Printed circuit board semi-finished product conveying and partition plate feeding integrated device

A technology for printed circuit boards and semi-finished products, which is applied in the directions of conveyors, printed circuits, conveyor objects, etc., can solve the problems of conveying deviation, affecting process efficiency, and the circuit board cannot enter the turning area, etc., and achieves an effective guide limit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the embodiments described in the present invention are some of the embodiments of the present invention, not all of them .

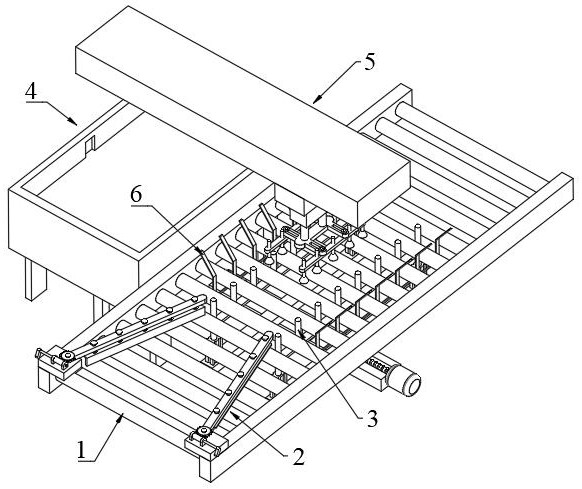

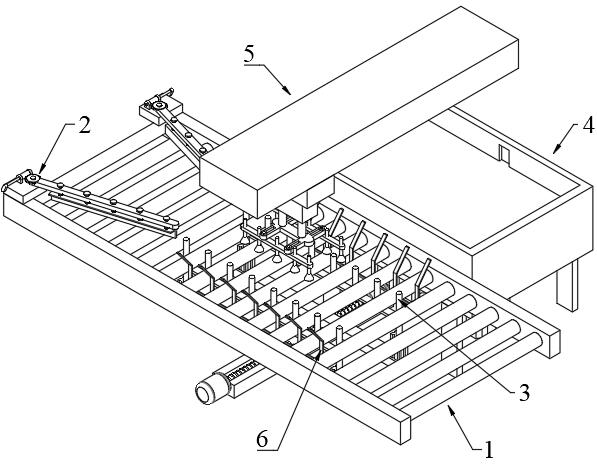

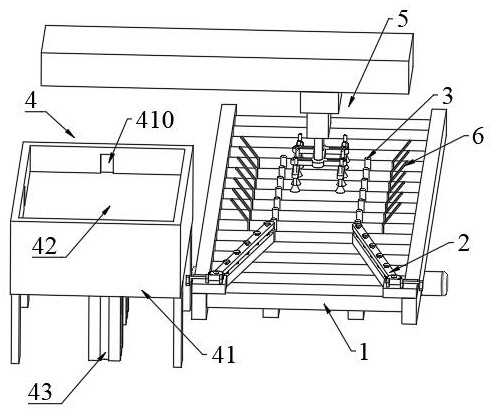

[0038] The embodiment of the present application provides an integrated device for transporting semi-finished printed circuit boards and feeding boards, which is applied to horizontally transport semi-finished printed circuit boards with metal lines on both sides, and undertakes the previous semi-finished product preparation process. And the next step is to undertake the turning mechanism, which turns the printed circuit board in the horizontal conveying state to the vertical state or the slightly inclined vertical state, so that the printed circuit board can be carried out in the vertical state or the slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com