Oolong tea platform-type full automatic green-making machine control system and method

A fully automatic greening machine and control system technology, applied in the general control system, control/adjustment system, computer control, etc., can solve the problems of large leaf area, low work efficiency, and the need for staff to work overnight, to ensure Continuity, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

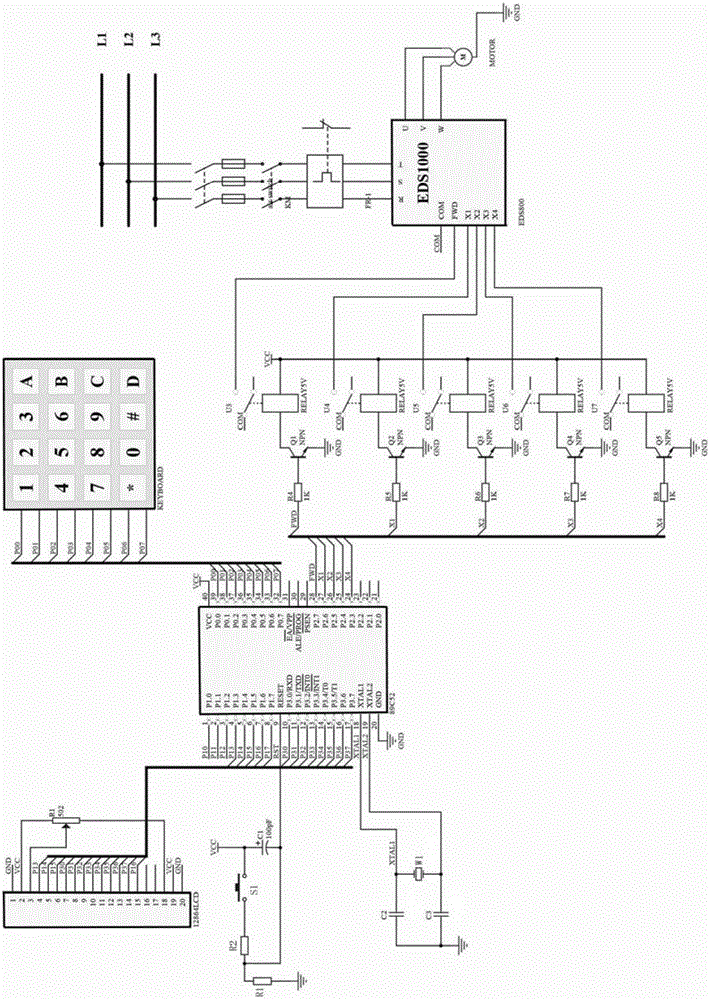

[0027] A control system for an oolong tea platform-type fully automatic greening machine, including a single-chip microcomputer, and a display circuit, a keyboard circuit, and N relay units connected to the single-chip microcomputer, and a motor main circuit inverter connected to the N relays, and a motor A motor connected to a frequency converter in the main circuit drives the oolong tea machine platform to move up and down at a set frequency, where N is a positive integer and N≥2.

[0028] The relay unit includes a resistor, a triode, and a relay body, wherein one end of the resistor is connected to the single-chip microcomputer, the other end is connected to the base of the triode, the emitter of the triode is grounded, and the collector of the triode is connected to the relay body. When the relay body is energized, the relay body When the normally open contact is closed, the circuit connected to the frequency converter of the main circuit of the motor is turned on, and the ...

Embodiment 2

[0038] Such as figure 1 , an oolong tea platform-type fully automatic greening machine control system, including a single-chip microcomputer, and a display circuit connected to the single-chip computer, a keyboard circuit, 5 relay units, and a motor main circuit inverter connected to the 5 relays, and The main circuit of the motor is a motor connected to a frequency converter, and the motor drives the oolong tea to move on the green machine platform.

[0039] Each of the five relay units includes a resistor, a triode, and a relay body. One end of the resistor is connected to the microcontroller, the other end is connected to the base of the triode, the emitter of the triode is grounded, and the collector of the triode is connected to the relay body. When the relay body is energized, the relay body The normally open contact is closed, and the circuit connected to the inverter of the main circuit of the motor is turned on.

[0040] Specifically:

[0041] (1) The function reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com