Non-base oil-displacing agent composition of bi-alkyl carboxylate and its use

A technology of alkyl carboxylate and composition, which is applied in the field of anionic gemini carboxylate alkali-free oil displacement agent composition, and can solve the problem problems such as materials, etc., to achieve the effect of easy implementation, good oil displacement effect and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

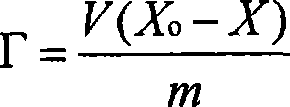

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Synthesis of Double Fourteen

[0062] ① Synthesis of myristyl chloride

[0063] Take 20-38 g of myristic acid and 15-25 g of thionyl chloride, stir and react for 2-4 hours, and reflux at 70-90°C until no gas is generated in the exhaust gas drying tube. Then the excess thionyl chloride was distilled off under reduced pressure, and then distilled under reduced pressure.

[0064] ②Synthesis of intermediate ethylenediaminediacetic acid

[0065] Chloroacetic acid 10-20g, water 30-50ml, anhydrous sodium carbonate 5-12g, to obtain sodium chloroacetate solution.

[0066] Anhydrous ethylenediamine 2-7g, water 20-45ml, sodium chloroacetate solution 12-21g. After constant temperature for 24h, reflux at 70-80℃ for 2-4h to keep the solution pH=8-9. After distillation under reduced pressure at 60-70℃, add concentrated hydrochloric acid to the concentrated solution to pH=1-2, with white precipitate Generated and washed with distilled water 3 times to obtain intermediate sodium ...

Embodiment 2

[0069] Example 2: Gemini alkyl carboxylate alkali-free oil-displacing agent composition, the components are as follows, all in mass percentage:

[0070] Dioleic acid 0.01wt%;

[0071] FBB-2 0.06wt%;

[0072] HF-2 0.08wt%;

[0073] HPAM 0.2wt%;

[0074] The mineralized water of the oilfield formation is 99.65wt%.

Embodiment 3

[0075] Example 3: Gemini alkyl carboxylate alkali-free oil-displacing agent composition, the components are as follows, all in mass percentage:

[0076] Dioleic acid 0.04wt%

[0077] FBB-2 0.09wt%;

[0078] HF-2 0.07wt%;

[0079] HPAM 0.2wt%

[0080] The mineralized water of the oilfield formation is 99.6wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas permeability | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com