Patents

Literature

253results about How to "Reach protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for controlling repeated gear engagement in DCT (dual clutch transmission) synchronizer gear engaging process

InactiveCN104154225AImprove shift qualityExtend your lifeControlled membersGearing controlControl engineeringProcess engineering

The invention provides a method for controlling repeated gear engagement in a DCT (dual clutch transmission) synchronizer gear engaging process. By the method, the problems that in a DCT gear shifting process, gear shifting cannot be realized or impact of gear shifting is caused under conditions that teeth face to each other, gear shifting fails and a synchronizer is worn are solved. In the method, a whole gear shifting process is divided into three stages comprising (1) a stage of approaching a synchronizing ring, (2) a synchronizing stage, and (3) a gear engaging stage after a gear sleeve is connected with connecting teeth. After the three stages are analyzed, the conditions that the teeth face to each other comprise the following two types of conditions: (1) teeth of the gear sleeve face teeth of the synchronizing ring; and (2) the teeth of the gear sleeve face the connecting teeth. The two types of conditions are analyzed, flexible gear engaging is realized and the synchronous ring is protected from being impacted by repeatedly engaging a gear, so that the service life of the synchronizing ring is prolonged, and the gear engaging success rate is increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

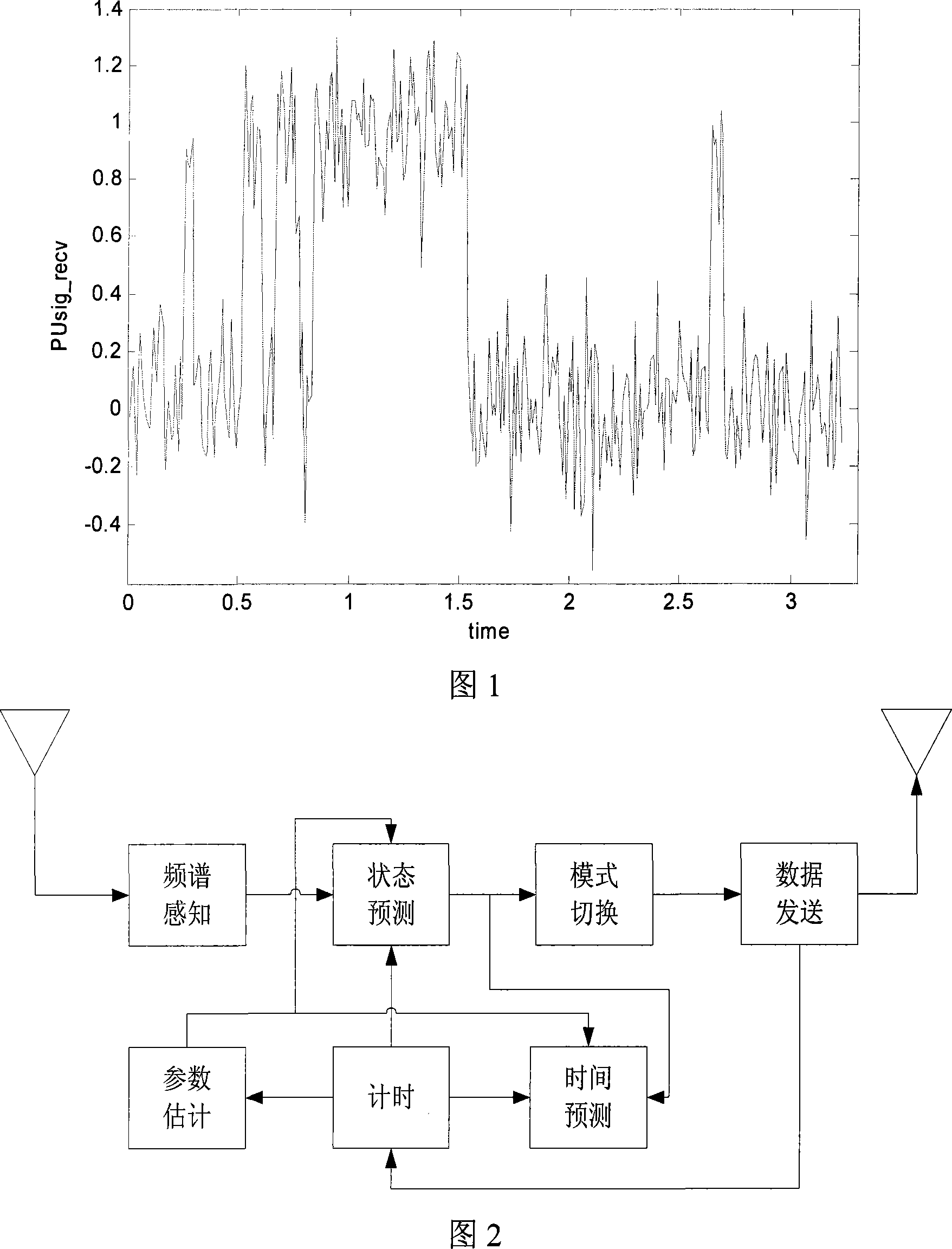

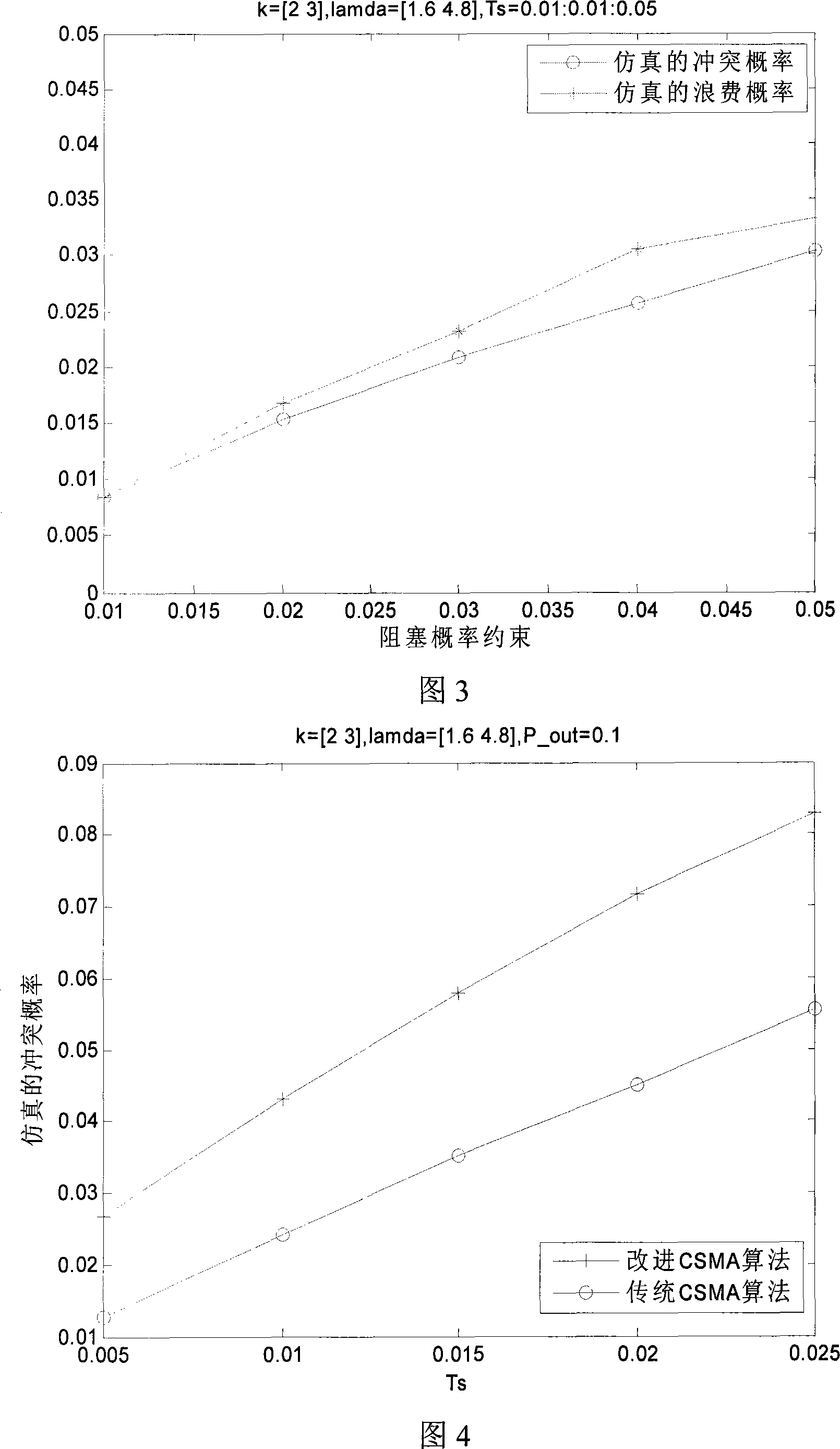

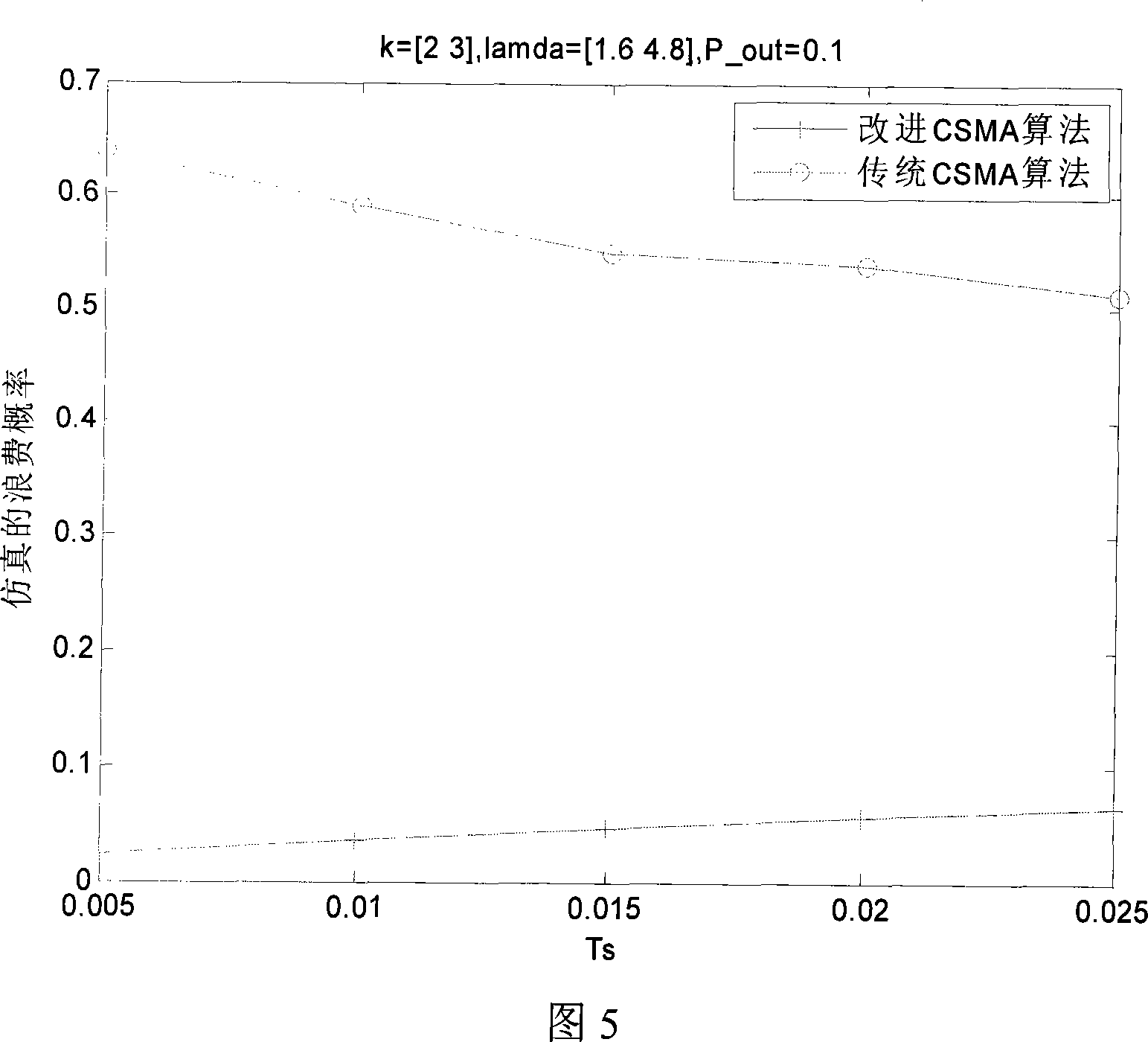

A multi-address access method based on channel sensing and prediction

InactiveCN101242333ATake advantage ofAvoid interferenceData switching networksFrequency spectrumAccess method

The invention discloses a multi access method based on channel sense and prediction. The method can self-adapting adjusts transmission time and backoff time of non-authorized user based on statistical law of authorized user busy channel. By using a modified carrier sense multi access arithmetic, the non-authorized user carries out a prediction on a frequency spectrum state and a state residual duration based on a present sensing time, a present time slot duration, the statistical law of authorized user busy channel and a blocking probability restrict of authorized user. Further, the invention provides a recursive parameter estimation method for avoiding a long-term observation to a non-authorized user required before frequency range is used. The method can increase a service efficiency of the channel under the premise of ensuring the blocking probability restrict of authorized user.

Owner:ZHEJIANG UNIV

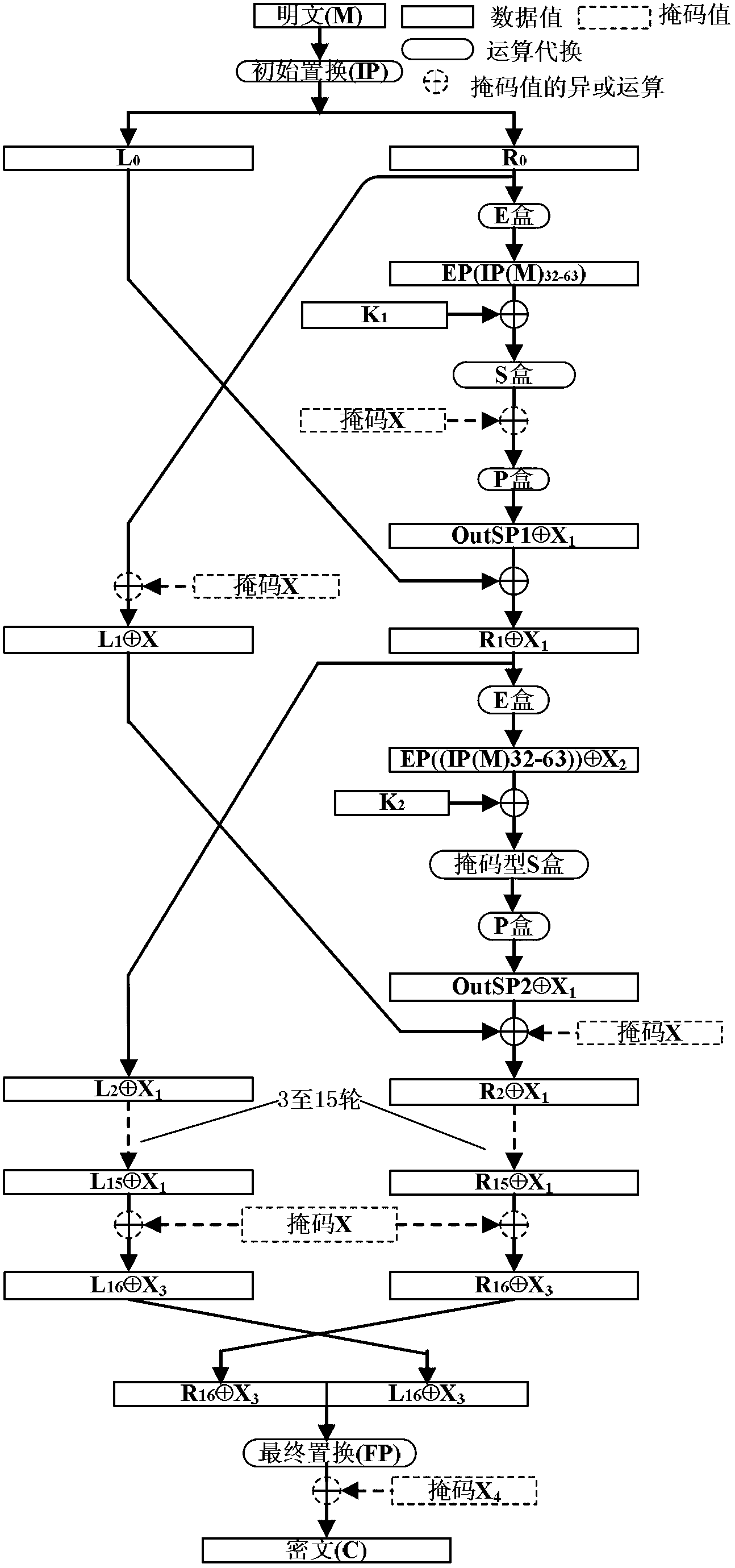

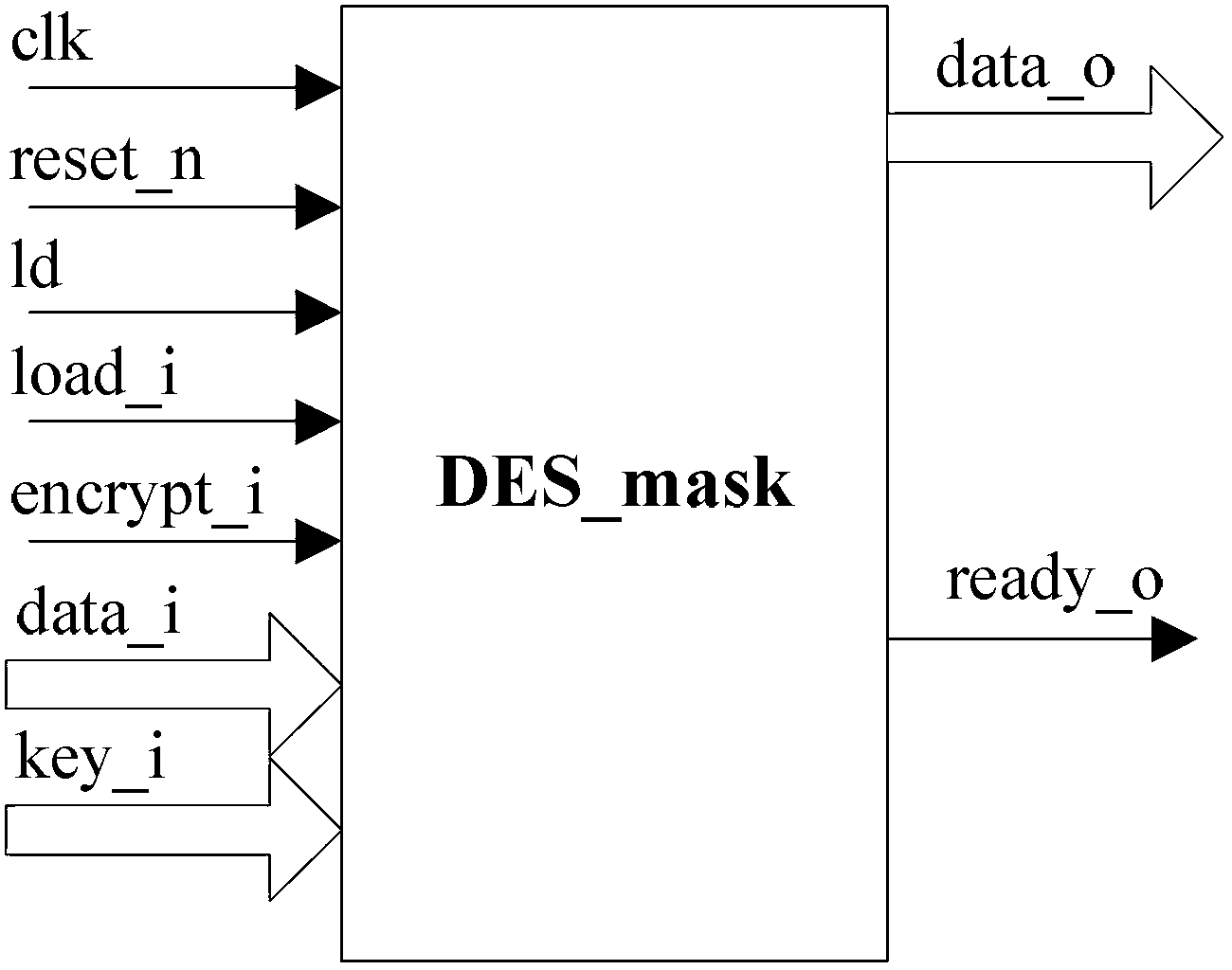

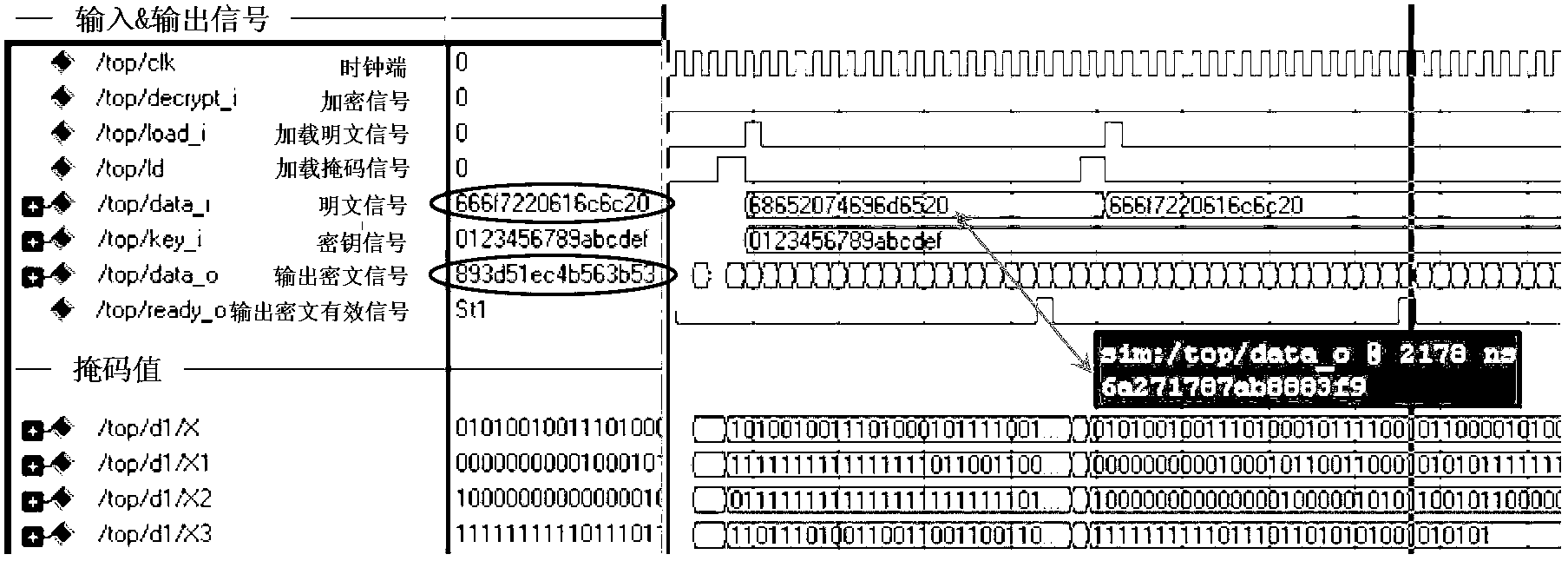

Method and test circuit for preventing data encryption algorithm (DES) attack based on power analysis

InactiveCN103067155AEnsure safetyReach protectionEncryption apparatus with shift registers/memoriesPower attackComputer hardware

The invention discloses a method and test circuit for preventing data encryption algorithm (DES) attack based on power analysis. Before a first subkey K1 carries out operation on data, an algorithm process is kept the same with an original DES process, after xor is conducted on a plaintext through the subkey K1 in a first round, a mask off code X is led in, operation of encryption processes from a following second round to a fifteenth round is similar, only numerical values of random numbers of the xor are different, and correctness of processing procedures in the arithmetic is ensured. At last, the mask off code X on the xor is output in a sixteenth round, real ciphertext information is restored through inverse permutation between initial permutation (IP) and final permutation (FP) and a mask off code X4. According to the DES, due to the fact that values and positions of mask off codes added in the first round and the last round are different from those of other rounds, namely encryption by non symmetrical mask off codes, so that effects of the mask off codes cannot be eliminated by adoption of a hamming distance model, and therefore power attack on the DES can be prevented, and the purpose of ensuring safety of a DES secret key is achieved.

Owner:SOUTHEAST UNIV

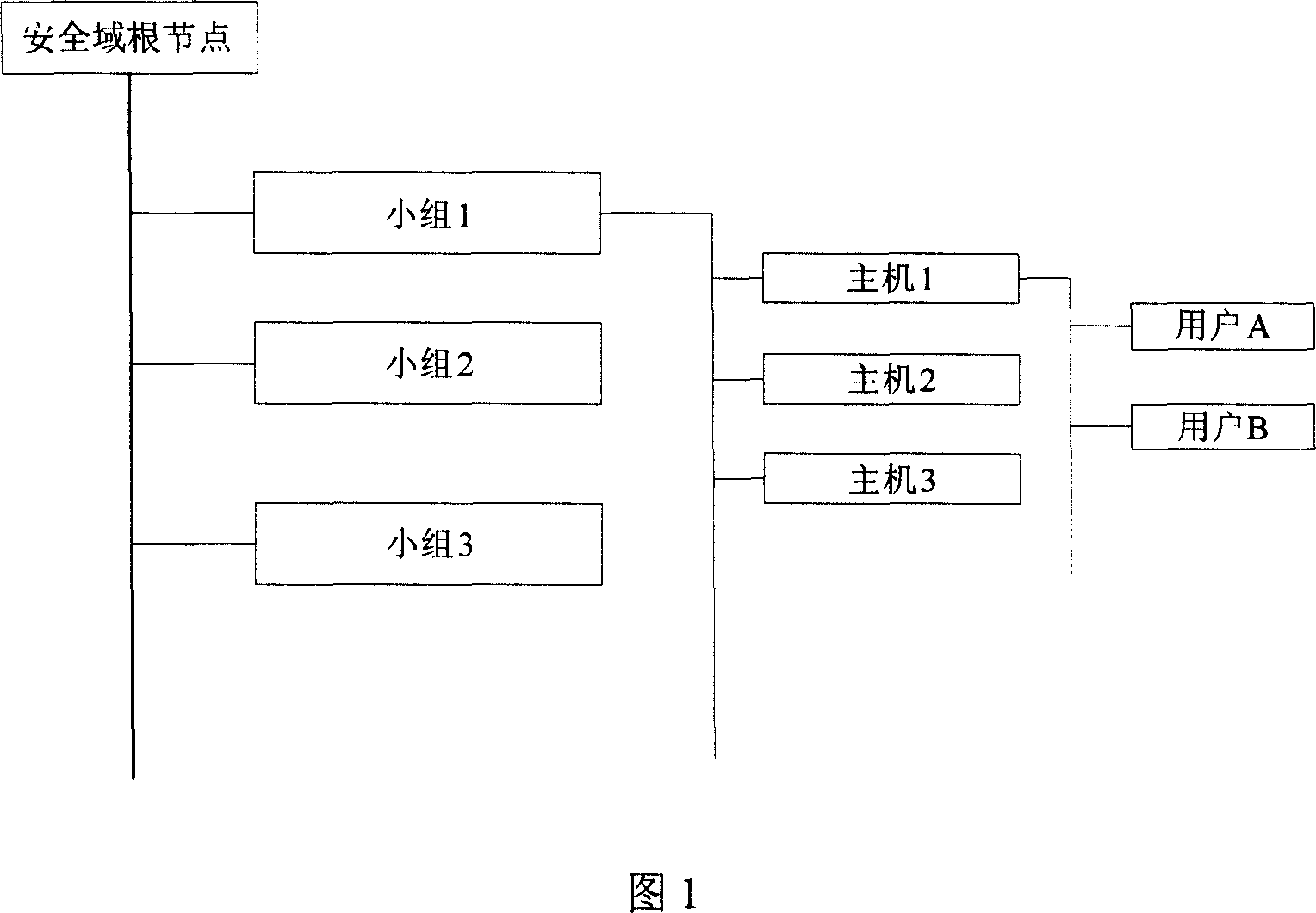

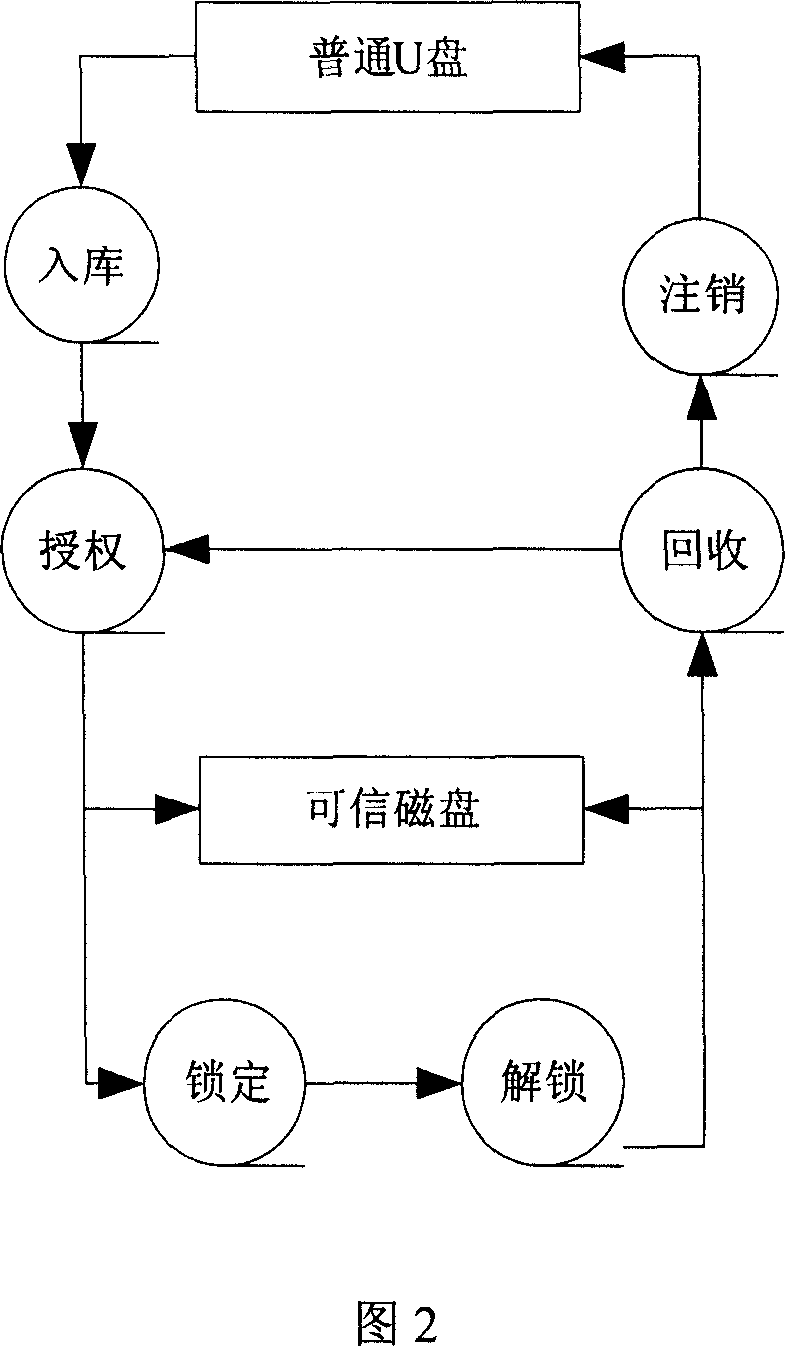

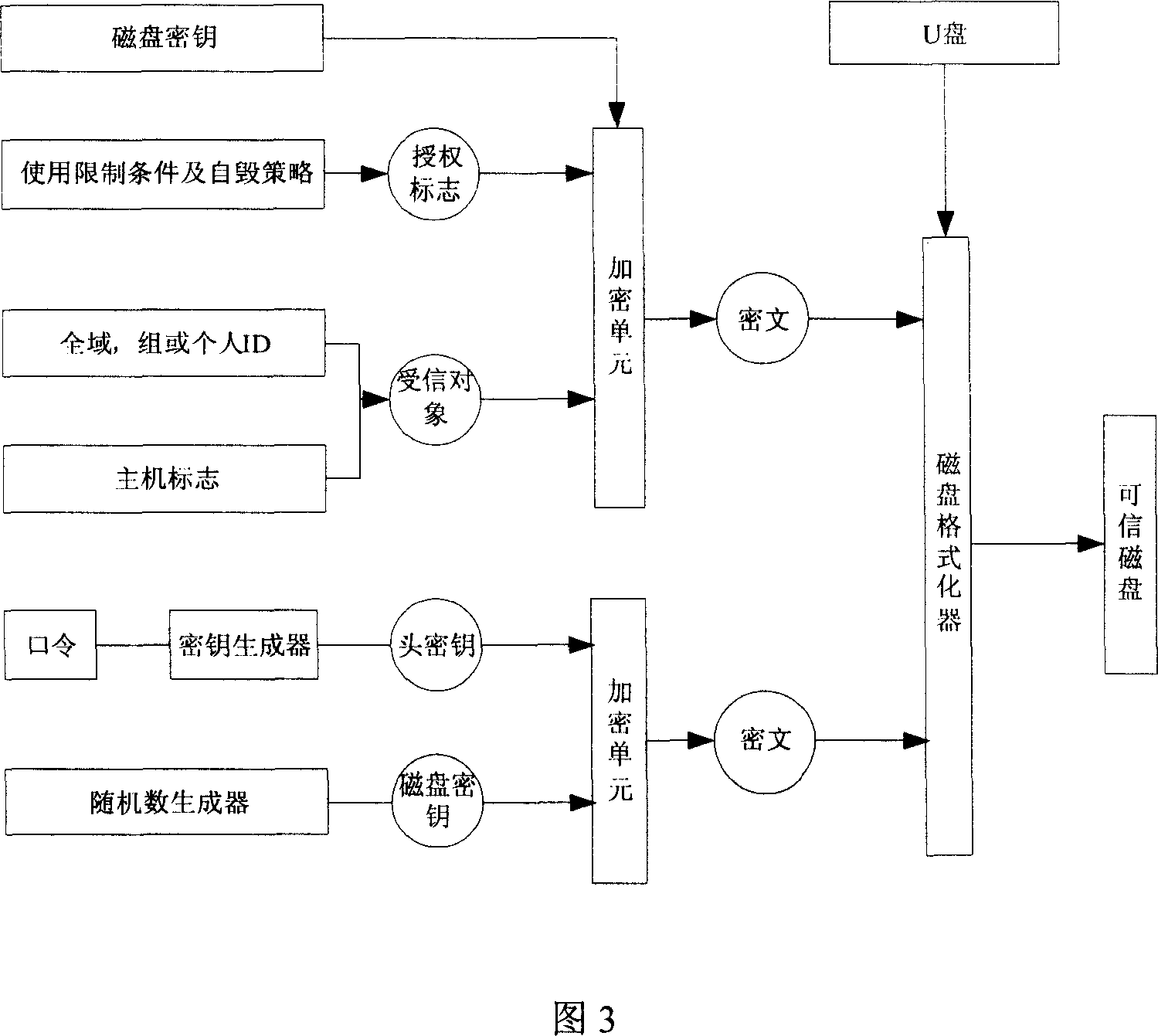

Mobile memory divulgence protection method and system

InactiveCN101079008AEasy to manageReach protectionUnauthorized memory use protectionInternal/peripheral component protectionCiphertextFloppy disk

The invention discloses a method of shifting memory leaking secret protection and system to realize the method, which is characterized by the following: utilizing virtual disk technique; adopting disk grade bridging method; proceeding encryption for the data in the common memory through the virtual disk with special pattern; storing the data on the shifting memory with cryptogram style; loading the virtual disk before reading or writing data; proceeding order checkout and user identification proved; non-loading without right order or special form; assuring the safety of the data in the shifting memory; setting the system as three module of server, warranting center and custom terminal. This invention can be used to various memories such as flash memory, shifting hard disk, soft disk and so on.

Owner:CHINA NAT SOFTWARE & SERVICE

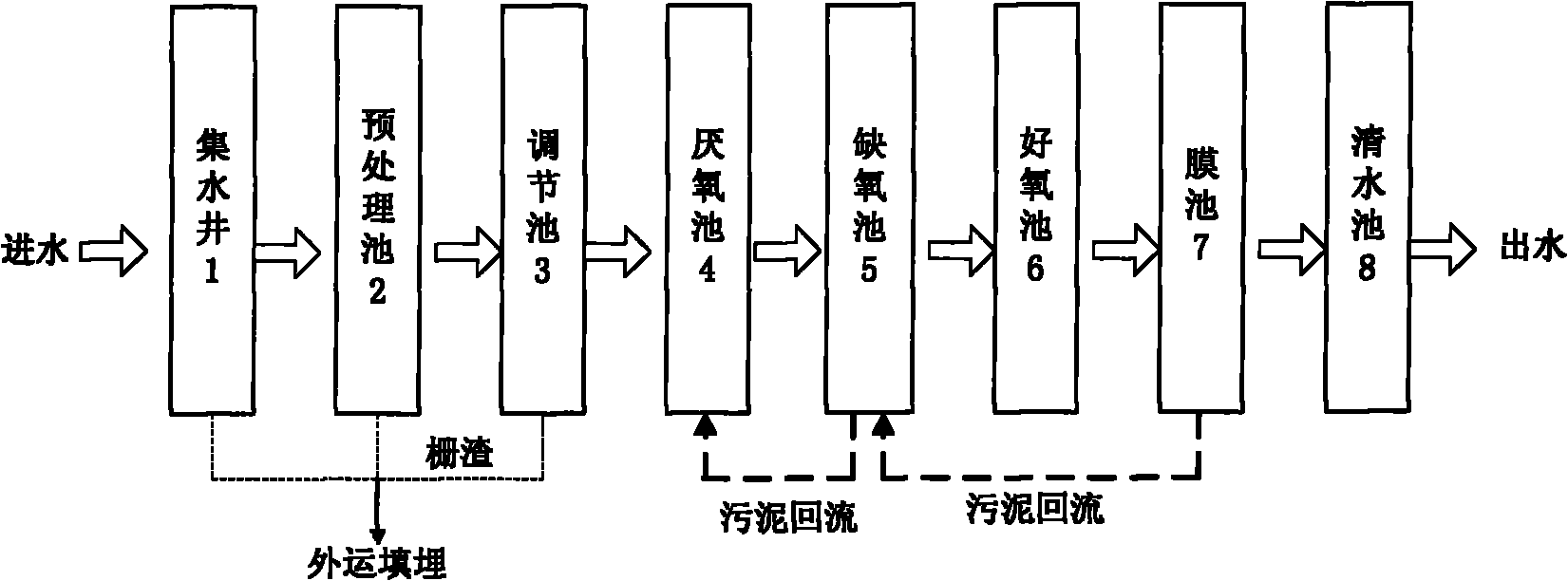

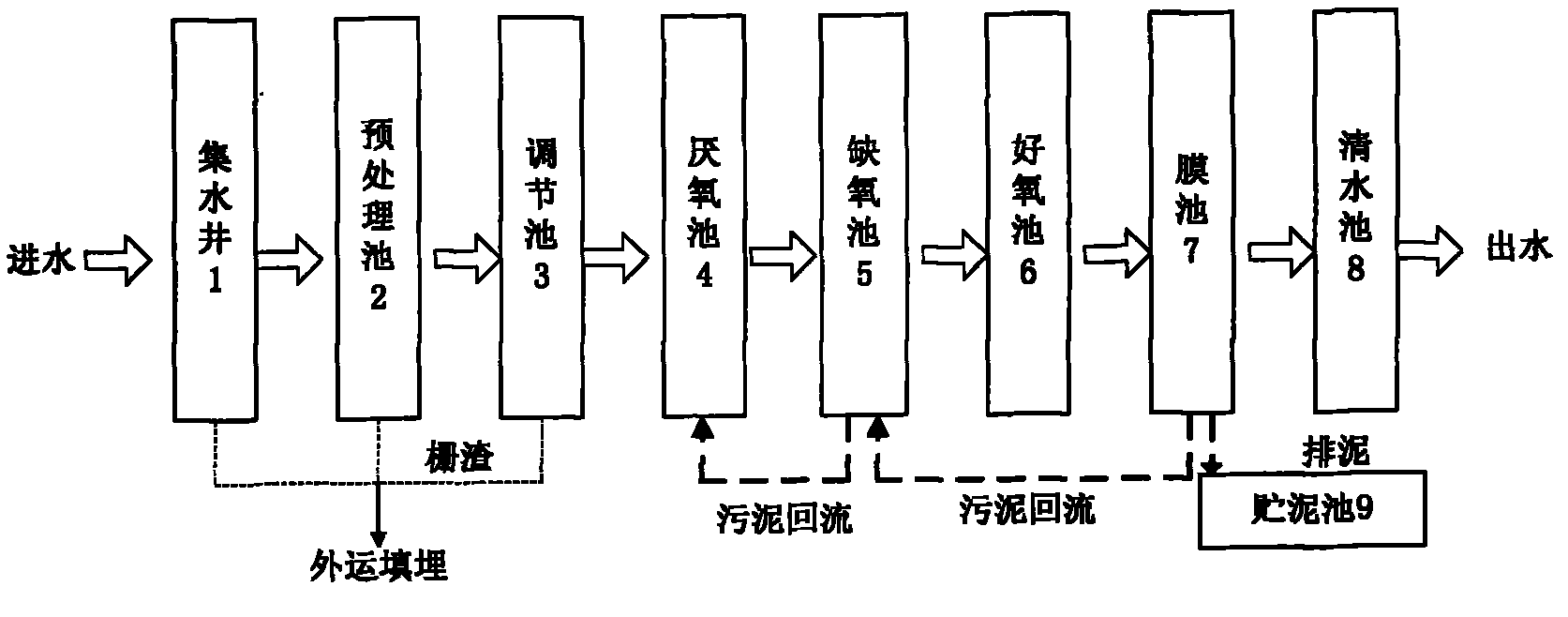

Sewage treatment method and system in ecological sensitive areas

InactiveCN101928096AEfficient removalReach protectionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentVegetable oilWater source

The invention discloses a sewage treatment method and a system in ecological sensitive areas. The method comprises the following steps: larger suspended matters in sewage are removed by using a collecting well the inlet of which is provided with a mechanical coarse screen, the treated sewage enters a pretreatment tank, the suspended matters are further removed by the coarse screen, animal and vegetable oils and mineral oils are removed by an oil separator, and the retreated sewage enters a regulating reservoir to equalize the water quantity and water quality; the pretreated sewage enters an anaerobic tank to be mixed with backflow mixed liquor from an anoxic tank; effluent from the anaerobic tank and the backflow mixed liquor from a membrane pool are mixed to enter the anoxic tank, and effluent from the anoxic tank enters an aerobic tank; effluent from the aerobic tank enters the membrane pool to be biodegraded; and the effluent is filtered by membranes. By adopting an anaerobic-anoxic-aerobic-MBR mode, the invention has higher treatment efficiency and stability and can effectively remove COD, BOD, TN, TP and oils in the sewage; and the effluent meets first grade A emission requirements, and can be used as a reuse water source, thereby protecting the environment and saving the water resources. The invention is especially suitable for treating rural domestic sewage and catering wastewater in the ecological sensitive areas.

Owner:TSINGHUA UNIV

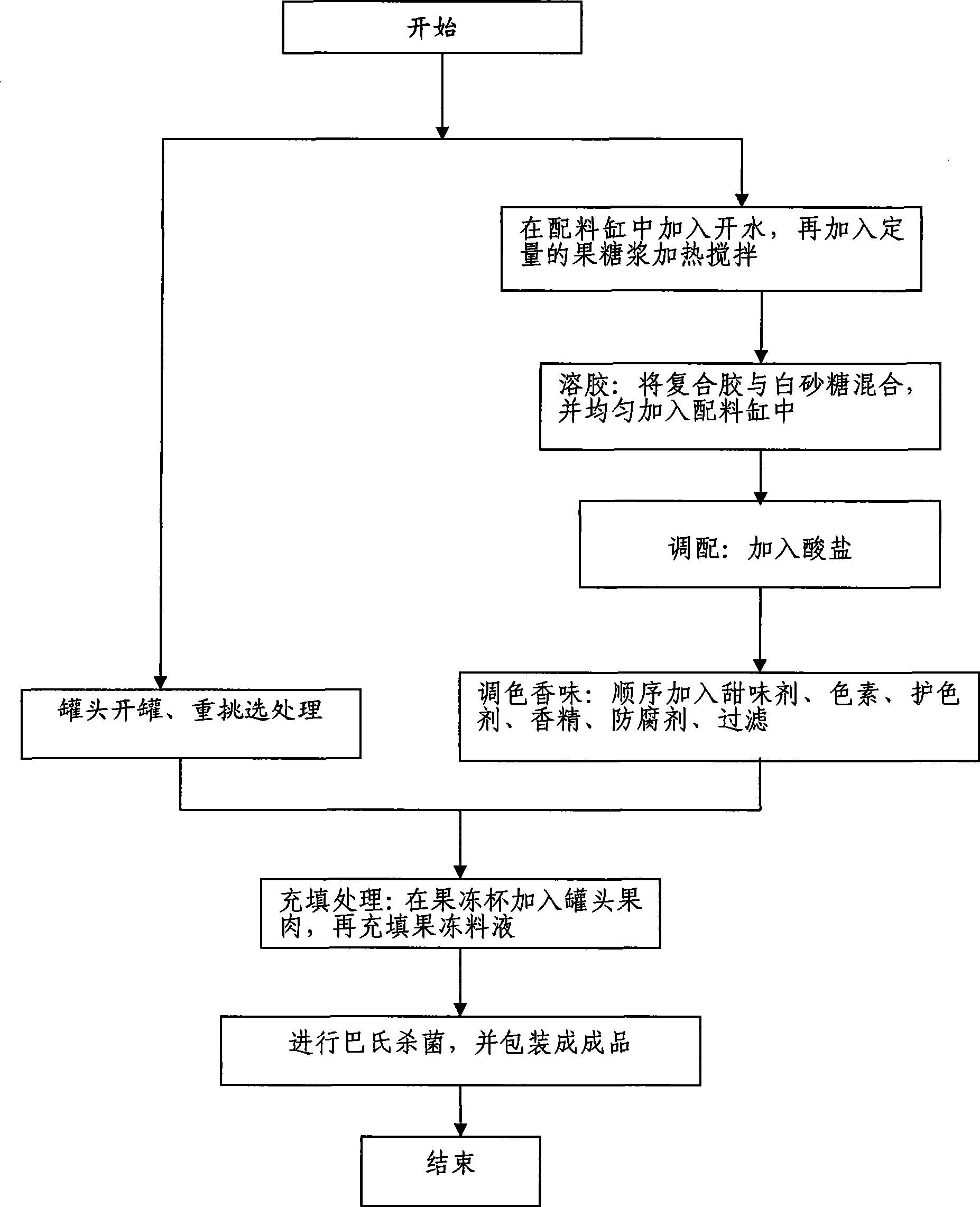

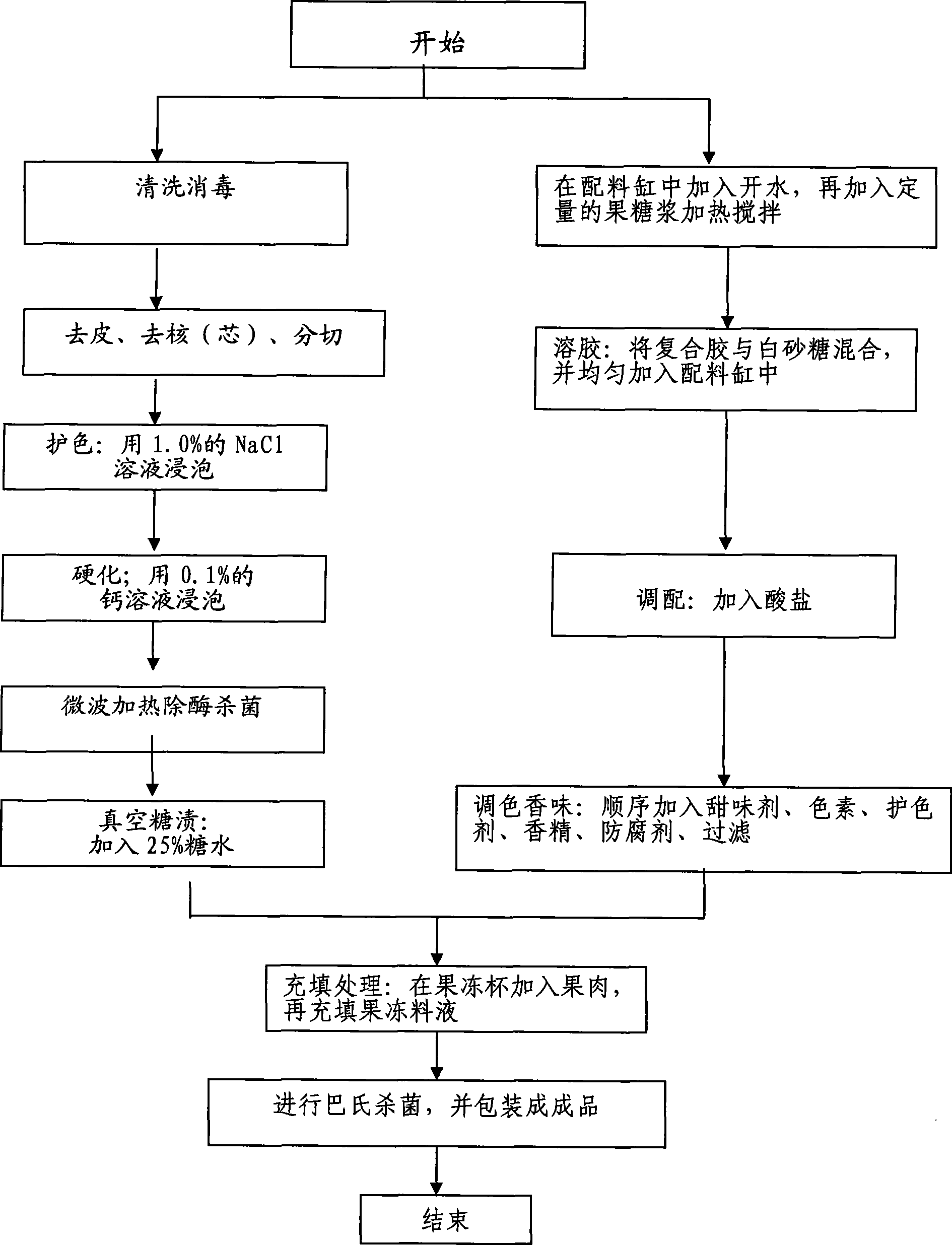

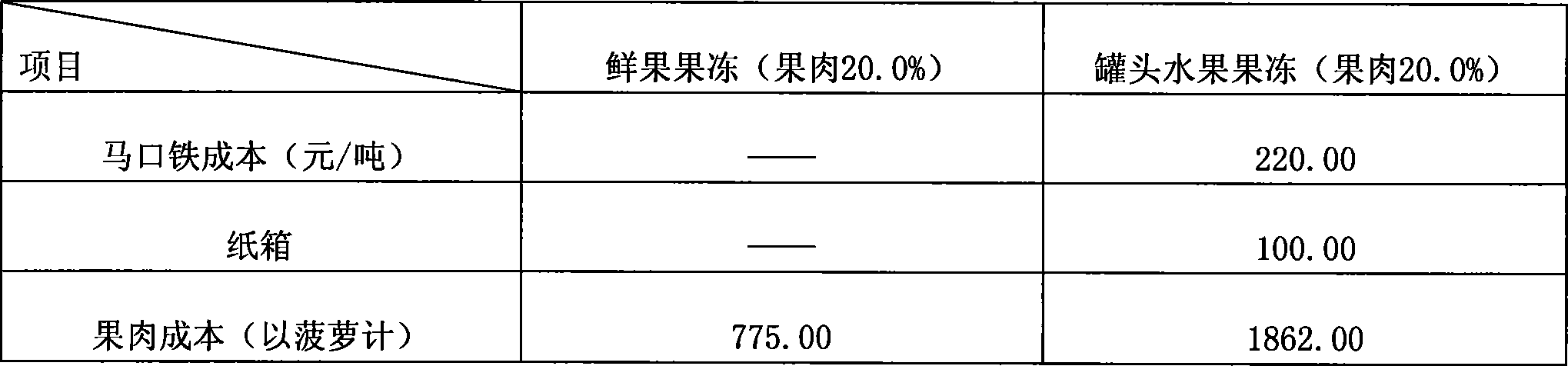

Fresh fruit pure jelly and method for producing the same

The invention discloses a fresh fruit jelly and preparation method thereof. The raw materials of the fresh fruit jelly comprises: water, fresh pulp, golden syrup, white granulated sugar, composite glue, citric acid, sodium citrate, sweetening agent, essence, color protecting agent, anticorrisive agent and pigment; the preparation method of the fresh fruit jelly comprises the following steps: A, treating fresh fruits; B, making jelly material liquid; C, fusing the fresh fruit pieces into the jelly material liquid and obtaining the fresh fruit jelly. In the invention, the pulp treatment includes microwave heat treatment, dezymotizing and sterilization, the treatment time is 1 / 10 of the can heat treatment time, which maintains the fresh taste and flavor of the fruit and reduces the loss of nutrition components such as vitamins; and vacuum stain is used, which shortens time and the whole flow.

Owner:NANJING LAIYIKOU FOOD CO LTD

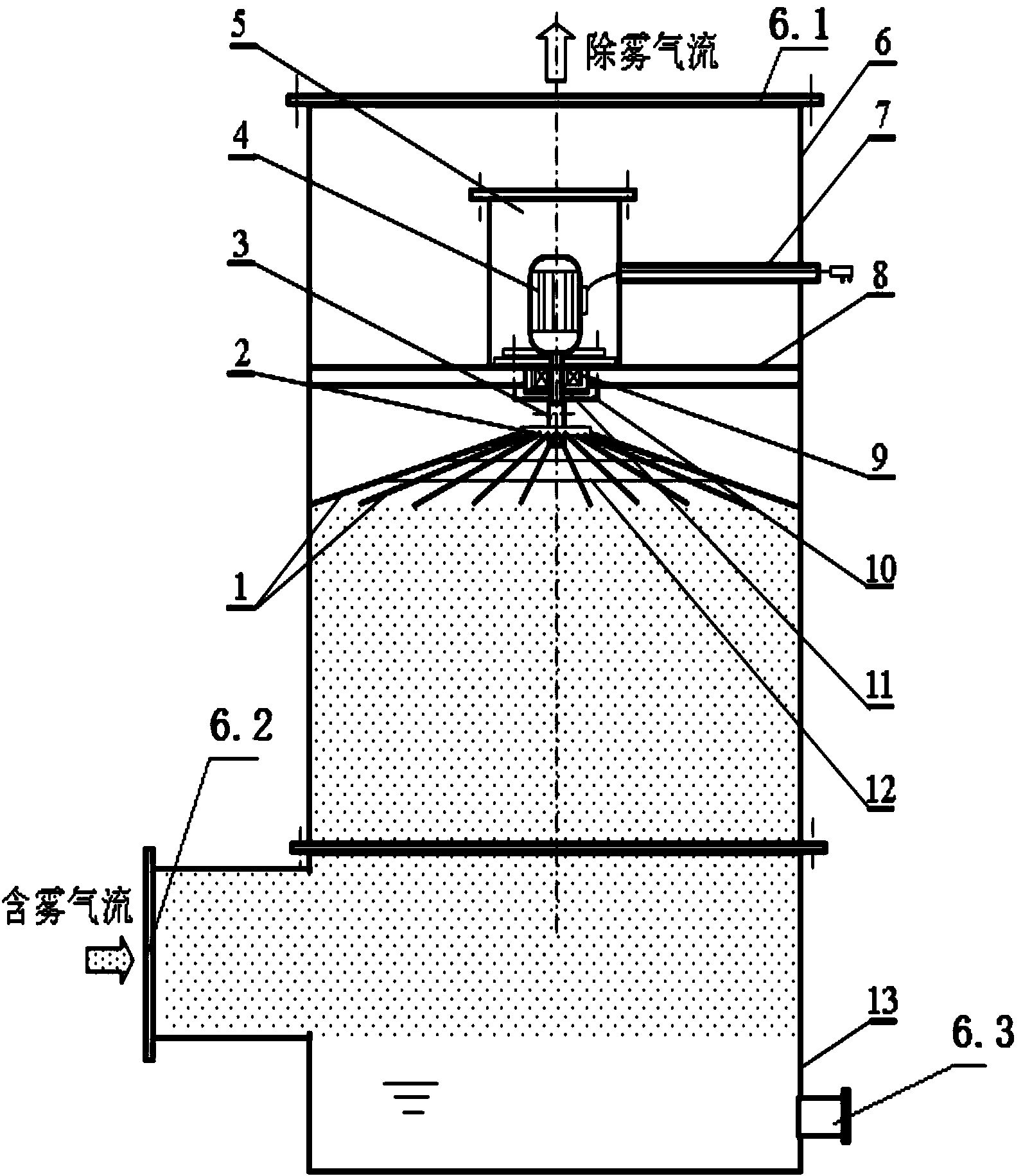

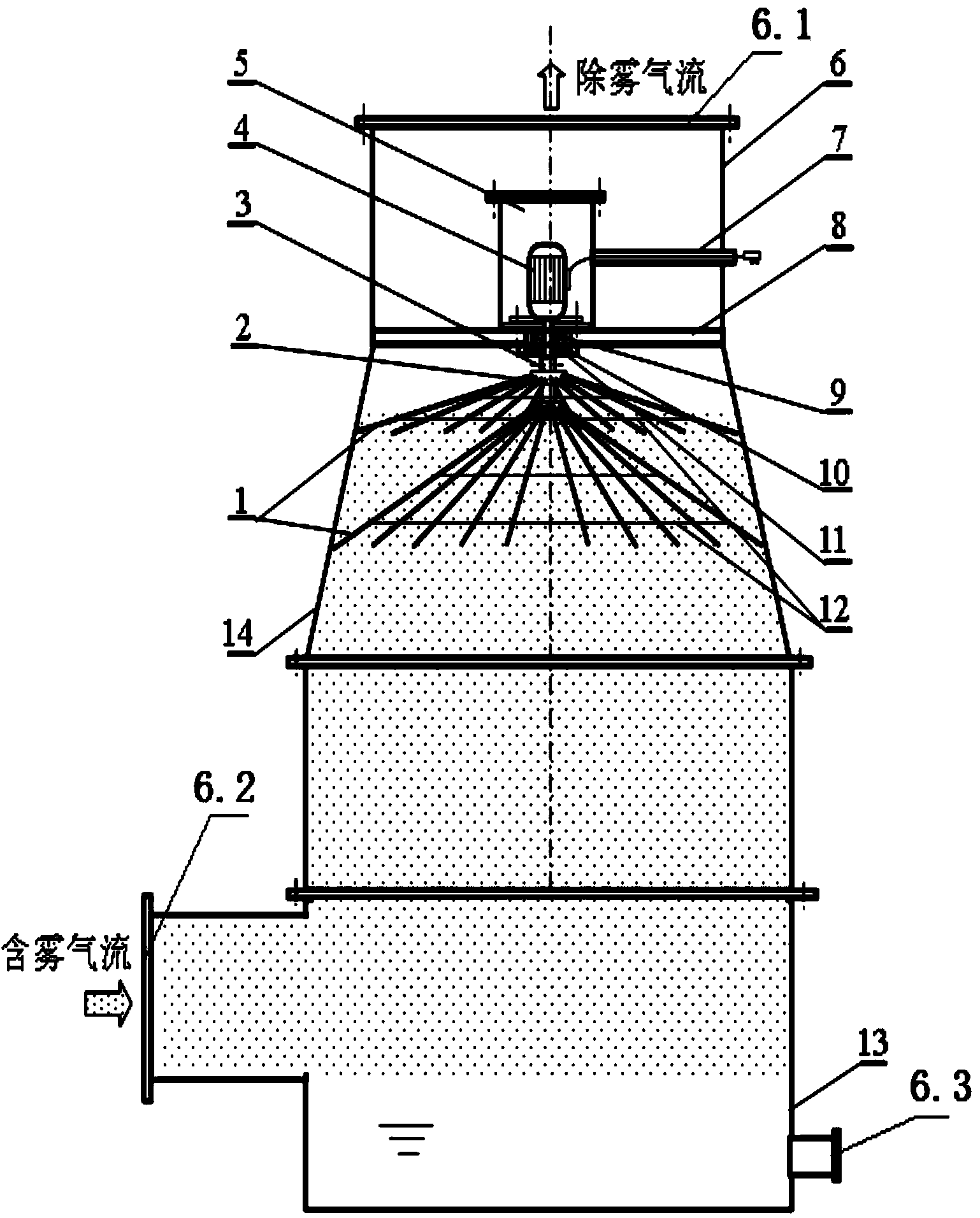

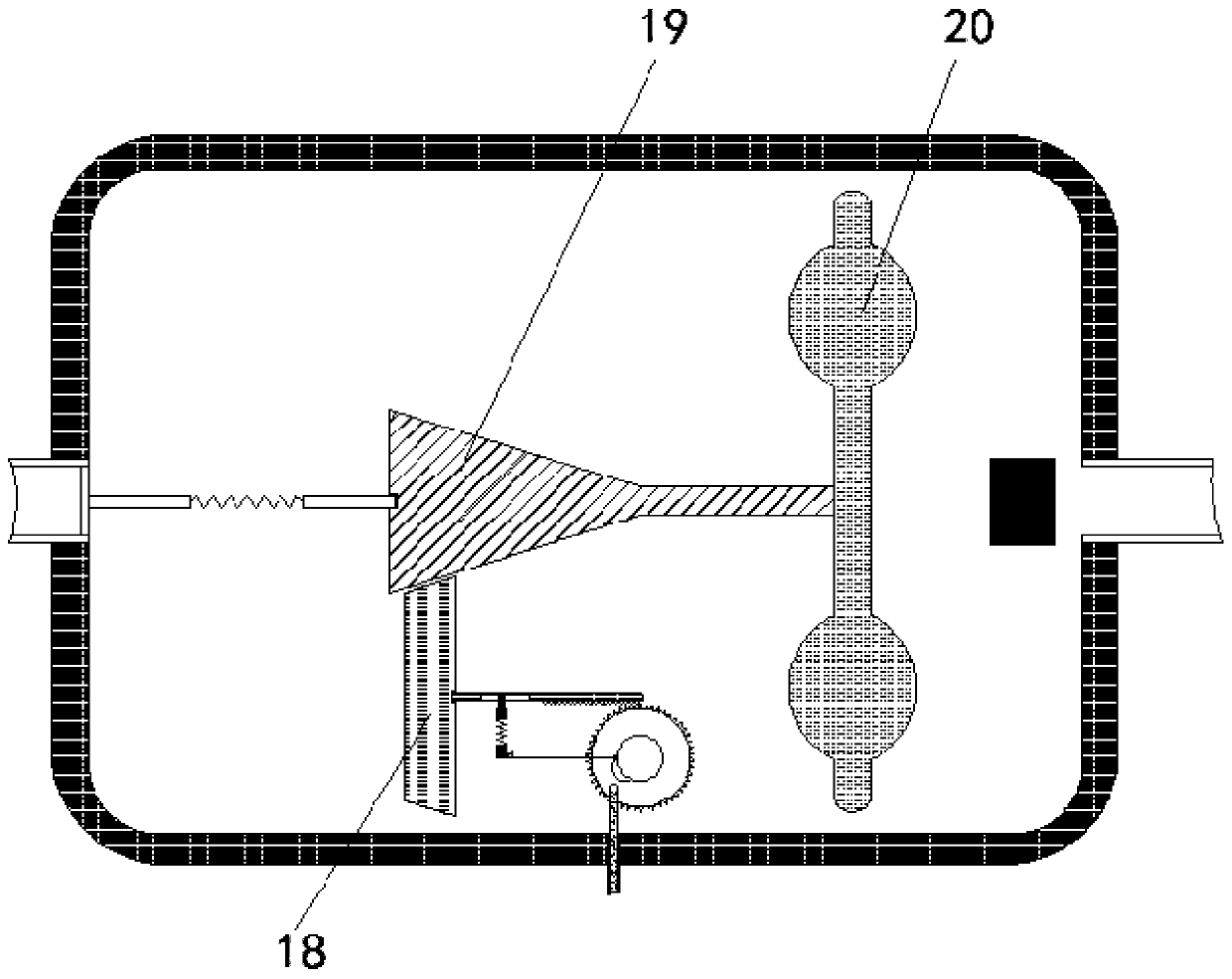

Flexible fiber spiral line demisting device

InactiveCN103657266AAvoid the problem of secondary sheddingStrong turbulent diffusion effectDispersed particle separationFlue gasEngineering

The invention relates to a flexible fiber spiral line demisting device, which solves the problems that the existing demising device has low demisting efficiency, the filter type demister is easy to block and the static demister is high in cost and large in occupied area and is corroded and scaled. According to the technical scheme, the flexible fiber spiral line demisting device comprises a gas inlet, a gas outlet and an exhaust cylinder of a liquid discharge pipe, wherein a motor is arranged on the vertical center line of the upper section of the exhaust cylinder; a rotating shaft of the motor is sleeved with a shaft sleeve; at least one layer of disc is arranged in the axis direction of the shaft sleeve; flexible fiber spiral lines are arranged on the disc; the flexible fiber spiral lines comprise a plurality of warps; one end of each warp is connected to the disc uniformly and the other end of each warp is a free end. The flexible fiber spiral line demisting device has the advantages of low resistance, high efficiency, no occupied area, no corrosion, no scaling and blockage, large flue gas treatment quantity, simple structure, light weight, low energy consumption and low cost.

Owner:JIANGHAN UNIVERSITY +2

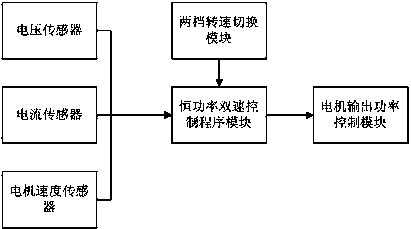

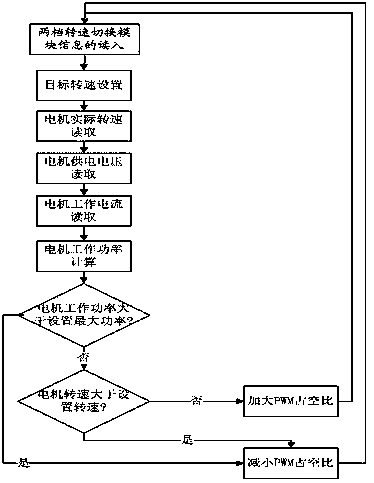

Constant power and double speed control system and control method based on direct current brushless electric tool

InactiveCN104362910AReach protectionAdapt to the load wellDC motor speed/torque controlSingle motor speed/torque controlMotor speedConstant power

The invention discloses a constant power and double speed control system and a constant power and double speed control method based on a direct current brushless electric tool. The constant power and double speed control system based on the direct current brushless electric tool comprises a two gear rotation speed switching module, a constant power and double speed control module, a motor output power control module and an electrical inductance device, wherein the electrical inductance device collects supply voltage, work current and motor speed information in running of a motor, the two gear rotation speed switching module provides different rotation speed choices, the constant power and double speed control module reads and judges information sent by the two gear rotation speed switching module and the electrical inductance device, and the motor output power control module regulates output power of the motor according to the judged information of the constant power and double speed control module. By adopting the above mode, the constant power and double speed control system and the constant power and double speed control method based on the direct current brushless electric tool not only can adapt to a load well, but also save energy, and simultaneously effectively guarantee that output power of a matched battery system is in a normal range so as to achieve protection for the battery system.

Owner:CHANGZHOU GLOBE CO LTD

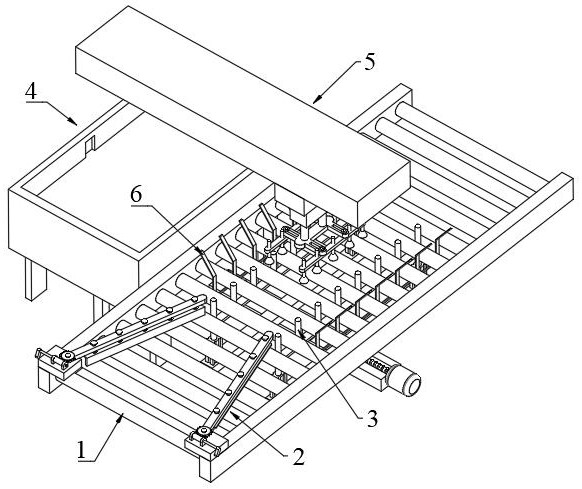

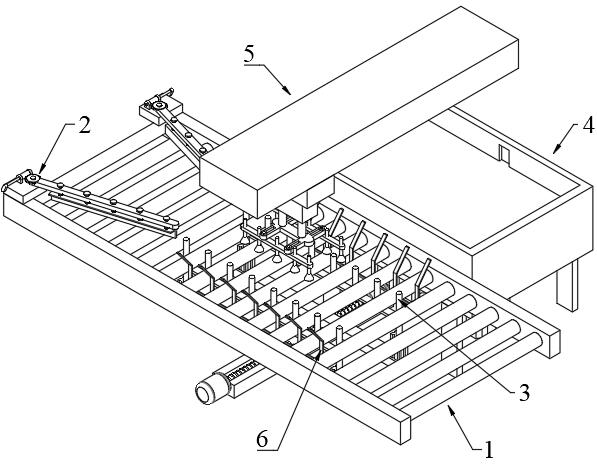

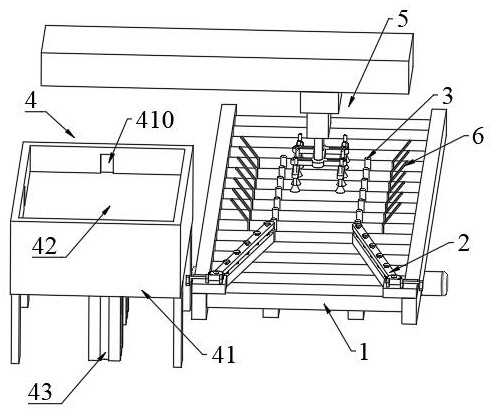

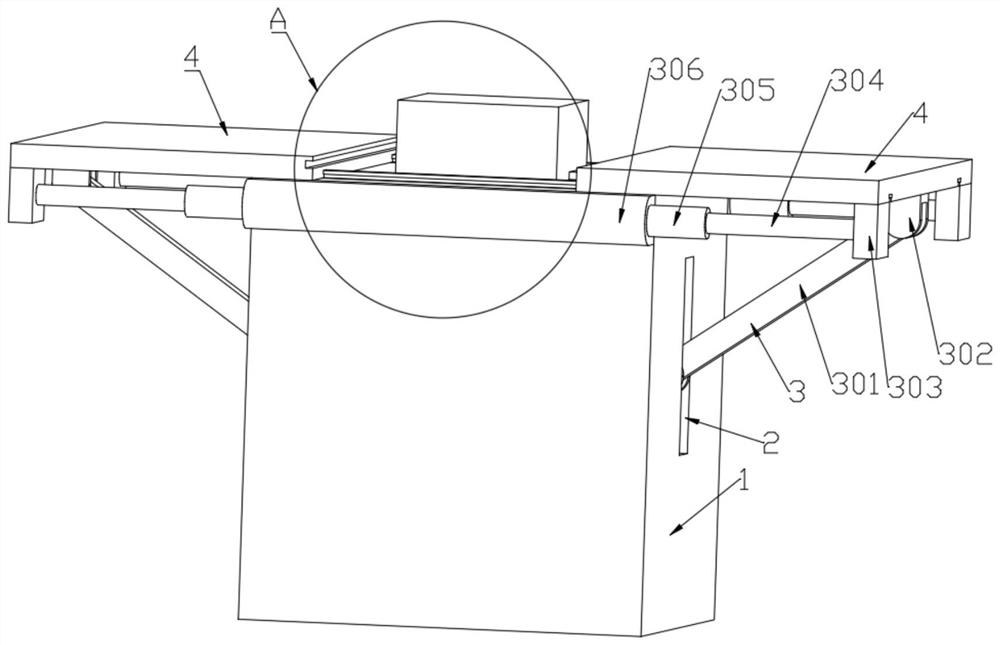

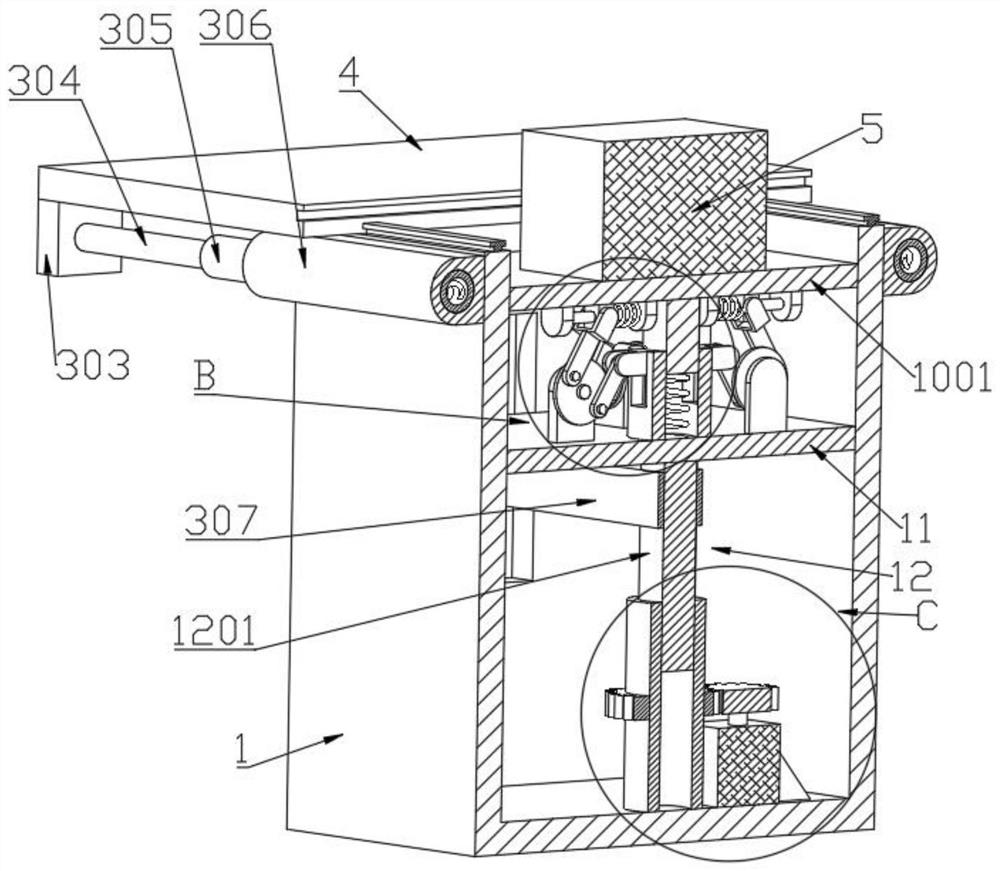

Printed circuit board semi-finished product conveying and partition plate feeding integrated device

ActiveCN113060514ARealize guide collimation adjustmentFlip normalConveyorsPrinted circuit manufactureStructural engineeringMechanical engineering

The invention provides a printed circuit board semi-finished product conveying and partition plate feeding integrated device. The printed circuit board semi-finished product conveying and partition plate feeding integrated device comprises a conveying roller set, a pair of adjustable guide assemblies, a pair of limiting supporting assemblies arranged in a spaced manner, a partition plate storage rack, a partition plate grabbing mechanism and a pair of partition plate bearing assemblies arranged in a spaced manner. Each limiting supporting assembly comprises a row of limiting supporting columns arranged in a spaced manner, wherein the limiting supporting columns are arranged in the gap between two adjacent roller bodies of the conveying roller set, the bottom ends of the row of limiting supporting columns are connected with the same connecting plate, the connecting plate is connected to the movable ends of a pair of first lifting air cylinders, the first lifting air cylinders are arranged on a base, and the base is arranged at the movable end of a first transverse linear mechanism. According to the printed circuit board semi-finished product conveying and partition plate feeding integrated device, conveying of printed circuit boards of different sizes is collimated and limited, the printed circuit boards can be normally overturned when conveyed to an overturning area, partition plate feeding is conducted on the printed circuit boards in the conveying process, partition plates are arranged between the overturned and stacked printed circuit boards, and protection on metal circuits on the two faces of a semi-finished product is formed.

Owner:四川英创力电子科技股份有限公司

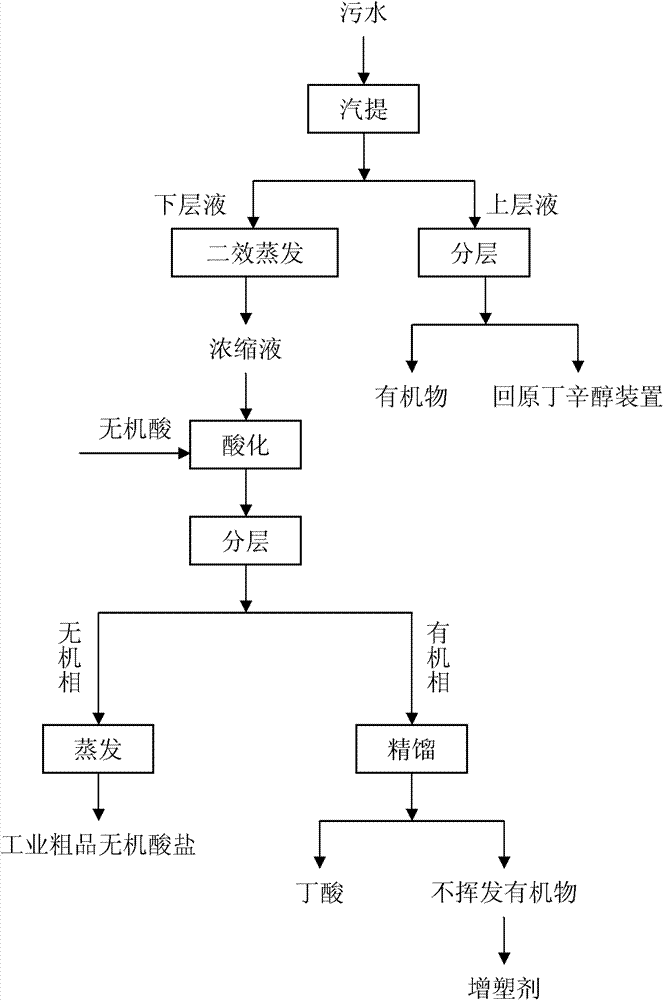

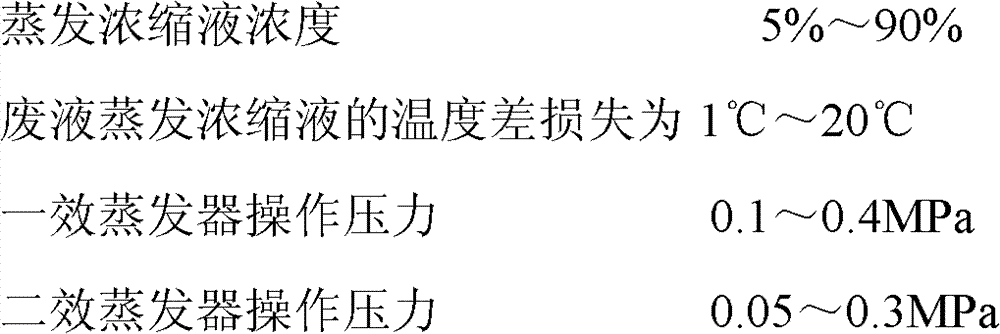

Method for treating waste alkaline liquor produced in butanol and octanol production device

InactiveCN102730894AHighlight substantive featuresSimple process routeMultistage water/sewage treatmentCarboxylic compound separation/purificationChemistryAfter treatment

The invention discloses a method for treating waste alkaline liquor produced in a butanol and octanol production device and belongs to the field of treatment on waste water produced by organic compound production. The method is characterized by comprising the following steps of a, normal-pressure steam stripping, b, low-pressure evaporation concentration, c, acidification phase-separation, d, organic phase rectification, and e, simple evaporation concentration. The method for treating waste alkaline liquor produced in a butanol and octanol production device has a high chemical oxygen demand (COD) removal rate, a low equipment investment, simple treatment processes, low energy consumption and a low treatment cost, is suitable for industrial production, realizes full recovery and use of all components, and does not produce secondary pollution. A COD removal rate of the method is great than or equal to 99%. Before treatment, the COD is great than or equal to 50000mg / L and after treatment, the COD is less than or equal to 500mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

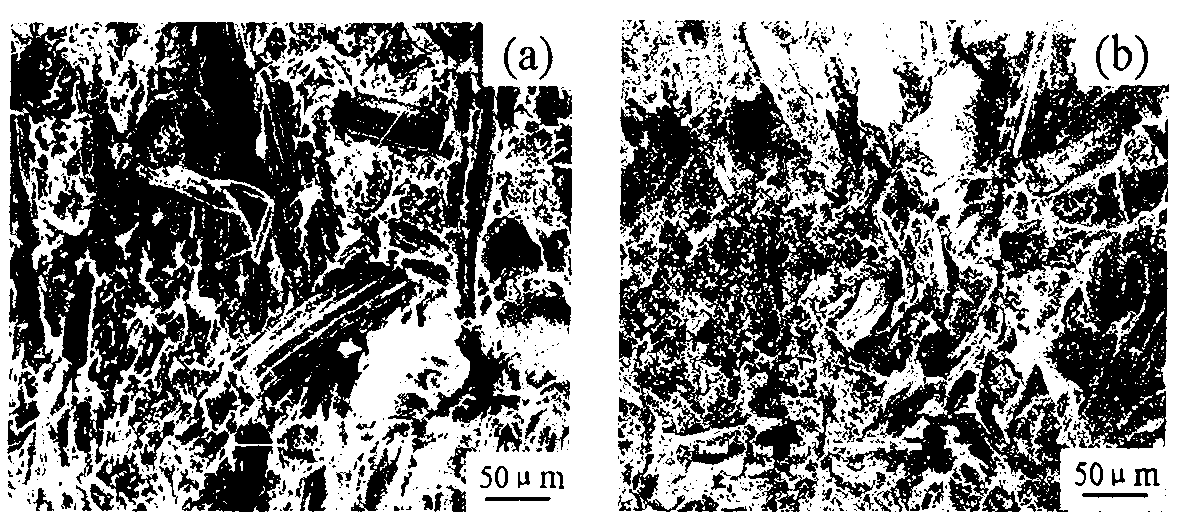

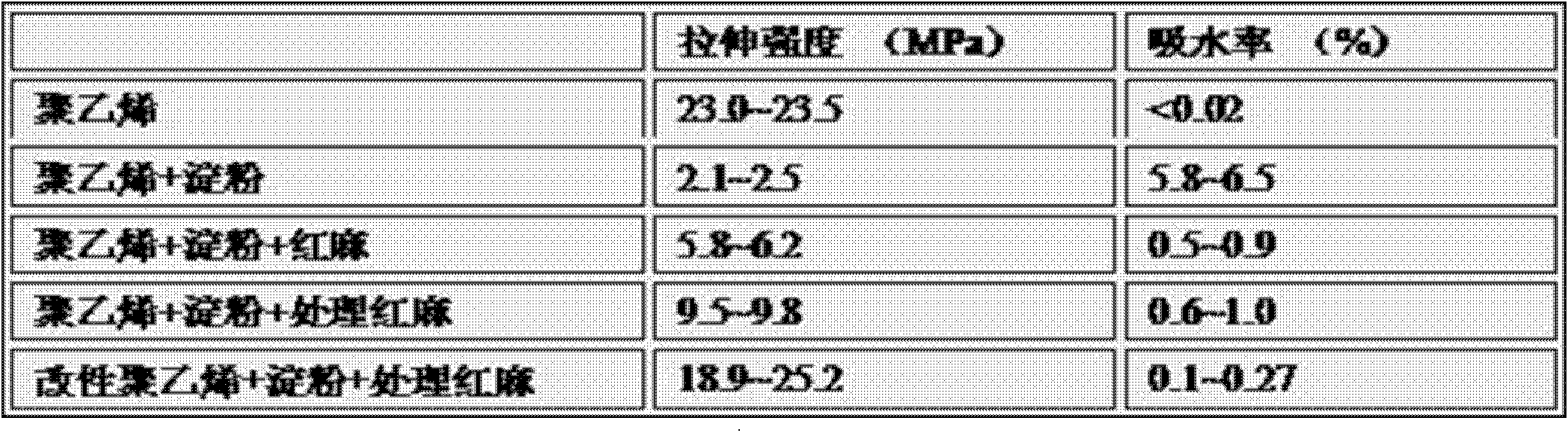

Degradable resin-starch-kenaf extruded plastic master batch

The invention belongs to the field of high polymer materials and in particular relates to a degradable resin-starch-kenaf extruded plastic master batch. The degradable resin-starch-kenaf extruded plastic master batch comprises the following components by volume percent: 30%-60% of polyethylene, 0-50% of starch and 5-40% of kenaf, wherein the polyethylene is composed of low-density polyethylene and maleic anhydride modified polyethylene in the volume ratio of (0.2-5):1. The extruded composite resin (master batch) material with higher tensile strength and good processing performance is prepared by virtue of a molecular design method; the biodegradation rate is 40%-70% in the presence of aerobiont; the using performance and the processing performance of the composite material are similar to those of the polyethylene, so that the material is green and environment-friendly, and therefore, the purposes of protecting the environment, efficiently utilizing the resources and lowering the cost are achieved.

Owner:赵振峰

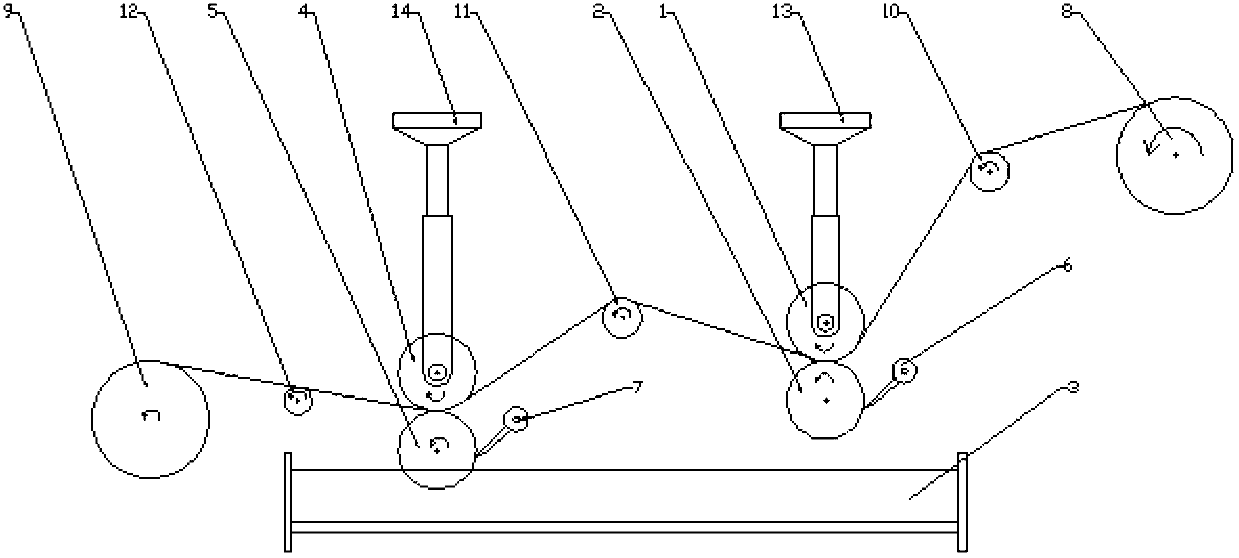

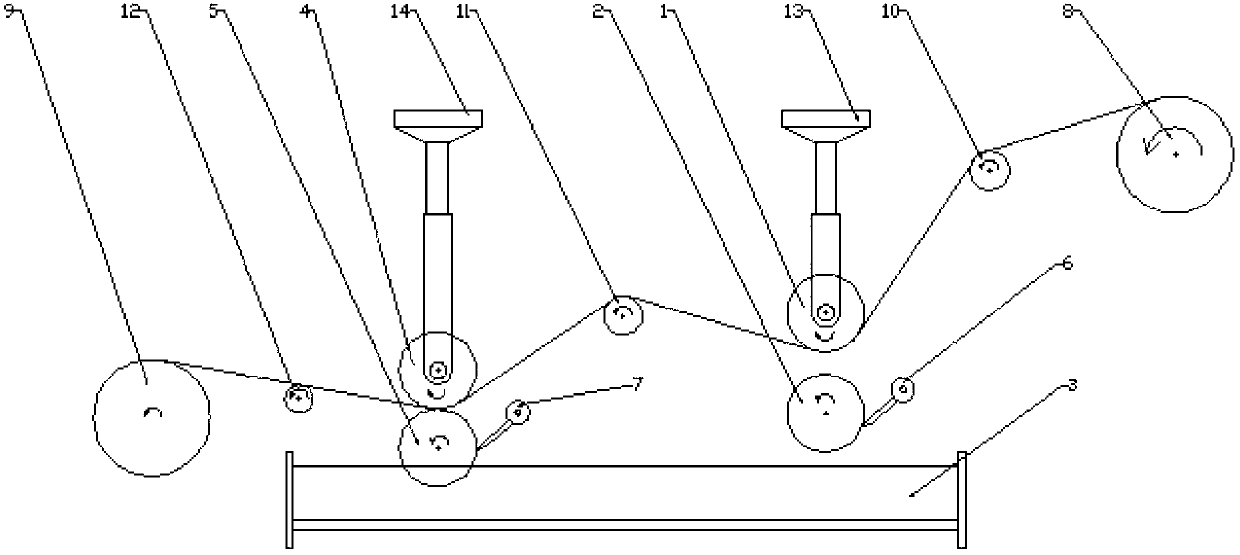

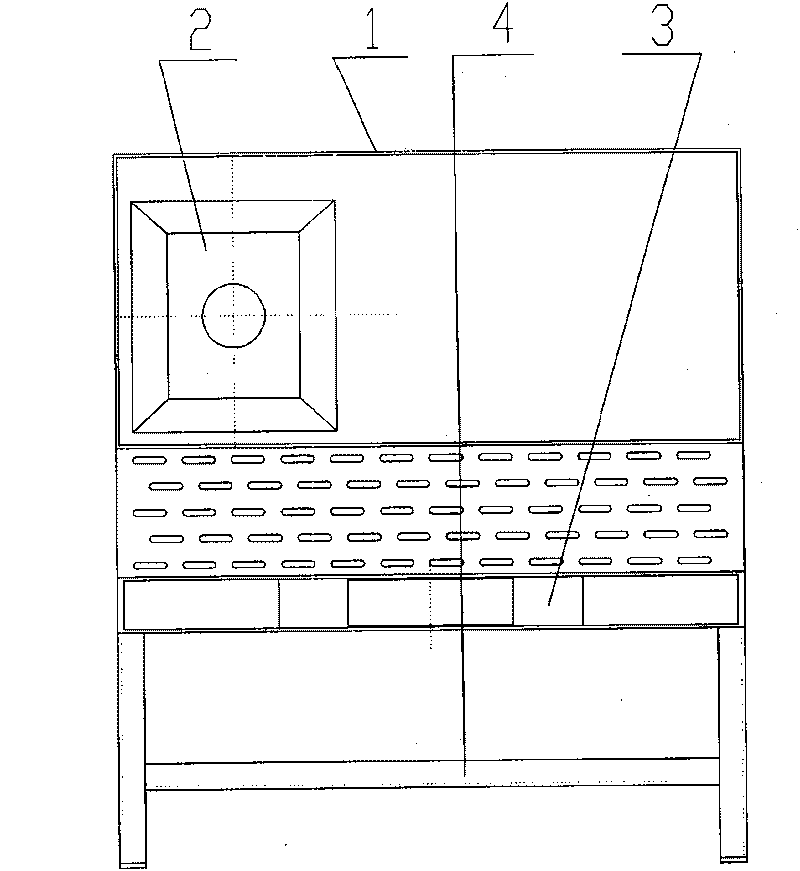

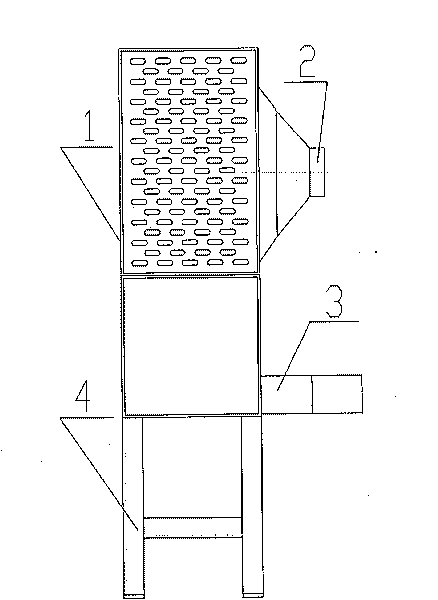

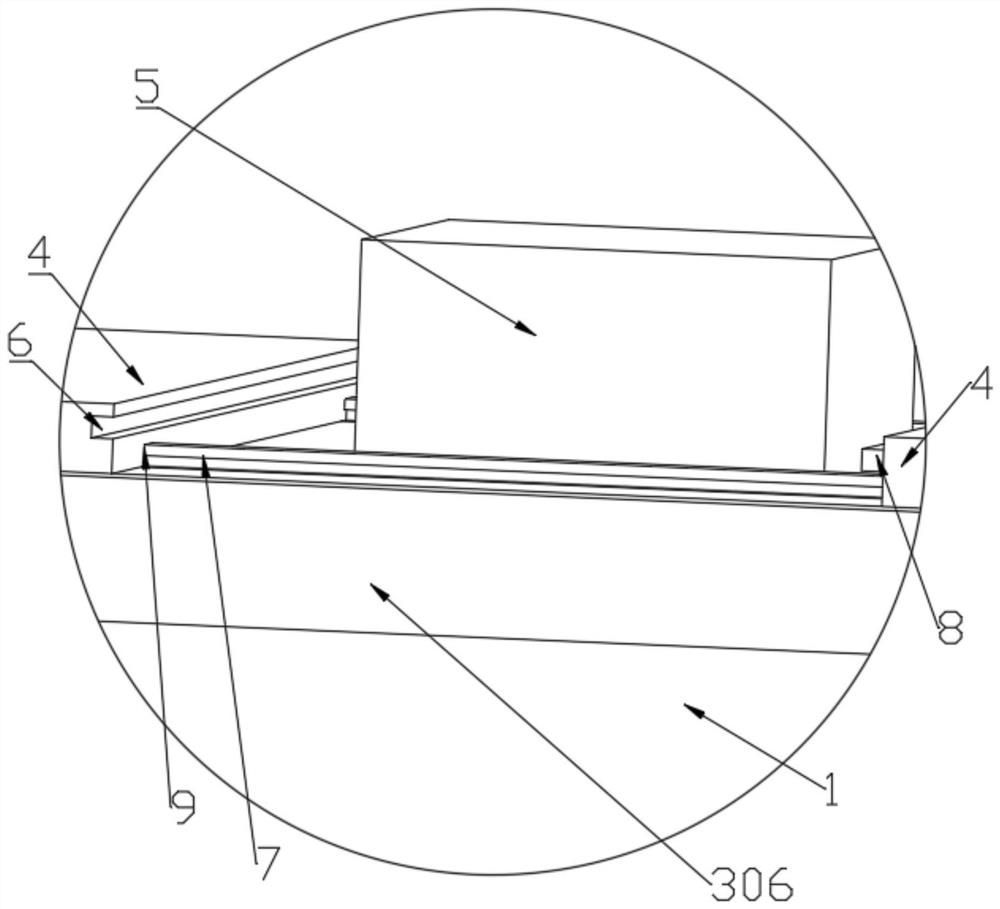

Method of regenerating waste thermal transfer color bars and device thereof

ActiveCN103129186ATo achieve the purpose of regeneration integrationReach protectionInk ribbonsEngineeringMechanical engineering

The invention discloses a method of regenerating waste thermal transfer color bars and a device of regenerating the waste thermal transfer color bars. The device comprises a basilemma ink separation device and / or an ink coating device, and the device is mainly formed by a hot pressing body 1, a receptor 2, an ink collector 3, a heat-resistant rubber roller 4, a ceramic anilox roll 5, a receptor body attached scraper 6, an anilox roller scraper 7, a releasing-scrolling shaft 8, a collecting-scrolling shaft 9, a tensioning shaft 10, a tensioning shaft 11, a guide roll 12, a hold-down gear 13 and a hold-down gear 14. The regeneration method includes that the thermal transfer color bars pass between the hot pressing body and the receptor which are mutually contacted, the hot pressing body presses a color bar ink layer on the ink receptor entirely by a fixed pressure in a hot mode to achieve the separation of the basilemma from the ink, and the recycled ink is coated on the basilemma evenly through the ink coating device, so that a regenerated color bar is manufactured. The method and the device are simple, microminiaturized in a system, integrated in waste thermal transfer ribbon processing and regenerated thermal transfer ribbon manufacture, so that the complex problems of the waste thermal transfer ribbon collection, transportation, and storage is enabled to be simple, the method and the device are low in cost and easy to popularize.

Owner:许秀峰

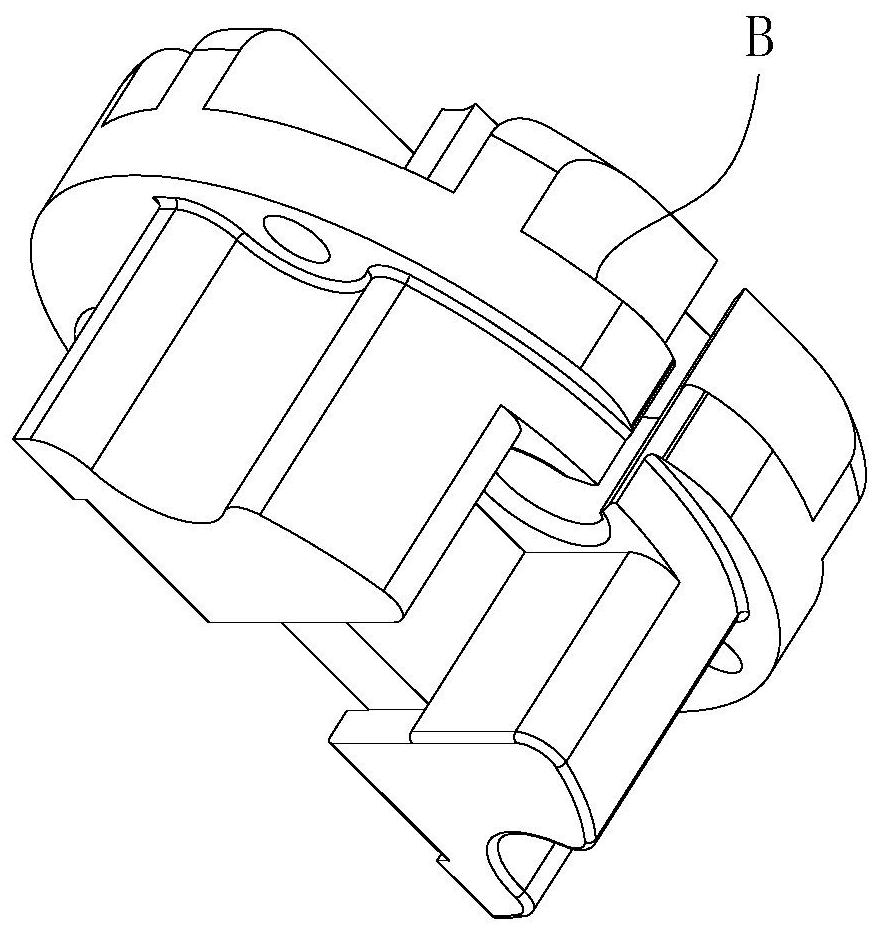

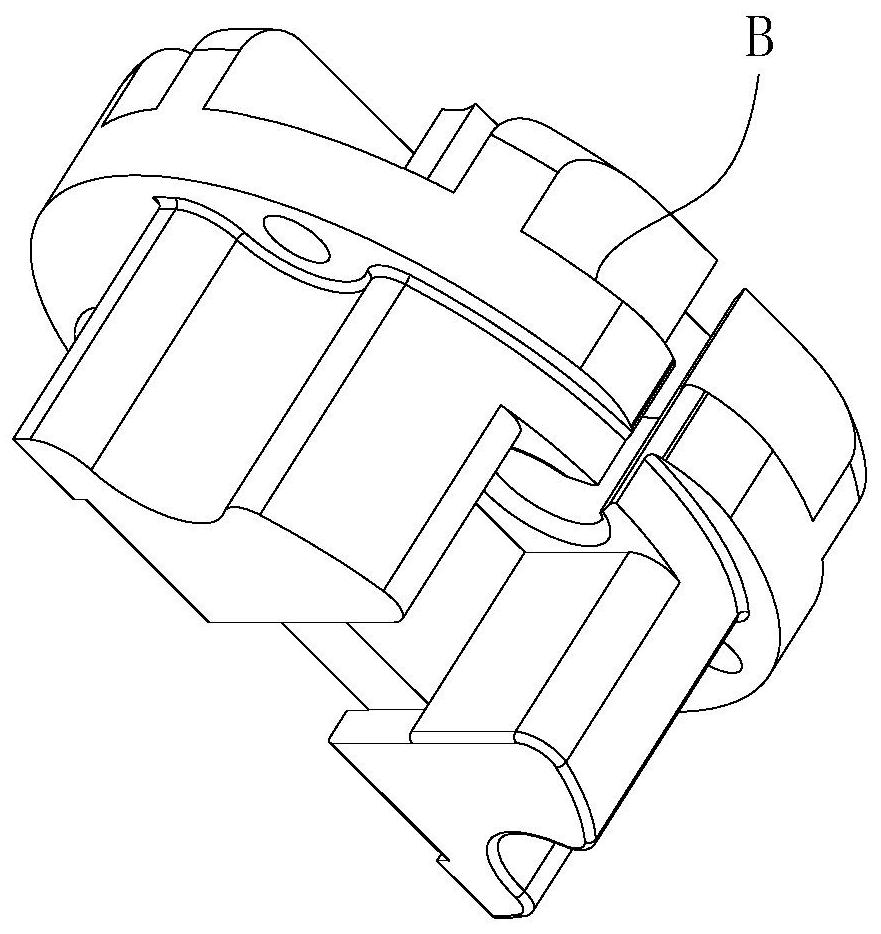

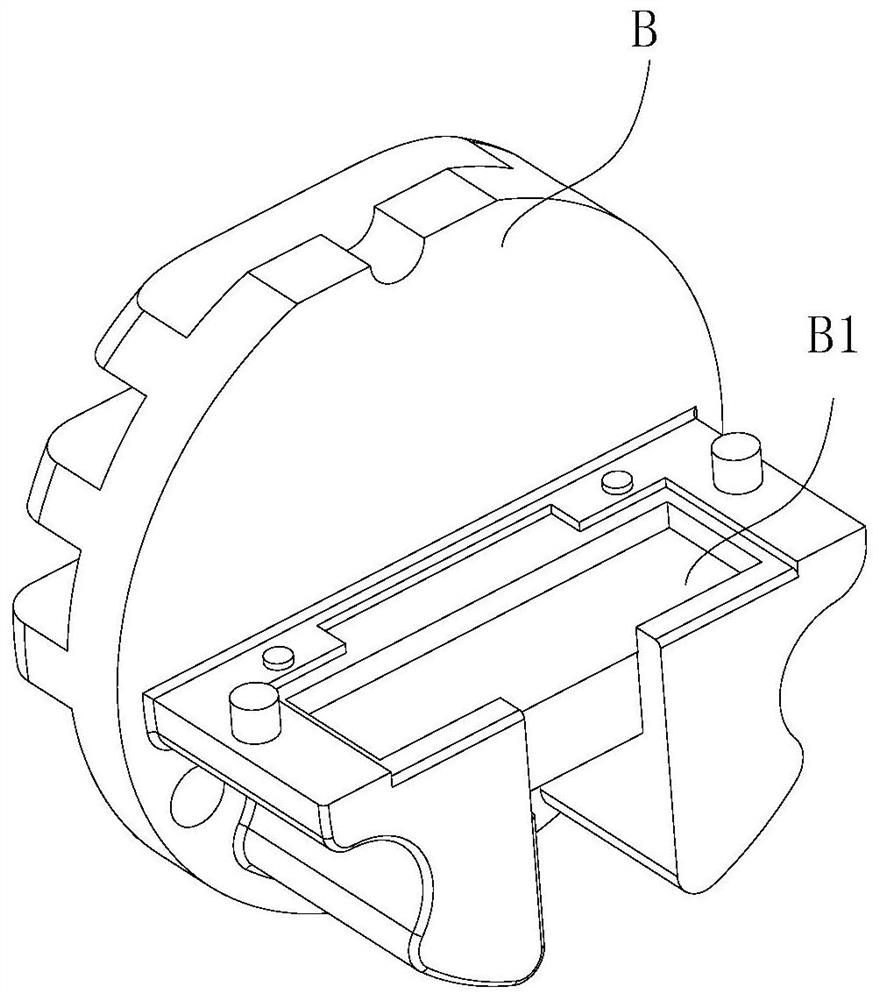

Intelligent lamp holder rear cover mounting device

ActiveCN112355628AIncrease productivityGuarantee the quality of productionLighting heating/cooling arrangementsAssembly machinesPhysicsMechanical engineering

The invention relates to an intelligent lamp holder rear cover mounting device. The intelligent lamp holder rear cover mounting device comprises a heat dissipation base feeding device and an LED lampbead feeding device, wherein the heat dissipation base feeding device is used for guiding out a heat dissipation base; the LED lamp bead feeding device is used for guiding LED lamp beads to the outletposition of the heat dissipation base feeding device and mounting the LED lamp beads on the heat dissipation base; a wire penetrating and sleeving device is arranged beside a positioning and mountingmechanism and used for enabling LED lamp bead wires to penetrate through mounting holes of the heat dissipation base; and a bottom cover feeding device is further arranged beside the outlet of the heat dissipation base feeding device and used for mounting a bottom cover on the heat dissipation base. By adoption of the intelligent lamp holder rear cover mounting device, the production efficiency of LED lamp holders can be improved, meanwhile, LED lamp wicks are protected, and the production quality of the lamp holders is guaranteed.

Owner:HEFEI WISDOM BRIDGE INFORMATION TECH CO LTD

Automatic LED lamp holder production method

InactiveCN112283604AIncrease productivityGuarantee product qualityElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLight head

The invention relates to an automatic LED lamp holder production method. The method comprises the steps that a heat dissipation base is led out to the outlet position of a heat dissipation base feeding device; a reflecting bowl is led out to the outlet position of a second leading-out rail of a reflecting bowl feeding device; LED lamp beads are led out to the positions of clamping blocks; a bottomcover is led out into a feeding pipe of a bottom cover feeding device; a lamp tube is led out to a lamp tube feeding channel of a lamp tube feeding device; a glue solution is extruded into a mountinggroove of the heat dissipation base; an LED lamp wick is pushed into the mounting groove of the heat dissipation base; the reflecting bowl is pushed to the position of the mounting face of the heat dissipation base; the bottom cover abuts against one end of the heat dissipation base and is integrally installed with the heat dissipation base; a wire is clamped in a notch of the heat dissipation base and an opening of the bottom cover, and clamping of the wire is achieved; and the heat dissipation base is inserted into the lamp tube, and installation operation of the heat dissipation base and the lamp tube is realized. By means of the method, the production efficiency of the LED lamp holder can be improved, meanwhile, the LED lamp wick is protected, and the production quality of the lamp holder is guaranteed.

Owner:肖永生

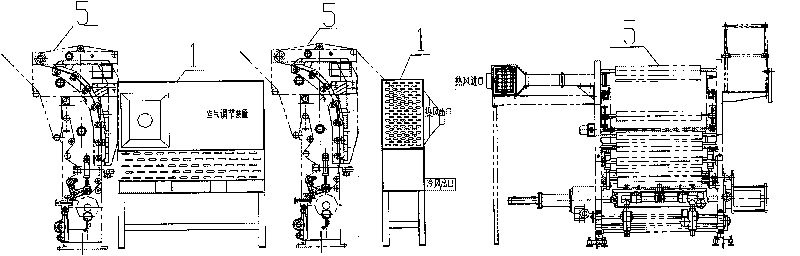

Efficient energy-saving environmental-friendly unit type photogravure press and energy-saving environmental-friendly method

InactiveCN101734002ASimple structureUse to achieveRotary intaglio printing pressPrinting press partsEnvironmental resistancePhotogravure

The invention relates to an efficient energy-saving environmental-friendly unit type photogravure press used for air temperature adjustment of the unit type photogravure press self as well as an energy-saving environmental-friendly method. The photogravure press comprises a unit type photogravure press, an air conditioning plant is arranged between units requiring constant temperature of the unit type photogravure press, a hot wind outlet arranged on the upper part of the air conditioning plant is communicated with an inlet of a drying box body in the unit type photogravure press, a cold wind outlet on the lower part is positioned below the unit in the unit type photogravure press. The invention has the advantages of high cost performance, can realize seamless butt joint with the traditional technology and saves electricity for 56% if compared with products with the same grade on the basis of satisfying the normal function of printing machinery and national environmental protection requirement and has obvious energy saving effect; the environmental impact assessment index is obviously lowered; the efficient energy-saving environmental-friendly unit type photogravure press can realize seamless butt joint with the technology and craft of the existing printing mechanical products under the condition that performance is greatly improved, and also can be used for energy saving modification of printing machinery with low energy efficiency ratio.

Owner:HANGZHOU YUEHUA PRINTING & PACKAGING MACHINERY

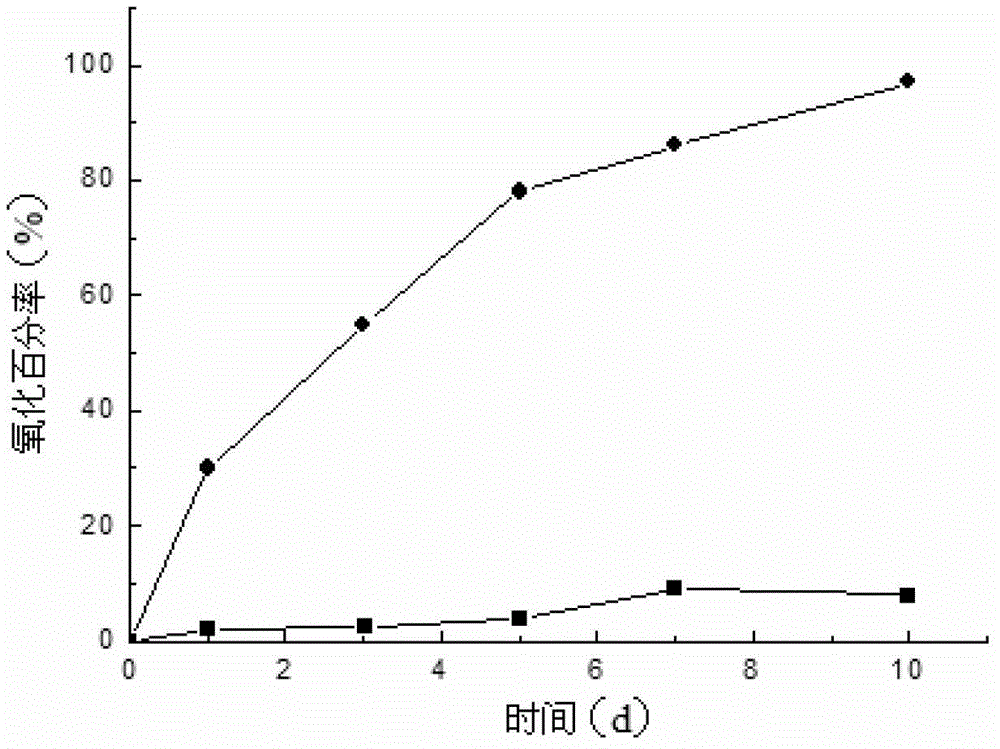

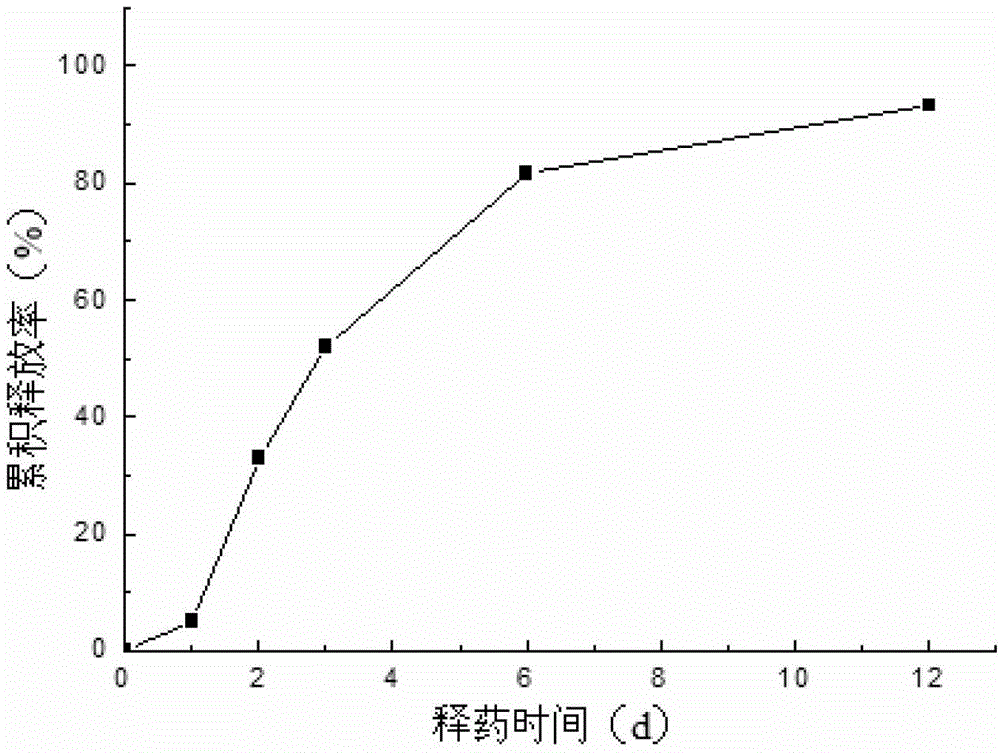

Method for preparing micro-capsule by taking xanthan gum and gelatine as wall materials through complex coacervation method

InactiveCN103142551ASimple particle size distributionUniform particle size distributionMacromolecular non-active ingredientsMicrocapsulesEmulsionOxidation resistant

The invention relates to the technical field of preparation of micro-capsules, in particular to a method for preparing a micro-capsule by taking xanthan gum and gelatine as wall materials through a complex coacervation method. The invention aims to solve the problems of being low in micro-capsule encapsulation efficiency and large in grain diameter prepared by the current method. The preparation method comprises the following steps of: 1, preparing gelatine solution; 2, preparing xanthan gum solution; 3, preparing steady O / W type emulsion, and then adding the xanthan gum solution to obtain mixed solution; 4, adding a curing agent after adjusting pH of the mixed solution; and 5, drying to obtain the micro-capsule. The method disclosed by the invention has the advantages that the encapsulation efficiency can be above 90%; the drug loading capacity can be up to 70% maximally; if being placed below 60 DEG C for 10 days, the micro-capsule is only oxidized by 3-8%; the antioxidant ability is strong; in the event of carrying out an in-vitro drug release test, the whole drug releasing time is 12 hours; the accumulated release rate can be above 90%; the slow-release effect is good; and the method disclosed by the invention is mainly used for preparing the micro-capsule by taking xanthan gum and gelatine as the wall materials through the complex coacervation method.

Owner:HEILONGJIANG UNIV

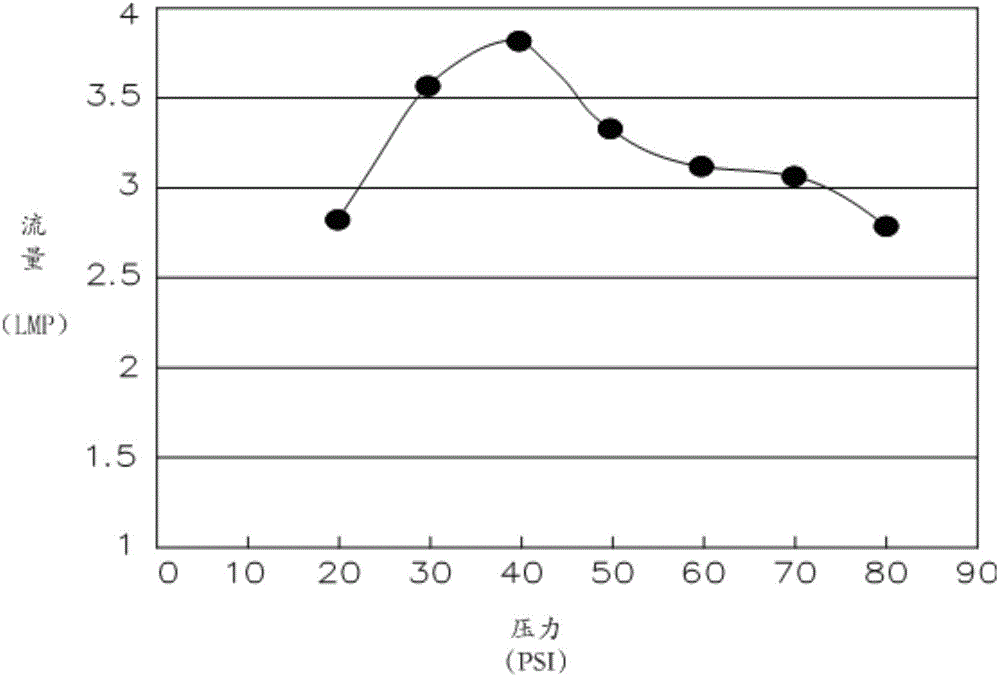

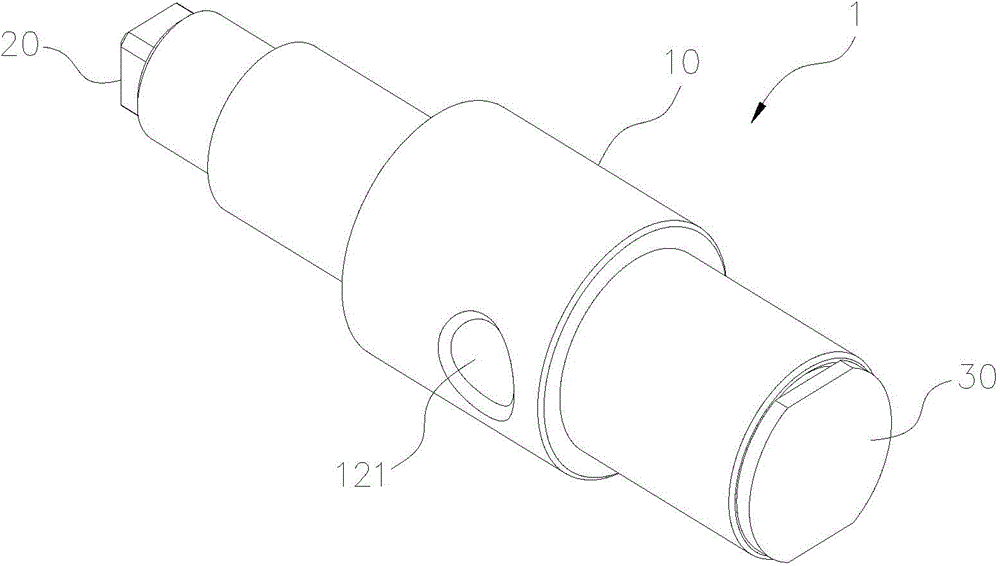

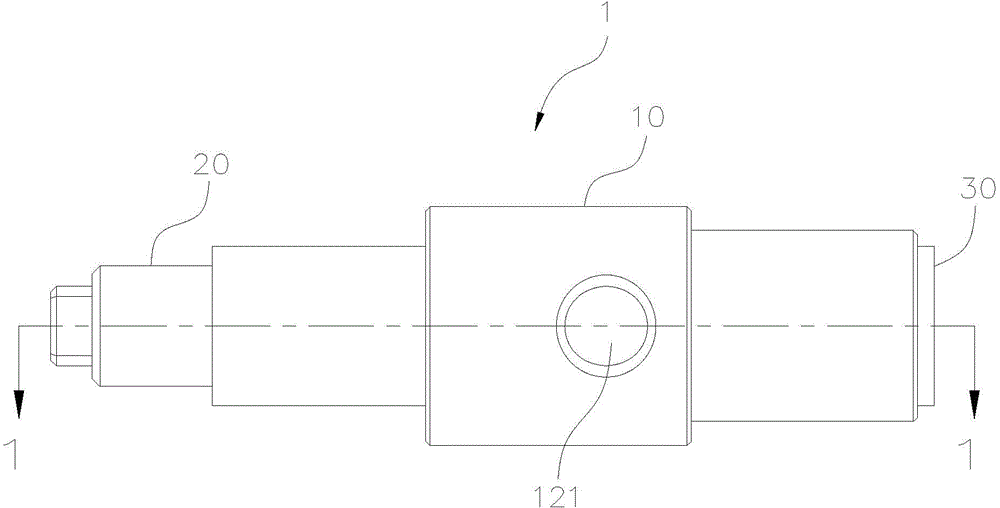

Pressure-stabilizing valve

InactiveCN104565460ADoes not produce drastic scale-down changesEasy to decompressOperating means/releasing devices for valvesEqualizing valvesWater sourceWater resources

The invention provides a pressure-stabilizing valve comprising a shell, a left end cover, a right end cover and a spool component. The shell comprises a left chamber, a right chamber and a valve hole provided between the left and right chambers; the peripheral wall of the right chamber is provided with a water inlet; the peripheral wall of the valve hole is provided with a water outlet; a junction of the right chamber and the valve hole is provided with a valve seat portion having an inner conical wall; the left end cover and the right end cover are hermetically connected to two ends of the shell, respectively; the spool component penetrates the valve hole of the shell and comprises a piston portion and a sealing portion; the piston portion is limited in the left chamber of the shell and hermetically slides in the axial direction; the sealing portion can be hermetically abutted to the inner conical wall. Through relieved changes in area of water passing between the sealing portion and the inner conical wall along with gradual increase of water pressure, the water from the water inlet to the water outlet is well pressure-relieved, pressure-stabilized and flow-stabilized, especially when a water resource is under the high pressure 50 PSI (pounds per square inch) to 100 PSI.

Owner:GLOBE UNION INDAL

Dearsenifying method for Cu-Zn-Co material

The present invention adopts sodium hydroxide solution to soak copper-zinc-cobalt material granules, the concentration of sodium hydroxide solution is 80-160 g / L, the mass matching ratio of sodium hydroxide solution and solid material is 3-7:1, soaking time is 0.5-2 hr. and soaking temp. is 80-95 deg.C. Said invention possesses high removing rate of removing arsenic and sulfur, and the harmful impurity contained in the obtained product is little, and the copper-zinc-cobalt crystal position also is relatively raised.

Owner:史汉祥

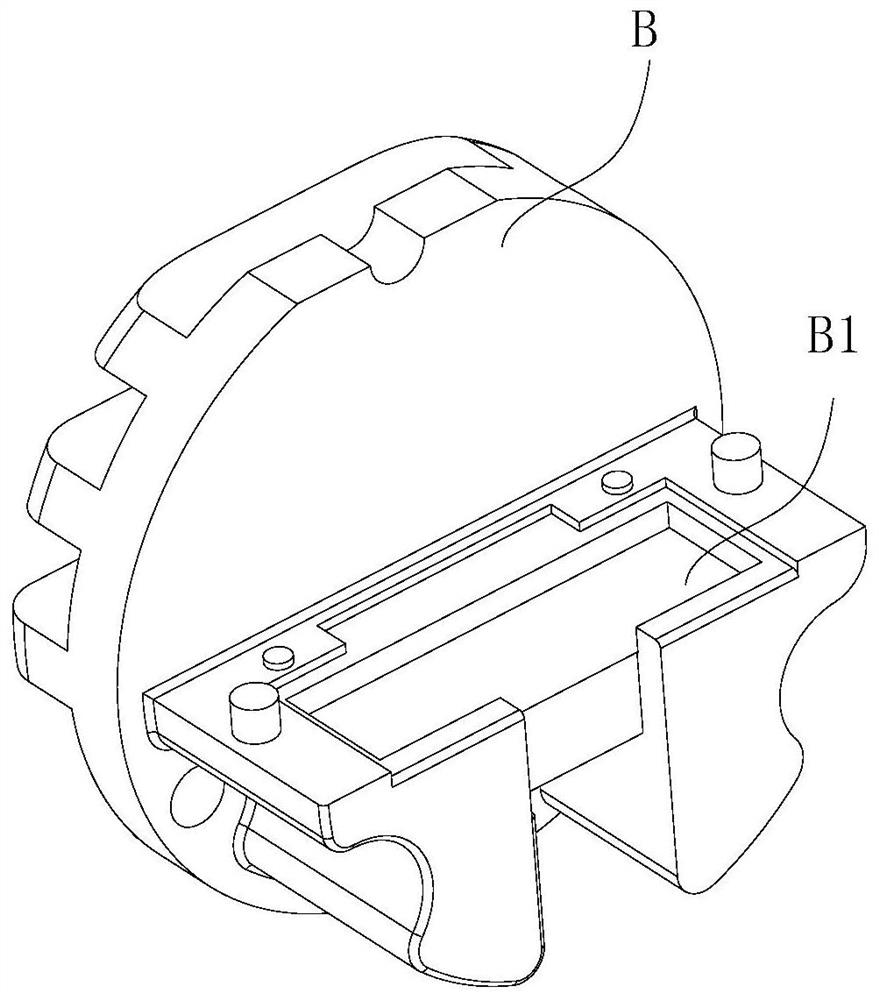

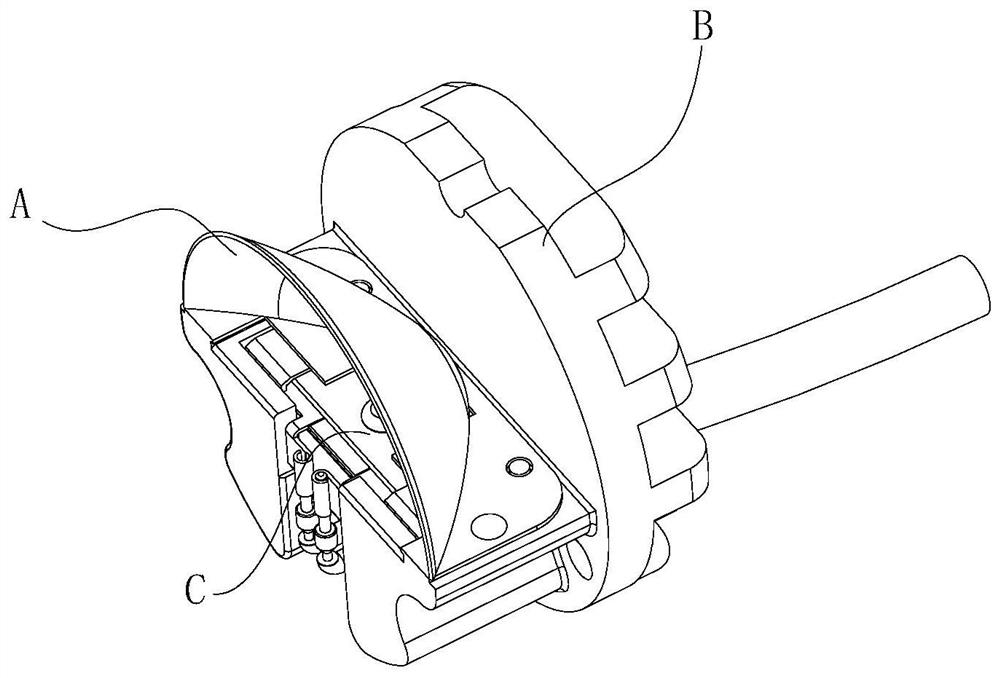

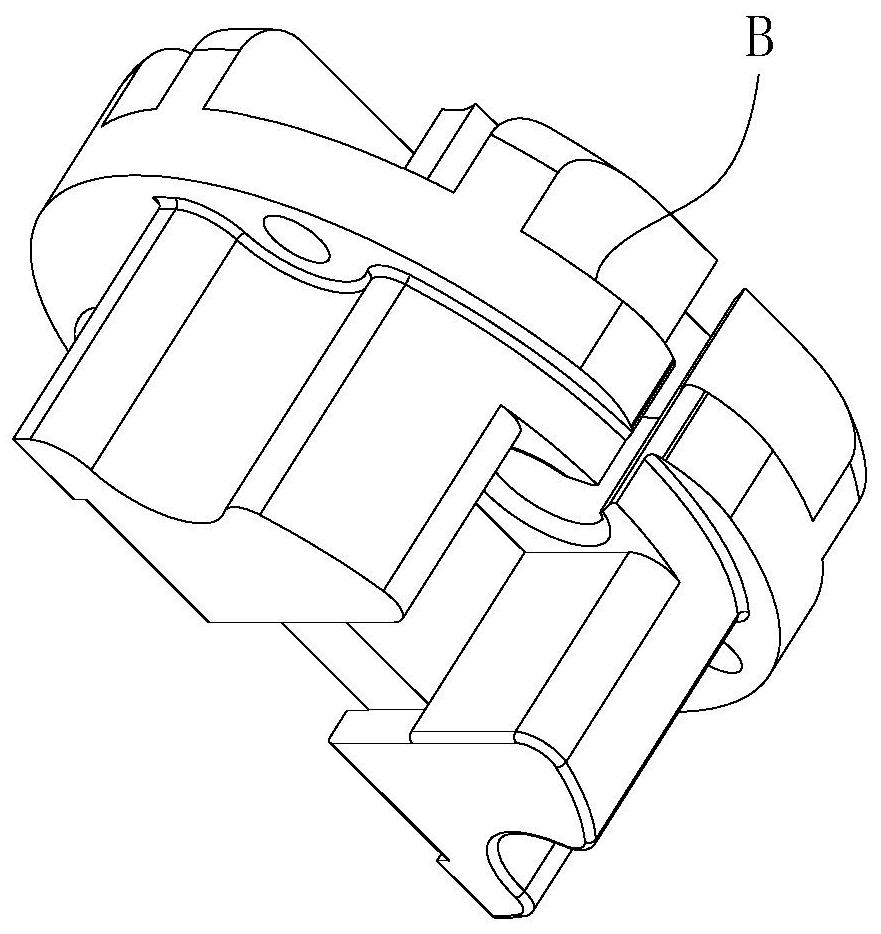

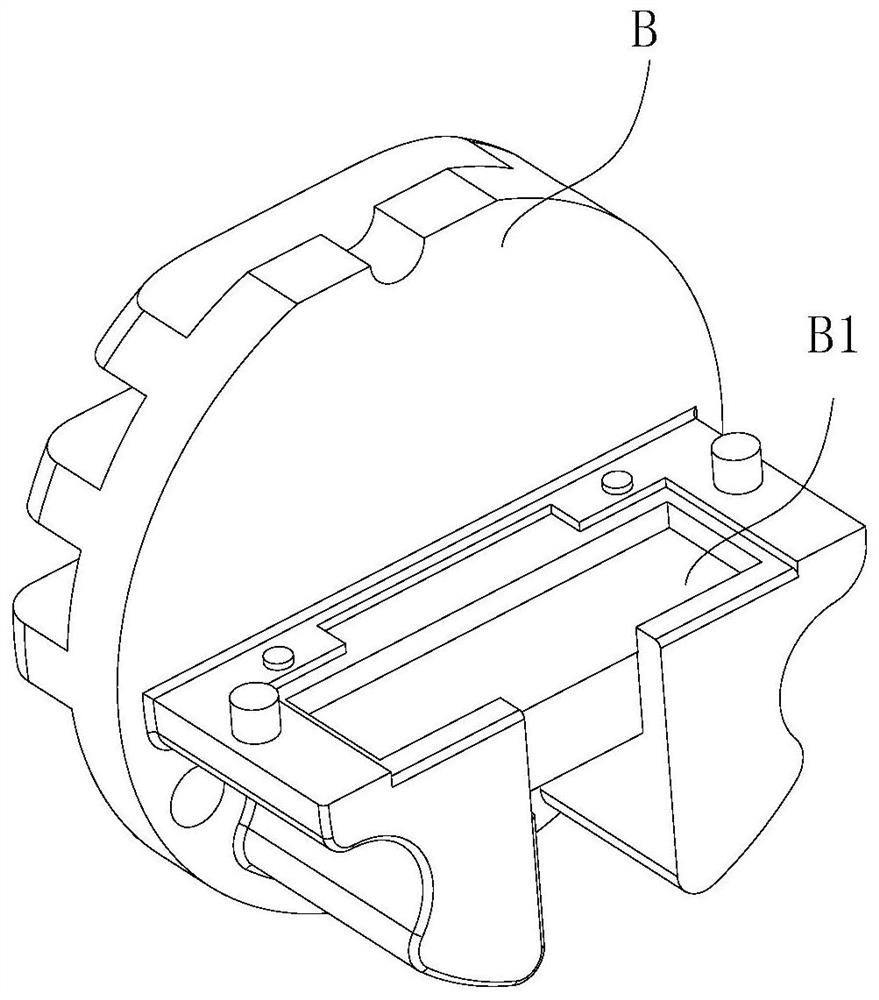

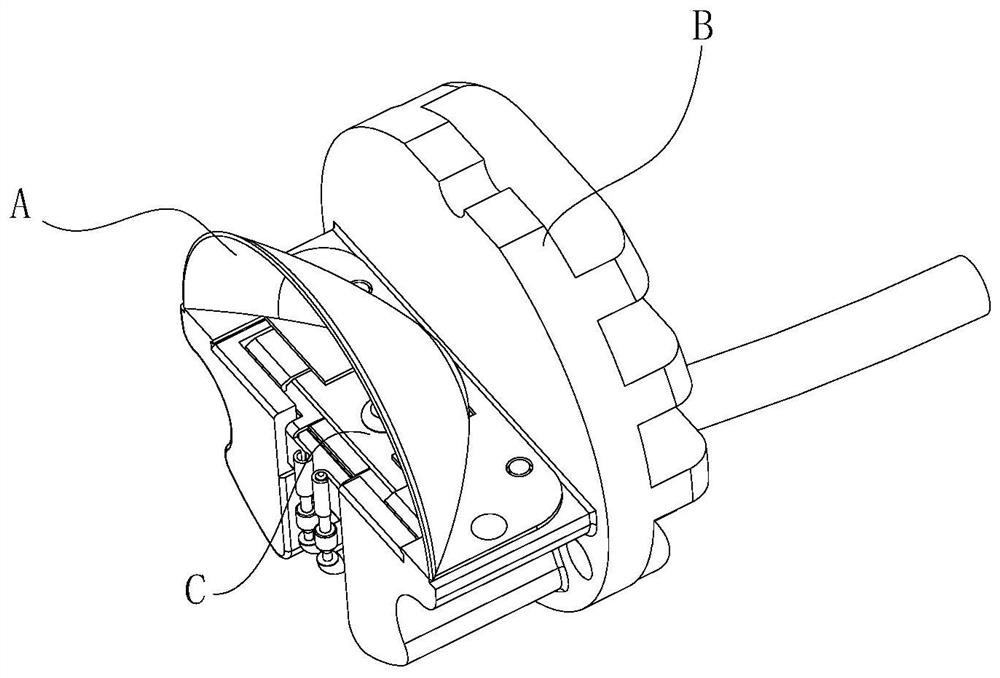

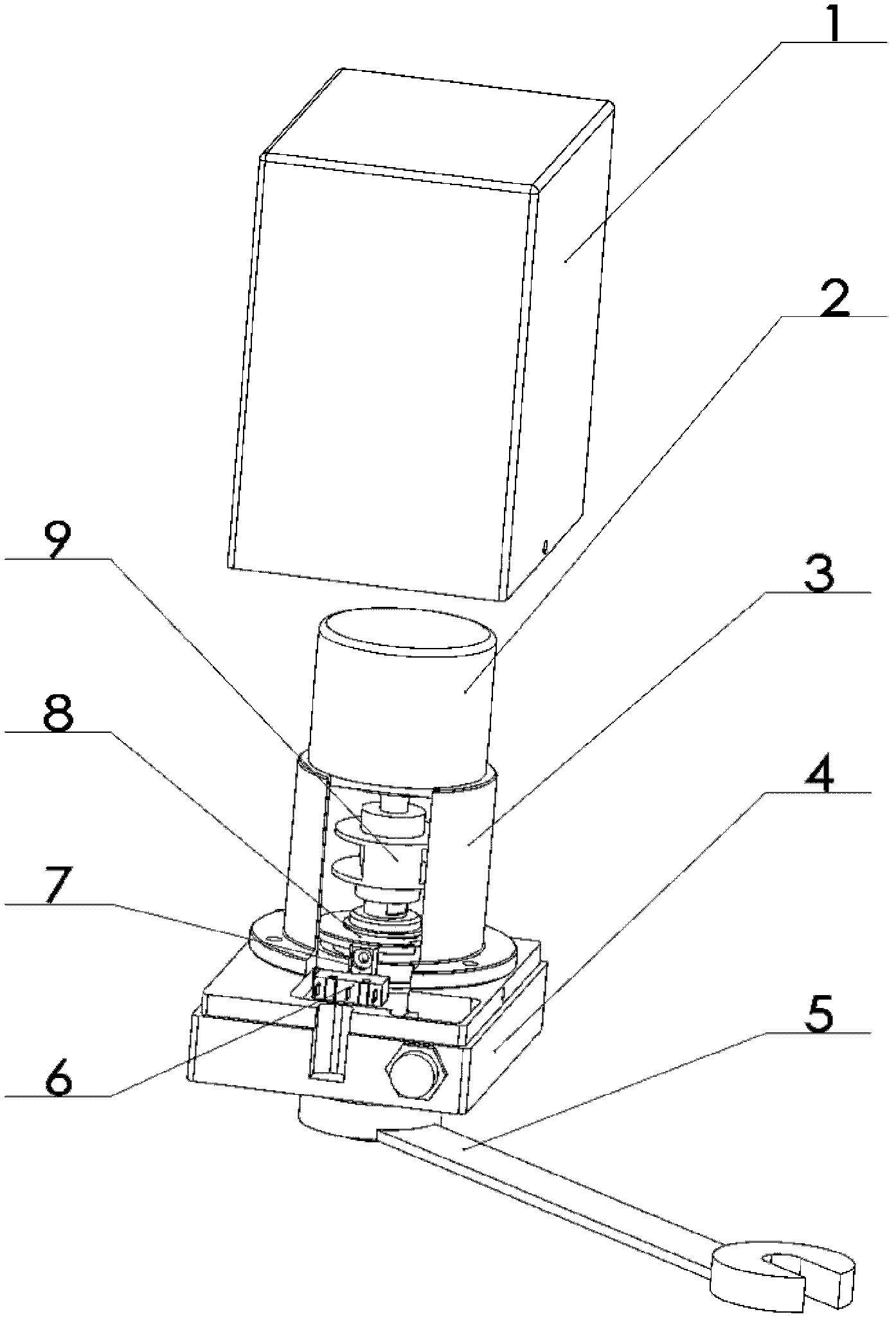

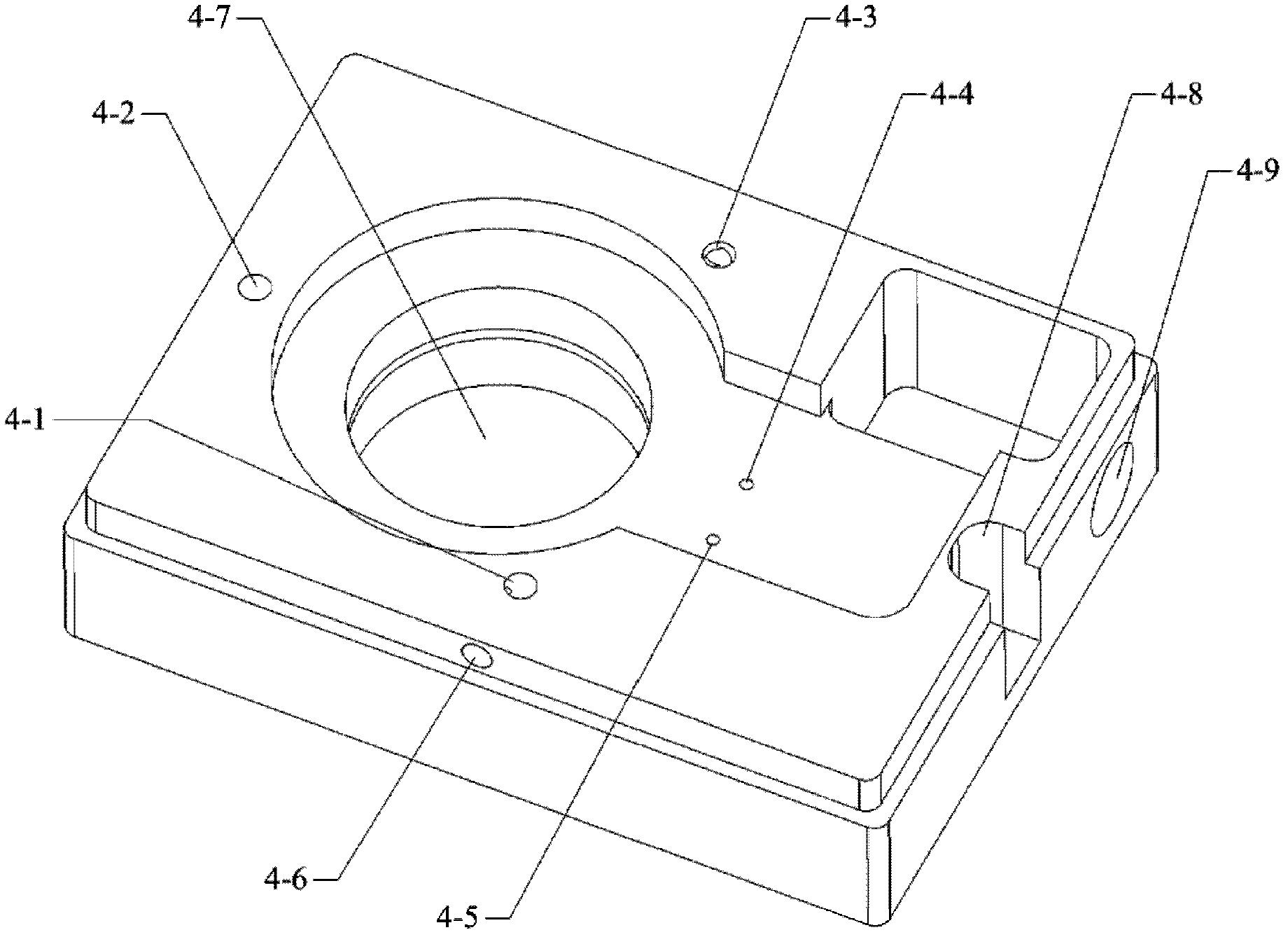

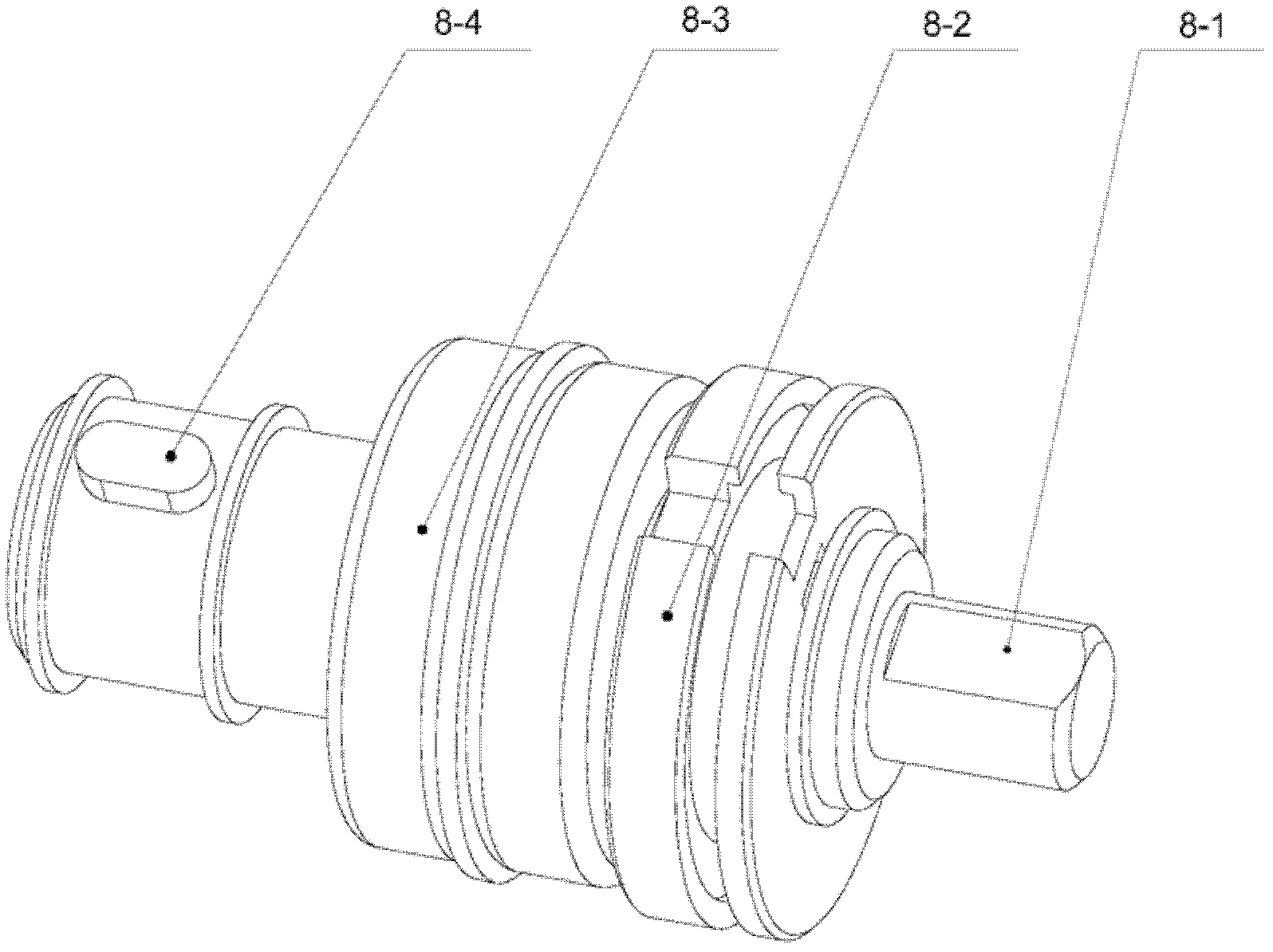

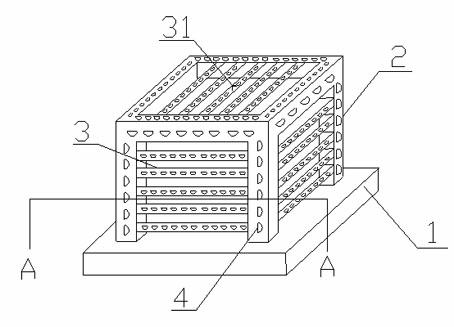

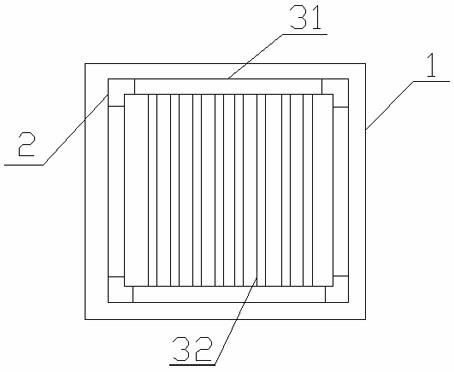

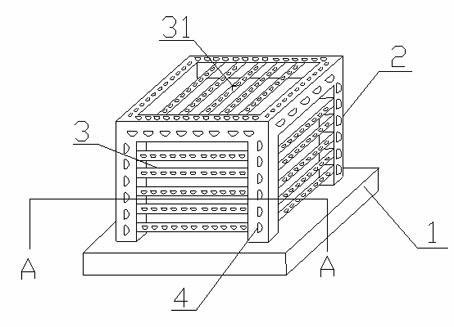

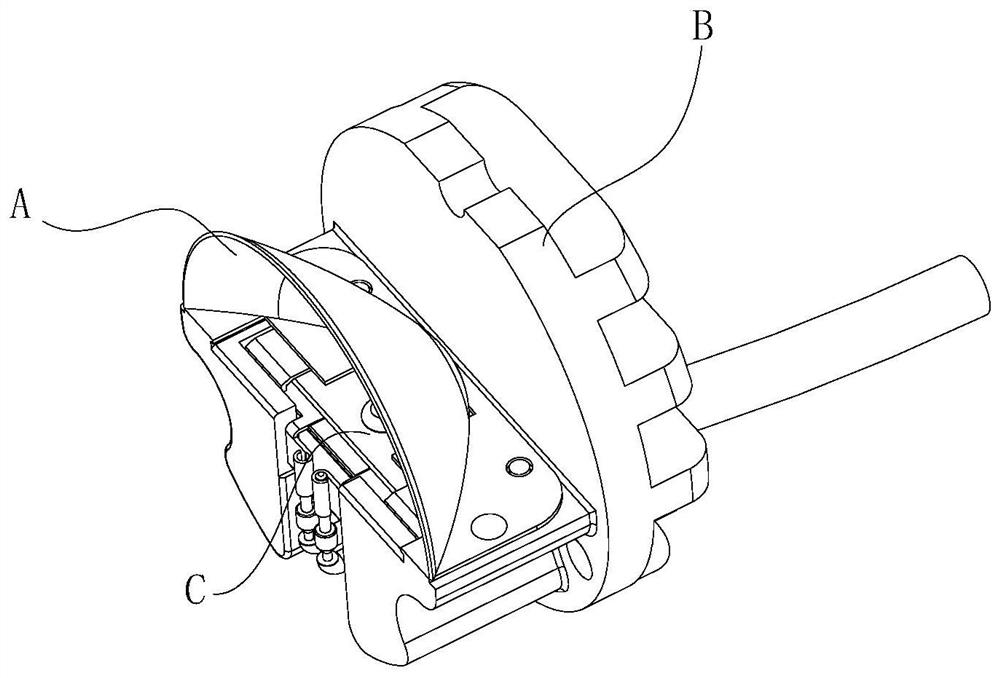

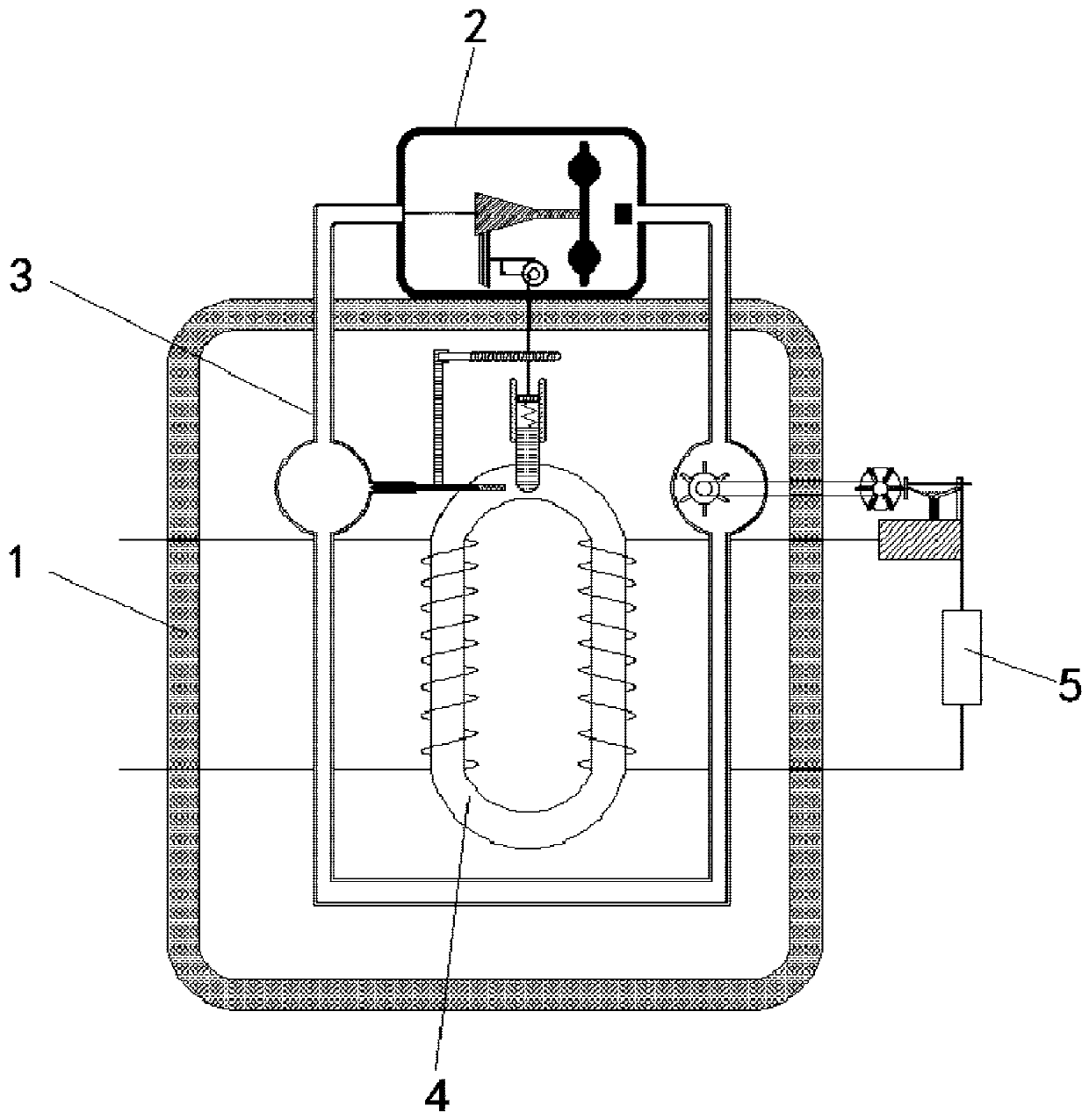

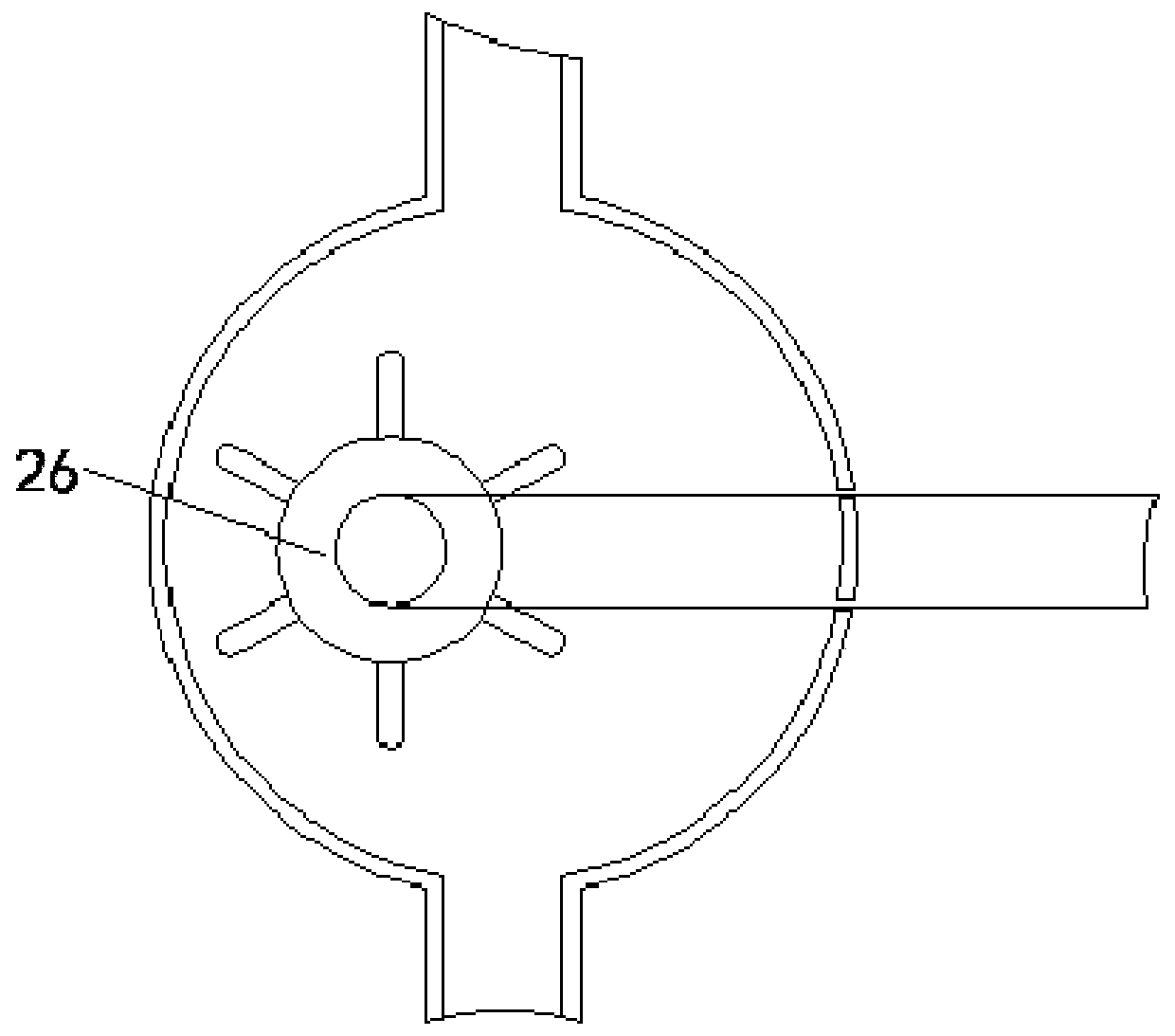

Solar photovoltaic tracking system angle position feedback module

ActiveCN102289232AHigh concentricityGuaranteed concentricityControl using feedbackCouplingEngineering

The invention discloses an angular position feedback module of a sun photovoltaic tracking system. The angular position feedback module is composed of a shell (1), a rotary encoder (2), a coded disc installation rack (3), a module base (4), a connecting rod (5), a limiting switch (6), a sliding block, a central shaft combination (8) and a flexible coupling (9). The shell (1) covers the module base (4), the rotary encoder (2), the coded disc installation rack (3), the limiting switch (6), the sliding block (7), the upper half part of the central shaft combination (8) and the flexible coupling (9) are sealed in a seal cavity consisting of the shell (1) and the module base (4). By integrating two functions of angular size feedback and extreme position alarming, the angular position feedback module provided by the invention has high integral protection level in comparison with the way of using independent components; meanwhile, the protection design for a sensor is added, a limiting angleis convenient for adjusting, the transport and installation are convenient; therefore, the angular position feedback is more stable and reliable.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

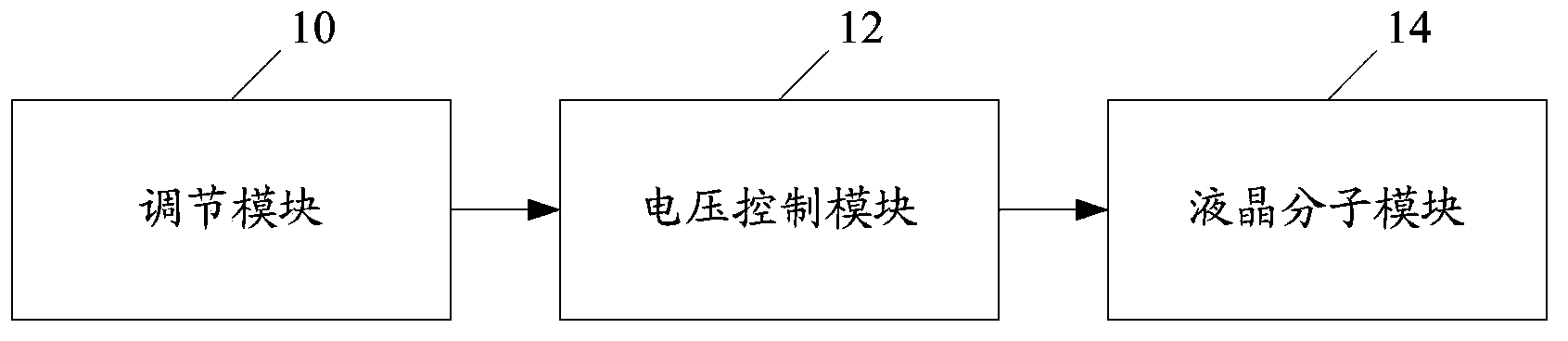

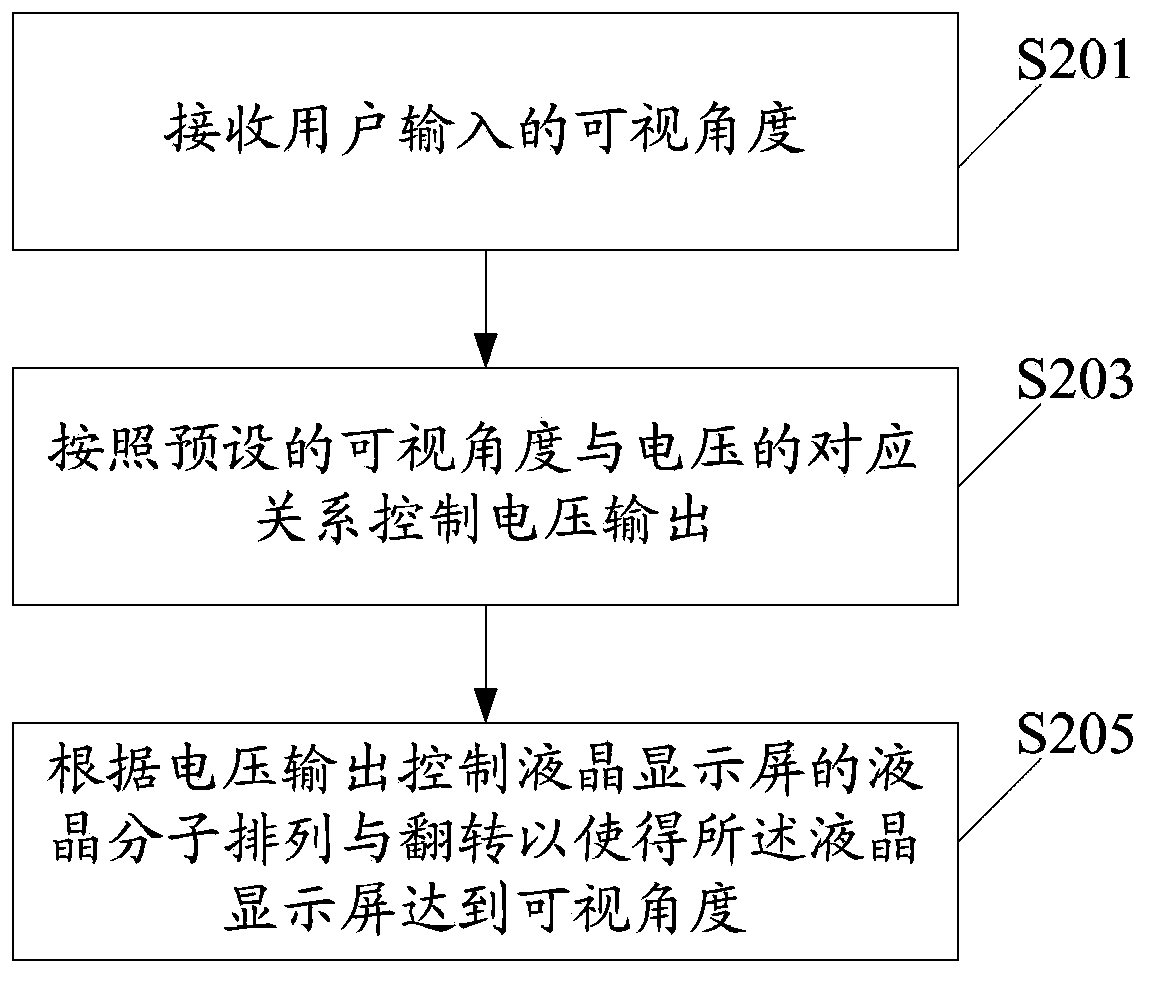

Adjusting method of visual angle of liquid crystal display, liquid crystal display and terminal

InactiveCN103728748AAdjustable viewing angleReach protectionStatic indicating devicesNon-linear opticsEngineeringVoltage control

The invention discloses an adjusting method of the visual angle of a liquid crystal display, the liquid crystal display and a terminal. The adjusting method is used for adjusting the visual angle of the liquid crystal display so as to protect individual privacy displayed on the display. The liquid crystal display comprises an adjusting module, a voltage control module and a liquid crystal molecule module, wherein a user uses the adjusting module for adjusting the visual angle of the liquid crystal display; the voltage control module is connected with the adjusting module and used for controlling an output voltage according to the visual angle input by the adjusting module; the liquid crystal molecule module is connected with the voltage control module and used for controlling arranging and turning-over of liquid crystal molecules according to the output voltage, so that the liquid crystal display is in the visual angle. By the adoption of the technical scheme, the visual angle of the liquid crystal display can be adjusted on occasions when the individual privacy needs to be protected, and the effect that content on the liquid crystal display cannot be seen by other people is achieved.

Owner:LENOVO MOBILE COMM TECH

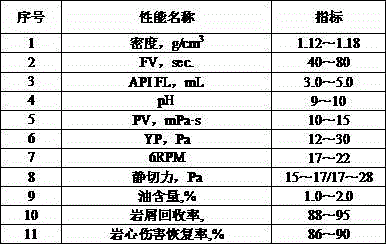

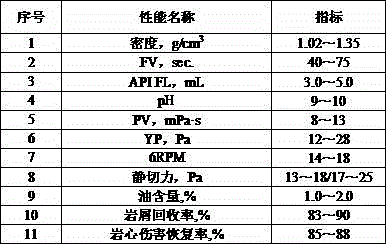

Formula and preparation method of low-pressure coefficient gas pool reservoir protection drilling fluid

InactiveCN103333667APrevent intrusionNo increase in solids contentDrilling compositionAlkalinityPreservative

The invention discloses a formula and preparation method of low-pressure coefficient gas pool reservoir protection drilling fluid. The drilling fluid formula comprises the following raw materials in percentage by mass: 3-8% of support temporary plugging agent, 1-3% of deformation particles, 0.1-0.3% of viscosity improver, 0.5-1.0% of fluid loss agent, 0.1-0.3% of alkalinity control agent, 0.03-0.1% of preservative, 0.5-0.8% of deoxidant, 0.1-0.5% of corrosion inhibitor and the balance of water. According to the formula disclosed by the invention, without clay, the rheological property is easy to adjust; the formula has the characteristics of adjustable density, low solid phase and strong inhibition; and particularly, a thin and dense barrier zone without permeation or with little permeation is quickly formed in a zone close to the well wall, and the liquid phase and solid phase particles in the drilling (after-drilling) fluid are prevented from further invading the reservoir so as to realize reservoir protection.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Method for preparing shell square reef

InactiveCN102217565AImprove stabilityStrong impact resistanceClimate change adaptationPisciculture and aquariaReinforced concreteEngineering

The invention relates to a method for preparing a shell square reef, which comprises the following steps of: (a) constructing the base, support column and beam structures of the shell square reef by selecting reinforcing steel bars with appropriate sizes; (b) pouring concrete towards the constructed steel structure of the shell square reef; (c) when the shell square reef is poured to be formed and the concrete on the surface of the shell square reef is not dried, inserting shells into the surfaces of the support columns and the beam; and (d) drying the concrete completely for forming to obtain the shell square reef which can be used. The invention also provides the shell square reef. The method has the advantages that: the shell square reef is manufactured by using reinforced concrete as a raw material, is provided with the base, and is high in stability and capacity of impact resistance, drifting resistance and overturn resistance; the shell square reef can generate shadows, adsorb algae and shellfish and attract fish to spawn or avoid stormy waves and natural enemies and provide excellent habitats for the fish to fulfill the aims of protection, proliferation and the improvement of fish catch.

Owner:SHANGHAI OCEAN UNIV

Automatic production system for LED lamp holder

PendingCN112361237AIncrease productivityGuarantee the quality of productionAssembly machinesMetal working apparatusMechanical engineeringLight tube

The invention relates to an automatic production system for an LED lamp holder, which comprises a heat dissipation base feeding device, a reflection bowl feeding device and an LED lamp bead feeding device, wherein the heat dissipation base feeding device is used for guiding out a heat dissipation base, the reflection bowl feeding device guides a reflection bowl out to the outlet position of the heat dissipation base feeding device and installs the heat dissipation base and the reflection bowl, the LED lamp bead feeding device is used for guiding LED lamp beads to the outlet position of the heat dissipation base feeding device and installs the LED lamp beads and the heat dissipation base, a lamp tube feeding device is further arranged beside the heat dissipation base feeding device, a positioning installation mechanism is arranged beside the lamp tube feeding device, and the positioning installation mechanism is used for achieving installation of the heat dissipation base and the lamp tube. The system can improve the production efficiency of the LED lamp holder, achieves protection for an LED lamp wick, and guarantees the production quality of the lamp holder.

Owner:HEFEI WISDOM BRIDGE INFORMATION TECH CO LTD

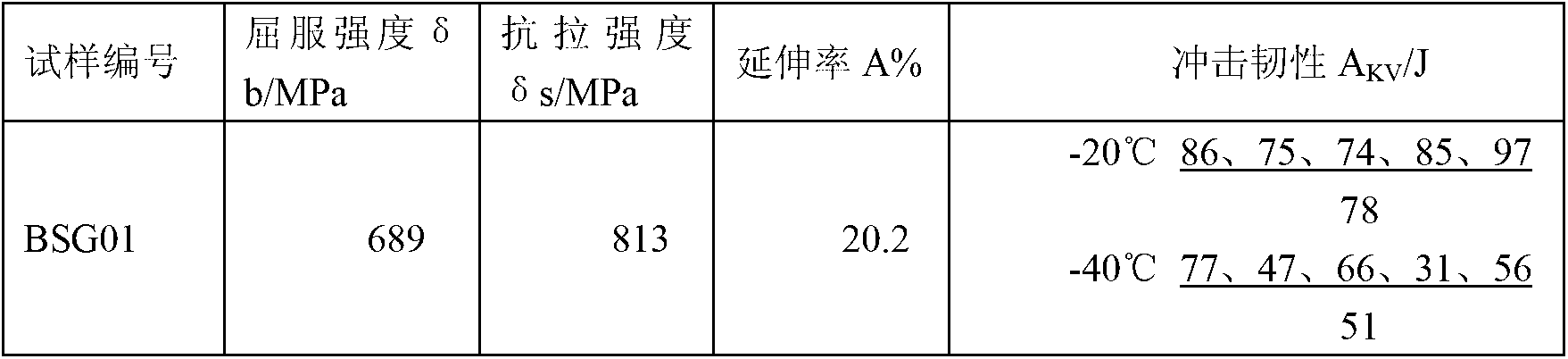

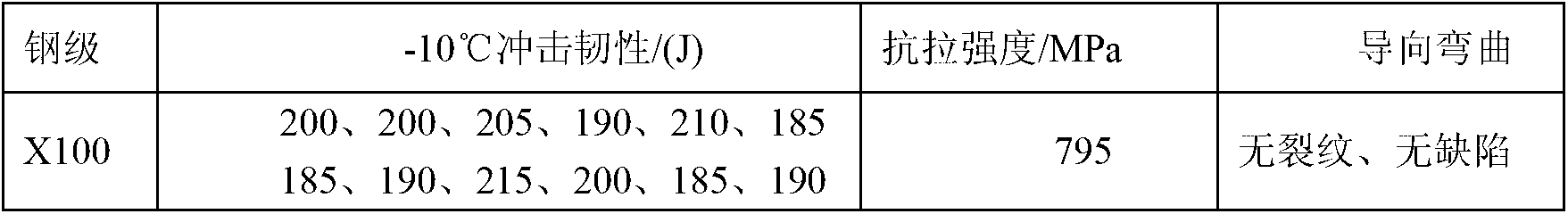

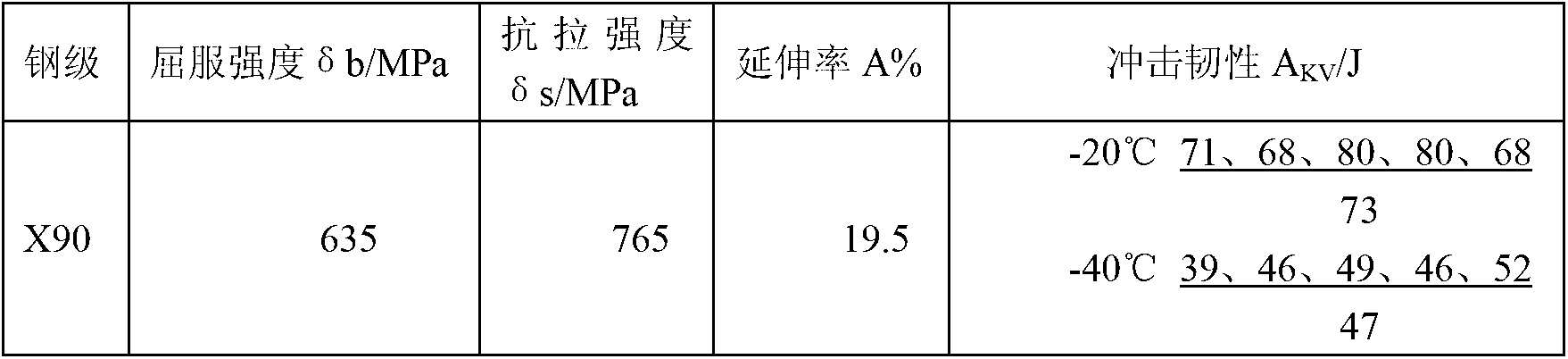

High-toughness high-welding speed sintered flux suitable for submerged-arc welding of X90/X100 ultrahigh-strength pipeline steel pipe

ActiveCN103192196AImprove impact toughnessImprove performanceWelding/cutting media/materialsSoldering mediaHydrogen contentWeld seam

The invention discloses a high-toughness high-welding speed sintered flux suitable for the submerged-arc welding of an X90 / X100 ultrahigh-strength pipeline steel pipe, and the high-toughness high-welding speed sintered flux comprises the following components in percentage by weight: more than or equal to 15 and less than or equal to 20 of CaF2, more than or equal to 20 and less than or equal to 25 of MgO, more than or equal to 15 and less than or equal to 20 of Al2O3, more than or equal to 10 and less than or equal to 15 of CaO, more than or equal to 1 and less than or equal to 5 of MnO, more than or equal to 25 and less than or equal to 30 of SiO2, more than or equal to 3 and less than or equal to 8 of Y2O3 and more than or equal to 1 and less than or equal to 4 of a reducing agent. The high-toughness high-welding velocity sintered flux disclosed by the invention ensures that the submerged-arc welding speed of the X90 / X100 ultrahigh-strength pipeline steel pipe is at the high welding speed of 1.5-1.8 m / minute, has good processing property of a welding seam, achieves the welding strength of more than 780 MPa, achieves the average toughness value of 130 J, achieves the deposited metal strength of more than 760 MPa, achieves the diffusible hydrogen content of less than 6.0ml / 100g (mercury method), belongs to a low-hydrogen welding material and can realize the high-strength high-toughness matching of the submerged-arc welding seam of the ultrahigh-strength pipeline steel pipe.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

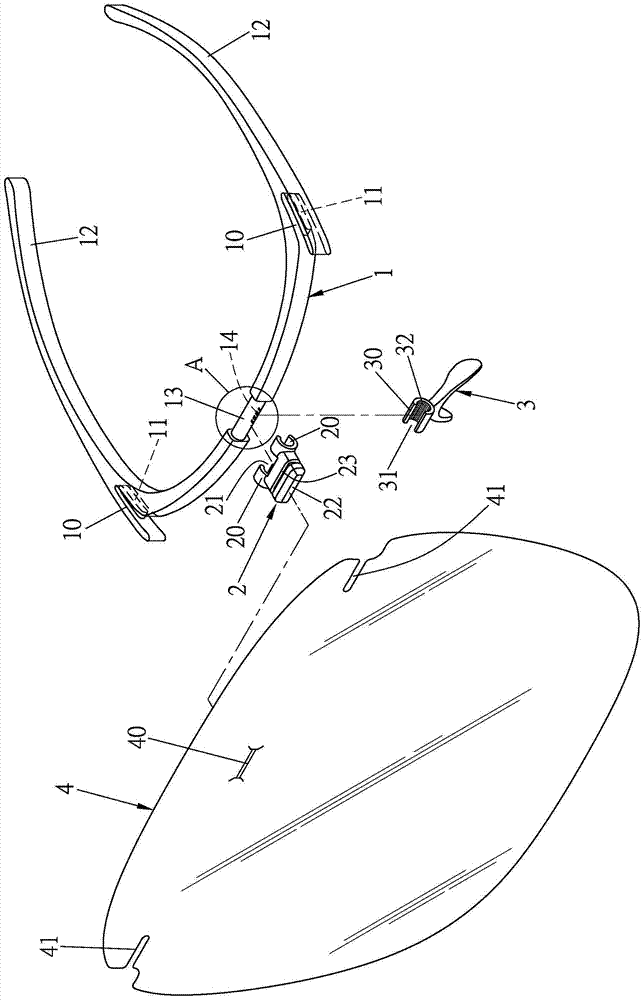

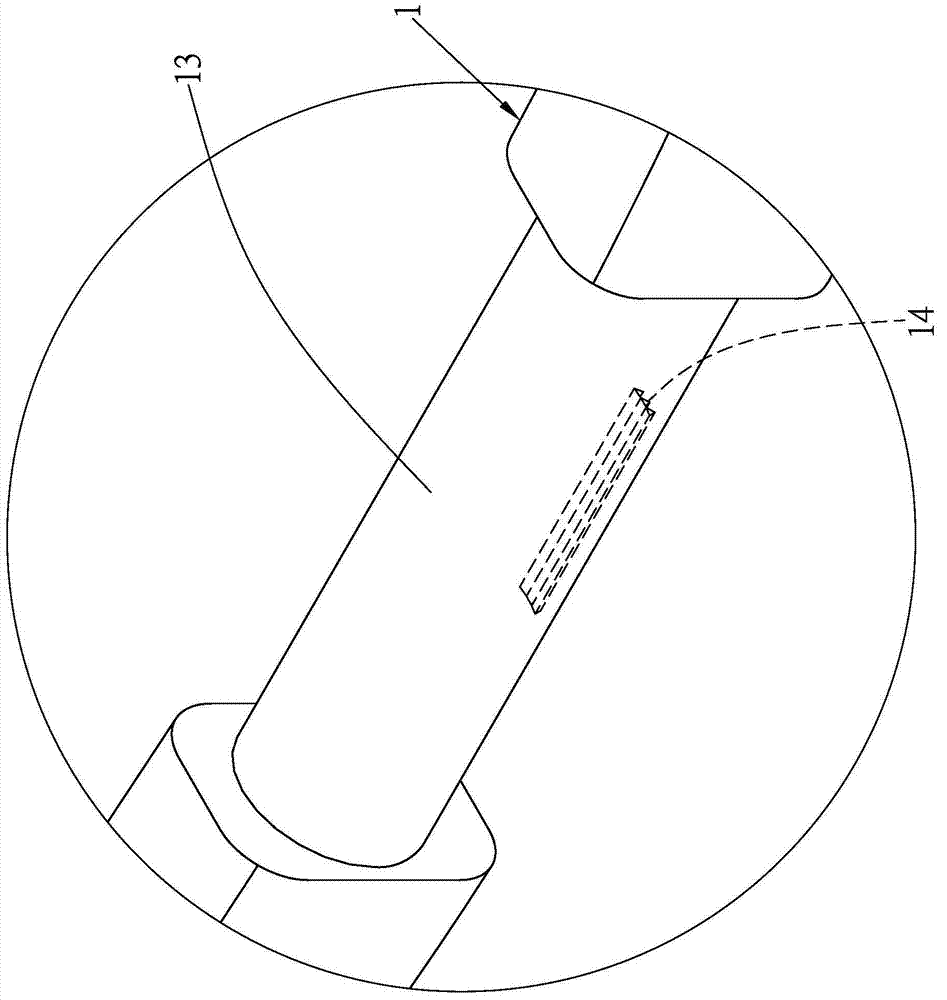

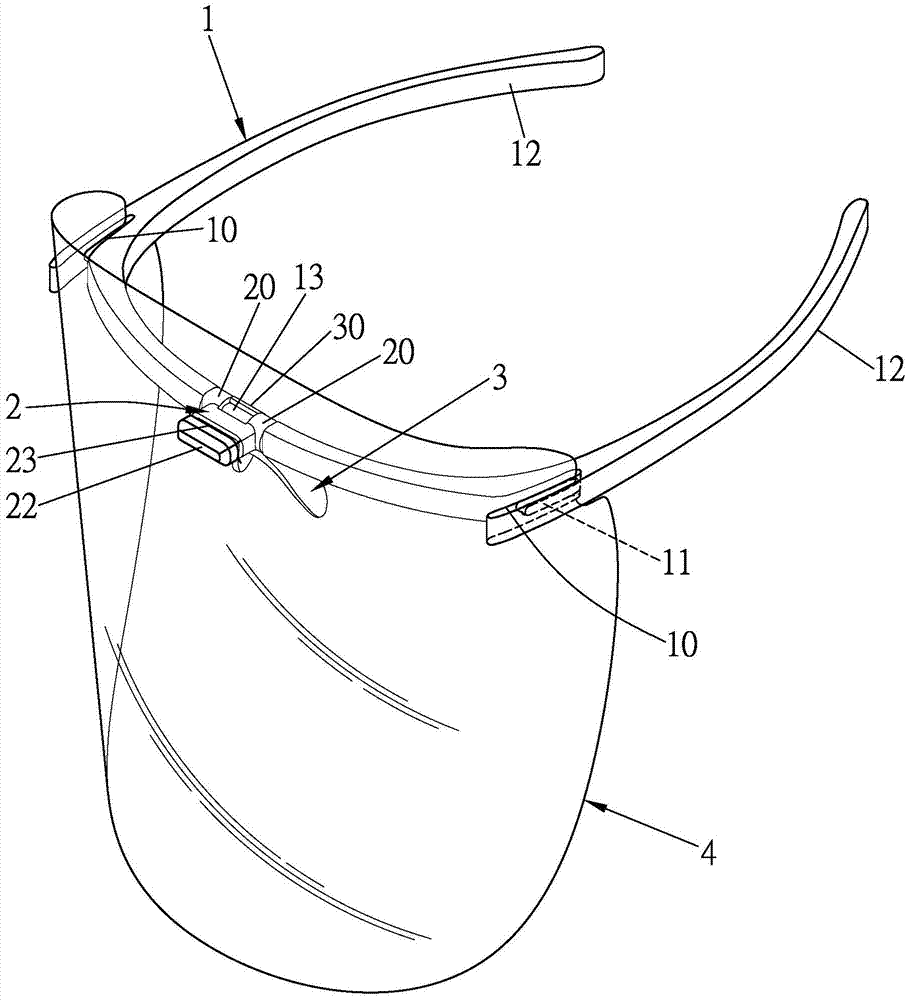

Protective mask

InactiveCN104489968AEasy to assembleEasy to carry and useGarment special featuresNon-optical partsArchitectural engineeringFace shield

The invention provides a protective mask mainly comprising a support frame, a connector, a noise rest and a proactive plate. Two ends of the support frame are provided with cut grooves in which positioning stops are disposed; two ends of the support frame are provided with hanging portions extending rearward; a fastening rod is disposed in the middle of the support frame; the connector is disposed on the fastening rod of the support frame; one end of the connector is provided with a C-shaped fastening groove; the middle of the C-shaped fastening groove is provided with a notch; the other end of the connector is provided with a protrusion which is provided with a circular groove; the nose rest is disposed on the fastening rod of the support frame; the upper end of the noise rest is provided with a fastening portion disposed in the notch of the connector; the fastening portion is provided with a fastening groove; the protective plate is disposed in front of the support frame; the middle of the protective plate is provided with a hole allowing the protrusion of the connector to pass through; two ends of the protective plate are provided with embedding slots; thus, the protective mask closable and allowing adjustable angle of the noise rest is formed.

Owner:王明正

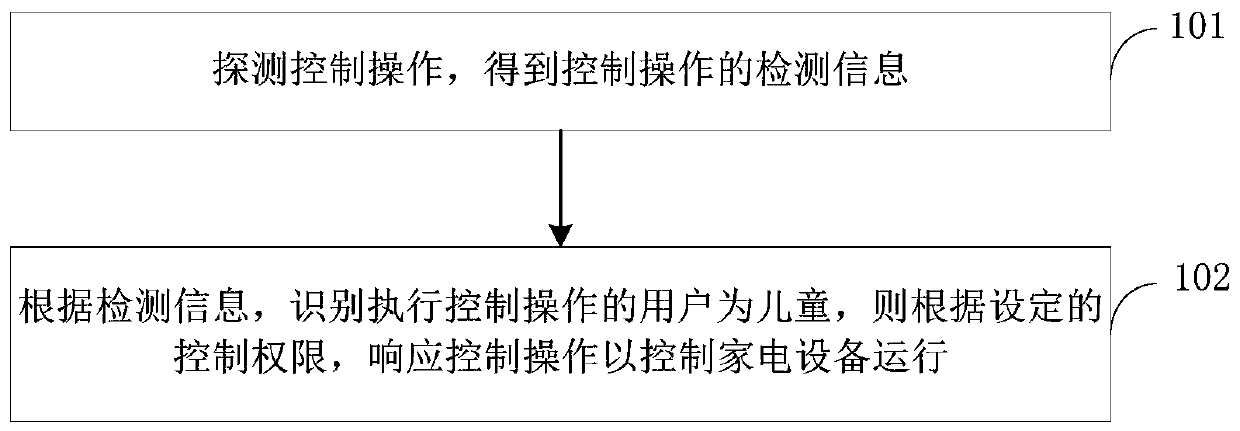

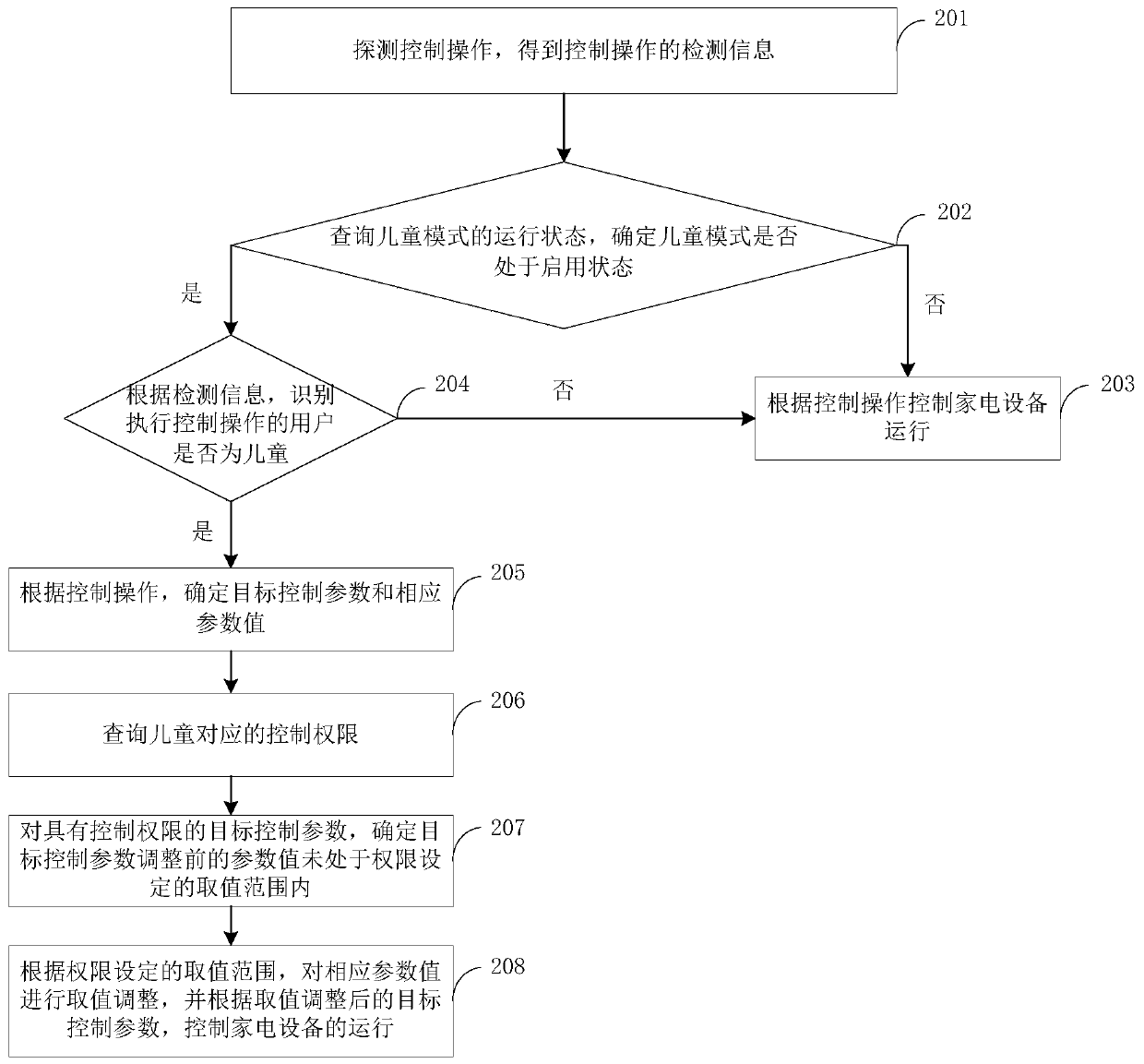

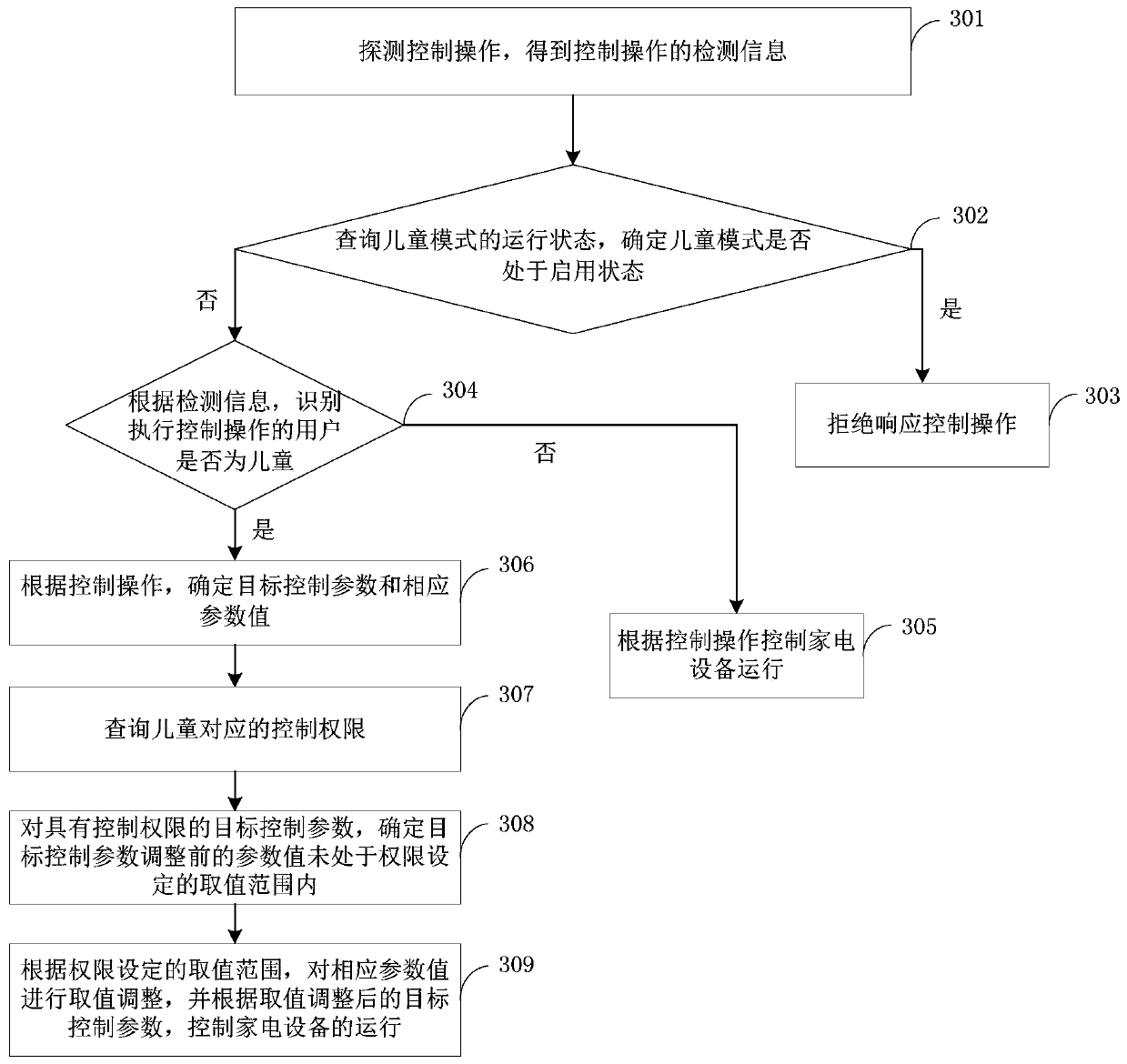

Control method, apparatus and electronic device of household appliance

ActiveCN110320815ARealize intelligent controlReach protectionComputer controlDigital data authenticationEmbedded systemExecution control

The invention provides a control method, an apparatus and an electronic device of a household appliance, wherein the method comprises: detecting a control operation to obtain detection information ofthe control operation; identifying a user executing the control operation as a child according to the detection information; in response to the control operation, controlling the operation of the household appliance according to a set control authority; identifying the user executing the control operation as the child according to the detection information; and controlling the operation of the household appliance according to the set control authority to realize smart control over the household appliance. Meanwhile, by setting the control authority, protection and restriction for the child areachieved. Therefore, the invention solves the technical problems of the prior art that a key combination is required for setting a child lock to realize protection and restriction for the child, theoperation is not convenient enough and user experience is poor.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

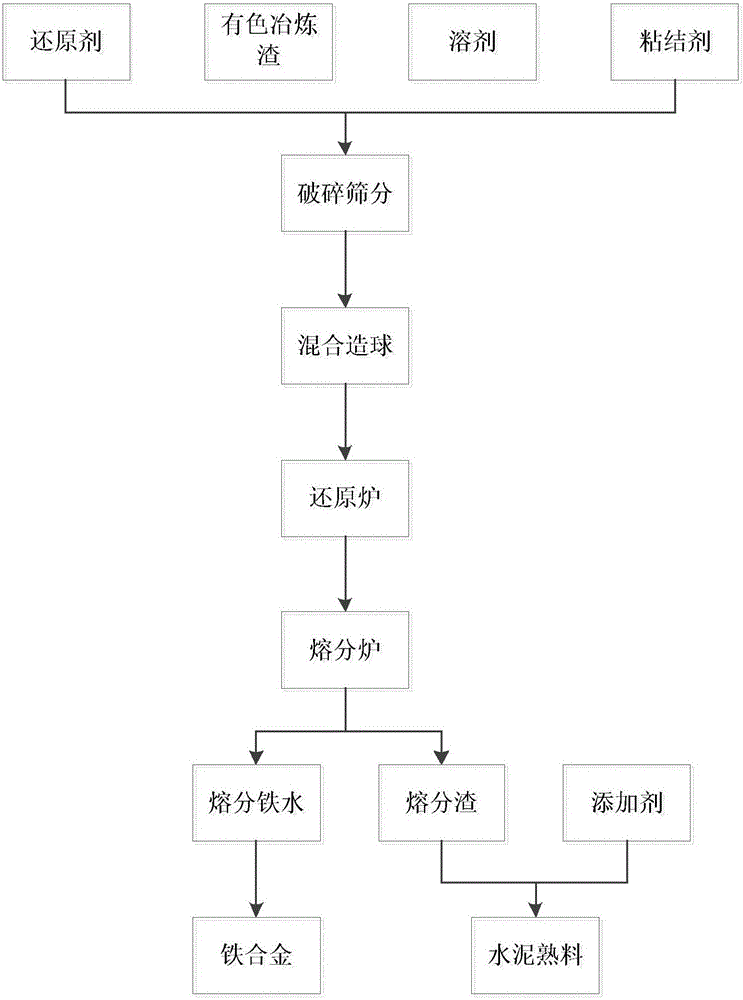

Non-ferrous metal smelting slag utilization method

ActiveCN106086428ARealize no solid waste utilizationRealize comprehensive utilizationCement productionProcess efficiency improvementSlagNon-ferrous extractive metallurgy

The invention discloses a non-ferrous metal smelting slag utilization method. The non-ferrous metal smelting slag utilization method is used for manufacturing iron alloy and cement clinker and comprises the following steps that non-ferrous metal smelting slag, reducing agents, solvents and binders are sufficiently and uniformly mixed according to the weight ratio, pelletized and then reduced; reduction is conducted for 10-30 min at the temperature of 800 DEG C-1300 DEG C, then, reduction products are heated to be 1500 DEG C-1700 DEG C, and iron and slag are separated; and molten iron is used for producing the iron alloy, and slag water is converted into the cement clinker. According to the non-ferrous metal smelting slag utilization method, metal and gangue components in the smelting slag are utilized at the same time, and energy consumption is reduced; in addition, the metal smelting slag is completely utilized, and no secondary waste slag is produced; smelting secondary slag serves as a valuable component to be used for producing cement, process links are greatly decreased, dust is reduced, exhaust gas pollution is relieved, and the product market application field is broadened; and more importantly, the current stacked and abandoned smelting waste slag can be processed, no new solid waste is produced, economic interests are achieved, and meanwhile the environment is protected.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Heat dissipation protection equipment based on oil-immersed high-frequency transformer

ActiveCN111312486AGuaranteed normal rotationSmall inner diameterTransformers/inductances coolingTransformerEngineering

The invention discloses heat dissipation protection equipment based on an oil-immersed high-frequency transformer. The equipment comprises a shell; an iron core is arranged in the shell; the top of the iron core is fixedly connected with a heat conduction rod; the top of the heat conduction rod is slidably connected with a mercury pipe; a stop block is connected into the mercury tube in a slidingmanner; the top of the stop block is fixedly connected with a bearing rod; a rotating wheel is arranged in the guide pipe; the right side of the rotating wheel is rotationally connected with a centrifugal wheel through a belt; a baffle is arranged on the right side of the centrifugal wheel; the side face of the baffle is rotationally connected with an extrusion rod; a conductive block is arrangedat bottom of the extrusion rod; a wire is arranged at bottom of conductive block; and a load element is arranged below the wire. According to the heat dissipation protection equipment based on the oil-immersed high-frequency transformer, through cooperative use of the transition box and the heat conduction rod, the effects that protection is generated during heat accumulation of the iron core, andthe iron core is prevented from being damaged due to overheating are achieved.

Owner:SHANDONG LUKONG ELECTRIC POWER EQUIP CO LTD

Carbon emission checking data acquisition device

InactiveCN113498289AReach protectionImprove protectionCasings/cabinets/drawers detailsRack/frame constructionData acquisitionControl theory

The invention discloses a carbon emission checking data acquisition device in the technical field of data acquisition. The carbon emission checking data acquisition device comprises a box body, a lifting device is rotatably connected in the box body, and a moving plate is fixedly connected to the upper end of the lifting device; a damping device is fixedly connected to the upper end of the moving plate, and a collector is fixedly connected to the upper end of the damping device; a sliding hole is formed in the front end face of the box body, an opening and closing device is slidably connected in the sliding hole, and a cover plate is fixedly connected to the upper end of the opening and closing device; a sliding groove is formed in the lower end face of the cover plate, a sliding rail is slidably connected in the sliding groove, and the lower end of the sliding rail is fixedly connected with the box body. Thecarbon emission checking data acquisition device is low in manufacturing cost, and can be protected only through simple operation.

Owner:湛江程新锂科技有限公司

Environment-friendly toothpaste for curing oral diseases

InactiveCN101536973AInhibition of re-spreadingAvoid spreadingCosmetic preparationsToilet preparationsOral diseaseDisease

An environment-friendly toothpaste for curing oral diseases comprises the following ingredients by weight percentage: 5-10 of pearl powder, 0.5-2.5 of turface, 3-5 of medical stone, 1.5 of bletilla striata polysaccharide, 1 of borneol, 20 of glycerol, 35 of calcium carbonate, 1.5 of sodium carboxymethyl cellulose, 1.5-2 of sodium dodecyl sulfate, 1 of essence, 0.05 of sodium benzoate and the balance of distilled water. The toothpaste can be used not only for curing oral diseases but also for achieving the purpose of protecting the environment.

Owner:胡宇鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com