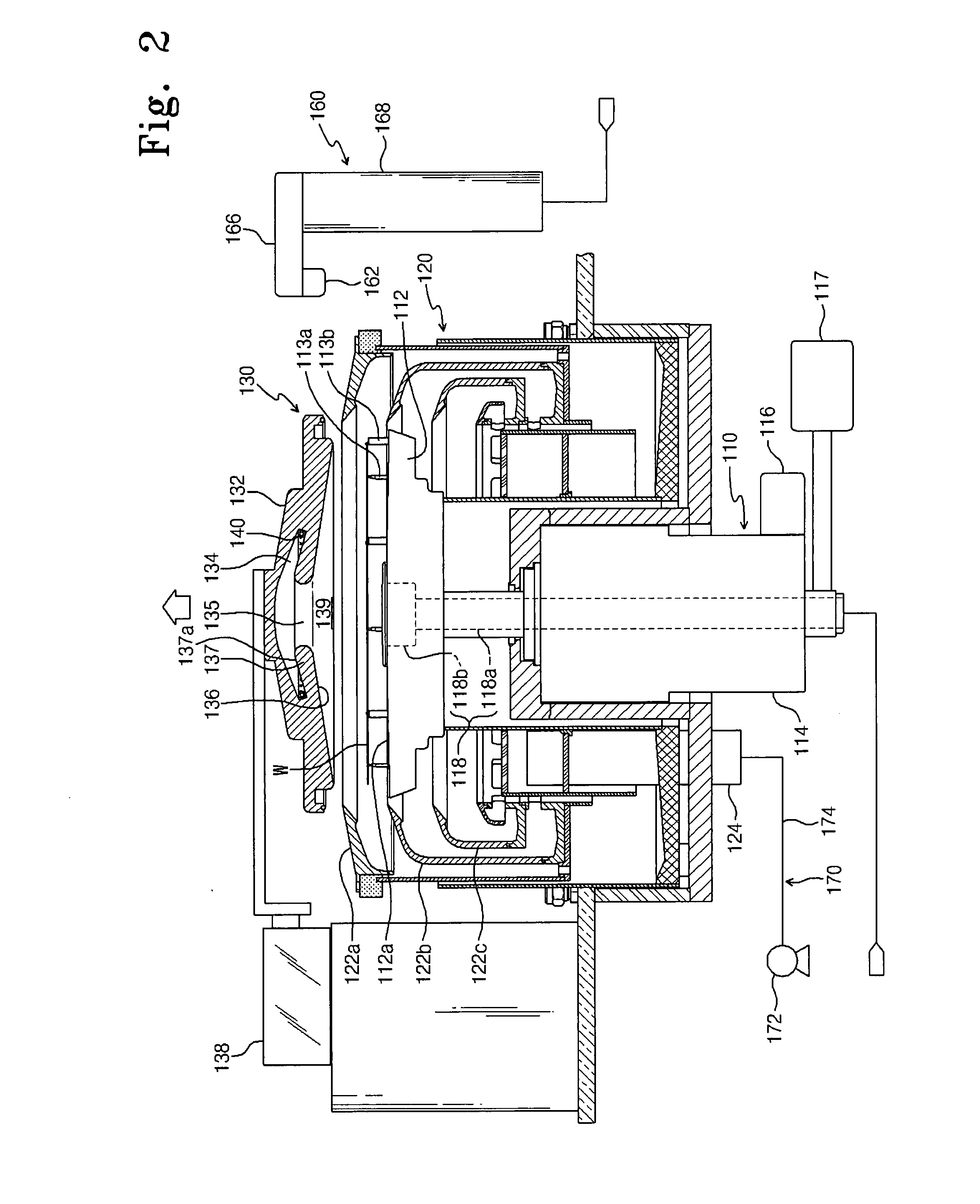

Apparatus and method for treating substrate

ActiveUS20080014358A1Reduce concentrationReduce the temperaturePretreated surfacesSemiconductor/solid-state device manufacturingSpray nozzleEngineering

An apparatus is provided for supplying a plurality of chemicals or gases to the surface of a substrate to clean and dry the substrate. The apparatus includes a substrate support unit with a chuck on which a substrate is loaded, a bottom chamber having an open top and configured to surround the circumference of the chuck, a top chamber configured to open or close the top of the bottom chamber such that a drying treatment for the substrate is performed while the substrate is isolated from the outside, and an indirect injection nozzle installed at the edge of the top chamber and configured to inject drying fluid toward the center of the top chamber such that the drying fluid is indirectly injected to the substrate. According to the apparatus, it is possible to enhance a substrate drying efficiency, suppress external contamination, and prevent the formation of an oxide layer.

Owner:SEMES CO LTD

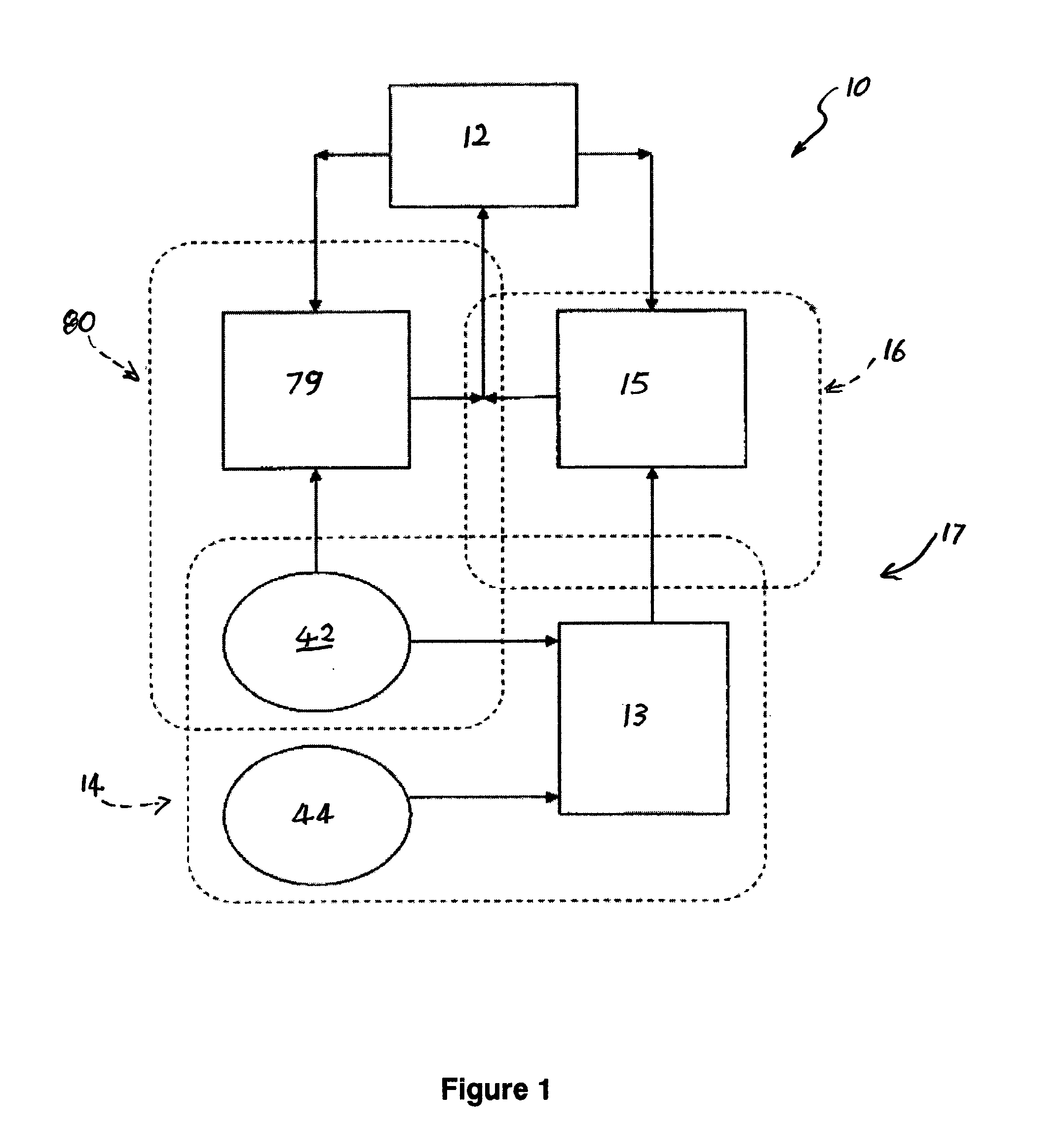

Method for controlling a supercharged engine, particularly an indirect injection engine, and engine using such a method

A method for controlling a supercharged engine, that includes determining an overlap of valves by opening a supercharged non-fuel-containing air inlet valve and closing an exhaust valve before the exhaust phase of an engine cylinder and in the vicinity of the top dead center (TDC), actuating a blocking means for blocking a supercharged non-fuel-containing air intake means to admit supercharged air flowing in the supercharged non-fuel-containing air intake means into a chamber to scavenge residual burned gases when a pressure of the supercharged non-fuel-containing air is greater than a pressure of the exhaust gases, and actuating the blocking means to shut off the supercharged air flowing from the supercharged non-fuel-containing intake means into the chamber when pressure of the supercharged non-fuel-containing air is less than pressure of the exhaust gases.

Owner:INST FR DU PETROLE

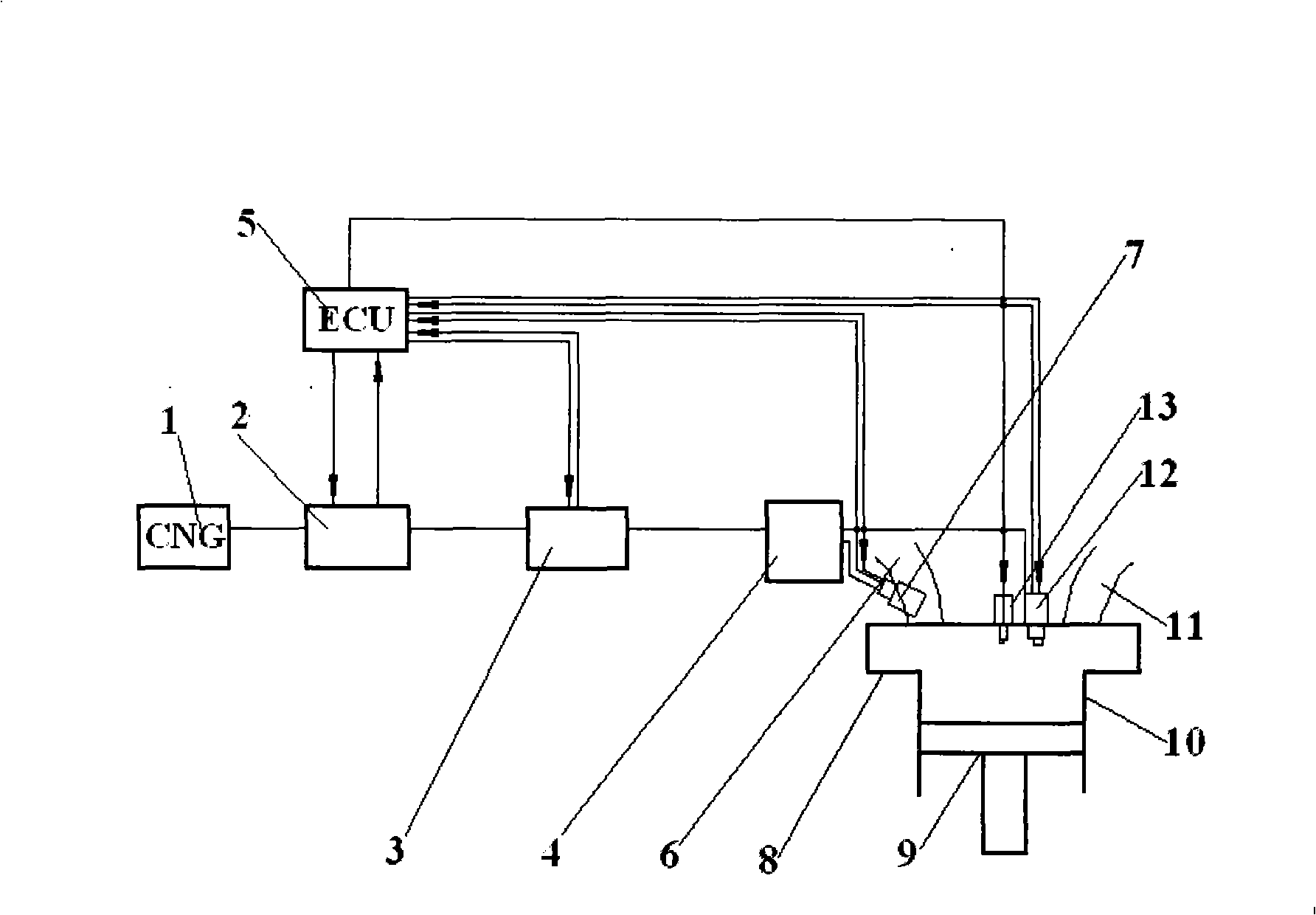

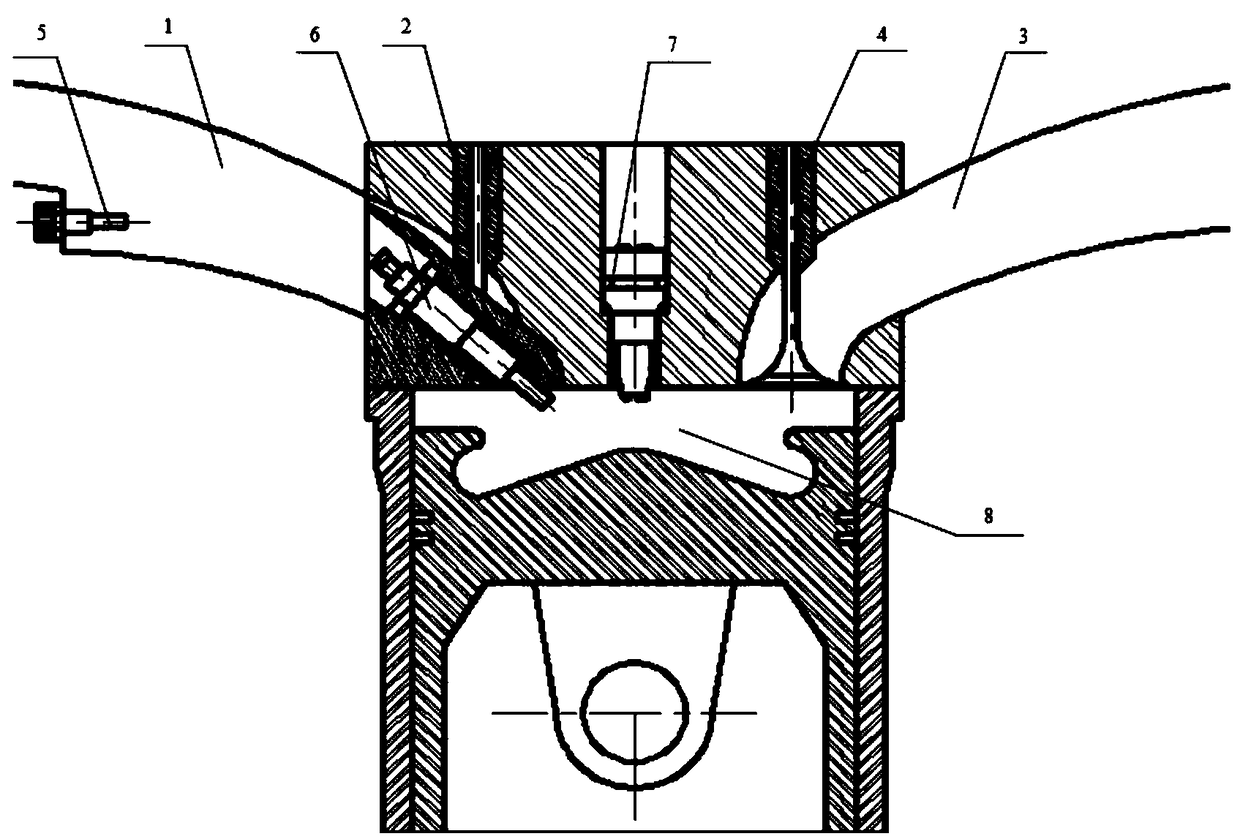

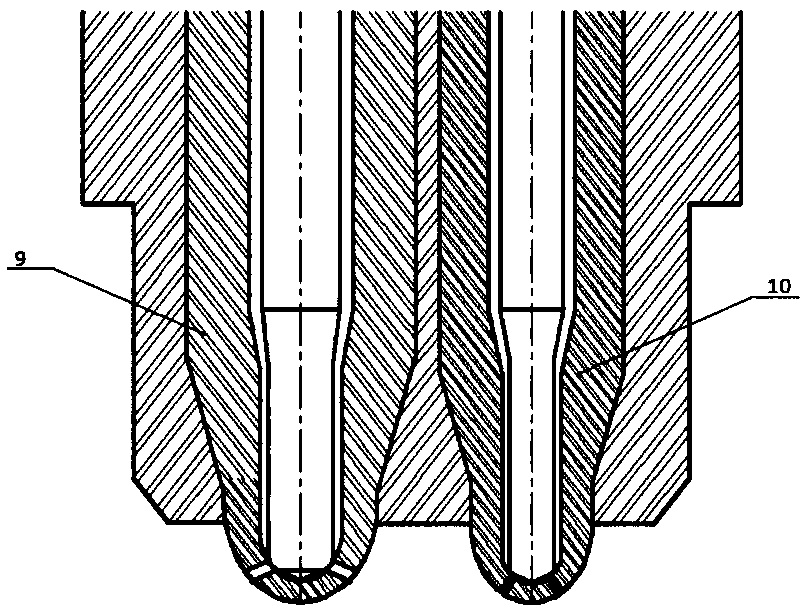

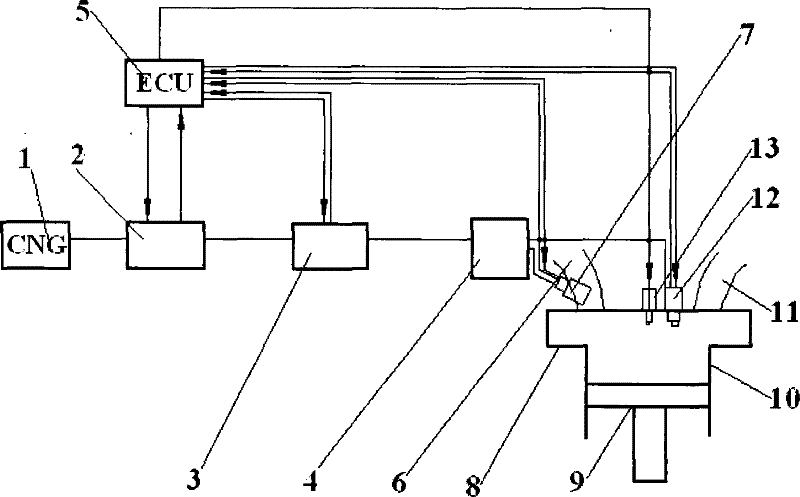

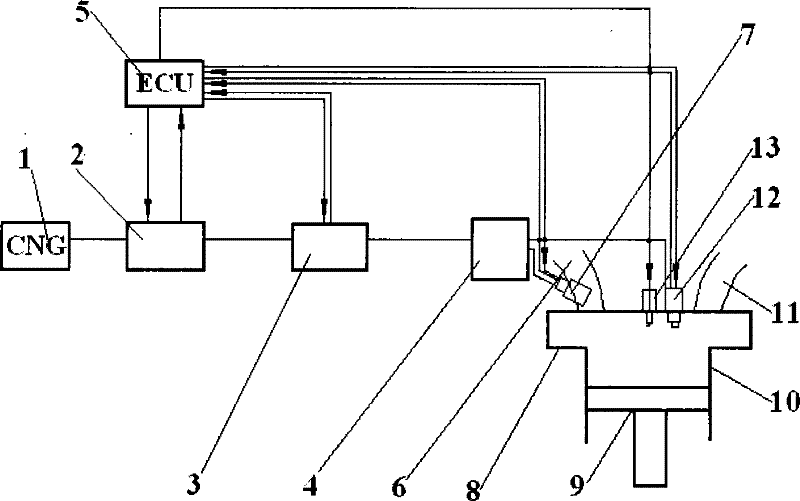

Hydrogen engines and its burnt gas jet method

ActiveCN101260846AInternal combustion piston enginesFuel supply apparatusControl mannerInlet manifold

The invention discloses a hydrogen engine, which comprises a fuel gas supply system, an intake manifold, a CNG special spark plug and a cylinder, wherein, fuel gas injectors are arranged on different positions of the end part of the fuel gas supply system extending into a cylinder cover of the engine; and hydrogen is directly injected into the cylinder of the engine through the fuel gas injector or is indirectly injected into the cylinder of the engine through the fuel gas injector after mixing with inlet gas in an inlet channel. By adoption of the technical proposal, direct injection of hydrogen in the cylinder of the engine is realized; compared with a general hydrogen engine, higher charging efficiency and thermal efficiency are obtained by adoption of higher compression ratio, and the power and the torque of the engine are increased; moreover, the hydrogen engine has the advantages of high power output, high response speed and so on; simultaneously, the combustion is improved and the exhaust is reduced. The problems of premature combustion and backfire are solved by adoption of the control means of combination of direct injection in the cylinder and indirect injection of the inlet channel, and simultaneously the maximum potential and exhaust advantages of hydrogen engines are given full play.

Owner:CHERY AUTOMOBILE CO LTD

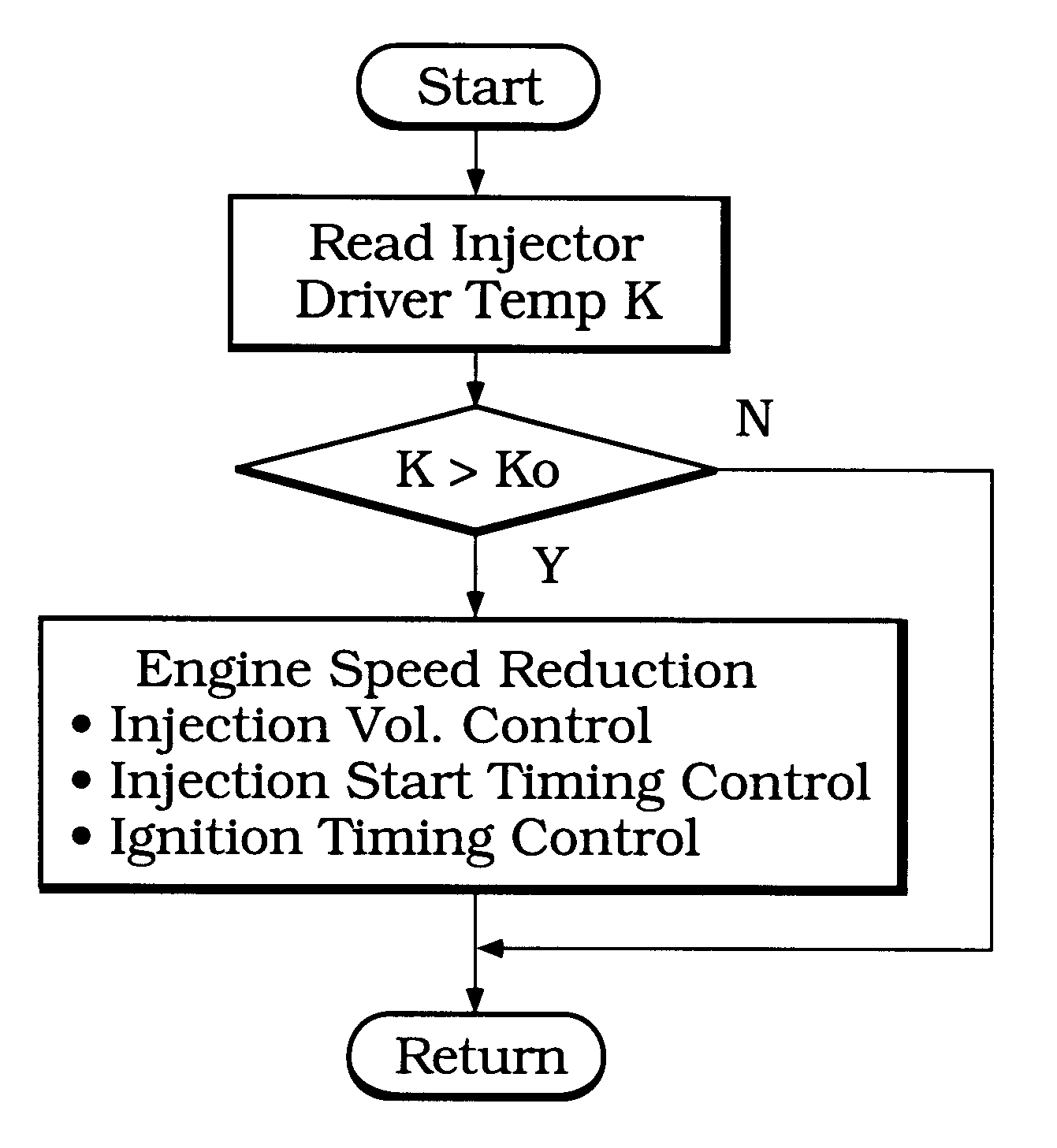

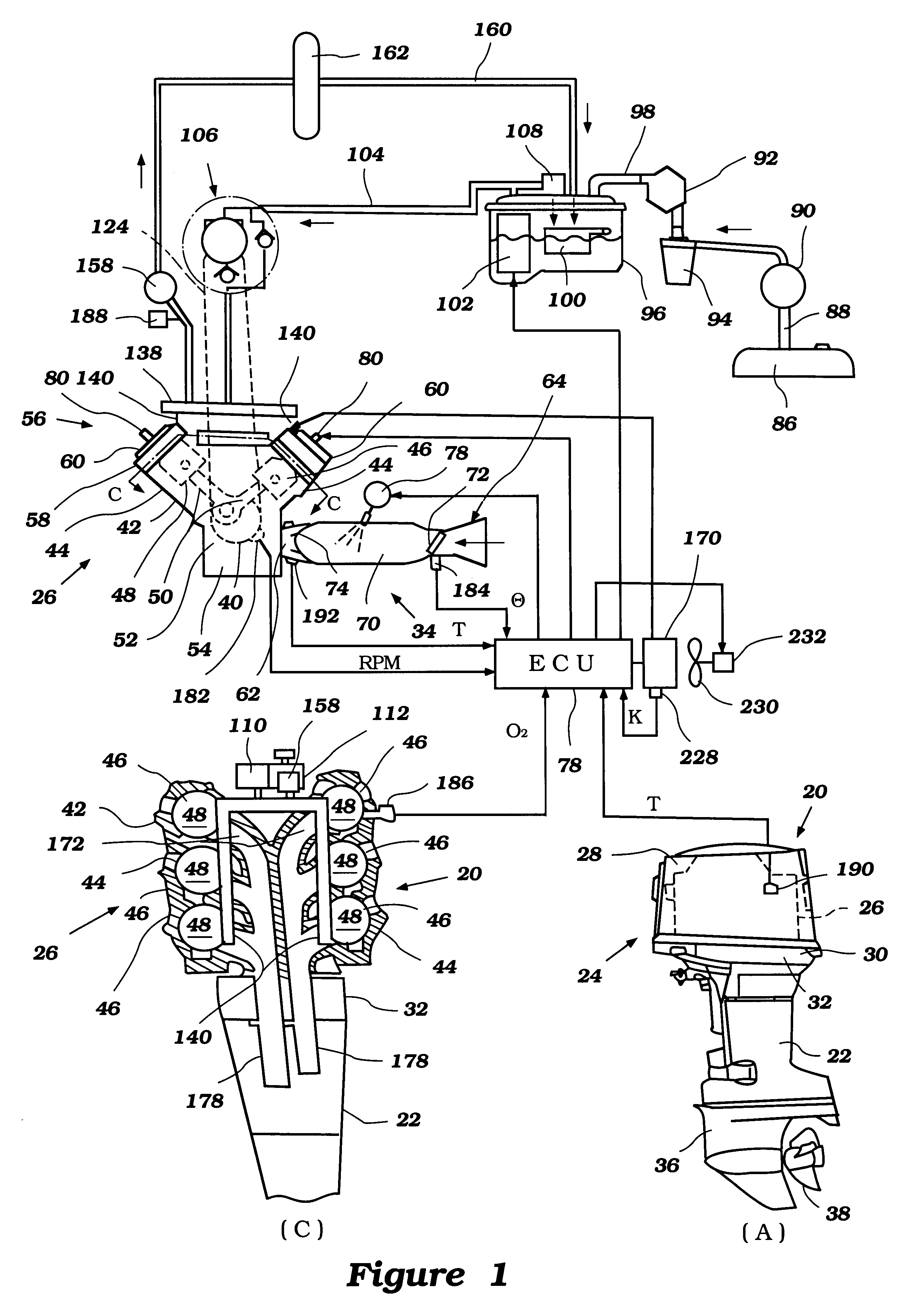

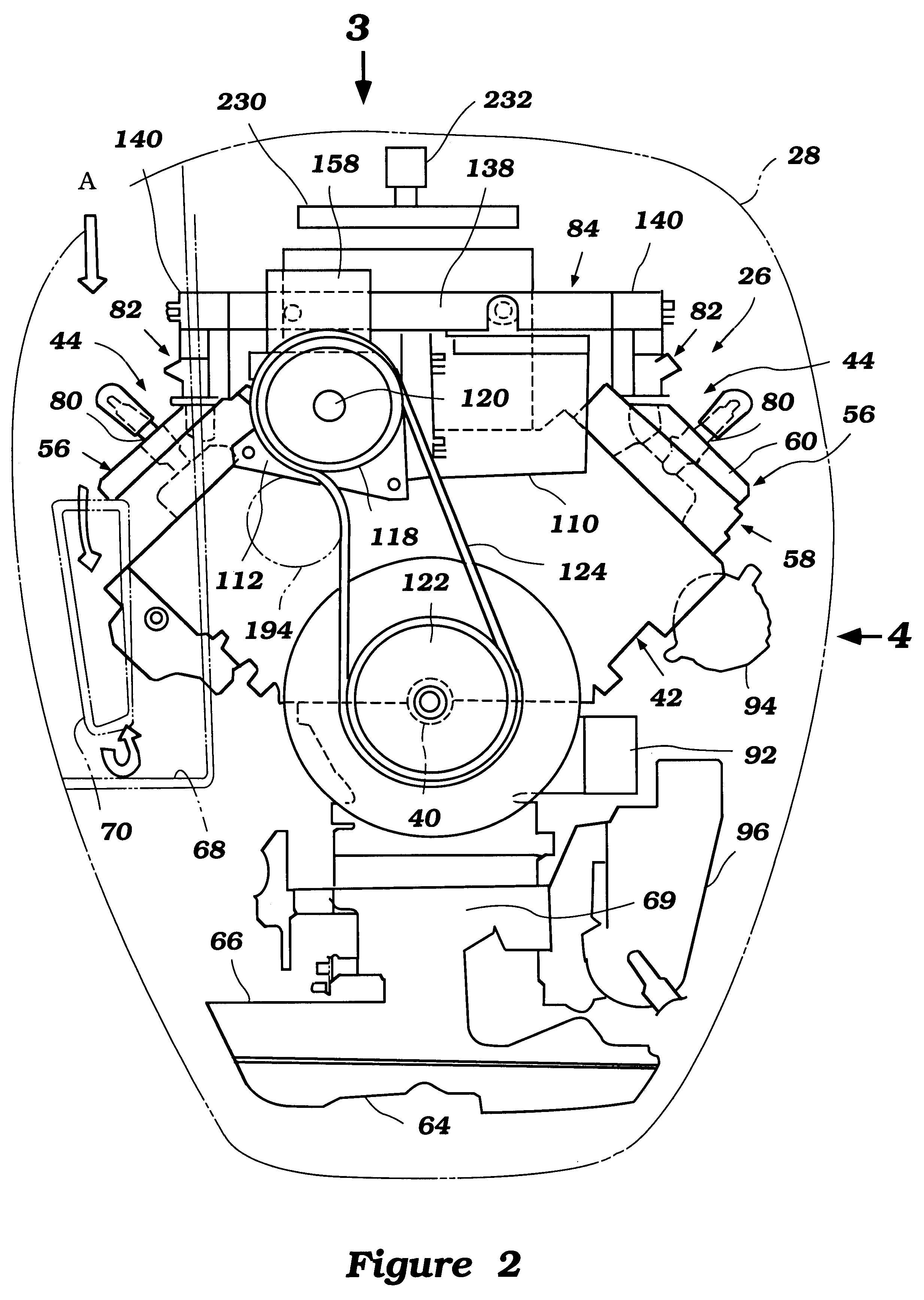

Fuel injection control system

InactiveUS6247441B1Electrical controlInternal combustion piston enginesExternal combustion engineControl system

An outboard motor has a fuel injected internal combustion engine operating on either a two-cycle or four-cycle principle. In some embodiments, the engine is directly injected while in others it is indirectly injected. The engine features one of a number of methods for reducing the temperature of injector drivers. The methods include sensing the temperature of the injector drivers and decreasing the engine speed if the temperature exceeds a predetermined temperature. Another method involves sensing the duration of a high-speed, high-load operating condition and slowing the engine speed if the duration exceeds a predetermined time period. Yet another method involves activating a cooling fan if the temperature of the injector drivers exceeds a predetermined temperature and activating a warning device if the temperature does not decrease with the fan operating.

Owner:SANSHIN KOGYO CO LTD

Method of controlling scavenging of the burnt gas of an indirect-injection engine, notably a supercharged engine, and engine using such a method

Owner:INST FR DU PETROLE

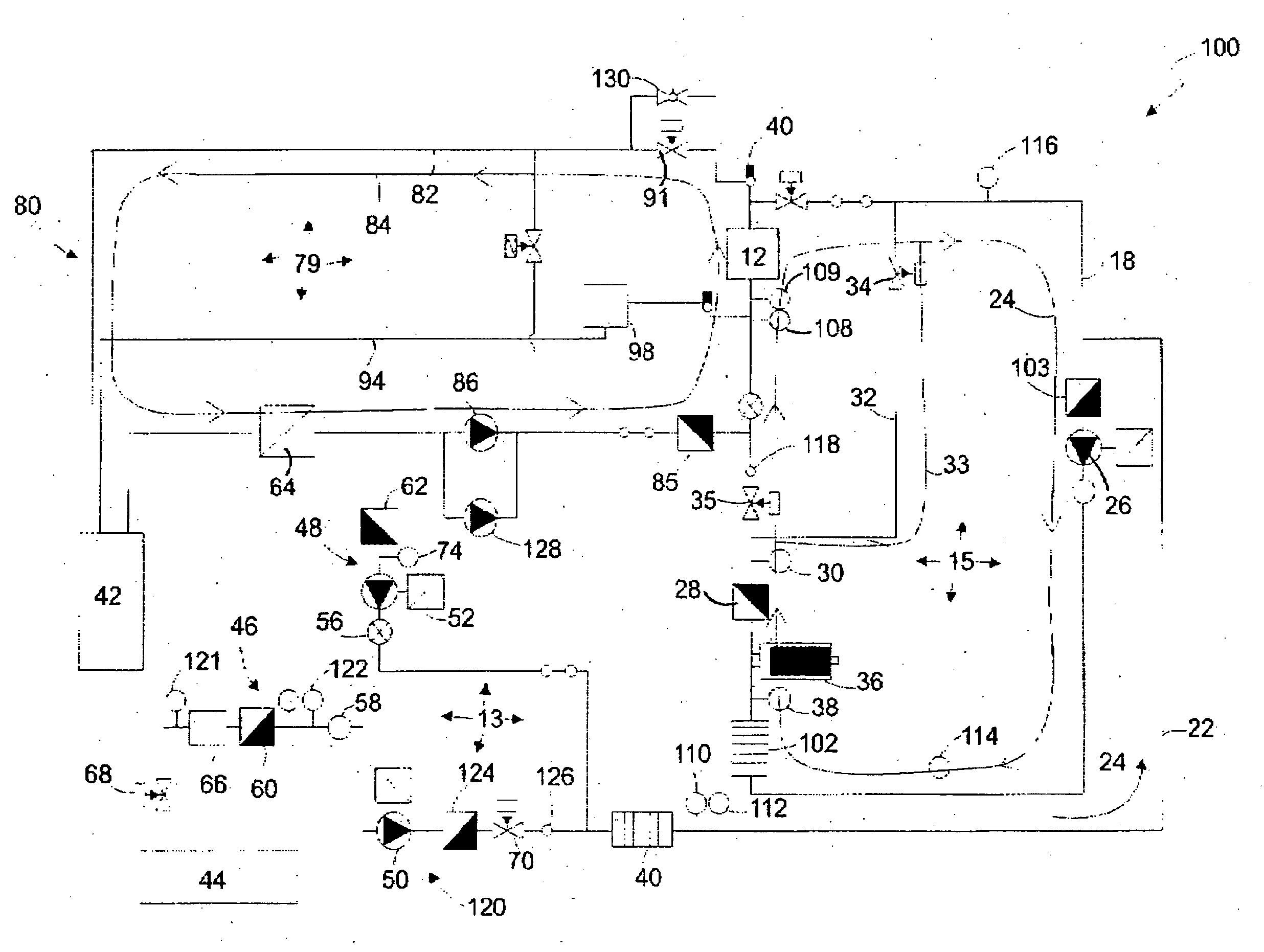

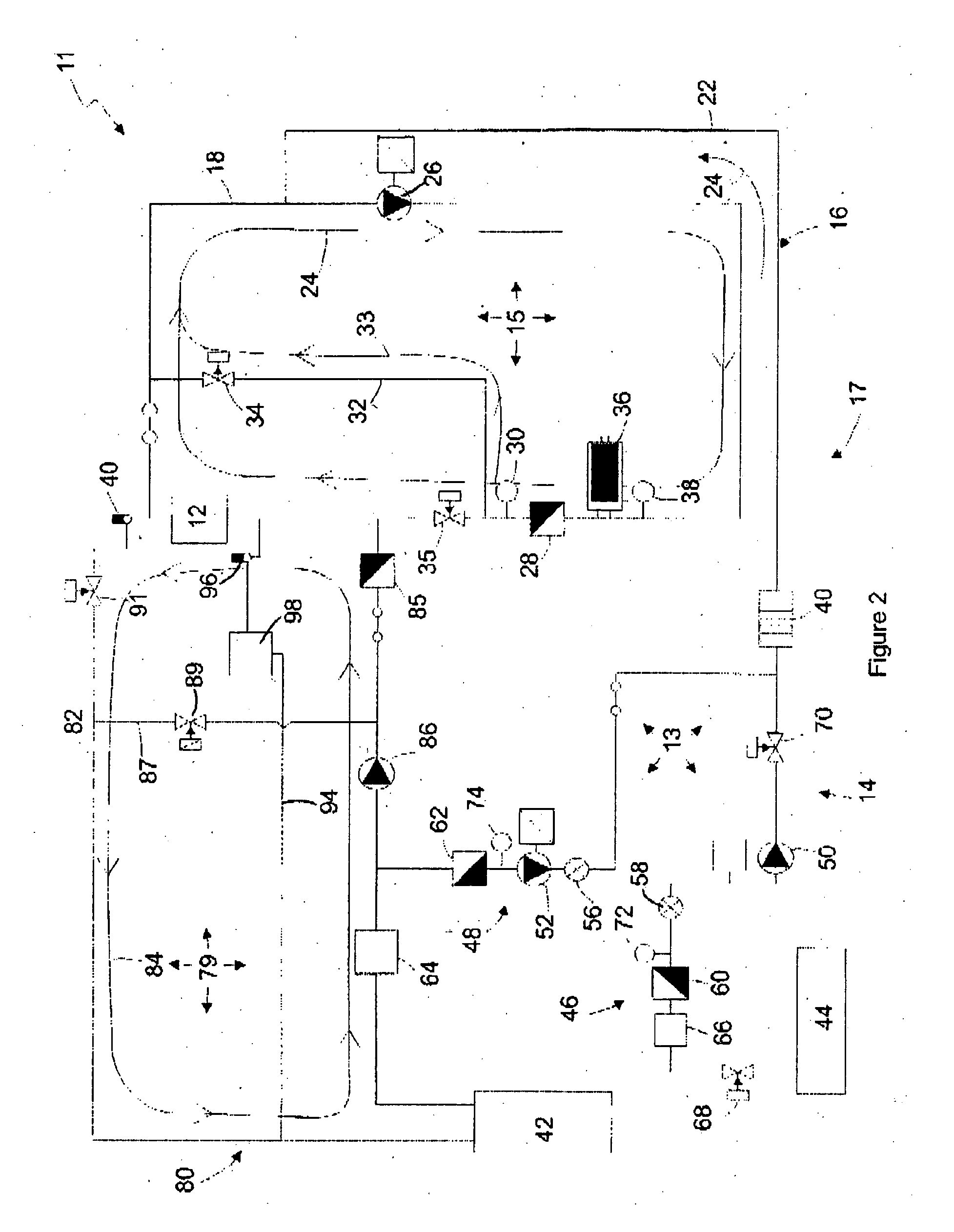

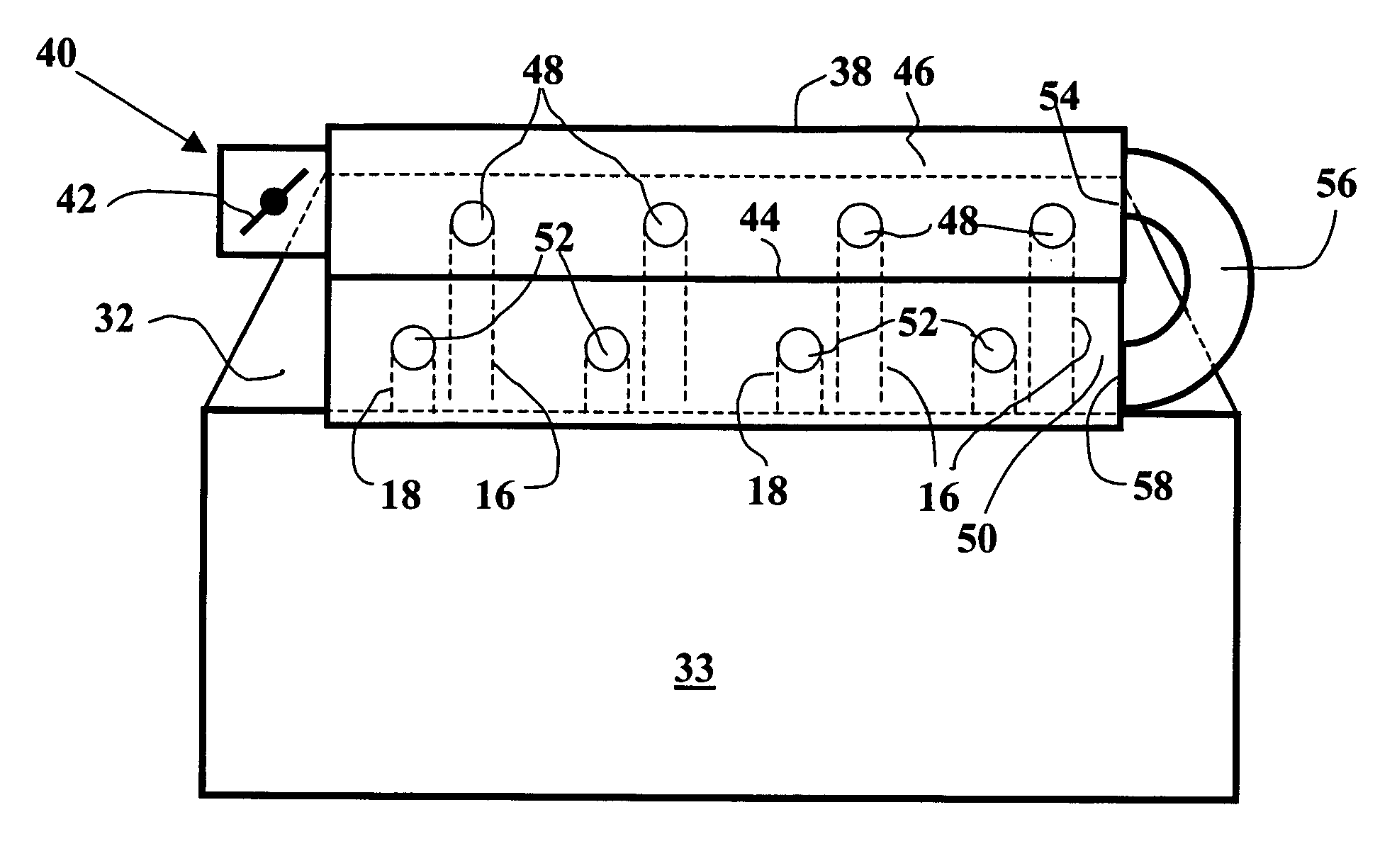

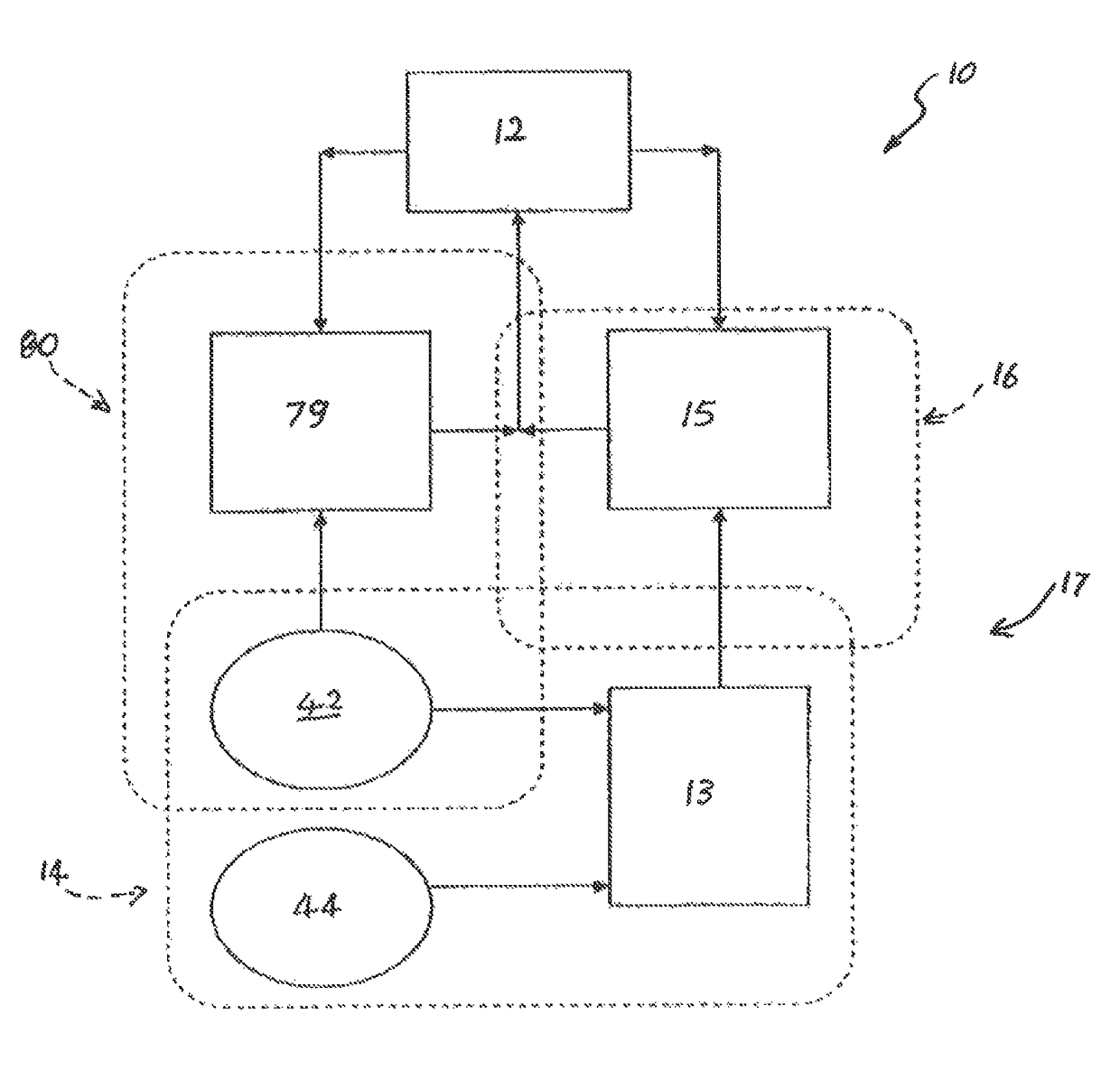

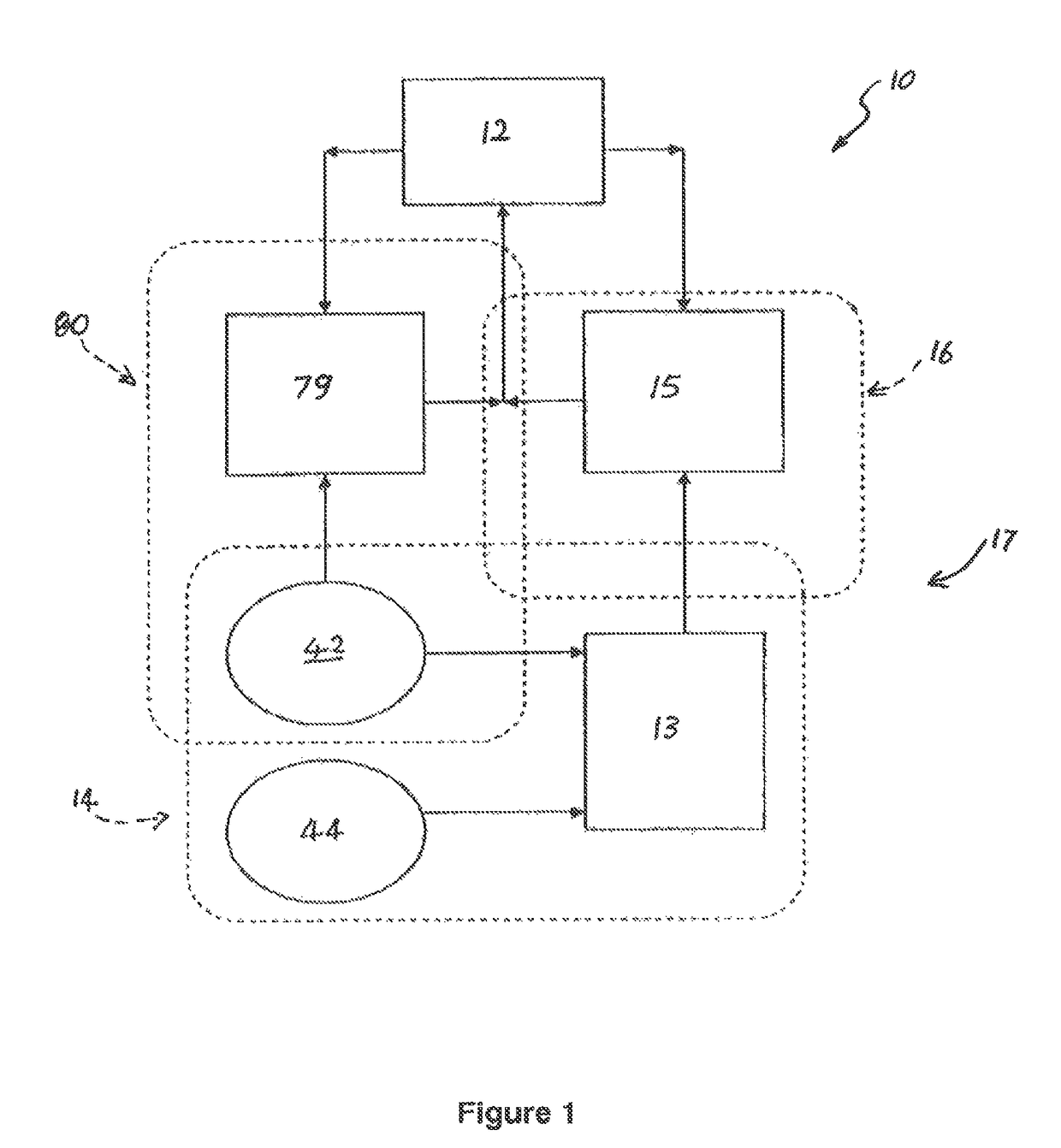

Burnt gas-scavenging indirect-injection internal-combustion supercharged engine and supercharged air supply method for such an engine

ActiveUS7082764B2Non-fuel substance addition to fuelInternal combustion piston enginesCombustionInternal combustion engine

The present invention relates to a supercharged internal-combustion, notably indirect-injection engine comprising at least one cylinder (10) with two types of supercharged air intake means (12, 14), one type for non-carbureted supercharged air intake (12) and another type for carbureted supercharged air intake (14), said intake means being supplied with supercharged air by supply means (38).According to the invention, supply means (38) comprise a specific supercharged air supply device (46, 50) for each type of intake means (12, 14).

Owner:INST FR DU PETROLE

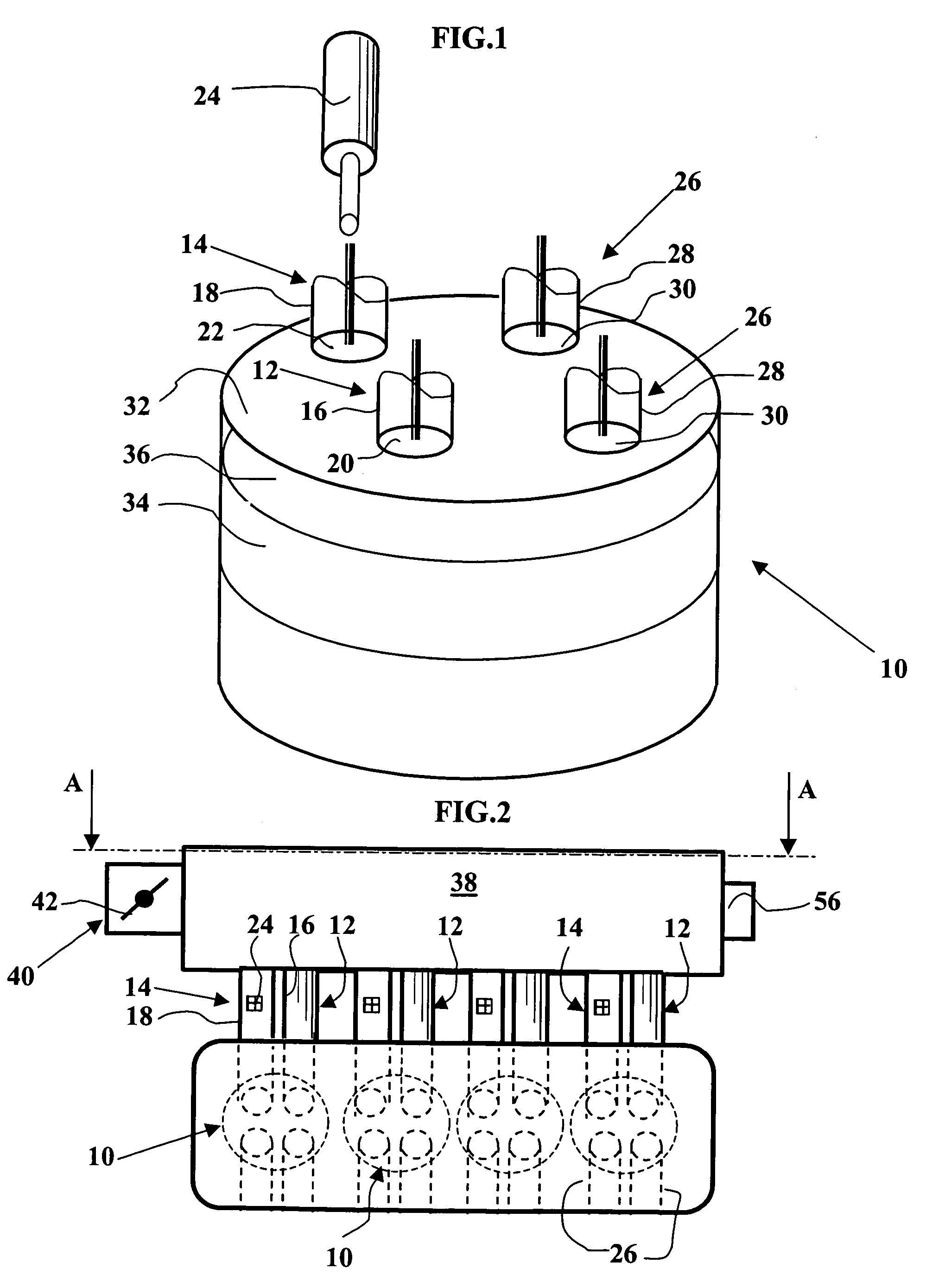

Internal combustion engine providing a phase of scavenging burned gases

InactiveCN101117911AAllow or prevent sprayingPrevent sprayingValve arrangementsInternal combustion piston enginesExhaust valveVariable valve timing

The engine has a cylinder (10) with carburized and uncarburized air inlet units (14, 16) with carburized and uncarburized air inlet valves (22, 24), respectively. The valve (24) is controlled by opening / closing of an opening by a variable valve timing type controlling unit (44) having a rotating camshaft (46) and a cam (48) for varying a raised status of the valve (24). The valve (22) is controlled by an additional controlling unit having a cam shaft and an activation unit (52) for activating the valve (22) controlled by an controlling unit (36) of a burned gas exhausting unit (28).

Owner:INST FR DU PETROLE

Combined air supply dual-fuel engine system with dual-needle valve fuel injector and combustion method

ActiveCN109268170AFlexible switchingGuaranteed concentrationElectrical controlInternal combustion piston enginesExhaust valveInlet valve

The invention discloses a combined air supply dual-fuel engine system with a dual-needle valve fuel injector and a combustion method, and belongs to the field of combustion methods of dual-fuel engines. The combined air supply dual-fuel engine system comprises an air inlet channel, an intake valve, an exhaust channel, an exhaust valve, a divided manifold low-pressure injection natural gas injection valve, a high-pressure in-cylinder direct injection natural gas injection valve, a dual-needle valve fuel injector, an omega-shaped combustion chamber and the like. When the engine operates at low load and medium load, the high-pressure in-cylinder direct injection natural gas injection valve is controlled to perform single or multiple gas injections into the cylinder; when the engine operates at high load, a combined air supply mode of the air inlet outside the cylinder and the direct injection inside the cylinder is adopted, and different fuel oil and gas injection control strategies are adopted under different engine operating conditions. By controlling the natural gas injection quantity, the injection times and the injection time of the divided manifold low-pressure injection naturalgas injection valve and the high-pressure in-cylinder direct injection natural gas injection valve, the high-efficiency low-emission combustion of the engine in the full operating conditions range can be achieved, thereby improving the in-cylinder combustion, widening the load range of the engine, and reducing NOx emission effectively.

Owner:HARBIN ENG UNIV

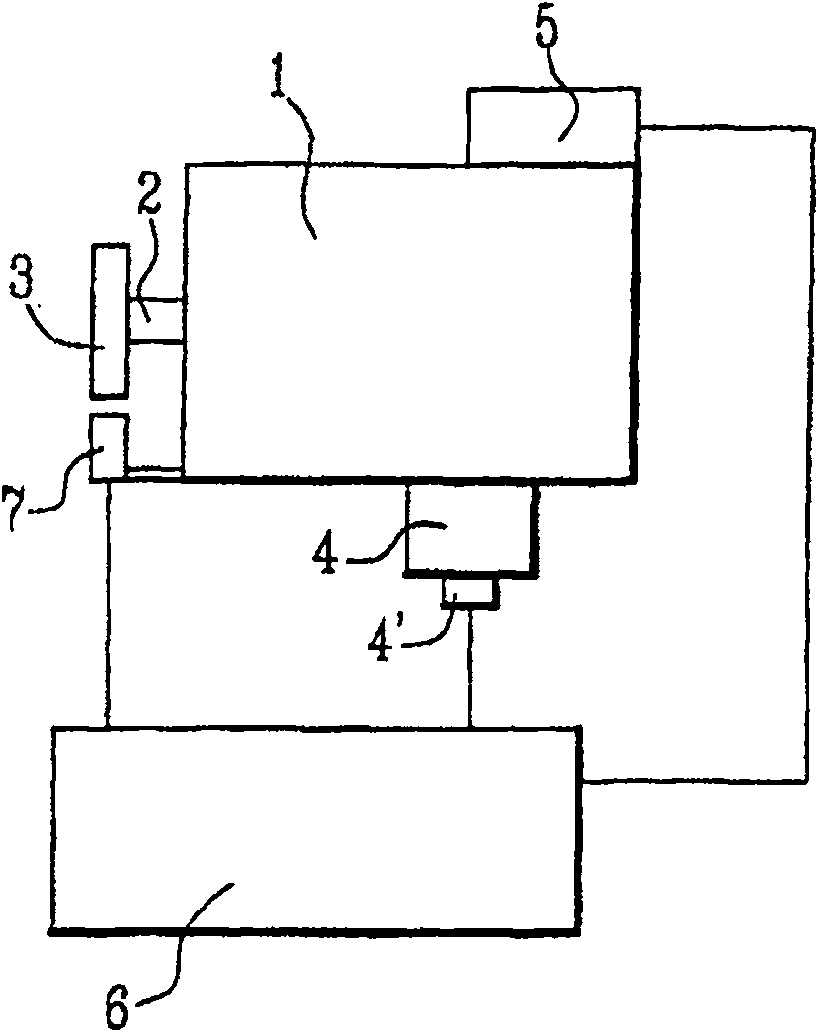

Method of stopping and restarting internal combustion engine with indirect injection

InactiveCN100587245CQuick restartElectrical controlInternal combustion piston enginesExternal combustion engineEngineering

The invention relates to a method of stopping and restarting an internal combustion engine with indirect injection. In order to stop the engine in a pre-determined position that facilitates the restart of the engine, the rotation speed and the angular position of the turning part (2, 3) of the engine (1) are measured continuously and the fuel injection is cut off for pre-determined speed and angular position values in relation to the turning part (2, 3). In order to restart the engine using a starter (4), fuel is injected into at least one cylinder of the engine when the piston moving in saidcylinder is in a determined position. The spark ignition and / or fuel injection is suspended for pre-determined speed and angular position values in relation to the turning part (2, 3) of the engine (1) and fuel is injected into at least one cylinder of the engine (1) during the last rotation of the engine before it stops. In order to restart the engine, ignition is carried out in at least one cylinder the piston of which is in the compression position when the engine is stopped (1).

Owner:PEZHO SITROEN AUTOMOBILS SA

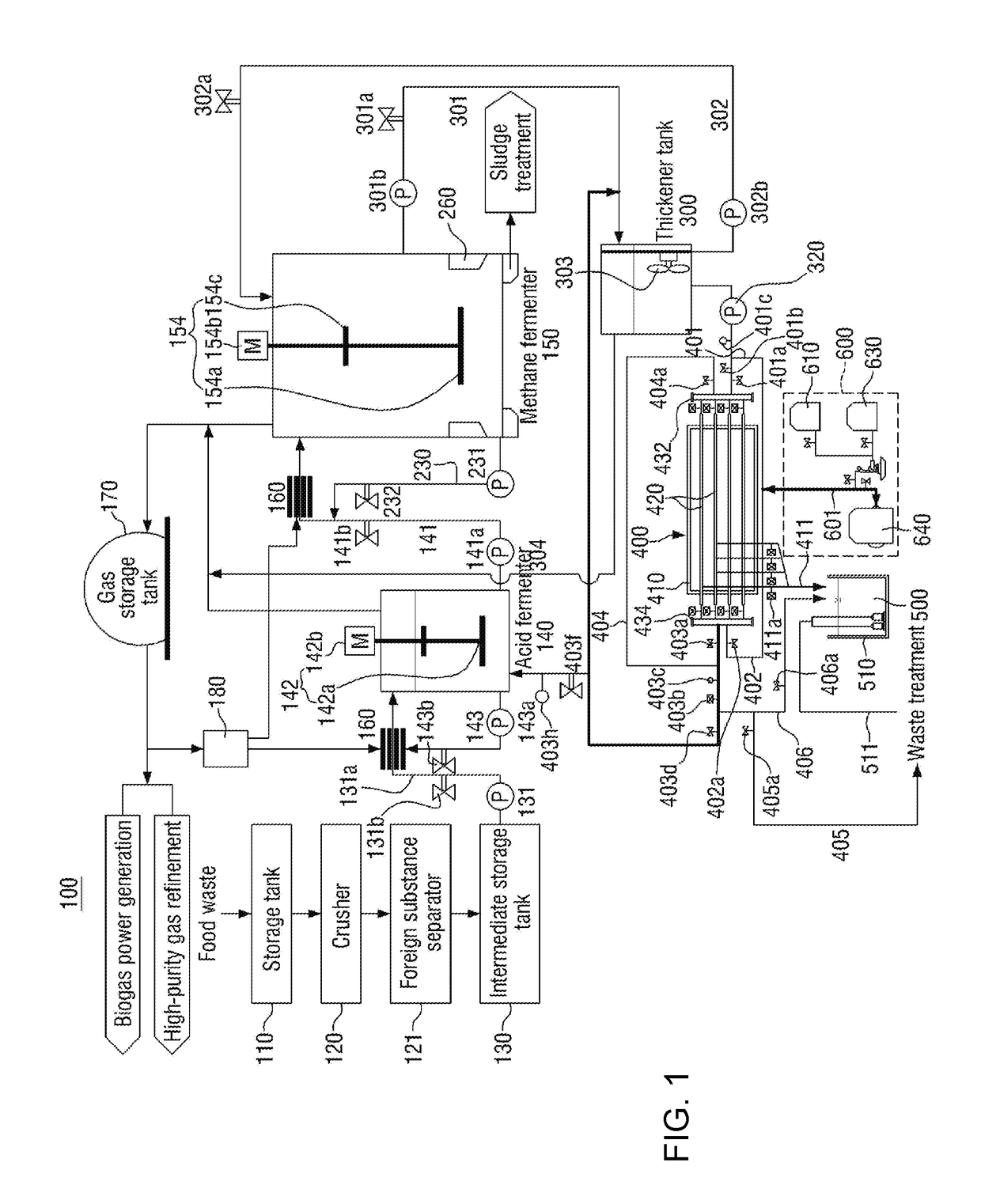

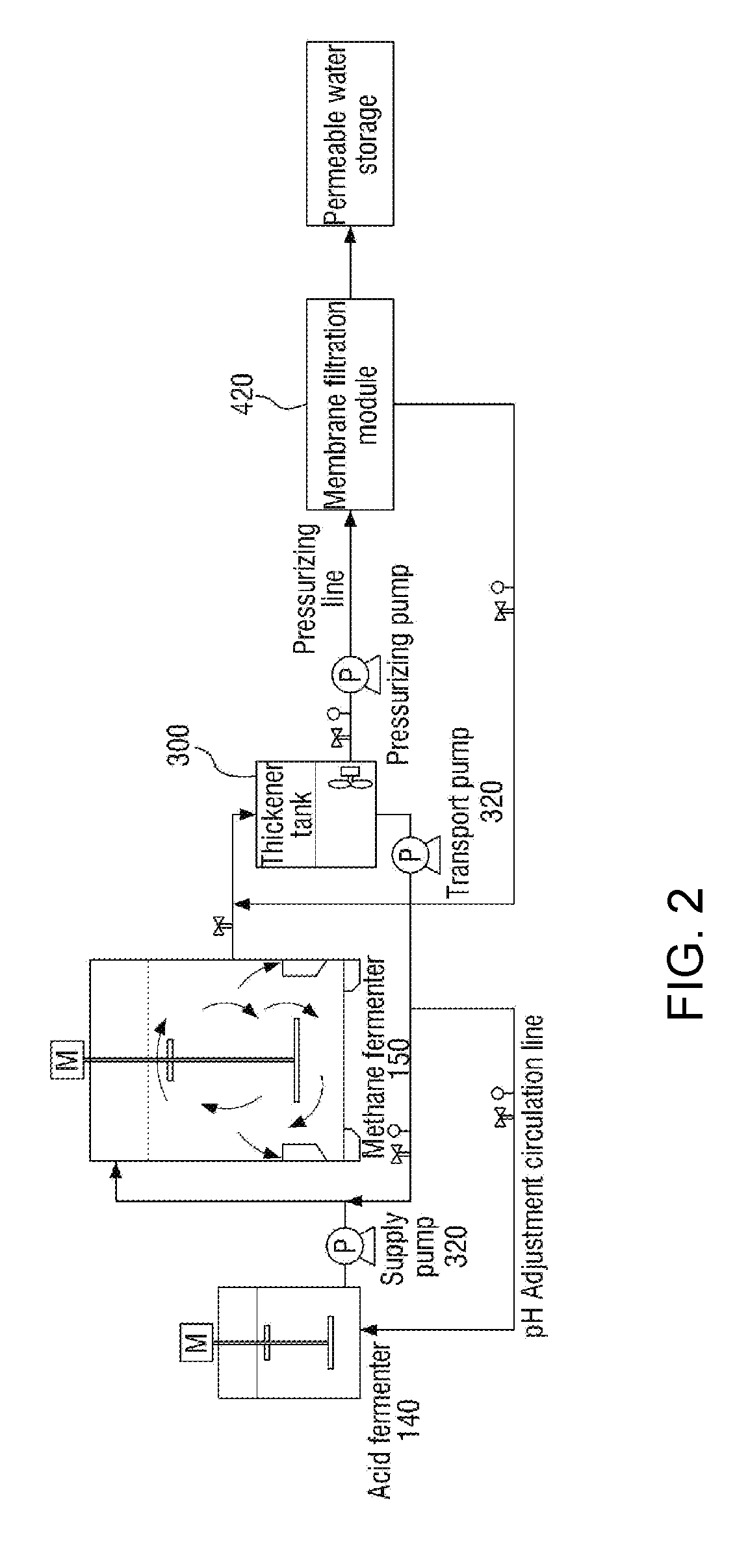

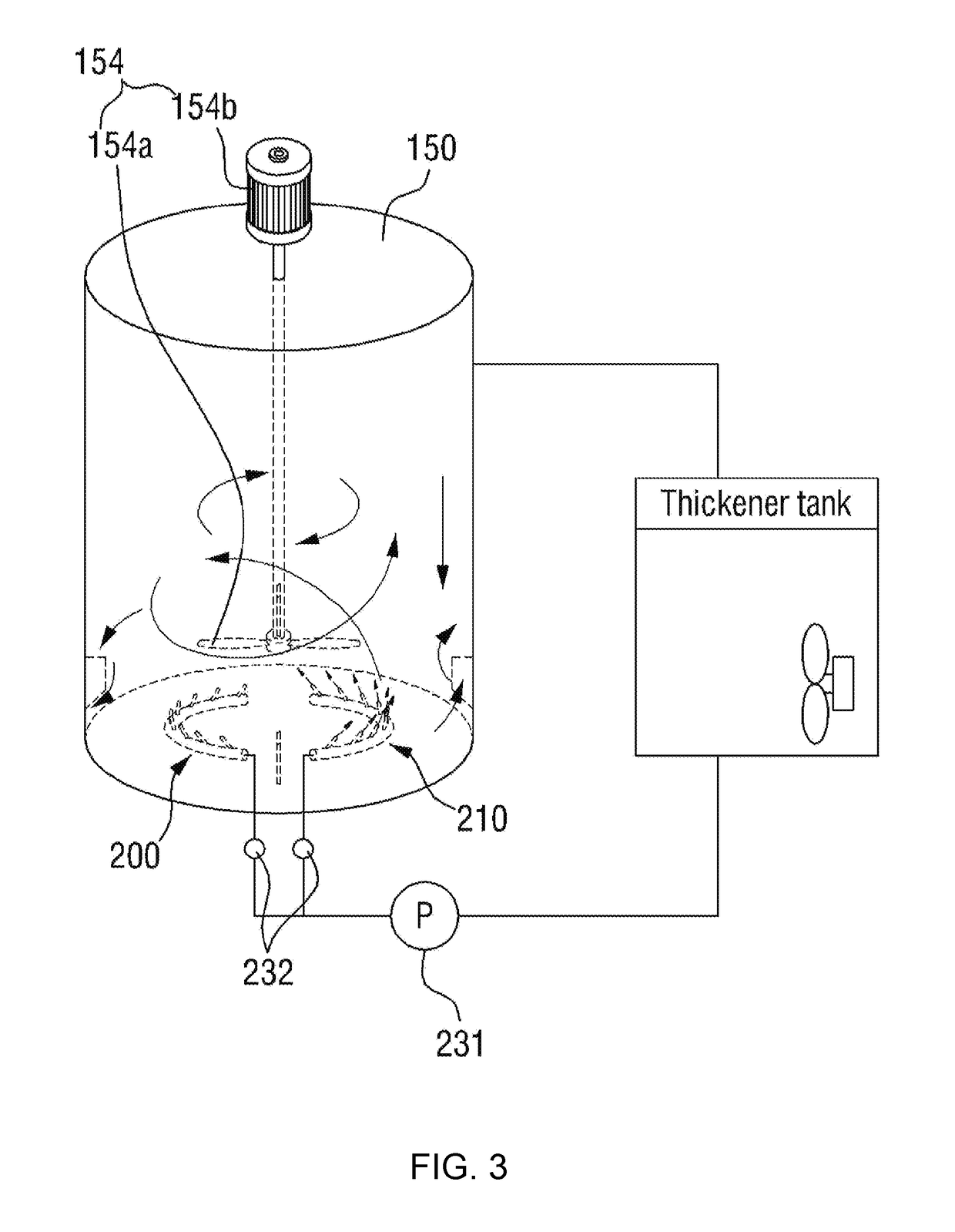

Alternate operation control type membrane-coupled organic waste treatment apparatus and method of operating the same

InactiveUS20180346858A1Improve the mixing effectMaximize reactionBioreactor/fermenter combinationsBiological substance pretreatmentsWaste treatmentHuman power

An organic waste treatment apparatus according to the present disclosure includes an acid fermenter 140, a methane fermenter 150, a thickener tank 300, and a separation membrane device 400, and includes: a first circulation line 141 in which a first circulation pump 141a is installed in a linked manner so that a part of organic waste being acid-fermented in the acid fermenter 140 is supplied to the methane fermenter 150; and a second circulation line 151 in which a second circulation pump 151a is installed in a linked manner so that a part of a anaerobic digestive fluid being methane-fermented in the methane fermenter 150 is supplied to the acid fermenter 140, in which the thickener tank 300 is installed between the methane fermenter 150 and the separation membrane device 400, supplied with concentrated circulating water from the separation membrane device 400, and supplies at least a part of the supplied concentrated circulating water to the methane fermenter 150 in an indirect injection manner, such that a means for perfectly removing offensive odor generated during a process of treating the anaerobic digestive fluid is organically coupled, and a high degree treatment process is performed, and as a result, it is possible to perfectly remove offensive odor and to reduce manpower and maintenance costs by automation of the entire facilities.

Owner:HYUNDAI ENGINEERING AND CONSTRUCTION

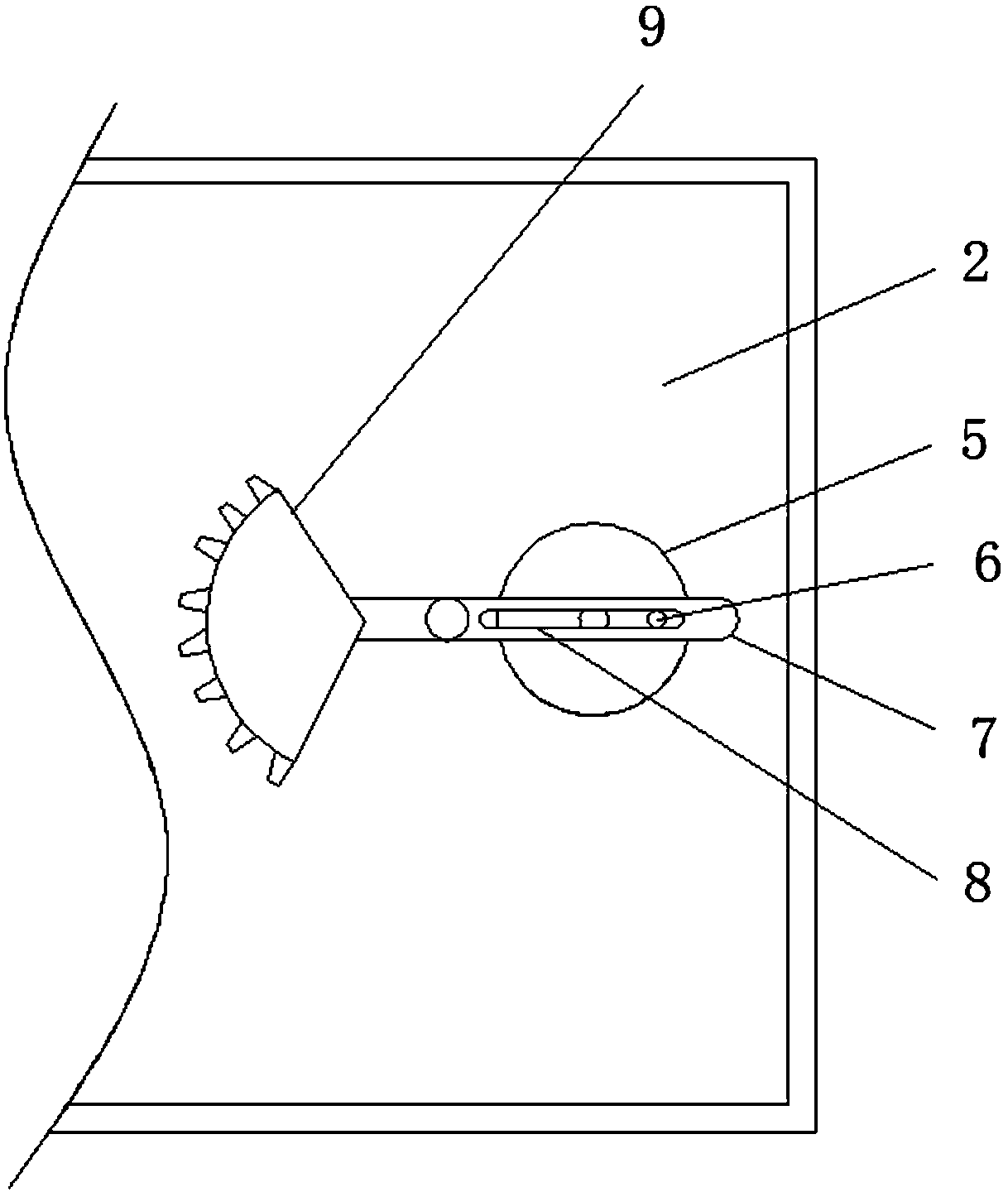

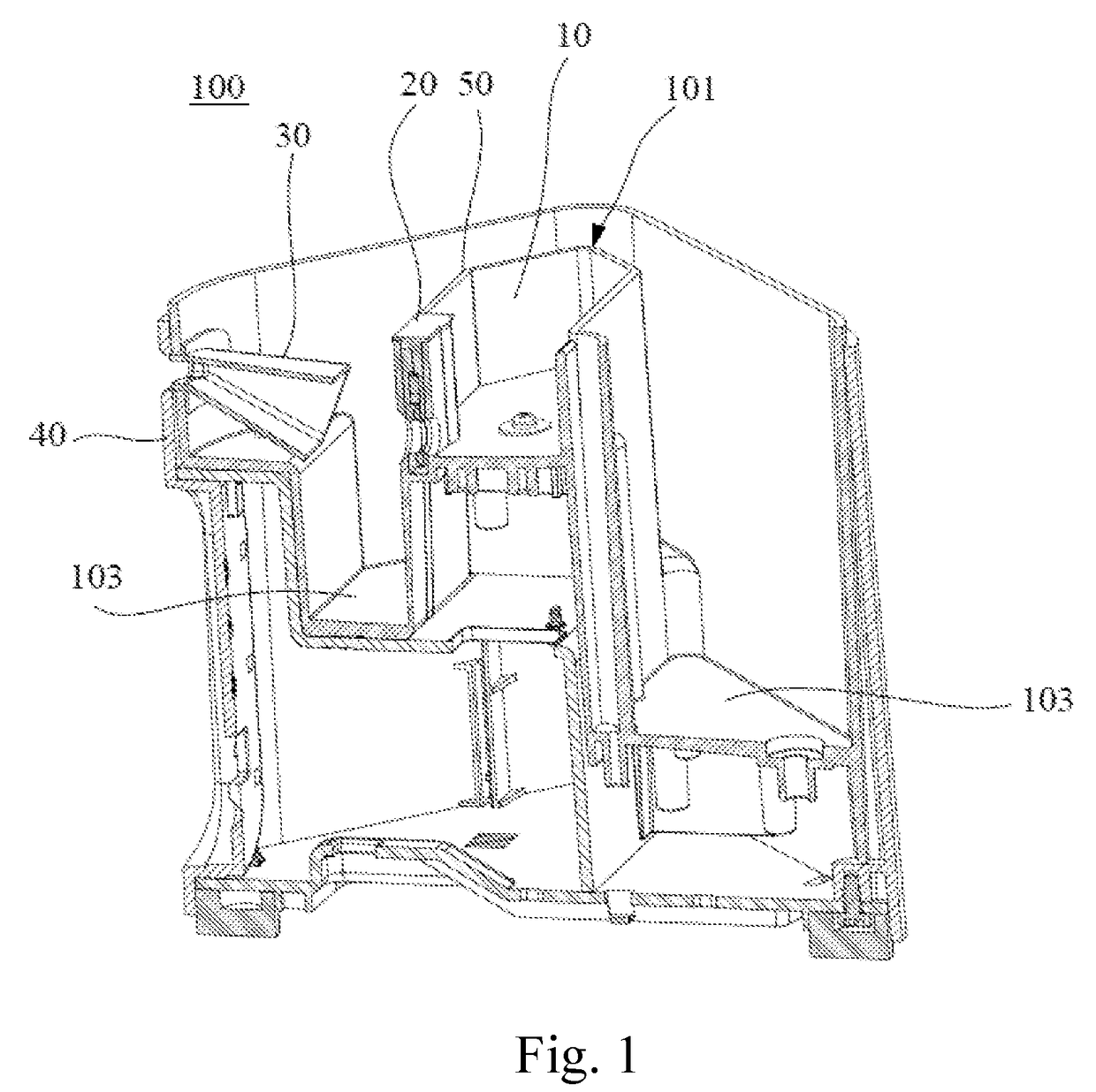

High efficiency compression ignition, indirect injected diesel engines and methods thereof

Inventive embodiments are directed to components, subassemblies, systems, and / or methods to improve combustion efficiency in compression ignition, indirect injection, diesel engines, and in particularly for diesel engines having a removable pre-chamber. In all embodiments, a combustion system is fitted with a pre-chamber adapted to cooperate with a piston in a manner that produces a highly efficient combustion process. In some embodiments, the pre-chamber has passages that have a variable cross-section and a variable angular orientation with respect to a centerline of the pre-chamber body. In one embodiment, the piston is provided with a number of surfaces that improve combustion of the fuel / air mixture within the combustion chamber. In some embodiments, the piston surfaces are generally aligned with angles of the combustion chamber such as the angle of the intake and exhaust valves. In other embodiments, the piston has surfaces that are adapted to cooperate with a tip of the pre-chamber.

Owner:OPFOR ADVANCED TECH

In-situ droplet monitoring for self-tuning spectrometers

ActiveUS7804064B2Speed up the gas flowFast dropletParticle separator tubesIsotope separationLow noiseLaser scattering

A laser scattering based imaging technique is utilized in order to visualize the aerosol droplets in an inductively coupled plasma (ICP) torch from an aerosol source to the site of analytical measurements. The resulting snapshots provide key information about the spatial distribution of the aerosol introduced by direct and indirect injection devices: 1) a direct injection high efficiency nebulizer (DIHEN); 2) a large-bore DIHEN (LB-DIHEN); and 3) a PFA microflow nebulizer with a PFA Scott-type spray chamber. Moreover, particle image velocimetry (PIV) is used to study the in-situ behavior of the aerosol before interaction with, for example, plasma, while the individual surviving droplets are explored by particle tracking velocimetry (PTV). Further, the velocity distribution of the surviving droplets demonstrates the importance of the initial droplet velocities in complete desolvation of the aerosol for optimum analytical performance in ICP spectrometries. These new observations are important in the design of the next-generation direct injection devices for lower sample consumption, higher sensitivity, lower noise levels, suppressed matrix effects, and for developing smart spectrometers. For example, a controller can be provided to control the output of the aerosol source by controlling the configuration of the source or the gas flow rate via feedback information concerning the aerosol.

Owner:GEORGE WASHINGTON UNIVERSITY

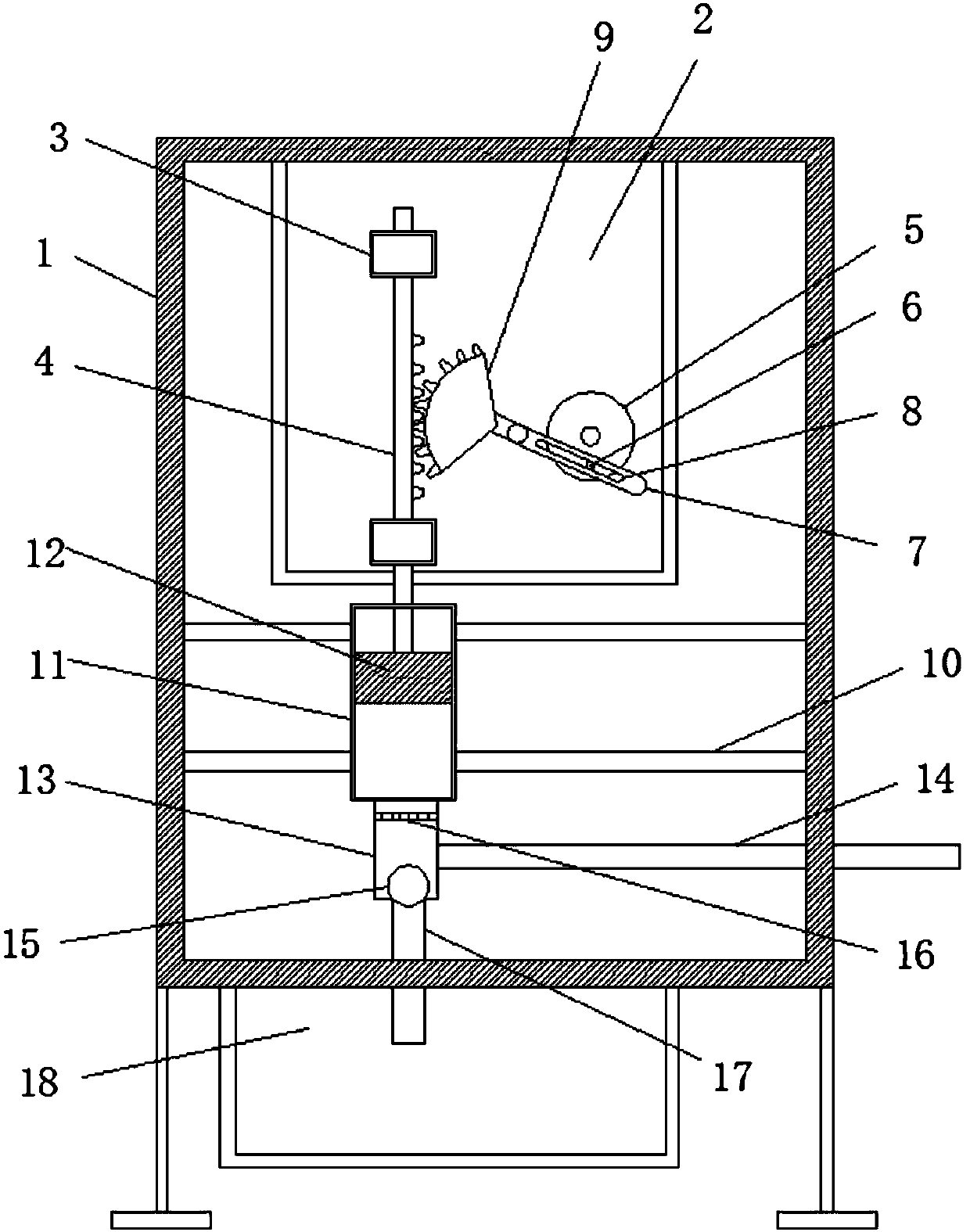

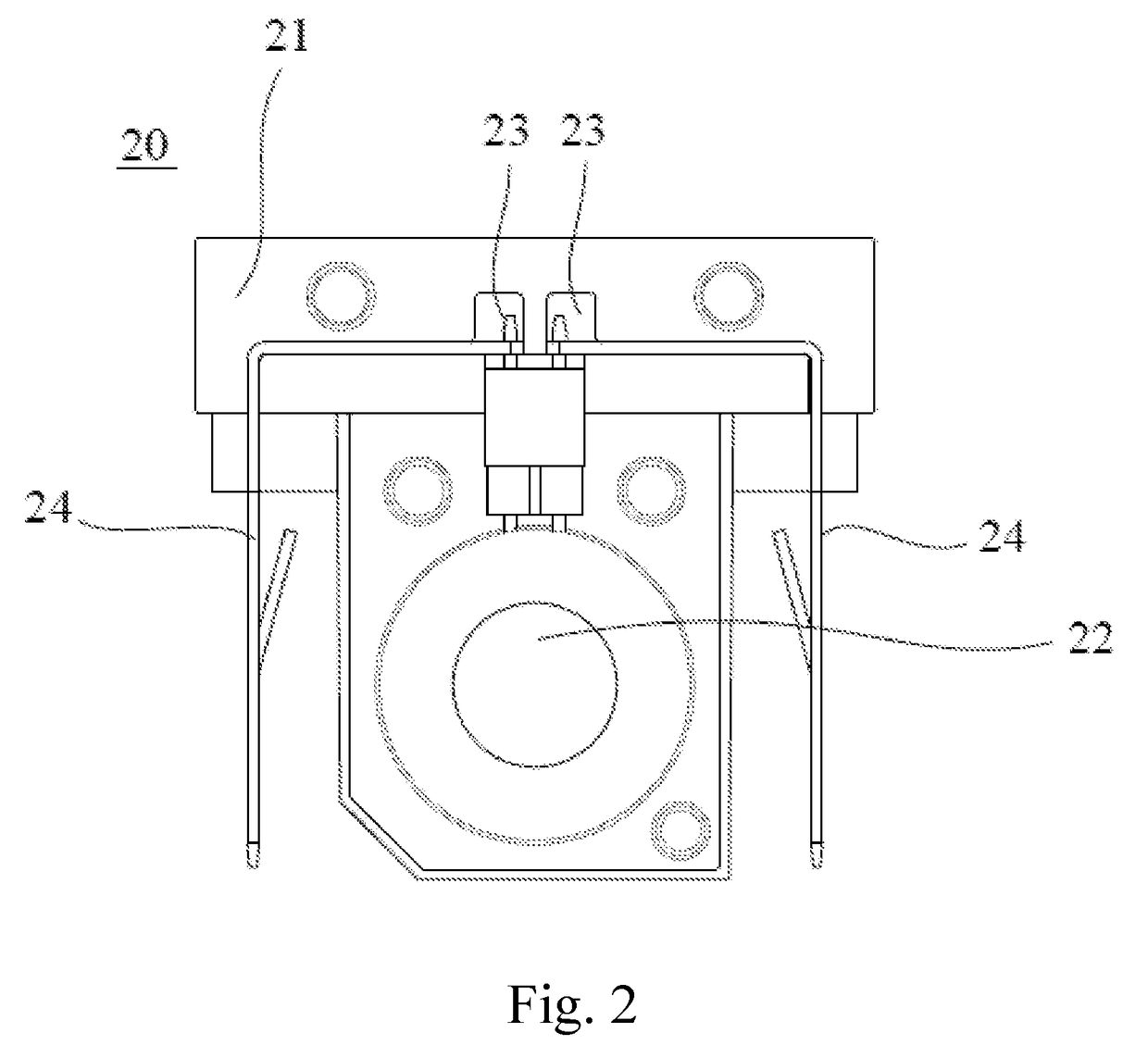

Urea-formaldehyde molding powder raw material injection system

The invention discloses a urea-formaldehyde molding powder raw material injection system which comprises a device body. A mounting plate is welded to the inner wall of the top of the device body, twolimiting blocks are fixedly connected to the mounting plate, and a vertically-arranged rack is slidably mounted in the limiting blocks. A rotating disc is rotatably mounted on the mounting plate, a first cylinder block is welded to the rotating disc, a swing rod is hinged to the mounting plate, and a track hole is formed in the swing rod and slidably connected with the first cylinder block. One end of the swing rod is fixedly connected with a half gear engaged with the rack, reinforcing rods are fixedly mounted in the device body, a power pipe is welded to the reinforcing rods, a piston is slidably mounted in the power pipe, and the bottom of the rack extends into the power pipe to be fixedly connected with the piston. Indirect injection of a water injection system is achieved, the using amount of liquid is reduced to a certain extent, liquid resources are saved, the using amount can be accurately adjusted and controlled, using is convenient, and popularization is easy.

Owner:嘉善中奥复合材料有限公司

Hydrogen engines and its burnt gas jet method

ActiveCN101260846BInternal combustion piston enginesFuel supply apparatusControl mannerInlet manifold

The invention discloses a hydrogen engine, which comprises a fuel gas supply system, an intake manifold, a CNG special spark plug and a cylinder, wherein, fuel gas injectors are arranged on different positions of the end part of the fuel gas supply system extending into a cylinder cover of the engine; and hydrogen is directly injected into the cylinder of the engine through the fuel gas injector or is indirectly injected into the cylinder of the engine through the fuel gas injector after mixing with inlet gas in an inlet channel. By adoption of the technical proposal, direct injection of hydrogen in the cylinder of the engine is realized; compared with a general hydrogen engine, higher charging efficiency and thermal efficiency are obtained by adoption of higher compression ratio, and thepower and the torque of the engine are increased; moreover, the hydrogen engine has the advantages of high power output, high response speed and so on; simultaneously, the combustion is improved and the exhaust is reduced. The problems of premature combustion and backfire are solved by adoption of the control means of combination of direct injection in the cylinder and indirect injection of the inlet channel, and simultaneously the maximum potential and exhaust advantages of hydrogen engines are given full play.

Owner:CHERY AUTOMOBILE CO LTD

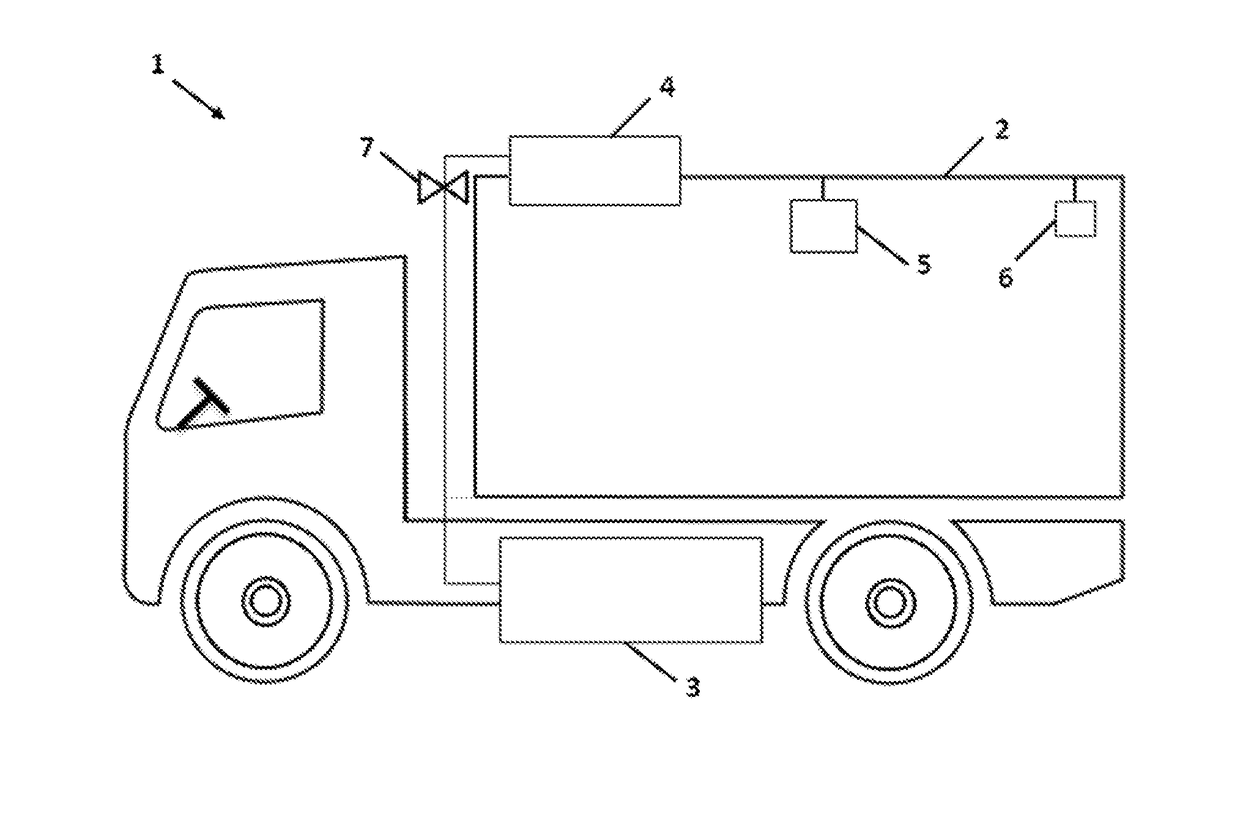

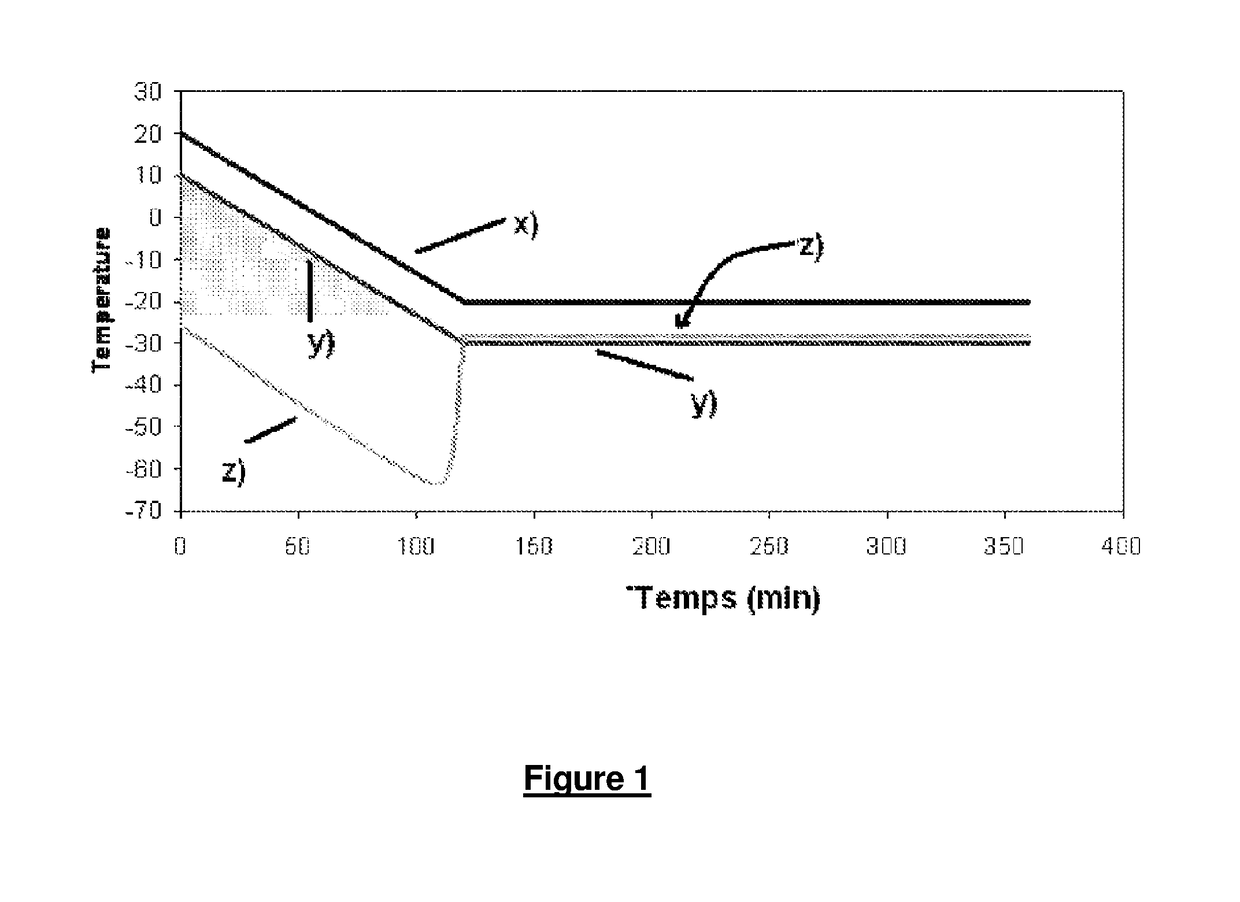

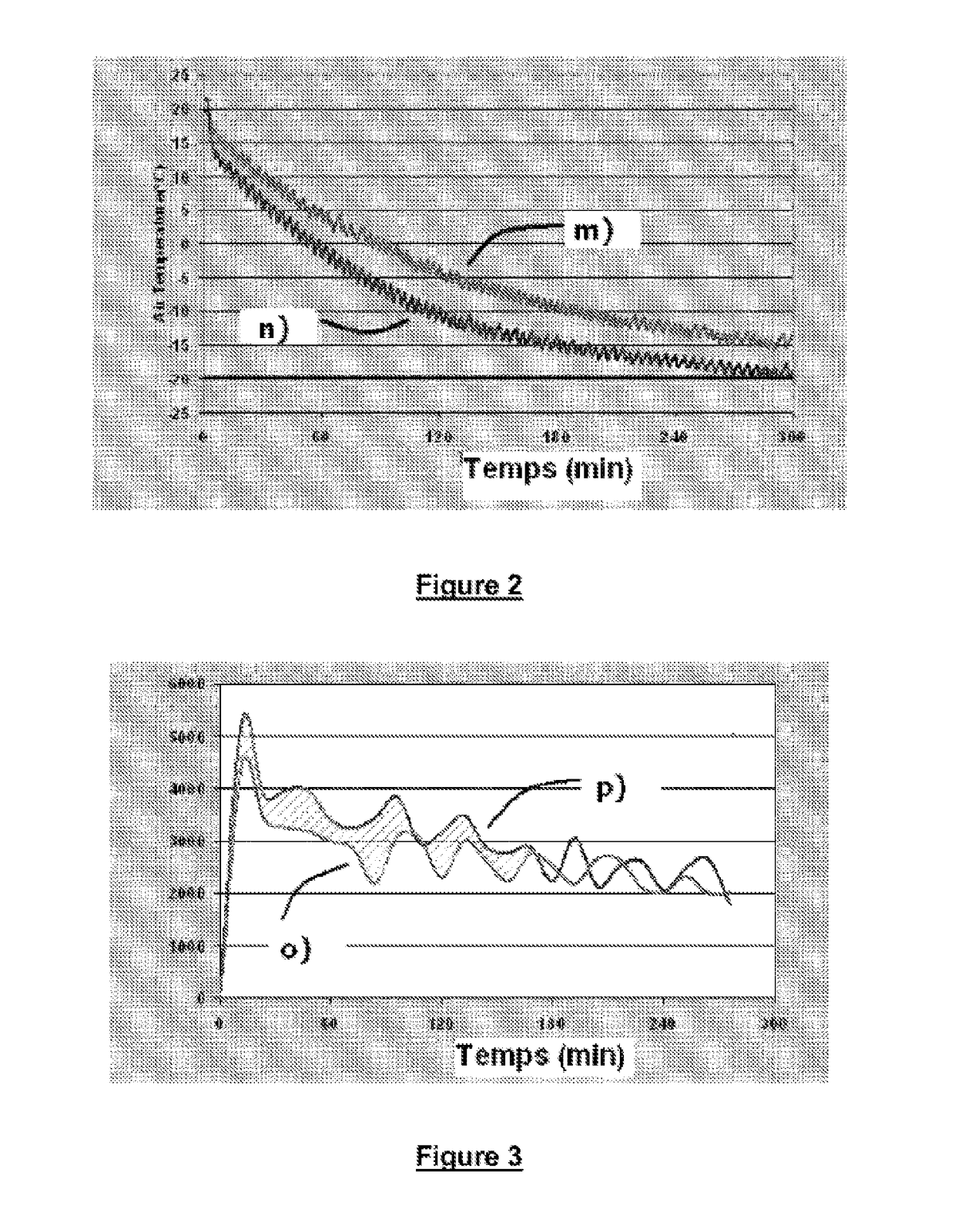

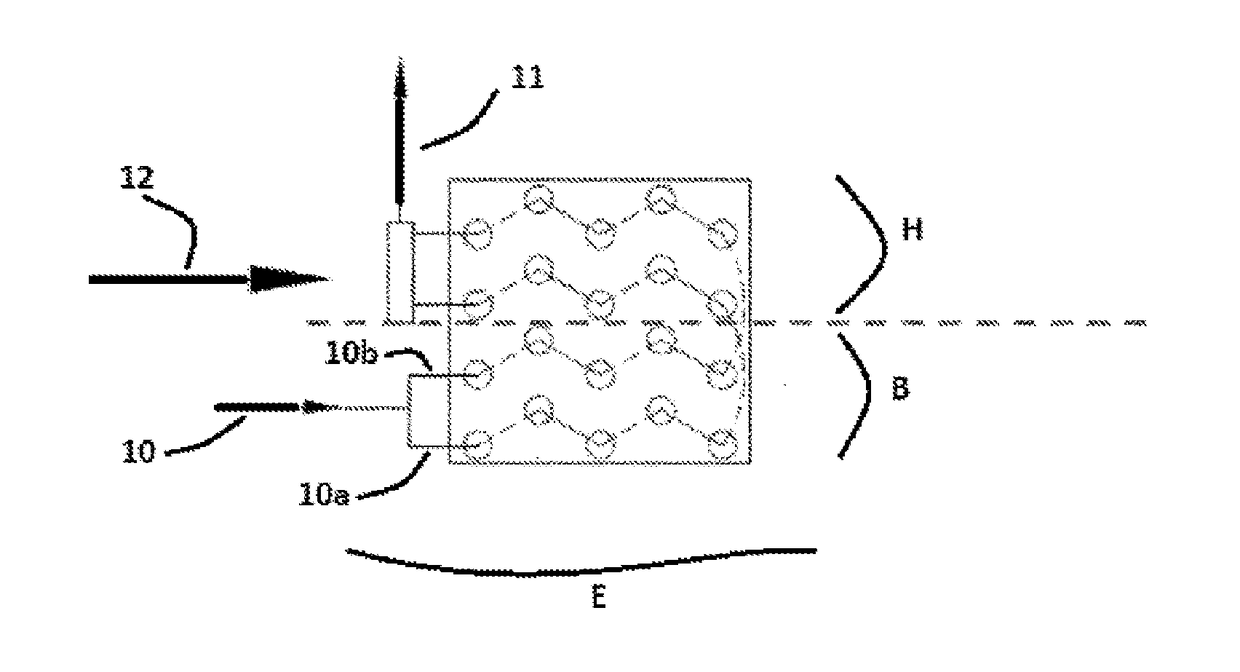

Method for regulating the temperature of the storage chamber for products of an indirect injection vehicle transporting heat-sensitive products

ActiveUS9797645B2Promote exchangeImprove performanceAir-treating devicesLighting and heating apparatusEngineeringHeat sensitive

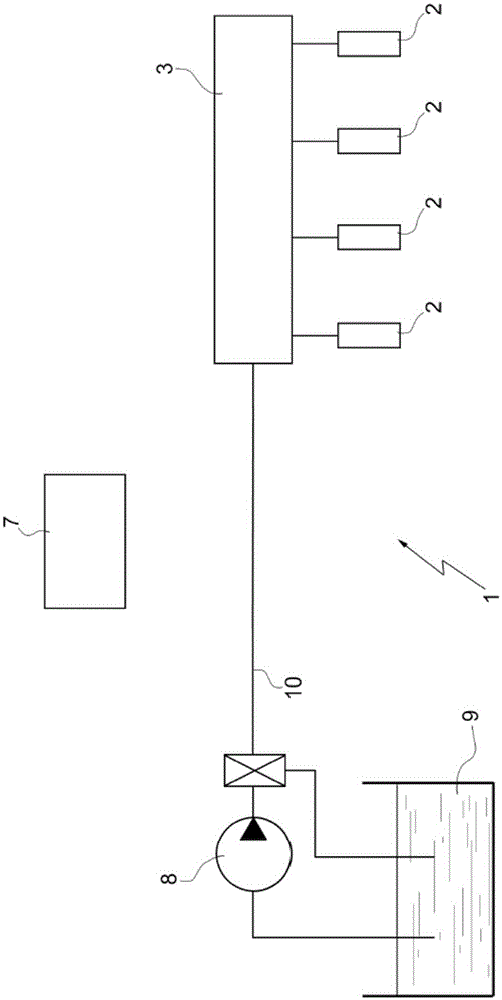

The invention relates to a method for transporting heat-sensitive products in a refrigerated lorry of the indirect injection type, wherein the temperature Tint inside the storage chamber is regulated by varying the pinch of the exchanger (Pinch=Tint−TFluid outflow) according to the position of the internal temperature Tint in relation to a temperature set value.

Owner:SINGAPORE HEALTH SERVICES PTE +1

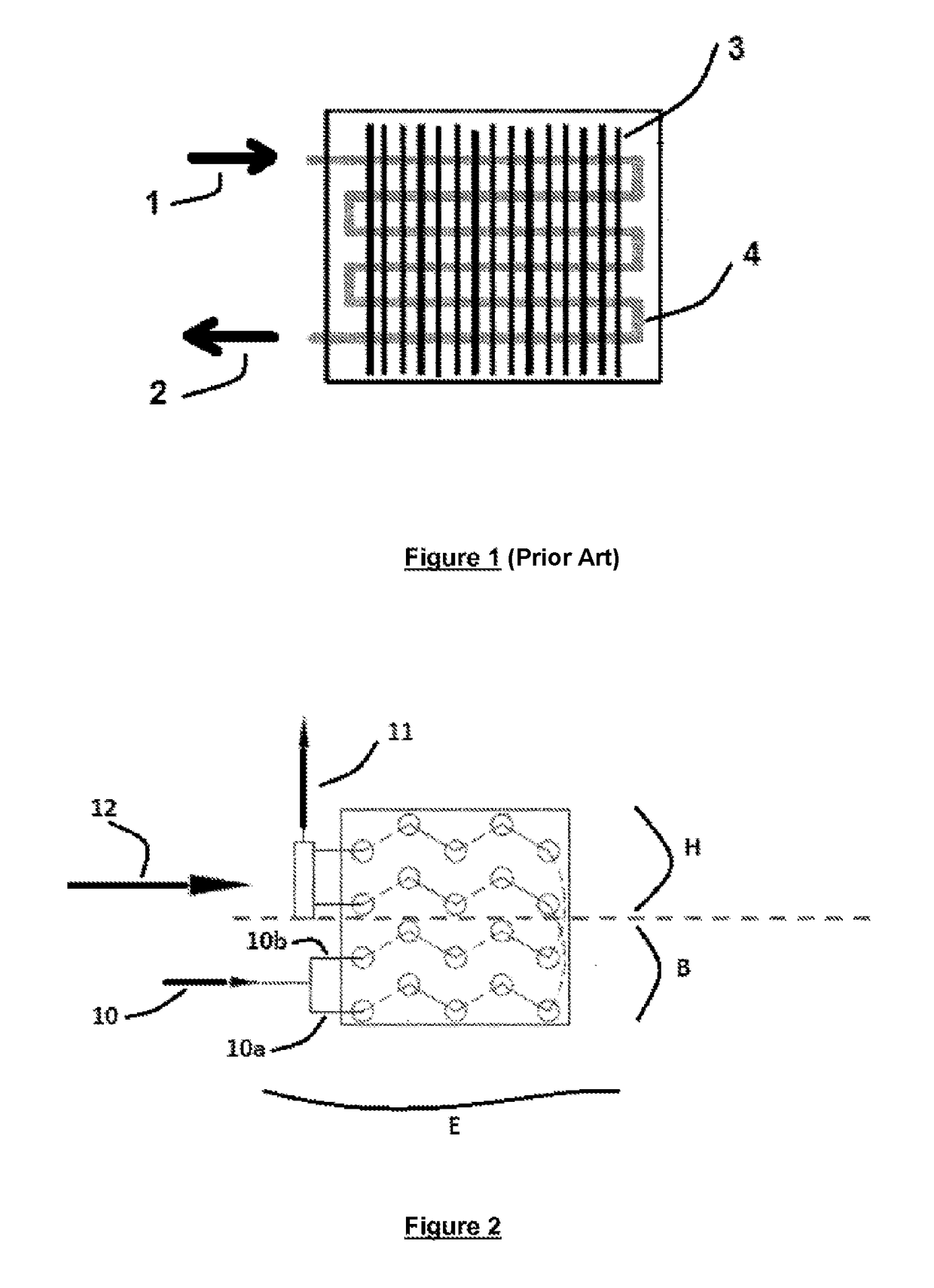

Compact exchanger for indirect-injection cyrogenic transportation

ActiveUS20180043754A1Improve the ease of assemblyImprove compactnessAir-treating devicesDomestic cooling apparatusIndirect injectionBiomedical engineering

Exchanger having a tube and fin bundle and comprising: a duct (4) through which a cryogenic fluid can flow between a fluid inlet (1) into the exchanger and a fluid outlet (2) from the exchanger; and a system of flat, continuous and parallel fins (3) through which said duct passes inside the exchanger, it being possible for air (12) to circulate within the exchanger by passing through channels delimited by the space between the duct and the parallel fins. The exchanger is characterized in that it comprises at least two independent ducts (10a, 10b) for the circulation of cryogenic fluid within the exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

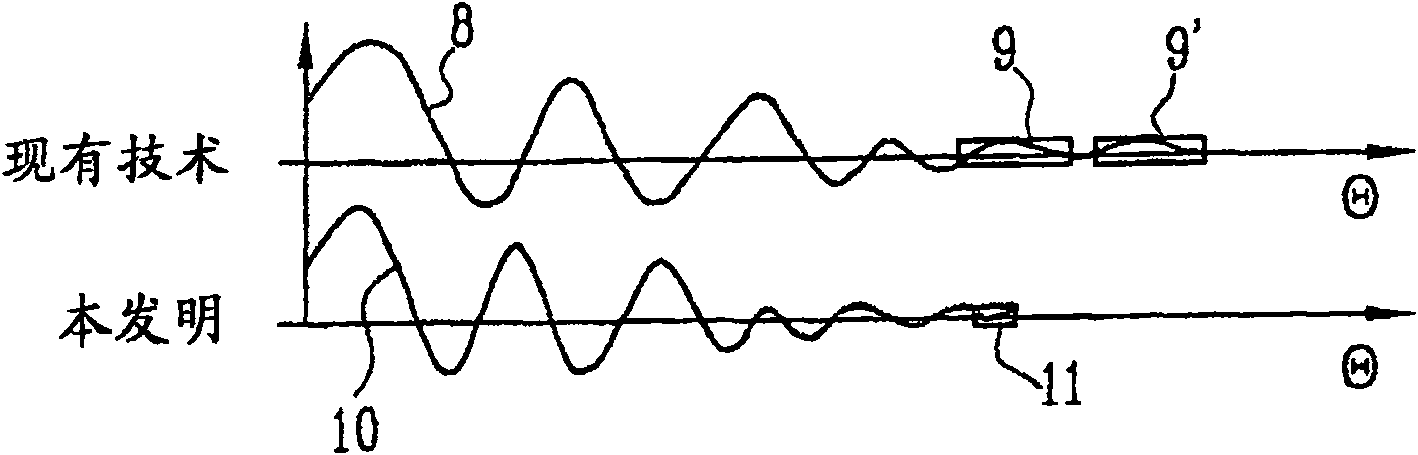

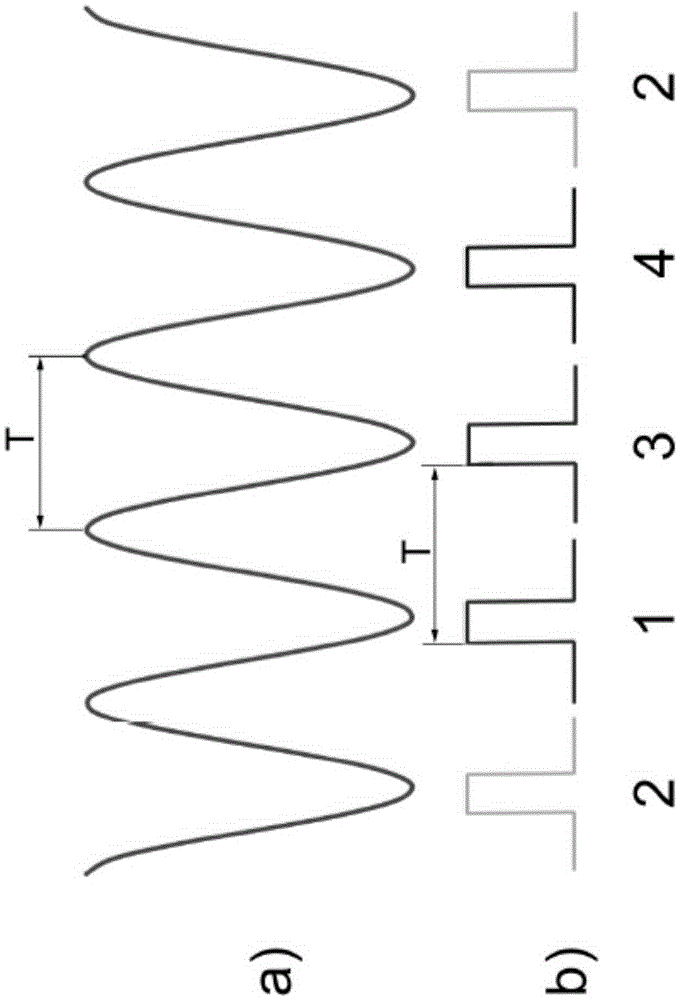

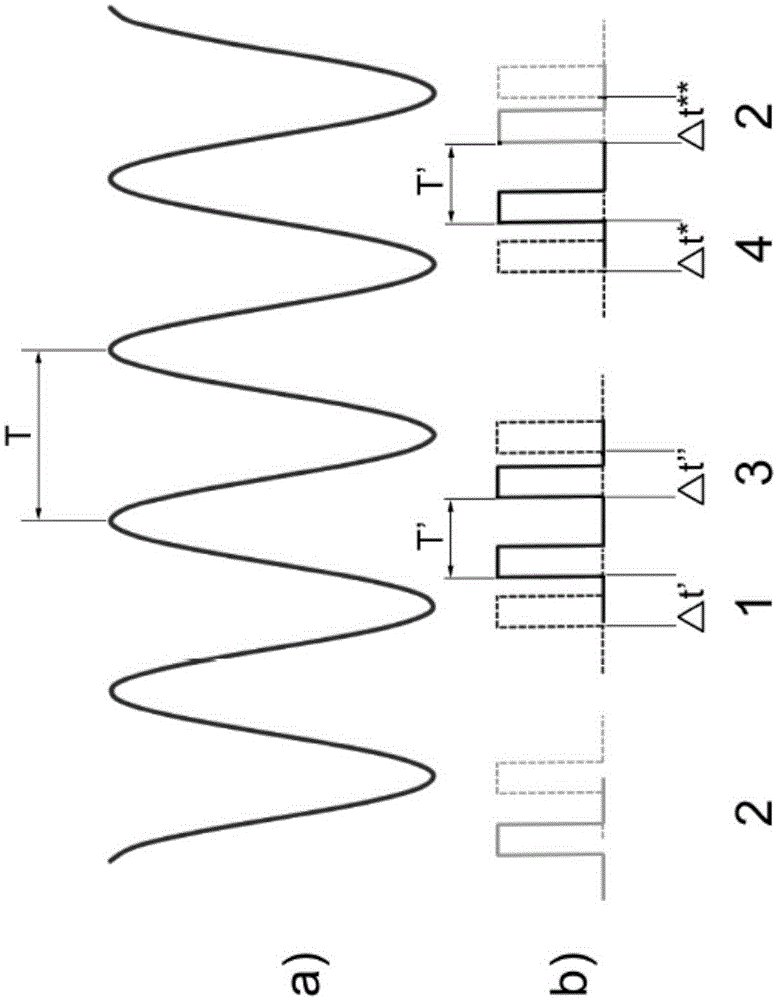

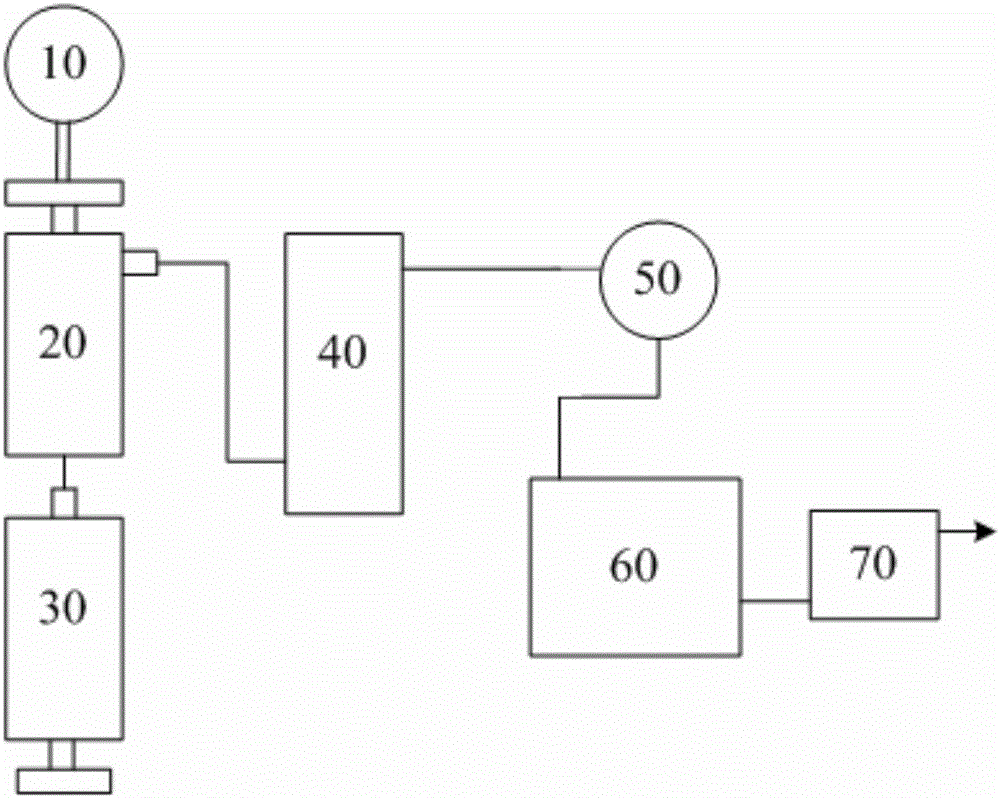

Method for controlling injection in combustion cycle of cylinder of internal combustion engine indirectly

ActiveCN105370423AEasy to implementLow costElectrical controlInternal combustion piston enginesCombustionExternal combustion engine

The invention provides a method for control injection of an internal combustion engine (ICE). The ICE comprises an indirect fuel injection system (1) including a plurality of injector (2) and a shared track (3) supplying fuel to the injector (2). The control method comprises the steps of obtaining a first critical inherent pulsation frequency of the injection system (1) and controlling the injectors (2) to supply the fuel to corresponding cylinders under pressure at injection frequency twice as much as the first critical inherent pulsation frequency of the injection system (1).

Owner:FAB ITAL MAGNETI MARELLI SPA

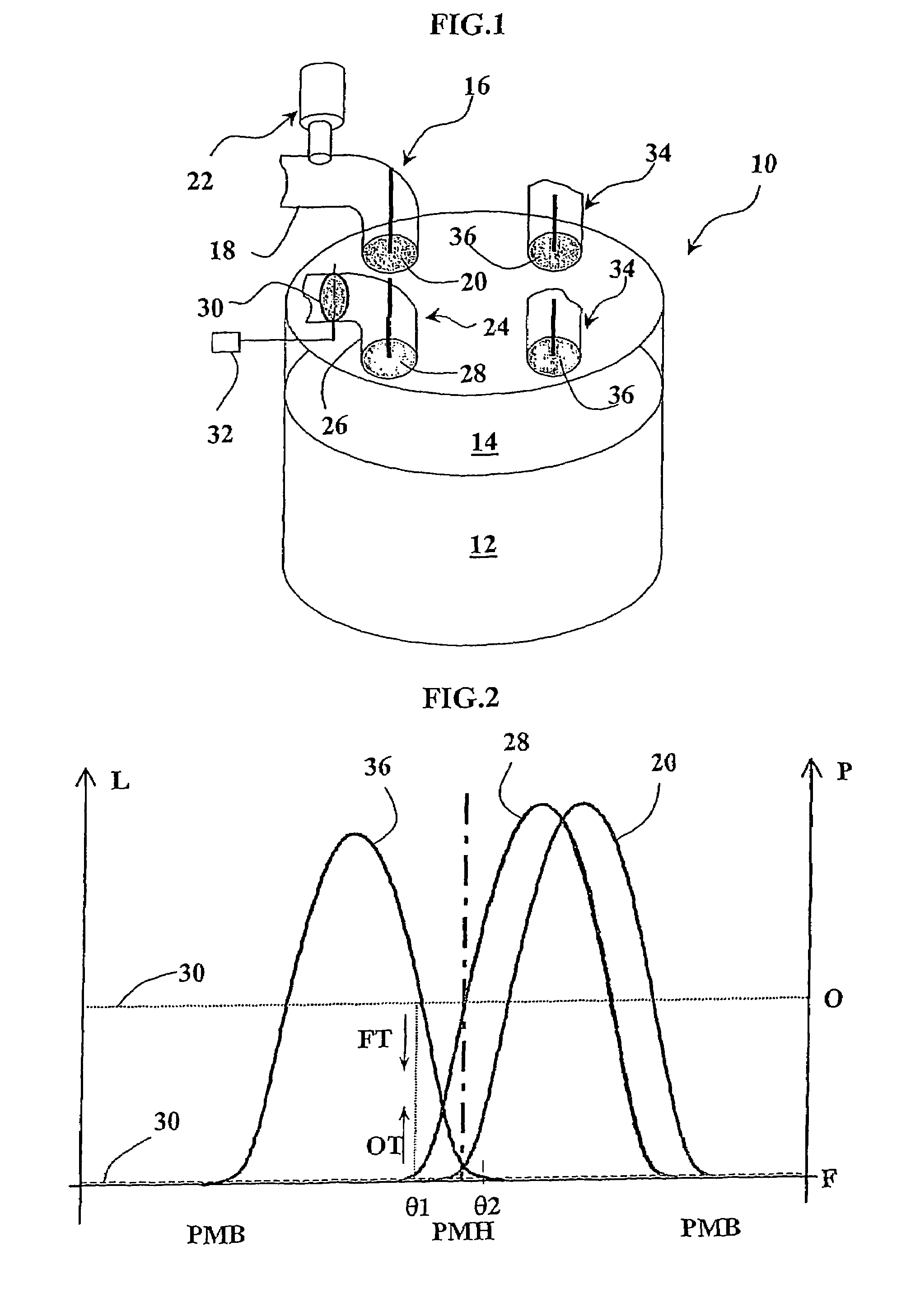

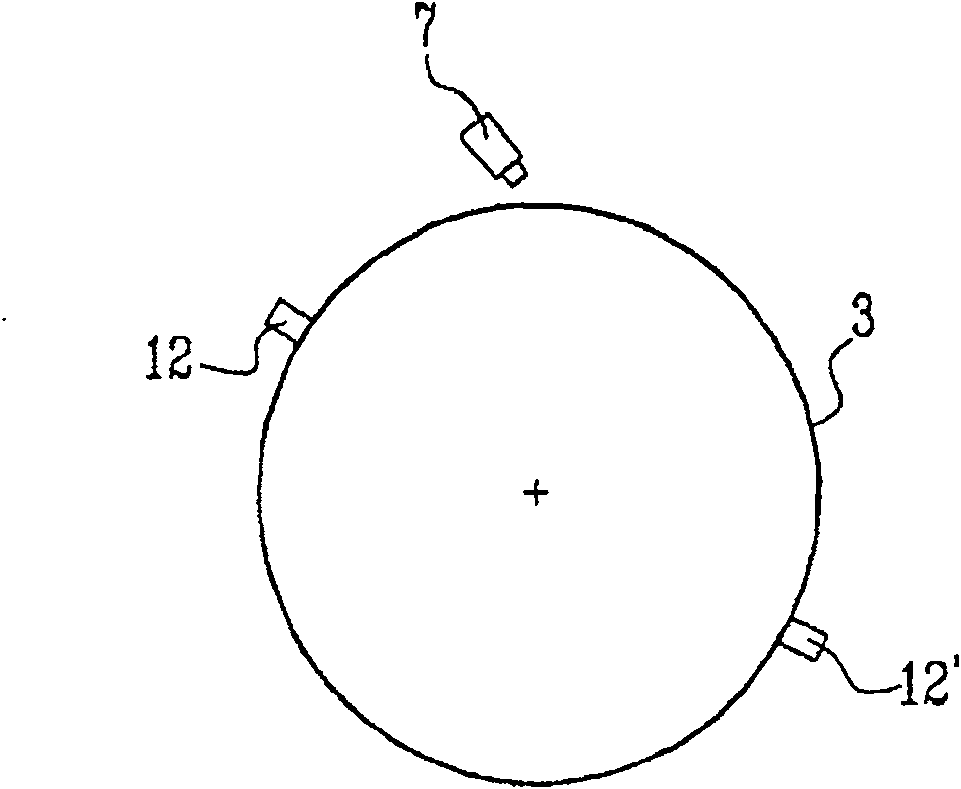

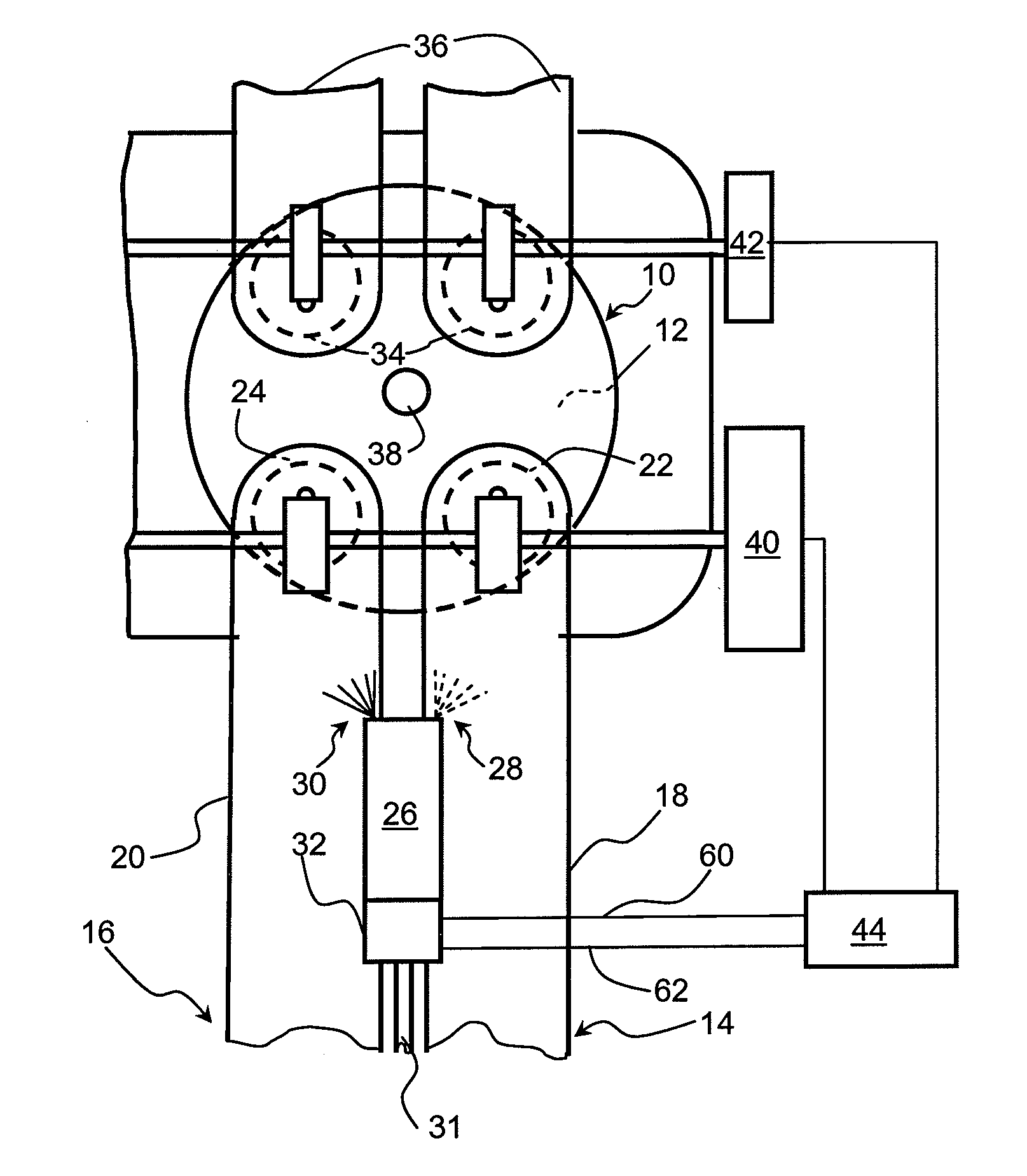

Indirect-injection internal-combustion engine, notably spark-ignition supercharged engine, with two intake means for carrying out a burnt gas scavenging stage

The invention relates to an internal-combustion engine, notably an indirect-injection supercharged engine, that can run with a burnt gas scavenging stage, comprising at least a cylinder (10) including a combustion chamber (12), non-carbureted air intake passage (16) with an air intake valve (24), carbureted air intake passage (14) with a carbureted air intake valve (22), burnt gas exhaust passage (28) with an exhaust valve (32), an exhaust camshaft (36) for controlling the exhaust passage (28), an intake camshaft (44) for controlling the air intake passage (16) and the carbureted air intake passage (14).

Owner:INST FR DU PETROLE

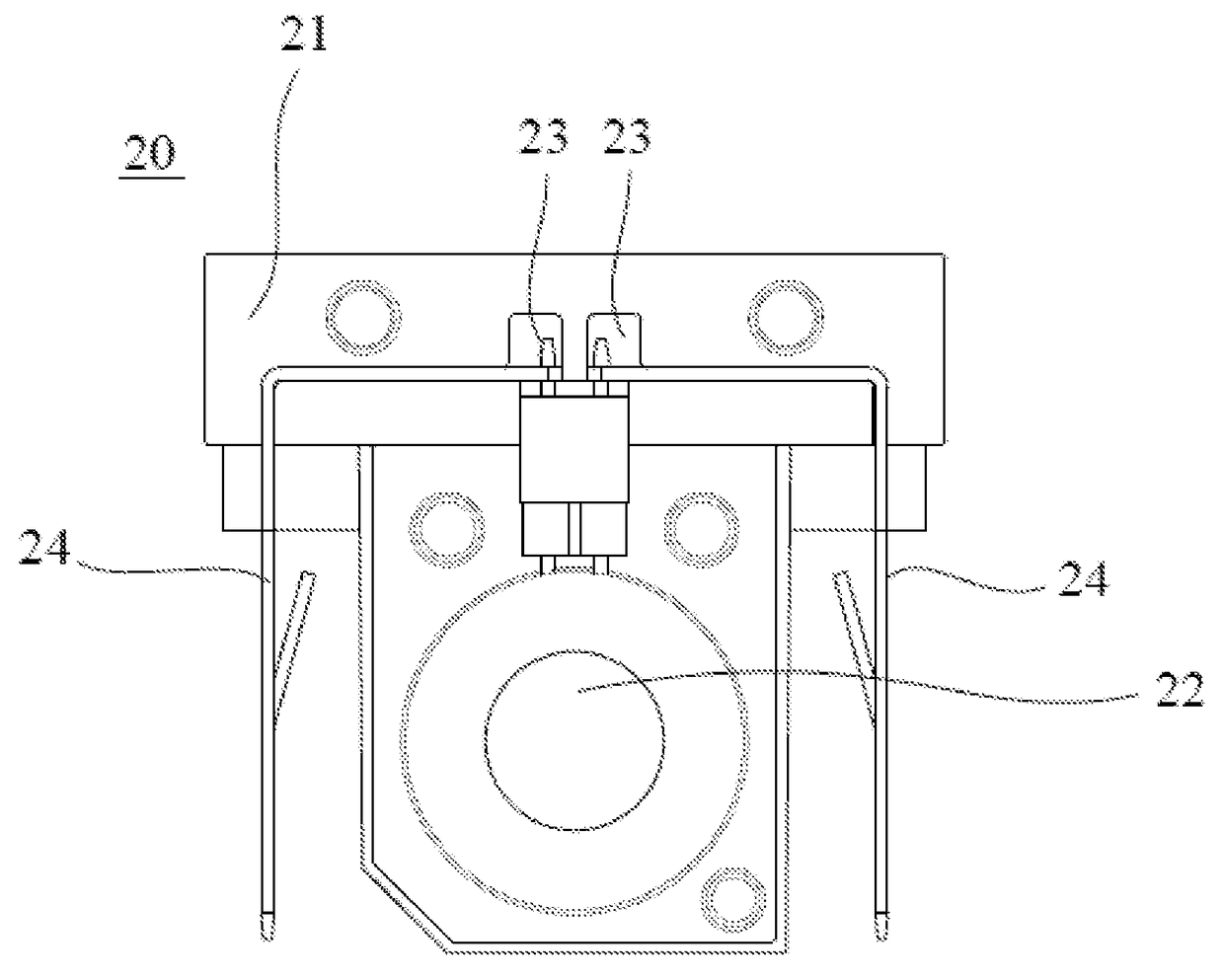

Atomizing device

ActiveUS20180029065A1Easy to understandLighting and heating apparatusFree-cooling systemsEngineeringIndirect injection

The present invention provides an atomizing device, which comprises: a first liquid chamber to store a liquid to be atomized; a nozzle plate unit disposed on the first liquid chamber and used to spray the liquid into first atomized droplets; and an indirect spray unit disposed at a position where the first atomized droplets are sprayed to accept the first atomized droplets. The indirect spray unit comprises a channel-like structure having a droplet inlet disposed toward a position where the nozzle plate unit sprays out the first atomized droplets; and a droplet outlet disposed on one side wall of the atomizing device. The droplet inlet receives the first atomized droplets to enter the indirect spray unit. The first atomizing droplets undertake striking and rebounding repeatedly in the channel-like structure to form the second atomized droplets. The second atomized droplets are sprayed out from the droplet outlet.

Owner:TAIWAN PURITIC

Internal-combustion and burnt gas scavenging supercharged engine with at least two intake means

The present invention relates to an indirect-injection internal-combustion engine, notably a supercharged engine, in particular of spark-ignition type, that can run according to a burnt gas scavenging mode or to a conventional mode, comprising at least one cylinder (10) with a combustion chamber (12), at least two air intake means (14, 16), one (14) of the means being a burnt gas scavenging intake means and the other (16) being a fuel injection intake means. The means comprising each a pipe (18, 20) controlled by an intake valve (22, 24), at least one burnt gas exhaust means with an exhaust valve (34) associated with an exhaust pipe (36) and at least one fuel injection means (26). According to the invention, the fuel injection means comprises an injector (26) with two nozzles (28, 30) allowing, when the engine runs in scavenging mode, the injection intake means (16) to be supplied with fuel through one (30) of the nozzles only and, when the engine runs under conventional conditions, scavenging intake means (14) and injection intake means (16) are respectively supplied with fuel through nozzles (28, 30).

Owner:INST FR DU PETROLE

Apparatus and method for measuring air flow of oil spray nozzle of indirect-injection diesel engine

ActiveCN105004390AQuick testInspection is accurateVolume/mass flow measurementVacuum pressureSpray nozzle

The invention discloses an apparatus and method for measuring air flow of an oil spray nozzle of an indirect-injection diesel engine. The apparatus herein is provided with a digital display dial gauge on a top portion of an oil sprayer assembly. The bottom portion of the oil sprayer assembly is provided with a depthometer. The oil spray nozzle is installed on the oil sprayer assembly. The oil spray nozzle is communicated with an air flow meter via air delivery pipeline. The air flow meter is communicated with a vacuum pump via a pressure-regulating tank. Air delivery pipeline which makes the air flow meter and the pressure-regulating tank communicated is provided with an adjustable vacuum pressure meter thereon. The method herein comprises: a stage of installing the oil spray nozzle to be measured; a stage of setting measurement conditions and parameters; and a stage of outputting a tested result after the measurement. The apparatus and method have the beneficial effects of: the apparatus and the method are used for measuring the air flow of the oil spray nozzle of the indirect-injection diesel engine, and can rapidly and accurately detect associated indexes of a diesel product with a low testing cost, and are markedly significant in regulating the use quality of diesel in the fuel market and refraining the emission of the diesel vehicles.

Owner:TIANJIN HTC CO LTD

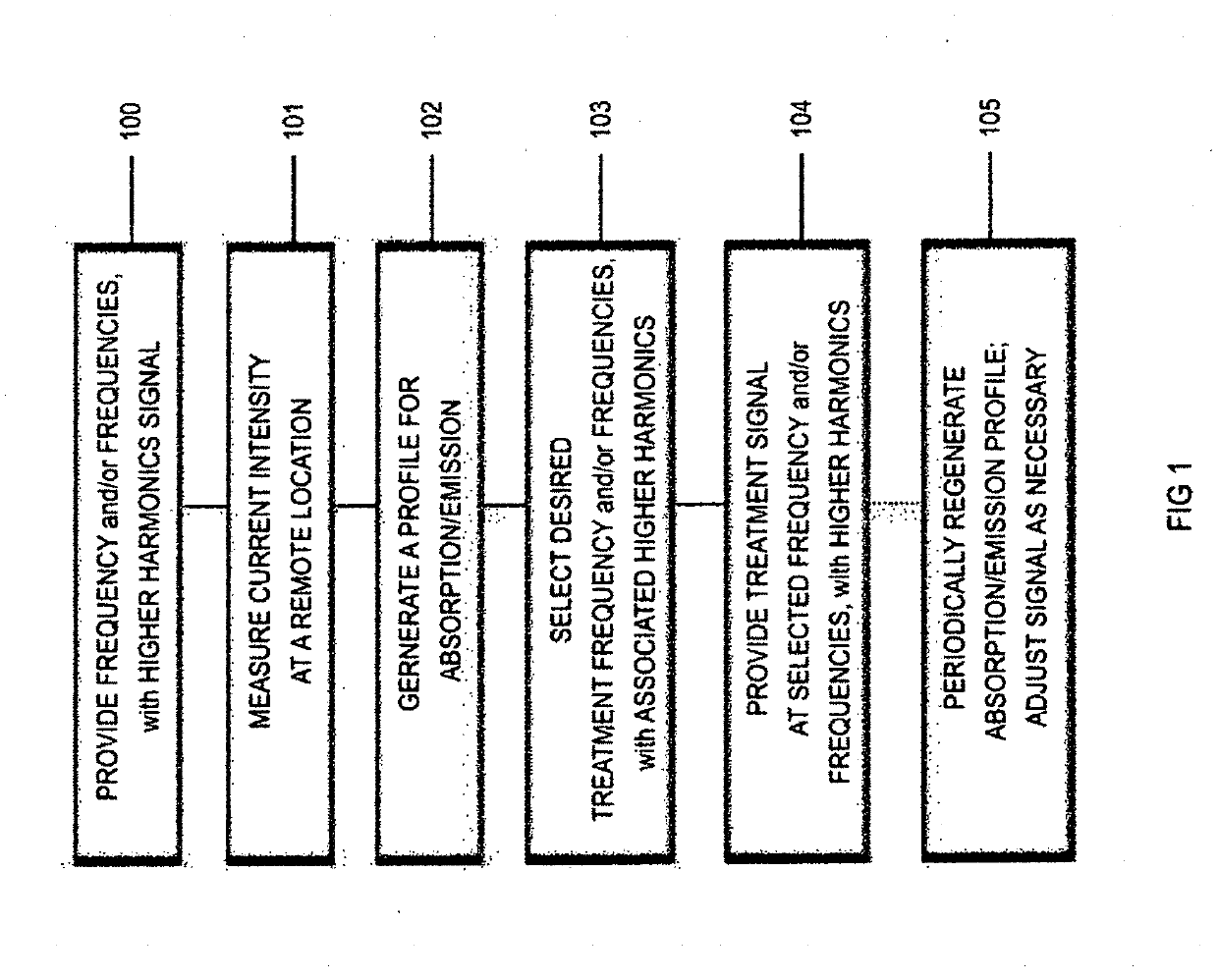

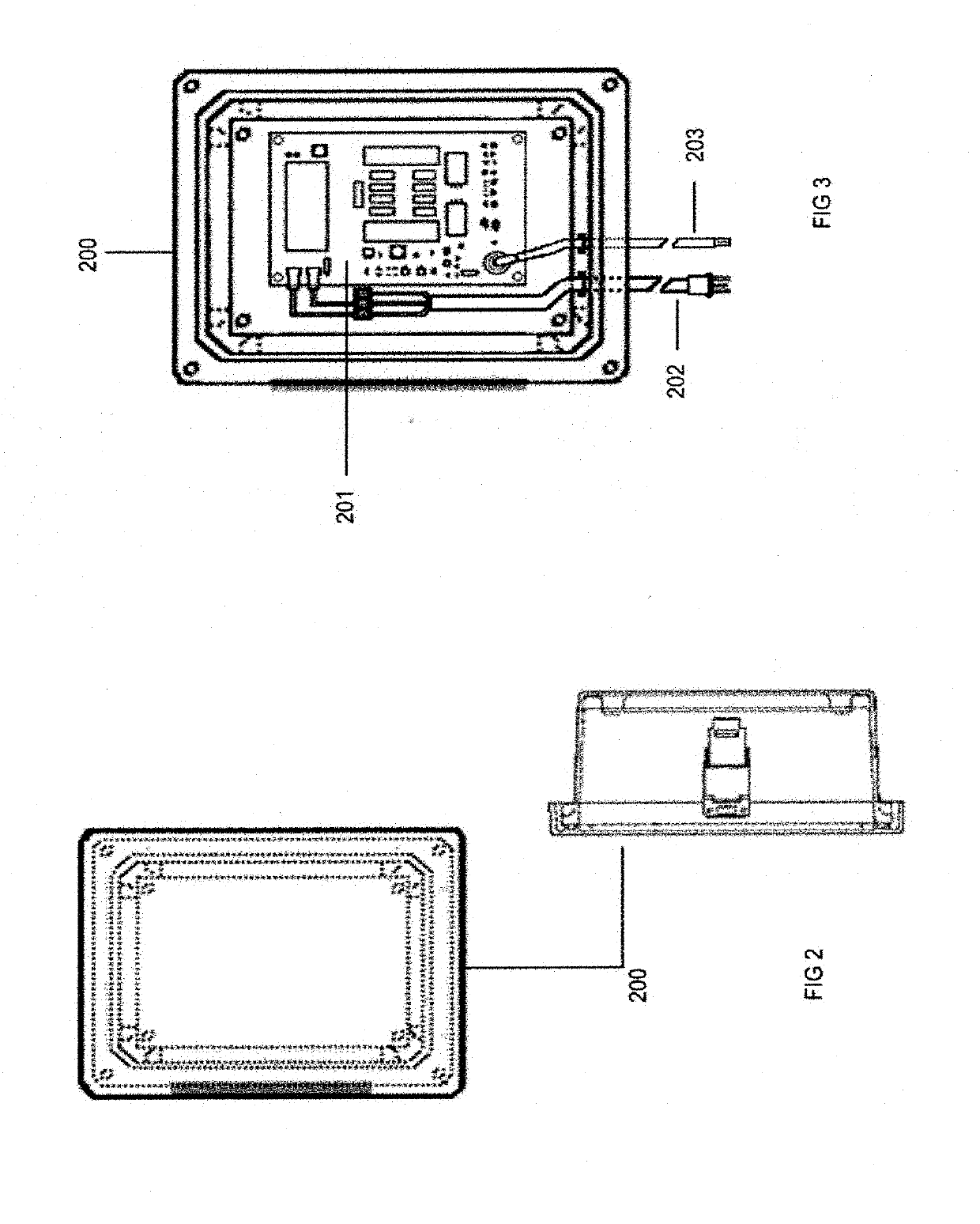

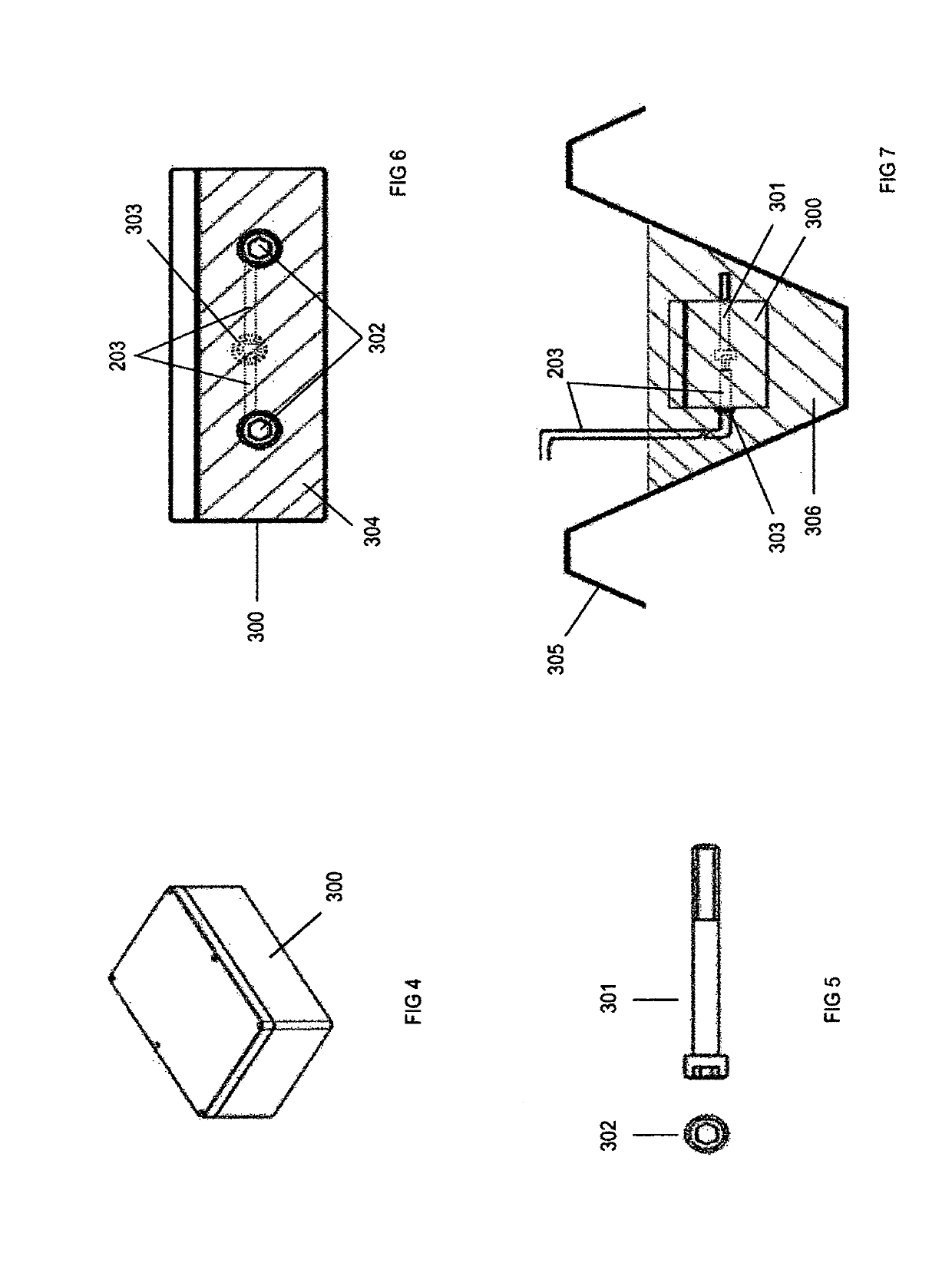

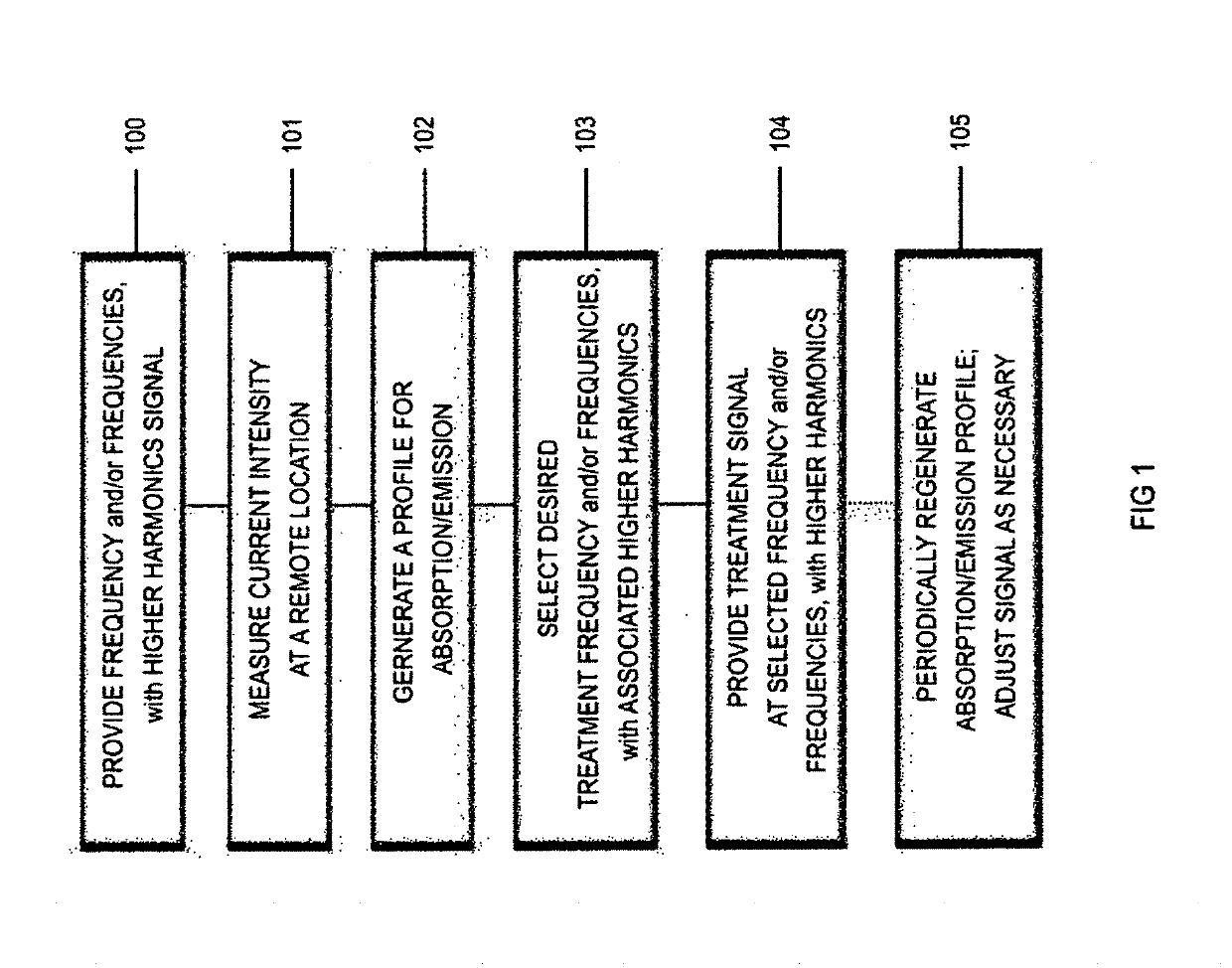

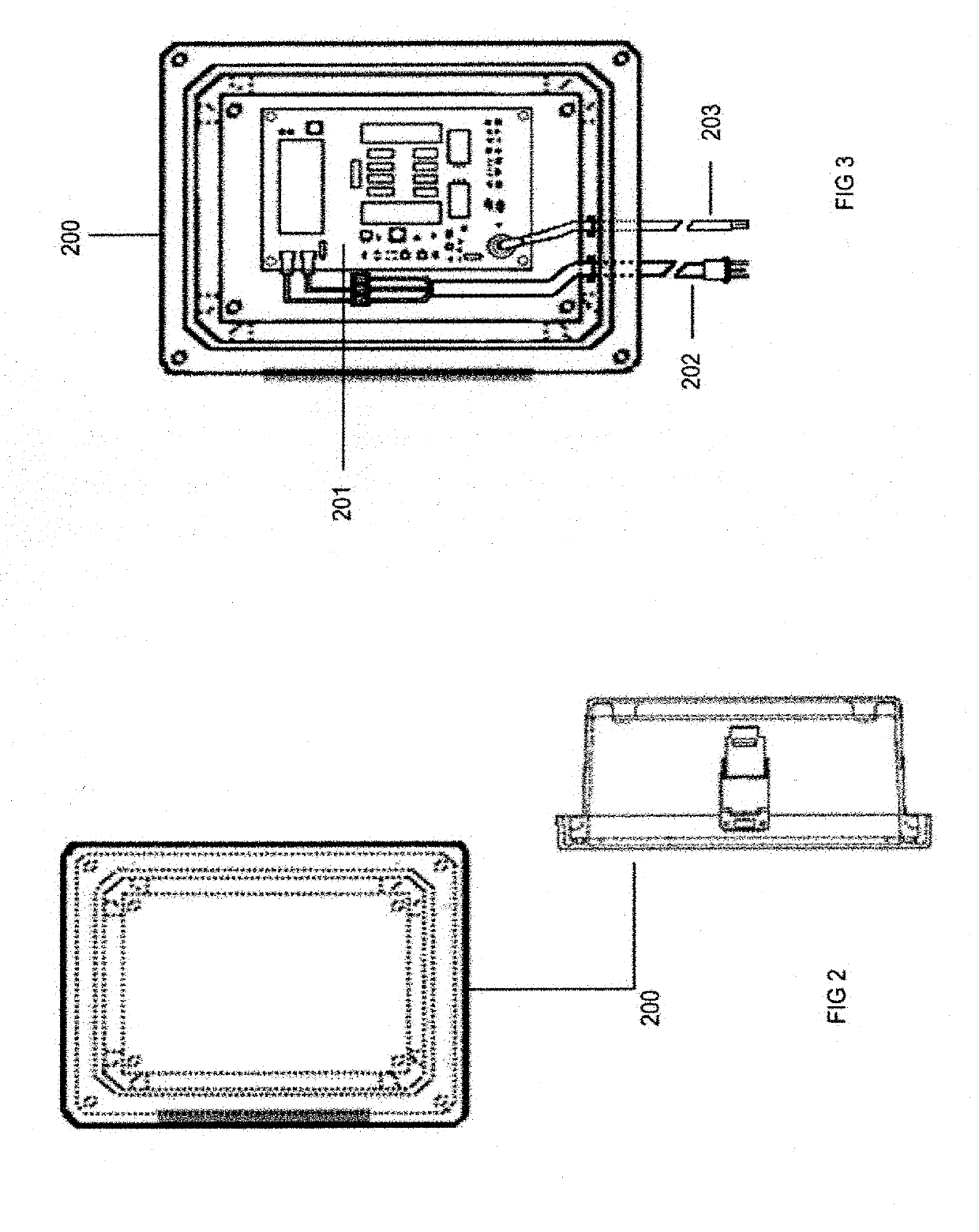

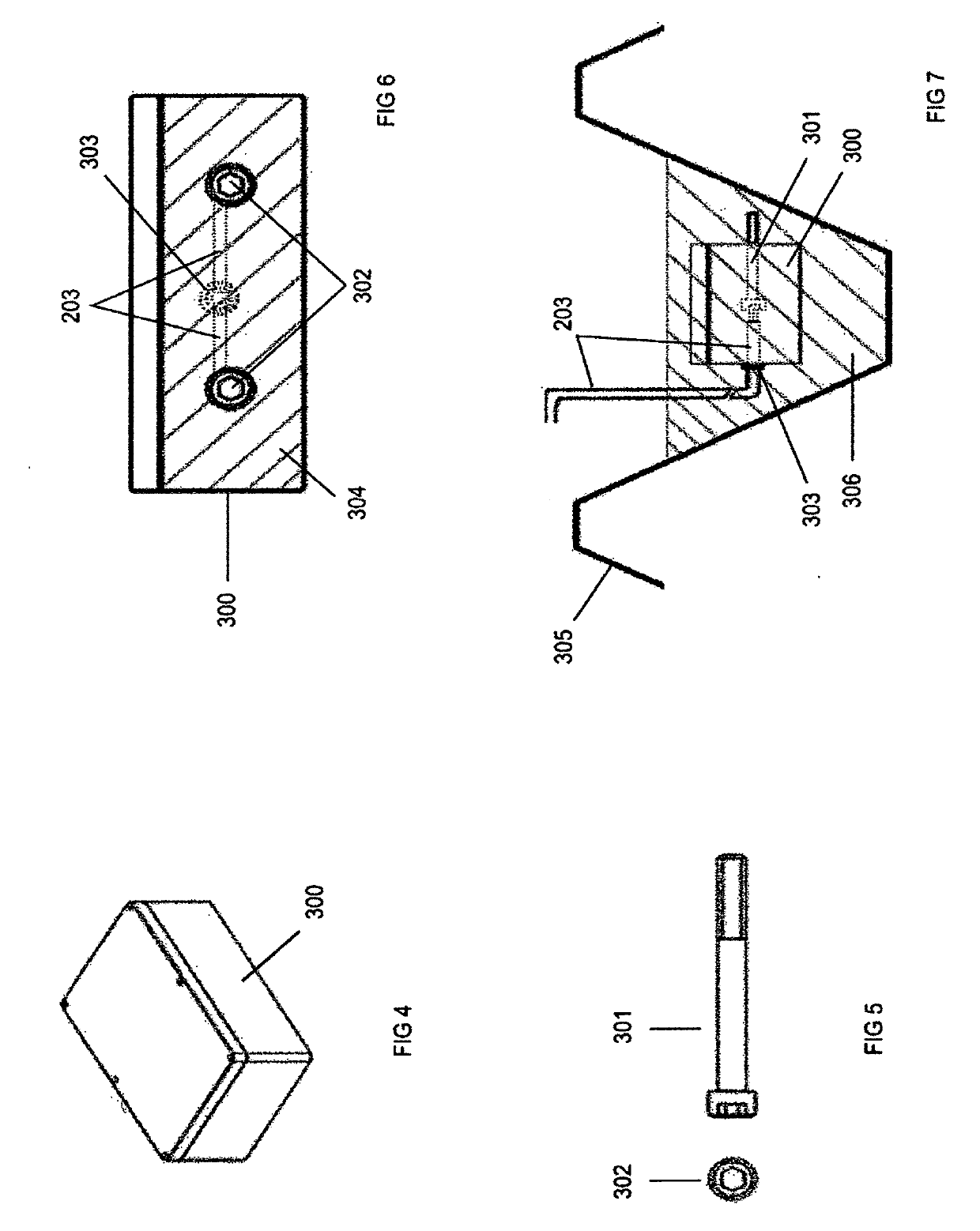

Method and system for electromagnetic fluid treatment utilizing frequencies and harmonics

InactiveUS20190150370A1Disruption of bondingOvercomes shortcomingWater treatment parameter controlSpecific water treatment objectivesEnergy absorptionHarmonic

A method and system for utilizing electromagnetic energy of a frequency, and / or multiple frequencies, and higher harmonics of those frequencies to disrupt the normal bonding of the fluid molecules and that of mineral structures within the body of the fluid is disclosed. Electromagnetic signals at a frequency, frequencies, and higher harmonics related to the energy absorption / emission profile of the fluid being treated are directed into the fluid through direct or indirect injection and / or induced coupling. The frequency, frequencies, and higher harmonics of the treatment signal, preferably between 0.1 KHz and 1000 MHz, may be changed if the absorption / emission profile of the fluid changes during treatment.

Owner:AQUA DYNAMICS SYST

Use of a particular copolymer for preventing deposits on the valves of indirect injection petrol engines

The invention relates to the use, in order to prevent deposits at low temperature on the fuel intake valves in indirect injection spark ignition engines, of one or more copolymer(s) comprising:at least one unit of following formula (I):andunits of following formula (II):The copolymers according to the invention are very particularly effective in preventing and / or cleaning the deposits on the valves while preventing the latter from sticking at low temperature.

Owner:TOTAL MARKETING SERVICES SA

Method and system for electromagnetic fluid treatment utilizing frequencies and harmonics

ActiveUS20190152812A1Disruption of bondingOvercomes shortcomingSpecific water treatment objectivesScale removal and water softeningHarmonicEnergy absorption

A method and system for utilizing electromagnetic energy of a frequency, and / or multiple frequencies, and higher harmonics of those frequencies to disrupt the normal bonding of the fluid molecules and that of mineral structures within the body of the fluid is disclosed. Electromagnetic signals at a frequency, frequencies, and higher harmonics related to the energy absorption / emission profile of the fluid being treated are directed into the fluid through direct or indirect injection and / or induced coupling. The frequency, frequencies, and higher harmonics of the treatment signal, preferably between 0.1 KHz and 1000 MHz, may be changed if the absorption / emission profile of the fluid changes during treatment.

Owner:ENGLE JON A +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com