Method for controlling repeated gear engagement in DCT (dual clutch transmission) synchronizer gear engaging process

A control method and transmission technology, applied in the direction of mechanical control device, transmission device control, control/adjustment system, etc., can solve problems such as inability to shift gears or shift shock, synchronous ring wear, unsuccessful gear shifting, etc., and achieve gear shifting Suppleness, impact avoidance, and more effective gear shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

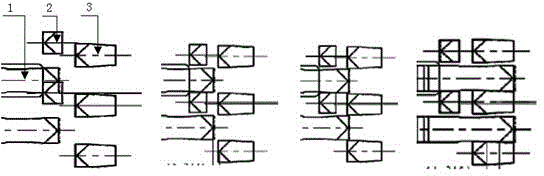

[0020] Such as figure 1 It is shown that the gear sleeve 1 of the present invention is engaged with the synchronous ring 2 under the push of the shift fork, and at the same time, after the synchronous ring is synchronized with the engaging teeth 3, the gear sleeve 1 is then engaged with the engaging teeth to complete the entire gear shift process.

[0021] Such as Figure 2A It shows that when the gear sleeve of the present invention is engaged with the synchronizing ring, the gear sleeve 1 and the synchronizing ring 2 are "tooth-to-teeth"; Figure 2B It is because when the tooth cover engages the engaging teeth, the tooth cover 1 and the engaging tooth 3 "tooth-to-teeth" situation occurs. The present invention analyzes and studies the strategy of repeatedly shifting gears according to the above two situations.

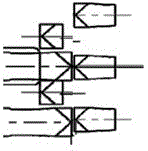

[0022] Such as image 3 Shown is a PID algorithm block diagram of the variation of the shift fork force value with the change of the fork position feedback value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com