Method of stopping and restarting internal combustion engine with indirect injection

A technology for internal combustion engines and engines, which is applied to the starting of engines, internal combustion piston engines, and electric motors for engines, etc., and can solve problems such as pollution and out-of-synchronization of the first injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

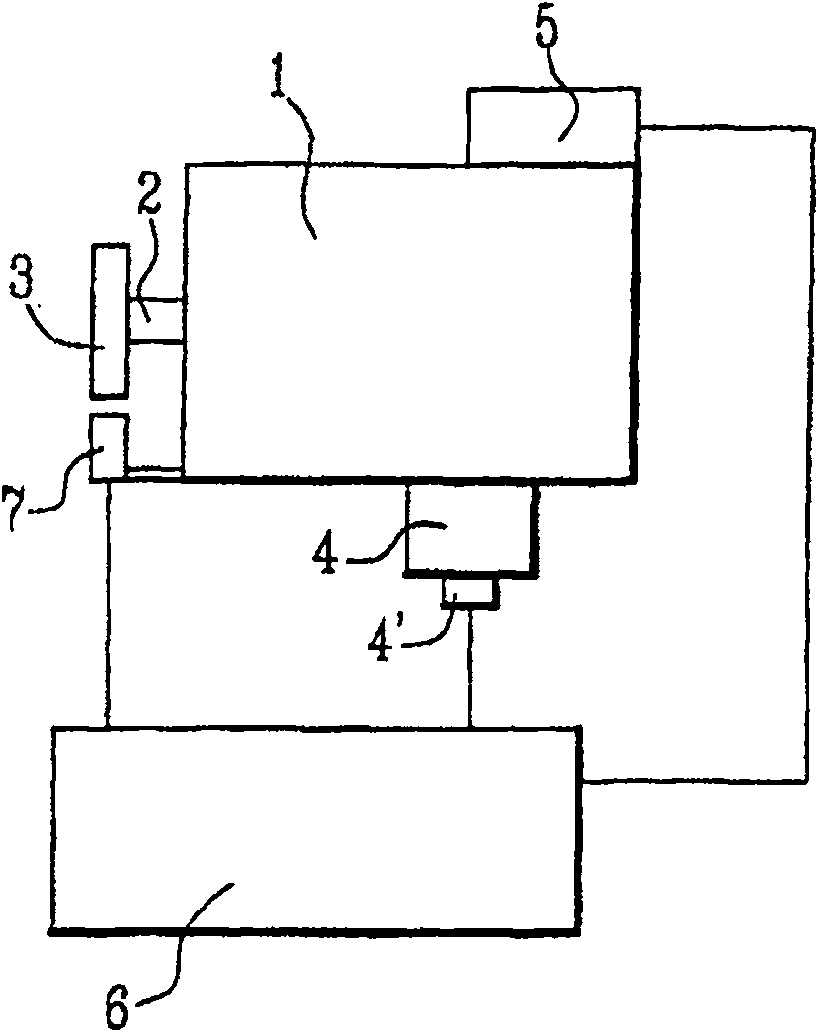

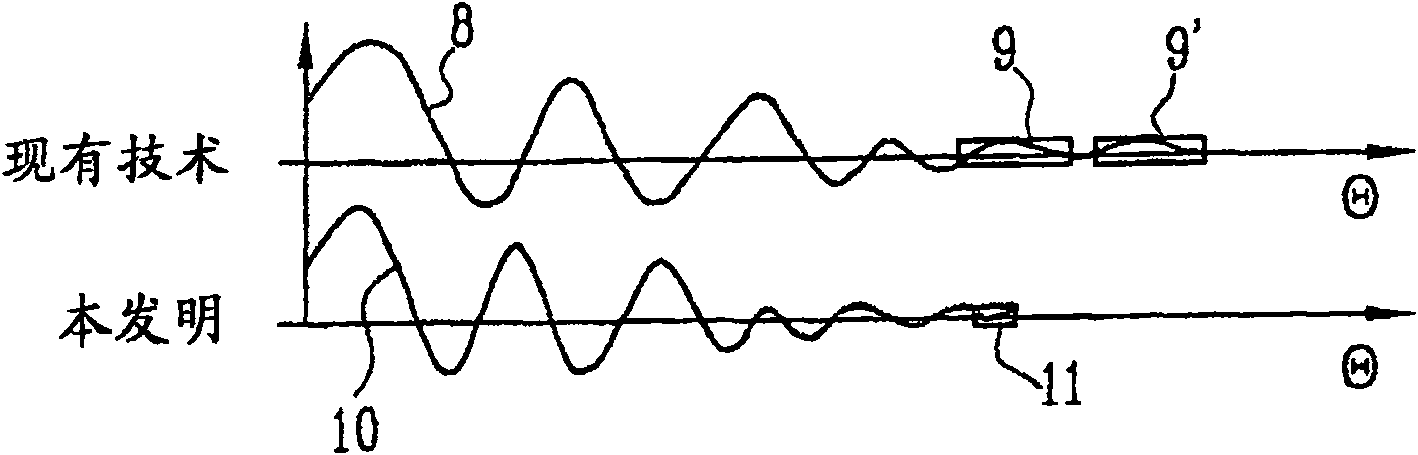

[0028] [27] figure 1 A heat engine 1 is shown schematically, for example an in-line four-cylinder engine.

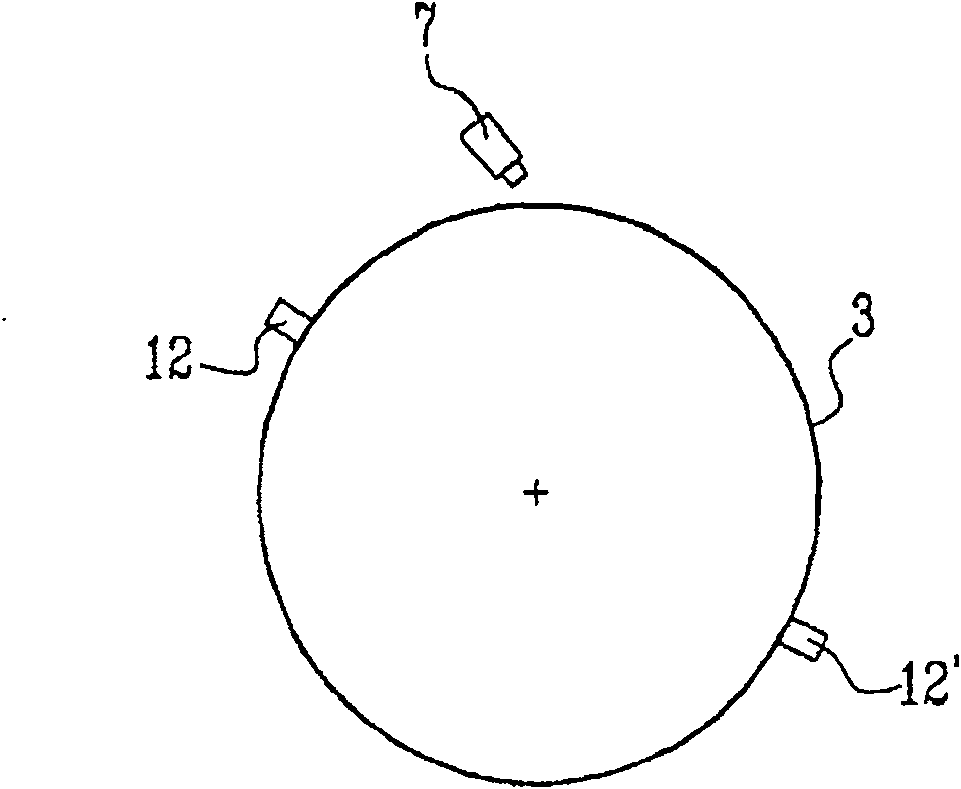

[0029] [28] Engine 1 has four cylinders (hereinafter marked as C 1 、C 2 、C 3 、C 4 ), a piston is moved in each cylinder, said piston is connected via a connecting rod to a crankshaft 2, said crankshaft 2 being connected at one end thereof to a flywheel 3.

[0030] [29] A piston that performs reciprocating motion, a connecting rod, a crankshaft 2 , and a flywheel 3 that performs rotational motion constitute a set of moving parts of the engine 1 .

[0031] [30] The engine 1 includes a starter 4 which may be an electric motor or a reversible alternator. The starter 4 has a control part 4', which can switch on or off the power supply of the starter 4 from the vehicle battery.

[0032] [31] Engine 1 is an indirect injection engine, where fuel is injected indirectly into the inlet ducts of each cylinder of the engine. The injectors are controlled by an electronic contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com