A kind of preparation method of bentonite for drilling mud

A drilling mud and bentonite technology, which is applied in the directions of drilling compositions, chemical instruments and methods, can solve problems such as inability to meet production, and achieve the effects of strong plasticity, simple preparation method and good thixotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

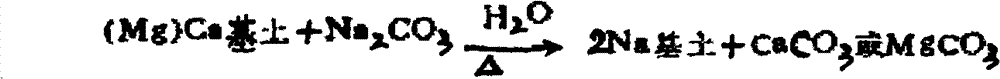

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of bentonite for drilling mud, comprising the following steps:

[0020] (1) collect bentonite ore;

[0021] (2) the bentonite ore collected by above-mentioned steps (1) is analyzed by a light-increasing photometer, wherein the sodium ion exchange capacity (ammonium chloride method) in the bentonite is 30-80mg / 100g;

[0022] The exchange capacity is the amount of other ions in the ore that can be exchanged with the added sodium ions.

[0023] (3) Regulate sodium ion: adjust the bentonite ore after the above-mentioned step (2) to adjust the sodium ion, and supplement the sodium ion in the bentonite to 110mg / 100g by batching;

[0024] The specific method is: add 5% soda ash, 0.6% caustic soda and 1% magnesium oxide of the total weight;

[0025] (4) Accumulated sodium: accumulate the bentonite ore after adjusting the sodium ion in the above step (3), the time is 3-15 days; the summer temperature is high, it takes 3-7 days, and the winter temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com