Bridge widening splicing structure and its construction method

A construction method and bridge technology, which is applied in bridge construction, bridge erection/assembly bridge, etc., can solve the problems of high maintenance cost of widened bridges, uneven settlement of new and old bridges, etc., to reduce maintenance costs and achieve good economic benefits With social value, the effect that construction is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

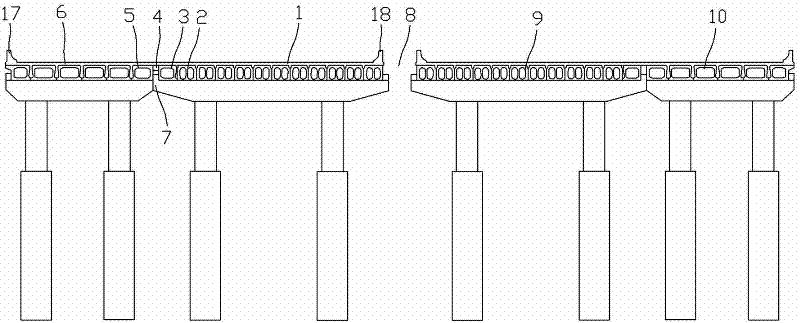

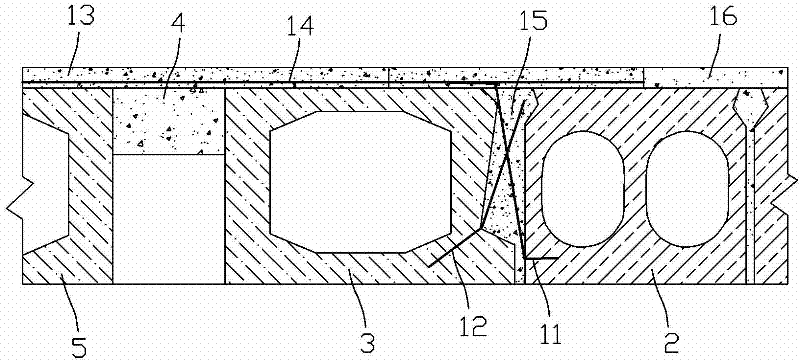

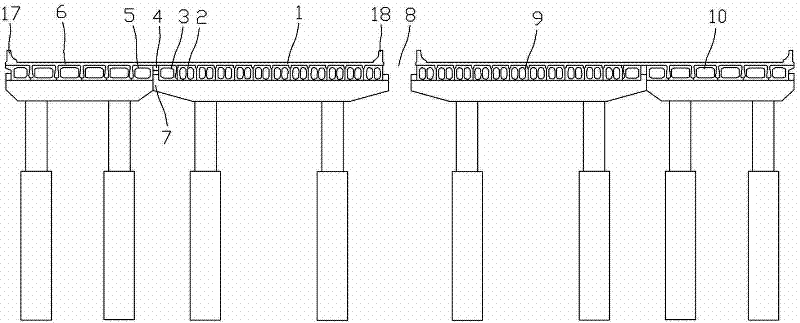

[0040] Embodiment 1 A bridge widening splicing structure, see figure 1 , figure 2 , including the old bridge 1 on the left and the old bridge 9 on the right, the new bridge 6 on the left that matches the height of the new erection on the outside of the old bridge 1 on the left and the old bridge 9 on the right, and is the same as the new bridge 6 on the left The edge of the adjacent old bridge 1 on the left side is a new hollow slab 3 that replaces the original side slab and its attached guardrail. Ribs 12 are hinged, and the grooved joint 11 between the new hollow slab 2 and the old bridge hollow slab 2 is connected by cast-in-place concrete, above which is the bridge deck pavement layer; the new bridge hollow slab 5 on the left new bridge 6 Between the new hollow slab 3 on the old bridge 1 on the left and above the flange 7 of the old bridge is the joint pavement cast-in-place wet joint 4 for the new and old bridge, above which is the new bridge deck pavement layer 13; Th...

Embodiment 2

[0067] Embodiment 2 Application example

[0068] (1) The new and old bridge widening project of the Anyang-Xinxiang section of the Beijing-Hong Kong-Macau Expressway. The project is located in Henan Province and spans Xinxiang, Hebi, and Anyang in Henan Province. The total length is 113km. The method described in Example 1 is used to The existing bridge was widened, and the project was completed and opened to traffic in November 2010. The widened bridge is in good condition, and no longitudinal cracks appear on the bridge deck.

[0069] (2) The new and old bridge widening project of the Zhengzhou-Luohe section of the Beijing-Hong Kong-Macao Expressway. The project is located in Henan Province and spans Zhengzhou, Xuchang, and Luohe in Henan Province. The total length is 119.638km. The method described in Example 1 is adopted The bridge was widened. The project was completed and opened to traffic in November 2010, and the operation is in good condition.

[0070] (3) The main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com