Preparation method of modified attapulgite clay for drilling fluid

A technology of attapulgite clay and drilling fluid, applied in the directions of aluminum silicate, silicate, etc., can solve the problems of low viscosity and high impurity content, and achieve the effect of low filtration loss, good modification effect and small filtration loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

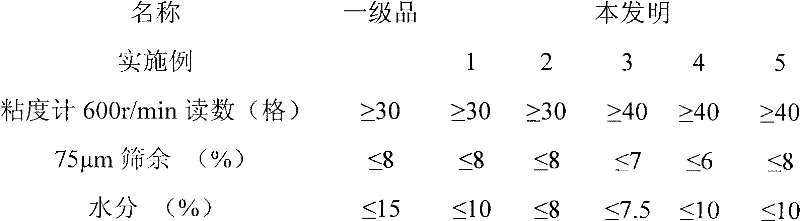

Examples

Embodiment 1

[0021] After the attapulgite clay raw ore with a water content of 30wt% is crushed by a crusher, the attapulgite clay is extruded by a pair of rollers to obtain a sheet-shaped attapulgite clay with a thickness of 1 to 2 mm; weigh 100kg of attapulgite clay, add 5kg of magnesium sulfate and mix it in a mixer Uniformly, extrude once on a double-roll machine, beating with a suspension concentration of 5wt%, passing through a 200-mesh sieve, centrifugal dehydration, drying, crushing, and packaging.

Embodiment 2

[0023] After the attapulgite clay raw ore with a water content of 40wt% was crushed by a crusher, it was extruded by a pair of rollers to obtain a sheet-shaped attapulgite clay with a thickness of 1 to 2 mm; 100 kg of attapulgite clay was weighed, and 7.5 kg of magnesia was added to mix evenly. Squeeze 3 times on the roller machine, beating with 7wt% suspension concentration, passing through 200 mesh sieve, centrifugal dehydration, drying, crushing, and packing.

Embodiment 3

[0025] After the attapulgite clay raw ore with a water content of 35wt% is crushed by a crusher, it is extruded by a pair of rollers to obtain a sheet-shaped attapulgite clay with a thickness of 1 to 2 mm; 100 kg of attapulgite clay is weighed, and 2.5 kg of magnesium stearate and 7.5 kg of magnesia is mixed evenly, extruded 5 times on a double roller machine, beaten with a suspension concentration of 10wt%, passed through a 200-mesh sieve, centrifugally dehydrated, dried, pulverized, and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com