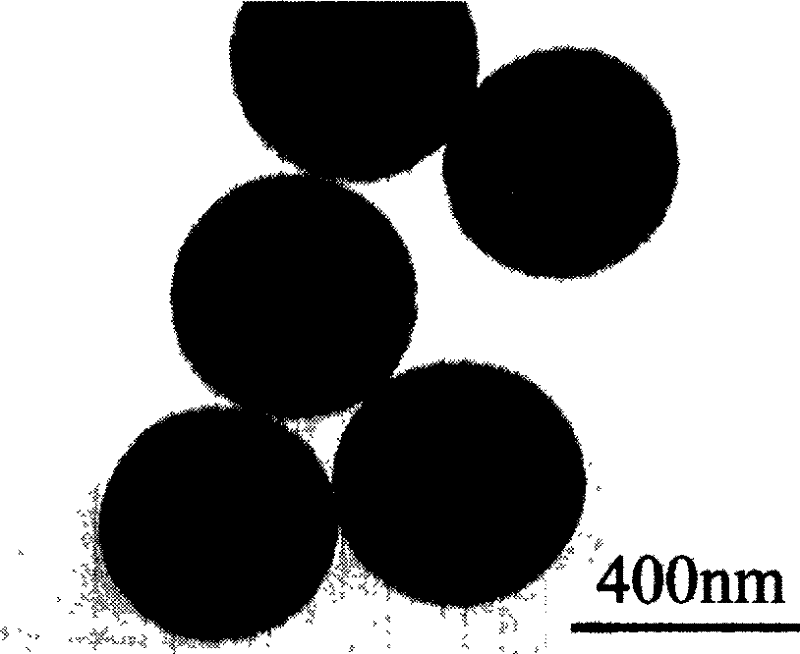

Hollow silicon dioxide sub-micron sphere with inner core and its preparation method and use

A technology of silica and spherical silica, applied in the field of nanomaterials, can solve the problems of cumbersome process, difficult to achieve uniformity, high cost, etc., and achieve broad application prospects and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Prepare hybrid silica submicron spheres by sol-gel method.

[0026] Prepare respectively 100 parts by volume, 20 parts by volume and 5 parts by volume of aqueous ammonia, ethyl tetrasilicate and trimethoxysilylpropylethylenediamine ethanol solution; The molar concentrations are 0.05mol / L, 0.5mol / L and 7×10 -4 mol / L.

[0027] Add 5 parts by volume of ethyl orthosilicate ethanol solution dropwise to the mixed solution of ammonia water and ethanol stirred by magnetic force, carry out hydrolysis reaction for 10 minutes, after obtaining the spherical silica inner core, add the above-mentioned trimethoxysilylpropyl ethylenediamine ethanol Solution and ethyl tetrasilicate ethanol solution are added to the above reaction mixture solution by double injection, and the reaction is continued on the spherical silica inner core to form an organic-inorganic hybrid silica intermediate layer until all the silicate alcohol solution is added dropwise to the reaction mixture. In ...

Embodiment 2

[0033] Step 1: Prepare hybrid silica submicron spheres by sol-gel method.

[0034] Prepare 160 parts by volume of aqueous ammonia mixed solution with the mixed solvent of methanol and acetonitrile, prepare respectively 30 parts by volume and 10 parts by volume of methanol solution of methyl orthosilicate and trimethoxysilylpropylethylenediamine; ammoniacal liquor, methyl orthosilicate and The molar concentrations of trimethoxysilylpropylethylenediamine are 1.5mol / L, 0.02mol / L and 1×10 -3 mol / L.

[0035] Add 15 parts by volume of methyl orthosilicate methanol solution dropwise to a magnetically stirred mixed solution of ammonia, methanol and acetonitrile, and perform a hydrolysis reaction for 5 minutes to obtain a spherical silica core; subsequently, the above-mentioned trimethoxysilane Propylethylenediamine methanol solution and methyl orthosilicate methanol solution are added to the above reaction mixture solution by double injection, and the reaction is continued on the sph...

Embodiment 3

[0041] Step 1: Prepare hybrid silica submicron spheres by sol-gel method.

[0042] Prepare 200 parts by volume of ammonia water mixed solution with a mixed solution of acetone and propanol, prepare 40 parts by volume of propanol mixed solution of ethyl orthosilicate and propyl orthosilicate and 20 parts by volume of propanol solution of γ-aminopropyltrimethoxysilane Parts by volume; the molar concentrations of ammonia, ethyl orthosilicate and propyl orthosilicate, and γ-aminopropyltrimethoxysilane are respectively 6.5mol / L, 1.5mol / L and 1.5×10 -3 mol / L.

[0043] Add 18 parts by volume of a propanol mixed solution of ethyl orthosilicate and propyl orthosilicate dropwise to a magnetically stirred mixed solution of ammonia, acetone and propanol, and perform a hydrolysis reaction for 25 minutes to obtain spherical silica After the inner core, double-inject the above-mentioned γ-aminopropyltrimethoxysilane propanol solution and the propanol mixed solution of ethyl orthosilicate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com