Patents

Literature

217results about How to "Delay uneven settlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

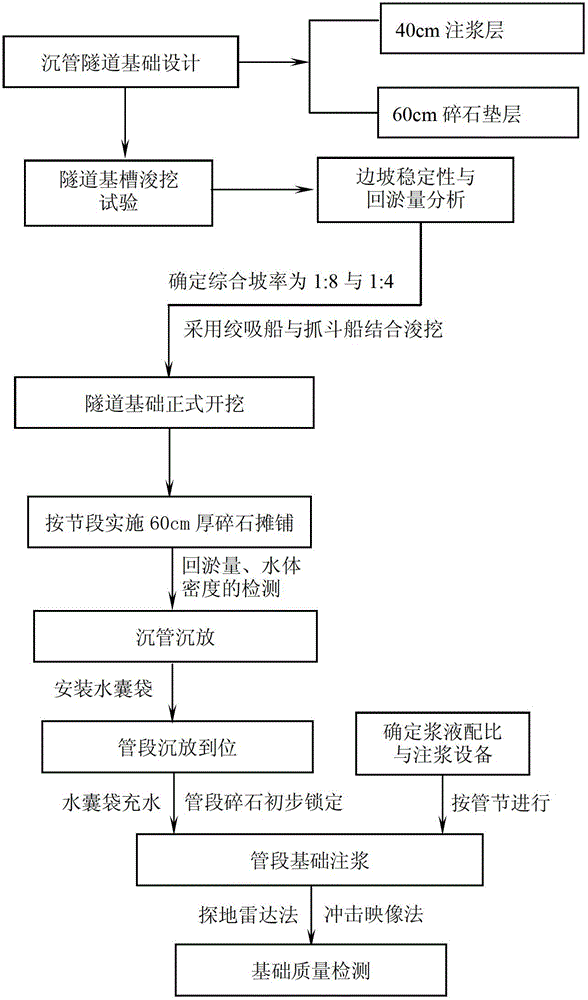

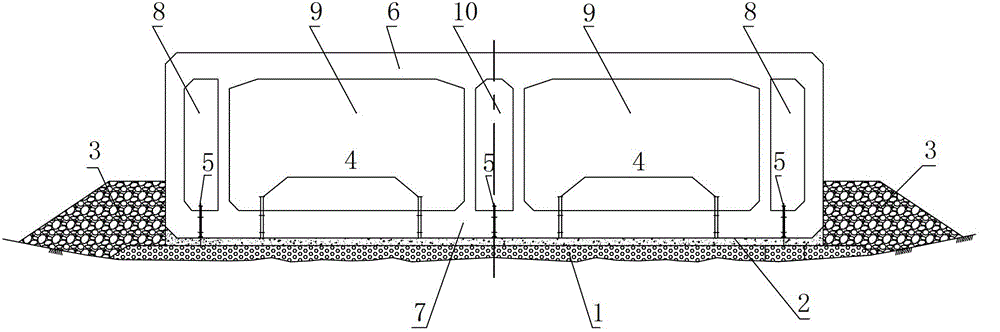

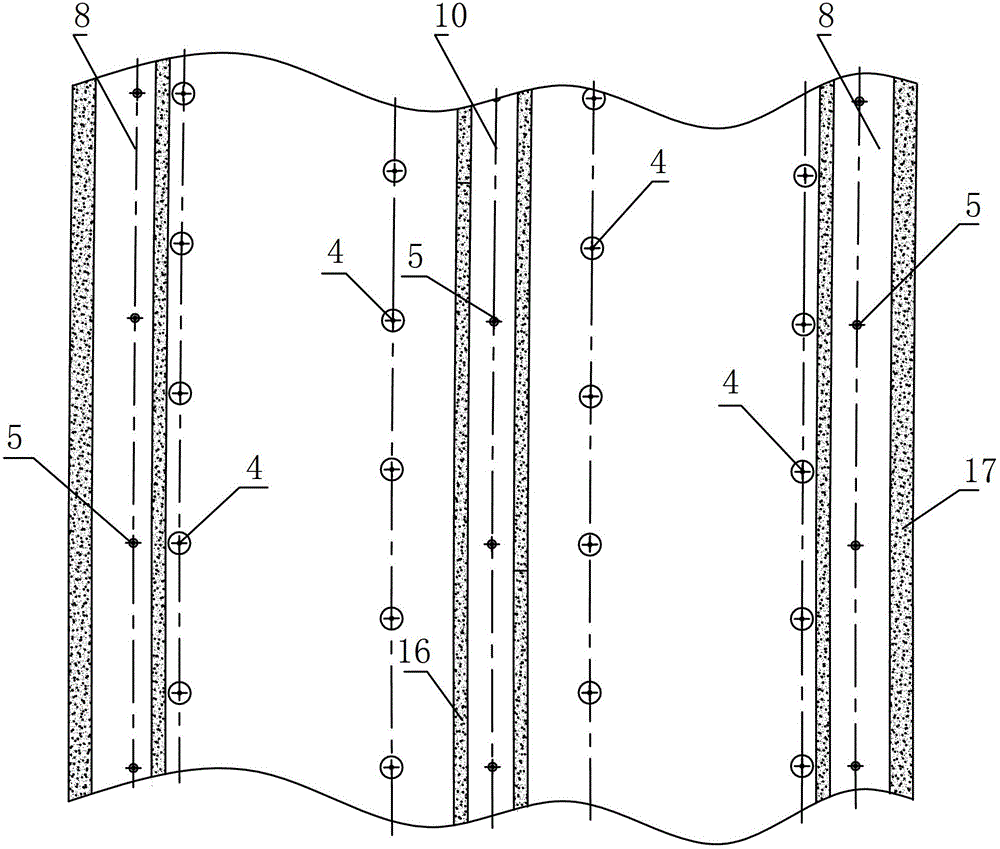

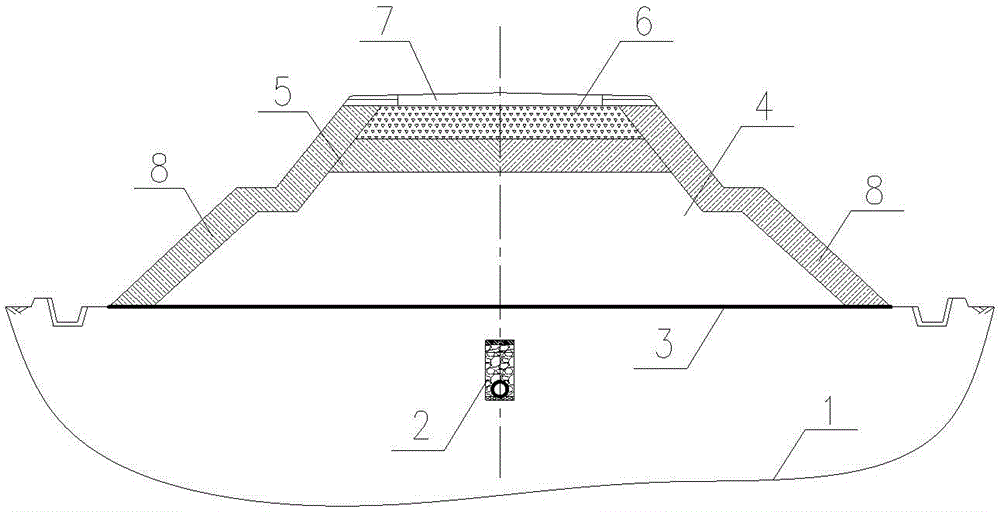

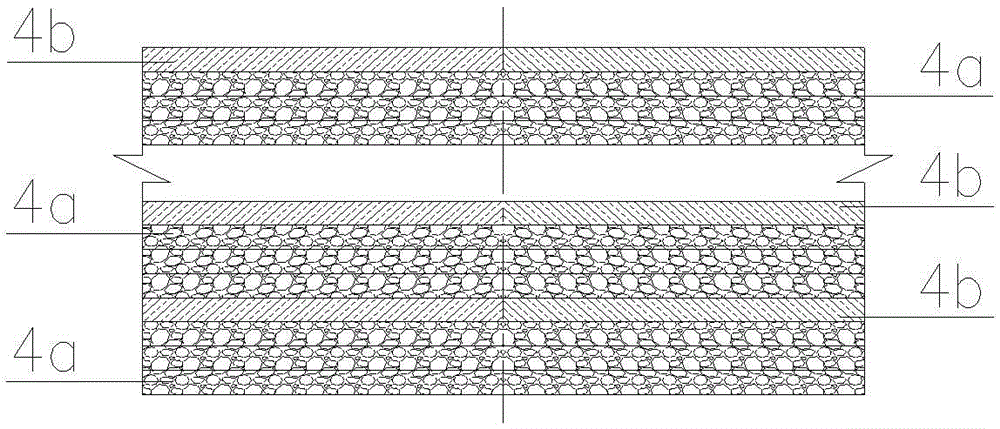

Underwater grouting grout based on soft-base large immersed tunnel foundation and grouting process thereof

The invention discloses a preparation of underwater grouting grout based on soft-base large immersed tunnel foundation and a grouting process thereof. The foundation is formed by a 60-cm thick macadam foundation base and a 40-cm thick sodium bentonite mortar foundation and is capable of meeting requirements for tunnel foundation rigidity and requirements for base seismic resistance and water flow scouring resistance. The grout is composed of cement, fine sand, coal ash and sodium bentonite. The grouting process is improved, and pipe inside grouting of embedded grouting holes is adopted. Therefore, large ships are not required to work on river face, underwater operation of divers and navigation risks are reduced, construction safety is greatly improved, and construction cost is reduced. The secondary grouting technology is first adopted in the field of the immersed tunnel to reduce uneven sedimentation in future operation stage of projects. The grouting process provides a reference guide and an experience guide for large dock projects, immersed tunnel projects, municipal administration soft earth foundation strengthening projects, high earthquake region basic project design and other similar projects.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +6

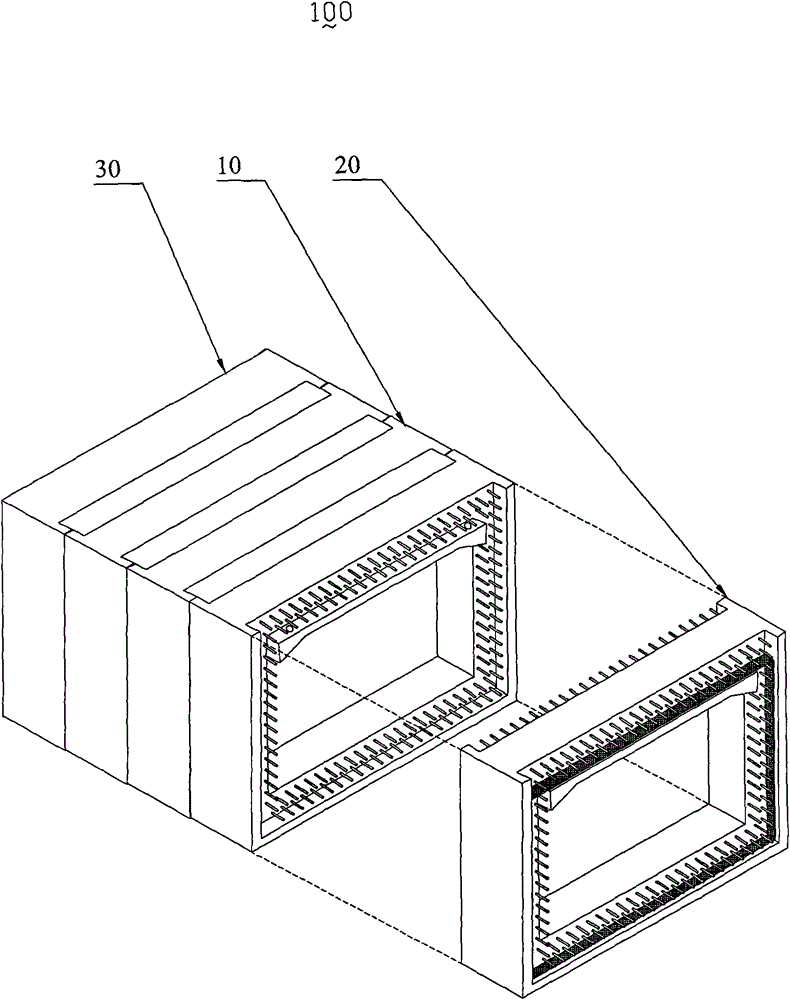

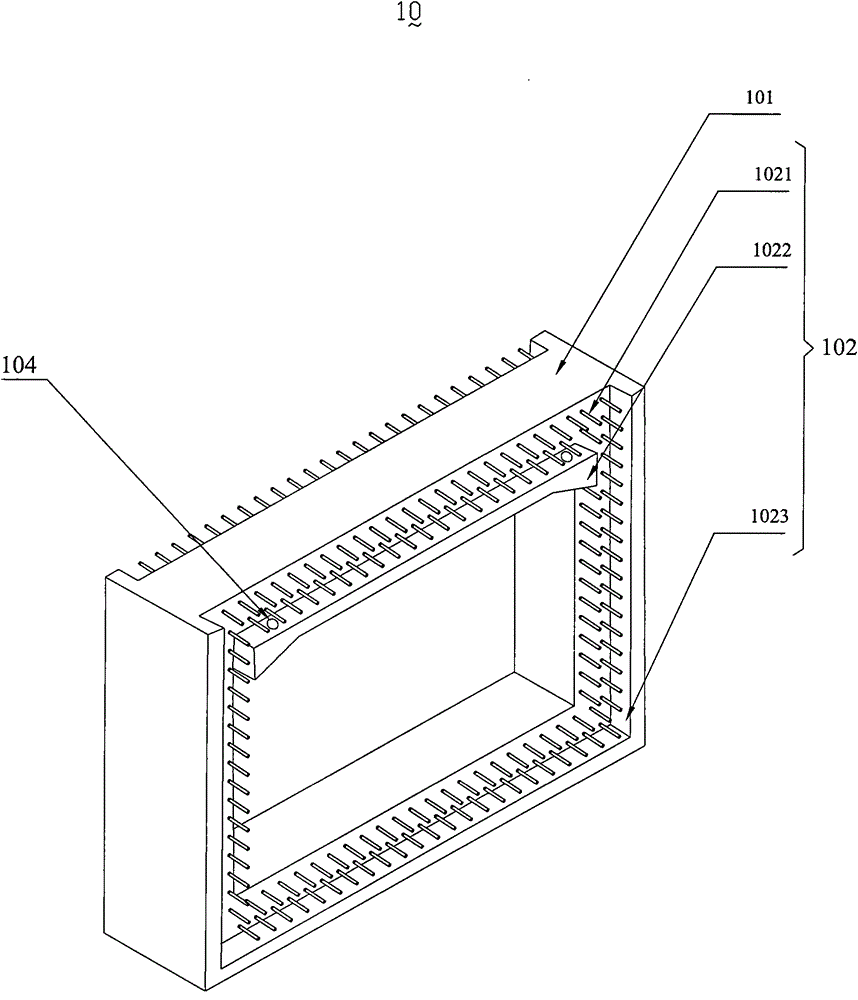

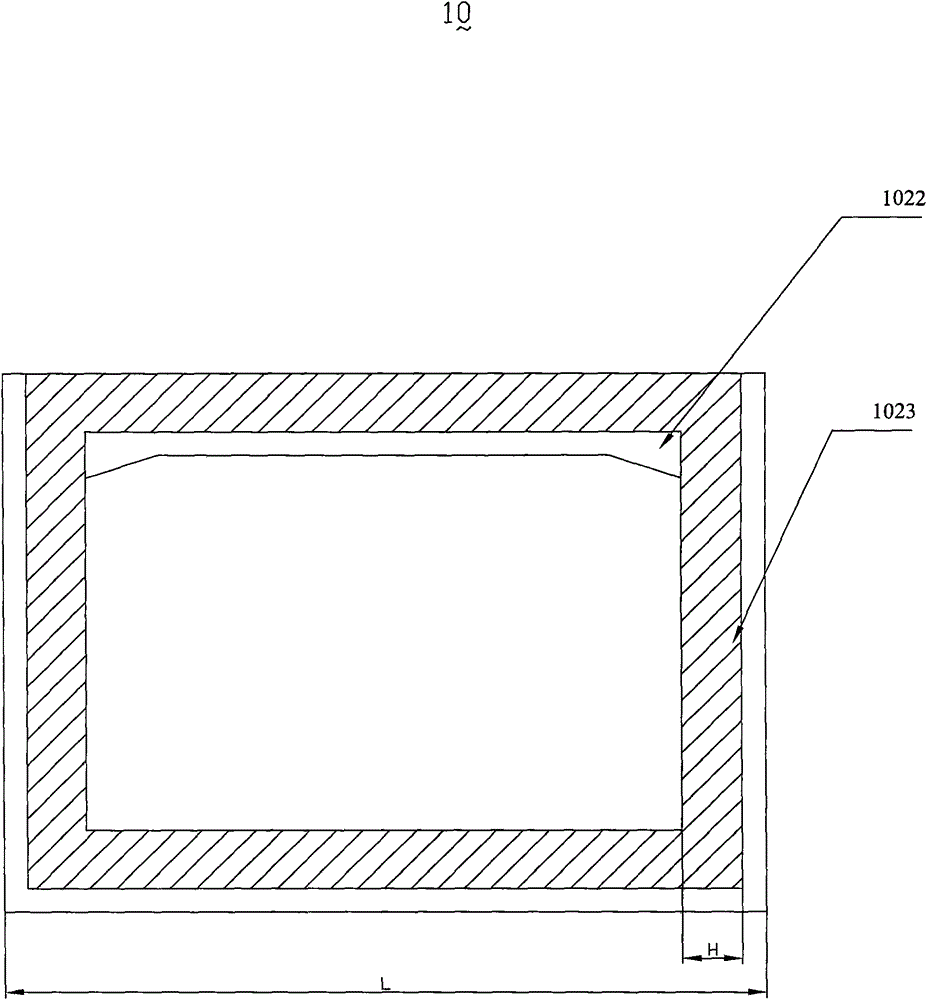

Prefabricated box culvert system and installation method thereof

The invention provides a prefabricated box culvert system. The prefabricated box culvert system comprises at least two prefabricated box culverts. Two prefabricated box culverts are located at the head end and the tail end of the prefabricated box culvert system, the prefabricated box culverts at the head end and the tail end respectively comprise a box body and two connectors, at least one connector of each box culvert comprises a bundle of bars or a pre-buried water stop belt, and the box culverts of the prefabricated box culvert system are connected through bars or the water stop belts formed through overlap welding, and are connected into the integrally-formed box culvert system through poured concrete. The invention further provides an installation method of the prefabricated box culvert system. The installation method is used for connecting the at least two prefabricated box culverts into a whole and laying the box culverts on the bottom face of a road. Compared with the prior art, the prefabricated box culvert system is simple in construction, short in construction period, low in cost, wide in application range, and suitable for municipal engineering and other large-scale traffic construction.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

Municipal road and construction method thereof

ActiveCN108867220AImprove compactnessGuaranteed compaction densityIn situ pavingsClimate change adaptationRoad engineeringBituminous concrete

The invention discloses a construction method for a municipal road, and belongs to the field of the road engineering. A technical scheme is that the construction method comprises the following steps:positioning and paying off, excavating a roadbed groove, backfilling the roadbed groove, paving and bedding, laying a cement stabilization layer, spraying emulsified asphalt, laying a modified asphaltconcrete pavement, processing a construction joint, and maintaining the road. The invention further provides the municipal road obtained by the above construction method. The provided municipal roadhas the advantages of small interspaces between various layers, uniform sedimentation, and less generated cracks.

Owner:四川先舟建设工程有限公司

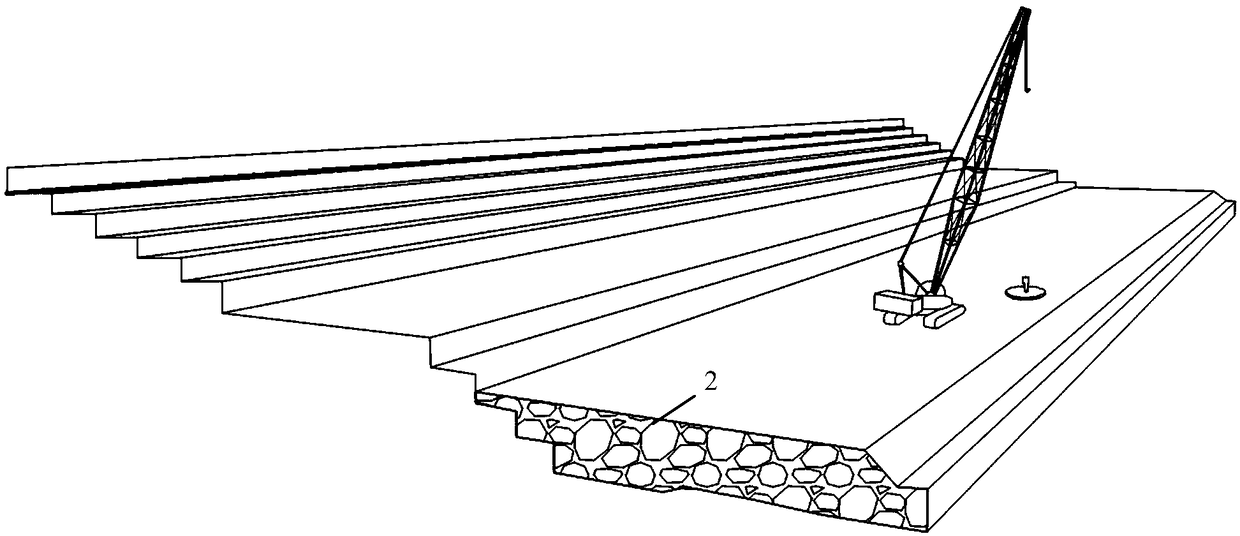

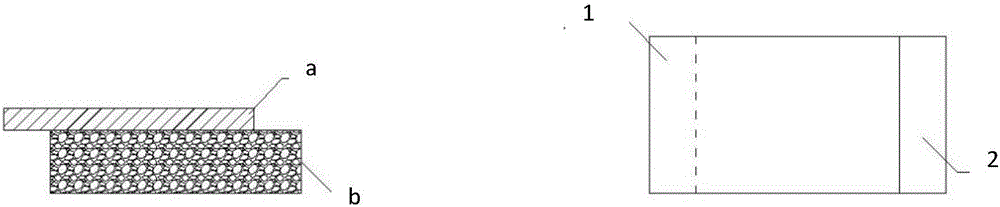

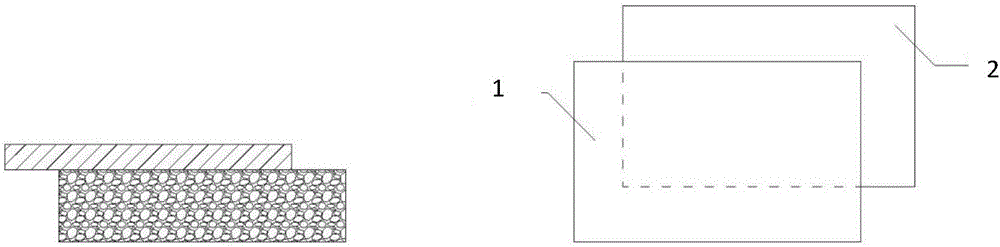

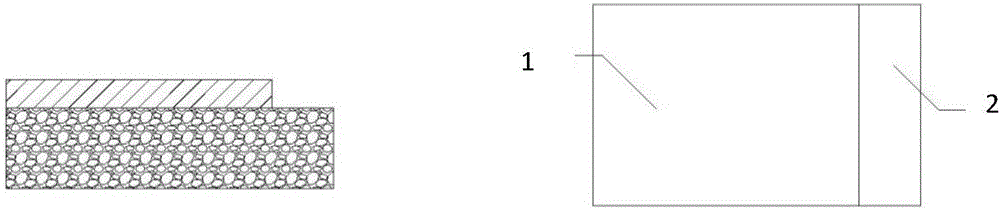

Panel construction method of concrete faced rock-fill dam

ActiveCN101906768APrevent structural cracksDelay uneven settlementEmbankmentsEarth-fill damsArchitectural engineeringRebar

The invention provides a panel construction method of concrete faced rock-fill dam, sequentially including the following procedures: vertical joint cushion layer and sloping surface renovating, emulsified asphalt spraying, reinforcing steel bar system safety, side form sealing up system safety, slip form system safety, concrete pouring, form removal maintenance and peripheral joint and vertical joint sealing up construction; wherein the concrete pouring adopts 'semi-closed type' chute warehousing, and pouring to the top in one step is carried out on the panel. The panel construction method of concrete faced rock-fill dam provided by the invention can carry out one-step construction of panel, thus reducing differential settlement among various dam materials after panel concrete construction, preventing structural crack of concrete panel after retaining water and avoiding that the top of the primary panel is cavity as construction is carried out by stages, so as to ensure the dam to operate safely.

Owner:SINOHYDRO ENG BUREAU 15

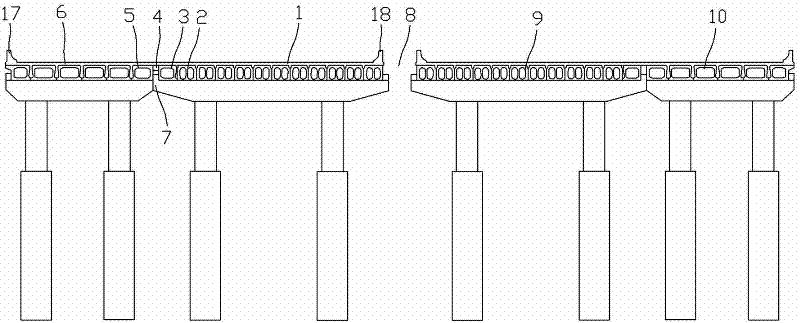

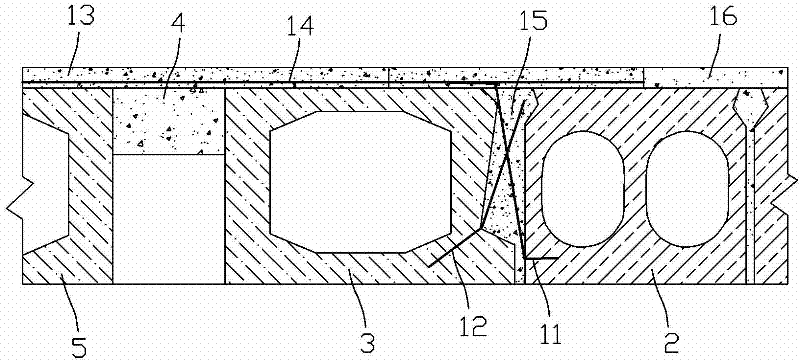

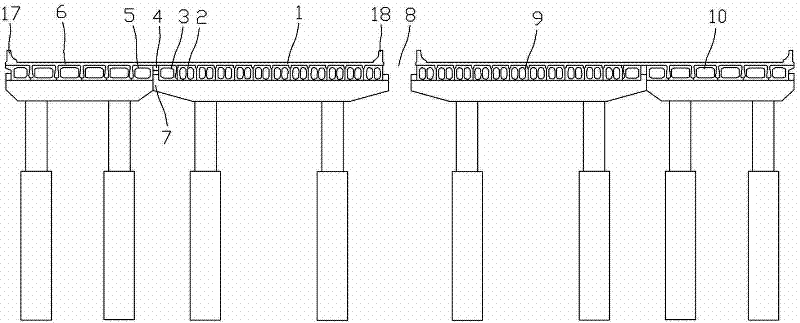

Bridge widening splicing structure and its construction method

InactiveCN102286921AEnsure connection integrityExtended service lifeBridge erection/assemblyBuilding energyResource saving

The invention relates to a bridge widening splicing structure and a construction method thereof. The present invention adopts the design principle of "connecting at the top and not connecting at the bottom", that is, the wet joint of cast-in-situ concrete is realized between the upper hollow slabs of the new and old bridges, the bridge deck is continuous, and the lower piers and foundations are no longer connected, and they are relatively independently stressed. To adapt to the differential settlement between the new and old bridges; the outer side plate of the old bridge is replaced, and the pier cover beam is not removed, only the anti-collision guardrail of the old bridge is removed. After the old bridge plate is replaced, the plate is replaced next to the old bridge The edge of the rear beam slab is connected with the beam slab of the new bridge by planting bars, so that the old and new bridges form a solid whole. The inventive method combines many advantages such as simple construction, short construction period, low construction cost, new and old bridges are formed into a whole to bear the force together, etc. The hollow slabs can be replaced by centralized prefabrication and factory construction, and are suitable for highway bridges of all grades. Wide construction, in line with the requirements of building energy saving, building a resource-saving, environment-friendly society, after promotion, it has good economic benefits and social value.

Owner:河南省九建工程有限公司 +1

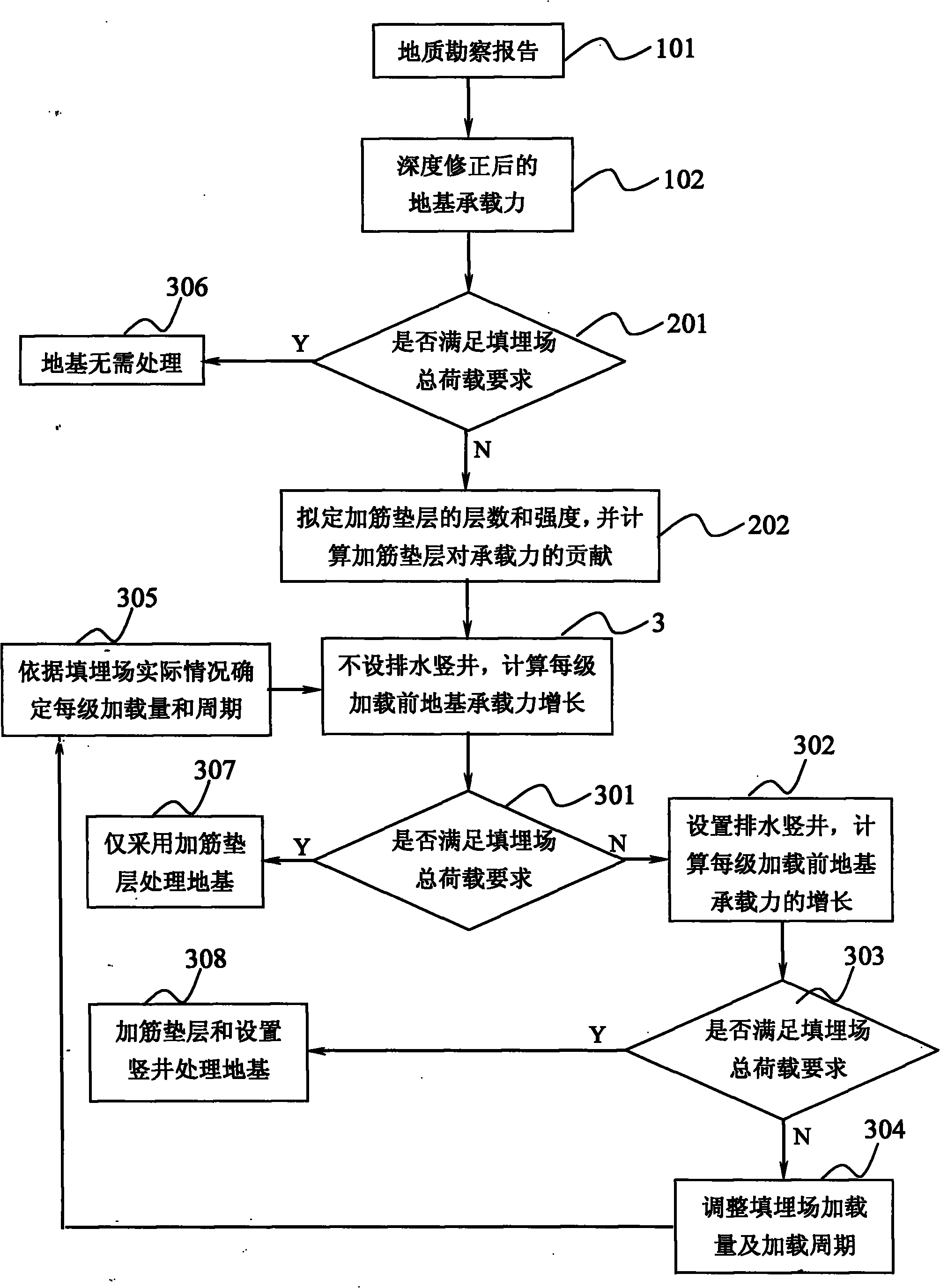

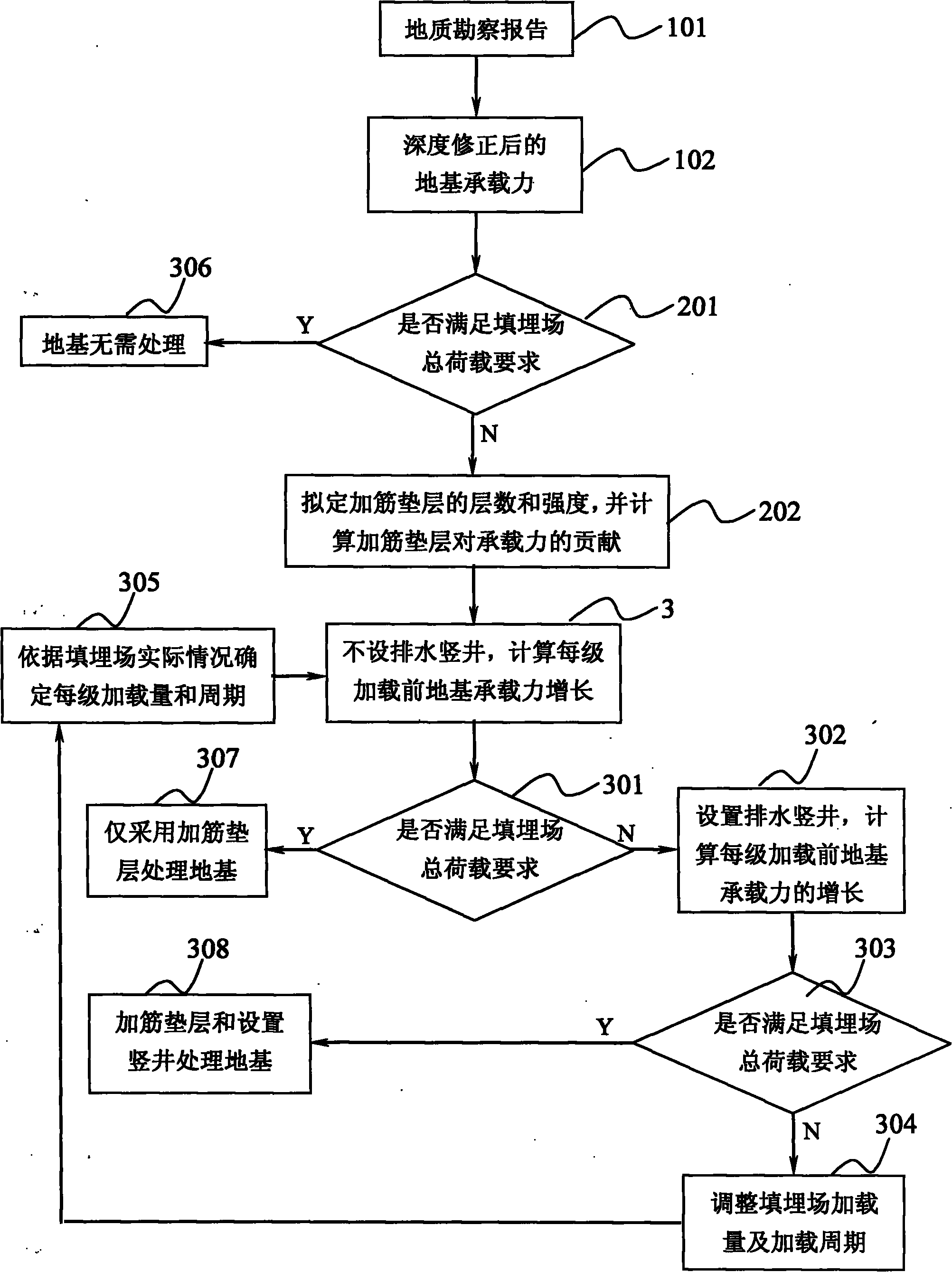

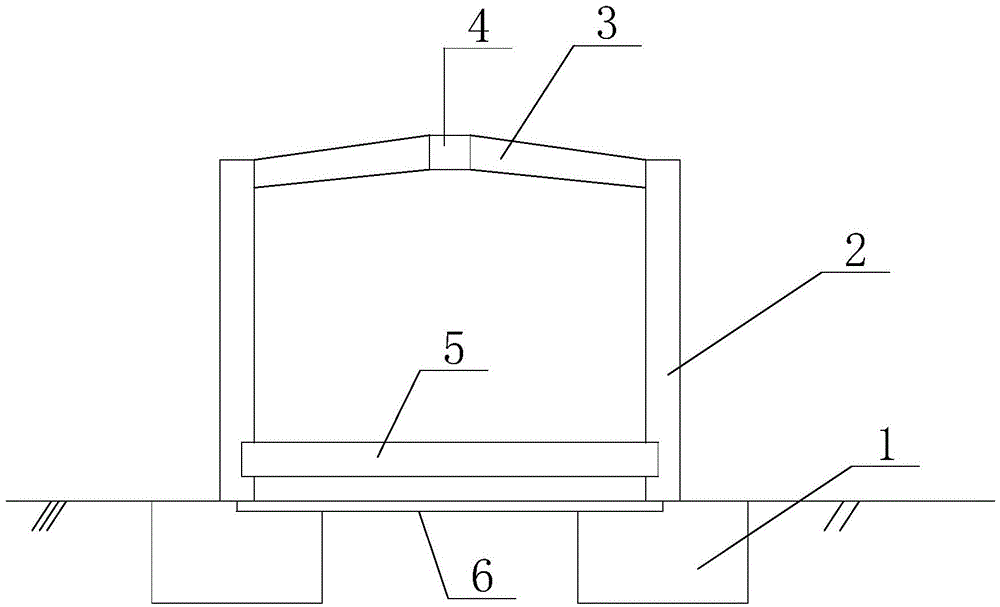

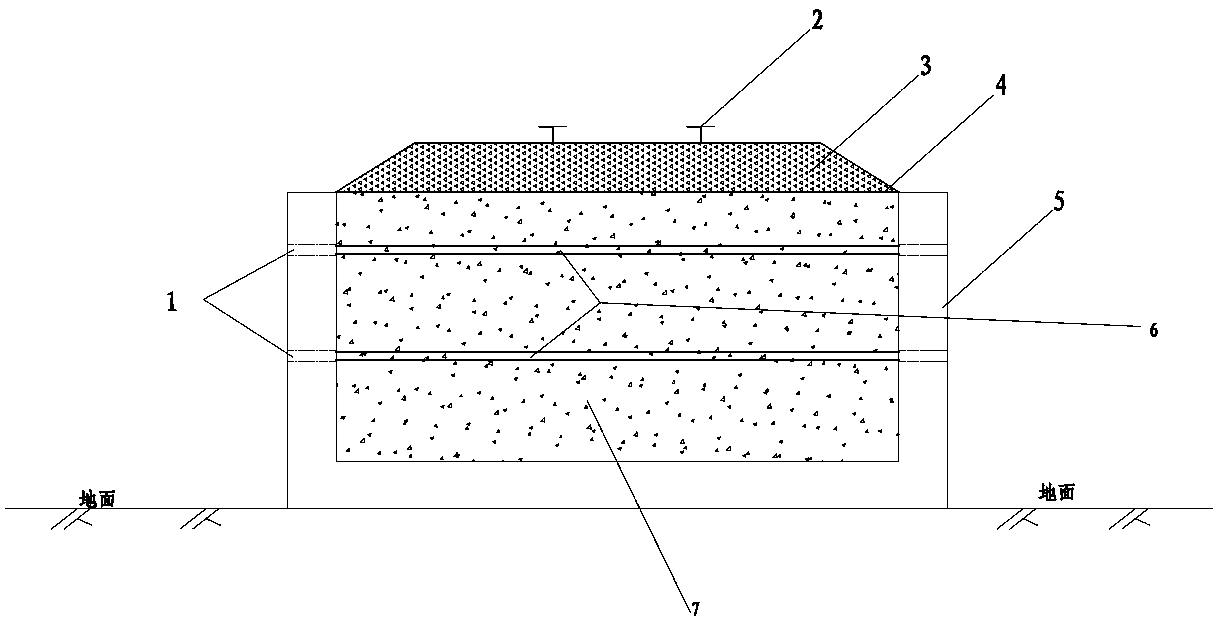

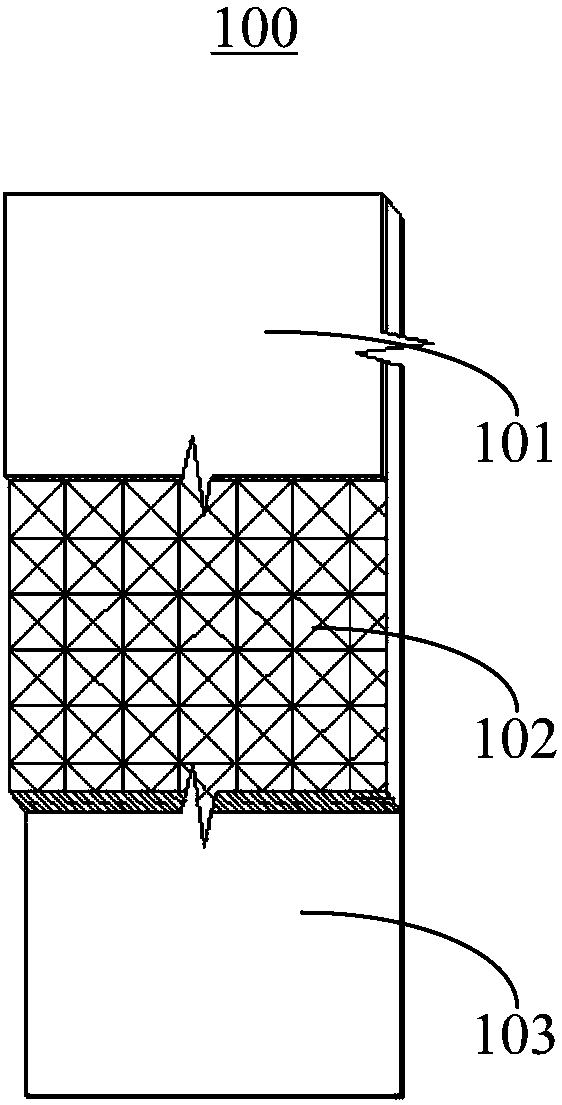

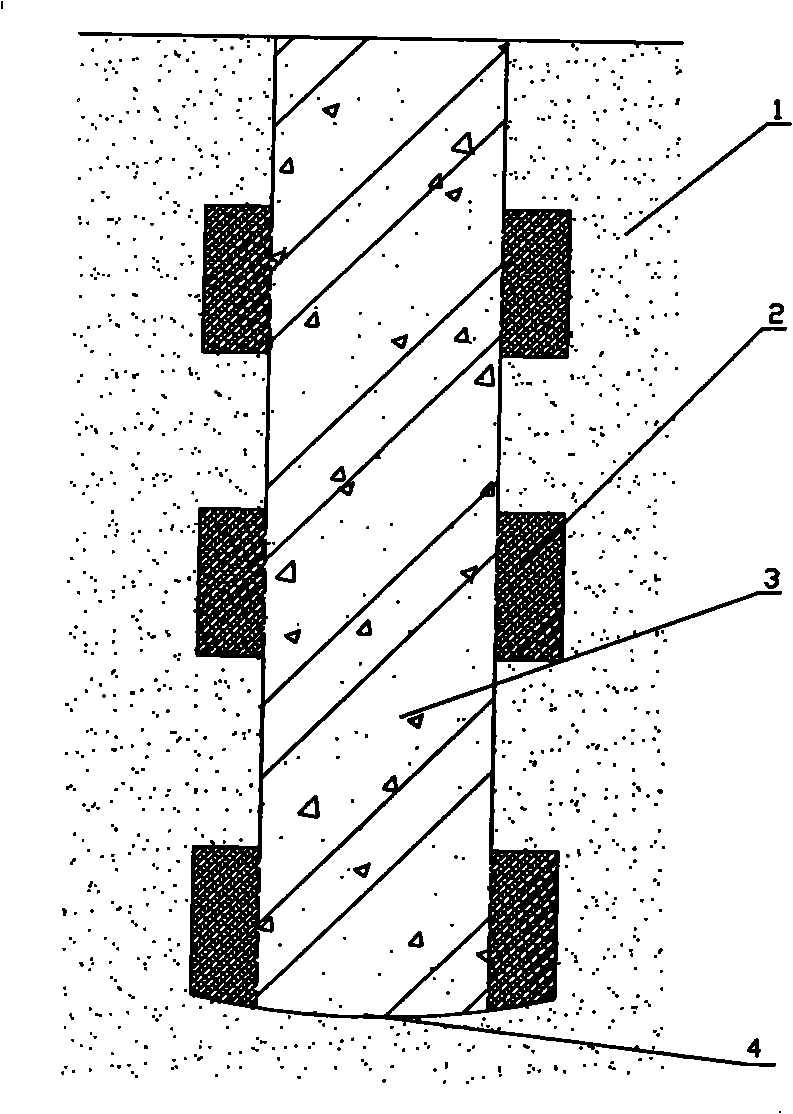

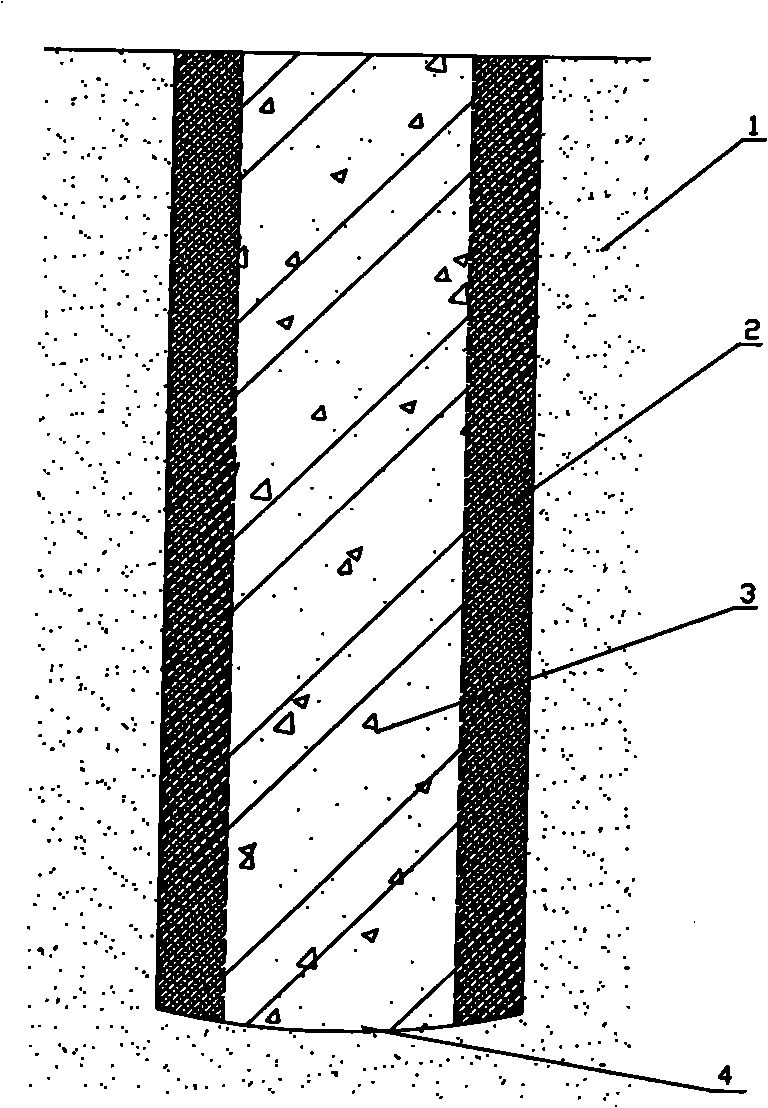

Method for determining soft soil foundation landfill site foundation treatment mode based on foundation bearing capacity

ActiveCN101831895AAccelerated consolidationImprove bearing capacitySoil preservationCushionGeological exploration

The invention discloses a method for determining soft soil foundation landfill site foundation treatment mode based on foundation bearing capacity. Firstly correction of foundation bearing capacity is carried out according to geological exploration report, then whether the corrected foundation bearing capacity meets landfill site total load requirement is judged, and whether treatment is required is determined according to the judging result, if treatment is required, the selected treatment mode includes foundation treatment by adopting reinforcement cushion rubber (1) or foundation treatment by adopting reinforcement cushion rubber and setting vertical shaft (2). The invention utilizes the load characteristics of large occupying area of landfill site, long load application period and step application, landfill process of landfill site is taken as step loading process, the improvement of foundation bearing capacity in operation period of landfill site is analyzed according to piling, loading and prepressing method, the landfill speed and foundation bearing capacity correspond over time by controlling operation procedure, and meanwhile reinforcement cushion rubber is arranged to provide a drainage layer for soft soil foundation, thus not only improving foundation bearing capacity but also being capable of effectively reducing differential settlement of small repository.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

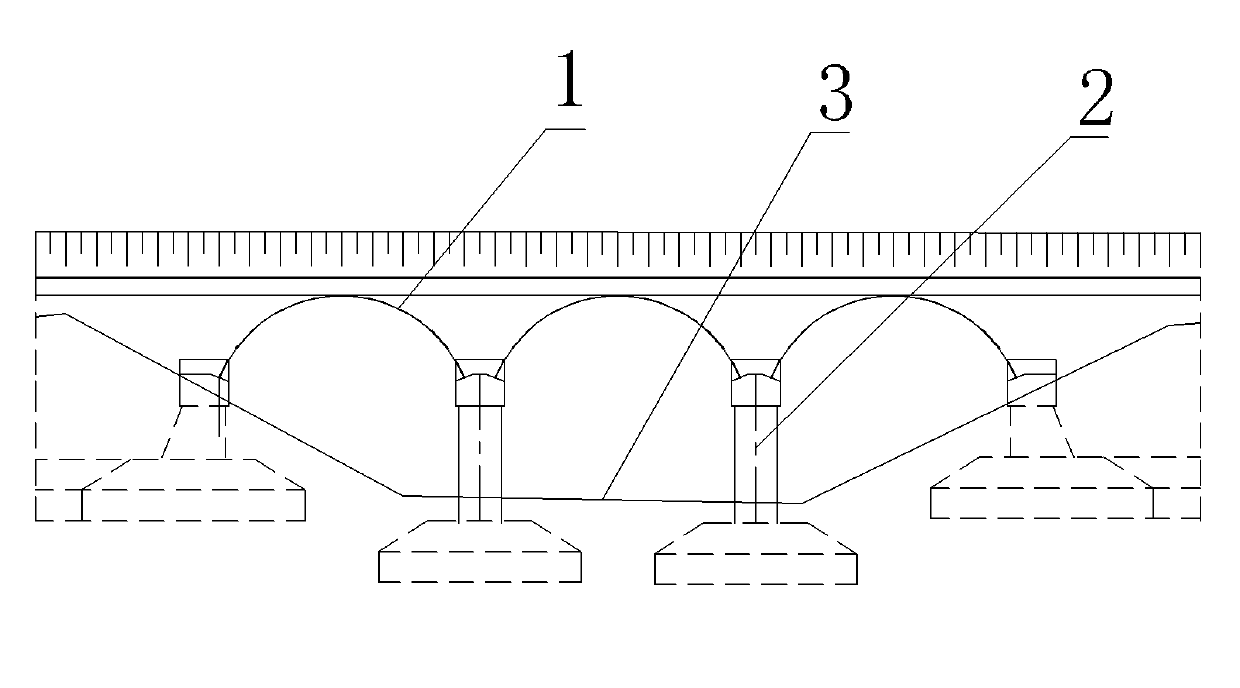

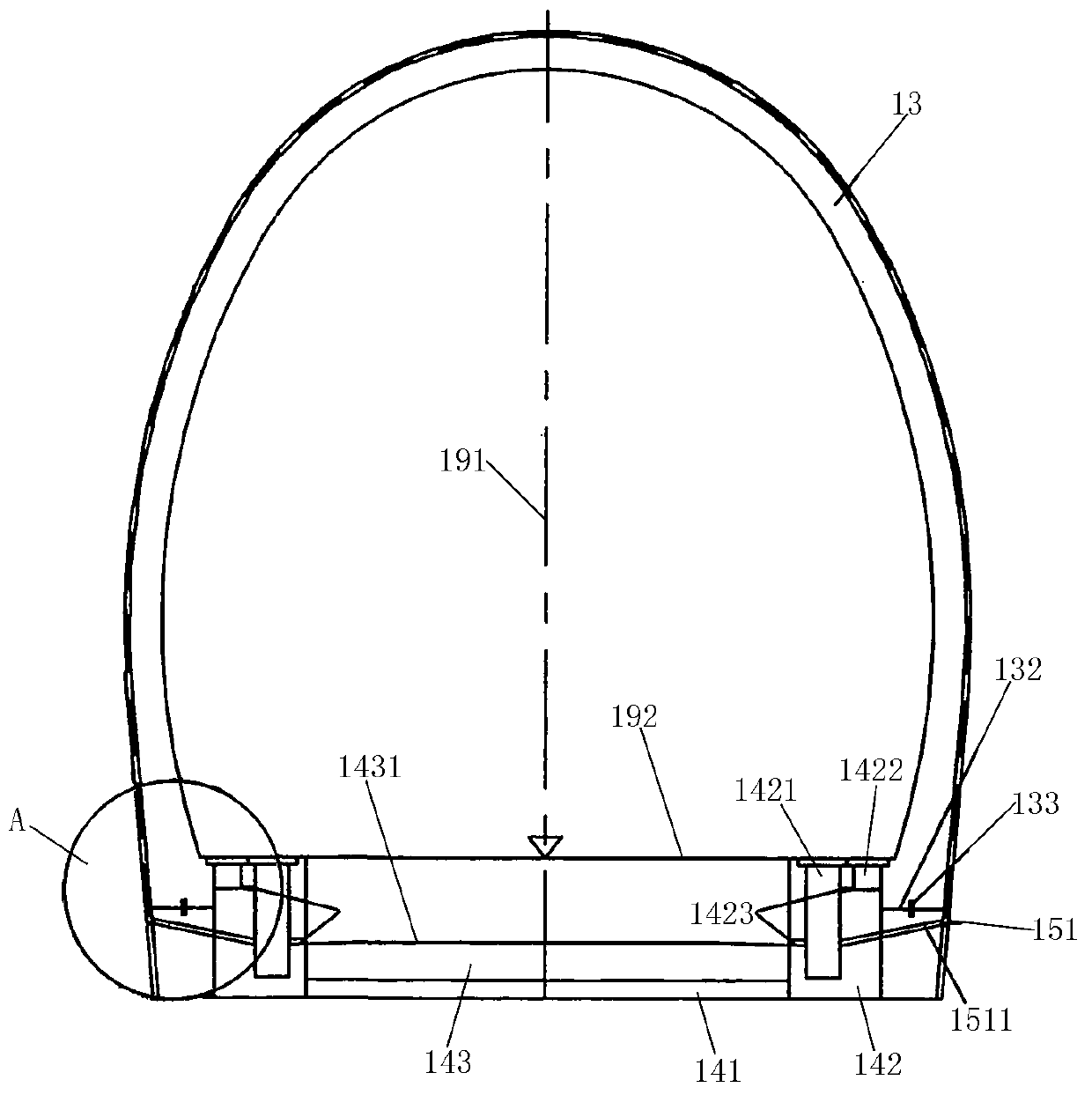

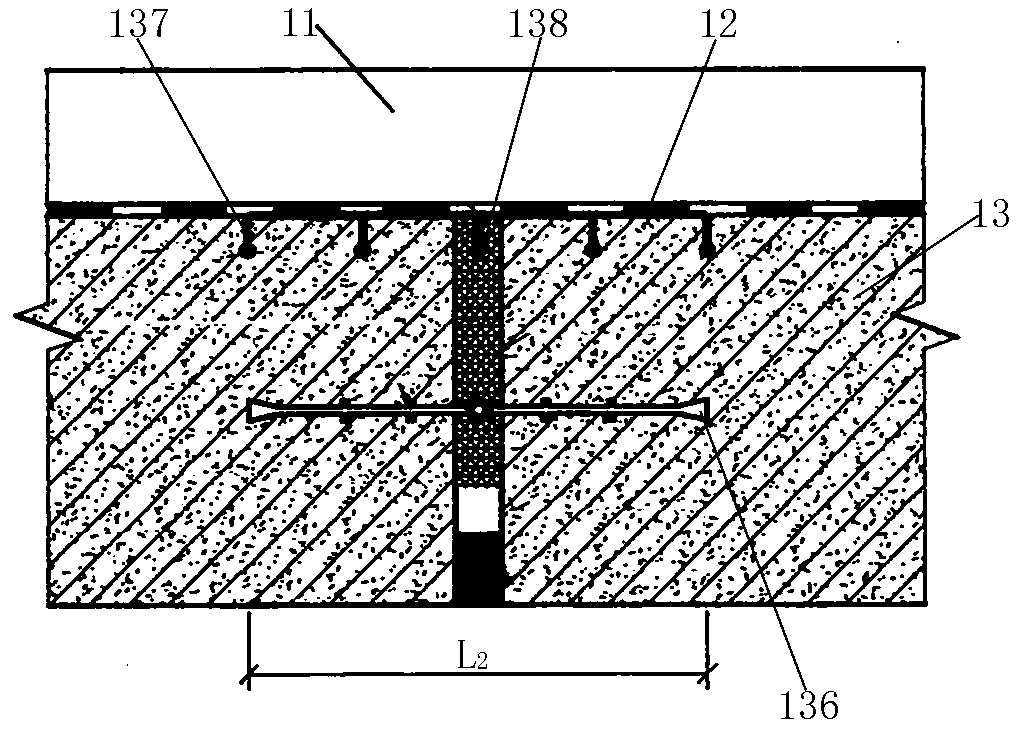

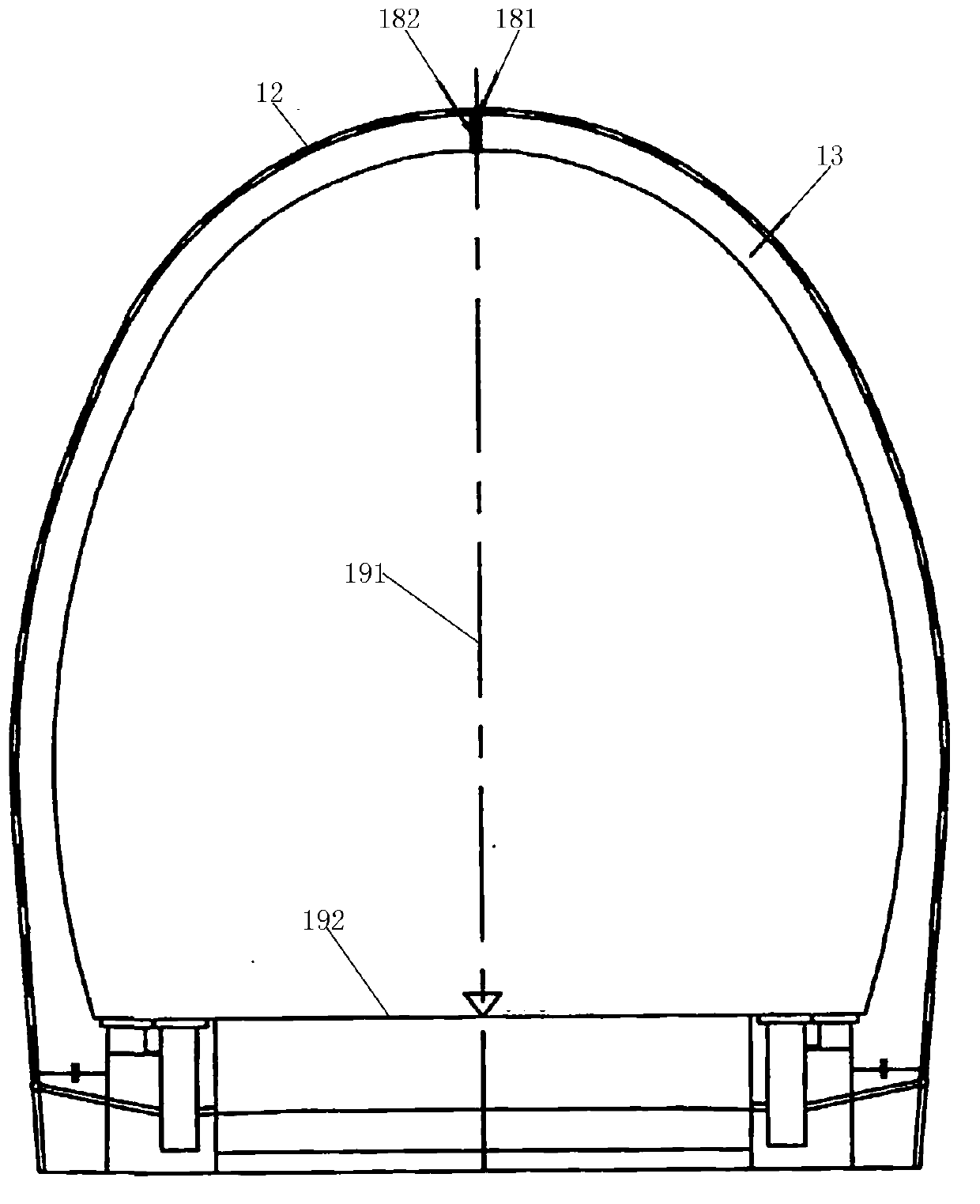

Circular-arched steel-corrugated-plate bridge and culvert structure

InactiveCN103276675AHigh tensile strengthNo cracking damageGround-workStress concentrationReinforced concrete

The invention relates to a circular-arched steel-corrugated-plate bridge and culvert structure. A circular-arched bridge and culvert with a reinforced concrete structure is not adaptable to foundation deformation and uneven settlement well, damages caused by earthquakes cannot be buffered effectively, construction cost is high and construction period is long. Bases are arranged at the lower portion of the bridge and culvert structure. Single-span or multi-span bridge arches are arranged on the upper portions of the bases, are steel-corrugated-plate circular arches and are formed by assembly and fixation of steel corrugated plates through bolts. The radius of each steel-corrugated-plate circular arch is 2.1648m, central angle is 135 degrees, arc curvature radius is 4.33m, single span is 4m, and rise height is 1.3365m. A circular-arched bridge and culvert with the structure has axial corrugations and excellent mechanics characteristics, stress strain caused by load is simultaneously distributed axially and radially, stress concentration of the load is effectively dispersed, advantages of a steel structure are exploited better, and wide application prospect is provided.

Owner:CCCC FIRST HIGHWAY CONSULTANTS

Method for processing roadbed by means of matching of waste tire piece bodies and reinforced soil

The invention discloses a method for processing a roadbed by means of matching of waste tire piece bodies and reinforced soil. The method includes the steps that (1) a waste tire is recycled and cut into pieces, soil used for the actual engineering roadbed is sampled, the recycled waste tire pieces are mixed into the soil, a triaxial compression experiment for solidification water discharging is carried out, an optimum ratio is determined according to the result of shearing strength, and accordingly the soil of the roadbed is improved; (2) geogrid is installed on a flat and compressed field, the stressed direction of the geogrid is vertical to the axis direction of a road embankment, the geogrid is pressed and fixed through plug pins, soil and stones, and the geogrid is under a tightened and stressed state in soil; (3) after the geogrid is laid and positioned, the geogrid is timely covered with soil, and the time when the geogrid is naked cannot exceed 48 hours; (4) in an reinforced soil project, water discharging must be well processed, and when necessary, geotechnical cloth should be arranged. The method can improve the water permeable performance of the roadbed; the shear-resistance is improved due to the fact that soil inner friction angles are increased; soil self-weight is reduced, the problem that the roadbed subsides unevenly is reduced, retaining wall soil pressure is reduced, and the structure of the roadbed is optimized.

Owner:SHANDONG UNIV

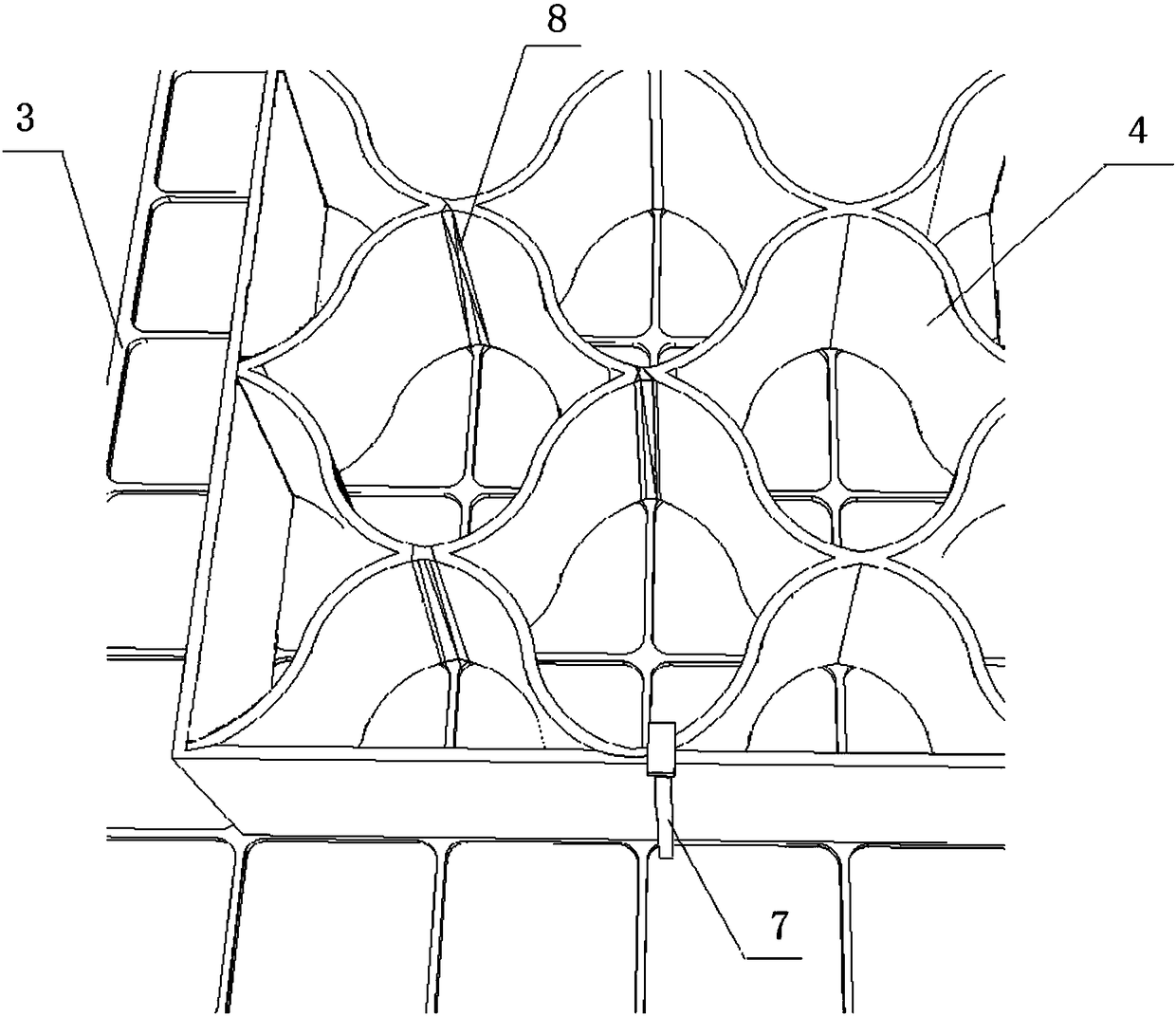

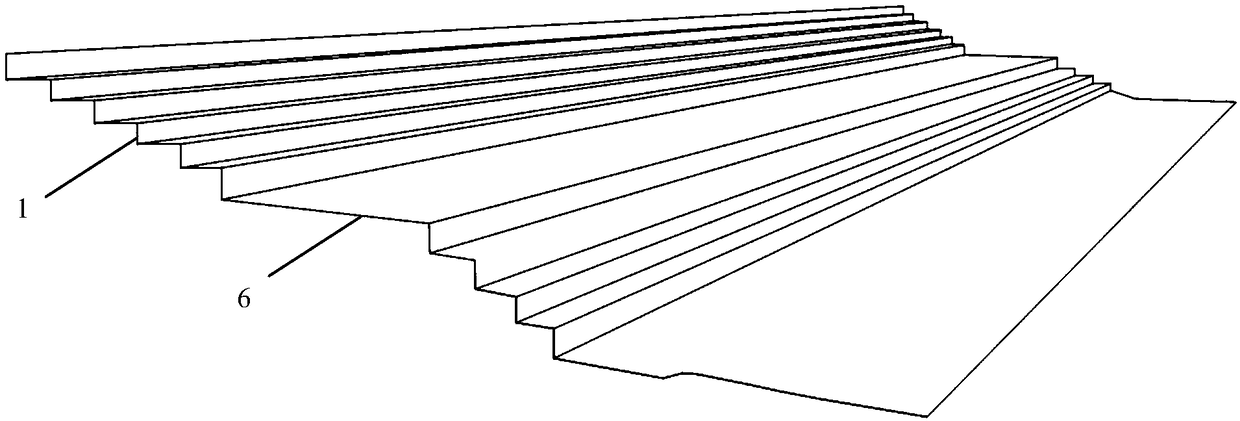

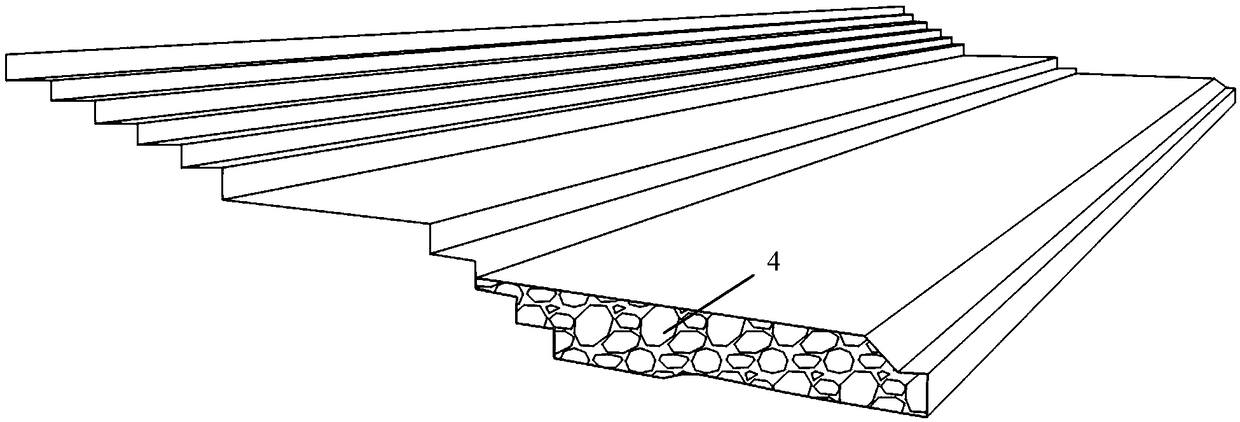

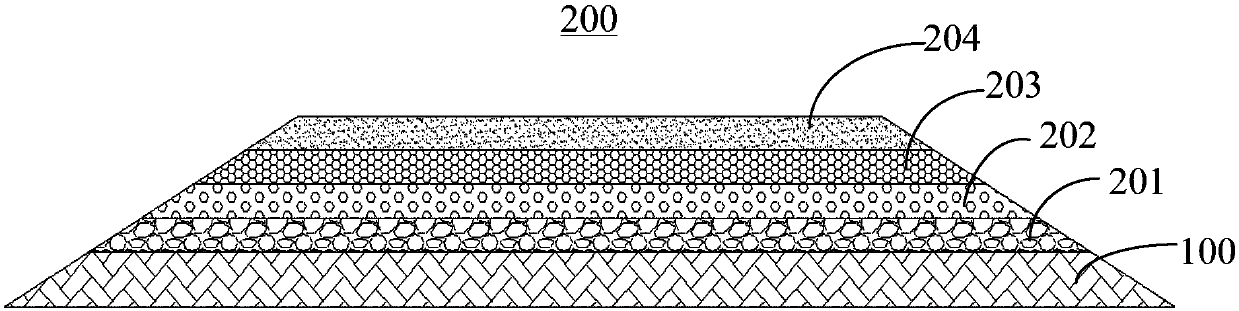

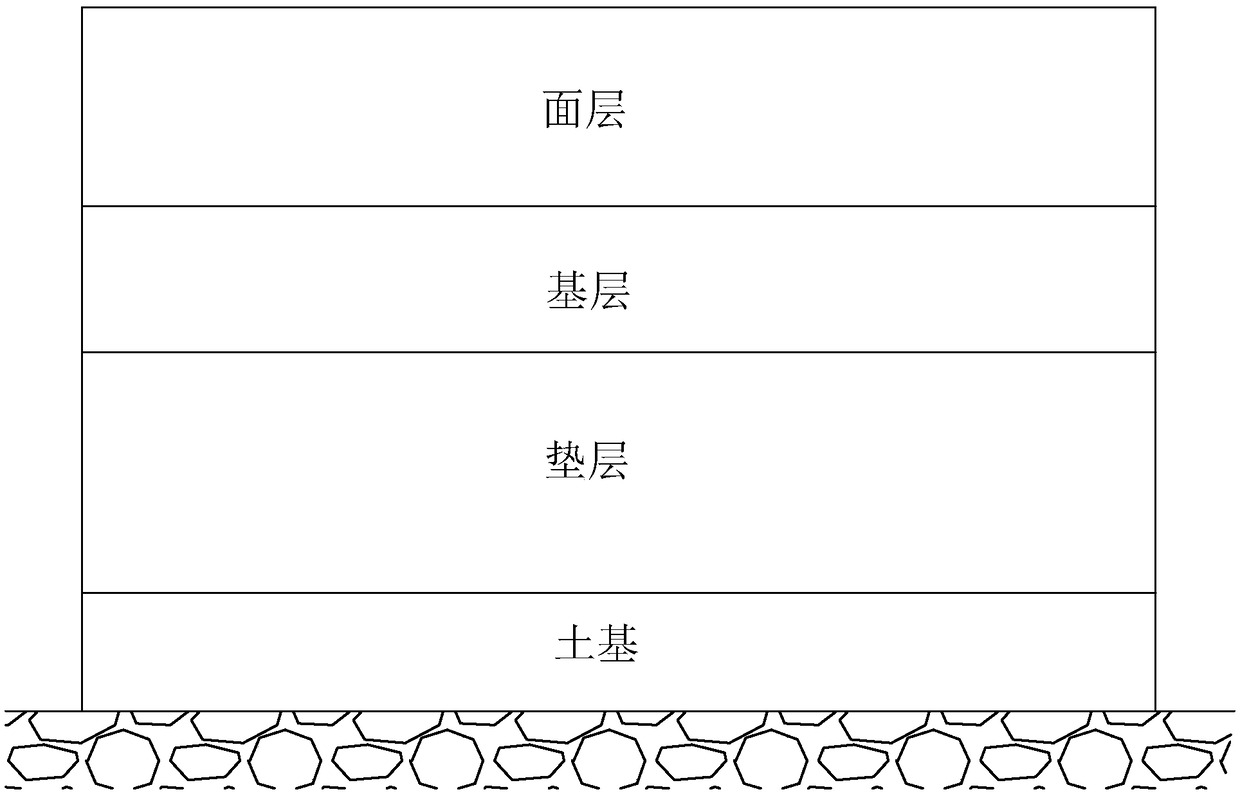

Domestic garbage incinerated ash and mixed soil composite reinforced subgrade and construction method thereof

ActiveCN108442200AImprove the bearing capacity of the foundationImprove stabilityRoadwaysGeocellsEngineering

The invention discloses a domestic garbage incinerated ash and mixed soil composite reinforced subgrade. The domestic garbage incinerated ash and mixed soil composite reinforced subgrade comprises a foundation layer, a subgrade layer paved on the top surface of the foundation layer and a road surface layer paved on the top surface of the subgrade layer, wherein the subgrade layer comprises a subgrade base body and a plurality of layers of reinforced structure layers; the subgrade base body is prepared from compacted filler and the filler is mainly prepared by mixing domestic garbage incinerated ash and clay; the reinforced structure layers are paved in the subgrade base body at intervals from bottom to top; the reinforced structure layer on the topmost layer is located on the bottom surface of the road surface layer; each reinforced structure layer is mainly composed of a geogrid and a geocell fixed at the top of the geogrid. According to the domestic garbage incinerated ash and mixedsoil composite reinforced subgrade disclosed by the invention, the urban domestic garbage incinerated ash is used as a filler component to be applied to subgrade construction, so that the environmentpollution is reduced, the land occupation problem caused by accumulation of garbage ash is alleviated and a novel way is provided for harmless and reclamation treatment on the ash; the domestic garbage incinerated ash and mixed soil composite reinforced subgrade disclosed by the invention has excellent strength and rigidity.

Owner:HUBEI UNIV OF TECH

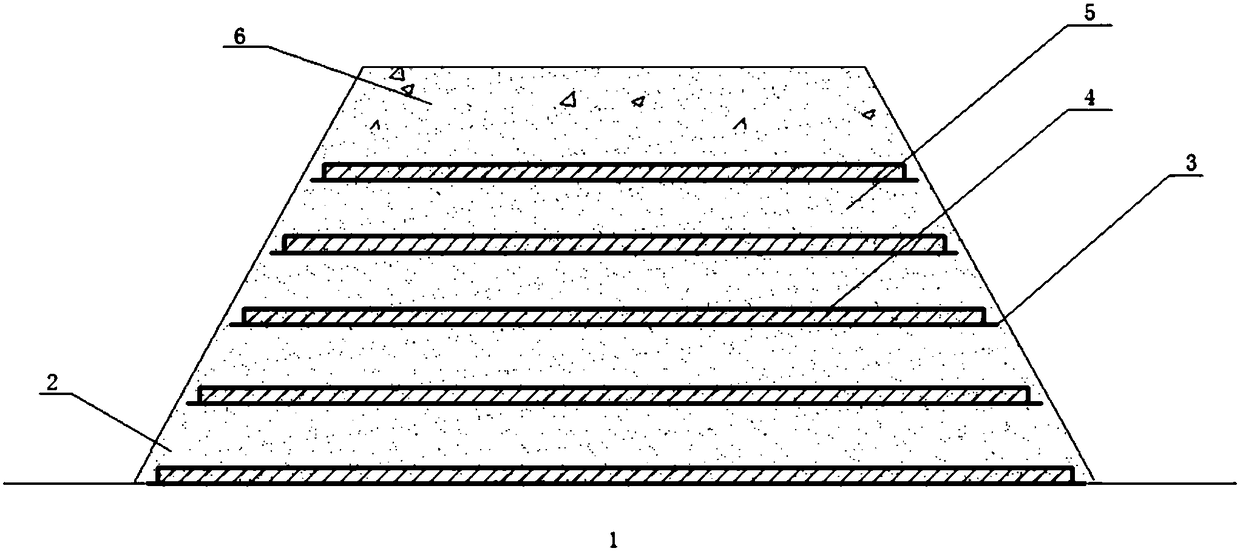

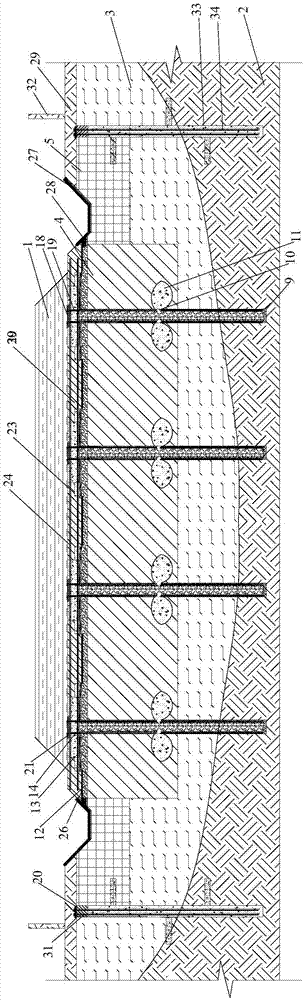

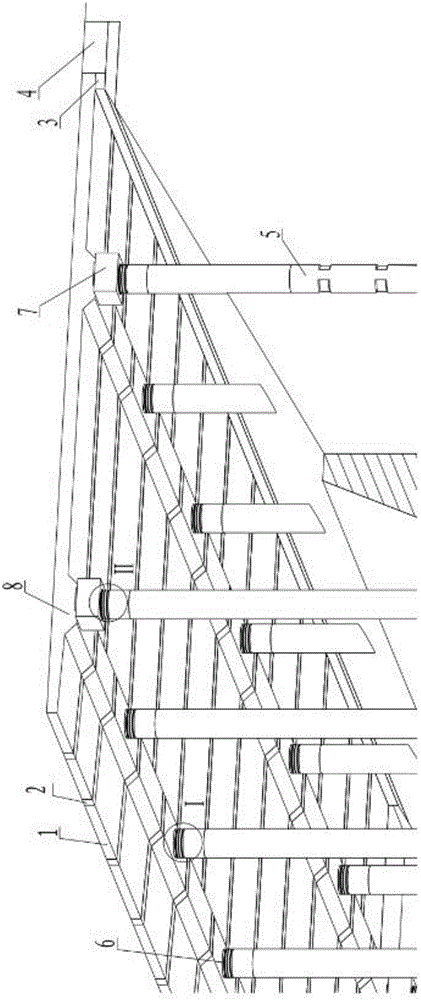

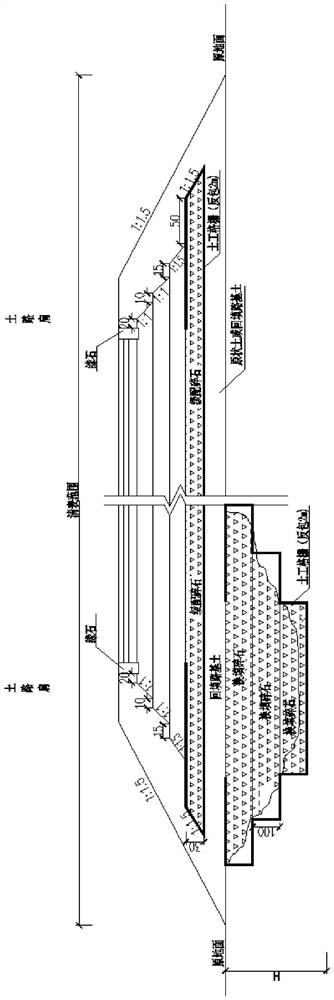

Multi-layered structure and construction method of high embankment near mountains

PendingCN109056439AGuaranteed filling qualityDelay uneven settlementRoadwaysEmbankmentsEngineeringSlope ratio

The invention relates to a multi-layered structure of a high fill roadbed alongside a mountain, comprising a mountain body, a rockfill embankment, a drainage canal, a block stone, a soil-stone mixture, a mountain platform, a platform and a cross slope, wherein the multi-layered structure comprises a mountain body, a rockfill embankment, a drainage canal, a block stone, a soil-stone mixture, a platform and a cross slope. The hill is excavated into a stepped structure, and the hill is provided with a hill platform; The subgrade of Shanao road section in the lower part of the stepped mountain body is filled with a rock-filled embankment, the thickness of the pavement layer of the rock-filled embankment is not more than 60cm, and the filling stones are blocks of different sizes of 20-30cm, andcrevices are left between the blocks; and the rock-filled embankment is filled with the rock-filled embankment. Non-woven geotextiles are laid on the top surface of the rockfill embankment; The rockfill embankment consists of graded slopes with platforms between each grade, and the slope ratio is consistent. An inverted trapezoidal drainage channel is arranged at the bottom of the slope of the rockfill embankment; Earth-rock mixture fills from the top surface of the rockfill embankment to the bottom of the roadbed in stages. The invention has the beneficial effects that the subgrade stratum is filled with a block stone, and can be used as a surface drainage water permeable layer, thus ensuring the smooth drainage of the subgrade after the subgrade is filled, and reducing the influence ofsurface water on the stability of the subgrade during the operation period.

Owner:杭州市交通规划设计研究院有限公司

Lightweight silt foam composite soil and preparation method thereof

InactiveCN103086680ADelay uneven settlementGreat engineering application valueSolid waste managementSoil scienceHydraulic engineering

The invention relates to lightweight silt foam composite soil which is characterized by comprising the following components by mass percent: 81% to 85% of raw soil as, 10.5% to 13.5% of cement as a curing agent, 2.5% to 4.5% of gypsum powder or silicon powder and 1% to 3% of lightweight materials. The invention further discloses a preparation method of the lightweight silt foam composite soil. The lightweight silt foam composite soil has the advantages of light weight, high strength, good independence, short construction period, waste recycling and environmental protection. In addition, the lightweight silt foam composite soil can solve the problems of uneven settlement and vehicle bumping at a bridge head, poor stability of a retaining wall, untight pressing of a pipe ditch, slumping of a side slope and the like due to the soil filling on a roadbed. Therefore, the lightweight silt foam composite soil is an ideal civil engineering material and can be widely applied to the construction of transportation, civil engineering and hydraulic engineering.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST

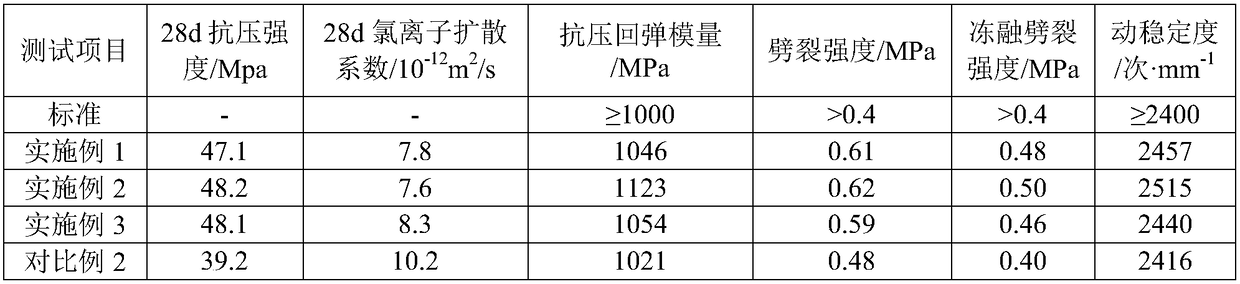

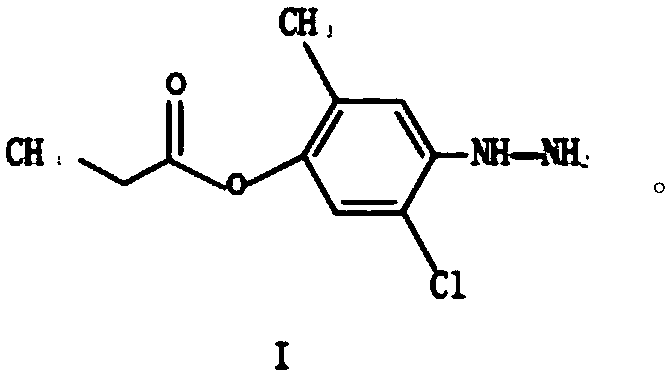

Cement-based material functionally gradient brick and preparation method thereof

ActiveCN106554180AReduce moisture infiltration into roadbedReduce uneven settlementSolid waste managementSingle unit pavingsDiseaseSubgrade

The invention relates to a cement-based material functionally gradient brick. The functionally gradient brick has an upper functionally gradient layer and a lower functionally gradient layer, i.e. a cement-based material toughening layer and a cement concrete base layer respectively. The fiber cement based material toughening layer is a fiber mortar layer, the cement concrete base layer is a fine aggregate concrete layer, and the vertical direction of the functionally gradient brick is a Z shaped section; the materials of the fiber mortar layer include a cementitious material, fine aggregate, water, a water reducing agent and fiber; the raw materials of the fine aggregate concrete layer include a cementitious material, coarse aggregate, fine aggregate and water. The invention also provides a preparation method of the cement-based material functionally gradient brick. The invention provides the functionally gradient brick and a preparation method thereof, and the functionally gradient brick can alleviate uneven pavement settlement, maintain the pavement shrinkability, at the same time reduces permeation of pavement water to roadbed, and has good breaking resistance and surface freeze-thawing damage resistance, and is suitable for industrial production, thereby reducing pavement diseases.

Owner:ZHEJIANG UNIV OF TECH

Tunnel waterproof and drainage structure and method

PendingCN109611150AAvoid damageReduce water pressureUnderground chambersDrainageEngineeringWater pressure

The invention discloses a tunnel waterproof and drainage structure and a method. The tunnel waterproof and drainage structure includes a tunnel arch wall composed of an initial supporting layer, a waterproof roll layer and a secondary model-building lining layer, wherein the initial supporting layer, the waterproof roll layer and the secondary model-building lining layer are sequentially arrangedon a wall surface of an excavated tunnel; longitudinally extending side ditches are arranged on both sides of an excavated tunnel bottom lining structure; a longitudinal blind pipe is embedded at thebottom of the tunnel arch wall; the two ends of the longitudinal blind pipe bend inward bend and communicate with the side ditches; circumferential drainage plates are arranged between the initial supporting layer and the waterproof roll layer at intervals; a transverse standby drainage pipe is further arranged at the bottom of the tunnel arch wall; and the outer end of the standby drainage pipe communicates with the corresponding side ditches, and the inner end of the standby drainage pipe is positioned at the initial supporting layer. According to the tunnel waterproof and drainage structureand the method, by arranging the standby drainage pipe, when the two end openings of the longitudinal blind pipe are blocked by solidified concrete, the standby drainage pipe can be used to reduce water pressure on the back of the tunnel arch wall, and the damages to the tunnel structure caused by the excessive water pressure are prevented.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

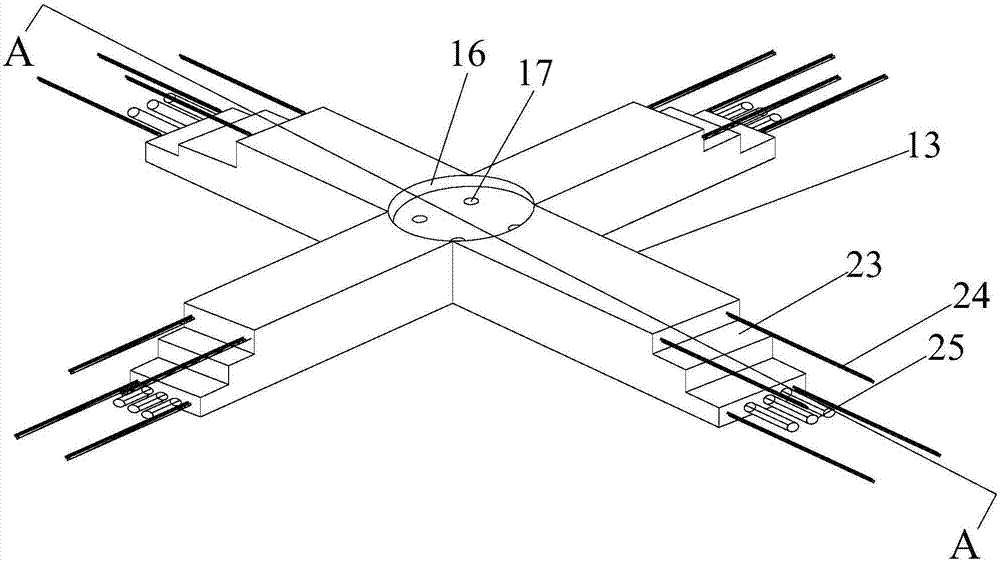

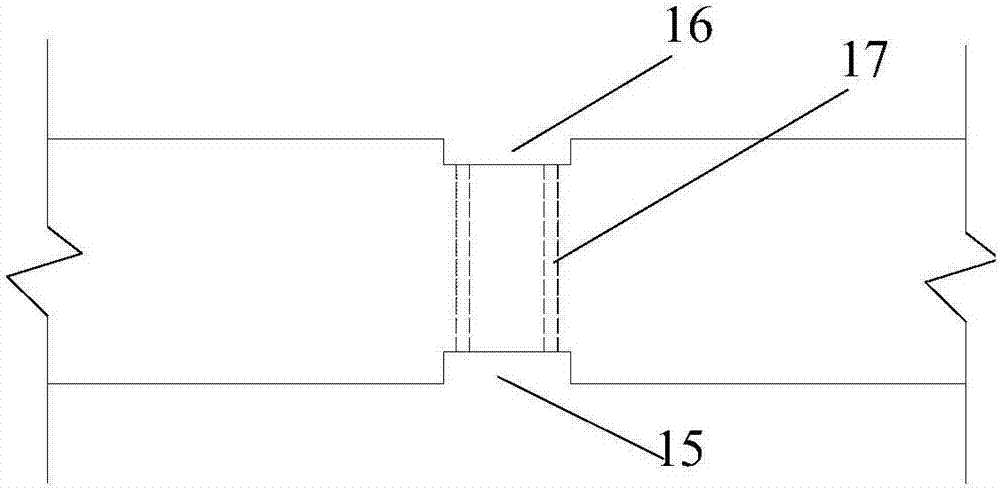

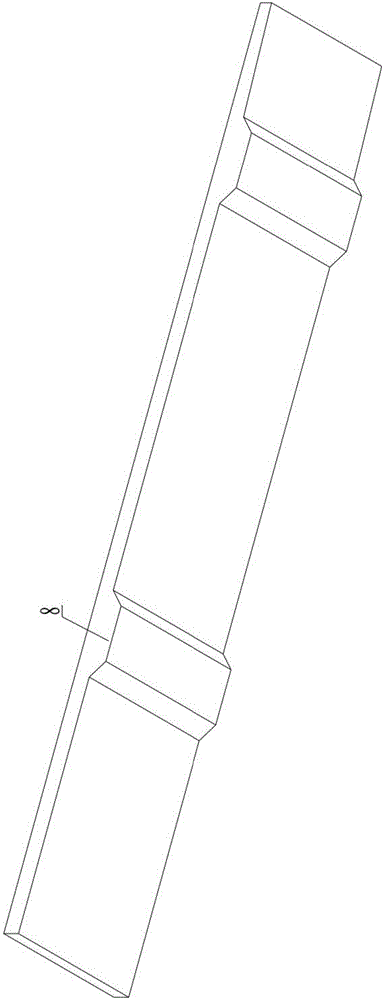

Thick and ultra-soft soil embankment and construction method

ActiveCN107447613ASolve instabilitySolve drainage problemsRoadwaysSoil preservationSoil scienceReinforced concrete

The invention relates to a thick and ultra-soft soil embankment. The thick and ultra-soft soil embankment comprises an embankment body, a cemented soil separating wall, reinforced area solidified cemented soil, transition area solidified cemented soil, a drainage blanket, cross-shaped prefabricated joints, separating geotechnical cloth, a reinforced concrete grid plate, linear prefabricated joints, ribbed slab piles and quick grouting equipment. The ribbed slab piles penetrate the reinforced area solidified cemented soil to arrive at an ultra-soft soil layer, vertical connection ribs B are bent by the ribbed slab piles on fixed positions to serve as carrying steel of rib bodies on a prefabricated slab pile foundation, and the rib bodies are provided with round holes; and rectangular anchoring steel plates and round anchoring steel plates are arranged and used for integrally anchoring vertical connection ribs A and the vertical connection ribs B. The thick and ultra-soft soil embankment has the beneficial effects that through the reinforced area solidified cemented soil, the transition area solidified cemented soil, rigid piles and the reinforced concrete grid plate, the integral stress of the embankment is improved, differential settlement of a foundation is greatly reduced, and the drainage problem of the post-construction foundation is effectively solved through vertical drainage bodies and the drainage blanket.

Owner:ZHEJIANG UNIV CITY COLLEGE

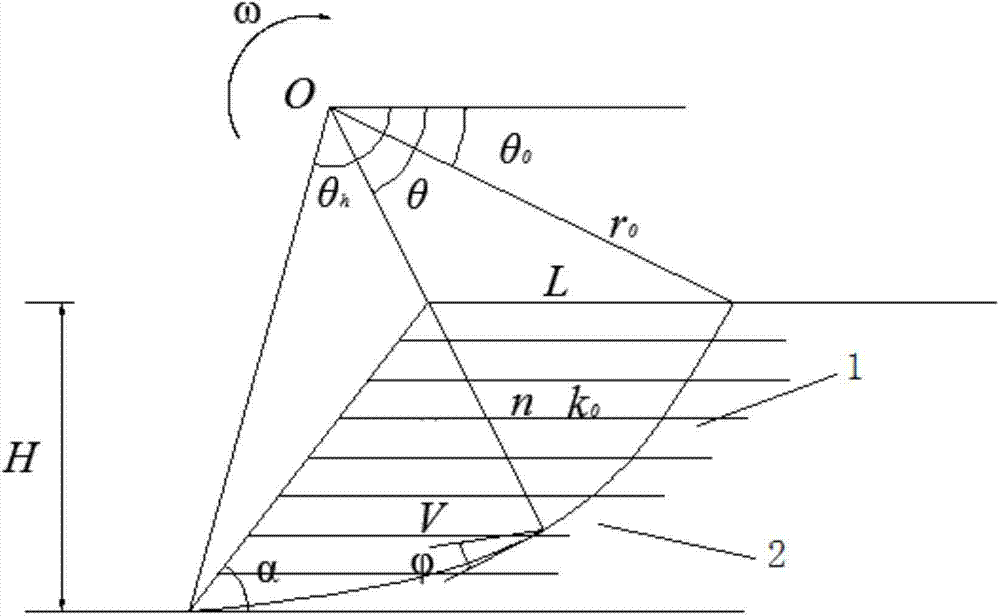

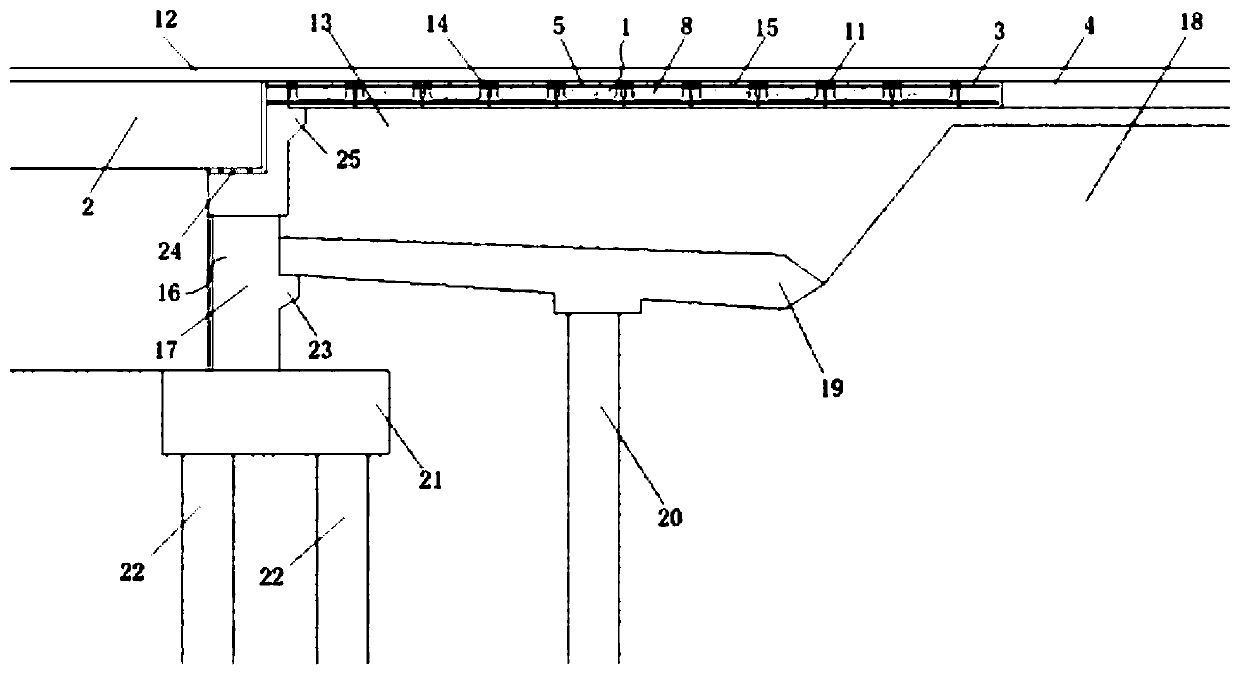

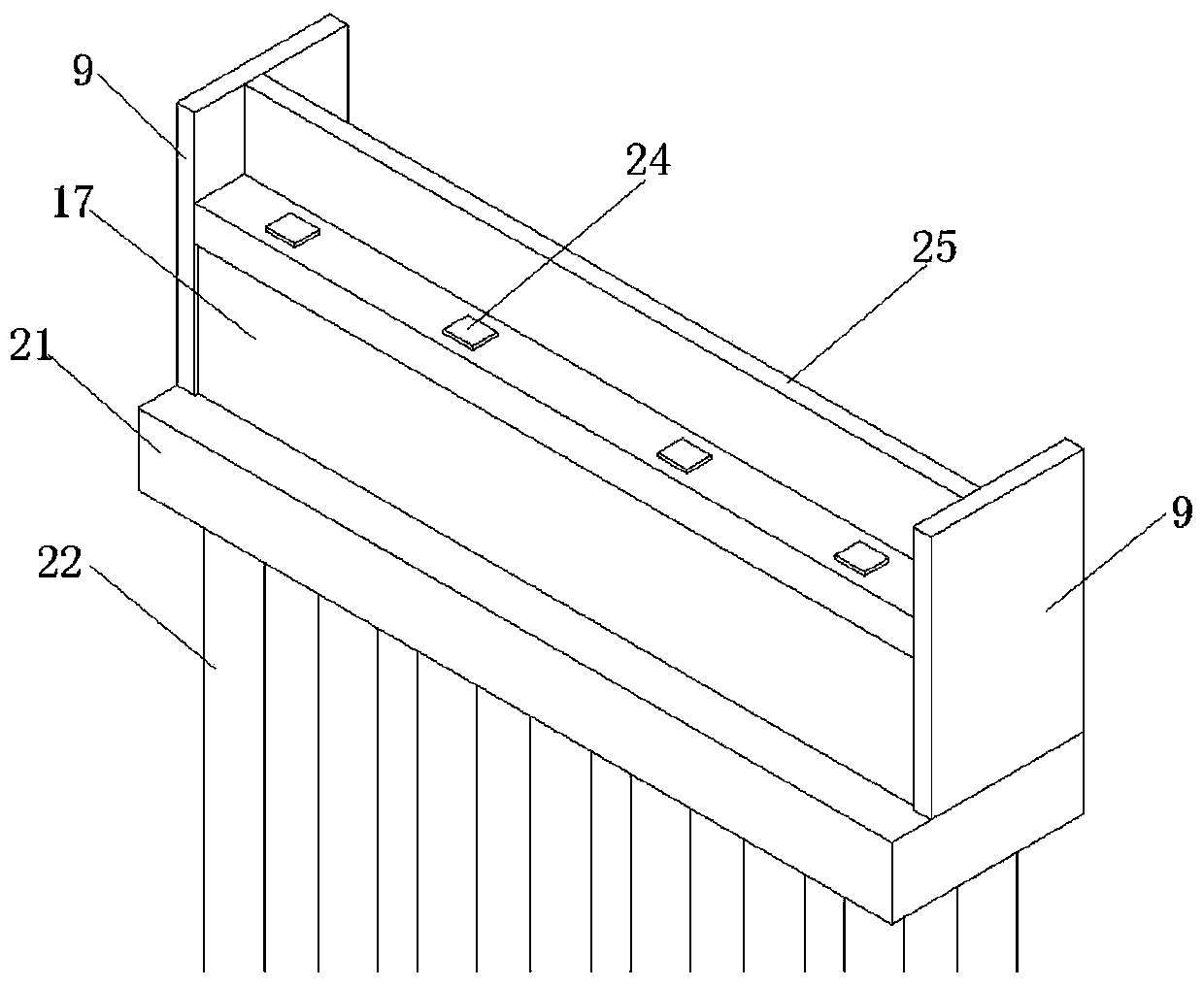

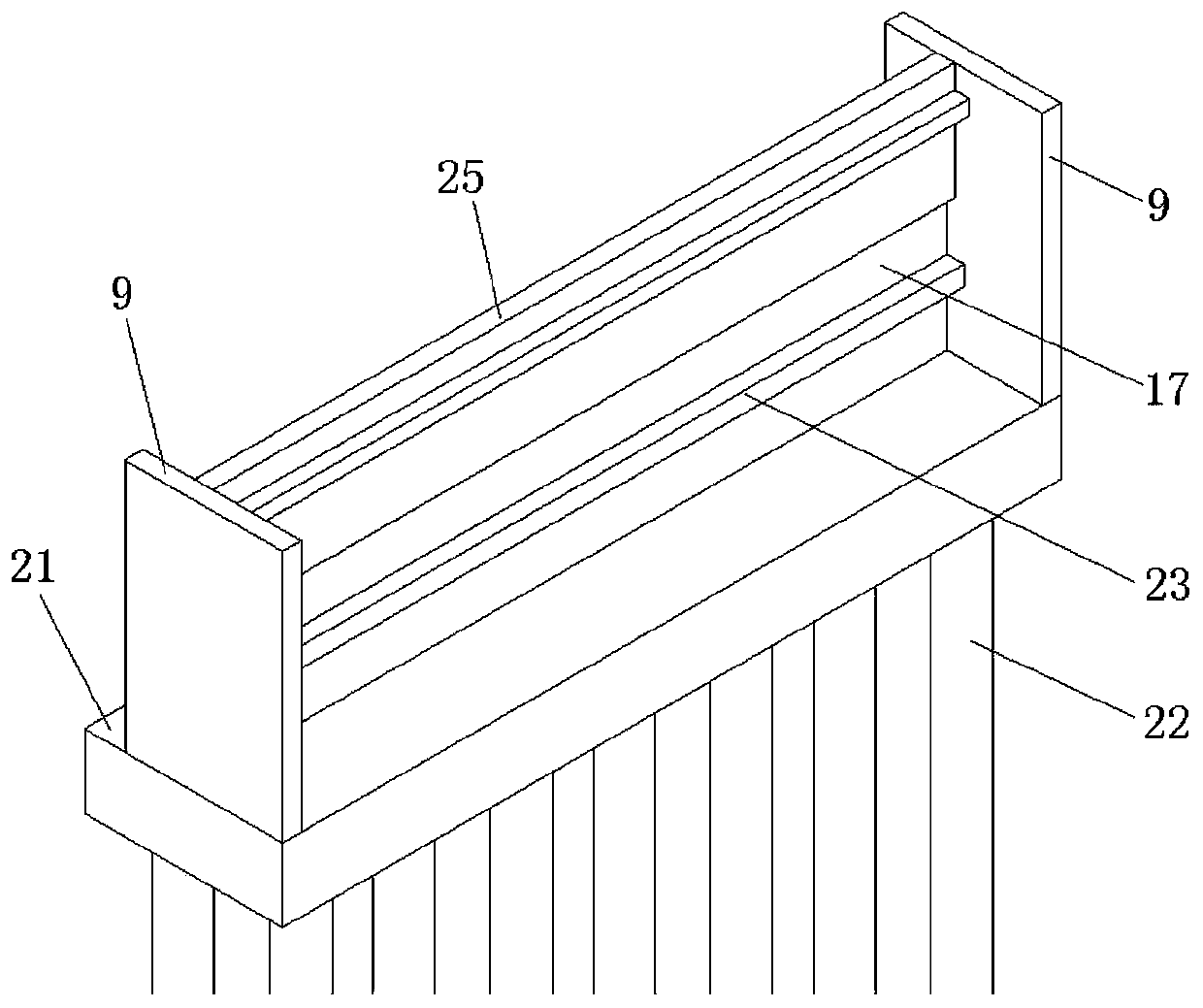

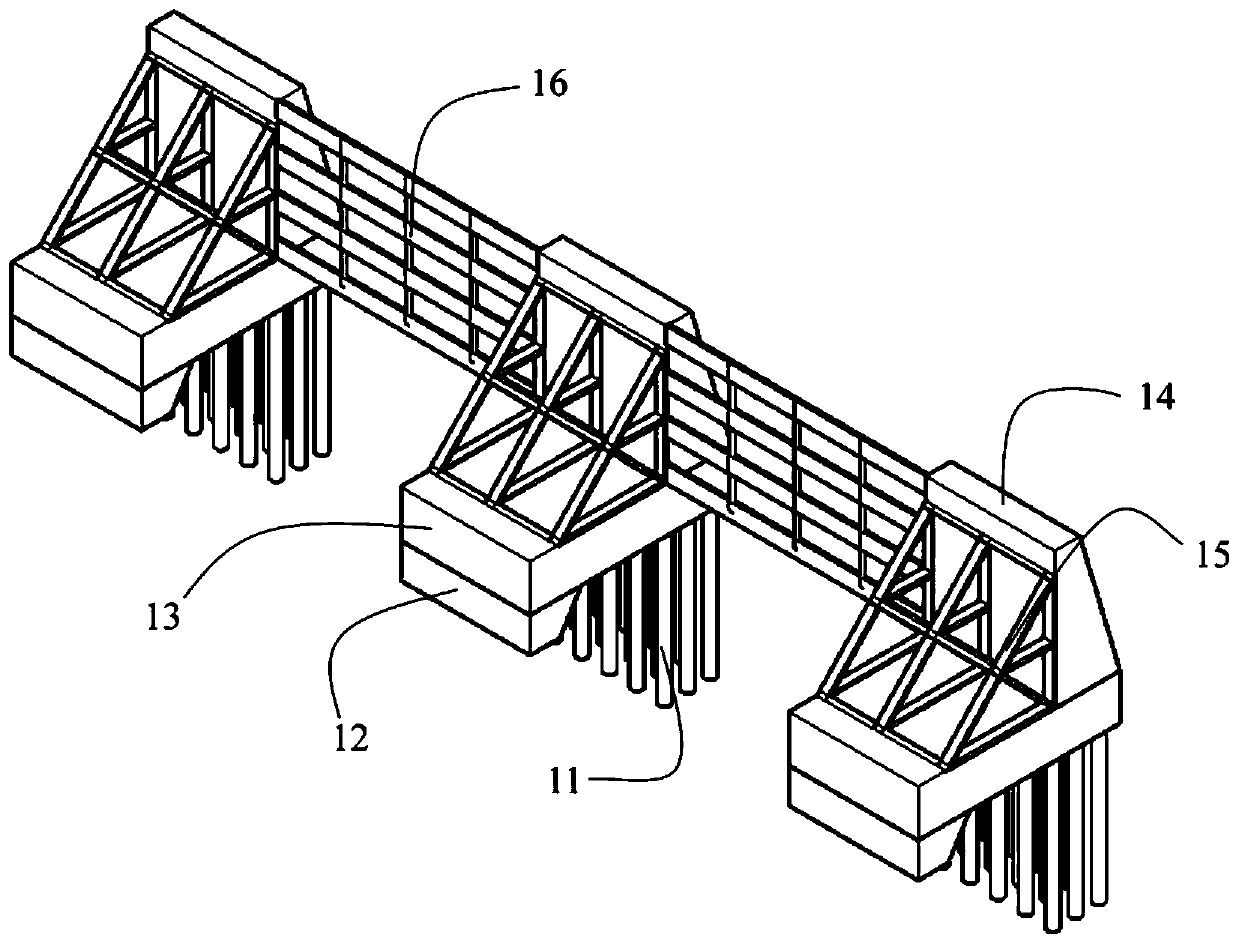

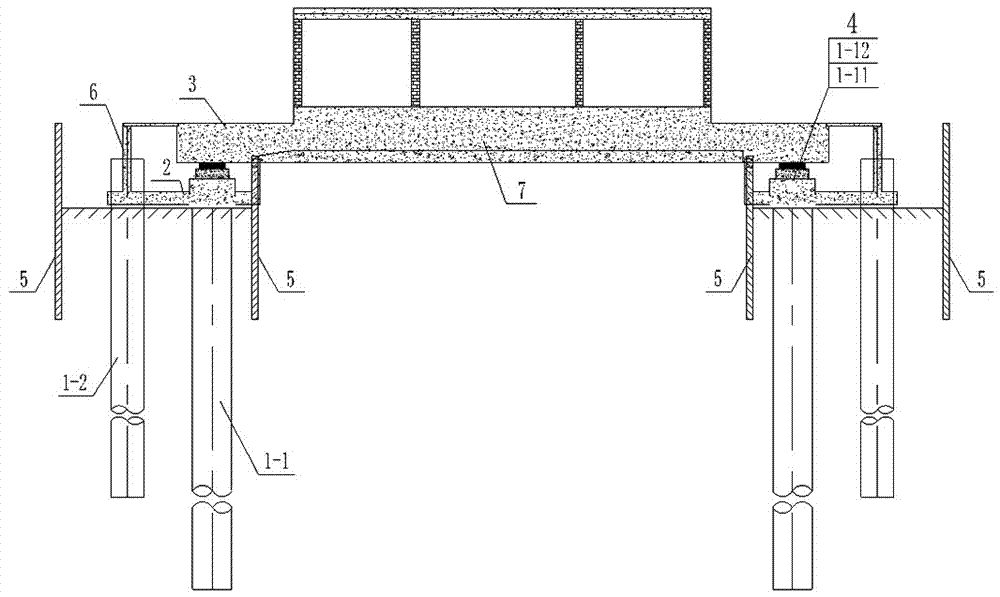

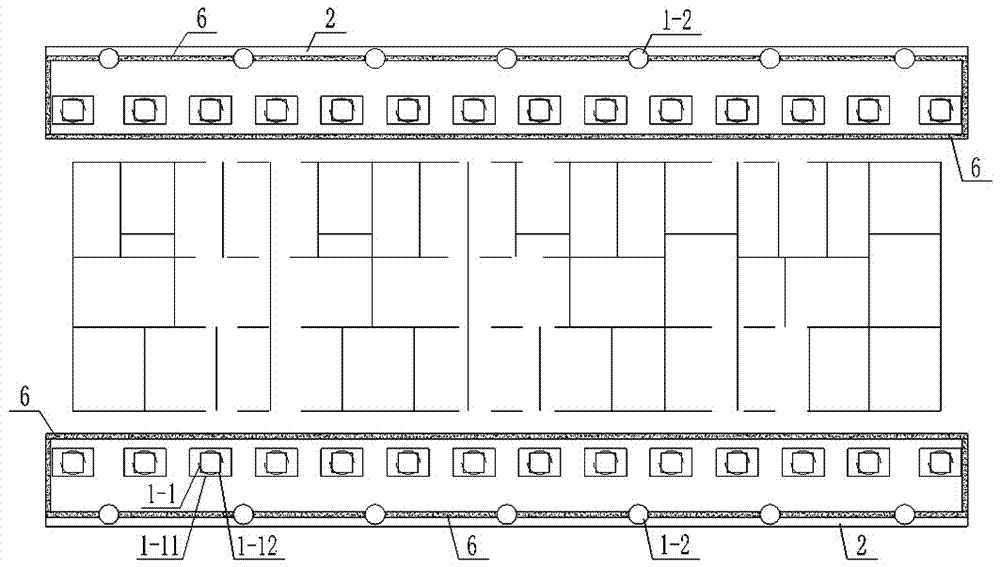

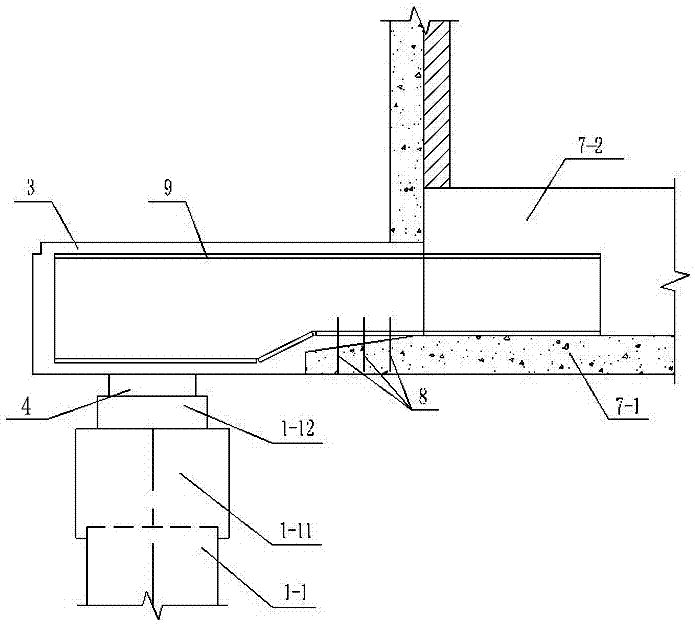

Lateral supporting pile plate type soilless subgrade of highway

InactiveCN106835880ASolve land acquisitionSolve the problem of fetching soilRoadwaysFoundation engineeringCushionSubgrade

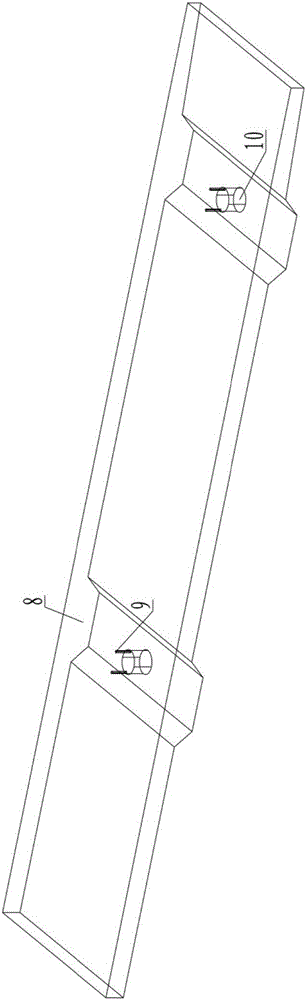

The laterally supported pile-slab soilless roadbed of expressway involves the new technology field of expressway construction. It consists of piles, pile-slab connection devices and end cap beams. The beneficial technical effects of the present invention are: a brand-new laterally supported pile-slab frame system is created, which can effectively transmit the upper vertical and horizontal loads caused by automobiles, etc., and the unique connection device of the pile-slab makes the pile and the slab not fully consolidated , have strong adaptability to temperature changes. Because there is no need to fill the piles, the land is saved, the impact on the surrounding environment is reduced, and it is beneficial to the protection of the environment. Pile and slab components are standardized and prefabricated in the factory and transported to the site. The degree of matching construction is high, showing the characteristics of short construction period and good economy. The innovative achievements of the invention will be in the leading position in China.

Owner:ANHUI TRANSPORT CONSULTING & DESIGN INST

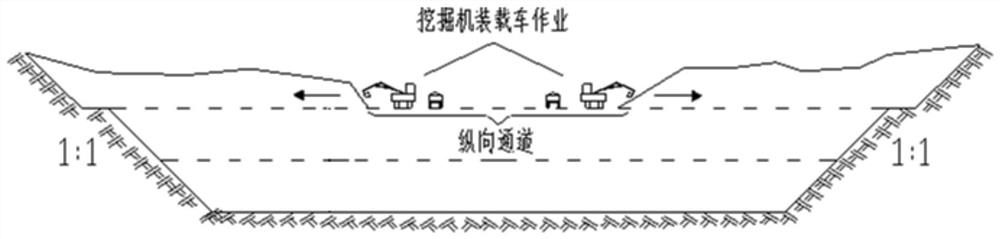

Rapid solidification construction method for sea mud on large-area coastal beach

ActiveCN108468325AConstruction technology and machinery are simpleConstruction progress is fastSoil preservationSubgradeSilt

The invention relates to a rapid solidification construction method for sea mud on a large-area coastal beach. The rapid solidification construction method specifically comprises the following steps of performing construction partition, performing mud excavation, mud piling and draining, spreading an HAS sea mud curing agent, stirring the HAS sea mud curing agent and the sea mud uniformly, performing enclosing material solidification on the mixed soil to obtain a sea mud consolidated body and performing layered and blocked / segmented backfilling and compaction on the sea mud consolidated body.The method has the beneficial effects that the foundation bearing capacity, compaction degree, deflection value and the like after the sea mud is cured by the HAS sea mud curing agent in situ can meetcorresponding standards, uneven settlement can be reduced after layered backfilling, the foundation bearing capacity can reach more than 110 kPa, and common foundation requirements such as field-leveling foundation, building foundation and road subgrade can be met.

Owner:GEZHOUBA ZHONGGU TECH CO LTD

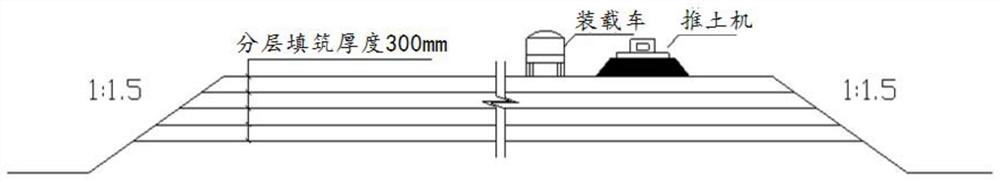

Construction process of urban main road

InactiveCN111893827ADelay uneven settlementReduce car jumpingExcavationsRoads maintainenceUrban main roadArchitectural engineering

The invention discloses a construction process of an urban main road. The construction process comprises the steps of construction preparation, roadbed excavation, roadbed filling, embankment slope protection and pavement construction. The construction preparation process comprises the steps of determining an on-site working boundary line, survey and setting out and cleaning a site; the roadbed excavation process comprises the steps of excavating a base, trimming a slope of a subgrade bed and compacting the subgrade bed; the roadbed filling process comprises the steps of survey and setting out, base treatment, filling, soil filling and rolling compaction, filling and excavating joint part construction and fill section drainage; the embankment slope protection process is carried out, and grass planting protection is adopted when the height H of the embankment slope is less than or equal to 3m; when the height H of the embankment slope is greater than 3m, a mortar rubble framework is adopted for protection; a solid revetment is adopted in the fill pond section; the pavement construction process comprises the steps of laying a graded broken stone hardcore, constructing a cement stabilized broken stone base layer and constructing an asphalt concrete surface layer. According to the construction process, the overall stability of the road surface can be improved, and differential settlement is avoided.

Owner:CCCC SHANGHAI DREDGING

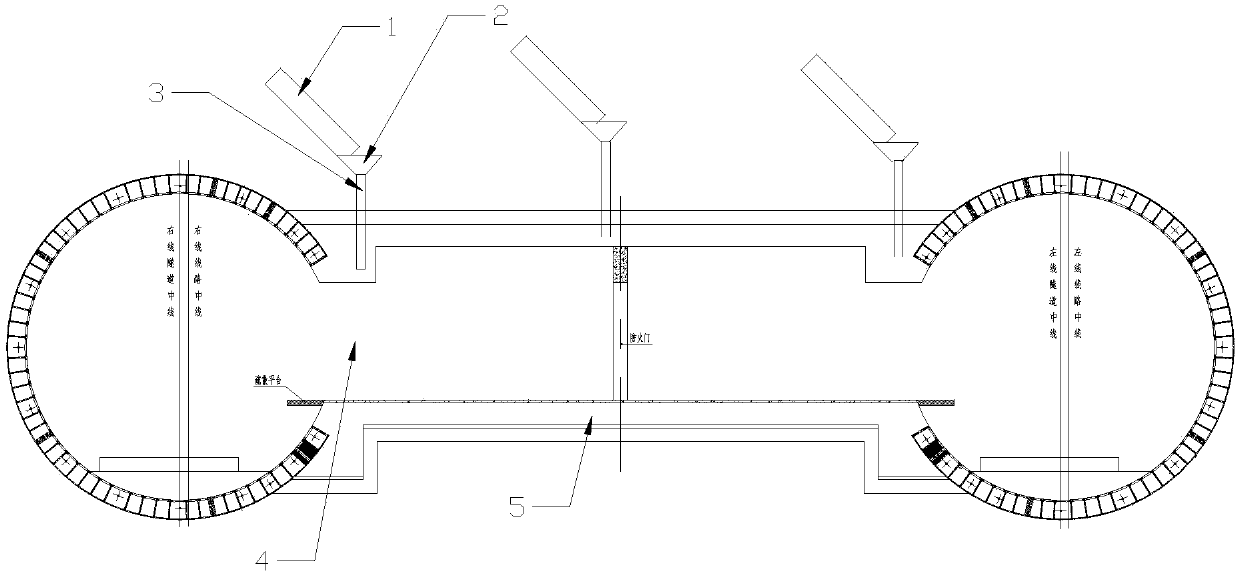

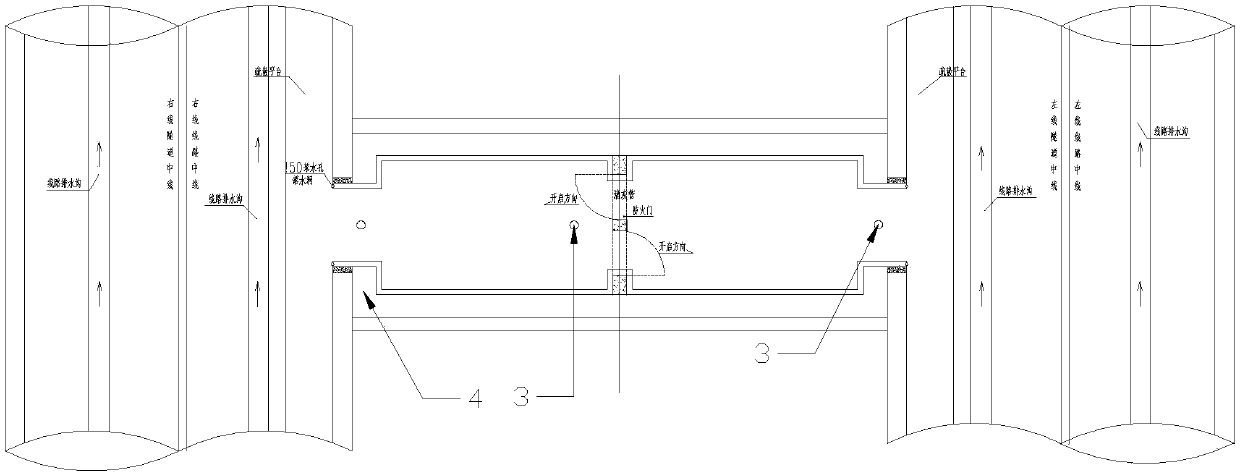

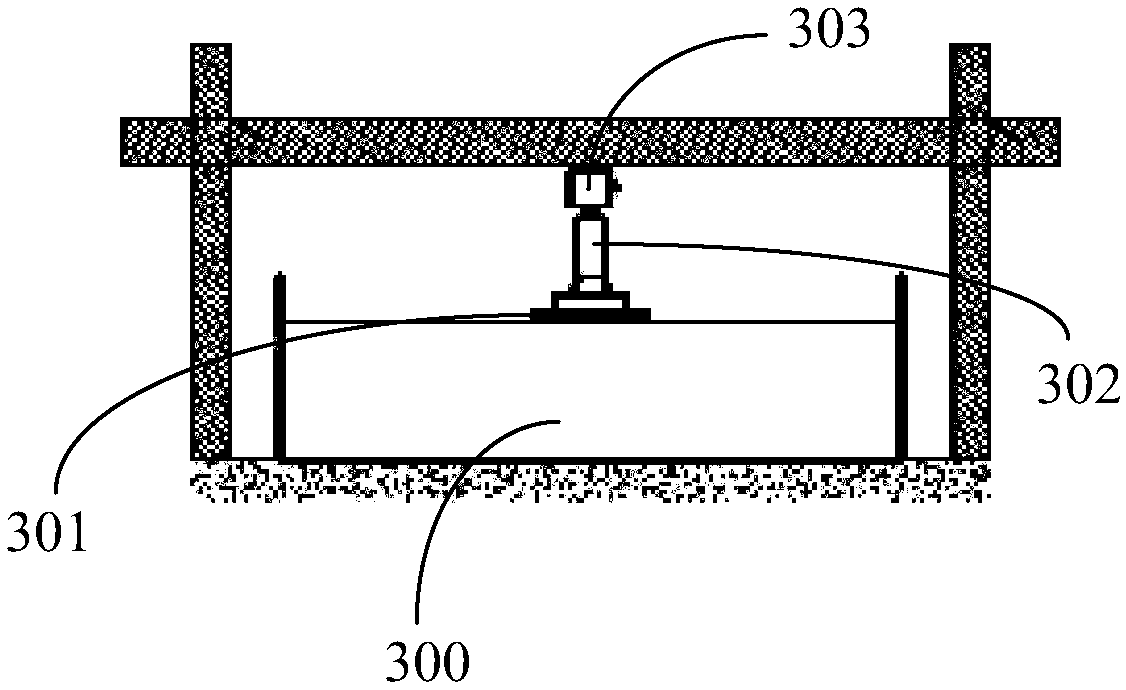

Method for constructing concrete structure of subway contact passage through ground pouring and freezing method

ActiveCN107740699AGuarantee unimpededEnsure that the pouring is denseUnderground chambersTunnel liningStructural engineeringClerestory

The invention discloses a method for constructing a concrete structure of a subway contact passage through a ground pouring and freezing method. The method for constructing the concrete structure of the subway contact passage comprises the following steps that (1) drilling is conducted from the ground above the contact passage toward the interior of the contact passage; (2) concrete sliding tubesare placed downwards in drilled drill holes in the step (1); (3) after a frozen wall meets the excavation condition of the contact passage, earth excavation of the contact passage is conducted in a subway tunnel, and protective treatment is conducted on the concrete sliding tubes after the concrete sliding tubes are dug out; and (4) the concrete structure of a bottom plate (5) of the contact passage is poured by utilizing the concrete sliding tube located in the center of the contact passage, and the side wall concrete structure and the arch crown concrete structure concrete structure are poured by utilizing the concrete sliding tubes located in the flare opening position. According to the method for constructing the concrete structure of the subway contact passage through the ground pouring and freezing method, compact pouring of concrete on an arch crown of the contact passage can be achieved, opening or holes in the concrete on the arch crown of the contact passage can be effectively prevented, it is effectively ensured that the thickness of the concrete structure of the contact passage meets the design requirement, and hidden dangers caused by the quality of the concrete structure of the contact passage are eliminated.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

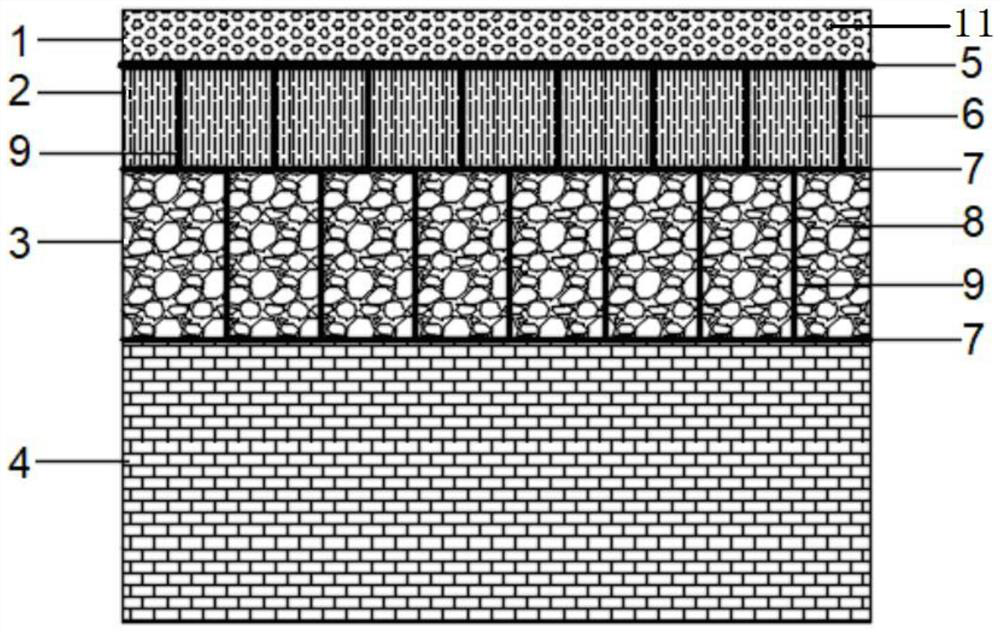

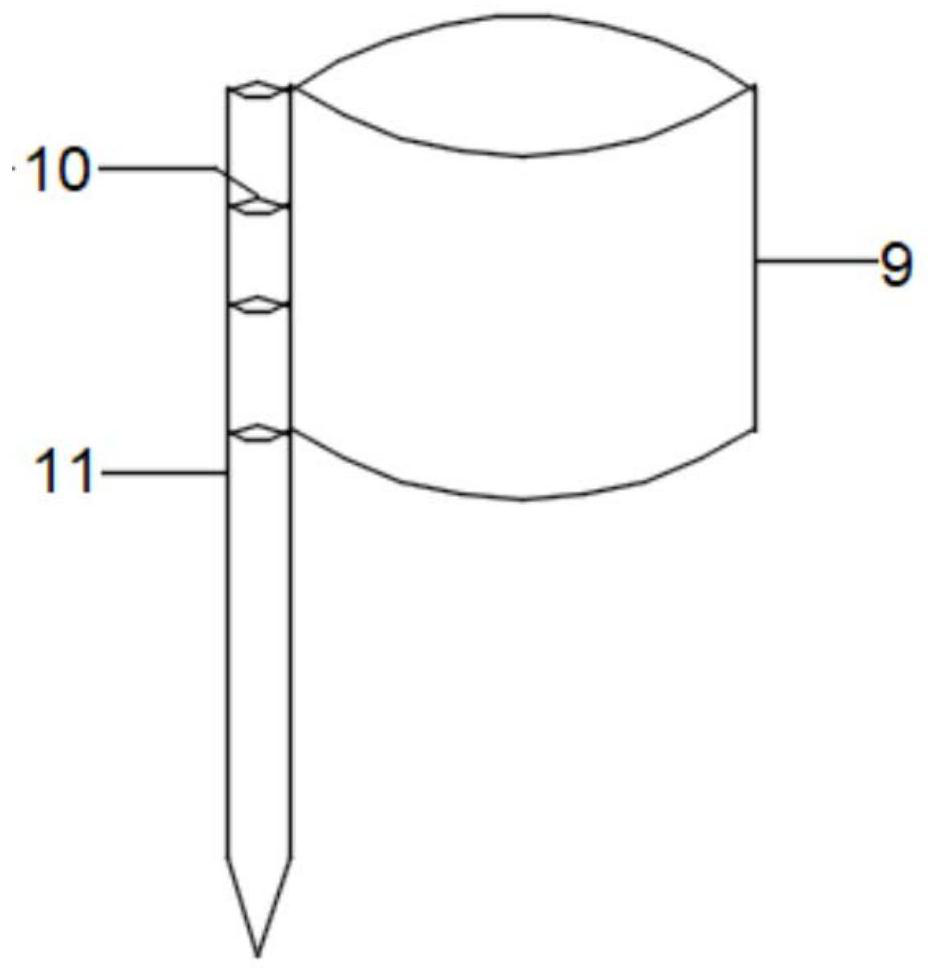

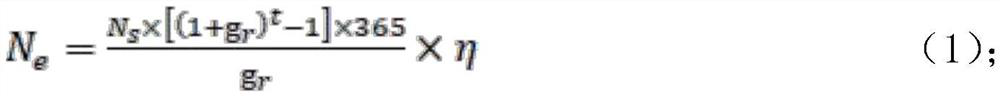

Geocell reinforced cement concrete pavement structure and surface layer plate thickness calculation method

PendingCN111962350AReduce crackingReduce thicknessIn situ pavingsRoads maintainenceCrushed stoneGeocells

The invention discloses a geocell reinforced cement concrete pavement structure and a surface layer plate thickness calculation method. The pavement structure mainly comprises a base layer, a surfacelayer and a wearing layer which are sequentially laid from bottom to top. The base layer is composed of an upper geotextile layer, a lower geotextile layer and a middle geocell reinforced graded broken stone layer; the surface layer is a cement concrete layer reinforced by a geocell; the wearing layer comprises a cement mixture wearing layer and a geogrid; pull rings are reserved on the two sidesof each geocell in a road direction, the geocells are stretched to be in a tensioned state, and wooden wedges penetrate through the pull rings to fix the geocell at the outermost end. The surface layer plate thickness calculation method mainly comprises the steps of traffic analysis, initial simulation of a pavement structure, determination of pavement material parameters, and checking of load stress, temperature stress and a structure limit state. The problems that an existing pavement structure is low in strength, and a cement concrete pavement is subjected to fatigue fracture, mud pumping,slab staggering and the like under heavy-load traffic are solved, so that the pavement structure has high bearing capacity and deformation resistance, and damage to the pavement structure is reduced.

Owner:HUNAN UNIV OF SCI & TECH

Mudstone filled roadbed structure and construction method thereof

ActiveCN105297571ALower the water tableAvoid infringementRoadwaysClimate change adaptationPunchingStructure of the Earth

The invention relates to a mudstone filled roadbed structure and a construction method thereof. When the roadbed is constructed in a mudstone developing area, a water collecting tank is arranged in a soil base, a waterproof layer is paved on the surface of soil base, a mudstone layer is constructed on the waterproof layer, a water-sealing leveled layer is constructed on the mudstone layer, a leveled acceptance layer is constructed on the lower embankment, and a modified soil layer is paved on the road bed. The roadbed is pressed by a crusher, a bulldozer, and sheep-foot roller and is pressed by a layering vibrating press technology and a punching supplement pressure technology. Through controlling the size and uniformity of mudstone particles, the overall stability and strength of roadbed are improved, and the uneven settlement of roadbed is reduced. Moreover, the phenomenon that mudstone is softened by water and is converted into mud is avoided. The engineering quality can be guaranteed, and at the same time, the modified soil bed can meet the related acceptance standards. The practices have proven that the provided method can achieve a good technical effect in mudstone roadbed construction.

Owner:ANHUI TRANSPORTATION HLDG GRP CO LTD

Light subgrade material and preparation method thereof

InactiveCN1385389ADelay uneven settlementLow maintenanceRoadwaysSolid waste managementSlagUltimate tensile strength

The present invention relates to a new-type light road bed material and its preparation method. It is made up by using industrial waste slag and discarded foamed plastics as main raw material, addingactivating agent and water and stirring them. Said method possesses high strength, good hydraulicity and strong deformation resistance, so it is an ideal roadbed material.

Owner:TENGDA CONSTR GROUP CORP

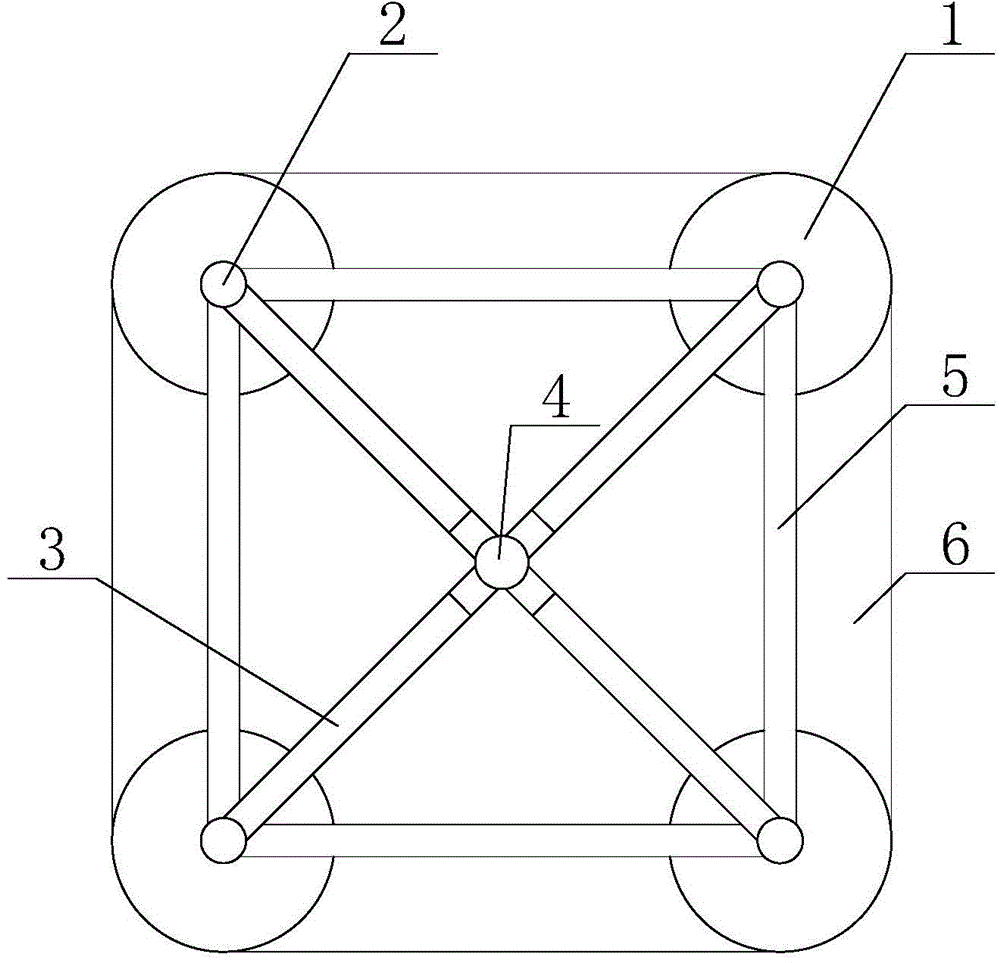

Multi-cylindrical foundation combined foundation structure system

InactiveCN103981894AIncreased anti-overturning momentImprove stabilityFoundation engineeringElectric fieldBending moment

The invention discloses a multi-cylindrical foundation combined foundation structure system. The connecting lines of the center points of four cylindrical foundations form a quadrangle; a pile body is arranged on the top of each cylindrical foundation; the central line of each pile body and the central line of the cylindrical foundation corresponding to the pile body are on the same straight line; a node connecting component is arranged above the center positions of the four cylindrical foundations; a profile steel beam is connected between the node connecting component and the outer side of the top of each pile body; each profile steel beam is downwards inclined from the end part connected with the node connecting component to the end part connected with the pile body; an inter-pile support are connected between the roots of the pile bodies; an overall steel pipe is connected between every two cylindrical foundations. The relatively large torque transferred by an upper part structure is approximately converted into tensile force and pressing force at the cylindrical foundations through each profile steel beam and each pipe body, so that the highest bearing capacity of the cylindrical foundations is achieved, materials are saved, the complete technology of 'floatation transportation, sinking and leveling' can be realized during construction, the construction period is short, and the building cost of an offshore wind power station is reduced.

Owner:TIANJIN UNIV

Transition structure for preventing and treating bump at bridge-head and construction method thereof

PendingCN109853381AShorten the construction periodGuaranteed accuracySingle unit pavingsBridge structural detailsRoad surface roughnessAbutment

The invention provides a transition structure for preventing and treating bump at bridge-head and a construction method thereof. The structure of the transition structure for preventing and treating the bump at the bridge-head comprises a beam body; bridge abutments are fixedly mounted at the two ends of the beam body; one ends of towing plates are fixedly mounted at the middle parts of the bridgeabutments; the other ends of towing plates are buried in a subgrade; the parts behind the bridge abutments and the upper parts of the towing plates are filled with backfilled earth; combined approachslab members are laid on the upper surface of the backfilled earth; and one ends of the combined approach slab members are fixedly mounted on the external sides of the upper ends of the bridge abutments. The construction method comprises the steps of erecting the bridge abutments molded with brackets, constructing the towing plates on the brackets to form two layers of backfill structures, and arranging the combined approach slab members to improve a bearing structure; and therefore, road surface roughness and breakage at the bridge head connecting part caused by uneven settlement of the backfilled earth in the using process are reduced to realize an effect of preventing and treating the bump at the bridge-head; and meanwhile, through the structure combination, energy saving and environmentally friendly properties are realized, the construction period is shortened, template members are saved, and accuracy and quality are very well guaranteed.

Owner:SHENYANG JIANZHU UNIVERSITY

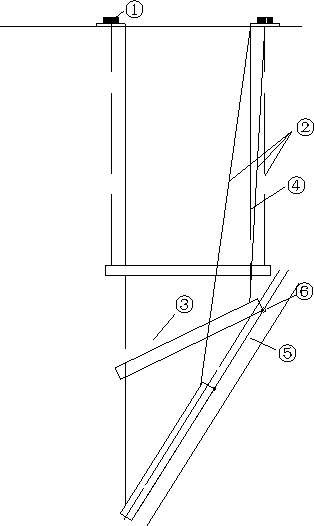

Railway roadbed structure for reducing roadbed settlement deformation through opposite-pulling rib U-shaped groove

The invention relates to a railway roadbed structure for reducing roadbed settlement deformation through an opposite-pulling rib U-shaped groove. The U-shaped reinforced concrete groove with an upwardnotch is formed in the bottom and filled with a roadbed stacking and filling material, the top of the roadbed stacking and filling material is flush with the top edge of the U-shaped reinforced concrete groove and provided with railway ballast, and a railway track structure is arranged above the railway ballast; and opposite-pulling ribs are transversely arranged in the U-shaped reinforced concrete groove, and the two ends of each opposite-pulling rib extend out of the U-shaped reinforced concrete groove. On the one hand, lateral deformation of a roadbed body is greatly restrained through theU-shaped opposite-pulling reinforced concrete groove, roadbed body stuffing is stacked and filled or concrete is poured within the limited space with lateral confinement, and roadbed body settlementis controlled to a great degree; and on the other hand, the occupied width of the bottom of a roadbed is greatly reduced, and plenty of requisition land and plenty of foundation treatment area are saved.

Owner:XIAN RAILWAY SURVEY & DESIGN INST CO LTD

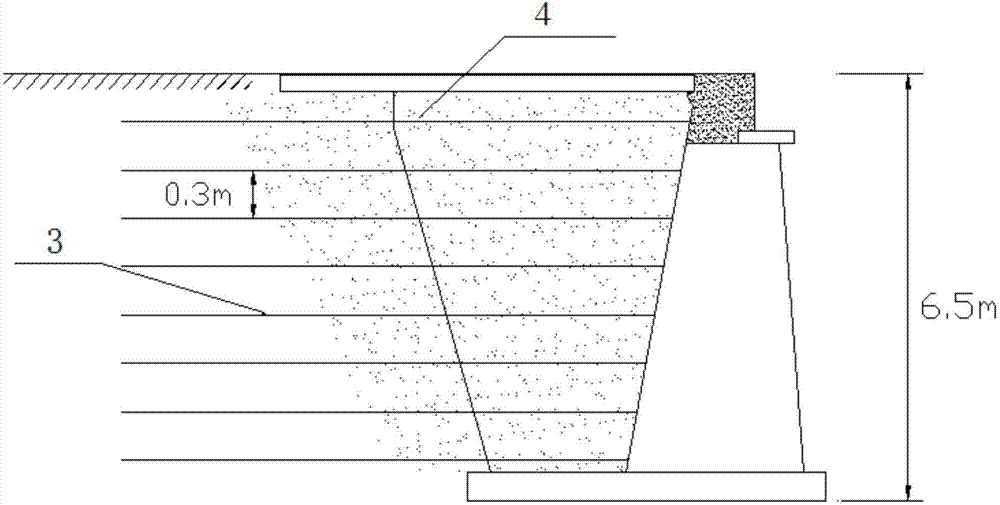

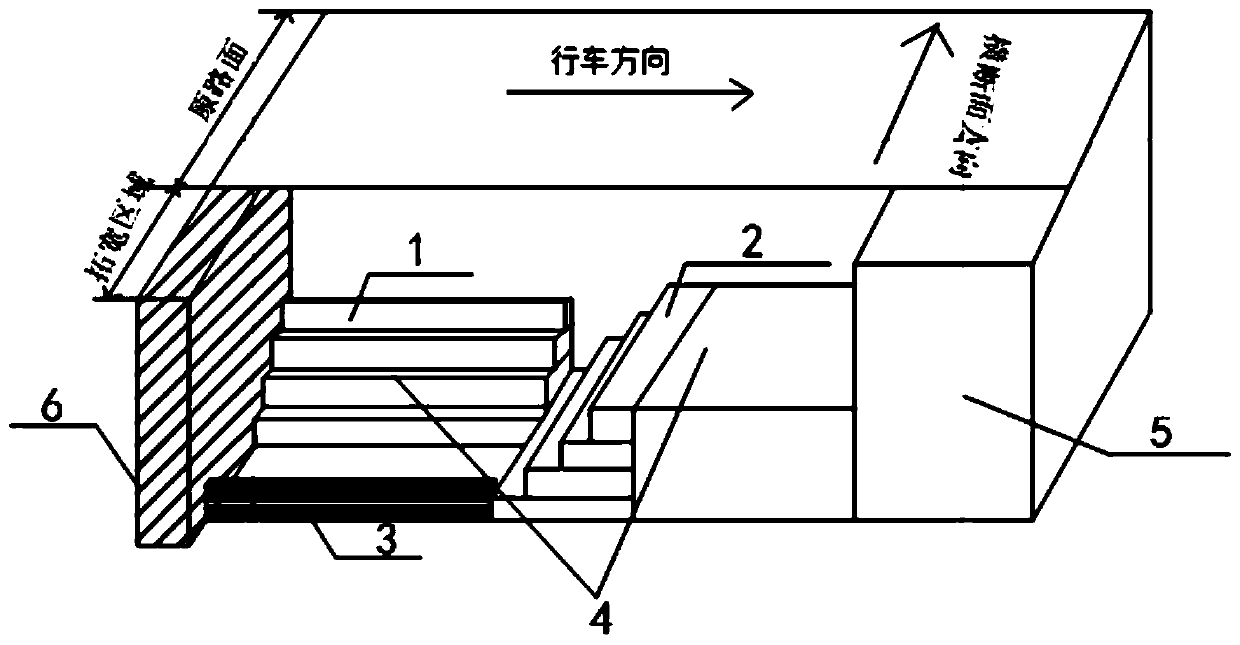

Foam light soil pouring retailing backwall structure in highway reconstruction and extension project and construction method thereof

The invention relates to a construction method of pouring a retailing backwall using foam light soil in a highway reconstruction and extension project. Firstly a base is cleaned and compacted, a layerof broken stones with the thickness of 30 cm is laid, steps are arranged along the route driving direction and along one side, close to a road center line, of the cross section direction, a convex step is poured by using a form hanger on the side close to a side slope, and the steps are arranged for better lapping of the foam light soil and subgrade soil. Waterproof geomembranes are laid on the lowest layer and the topmost layer of a foam light soil structure, and earthwork standard rooms are laid on the positions which are respectively 50 cm from the bottom layer and 50 cm from the top layerto enhance the overall strength. By adopting the construction method, under the condition that the area at the retailing backwall is small and is not favorable for construction of a large-scale instrument, the construction can be simplified, the operation is convenient, by utilizing the features of quick early strength formation and good integrality of the foam light soil, the dependency on lateral wrapping soil is reduced, and template supports are used instead for pouring. The construction method has a relatively good effect on reducing bump at bridge-head.

Owner:SHANDONG UNIV

Ribbed waterproof and water-draining coiled material and construction method thereof

InactiveCN108035333AImprove carrying capacityPrevent reflective cracksRoadwaysProtective foundationSubgradeMaterials science

The invention discloses a ribbed waterproof and water-draining coiled material and a construction method thereof. The ribbed waterproof and water-draining coiled material comprises a waterproof layer,a supporting layer and a water-draining layer, wherein the supporting layer is positioned between the waterproof layer and the water-draining layer; and the waterproof layer, the supporting layer andthe water-draining layer are connected integrally. The waterproof layer, the supporting layer and the water-draining layer are simultaneously arranged on the ribbed waterproof and water-draining coiled material, so that the ribbed waterproof and water-draining coiled material simultaneously has functions of improving foundation or roadbed carrying ability, obstructing underground water and solving the problem of water drainage of a foundation or a roadbed, then uneven sedimentation of the pavement of the foundation and roadbed is reduced, reflection cracks between structure layers of the pavement of the foundation and roadbed are prevented, the stability of the integral structure of the foundation and roadbed is improved, and the service lives of a building structure and a road are prolonged.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Construction process of airport runway

InactiveCN108867236AImprove compactnessReduce uneven settlementTemporary pavingsAirplaneSurface layer

The invention discloses a construction process of an airport runway, which belongs to the field of the airport construction. The construction process comprises the following steps: removing the surface plant soil, flattening the field, tamping the soil foundation, constructing a liner layer, constructing a basic layer, and constructing a surface layer. The construction process not only can solve the problems of foundation settlement, frost heaving and salt heaving caused by the water permeation, but also can improve the overall performance of the foundation, and can improve the rigidness of the foundation, so that the dynamic response of the pavement surface layer under the dynamic load effect of an airplane can be improved, and the disease problem of the airport pavement can be fundamentally solved.

Owner:四川先舟建设工程有限公司

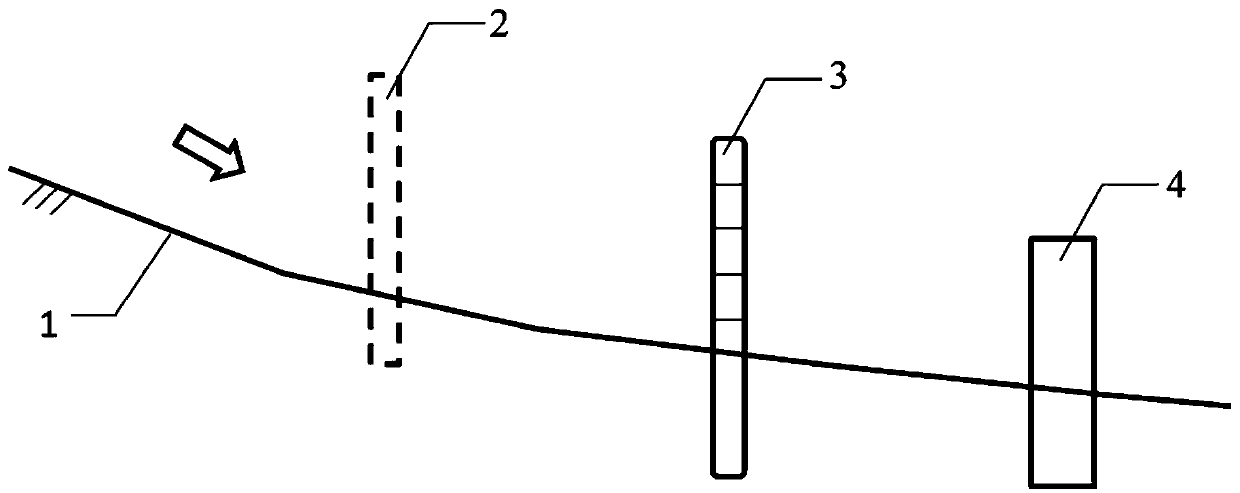

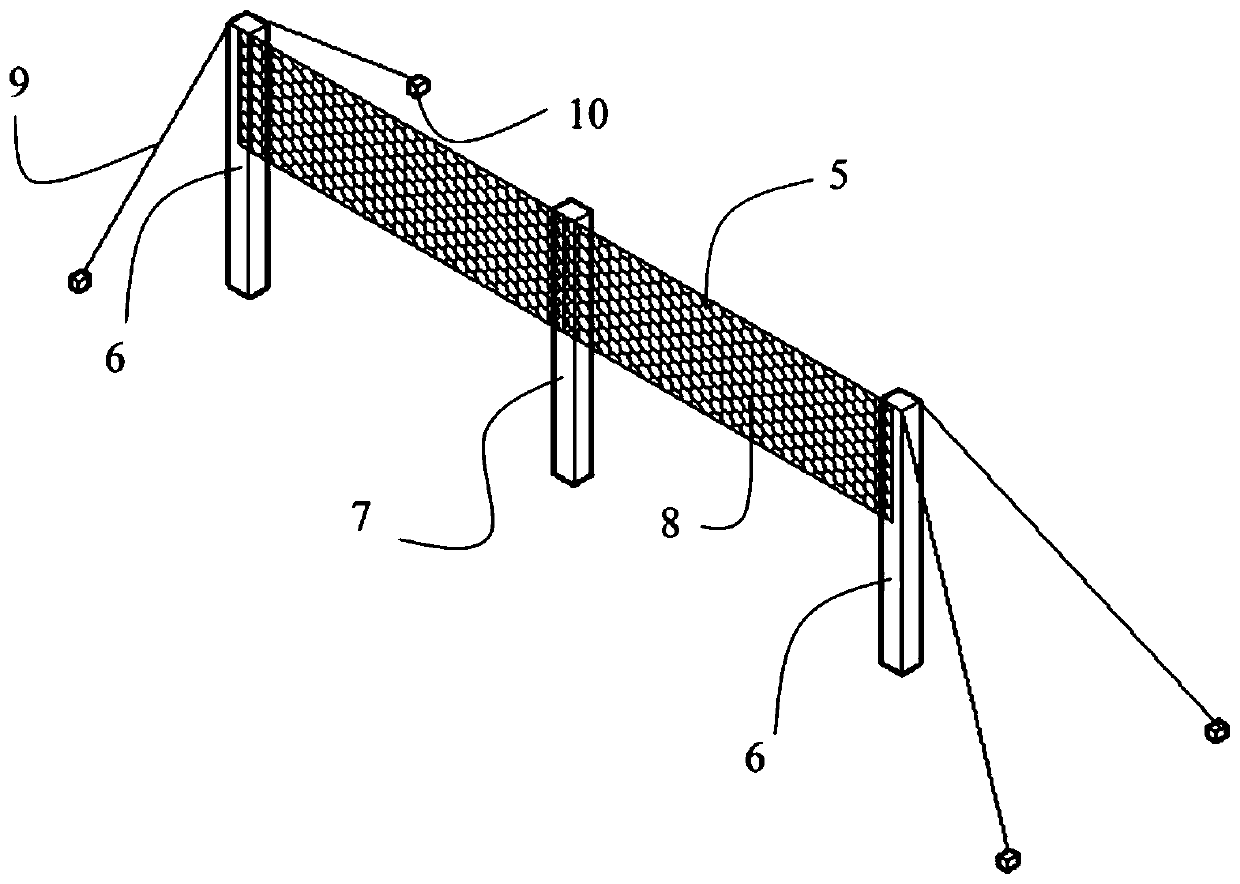

Debris flow multi-stage dissipative blocking structure

PendingCN110004882AConsume impact energyReduce shockProtective constructionFoundation engineeringButtressEngineering

The invention relates to the technique of prevention of geological hazards, in particular to a debris flow prevention technique. The invention discloses a debris flow multi-stage dissipative blockingstructure, thus damage action of a debris flow can be lowered, and the disaster loss is relieved. According to the debris flow multi-stage dissipative blocking structure, from flowing area of the debris flow to the accumulation area, the debris flow multi-stage dissipative blocking structure is arranged in a step-by-step mode along debris flow channels from the upstream to downstream, and at leastincludes a flexible blocking net, a pile-carrying-type grid wall and a permeable buttress-type gravity dam. According to the debris flow multi-stage dissipative blocking structure, according to different geological conditions, types of the debris flows and the like, the matching structure of the flexible blocking net 2, the pile-carrying-type grid wall 3 and the permeable buttress-type gravity bam is reasonably selected, benefits of the investment in engineering construction can be given full play to the maximum extent, and cost benefit optimization is achieved. The debris flow multi-stage dissipative blocking system is very suitable for prevention of the debris flow disasters.

Owner:SOUTHWEST JIAOTONG UNIV

Adjustable reinforcing and deviation rectifying method and structure for reducing differential settlement of building

ActiveCN107044142ADelay uneven settlementDesign scienceFoundation engineeringArchitectural engineeringStructural engineering

The invention discloses an adjustable reinforcing and deviation rectifying method and structure for reducing differential settlement of a building. On the basis of reinforcement of the settling building, differential settlement of the building is adjusted by mounting rubber supports in different thicknesses, the method and the structure are scientific in design, reasonable in planning, easy to realize and high in reliability, the structure is excellent in mechanical property, differential settlement of the building can be effectively reduced, adjustment can be performed, that is, in the later building monitoring process, when the condition of differential settlement of the building occurs again, deviation rectification can be performed again by changing the rubber supports.

Owner:NANJING UNIV OF TECH

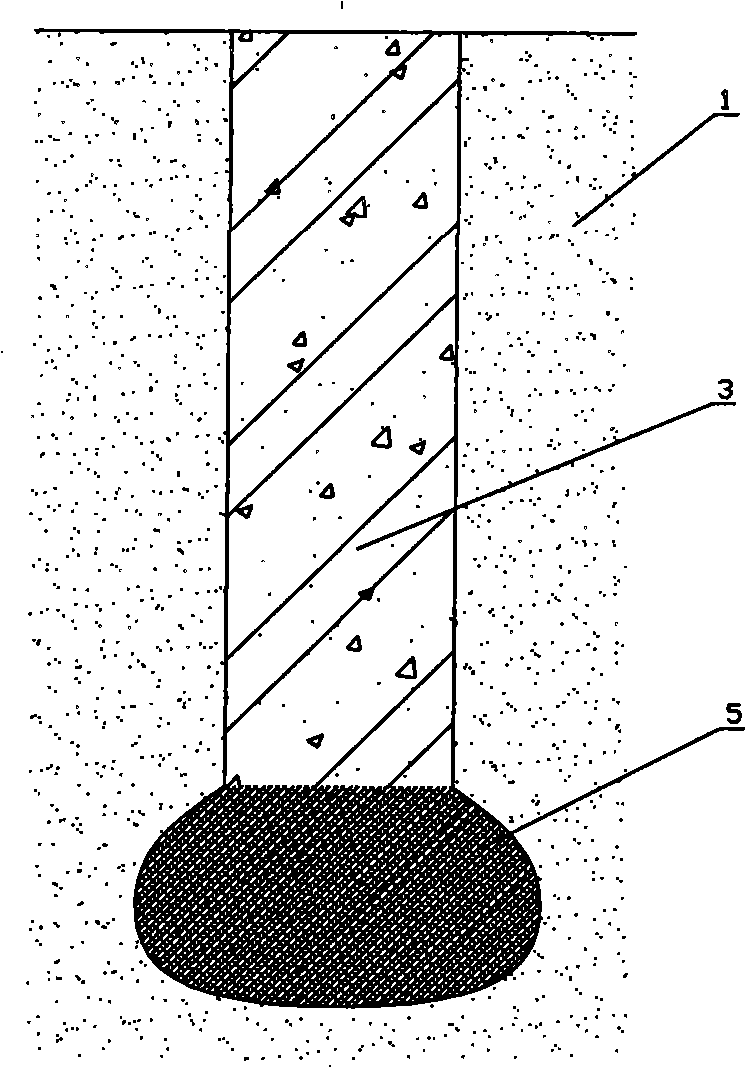

Concrete and induration formed composite type pile and its manufacture method

InactiveCN101260668AIncrease pile tip resistanceImprove pile side frictionBulkheads/pilesRebarReinforced concrete

The invention discloses a composite pile body formed by concrete and a concretion body and a construction method thereof; the composite pile body is formed by the different combination of the concrete pile body, a pile side concretion body formed by slurry sprayed from the pile side and a pile bottom concretion body formed by slurry sprayed from the pile bottom; the construction method comprises that: a hole is drilled to a preset depth by a driller; according to the need of a design proposal, the pile bottom concretion body is formed after slurry is sprayed from the pile bottom; the concrete is affused by lifting a drill stem, and the pile side concretion body with different shapes is formed by controlling the rotation of the drill stem and the spraying of the slurry; after the drill stem is lifted to the pile top and a height mark is designed, if the pile body is a reinforced concrete type composite pile body, a steel reinforcement cage also needs to be inserted to complete the construction of the composite pile body. The composite pile body formed by the concrete and the concretion body and the construction method can effectively improve the bearing capacity of the pile body and has high construction efficiency and high economical efficiency.

Owner:王力纬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com