Patents

Literature

35 results about "Suberedamine B" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-base oil-displacing agent composition of bi-alkyl carboxylate and its use

InactiveCN101029225AReduce interfacial tensionSimple preparation processDrilling compositionEthylenediamineSuberedamine B

A dual alkyl carboxylate alkali-free oil-displacing agent composition and its use are disclosed. It consists of dual alkyl carboxylate and C14-18 mixed carboxylate 0.01-0.1wt%, C14-18 mixed carboxylic polyethenoxy ether, HPAM and water. The process is carried out by taking organic acid and sulfoxide chloride as raw materials, acyl chloride synthesizing, reacting ethylenediamine with sodium chloroacetate to synthesize intermediate sodium EDDA, and reacting it with acyl chloride to synthesize the final product. It has excellent oil-displacing effect.

Owner:SHANDONG UNIV

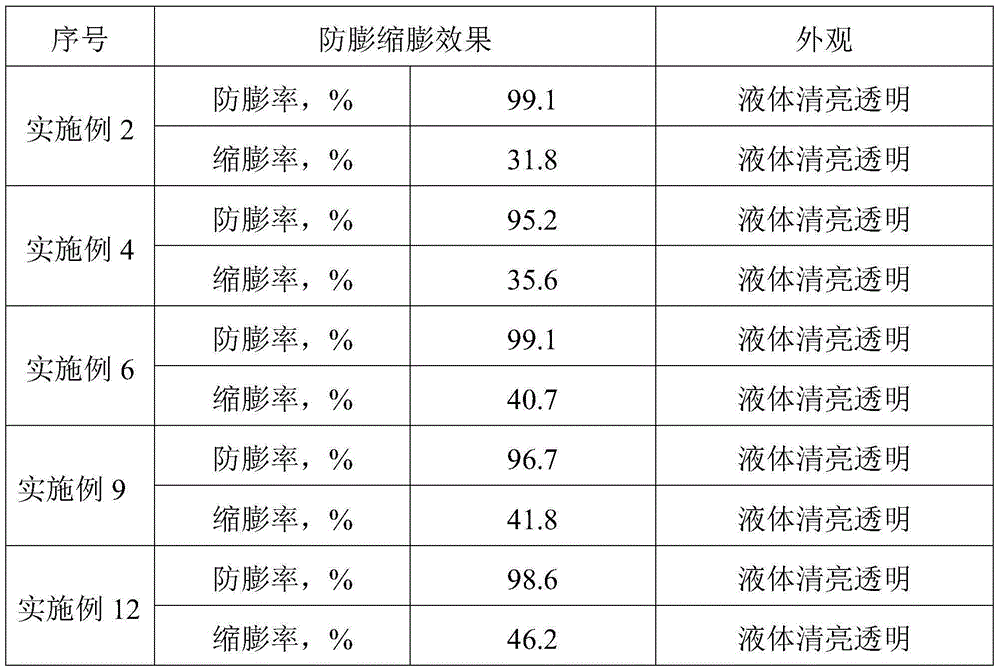

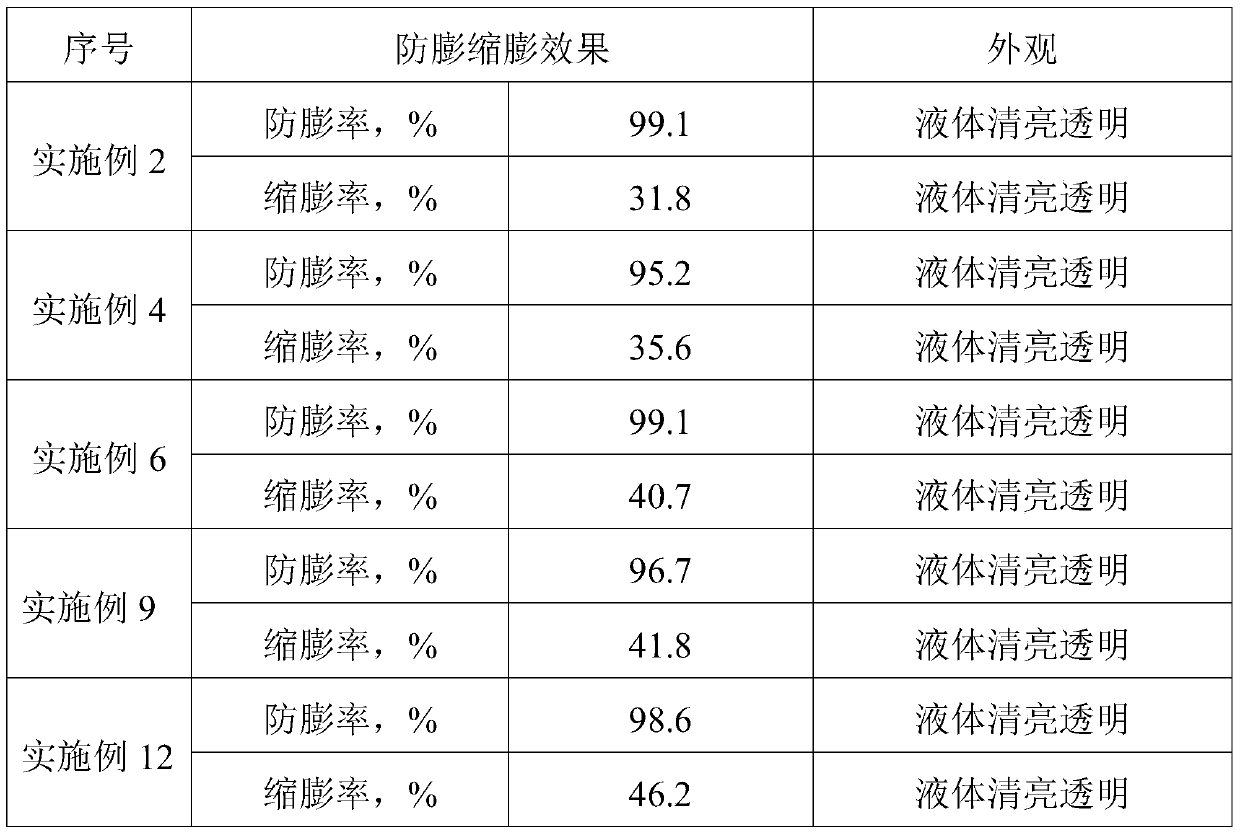

Anti-swelling shrinking agent

ActiveCN105154034AGood anti-expansion and contraction effectGood anti-expansionDrilling compositionSuberedamine BEthylene diamine

The invention discloses an anti-swelling shrinking agent which is an ethylene diamine diacetate solution. This solution avoids the adverse factor that traditionally bridge blinding occurs in capturing of large cations, also overcomes the adverse factor that small cations are low in charge density and short in effective life, has a good clay stabilizing function and is also well capable of shrinking swelled clay. The anti-swelling shrinking agent composited by adding magnesium chloride and / or amino trimethylene phosphonic acid has better anti-swelling and shrinking effects. A liquid of the anti-swelling shrinking agent is clear and crystal, has anti-swelling agent higher than 95% and shrinking rate higher than 35%, and is applicable to preventing and solving the clay swelling problem caused in oilfield development.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

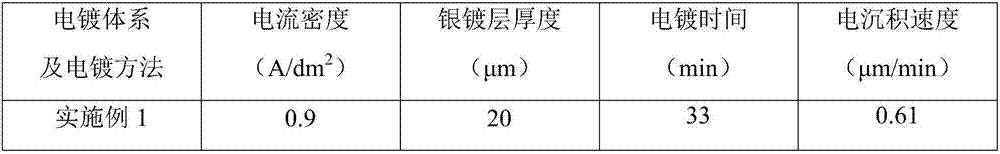

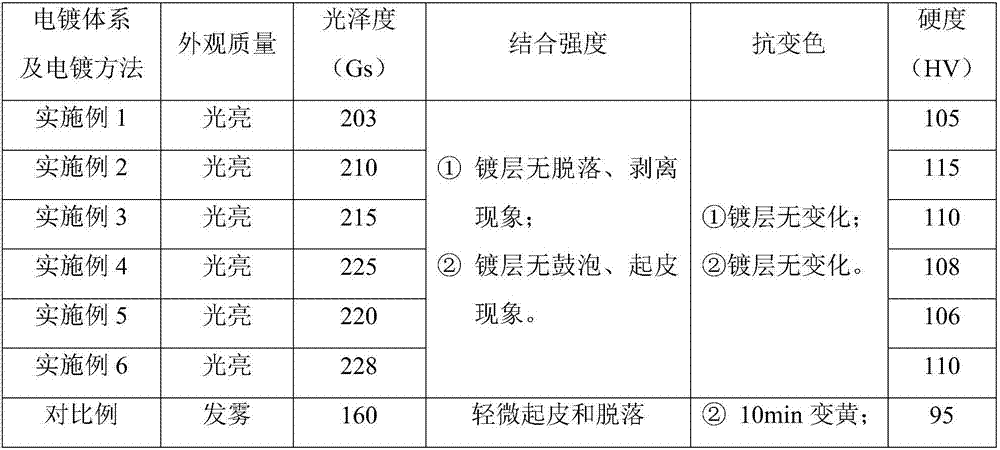

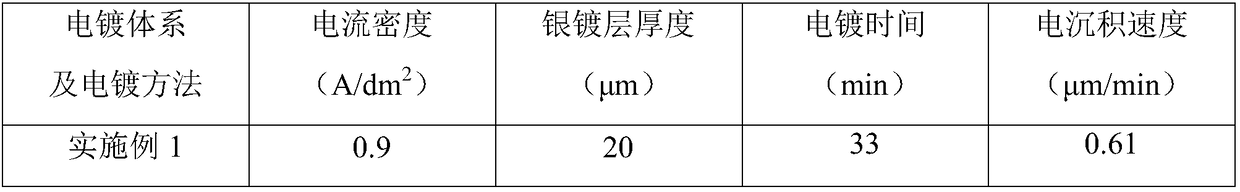

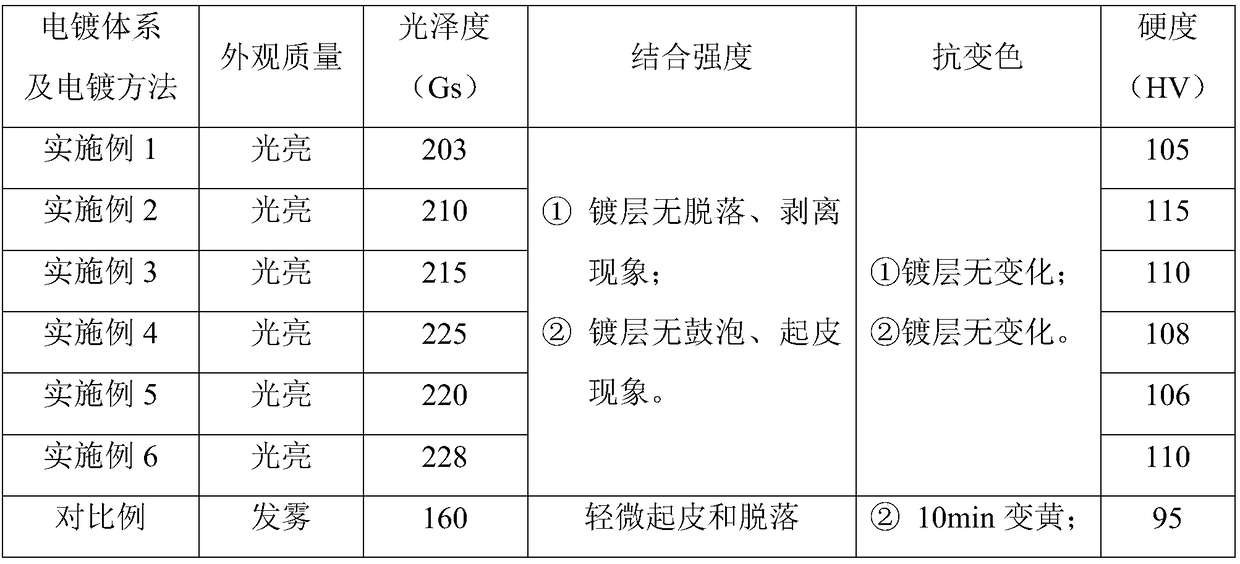

Alkaline cyanide-free silver plating electroplating liquid and silver plating method

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

Production process of ethylene diamine tetraacetic acid and its salt with hydrocyanic acid synthesis gas as raw material

InactiveCN1388113AImprove protectionHigh reaction yieldOrganic compound preparationAmino-carboxyl compound preparationSuberedamine BAcetic acid

The present invention is the production process of ethylene diamine tetraacetic acid and its salt with coarse synthetic hydrocyanic acid gas as material. The technological process includes the steps of: mixing and reacting formaldehyde and ethylene diamine inside a reactor to synthesize aldehyde-amine mixture liquid; introducing synthetic hydrocyanic acid gas and reacting with aldehyde-amine mixture to produce intermediate product ethylene diamine diethyl cyanamide; introducing formaldehyde, acid and synthetic hydrocyanic acid gas to produce ethylene diamine tetraethyl cyanamide simultaneously; hydrolyzing ethylene diamine tetraethyl cyanamide with acid or alkali aqueous solution to produce ethylene diamine tetraacetic salt; and adding acid to regulate pH to 1-5 to obtain ethylene diamine tetraacetic acid and its salt.

Owner:四川省天然气化工研究院

Plating solution formula and electroplating method for electroplating thick palladium on stainless steel

The invention discloses a plating solution formula and an electroplating method for electroplating thick palladium on stainless steel. According to the plating solution formula, a plating solution comprises 20-30 g / L of tetraammine dichloropalladium, 80-100 g / L of ammonium chloride, 2-4 g / L of sodium ethylenediamine diacetate and 8-12 g / L of alanine. According to the plating solution formula and the electroplating method for electroplating the thick palladium on the stainless steel, the white appearance of the stainless steel is maintained by electroplating the thick palladium on the stainless steel. Nickel plating and copper plating are carried out before electroplating of the stainless steel, so that the performance of a thick plated palladium layer on the stainless steel is improved, the thick plated palladium layer is not prone to generation of cracks, and the palladium plating solution is stable.

Owner:佛山市宝惠不锈钢有限公司

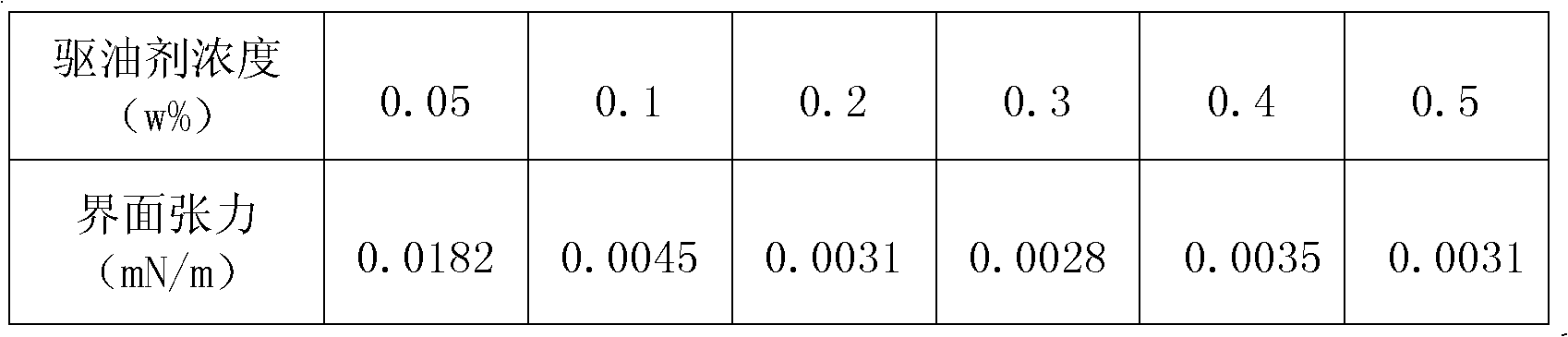

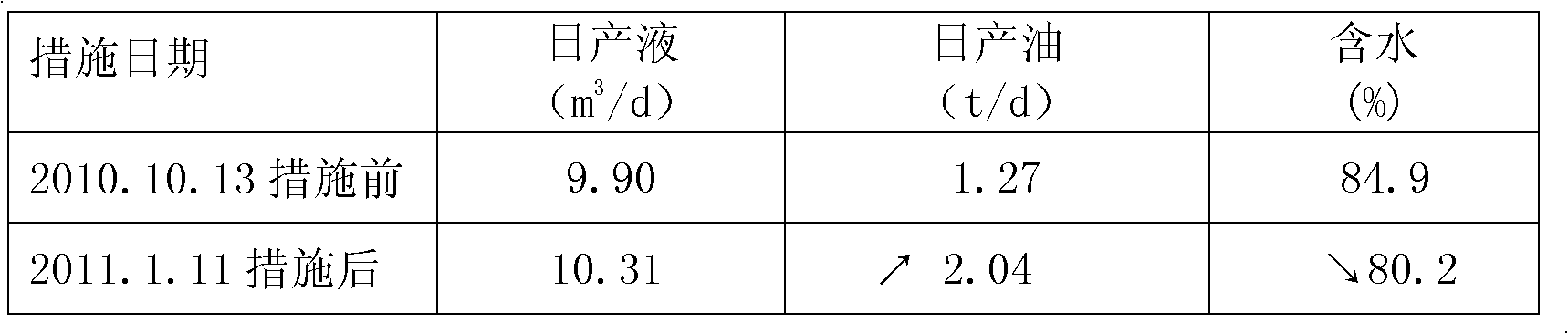

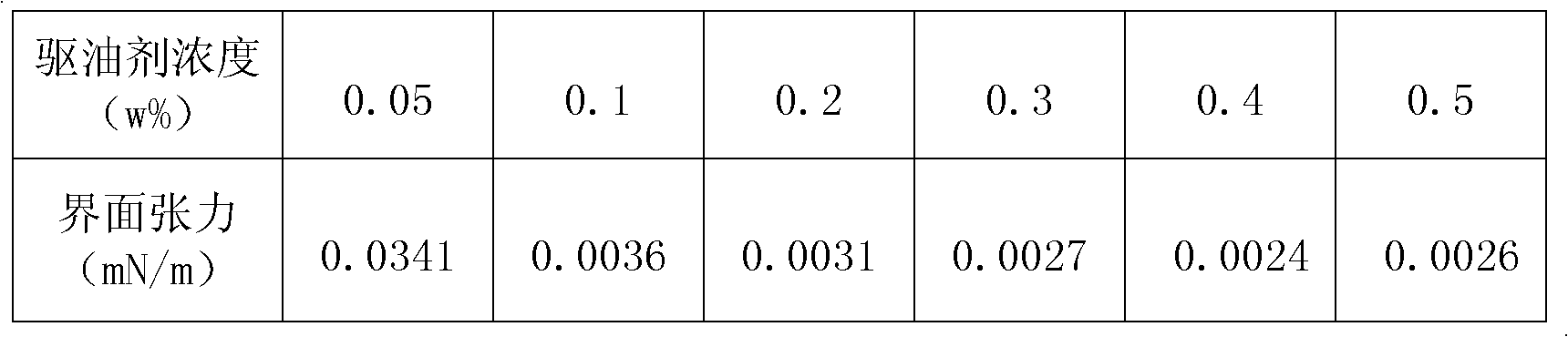

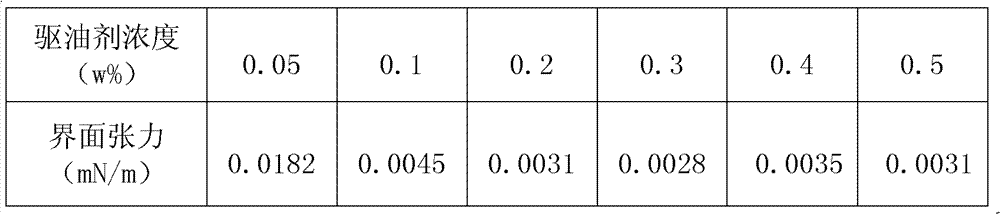

Surfactant flooding system and application thereof

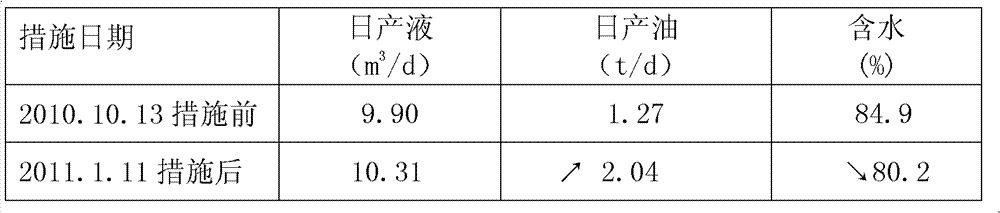

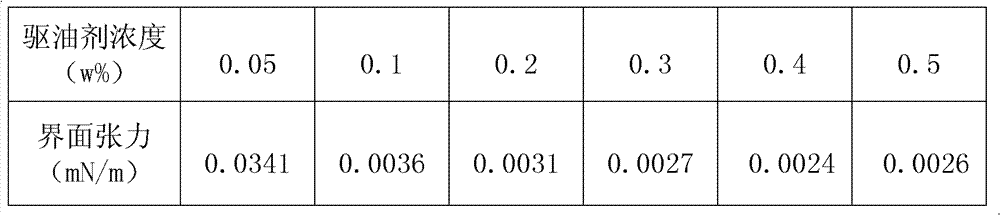

ActiveCN103045221AReduce interfacial tensionGood emulsificationFluid removalDrilling compositionSuberedamine BEthylenediamine

The invention relates to a surfactant flooding system and application thereof. The surfactant flooding system comprises the following materials in percentage by weight: 1-4% of sodium petroleum sulfonate, 0.5-1% of isomeric alcohol ethoxylate, 0.5-1% of N,N'-dilauroyl-ethylenediamine-sodium diethanesulfonate, 1-4% of organic cosolvent isopropanol and the balance of water, and the sum of the weight percents of all the materials is 100%. In the wide concentration range (0.1-0.5%) of the surfactant, the oil-water interfacial tension can be reduced to an ultralow value at such order of magnitude as 10<-3> mN / m, the field experiment effect is remarkable, and the system is resistant to temperature (80 DEG C) and can be slightly influenced by the change of temperature.

Owner:PETROCHINA CO LTD

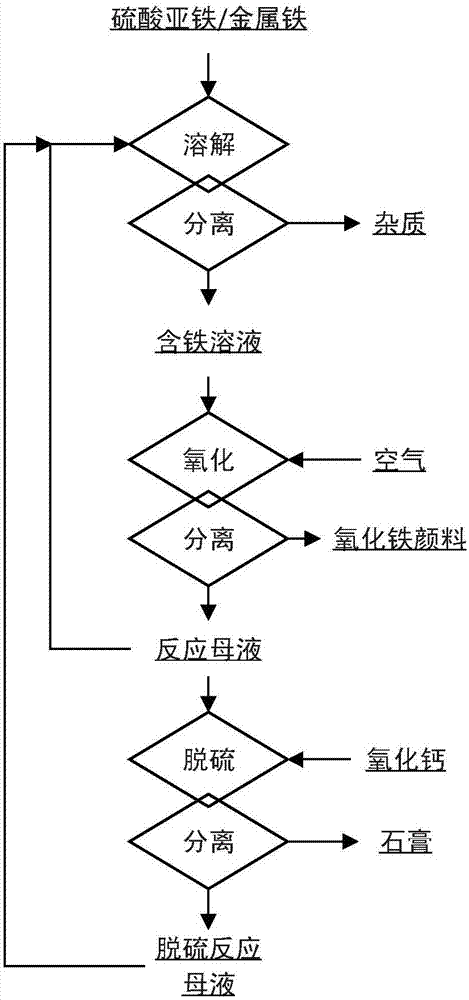

Iron oxide pigment and its production method

The invention discloses an iron oxide pigment and its production method. The method includes steps of 1) preparing reaction fluid, wherein the reaction fluid contains complexing agent and inert gas and its pH value is 7.0-13.0; adding scrap iron or ferrous compound or ferric ion compound therein; after dissolving, separating impurities to obtain iron solution; 2), charging oxygen gas in the iron solution so that the ferric ion in the iron solution is oxidized to be iron oxide yellow, iron oxide red or iron oxide black sediment; separating to obtain iron oxide pigment and reaction mother liquor, wherein the complexing agent is one or two of methylamine, ethylamine, ethylenediamine, propylene amide, ethanolamine, imidazole, diethylenetriamine, triethylenetetramine, ethylenediamine tetraacetic acid, ethylene diamine diacetate, nitrilotriacetic acid, glutamic acid, valine, histidine, proline, aspartic acid, alanine, serine, phenylalanine, arginine, threonine, glycine, lysine, asparaginate and glutamine.

Owner:北京中金瑞丰环保科技有限公司

Aloe beverage

The aloe beverage contains aloe gel juice 35-45 wt%, cane sugar 8-15 wt%, citric acid 0.05-0.1 wt%, malic acid 0.05-0.1 wt%, isoascorbic acid 0.1-0.2 wt%, sorbic alcohol 0.1-0.2 wt%, sodium ethylene diamine diacetate 0.05-0.1 wt%, butylated hydroxytoluene 0.01-0.05 wt%, ethanol 0.2-1 wt%, pure water 40-50 wt% and cellulase 0.01-0.05 wt% compounded scientifically. The beverage of the present invention contains rich aloe nutrients, has special aloe flavor and natural aloe color.

Owner:湖南金正方生物科技有限公司

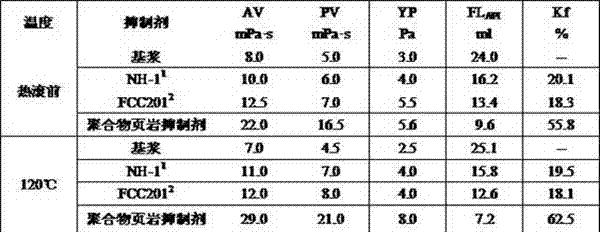

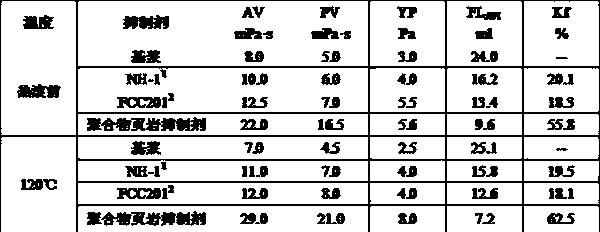

Preparation method of polymer shale inhibitor for drilling fluid

ActiveCN107488247AImprove scroll recoveryEasy accessDrilling compositionEthylenediamineSuberedamine B

The invention discloses a preparation method of a polymer shale inhibitor for a drilling fluid. The polymer shale inhibitor is prepared from acrylamide, acrylic acid, potassium hydroxide and dimethyldiallylammonium chloride through an inverse emulsion polymerization technology, and optimum synthesis conditions are as follows: a weight part ratio of the acrylamide monomer to the acrylic acid monomer to the dimethyldiallylammonium chloride monomer is (70-80):(70-80):(15-75), the three monomers are processed to prepare an aqueous phase with the pH value being 10, 10 parts by weight of emulsifiers Sp-80 and T-60 are added to emulsify and disperse the aqueous phase in 100 parts by weight of white oil, and 1-3 parts of a stabilizer N,N'-dilauroyl ethylenediamine diethanesulfonate, the reaction temperature is 30-40 DEG C, the reaction time is 8 h, an oxidation / reduction initiator ratio of n(potassium persulfate):n(sodium hydrogen sulfite) is 1:1, and the weight part number of the initiator is 4. The product can be adsorbed on the surface of clay to form a semi-permeable membrane, has a strong coating effect, can effectively encase rock debris to weaken the hydration and dispersion effect, can compress a double electrode layer to prevent the hydration swelling of the clay, and has a prominent inhibition effect.

Owner:DAQING BEIHUA CHEM PLANT

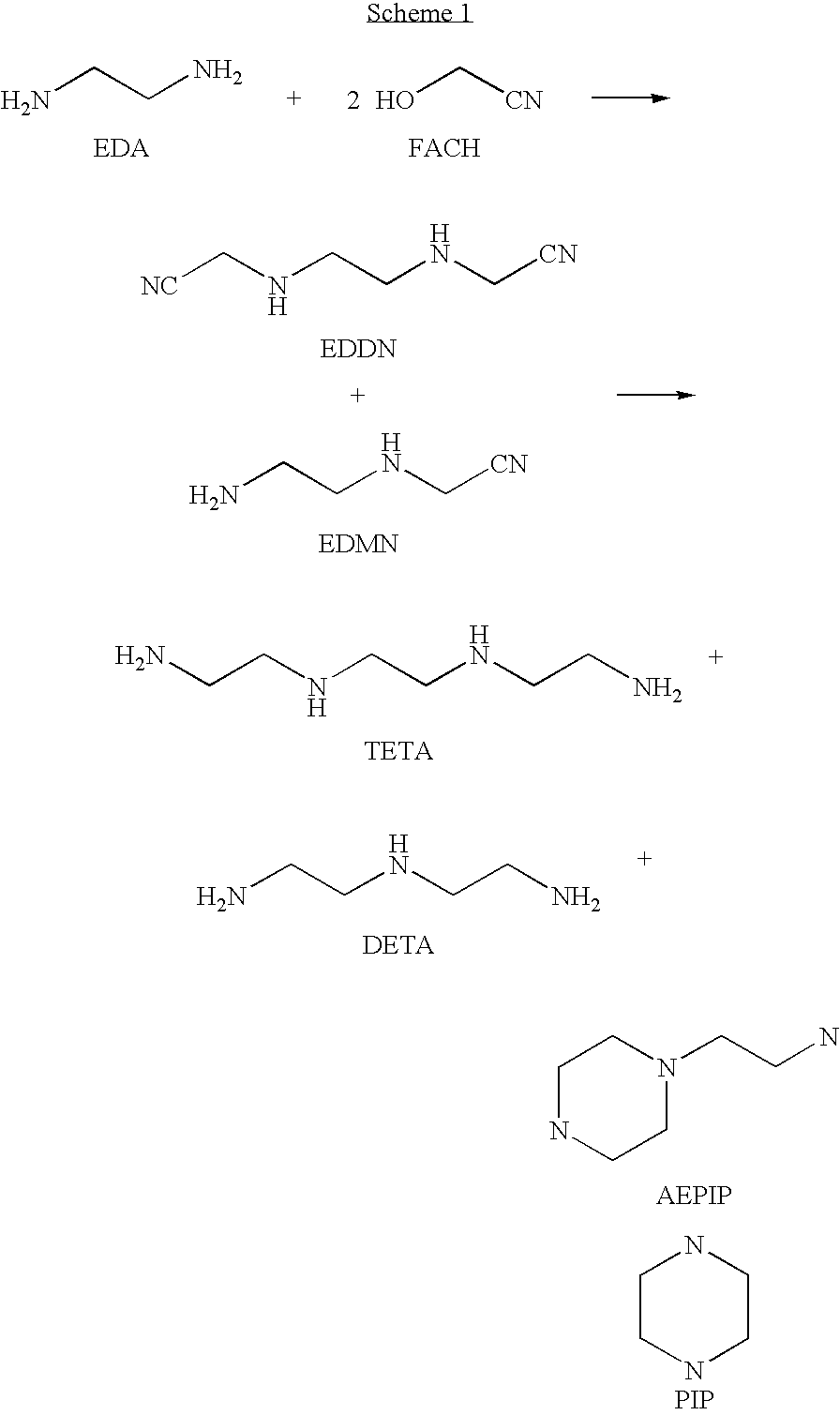

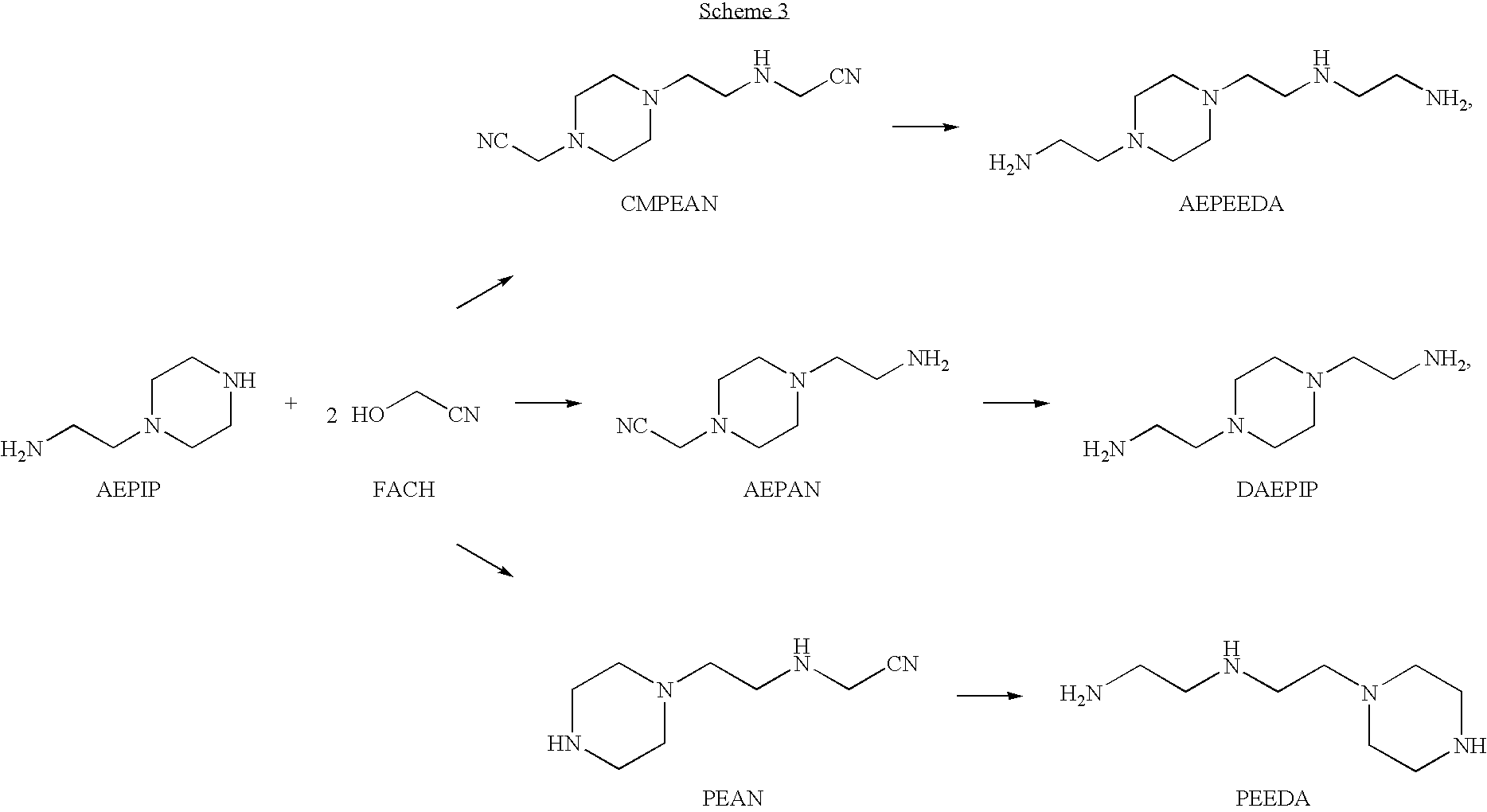

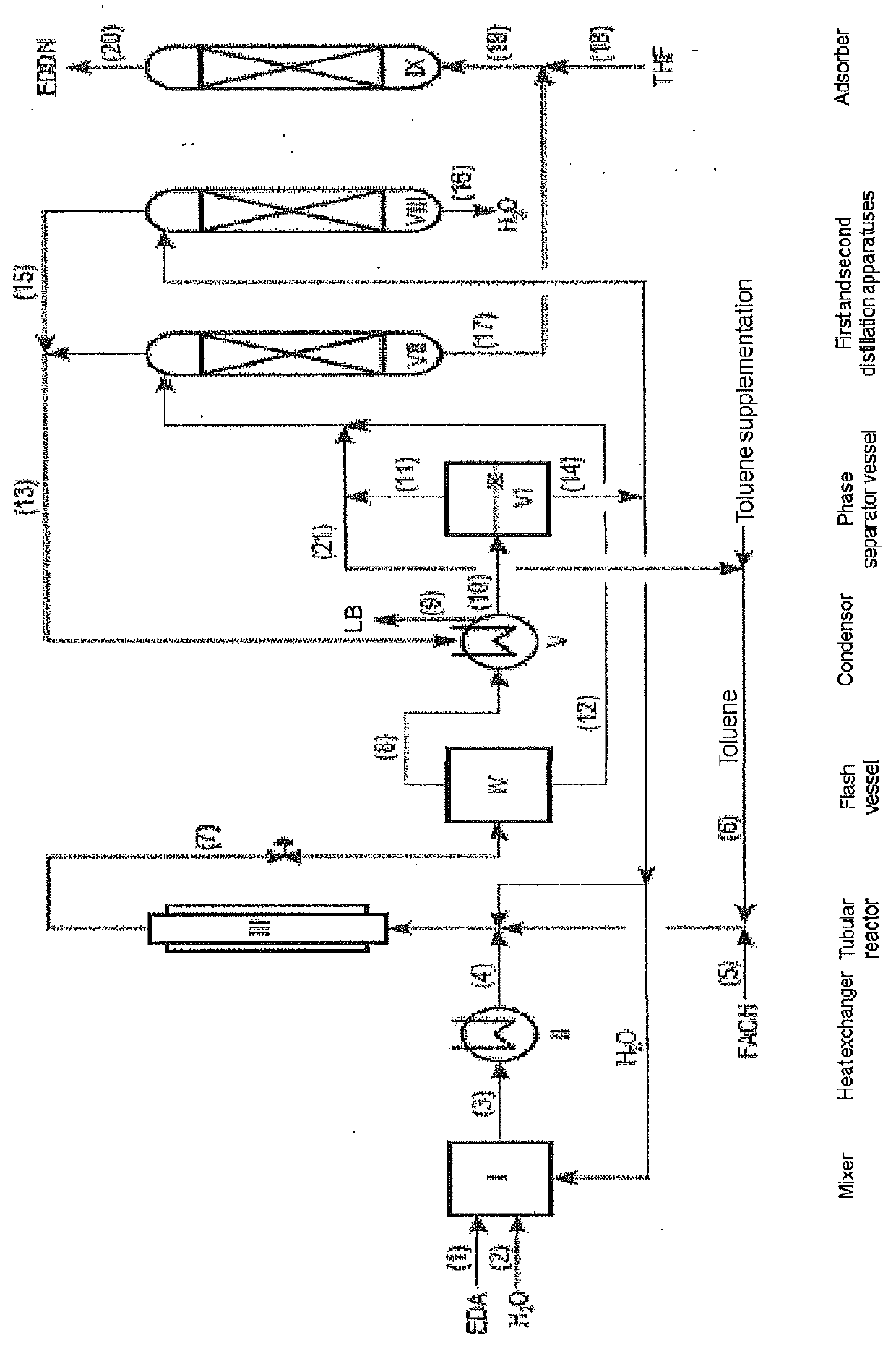

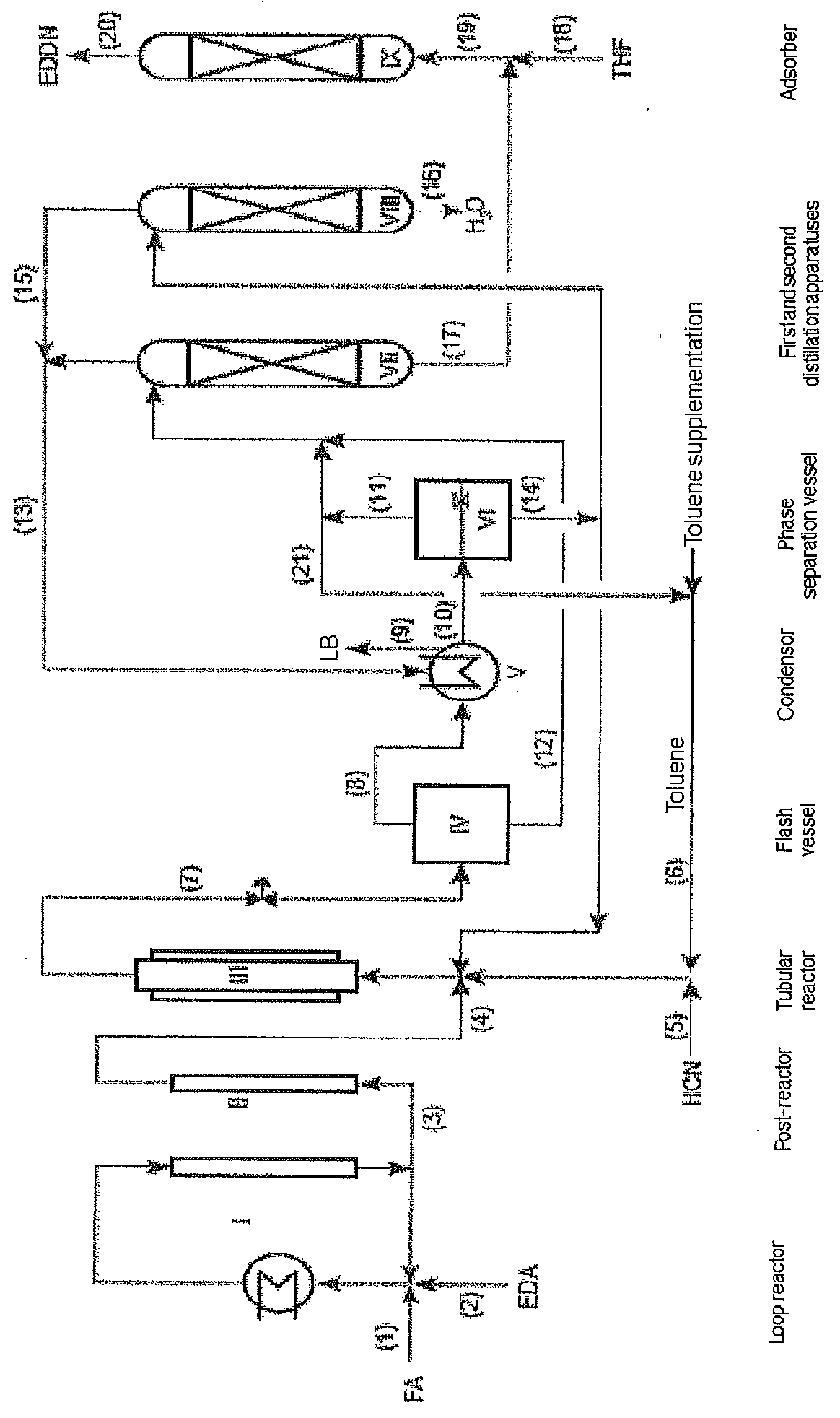

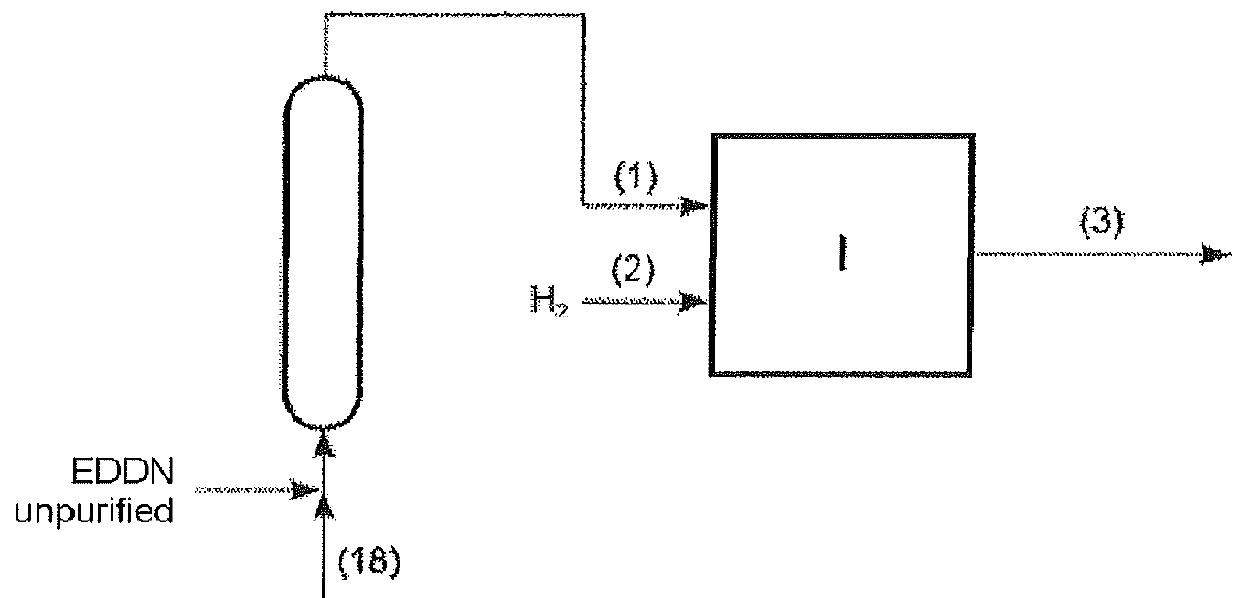

Method for producing TETA by means of EDDN

ActiveUS8299249B2Simple and inexpensiveSimple and inexpensive processCarboxylic acid nitrile preparationOrganic compound preparationEthylenediamineSuberedamine B

The invention relates to a process for preparing triethylenetetramine (TETA), which, comprises the following steps:a) reaction of ethylenediamine (EDA) with formaldehyde and hydrocyanic acid (HCN) in a molar ratio of EDA to formaldehyde to HCN of from 1:1.5:1.5 to 1:2:2 to give ethylenediaminediacetonitrile (EDDN),b) hydrogenation of the EDDN obtained in step a) in the presence of a catalyst and a solvent.

Owner:BASF AG

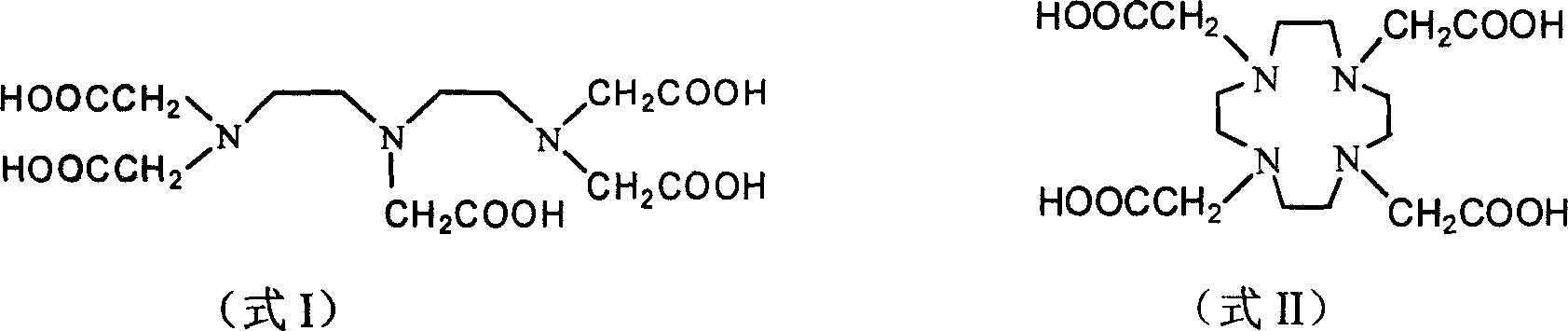

MRI molecular image probe and its preparing method

InactiveCN100998506ASmall molecular weightImprove biological performanceMagnetic property measurementsDiagnostic recording/measuringSuberedamine BBiological body

Owner:PEOPLES HOSPITAL PEKING UNIV

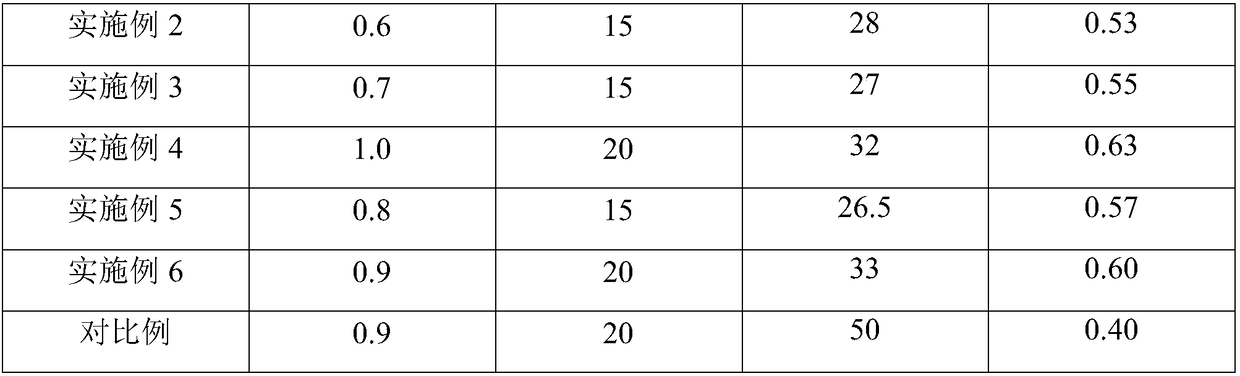

Preparation method of asphalt release agent

InactiveCN102942499ALong-lastingLow costOrganic compound preparationAmino-carboxyl compound preparationWater bathsSuberedamine B

The preparation method of an asphalt release agent of the present invention prepares a long-lasting environmental-friendly asphalt release agent through an ice water bath reaction of chloroacetic acid and ethylenediamine in an ethanol system under a certain process condition. The asphalt release agent is a associated liquid system of a Bola-type nitrogen-containing surface active agent of ethylenediamine diacetic acid and ethanol, can form a layer of non-migrating type micron grade film on a mold surface, and can play a corrosion preventive role on a metallic mold, and can naturally alienate the film surface through the interface interaction on encountering lyophobic asphalt, so as to achieve the effect of demolding. The asphalt release agent is not only able to solve the problems of asphalt demolding difficulties, asphalt use performance affected by the releasing agent, and high migration rate of the release agent after demolding, but has long-lasting and environment-friendly excellent performances. The asphalt release agent is innovative in the preparation method, simple in process and low in cost, and can be applied to the fields of processing, transportation, building materials, and water conservancy.

Owner:SHAANXI NORMAL UNIV

A kind of alkaline cyanide-free silver-plating electroplating solution and silver-plating method

InactiveCN107313084BImprove current efficiencyImprove electroplating production efficiencySuberedamine BEthylenediamine

The invention relates to alkaline cyanide-free silver plating electroplating liquid and a silver plating method. The electroplating liquid is composed of the following components including 20 g / L-50 g / L of silver nitrate, 40 g / L-100 g / L of 5,5-dimethyl hydantoin, 70 g / L-100 g / L of potassium pyrophosphate, 0.8 g / L-1.2 g / L of 3,3'-dithiobis-1-propanesulfonic acid disodium salt, 0.10 g / L-0.15 g / L of benzotriazole, 10 mg / L-15 mg / L of N,N'-bi-oleoyl-Ethylenediamine-Sodium Diethyl sulfonate, 0.10 g / L-0.30 g / L of polyethylene glycol and the balance water, wherein due to a pH adjusting agent, the pH value of the system ranges from 8 to 12. By means of the alkaline cyanide-free silver plating electroplating liquid, all the components are matched and work collaboratively, stability is good, the copper replacement resisting performance is high, and the scattering capability of the plating liquid is high; crystal grains of a silver plated layer are fine, the crystal grains are densely and neatly arranged, the surface is flat and bright, glossiness is good, and the color changing resisting capability is high; and the hardness of the plated layer is high, the combining force with a base body is high, and the alkaline cyanide-free silver plating electroplating liquid is suitable for application and popularization.

Owner:佛山市南博旺环保科技有限公司

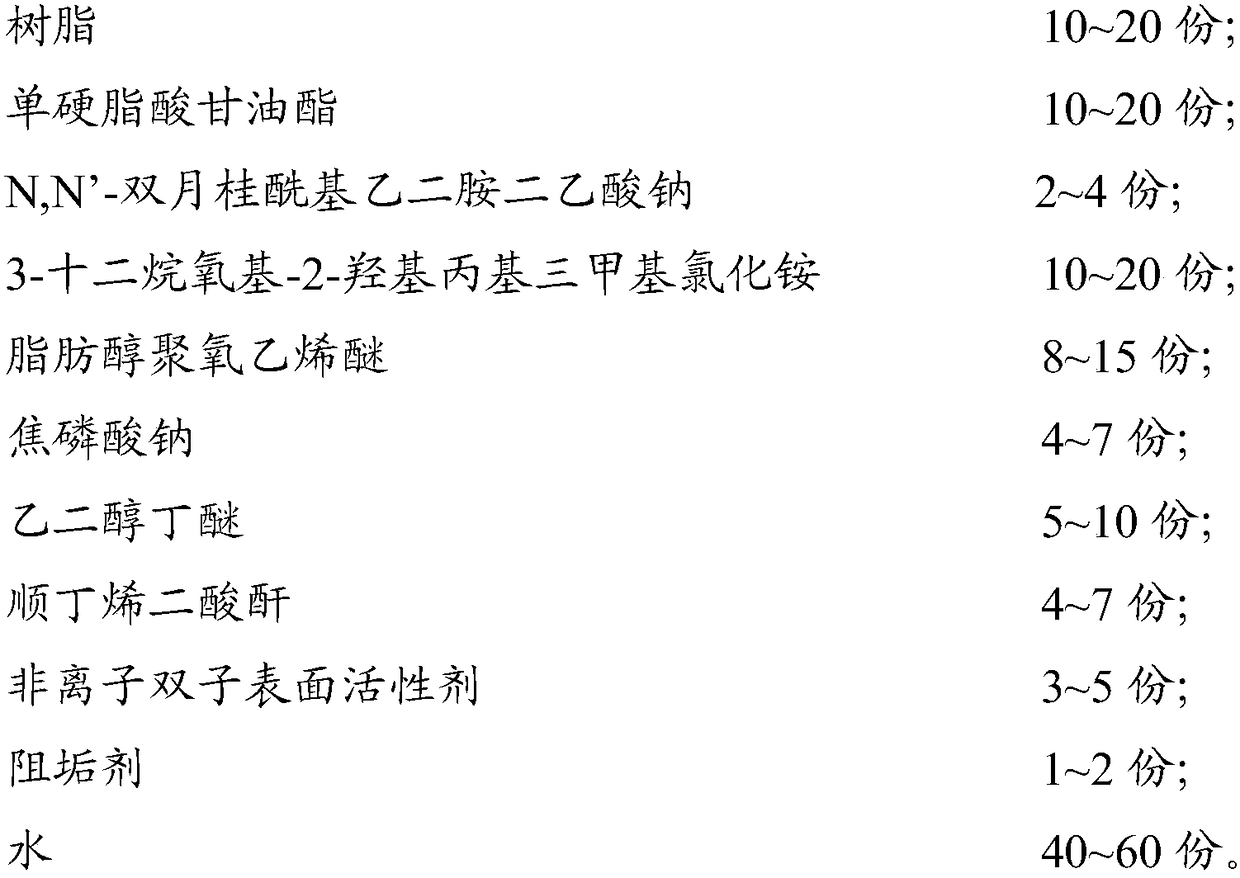

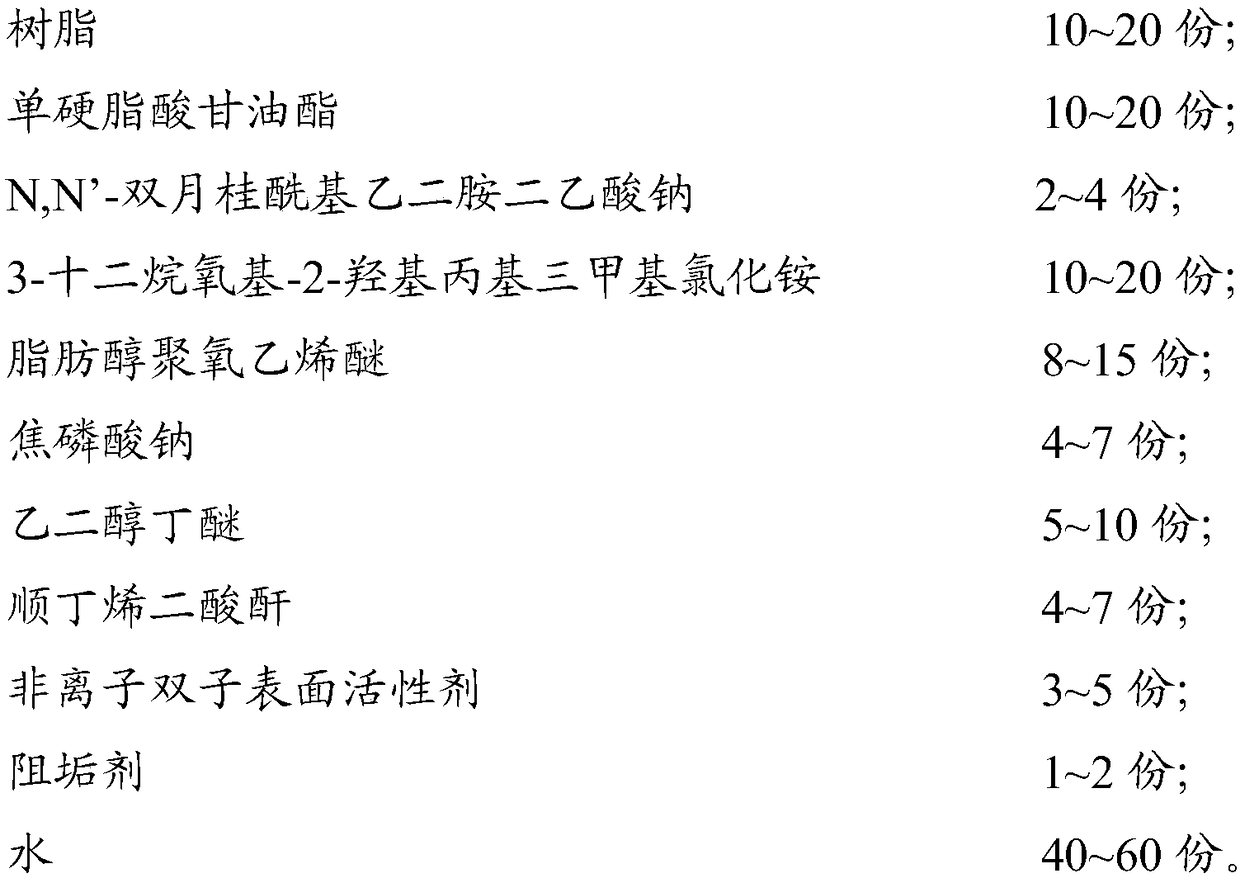

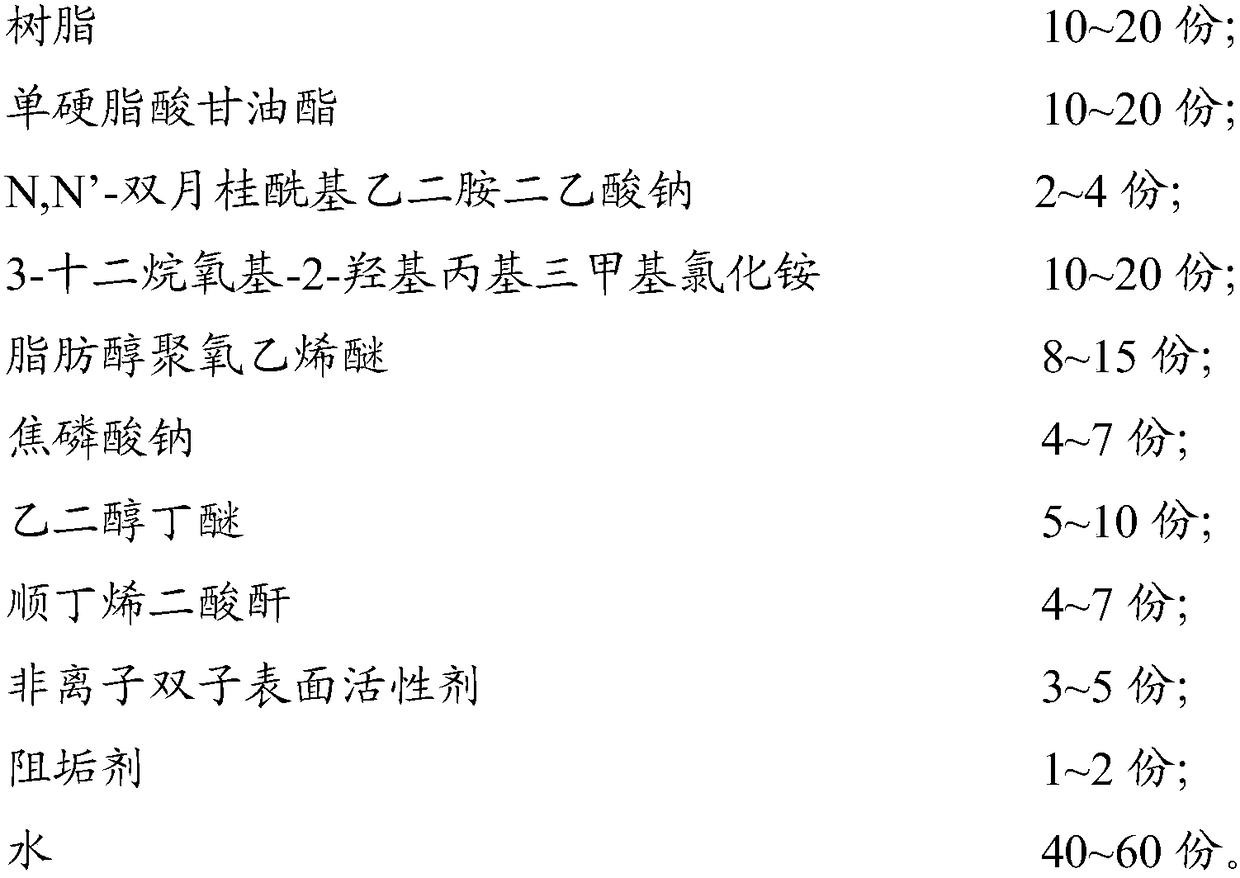

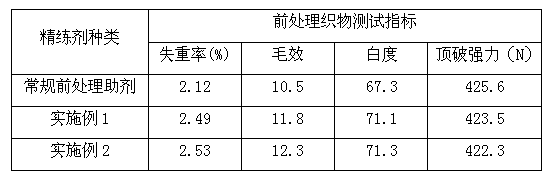

Environment-friendly paraffin remover and inhibitor used for oil field and oil well and preparation method thereof

ActiveCN108997992AImprove securityNo corrosionCleaning apparatusDrilling compositionSuberedamine BPyrophosphate

The invention discloses an environment-friendly paraffin remover and inhibitor used for an oil field and an oil well and a preparation method thereof, wherein the paraffin remover and inhibitor, having high paraffin removal and inhibition efficiency, is prepared from: resin, glyceryl monostearate, N,N'-bislauroylethanediamine sodium diacetate, 3-dodecyloxy-2-hydroxypropyltrimethyl ammonium chloride, fatty alcohol-polyoxyethylene ether, sodium pyrophosphate, ethylene glycol butyl ether, maleic anhydride, a nonionic gemini surfactant, a scale inhibitor and water. The paraffin remover and inhibitor is free of volatilization of irritating odors, is safe to human body and environment, is free of corrosion on equipment, and has great safety.

Owner:沧州中润化学助剂有限公司

Preparations for treating mastitis of cow and preparation thereof

InactiveCN101209343AInhibitory activitySlow degradationPeptide/protein ingredientsSexual disorderSuberedamine BVitamin C

The invention relates to a preparation for the treatment of dairy cow mastitis and the preparation method thereof, the preparation is a water or physiological saline solution containing nisin, vitamin C and EDTA-Na2; each milliliter of water or physiological saline solution contains 0.05 to 0.125 million units of nisin, 4 to 10 milligrams of vitamin C and 16 to 40 milligrams of EDTA-Na2. The nisin, vitamin C and EDTA-Na2 sterile powder with the proportion are mixed and packaged, and the sterile powder is dissolved in water or physiological saline before use. The experiments prove that the medicament can inhibit the activity of protease in milk after the EDTA-Na2 is added, so as to slow the degradation speed of nisin in milk, prolong the action time of the drug and prolong the efficacy for the treatment of dairy cow mastitis.

Owner:ZHEJIANG UNIV

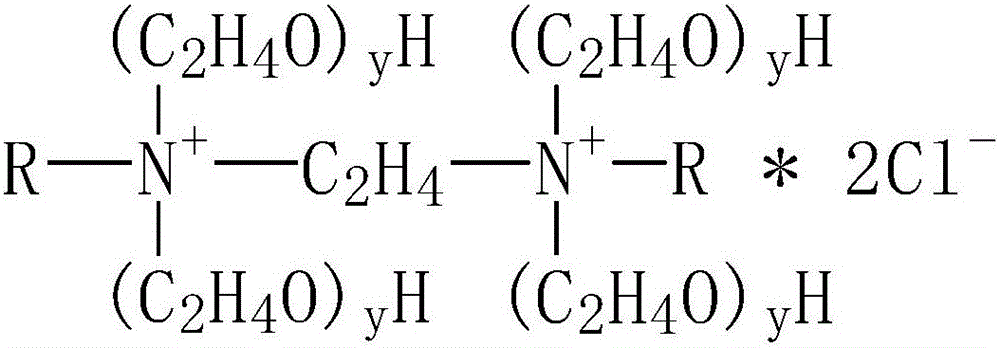

Low-temperature pretreatment auxiliary with easiness in biodegradation and for cotton fabric

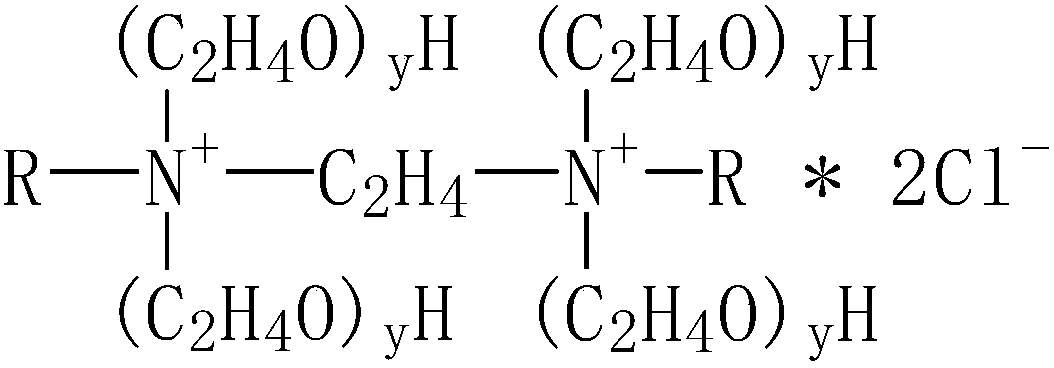

InactiveCN103276595AImprove surface activityImprove the effect of pre-processingVegetal fibresSuberedamine BAlkyl polyglycoside

The invention discloses a low-temperature pretreatment auxiliary with easiness in biodegradation and for cotton fabric. The low-temperature pretreatment auxiliary comprises components in percentage by mass as follows: 15%-30% of N, N'-DTM 8, 5%-15% of alkyl glycoside as a nonionic surfactant, 5%-10% of low molecular weight sodium polyacrylate, 2%-5% of inorganic salt and the balance of water. According to the low-temperature pretreatment auxiliary, Gemini surfactant N, N'-DTM 8 is taken as the main component of the pretreatment auxiliary, the surface activity is higher than that of a general surfactant, so that the wetting and washing effects of a scouring agent are enhanced; alkyl polyglycoside as the nonionic surfactant is adopted for compound, the compound beneficiating function is achieved, and the treatment effect is further improved; the used surfactant is good in biodegradability, accordingly, the biodegradability of pretreatment waste water can be improved effectively, the treatment difficulty of dyeing wastewater is reduced, energy conservation and emission reduction are promoted, and requirements for ecological textile processing and environment protection are met.

Owner:SUZHOU UNIV

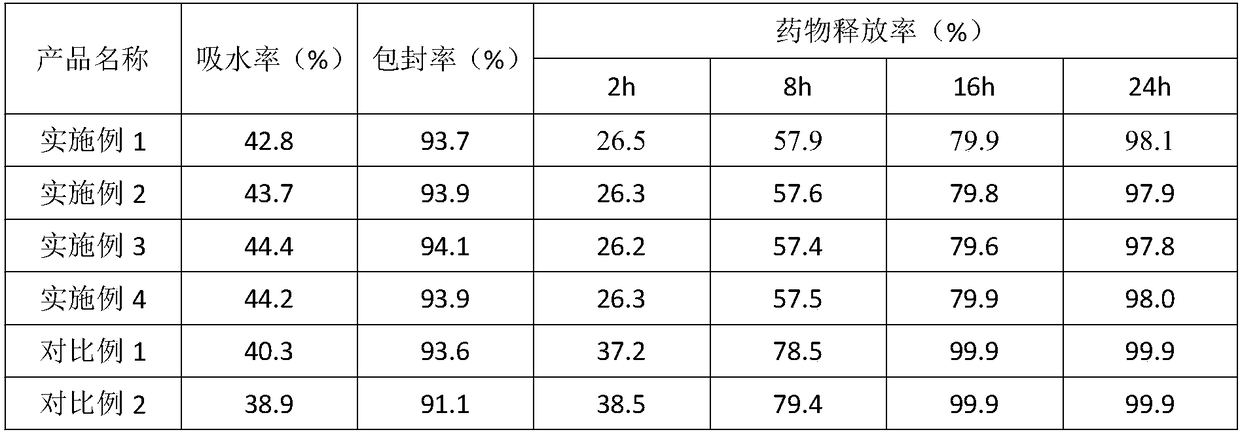

Drug sustained-release material and preparation method thereof

InactiveCN108159428AImprove water absorptionImprove hydrophilicityInorganic non-active ingredientsOrganic non-active ingredientsCelluloseSuberedamine B

The invention provides a drug sustained-release material and a preparation method of the drug sustained-release material. The preparation method of the drug sustained-release material is as follows: (1) mixing and stirring low molecular weight chitosan, polyanionic cellulose, silk fibroin peptide, polycaprolactone, bovine serum albumin, glycollic acid, aloe polysaccharide and deionized water to obtain a component A; (2) mixing and stirring garlic oil, N,N'-bioleoyl ethidene diamine diethyl sodium sulfonate and polyethylene glycol to obtain a component B; (3) mixing the component A with the component B, and conducting ultrasonic shearing; (4) adding sodium tripolyphosphate and glutaraldehyde, heating and stirring; (5) standing and separating to obtain an aqueous phase, regulating the pH value to 8, centrifuging at the low speed to remove larger particles; (6) regulating the pH value of a suspension to neutral, centrifuging, abandoning a solvent, and drying. The drug sustained-release material is higher in water absorption, good in hydrophily and high in encapsulation efficiency, has an excellent drug sustained-release effect at the same time, and is most suitable for a drug taking 1dose per 24h.

Owner:FOSHAN RUISHENGTONG TECH CO LTD

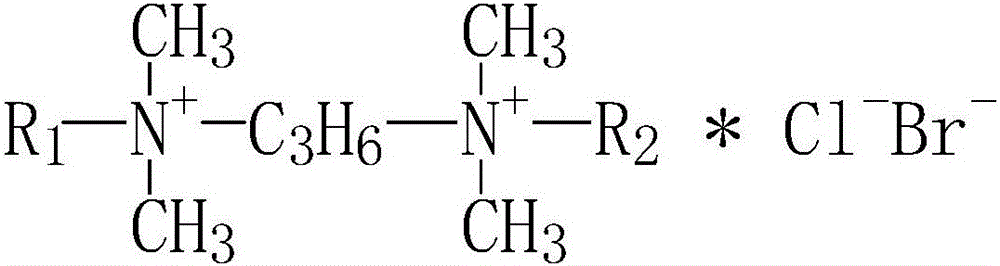

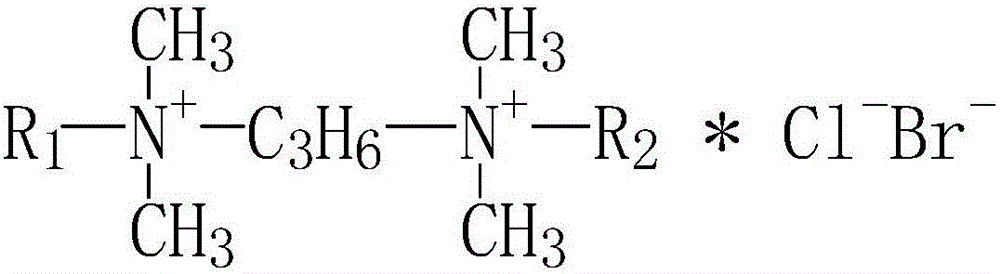

Novel flotation agent composition

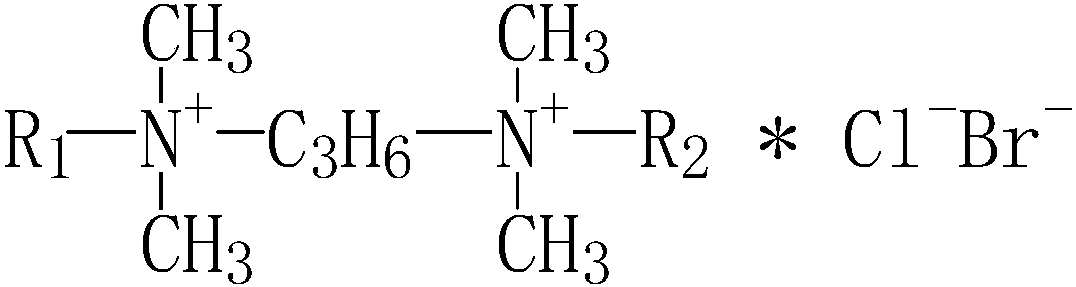

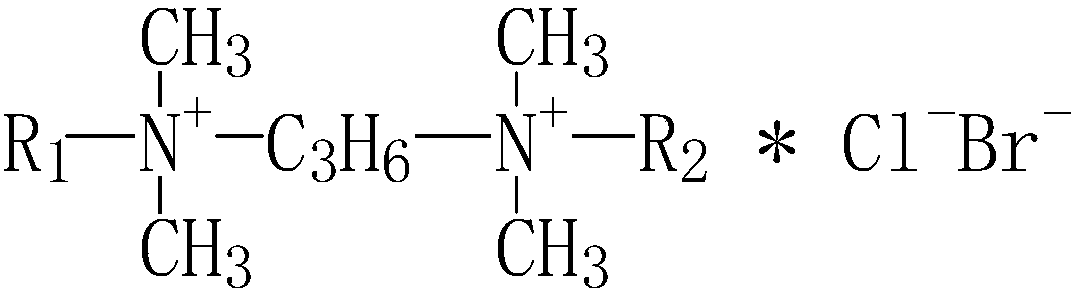

ActiveCN106140485AUnique Monoquaternary Ammonium SaltUnique double quaternary ammonium salt formulaFlotationEthylenediamineSuberedamine B

The invention relates to a novel floatation agent composition and belongs to the technical field of the petroleum industry. The novel floatation agent composition comprises, by mass percentage, 1%-30% of alkyl tertiary amine quaternary ammonium salt, 1%-30% of trimethylene group[(alkyl dimethyl amine / alkyl dimethyl amine) chlorine / ammonium bromide], 1%-10% of nonylphenol polyoxyethylene polyoxypropylene ether, 1%-10% of N,N'-dilauroyl-ethylenediamine-sodium diacetate, 1%-30% of ethylene group di(alkyl polyethylene group ammonium chloride), 0%-15% of a pour point depressant and the balance water. The novel floatation agent composition has the beneficial effects that the dosage is little, few residues exist, the separating efficiency is high, and corrosion to pipeline equipment is low.

Owner:BEIJING DONGXINLONG PETROLEUM TECH CO LTD

Polyester-viscose fabric short-process dyeing and finishing technology

InactiveCN108265534AShort processSimple process equipmentDry-cleaning apparatus for textilesDyeing processPolyesterSuberedamine B

The invention relates to a polyester-viscose fabric short-process dyeing and finishing technology. The technology comprises the process: one-bath method desizing, boiling and bleaching, presetting, dyeing, and setting and finishing; the one-bath method desizing, boiling and bleaching process comprises the steps of pad-rolling a polyester-viscose fabric in a pretreatment liquid, steaming for 60 minat the temperature of 100 DEG C, then washing with water and drying; the treatment liquid comprises 4 g / L of a scouring agent, 3 g / L of a chelating agent, 5 g / L of hydrogen peroxide and 2 g / L of a hydrogen peroxide stabilizer, and the pH is regulated to 10.5-11 with sodium hydroxide. A preparation method of a chelating dispersant comprises the steps: a, putting 15 parts of disodium ethylenediamine diacetate and 140 parts of deionized water into a reactor, stirring, and dissolving; and b, firstly adding 8 parts of sodium hydroxide, after dissolving, adding 7 parts of carbon disulfide, and carrying out a reaction for 3 h, to obtain the chelating dispersant. The one-bath method integrates desizing, scouring and bleaching into one, the active and dispersed one-bath method dyeing technology isused, the technological process is shortened, the technological equipment is simplified and energy consumption is reduced.

Owner:绍兴塞特印染有限公司

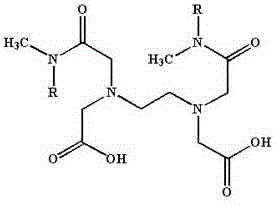

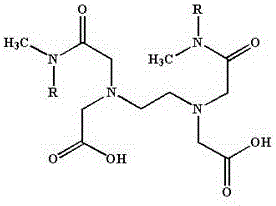

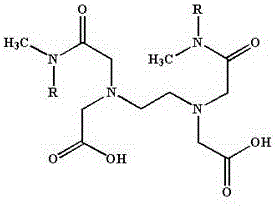

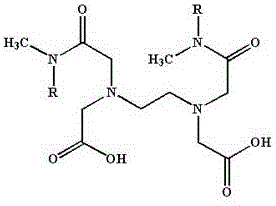

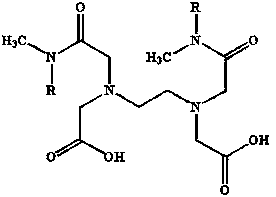

Novel extracting agent for efficiently enriching micro nickel ions in environment

ActiveCN106565515AStripping is easyRealize recyclingOrganic compound preparationWater contaminantsSuberedamine BEthylenediamine

The invention relates to a novel nickel ion extracting agent and a preparation method thereof, and aims to extract and recycle nickel ions in water phases. The novel nickel ion extracting agent can be utilized to enrich and extract nickel ions, is named as bi-N-(N-methyl-N-alkyl acetyl)-ethylenediamine diacetate, and is prepared through carrying out amidation reaction on EDTA (ethylenediaminetetraacetic acid) and N-methyl-N-alkylamine. The novel nickel ion extracting agent has the characteristics that preparation is easy and convenient, the price is low, the novel nickel ion extracting agent can be widely applied to removal and enrichment of nickel ions in sewage and water phases, the rate for extracting micro nickel from a water body can reach 97% or above, extraction capacity is high, loss during the extraction process is low, stability is good, and the extracting agent has quite good extracting properties for micro nickel ions in a relatively dilute solution, can easily perform reverse extraction under the acid condition, and is circularly and repeatedly utilized. In the formula (referring to the description), R represents an alkyl chain.

Owner:UNIV OF JINAN

Novel extraction agent capable of efficiently enriching micro copper ions in environment

ActiveCN106544504AEasy extractionStripping is easyProcess efficiency improvementSuberedamine BEthylenediamine

The invention relates to a novel copper ion extraction agent and a preparation method thereof. The extraction agent has very strong capability of combining copper ions, can be used for enriching and recycling micro or trace copper ions in water, is named as 2-N-(N-methyl-N-alkylacetyl)-ethylenediamine diacetate and is formed by amidation between EDTA (ethylenediaminetetraacetic acid) and N-methyl-N-alkylamine. The extraction agent has the characteristics that the preparation is simple and convenient, the price is low, and the extract agent can be widely applied to removal and enrichment of copper ions in industrial waste water or sewage, has the one-time extraction rate of 97% or above when used for extracting micro copper from weak-acid and neutral water, is high in extraction capacity, small in loss during extraction and good in stability, and has very good extraction performance when used for extracting micro copper ions in a dilute solution. The extraction agent can easily perform reverse extraction under an acid condition, and can be recycled. In the formula (as shown in the description), R represents alkyl chain.

Owner:UNIV OF JINAN

A new extractant for highly efficient enrichment of trace nickel ions in the environment

ActiveCN106565515BNovel structureLow priceOrganic compound preparationWater contaminantsSuberedamine BAcetic acid

The patent of the present invention relates to a novel nickel ion extractant and its preparation method, which aims to extract and recover nickel ions in the water phase, and can be used to enrich and extract nickel ions; it is named as di‑N‑(N‑methyl‑N ‑Alkylacetyl)‑ethylenediaminediacetic acid, this extractant is produced by amidation reaction of EDTA (ethylenediaminetetraacetic acid) and N‑methyl‑N‑alkylamine. It is characterized by simple preparation and low price, and can be widely used for the removal and enrichment of nickel ions in sewage and water phase. The extraction rate of a single extraction of trace nickel from water can reach more than 97%, and the extraction capacity is high. The process loss is small, the stability is good, and it has good extraction performance for trace nickel ions in a relatively dilute solution. This extractant can be easily stripped under acidic conditions, and the recycling of the extractant is realized. In the formula, R represents an alkyl chain.

Owner:UNIV OF JINAN

A kind of preparation method of polymer shale inhibitor for drilling fluid

ActiveCN107488247BImprove scroll recoveryEasy accessDrilling compositionEthylenediaminePotassium persulfate

The invention discloses a preparation method of a polymer shale inhibitor for a drilling fluid. The polymer shale inhibitor is prepared from acrylamide, acrylic acid, potassium hydroxide and dimethyldiallylammonium chloride through an inverse emulsion polymerization technology, and optimum synthesis conditions are as follows: a weight part ratio of the acrylamide monomer to the acrylic acid monomer to the dimethyldiallylammonium chloride monomer is (70-80):(70-80):(15-75), the three monomers are processed to prepare an aqueous phase with the pH value being 10, 10 parts by weight of emulsifiers Sp-80 and T-60 are added to emulsify and disperse the aqueous phase in 100 parts by weight of white oil, and 1-3 parts of a stabilizer N,N'-dilauroyl ethylenediamine diethanesulfonate, the reaction temperature is 30-40 DEG C, the reaction time is 8 h, an oxidation / reduction initiator ratio of n(potassium persulfate):n(sodium hydrogen sulfite) is 1:1, and the weight part number of the initiator is 4. The product can be adsorbed on the surface of clay to form a semi-permeable membrane, has a strong coating effect, can effectively encase rock debris to weaken the hydration and dispersion effect, can compress a double electrode layer to prevent the hydration swelling of the clay, and has a prominent inhibition effect.

Owner:DAQING BEIHUA CHEM PLANT

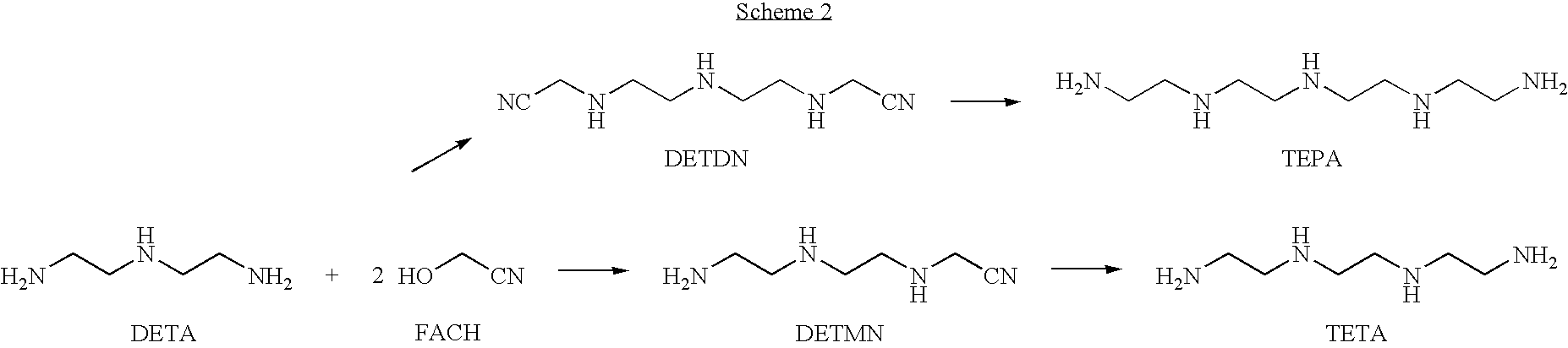

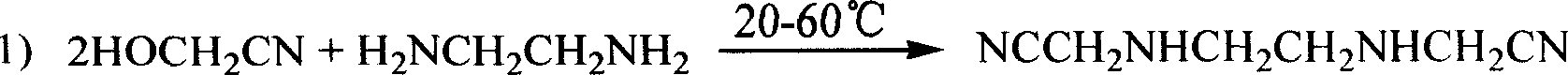

Method of preparing ethylenediamine tetracetonitrile and ethylenediamine tetraacetic acid using hydroxy acetonitrile as raw material

InactiveCN1317261CIncreased side effectsCarboxylic acid nitrile preparationOrganic compound preparationSuberedamine BEthylenediamine

A process for preparing ethyldiamine tetraacetonitrile and ethyldiamine tetraacetic acid includes such steps as regulating the pH value of ethyldiamine solution to 6-8, adding hydroxyacetonitrile, reacting to obtain ethyldiamine diacetonitrile, heating to 60-100 deg.C, adding hydroxyaceto nitrile reacting to generate ethyldiamine tetraacetonitrile, cooling, filter, hydrolyzing in alkaline aqueous solution to obtain ethyldiamine tetraacetate, and adding acid to make pH=1-3 for obtaining ethyldiamine tetraacetic acid.

Owner:SOUTHWEST UNIV +1

A kind of plating solution formula and electroplating method for electroplating thick palladium on stainless steel

The invention discloses a plating solution formula and an electroplating method for electroplating thick palladium on stainless steel. According to the plating solution formula, a plating solution comprises 20-30 g / L of tetraammine dichloropalladium, 80-100 g / L of ammonium chloride, 2-4 g / L of sodium ethylenediamine diacetate and 8-12 g / L of alanine. According to the plating solution formula and the electroplating method for electroplating the thick palladium on the stainless steel, the white appearance of the stainless steel is maintained by electroplating the thick palladium on the stainless steel. Nickel plating and copper plating are carried out before electroplating of the stainless steel, so that the performance of a thick plated palladium layer on the stainless steel is improved, the thick plated palladium layer is not prone to generation of cracks, and the palladium plating solution is stable.

Owner:佛山市宝惠不锈钢有限公司

MRI molecular image probe and preparing method thereof

InactiveCN100459932CSmall molecular weightImprove biological performanceMagnetic property measurementsDiagnostic recording/measuringSuberedamine BBiological body

Owner:PEOPLES HOSPITAL PEKING UNIV

anti-expansion agent

ActiveCN105154034BGood anti-expansion and contraction effectFast convergenceDrilling compositionSuberedamine BEthylene diamine

The invention discloses an anti-swelling shrinking agent which is an ethylene diamine diacetate solution. This solution avoids the adverse factor that traditionally bridge blinding occurs in capturing of large cations, also overcomes the adverse factor that small cations are low in charge density and short in effective life, has a good clay stabilizing function and is also well capable of shrinking swelled clay. The anti-swelling shrinking agent composited by adding magnesium chloride and / or amino trimethylene phosphonic acid has better anti-swelling and shrinking effects. A liquid of the anti-swelling shrinking agent is clear and crystal, has anti-swelling agent higher than 95% and shrinking rate higher than 35%, and is applicable to preventing and solving the clay swelling problem caused in oilfield development.

Owner:XIAN AODE PETROCHEM ENG TECH CO LTD

Process for preparing eddn, edmn, teta and deta

InactiveUS20130053597A1Carboxylic acid nitrile preparationOrganic compound preparationSuberedamine BEthylenediamine

A process for preparing ethylenediaminediacetonitrile (EDDN) and / or ethylenediamine-monoacetonitrile (EDMN) by conversion of formaldehyde (FA), hydrogen cyanide (HCN) and ethylenediamine (EDA), which comprises using stabilizer-free HCN, or HCN which has been stabilized with an organic acid, in the process.

Owner:BASF AG

A new type of flotation agent composition

Owner:BEIJING DONGXINLONG PETROLEUM TECH CO LTD

Surfactant flooding system and application thereof

ActiveCN103045221BLarge flow ratioOil displacement effect is goodFluid removalDrilling compositionSuberedamine BEthylenediamine

The invention relates to a surfactant flooding system and application thereof. The surfactant flooding system comprises the following materials in percentage by weight: 1-4% of sodium petroleum sulfonate, 0.5-1% of isomeric alcohol ethoxylate, 0.5-1% of N,N'-dilauroyl-ethylenediamine-sodium diethanesulfonate, 1-4% of organic cosolvent isopropanol and the balance of water, and the sum of the weight percents of all the materials is 100%. In the wide concentration range (0.1-0.5%) of the surfactant, the oil-water interfacial tension can be reduced to an ultralow value at such order of magnitude as 10<-3> mN / m, the field experiment effect is remarkable, and the system is resistant to temperature (80 DEG C) and can be slightly influenced by the change of temperature.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com