A kind of preparation method of polymer shale inhibitor for drilling fluid

A shale inhibitor and polymer technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the mechanism of anti-slump inhibition is few, affects the application effect of other treatment agents, and destroys the contact of drilling fluid. denaturation and other problems, to achieve the effects of easy acquisition, enhanced stability, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

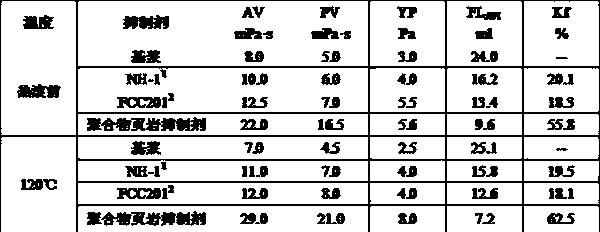

Image

Examples

Embodiment 1

[0011] Mix 75 parts of acrylic acid with the same number of potassium hydroxide and stir evenly, add 75 parts of acrylamide and 25 parts of dimethyl diallyl ammonium chloride to prepare a mixed aqueous phase with a pH of 10, add 10 parts by weight Parts of emulsifier Sp-80, 100 parts by weight of white oil of T-60 were slowly added to the mixed water phase and stirred in a shear emulsification mixer at a shear speed of 500r / min for 1h to emulsify and disperse to form a water-in-oil emulsion. Transfer the emulsion into a reaction kettle, add 7 parts by weight of nano-stabilizer while stirring, then fill with nitrogen, and heat up. press n 过硫酸钠 :n 亚硫酸氢钠 =1:1 Weigh 0.4 parts by mass of the initiator to make a solution, slowly and alternately add it to the reactor, stir slowly at 100r / min for 5h, when the viscosity of the emulsion in the reactor reaches 650cp or more, discharge and cool to obtain polymer shale Inhibitors.

[0012] Above-mentioned stabilizer preparation method i...

Embodiment 2

[0017] Mix 70 parts of acrylic acid with the same number of potassium hydroxide and stir evenly, add 70 parts of acrylamide and 35 parts of dimethyl diallyl ammonium chloride to prepare a mixed aqueous phase with a pH of 10, add 10 parts by weight Parts of emulsifier Sp-80, 100 parts by weight of white oil of T-60 were slowly added to the mixed water phase and stirred in a shear emulsification mixer at a shear speed of 500r / min for 1h to emulsify and disperse to form a water-in-oil emulsion. Transfer the emulsion into a reaction kettle, add 8 parts by weight of a stabilizer while stirring, then fill with nitrogen, and heat up. press n 过硫酸钠 :n 亚硫酸氢钠 =1:1 Weigh 0.4 parts by mass of the initiator to make a solution, slowly and alternately add it to the reactor, stir slowly at 100r / min for 5h, when the viscosity of the emulsion in the reactor reaches 650cp or more, discharge and cool to obtain polymer shale Inhibitors.

Embodiment 3

[0019] Mix 80 parts of acrylic acid with the same number of potassium hydroxide and stir evenly, add 80 parts of acrylamide and 20 parts of dimethyl diallyl ammonium chloride to prepare a mixed aqueous phase with a pH of 10, add 10 parts by weight Parts of emulsifier Sp-80, 100 parts by weight of white oil of T-60 were slowly added to the mixed water phase and stirred in a shear emulsification mixer at a shear speed of 500r / min for 1h to emulsify and disperse to form a water-in-oil emulsion. Transfer the emulsion into a reaction kettle, add 9 parts by weight of a stabilizer while stirring, then fill with nitrogen, and heat up. press n 过硫酸钠 :n 亚硫酸氢钠 =1:1 Weigh 0.4 parts by mass of the initiator to make a solution, slowly and alternately add it to the reactor, stir slowly at 100r / min for 5h, when the viscosity of the emulsion in the reactor reaches 650cp or more, discharge and cool to obtain polymer shale Inhibitors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com