Method for preparing magnetic mesoporous apatite microsphere material by utilizing hydrothermal method

A technology of mesoporous apatite and hydrothermal method, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of affecting drug sustained release performance and biodegradability, and the difficulty of magnetic hydroxyapatite surface morphology Control and other issues to achieve excellent drug sustained release performance, excellent biocompatibility and biological activity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of calcium chloride solution containing shell organic matter: Soak shell nacre in 1.0 mol / L HCl solution for 1 day. Filter with a Buchner funnel to filter out the shell organic matter that is insoluble in hydrochloric acid. Add 1.0 mol / L NaOH solution dropwise until the pH of the filtrate is 7.0, then dilute with deionized water until the concentration of calcium ions in the solution is 0.25 mol / L, to obtain the CaCl containing shell organic matter 2 solution.

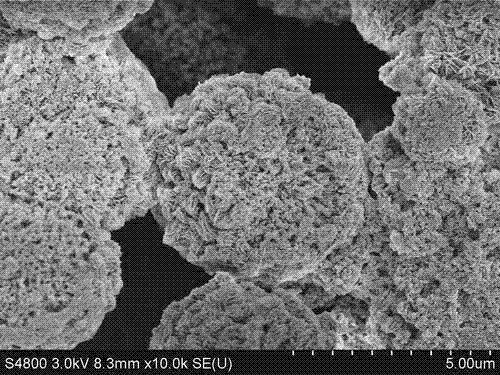

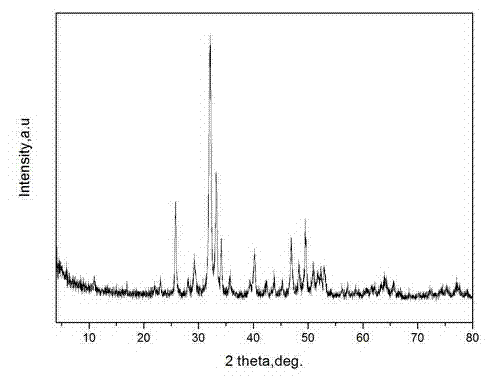

[0024] (2) Preparation of magnetic calcium carbonate microspheres: 0.55 g Fe 3 o 4 Magnetic nanoparticles (specific saturation magnetization 62.4emu / g, particle size 10-15nm) dispersed in 200 mL of 0.25 mol / L CaCl containing shell organic matter 2 solution, and then quickly poured 200 mL of 0.25 mol / L sodium carbonate solution to form a brown precipitate, and continued to stir for 1.5 h. After filtering, washing with deionized water several times, and drying in an oven at 80°C, magnetic calci...

Embodiment 2

[0032] Four kinds of magnetic mesoporous hydroxyapatite microspheres prepared in Example 1 were selected to carry out drug sustained-release experiments.

[0033] (1) Prepare PBS solution: weigh 8.00 g sodium chloride, 0.20 g potassium chloride, 2.98 g NaCl 2 HPO 4 12H 2 O, 0.52 g NaH 2 PO 4 2H 2 O was dissolved in distilled water and the volume was adjusted to 1000ml.

[0034] (2) Drug loading: 0.40 g vancomycin was weighed and dissolved in 20 ml phosphate buffer solution (PBS), and 0.40 g magnetic mesoporous hydroxyapatite microspheres were added to the above solution. Stir at 37 °C for 12 h at 150 r / min, centrifuge, and vacuum-dry the obtained precipitate at 50 °C to obtain drug-loaded magnetic mesoporous hydroxyapatite microspheres.

[0035] (3) Drug release from drug-loaded magnetic mesoporous hydroxyapatite microspheres: Weigh 0.04 g of drug-loaded magnetic mesoporous hydroxyapatite microspheres and wrap them in a semipermeable membrane dialysis bag with a dialysis...

Embodiment 3

[0038] (1) Preparation of calcium chloride solution containing shell organic matter: Soak shell nacre in 1.0 mol / L HCl solution for 1 day. Filter with a Buchner funnel to filter out the shell organic matter that is insoluble in inorganic acids. Add 1.0 mol / L NaOH solution dropwise until the pH of the filtrate is 7.0, then dilute with deionized water until the concentration of calcium ions in the solution is 0.10 mol / L, and finally obtain CaCl containing shell organic matter 2 solution.

[0039] (2) Preparation of magnetic calcium carbonate microspheres: 0.55 g Fe 3 o 4 Magnetic nanoparticles, (specific saturation magnetization 62.4emu / g, particle size 10-15nm) dispersed in 200 mL of 0.10 mol / L CaCl containing shell organic matter 2 solution, and then quickly poured 200 mL of sodium carbonate solution with a concentration of 0.10 mol / L to form a brown precipitate, and continued to stir for 1.5 h. After filtering, washing with deionized water several times, and drying in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com