Method for preparing micro-capsule by taking xanthan gum and gelatine as wall materials through complex coacervation method

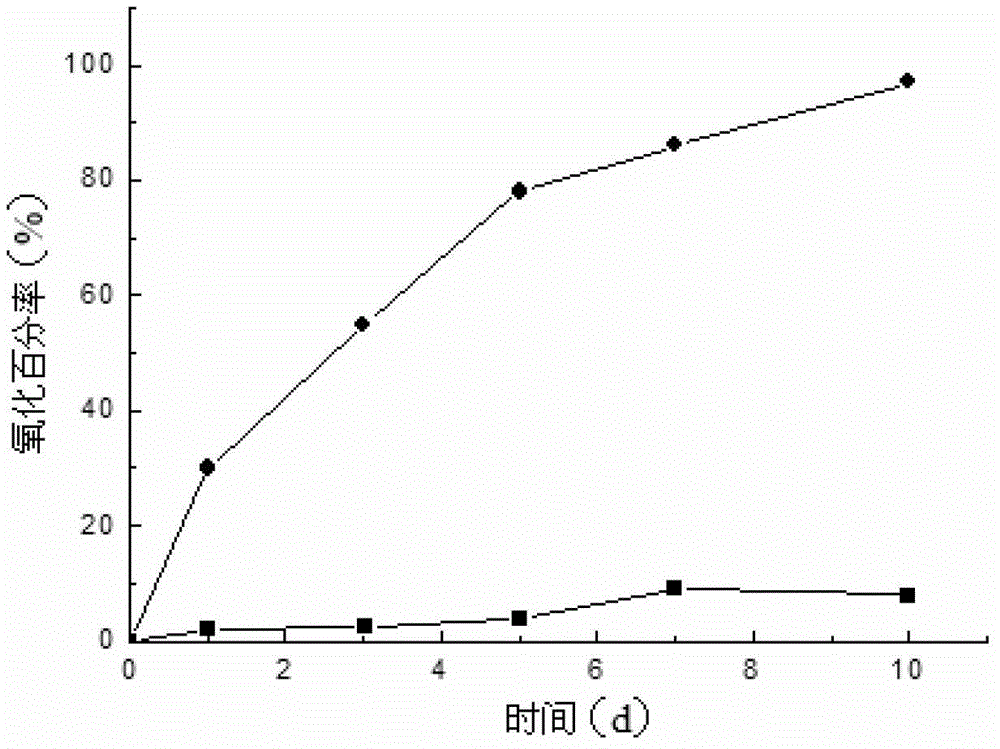

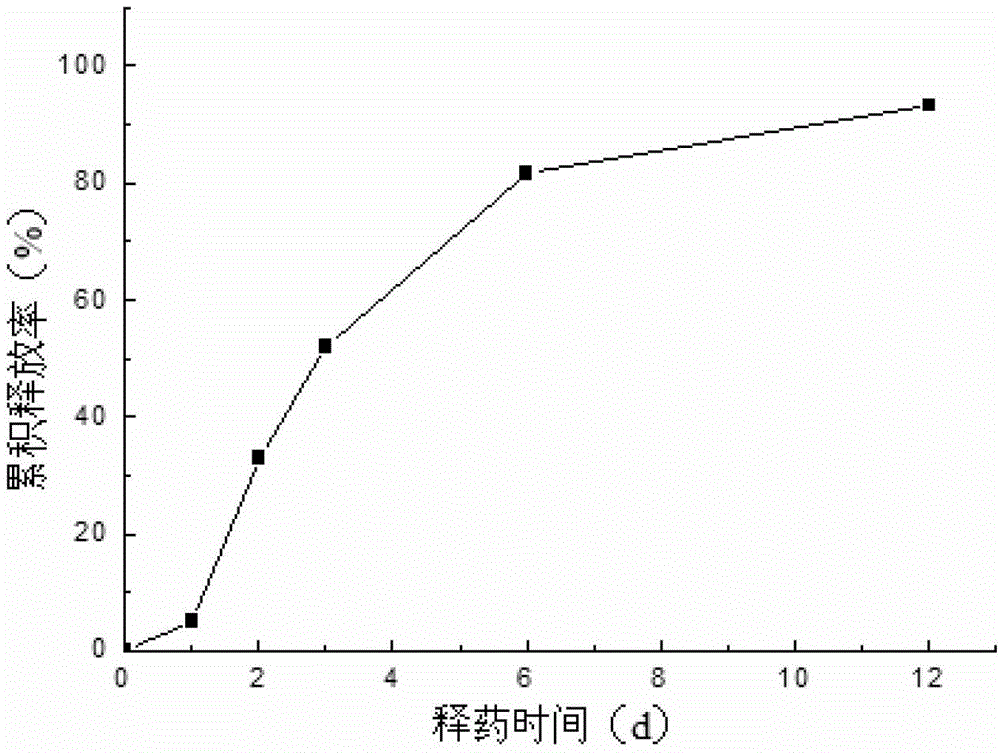

A technique of complex coacervation and xanthan gum, which is applied in the direction of microcapsules, capsule delivery, and pharmaceutical formulations, can solve the problems of large particle size and low encapsulation rate of microcapsules, and achieve narrow particle size distribution, cheap excipients, good slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: In this embodiment, a method for preparing microcapsules by using xanthan gum and gelatin as the wall material complex coacervation method comprises the following steps:

[0018] 1. Add gelatin to water, soak for 20-30 minutes, heat to dissolve, and obtain a gelatin solution with a concentration of 0.05g / mL-0.45g / mL, and let it stand for 6h-8h;

[0019] 2. Add xanthan gum into water, soak for 20min-30min, heat to dissolve, and obtain a xanthan gum solution with a concentration of 0.001g / mL-0.05g / mL, and let it stand for 6h-8h;

[0020] 3. Add the core material to the gelatin solution prepared in step 1, high shear 20s ~ 40s to obtain a stable O / W emulsion, then add the xanthan gum solution prepared in step 2 dropwise therein, at a temperature of 50 Under the condition of ~60°C, stir at constant temperature for 15min ~ 25min to obtain a mixed solution; wherein the ratio of the quality of gelatin in the gelatin solution described in step 3 to the ...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a gelatin solution with a concentration of 0.25 g / mL is obtained in Step 1, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: in step 2, a xanthan gum solution with a concentration of 0.01 g / mL is obtained, and other steps and parameters are the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com