Patents

Literature

49results about How to "High pulping rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

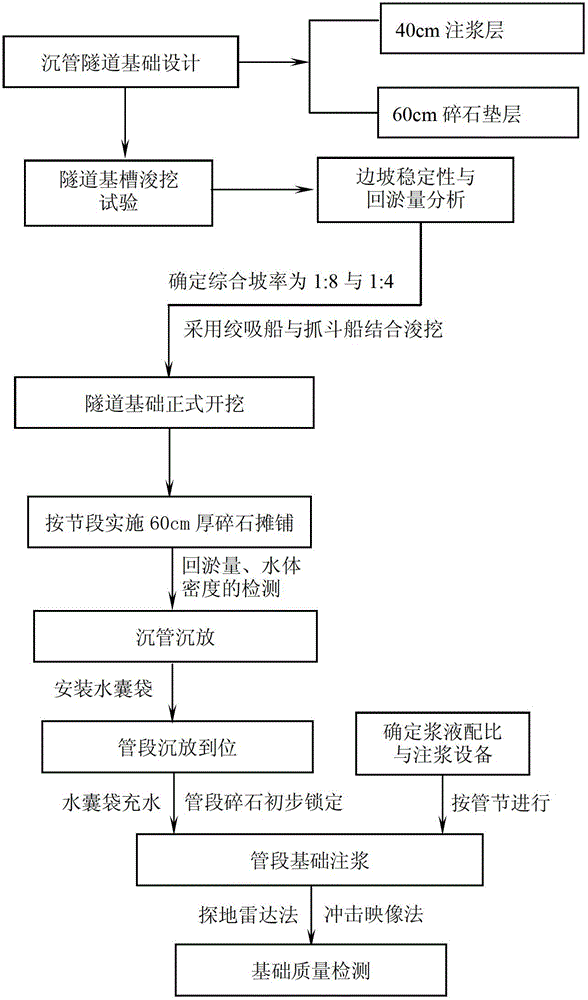

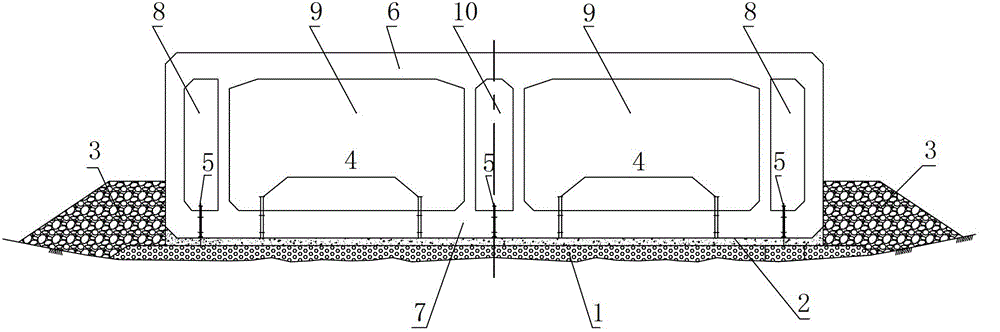

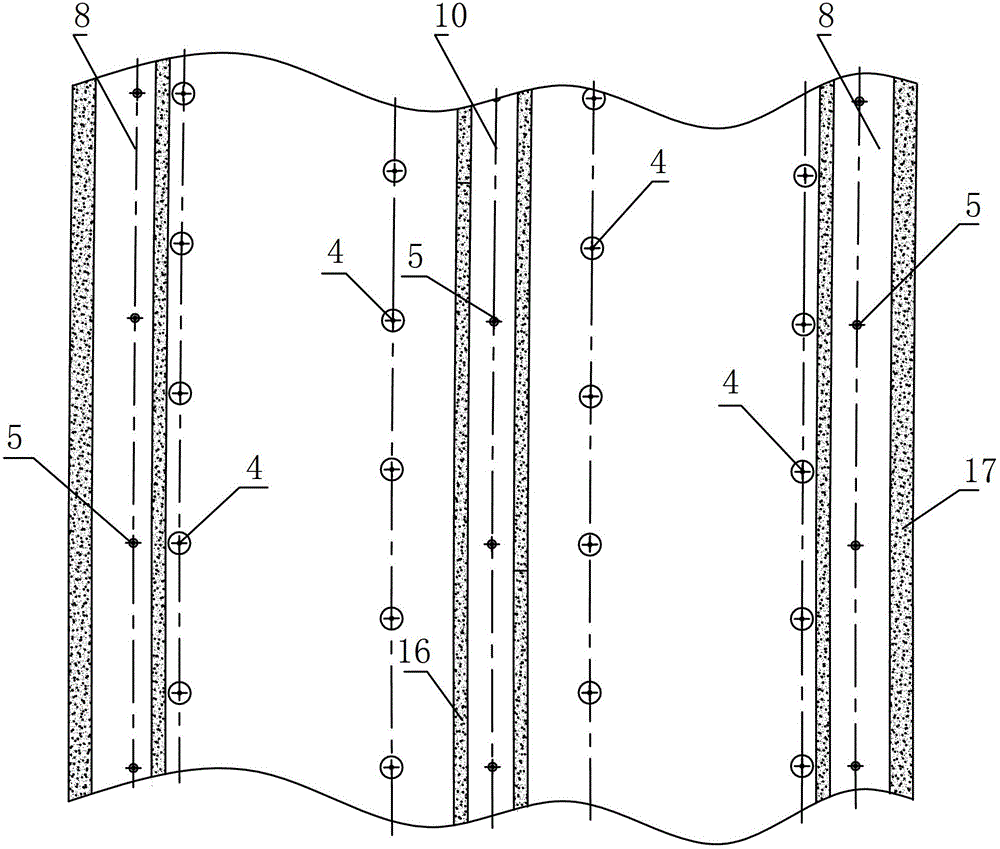

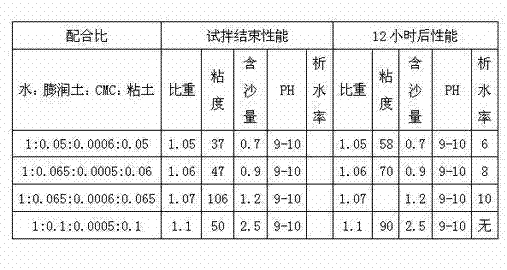

Underwater grouting grout based on soft-base large immersed tunnel foundation and grouting process thereof

The invention discloses a preparation of underwater grouting grout based on soft-base large immersed tunnel foundation and a grouting process thereof. The foundation is formed by a 60-cm thick macadam foundation base and a 40-cm thick sodium bentonite mortar foundation and is capable of meeting requirements for tunnel foundation rigidity and requirements for base seismic resistance and water flow scouring resistance. The grout is composed of cement, fine sand, coal ash and sodium bentonite. The grouting process is improved, and pipe inside grouting of embedded grouting holes is adopted. Therefore, large ships are not required to work on river face, underwater operation of divers and navigation risks are reduced, construction safety is greatly improved, and construction cost is reduced. The secondary grouting technology is first adopted in the field of the immersed tunnel to reduce uneven sedimentation in future operation stage of projects. The grouting process provides a reference guide and an experience guide for large dock projects, immersed tunnel projects, municipal administration soft earth foundation strengthening projects, high earthquake region basic project design and other similar projects.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +6

Construction slurry for rotary pile drilling

InactiveCN102226077ARich and stableEnrich and perfect mechanicsDrilling compositionSlurry wallSodium Bentonite

The invention discloses a type of construction slurry for rotary pile drilling. The slurry is a type of compound slurry comprising water, bentonite, hydroxypropyl methyl cellulose solution, clay and soda ash. The construction slurry provided by the present invention can be widely applied in fields of well drilling, rotary pile drilling, and underground diaphragm wall. During a preparing process, the slurry can be mixed quickly and well. The slurry also has advantages of high efficiency, low pollution, low energy consumption and low cost.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG

High-temperature low-density cement and applications thereof

ActiveCN101747009AHigh strengthHigh compressive strengthSolid waste managementDrilling compositionOil productionTemperature resistance

The invention relates to a high-temperature low-density cement and applications thereof, belonging to the field of building materials. The high-temperature low-density cement provided by the invention has excellent high temperature resistance and comprises the following components in percentage by weight: 30%-70% of cement substrate, 14%-40% of lightening material, 14%-30% of high-temperature strength stabilizer and 0.02%-0.10% of high-temperature retarder, wherein the high-temperature retarder is organic acid sodium salt, and the high-temperature strength stabilizer material is one of micro silicon and silicon powder or the combination of micro silicon and silicon powder. The cement has the characteristics of simple construction processes, high pulping rate, excellent high temperature resistance and the like, can be applied to special environments such as oil well cementing and the like, and can obviously improve well cementing quality and crude production rate. When the cement of the invention is used for well cementing operation and high-temperature oil production operation, the well cementing construction performance can be ensured, and the unabated performance of the strength of the cement stone at high temperature can be ensured.

Owner:JIAHUA SPECIAL CEMENT

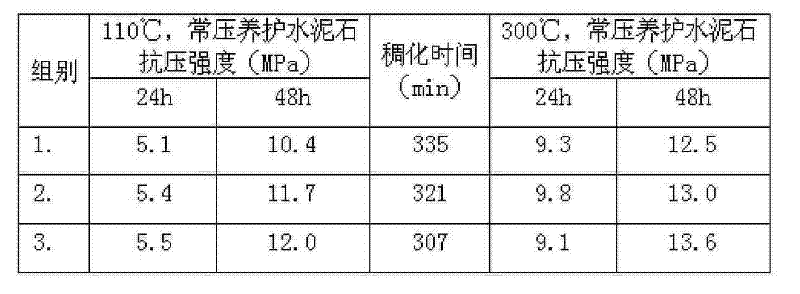

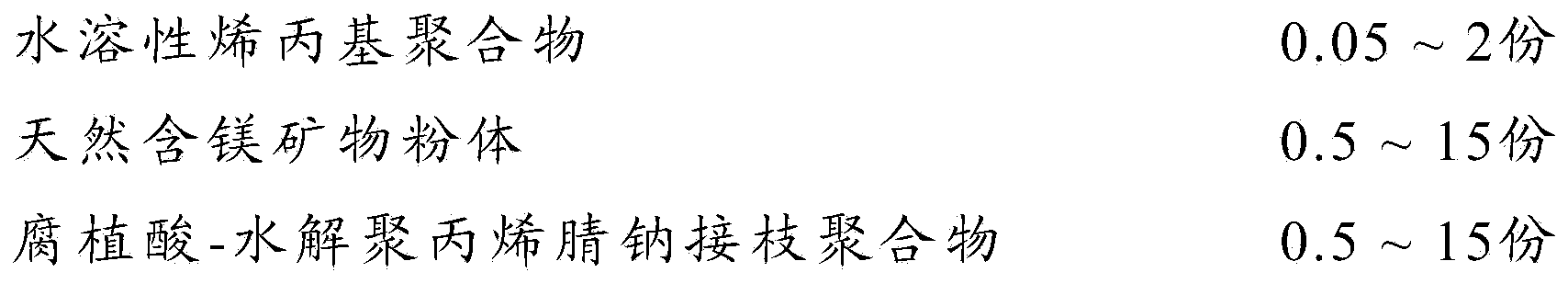

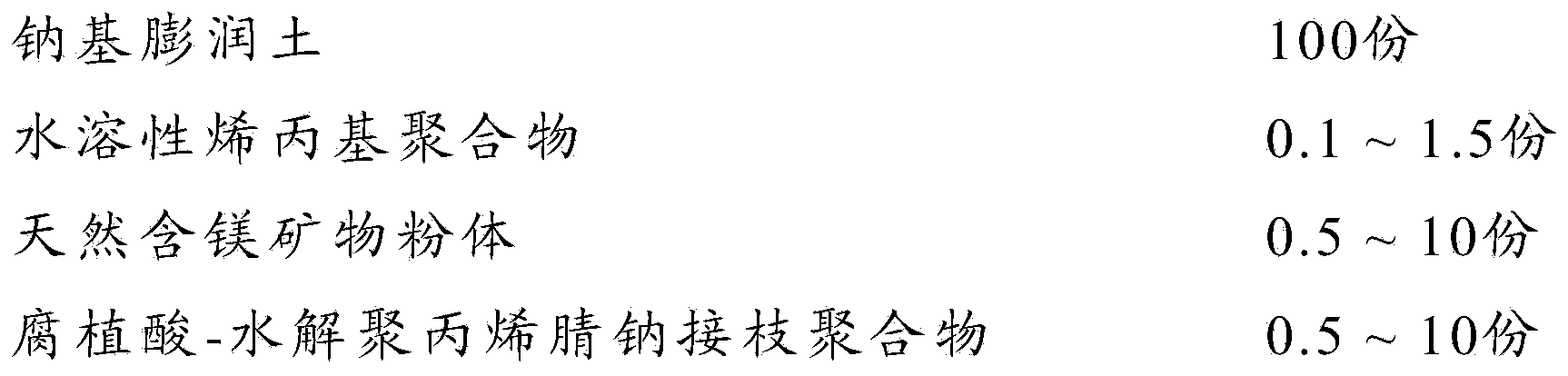

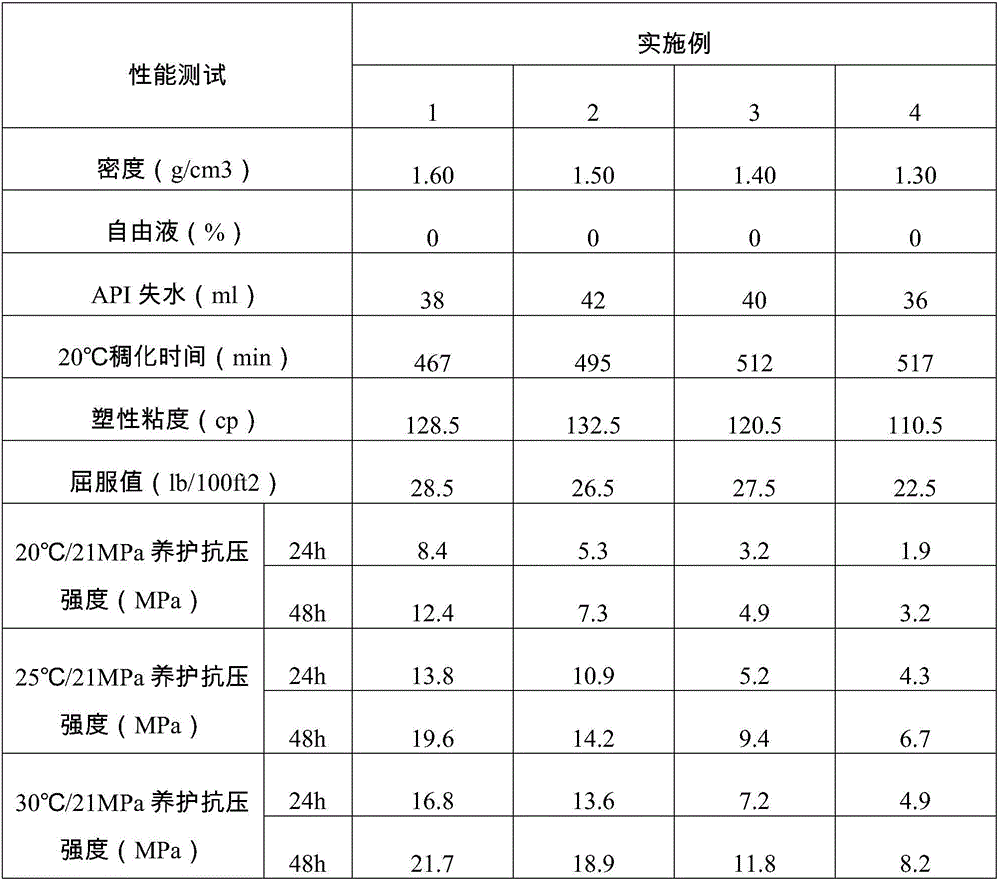

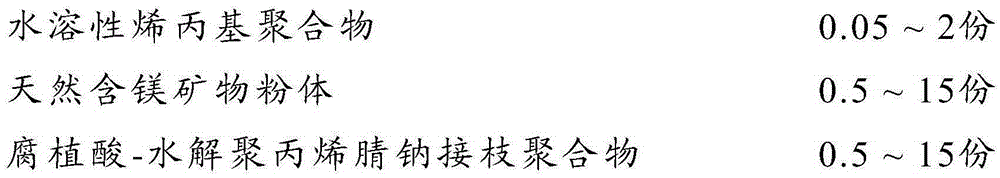

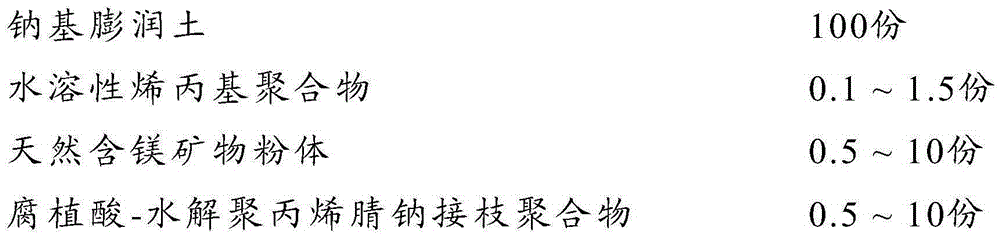

Thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and preparation method thereof

ActiveCN103525384AHigh pulping rateViscosity increase efficiencyDrilling compositionFiltrationWell drilling

The invention discloses thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and a preparation method of the thixotropy bentonite slurry. The thixotropy bentonite slurry is modified by a modifying agent comprising a water-soluble allyl polymer, natural magnesium containing mineral powder and a humid acid-hydrolysis sodium polyacrylonitrile graft polymer. The preparation method of the thixotropy bentonite slurry comprises the following steps: preparing sodium bentonite, preparing bentonite-based slurry, preparing the modifying agent and finally preparing the modified bentonite. The mud-making rate, the viscosity increasing efficiency and the de-filtration effect of the bentonite prepared by the method provided by the invention are greatly improved, and the modifying effect of the bentonite is far superior to that of bentonite modified by using a single modifying agent.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Floating-bead-free low-density oil well cement paste

ActiveCN105255465AImprove early strengthImprove cementing qualityDrilling compositionFilling materialsOil well

The invention discloses floating-bead-free low-density oil well cement paste and belongs to the technical field of oil and gas well cementation. The cement paste is prepared from 10-30% of cementing material A, 15-50% of cementing material B, 2-48% of filling material, 1-3% of fluid loss agent, 1-4% of early strength agent and 0.5-1.5% of dispersing agent. The cementing material A is one of G-grade oil well cement, D-grade oil well cement and ordinary Portland cement. The cementing material B is superfine ordinary Portland cement. The cement paste has the advantages of being low in cost, low in density, and high in early strength, density stability and quality stability.

Owner:JIAHUA SPECIAL CEMENT

Modified Leituoshi stone for drilling liquor and its production mehtod

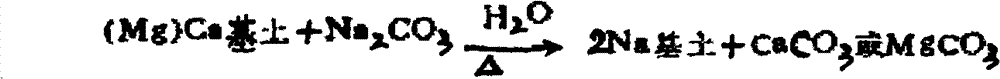

The present invention uses calcium base leituoshi stone ore as raw material, and adopts semi-dry artificial modification process including the steps: breaking clay mineral, adding 1%-5% sodium salt, uniformly mixing them, water-spraying, shearing, pressing, piling and ageing for 7-10 days, drying so as to obtain modified leituoshi stone. Said invention is simple in production method, convenient for operation, less in dosage of modifying agent and low in energy consumption and cost. The phi-600 reading value of drilling fluid prepared with modified leituoshi stone is greater than or equal to 60, mud-making rate is greater than or equal to 18 cu.m / t, filter loss is less than or equal to 13.5 ml and dynamic shear force is less than or equal to 1.2XPVPa. It is superior to sodium base bentonite in all the properties, and is applicable for drilling in the fields of petroleum industry, natural gas engineering, geologic drilling engineering and building engineering, etc.

Owner:湖北名流累托石科技股份有限公司

Size for abrasive material slurry jet flow cutting and its preparing method

The slurry consists of abrasive material of garnet, quartzite or bauxite corundum; water as medium liquid; and additive bentonite. The preparation of the slurry is one physical process including dry mixing of abrasive material and bentonite through stirring, and mixing the mixture with water. The slurry is stable in structure and is less likely to take chemical change and suitable for high speed jet flow cutting. The slurry may be reused, and is non-toxic, smell-less, no mildew and environment friendly.

Owner:SHANGHAI UNIV +2

Low-density cement slurry system for deepwater surface layer well cementation and application thereof

ActiveCN106673530AThickening time is easy to adjustDehydration is easy to adjustDrilling compositionSlurryMaterials science

The invention discloses a low-density cement slurry system for deepwater surface layer well cementation and application thereof. The low-density cement slurry system comprises the following components in parts by weight: 100 parts of cement, 5-40 parts of liquid suspending agent, 5-40 parts of liquid reinforcer, 4-10 parts of liquid water-loss control agent, 2-10 parts of early strength agent, 0.05-1.5 parts of defoaming agent and 50-250 parts of fresh water or sea water. The additives of the cement slurry system have definite performance and are all liquids; and the system is simple in composition, high in slurry making rate and excellent in low-temperature early-strength performance.

Owner:CHINA NAT OFFSHORE OIL CORP +1

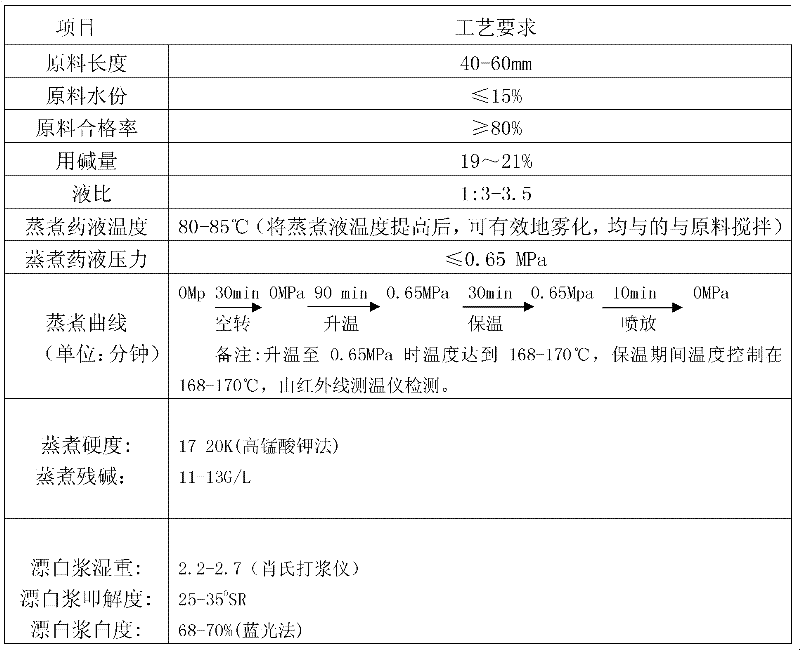

Grape branch pulp

InactiveCN102517972ALower requirementEfficient use ofPulping with inorganic basesNon-woody plant/crop pulpEngineeringPulp and paper industry

The invention relates to a grape branch pulp, which is prepared by using grape branches as materials and adopting soda-process pulping. The grape branch pulp adopts the grape branches which are not ever applied to the paper-making industry as the materials to prepare pulp, so that not only the effective utilization of the resources is achieved and the utilization value of the resources is greatly improved, but also the material source of paper-making and pulping is broadened; serious defects of wheat straw pulping materials are compensated, and a new pulp is added to the paper-making and pulping. In the invention , the soda process is used to prepare the grape branch pulp, so that the material utilization rate is high, the pulping rate is high, the yield is high, the coarse pulp yield can reach 40-45%, and the effective cooking time is only 2.7 hours, thus the production efficiency is high, the cooking quality is table, the production process is reliable, the cost is low, in particular the requirements to the material are low; besides, the pulp can be used to a bottom layer or a core layer of corrugated paper, and has certain popularization value.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

Preparation method of modified attapulgite clay for drilling fluid

InactiveCN102476804AEasy to operateGood modification effectAluminium silicatesClay mineralsWell drilling

The invention discloses a preparation method of modified attapulgite clay for drilling fluid. According to the invention, attapulgite clay is used as a raw material and a magnesium-containing substance is used as a modifier. By the adoption of a semi-dry production technology, the preparation method contains the following steps of: crushing clay mineral, adding the modifier for mixing, extruding, pulping, sieving, dehydrating, drying, crushing and packaging. The product provided by the invention can meet requirements of various geological drilling, geothermal drilling and petroleum drilling, and is especially applicable to inland saliferous strata drilling, offshore drilling and ultra-deep drilling.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Extended bentonite for drilling fluid and method for making same

InactiveCN1594491AHigh pulping rateFilter vector lowInorganic pigment treatmentCelluloseSodium Bentonite

The invention relates to extended bentonite for drilling fluid and method for making same, wherein the bentonite comprises alta-mud, sodium hydroxide, sodium salt, cellulose, starch, polypropylene ammonia, positive electricity adhesive, composite glue, and the preparing process comprises coarse crushing, finely crushing, screening, watering and stirring, squeezing, drying, and milling.

Owner:赵玉梅

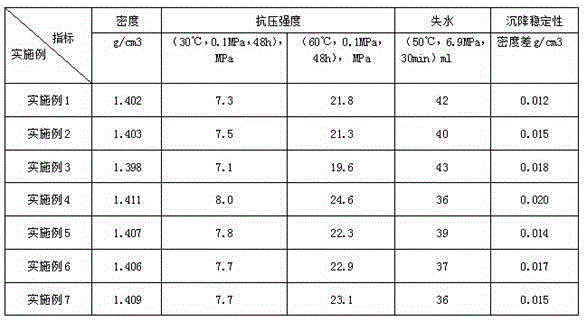

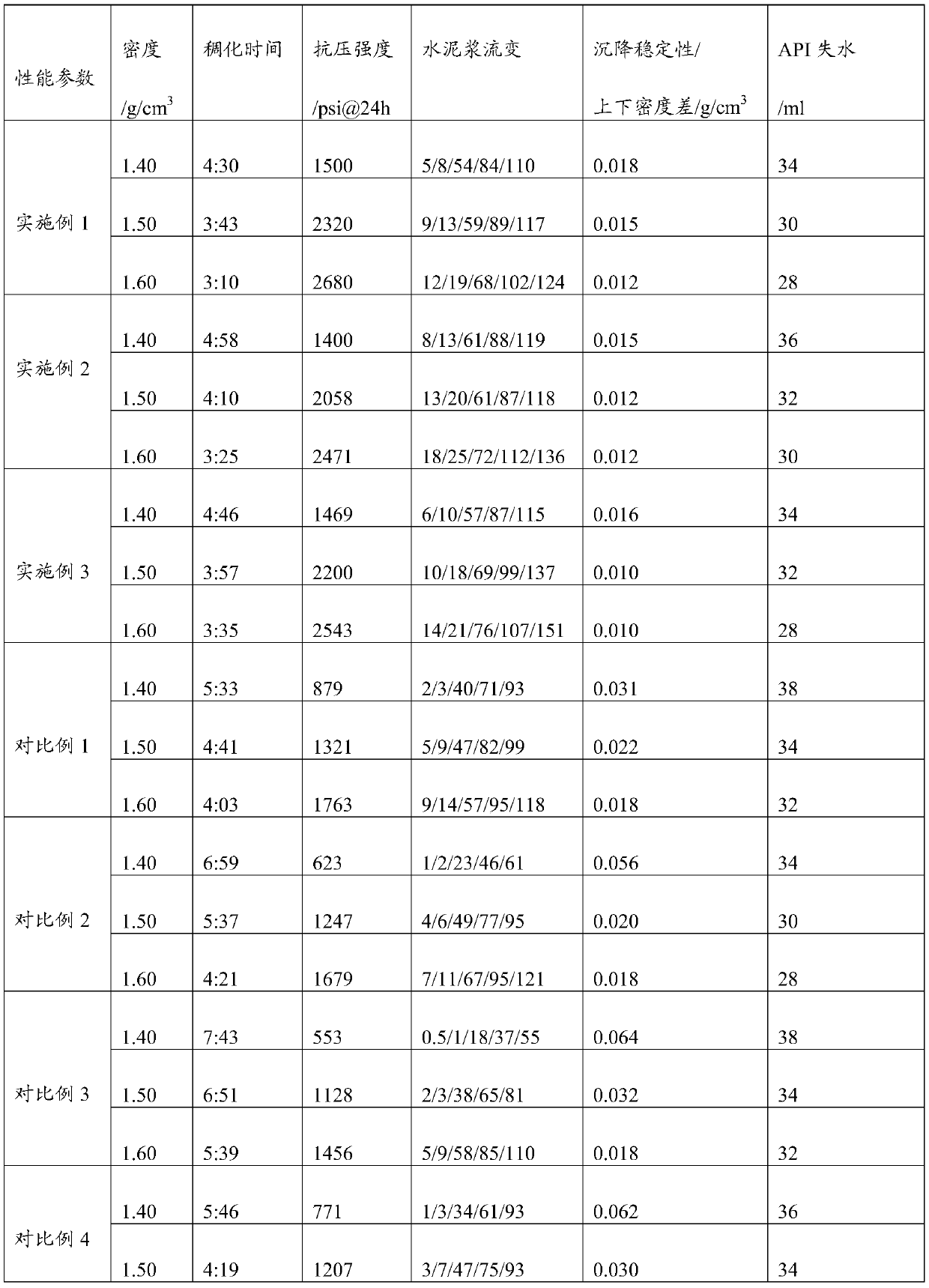

Oil well cement composition and application thereof

ActiveCN111116113ASimple compositionHigh pulping rateDrilling compositionCompressive resistancePhysical chemistry

The invention discloses an oil well cement composition and an application thereof. The oil well cement composition is prepared from the following components in parts by weight: 100 parts of G-grade oil well cement and 15-30 parts of cement kiln ash. Optionally, the oil well cement composition can further comprise 1-5 parts of a suspending agent, 5-15 parts of an early strength agent, 5-10 parts ofan ultrafine material and 1-5 parts of an expanding agent. The density of the cement paste prepared from the oil well cement composition is adjustable between 1.4 g / cm<3> and 1.6 g / cm<3>, the cementpaste formula is simple in composition, high in paste making rate, high in compressive strength and good in sedimentation stability, the field construction requirement can be met without adding floating beads and the like to reduce the material performance, the cost is low, and construction is convenient. The construction problems that in the prior art, well cementation hollow floating beads and microbead cement paste of a full-sealing section of a low-pressure leaky stratum and a low-pressure oil-gas layer are high in cost, limited in pressure bearing capacity, low in paste making rate, largein ash demand, limited in site ash storage space, incapable of achieving full sealing and the like are solved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

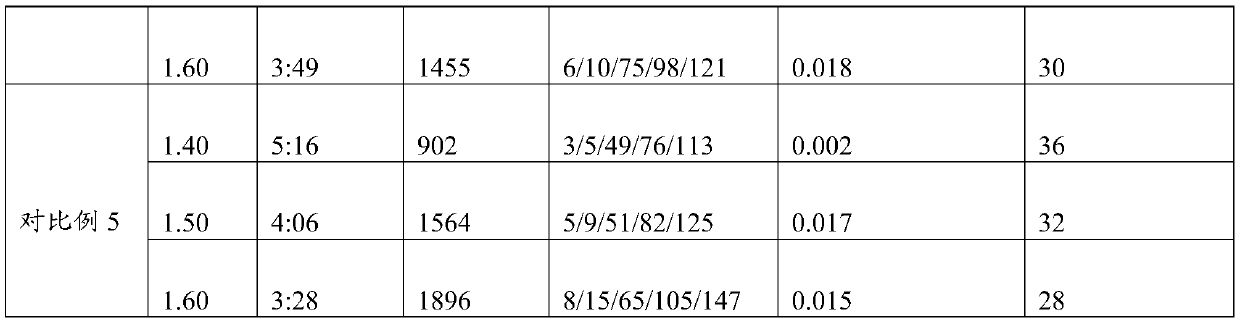

Pulping method for waste Renminbi

InactiveCN103103842AImprove evennessHigh pulping ratePaper recyclingWaste paper working-upEnergy consumptionChemistry

The invention relates to a pulping method for waste Renminbi. The method adopts a caustic soda-anthraquinone pulping method. The process comprises stewing and bleaching, wherein alkali charge is controlled between 18% to 20% in the stewing, liquor ratio is 1:3.5-4.5, the stewing liquor temperature is 80 DEG C to 85 DEG C, and before the temperature rises, idling for 30 min, then rising temperature, and rising the temperature according to the temperature rising time and vapor pressure. By the adoption of the caustic soda-anthraquinone pulping method, the waste Renminbi is carried out by pulping, and the waste Renminbi can be fully resolved through controlling the stewing parameters, so that the pulping method for the waste Renminbi can be effectively used in papermaking system. Evenness of pulp got and full stuff efficiency are high, stewing quality is stable, and meanwhile usage amount of chemical materials is small and various energy consumptions are low, process investment is small, and the cost is low. The pulping method for the waste Renminbi achieves the recycle of waste resource, and meanwhile provides a novel pulp to the paper technology. The pulp of the process can be used for manufacturing specialty paper, and the pulping method for the waste Renminbi has a certain promotional value.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

Method of mechanical pulp making by using cotton pole

InactiveCN101117779AEasy to separateReduce difficultyWashing/displacing pulp-treating liquorsDigestersFiberHigh concentration

The present invention discloses a method for mechanical pulping with a cotton stalk, and the method is realized by the following steps that the method includes material preparation, dust removal and wire division, cooking, spraying, high concentration grinding, cleaning, black liquid removal, intermediate concentration grinding, screening and condensation, wherein, the dust removal and the wire division also include a first dust removal and wire division and a second dust removal and wire division, which are used to remove sand dust, impurity and core in the stalk completely. In the steps of material preparation, dust removal and wire division of the present invention, sufficient pretreatment is done for the cotton stalk to make fiber of the cotton stalk is fully grinded and refined. In the cooking, less chemical agent is added, which facilitates sewage treatment. The method in the present invention is more applicable for pulping of the cotton stalk, which realizes material preparation of the total cotton stalk, high pulping rate of the cotton stalk, the paper quality is improved and chemical composition in the waste liquid is low which is easy for treatment. The technology is optimized, and the power consumption and the production cost are reduced.

Owner:安明军

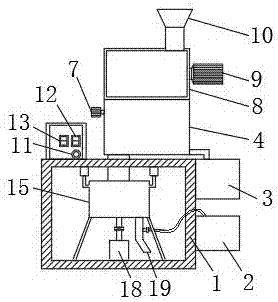

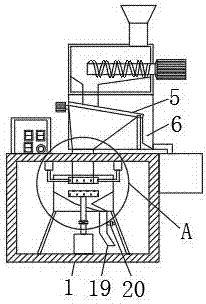

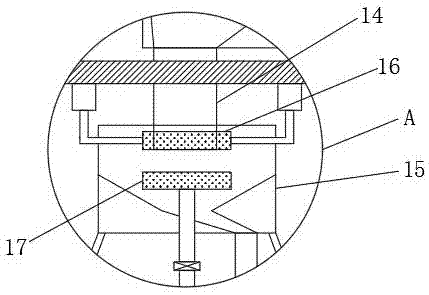

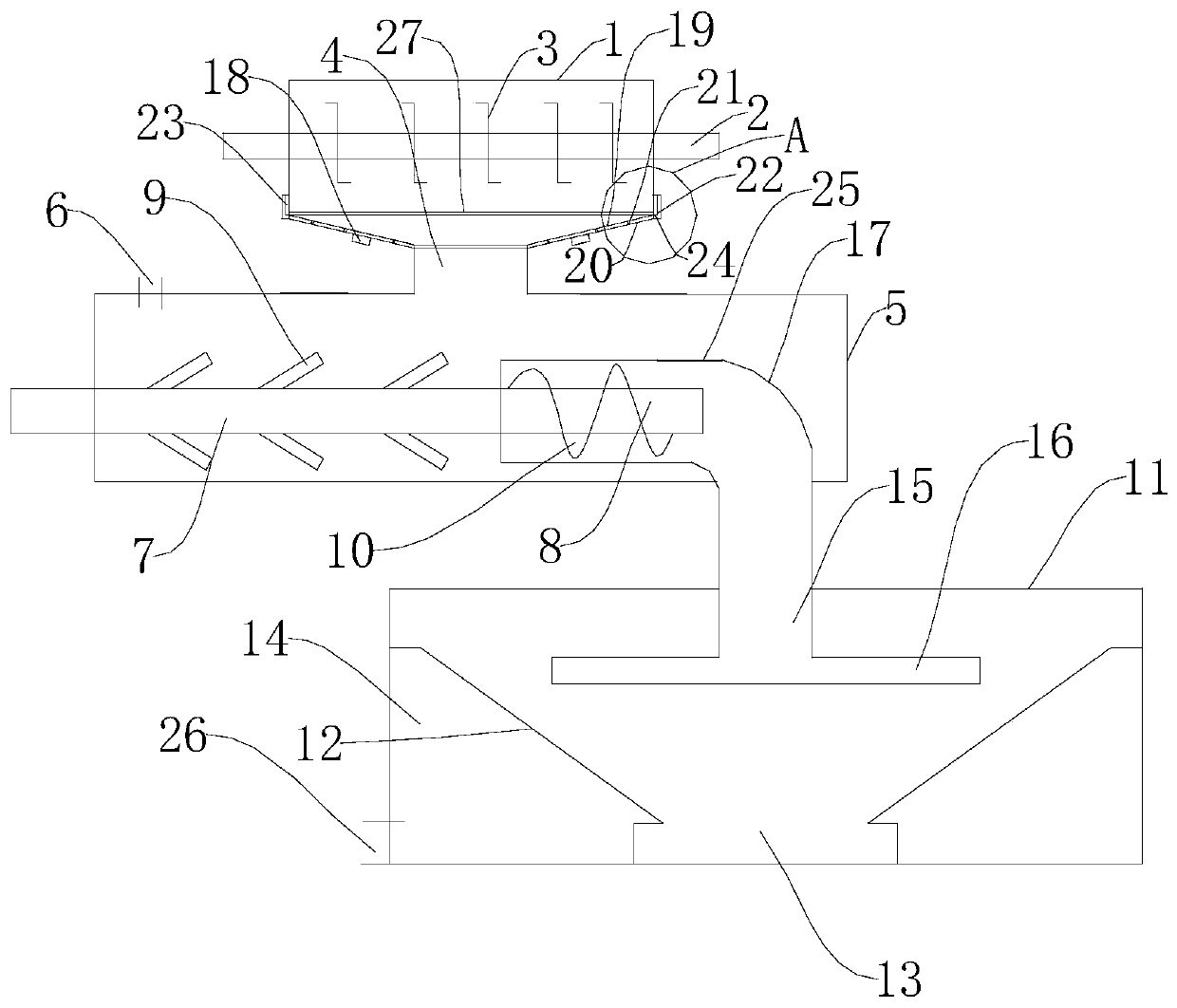

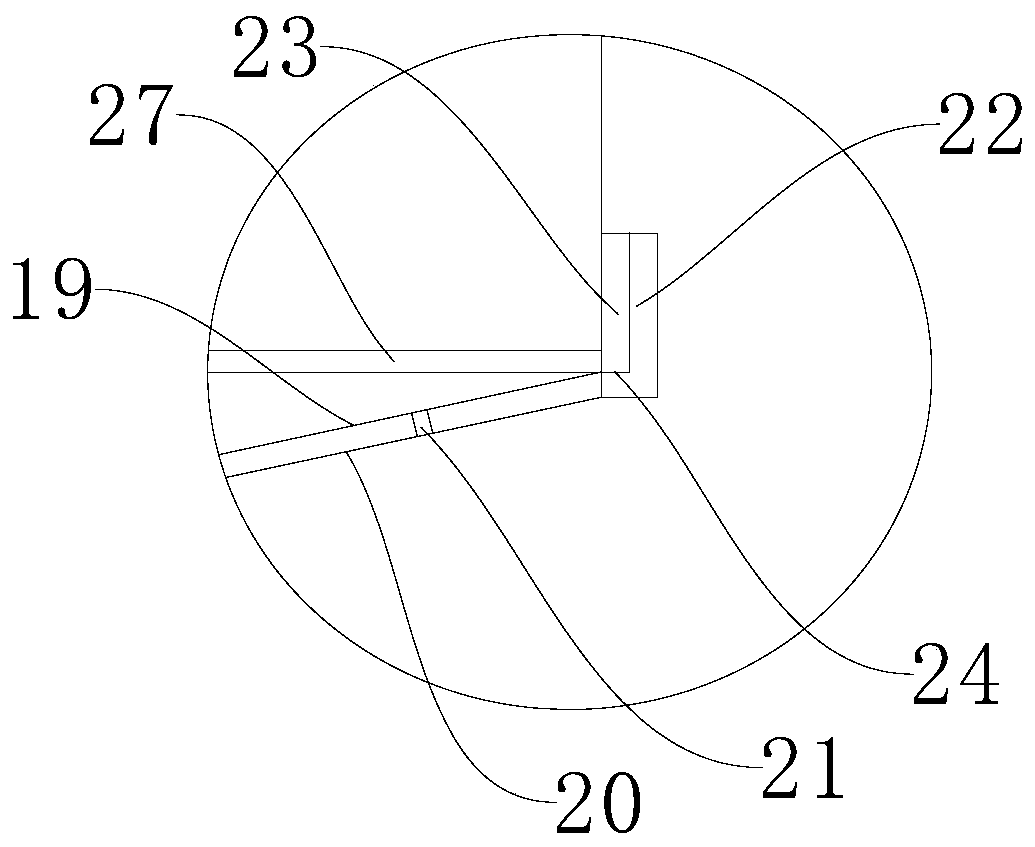

Pulping machine for papermaking

PendingCN107476107AEnergy savingImprove discharge efficiencyPulp beating/refining methodsElectric machineryPapermaking

The invention discloses a pulping machine for papermaking. The pulping machine comprises a machine frame, a large paper pulp recycling box, a filtering box, a cutting box, a grinding machine and an air hammer, wherein the large paper pulp recycling box is arranged on one side of an air compressor, one side of the large paper pulp recycling box is provided with the filtering box, one side of the filtering box is provided with a vibrating screen, one side of a vibration motor is provided with the cutting box, the top of a fine paper pulp outlet is provided with the grinding machine, an upper grinding wheel is arranged on one side of the grinding machine, and a lower grinding wheel is arranged on one side of the upper grinding wheel; a grinding motor is arranged on one side of the lower grinding wheel, one side of the grinding motor is provided with a discharge port, and one side of the discharge port is provided with the air hammer. Paper pulp obtained after cutting can be filtered, so that the size of the filtered paper pulp is uniform, the large paper pulp can be recycled and reused, and energy is saved; meanwhile, the pulp discharging rate is high, the paper pulp cannot adhere to the inner wall of the outlet, and the pulping machine is convenient to use.

Owner:枣庄市恒宇纸业有限公司

Preparation method of efficient anti-sloughing leak-proof drilling fluid

A preparation method of an efficient anti-sloughing leak-proof drilling fluid, belongs to the technical field of oil field chemistry. The drilling fluid comprises the following raw materials by weight: 1-6% of sodium bentonite, 1-10% of a heavier material, 0.5-1% of a lubrication agent, 0.7-3% of oxidized bitumen, 1-3% of sodium silicate, 1-4% of quick lime, 0.5-2% of sodium hydroxide, 0.7-2% of cottonseed hull powder, 30%-40% of deionized water and the balance of brine. The method comprises the steps of: first pre-hydrating the sodium bentonite in deionized water for 24 h, then adding the sodium bentonite to brine, then adding a weighting material, a lubricant, oxidized bitumen, sodium silicate, quick lime and sodium hydroxide, respectively stirring for 2 h, and finally adding cottonseed hull powder and stirring for 1 h. The efficient anti-sloughing leak-proof drilling fluid provided by the invention contains ingredients in a proper proportion, the obtained product has good anti-sloughing and leak-proof effect, can cram slits for different stratums. Moreover, the preparation method is simple.

Owner:山东聚鑫化工有限公司

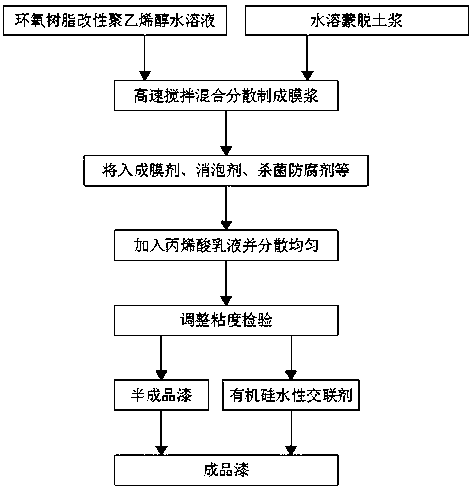

Nanometer multifunctional aqueous anticorrosive paint

InactiveCN110628275ASolve the costFix performance issuesAntifouling/underwater paintsPaints with biocidesEmulsionPolyvinyl alcohol

The invention discloses a nanometer multifunctional aqueous anticorrosive paint, which comprises, by mass, 10% of water, 10% of montmorillonite slurry, 25% of an epoxy modified polyvinyl alcohol liquid, 0.2% of a dispersing agent, 4% of a film-forming agent, 0.2% of a defoaming agent, 0.2% of a bactericide, 40% of acrylic emulsion and 0.6% of a thickening agent. The preparation method comprises: mixing a modified polyvinyl alcohol liquid and montmorillonite slurry according to a certain ratio, and dispersing at a high speed to prepare nano-scale polyvinyl alcohol film-forming slurry with a certain film-forming property; and carrying out a polymerization reaction with acrylic emulsion to prepare the high-performance aqueous anticorrosive paint. According to the invention, the film-forming slurry has a certain film-forming function and thixotropic property so as to substantially reduce the adding amounts of the film-forming agent and the emulsion to greatly reduce the cost, montmorillonite has high expansion performance when meeting water, and industrial dust can be even added during the paint preparation process so as to turn waste into treasure and protect the environment, such that the problems of high production cost and poor performance of the existing multifunctional aqueous anticorrosive paint are solved.

Owner:佛山市顺德区博宜防腐涂料科技有限公司

A kind of preparation method of bentonite for drilling mud

InactiveCN102965086BImprove thixotropyHigh pulping rateDrilling compositionSodium BentoniteWell drilling

The invention discloses a preparation method of bentonite for drilling mud. The method includes the steps of mining, sodium ion exchange capacity analysis, sodium ion regulation, accumulation sodium modification, drying and crushing, etc. The invention has the advantages that: the preparation method is simple, the use effect is good, the bentonite obtained by the method can be used to resist seawater and chemical polluted water, and can completely block seawater and chemical polluted water.

Owner:董宪姝

Pulping equipment for papermaking

ActiveCN111041877APrevent backflowAvoid blockingPaper recyclingCellulose material pulpingHelical bladePapermaking

The invention provides pulping equipment for papermaking. The pulping equipment comprises a paper shredding device, a primary pulp mixing device, a pulping device and a pulp return pool, wherein the paper shredding device comprises a first device shell; a paper inlet is arranged on the upper end surface of the first device shell; a rotating shaft is arranged in the first device shell; a pluralityof paper shredding knives are fixedly arranged on the rotating shaft; a shredded paper outlet is arranged at the bottom part of the first device shell; the primary pulp mixing device comprises a second device shell; a water inlet is arranged on the second device shell; a stirring shaft is arranged in the second device shell and comprises a stirring section and an extrusion section; stirring bladesare fixedly arranged at the stirring section; and spiral blades are arranged at the extrusion section. According to the invention, by utilization of the paper shredding device, waste paper is cut into shredded paper; the shredded paper and water are mixed through the primary pulp mixing device and stirred through the stirring blades to form a mixed pulp; the mixed pulp is conveyed to a barrel-shaped shell under the rotating thrust action of the stirring blades inclining towards the extrusion section; the shredded paper is further continuously torn in the barrel-shaped shell and then discharged to the pulp forming device; and the pulp is further filtered through a filter screen in the pulping device to obtain a finished pulp.

Owner:JIANGSU JINLIAN PAPER

Preparation method of mechanical rotary drilling pile wall-retaining slurry

The invention discloses a preparation method of mechanical rotary drilling pile wall-retaining slurry. The method is characterized by comprising the following steps: a, using a main material of a pulping agent having excitation expansion performance and main component SiO2 to prepare powder, performing uniform stirring, and allowing the stirred material to stand for 1-2 days for homogenization toform a uniform pulping material; b, adding an excitant and a swelling agent into the pulping material obtained in the step a, performing uniform mixing, adding water, and performing mixing under stirring to complete excitation and expansion of the main material of the pulping agent; and c, adding a dispersant, a tackifying agent, a thickening agent and a water retaining agent as auxiliary materials, and performing uniform mixing under stirring to prepare the wall retaining slurry. According to the preparation method provided by the invention, the wall retaining slurry prepared by the method has the advantages of better quality, lower preparation costs and better self-consolidation performance.

Owner:CHONGQING CONSTR ENG SECOND CONSTR CO LTD +1

Attapulgite spinning slurry adjuvant

The invention discloses a concave-convex weave slurry agent. The invention is characterized in that the concave-convex weave slurry agent is formed by high-viscosity concave-convex rod clay, active concave-convex rod clay, polyacrylamide, sodium carboxymethylstarch, carbowax and alkyl sodium sulfonate; mixing the materials and processing into powder material, packing into final product. The inventive agent can be used in variable weave slurries, to accelerate the penetration and adhesive of slurry, to improve the adhesion and make the slurry uniform, the film flexible and smooth, with wide application, low cost and high biological degradation, without pollution. The inventive agent can absorb the harmful material and gas of weave slurry.

Owner:许盛英

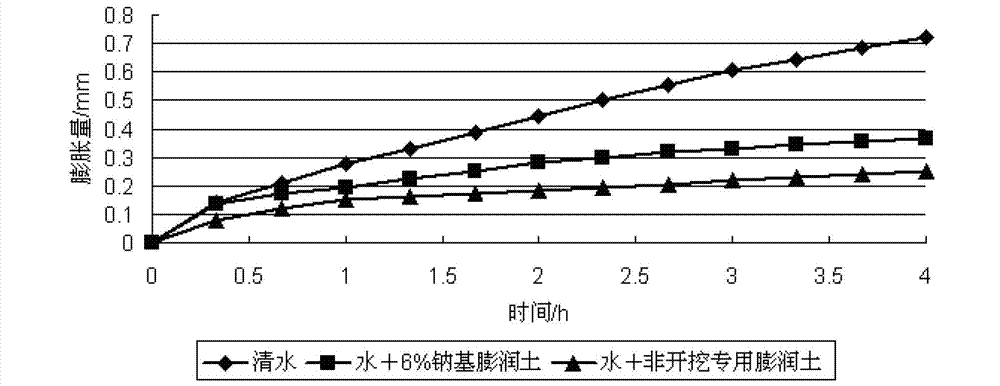

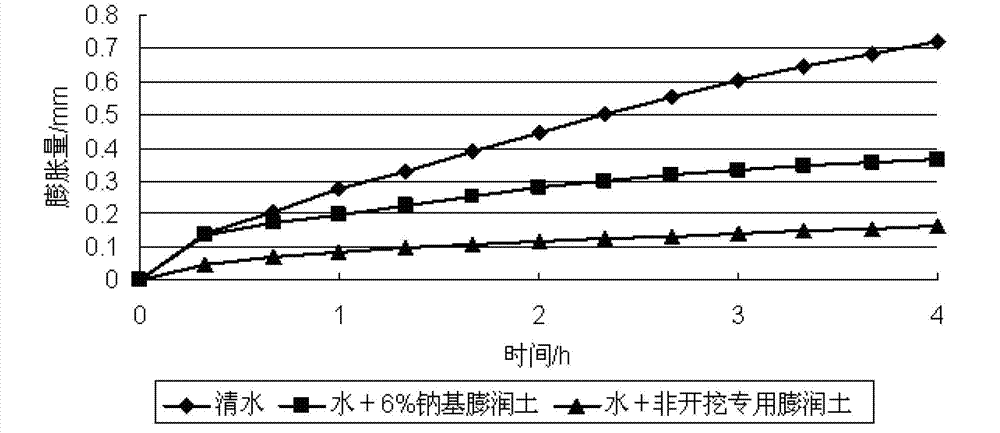

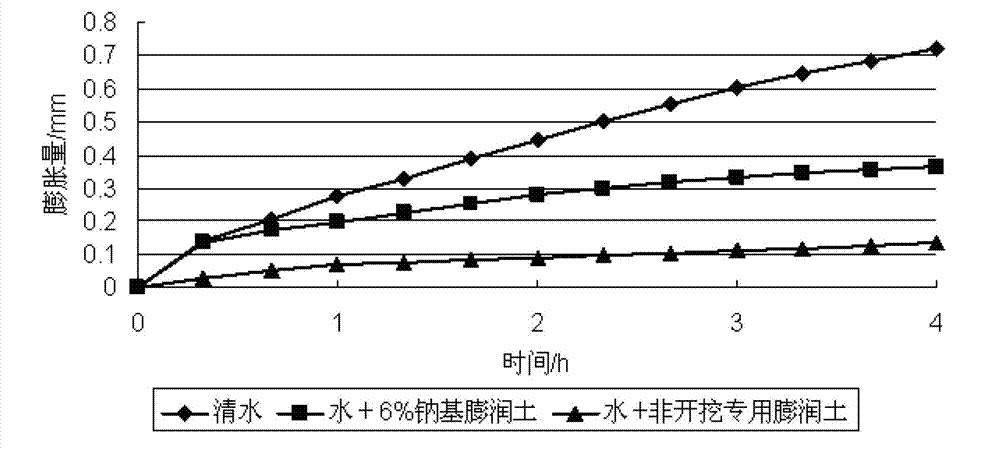

Betonite for non-excavation drilling fluid

ActiveCN103242811AGood value for moneyHigh pulping rateDrilling compositionSodium BentoniteWell drilling

The invention discloses a betonite for a non-excavation drilling fluid. The betonite is a mixture of the dry powders of sodium bentonite, polymer and a shale inhibitor in a mass ratio of (15-17):(1.75-2.25):(2.75-3.25), wherein the polymer is konjac. The pulping rate of betonite is not less than 30m<3> / T, and compared with a common drilling fluid betonite, the betonite has the advantages of higher pulping rate, convenience in use and better cost performance. A drilling liquid prepared by using the betonite has good rheological property, de-filtration property and a good inhibition effect, and can satisfy requirements on debris carrying and hole wall stability of water sensitive stratum during non-excavation horizontal directional drilling.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

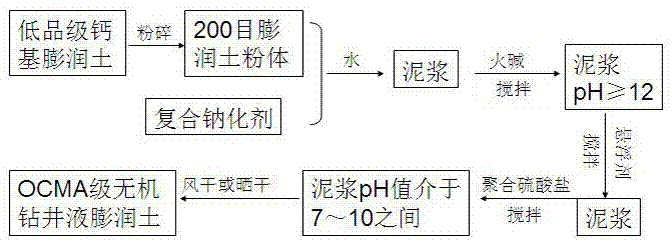

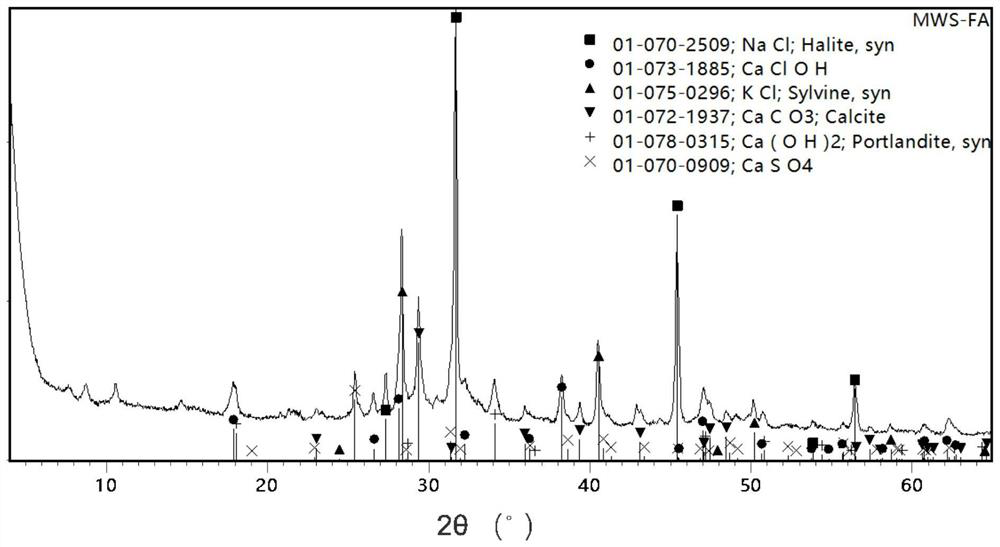

Preparation method of inorganic bentonite for drilling fluid

The invention relates to a preparation method of inorganic bentonite for drilling fluid. The preparation method specifically comprises the following steps: (1) taking low-grade calcium-based bentonite for crushing, adding a composite sodium agent into the bentonite, uniformly mixing to obtain a mixture, dissolving the mixture into water, regulating the pH value to be greater than or equal to 12 by caustic soda, and uniformly stirring, thereby obtaining mud for later use; (2) adding an inorganic composite suspending agent into mud prepared in the step (1), uniformly stirring, then adding polymerized sulfate to enable the pH value of the mud to be 7-10, filtering after uniformly stirring, taking precipitates to remove water to obtain the inorganic bentonite for the drilling fluid. According to the preparation method disclosed by the invention, the low-grade calcium-based bentonite is adopted to prepare OCMA-grade inorganic bentonite for the drilling fluid, so that a low-grade bentonite purifying step is omitted, a processing process of inorganic pulping bentonite is optimized, an organic high polymer material is not added in a preparation process, production cost of the bentonite is reduced, and the product pulping rate is high, so that the high-additional-value utilization of low-grade bentonite resources is realized.

Owner:LUOYANG INST OF SCI & TECH

Preparation method of insulating material for pipelines

The invention belongs to the technical field of insulating material manufacturing and provides an insulating material for pipelines and a preparation method. The insulating material for pipelines is prepared from, by weight, 50-75 parts of silicon dioxide particles with the average particle size pf 60-70 nm, 15-23 parts of hollow ceramic fiber, 2-9 parts of attapulgite clay particles and 11-15 parts of hollow glass fiber. The prepared insulating material has good insulating properties and high strength.

Owner:HEFEI ZHENXUN LOW TEMPERATURE TECH CO LTD

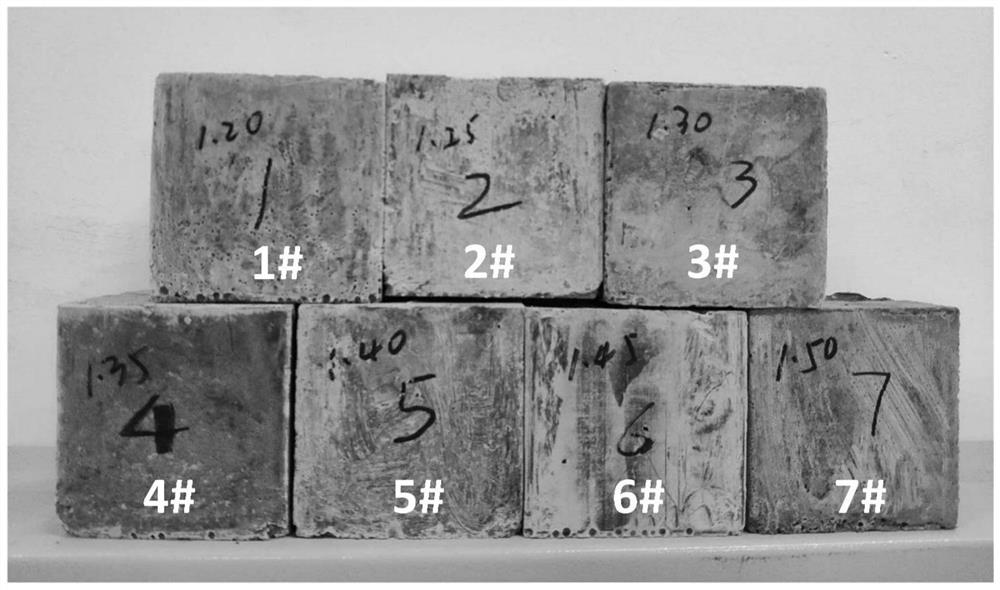

Solidifiable spacer fluid

PendingCN113185957ARealize resource utilizationRealize the curing processDrilling compositionSolid waste managementPolymer chemistryRaw material

The invention provides a curable spacer fluid. The curable spacer fluid is prepared from the following raw materials in parts by weight: 4-40 parts of diatomite, 40-80 parts of a cementing material, 10-15 parts of an exciting agent and 1-5 parts of a fluid loss agent. According to the technical scheme provided by the invention, the curable spacer fluid of 1.20 g / cm<3> to 1.50 g / cm<3> can be obtained only by increasing the slurry making rate on the premise that expensive hollow glass beads are not used as lightening agents, and the 30-d strength of a curable spacer fluid curing body is 3.0 MPa to 25.0 MPa.

Owner:CHINA OILFIELD SERVICES +1

Wood fiber treatment method

InactiveCN114855489AEasy to useIncrease throughputPulp de-wateringPaper recyclingCrude fibreWood fibre

The invention discloses a wood fiber treatment method. The method comprises the following steps: step 1, a pulping process: continuously pulping a wood fiber raw material; step 2, a desanding process: pumping the pulp after repulping to pass through a high-concentration desander to remove heavy impurities; 3, fine screening: diluting the desanded slurry, and separating crude fibers; step 4, pulping: pulping the screened and separated crude fibers, and continuing to enter a fine screening process after pulping is completed; and step 5, concentration regulation: concentrating the accepted pulp subjected to the fine screening process by adopting an inclined wire, regulating and controlling the concentration of the pulp according to production requirements in combination with an on-line automatic concentration regulation system, and pumping the pulp into a papermaking workshop for use. By adopting the method disclosed by the invention, after the wood fibers are not subjected to core pulp process treatment, the controllability and timeliness of pulp preparation are realized, the adjustment of the pulp preparation process is shortened to about 10 minutes from original 8 hours, and the stability of the product quality is improved.

Owner:YUANTONG PAPER SHANDONG

A wall protection slurry powder based on high-calcium and high-sulfur coal-fired ash

The invention discloses a wall protection slurry powder based on high-calcium and high-sulfur coal-fired ash. Carbide slag, the high-calcium and high-sulfur coal-fired ash and bentonite are used as the main material of the pulping agent, and the calcium carbide slag is used as the activator. The invention has the advantages of being more convenient for on-site construction and use, can be directly added to form wall protection mud, can better reduce costs, and can better improve the quality of finished wall protection mud.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +2

High slurry rate thixotropic bentonite slurry for horizontal crossing drilling and preparation method thereof

ActiveCN103525384BHigh pulping rateViscosity increase efficiencyDrilling compositionSodium BentoniteWell drilling

The invention discloses thixotropy bentonite slurry with high mud-making rate for horizontal crossing well drilling and a preparation method of the thixotropy bentonite slurry. The thixotropy bentonite slurry is modified by a modifying agent comprising a water-soluble allyl polymer, natural magnesium containing mineral powder and a humid acid-hydrolysis sodium polyacrylonitrile graft polymer. The preparation method of the thixotropy bentonite slurry comprises the following steps: preparing sodium bentonite, preparing bentonite-based slurry, preparing the modifying agent and finally preparing the modified bentonite. The mud-making rate, the viscosity increasing efficiency and the de-filtration effect of the bentonite prepared by the method provided by the invention are greatly improved, and the modifying effect of the bentonite is far superior to that of bentonite modified by using a single modifying agent.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Wet strength paper treatment technology

ActiveCN101538810BIncrease profitHigh pulping ratePulp de-wateringPaper recyclingFiberEconomic benefits

The invention relates to a wet strength paper treatment technology. Hot water and wet strength paper are added to a pulp kneader to pulp the wet strength paper, and heavy metal impurities contained in the wet strength paper are removed after the wet strength paper is pulped; and pulp is condensed by spiral condensing equipment, is heated by spiral heating equipment and enters a thermal dispersionmachine to be further torn, diluted and beaten to prepare fiber pulp. The wet strength paper treatment technology effectively improves the pulping yield of the wet strength paper, lessens the waste, reduces the production cost and improves the economic benefits.

Owner:玖龙纸业(沈阳)有限公司

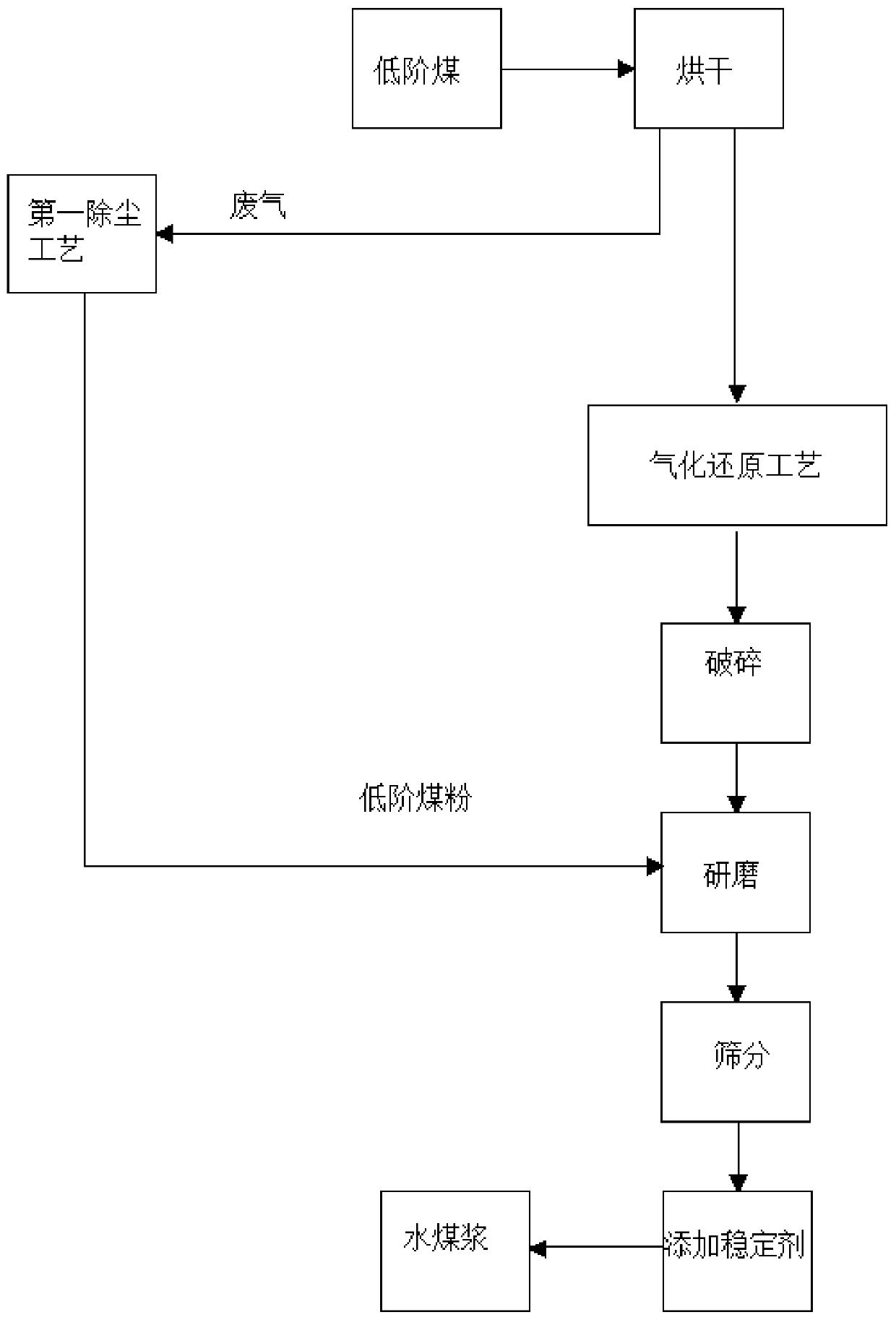

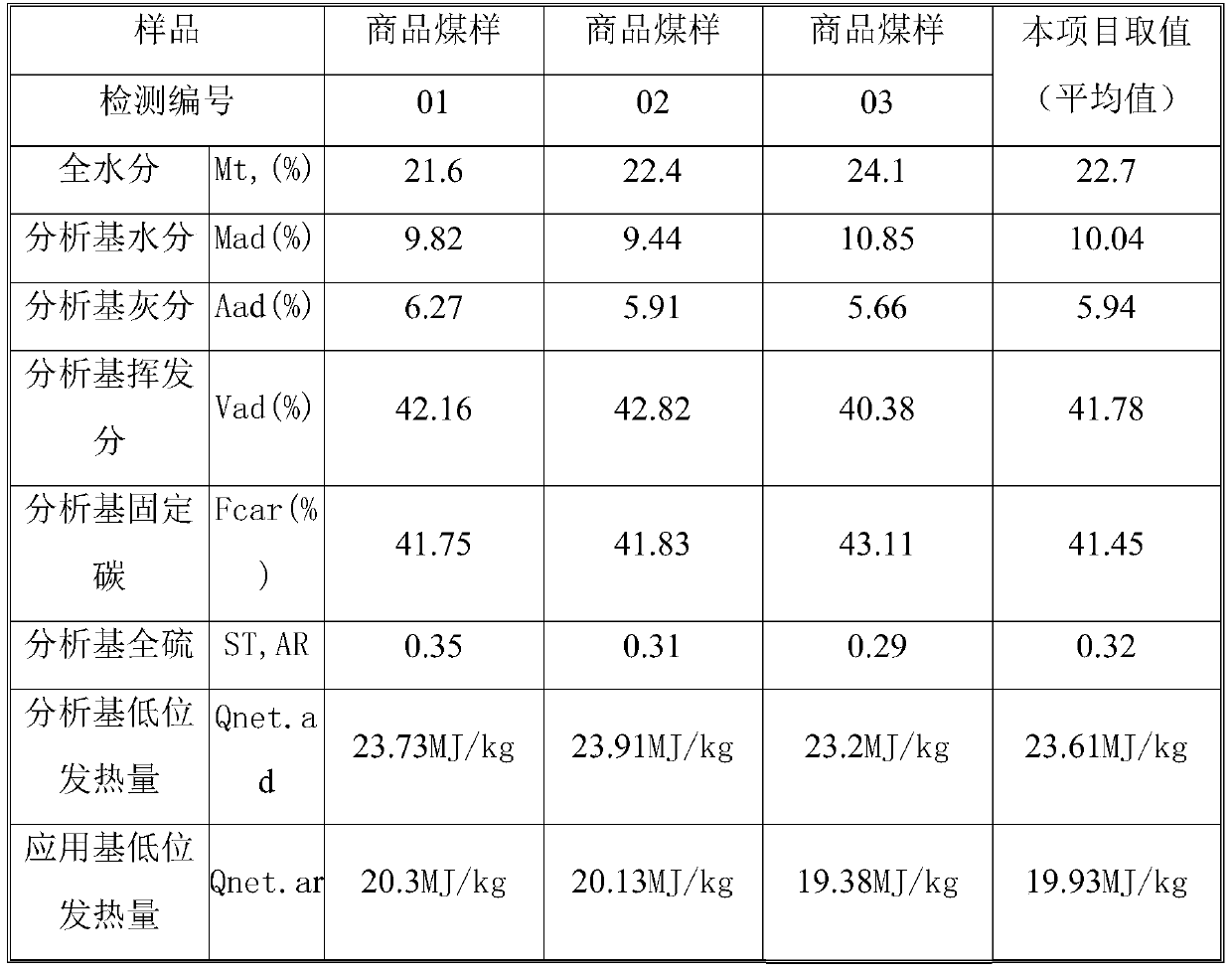

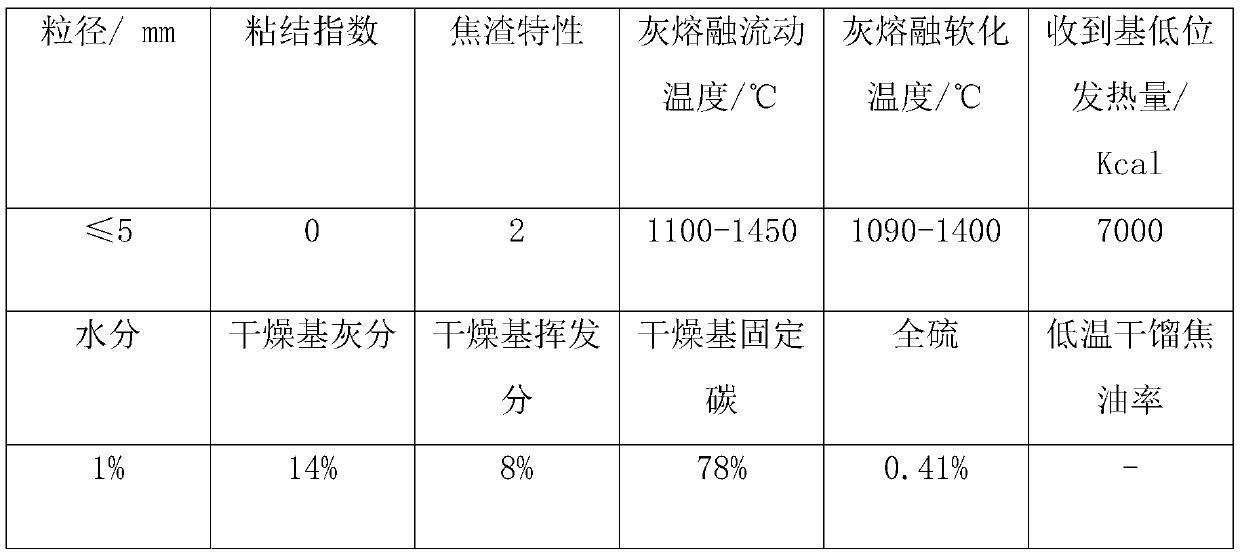

Method using quality-based utilization of low-rank coal to prepare coal-water slurry

PendingCN110055117AReduce moisture contentReduce consistencyLiquid carbonaceous fuelsCoal waterCoal tar

The invention provides a method using the quality-based utilization of low-rank coal to prepare coal-water slurry. The method includes: drying, performing gasification reduction, crushing and grinding. The method has the advantages that quality-improved coal, rice gas, clean water and coal tar are prepared by the quality-based utilization of the low-rank coal, the prepared quality-improved coal isqualitatively changed as compared with the low-rank coal in terms of coal properties, the low-range coal which is many and large in pore structure, excellent in hydrophilicity, high in water content,different in quality and low in consistency is prepared into the quality-improved coal which is few and small in pore structure, excellent in hydrophobicity, low in water content, identical in quality and high in consistency, and accordingly the coal-water slurry which is high in slurry forming rate (the slurry forming rate of the coal-water slurry can reach 70%) and prepared by different low-rank coal is small in quality difference and high in consistency; the method can provide clean water and use process water provided by other coal processing processes and has excellent system cooperationability.

Owner:浙江天禄环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com