Patents

Literature

320 results about "Drainage canal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drainage canal. An artificial canal built to drain water from an area having no natural outlet for precipitation accumulation.

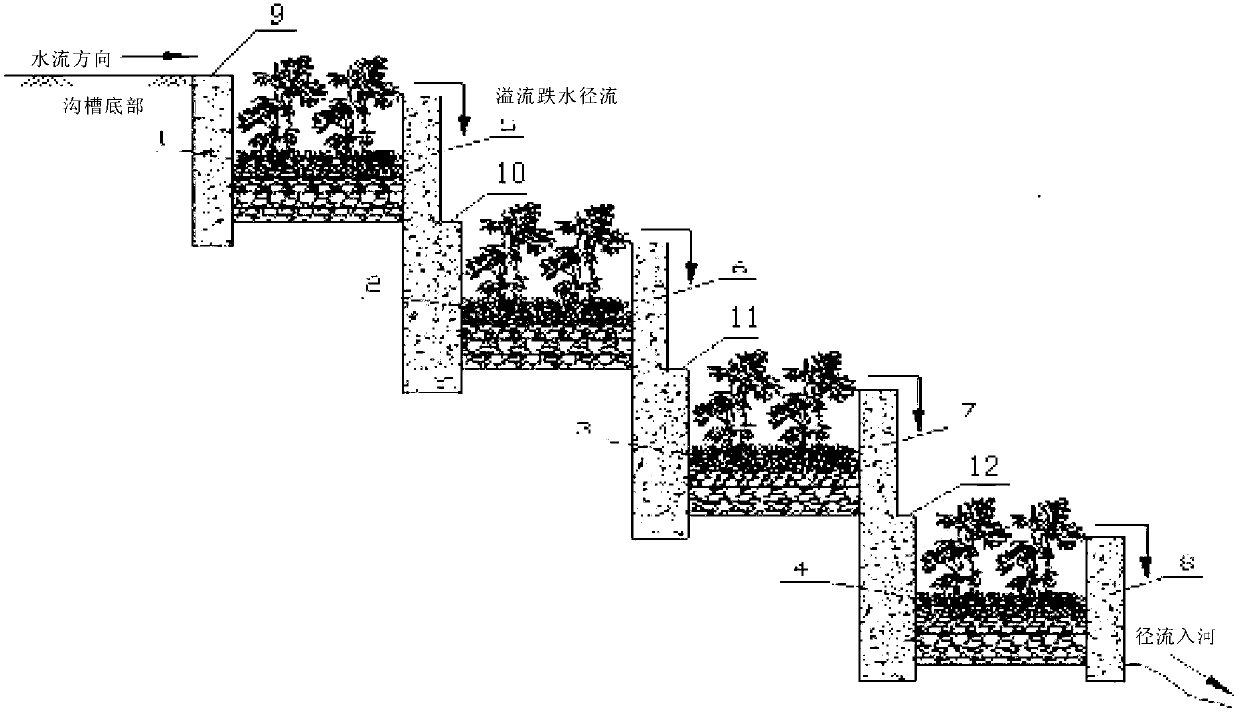

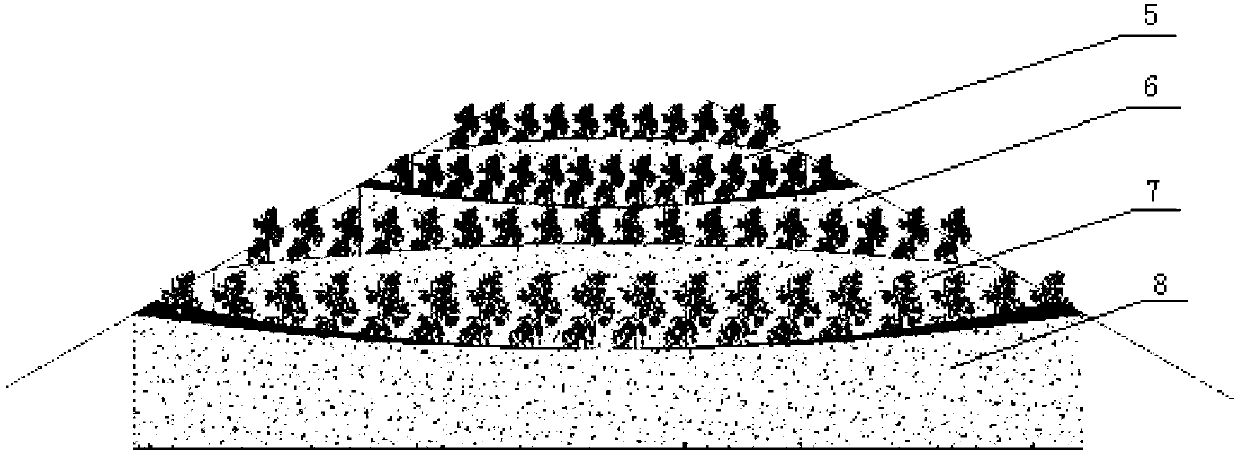

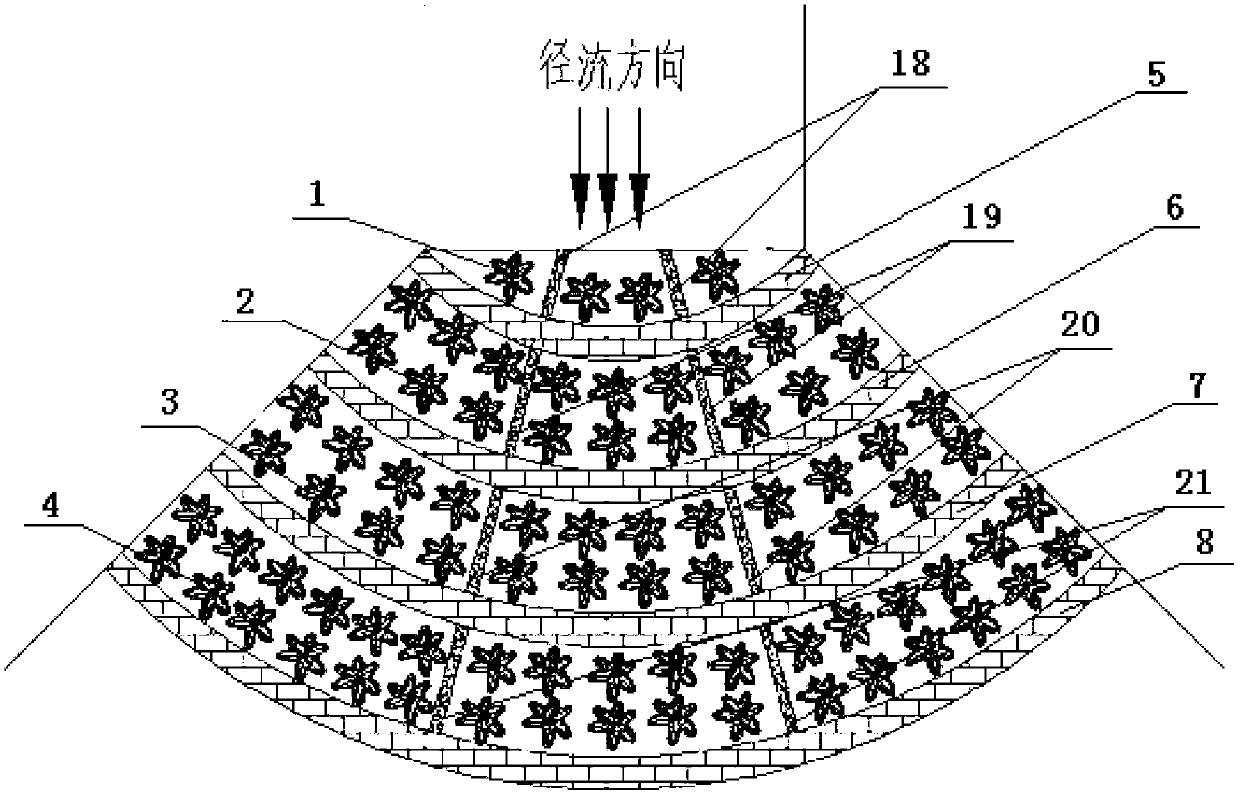

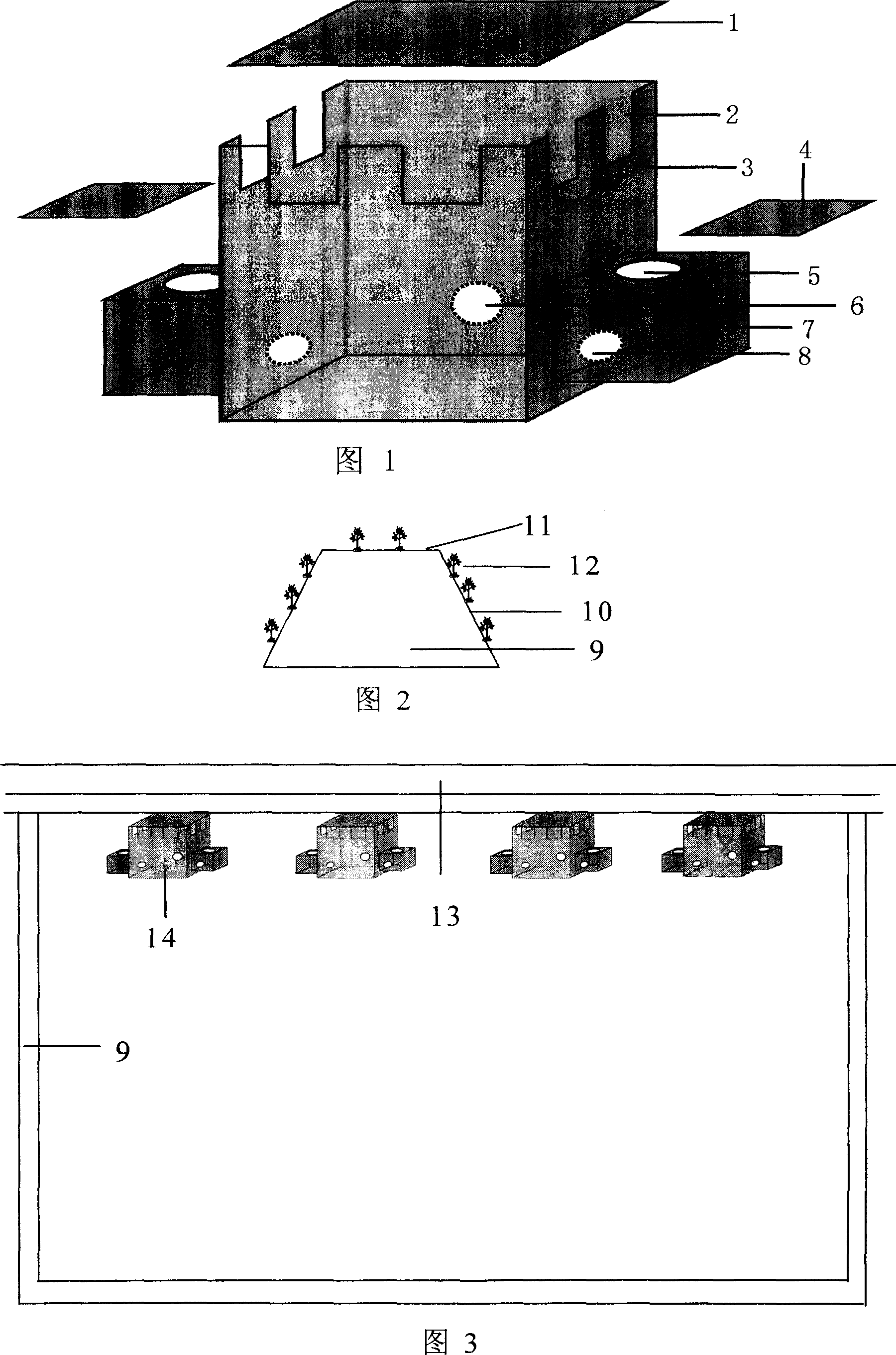

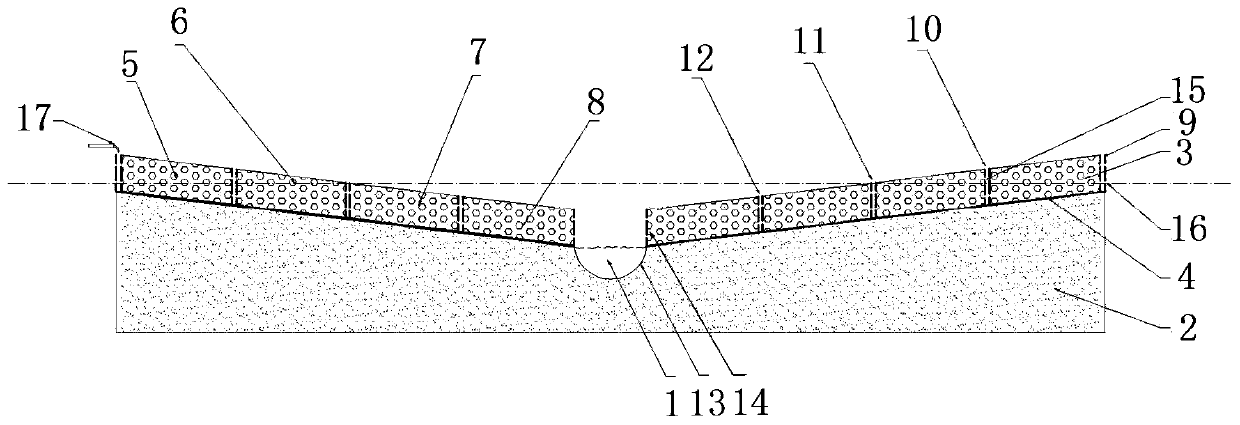

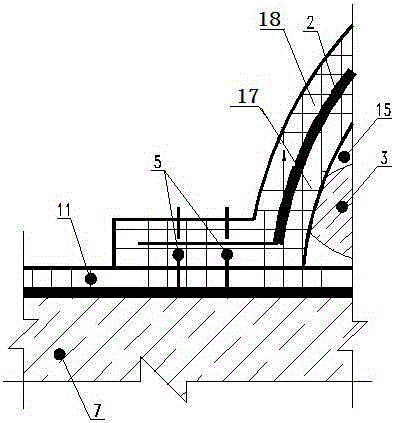

Sectored multi-step ecological buffer revetment system

InactiveCN103215920AMeet safety requirementsGood interception and purification effectClimate change adaptationCoastlines protectionEngineeringFlood water

The invention discloses a sectored multi-step ecological buffer type revetment system. The revetment system is provided with at least four levels of steps, blocking walls are sequentially arranged on the outer sides of the steps, one plant planting zone is arranged in the blocking wall of each level, soil matrix is arranged in the upper layer of each plant planting zone, yellow sand, ceramsite, soft rock and zeolite are sequentially in the lower layer of the plant planting zone of each level, and emersed landscape plants and submergence-tolerant plants are arranged in the plant planting zone of each level; hydraulic drop platforms are sequentially arranged in the corresponding positions of spaced plant planting zones of the blocking walls; and one guide plate is arranged between each blocking wall and the corresponding hydraulic drop platform; the plant planting zone of the first level is connected with a farmland drainage canal and is sectored towards the downstream to form a hydraulic-drop type hierarchical structure in an open sectored shape, the sector radius is 5-8 m, and the central angle is 45 degrees-75 degrees; and the blocking wall of the last level is connected with a river channel. The sectored multi-step ecological buffer type revetment system not only has the efficacies of protecting river channel side slope, and realizing flood water drainage and water and soil conservation, but also has good purification and landscape effects.

Owner:TIANJIN UNIV

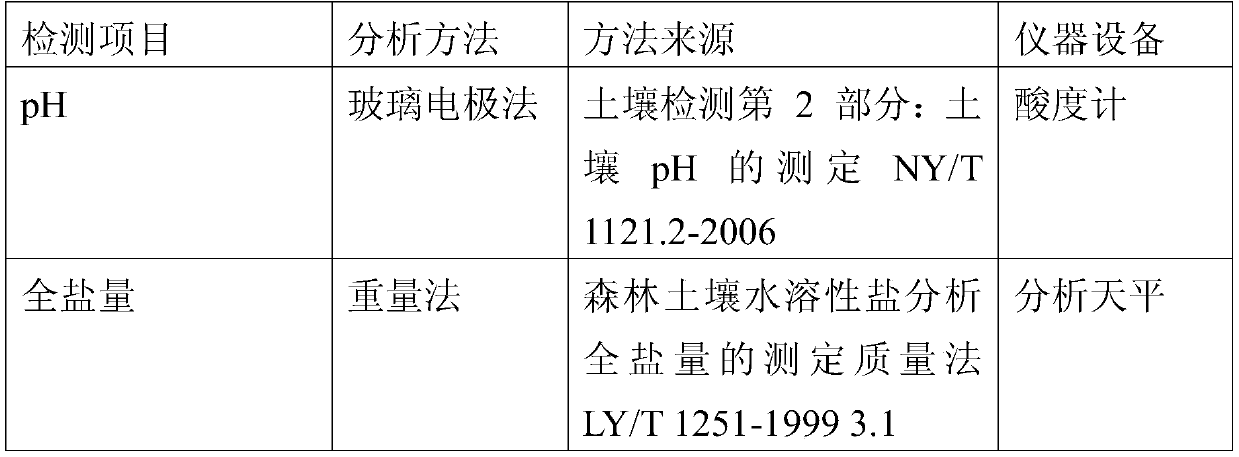

Method of planting lawn in saline-alkali soil

InactiveCN101828477AEffective coverageReduce water evaporationHorticultureSoil-working methodsAlkali soilEcological environment

The invention discloses a method for planting lawn in saline-alkali soil and relates to the fields of the saline-alkali soil control and planting technology. The method comprises the steps of: 1, soil arrangement; 2, establishment of a drainage canal; 3, straw application; 4, sand covering on a surface; 5, selection of grass seeds; 6, planting technology; 7, fertilizer application according to formulas; and 8, cultivation management. In the method, the bare surface of the saline-alkali soil can be covered effectively in short time, the water evaporation of the ground is reduced, and the saltness of the surface soil is reduced; the saline-alkali soil can be utilized comprehensively in a large area, and the vegetation structure of the saline-alkali soil can be adjusted; and the vegetation cover area of the saline-alkali soil is enlarged, and the ecological environment is protected and improved.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

Economical and quick method for planting salinized soil lawn

InactiveCN102845215ASimple structureReduce water evaporationHorticultureEcological environmentSalt content

The invention discloses an economical and quick method for planting salinized soil lawn, and relates to the field of the treatment of salinized soil. The method comprises the following steps of: (1) tidying the salinized soil; (2) building a drainage canal; (3) applying organic fertilizer, silver sand and base fertilizer; (4) building ridges, and desalting in an elution way; (5) selecting the grass variety; (6) building and planting a grass blanket; (7) transplanting the grass blanket; and (8) managing the cultivation. According to the method, the structure of the salinized soil can be effectively improved, the naked surface of the salinized soil can be covered, the evaporation of water on the surface of the ground can be reduced, and the salt content of surface soil can be reduced; the method is low in planting cost, the salinized soil can be comprehensively used in large area, and the structure of the plant of the salinized soil can be adjusted; and the plant cover area of the salinized soil can be enlarged, and the ecological environment can be protected and improved.

Owner:WUHAN BOTANICAL GARDEN CHINESE ACAD OF SCI

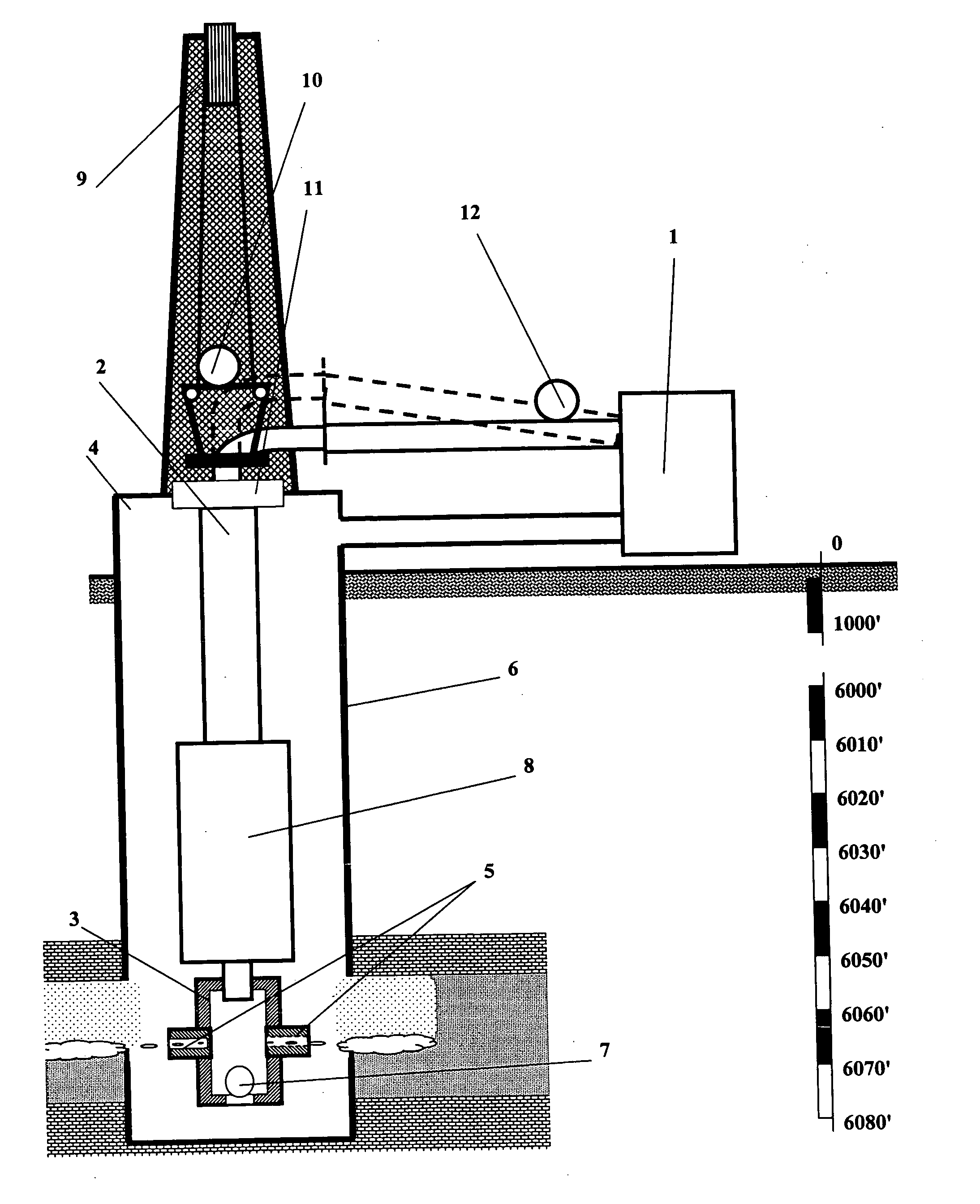

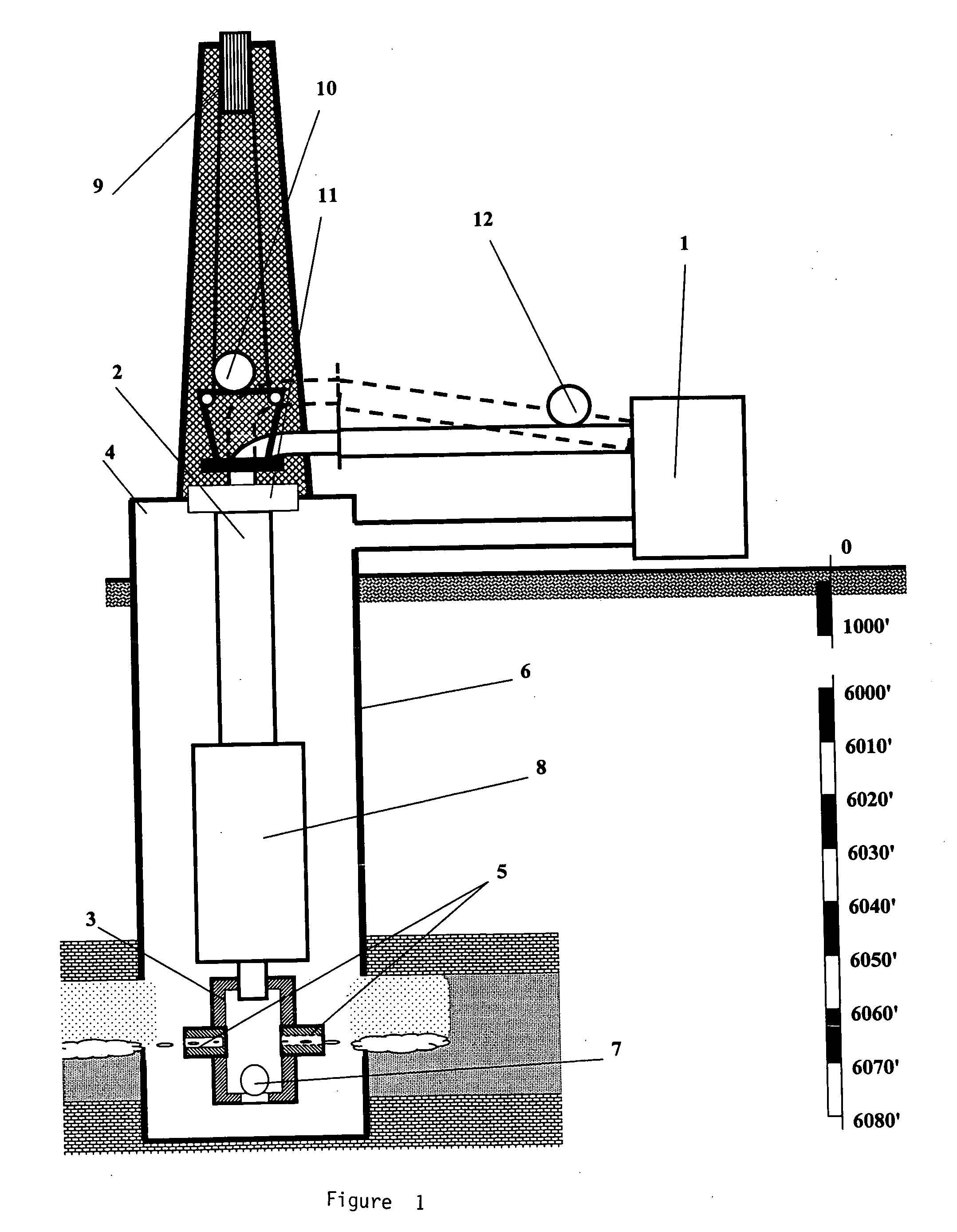

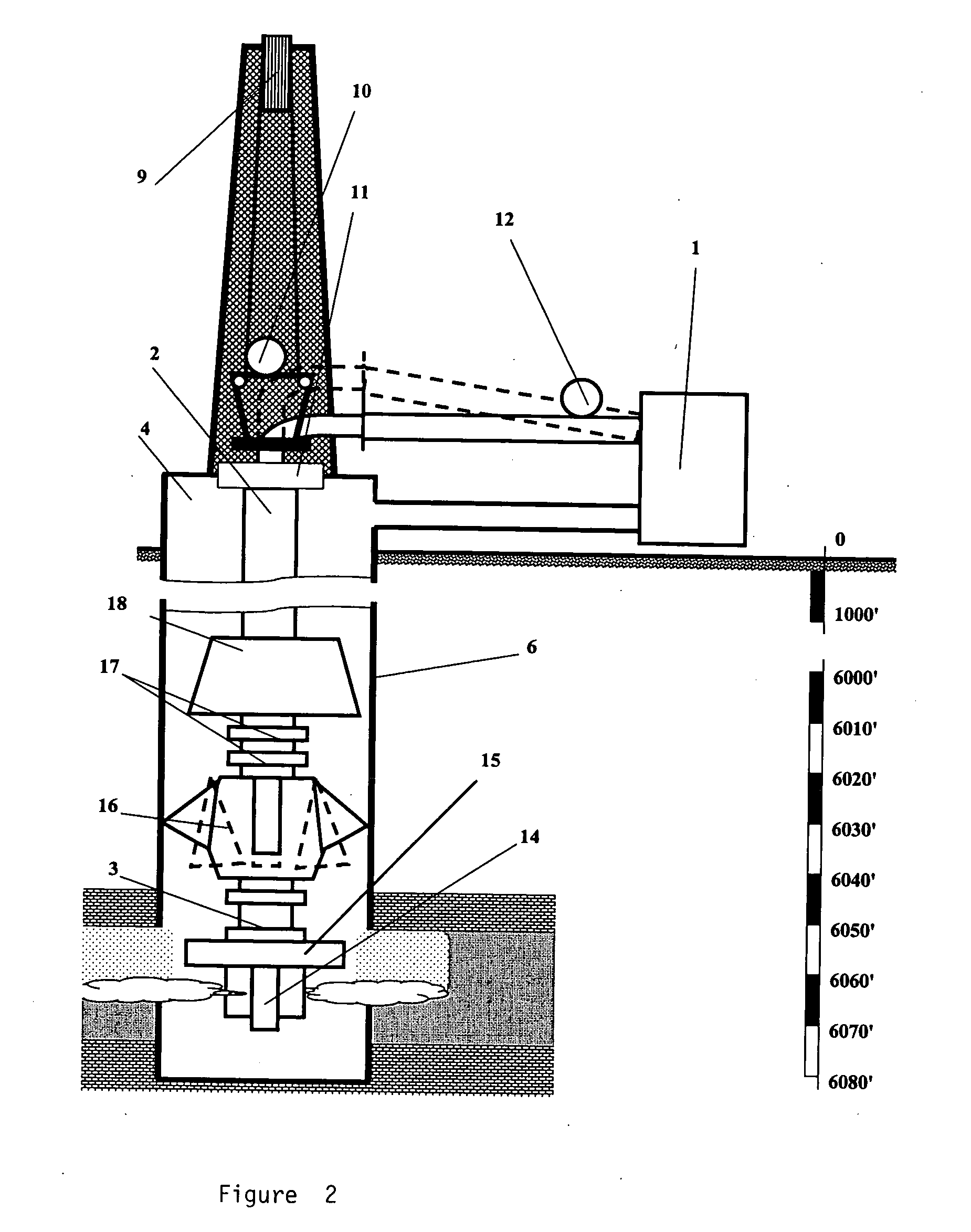

Device for cutting slot-shaped seats in wells by hydro-sandblasting method

This device relates to the fields of mining, specifically oil and gas industry, hydro-geological, geological engineering and water supply industries and is intended for cutting slot-shaped seats in well side zones of producing formation by hydro-abrasive blast. The determined task is solved by introducing essential changes into the known device for construction of cutting slot-shaped seats from the well wall inside the rock consisting of the hydro-abrasive jet generator connected with the perforator through the pump-and-compressor tubing string; the perforator is put into the casing pipe and has two diametrical nozzles which are directed at the well wall; there is a ball valve at the perforator end, as well as devices for adjustable partial unloading of PCS, PCS weight measuring device, abrasive jet pressure measuring device and the sealer for sealing of wellhead. The changes are as follows:—The perforator is directly connected with PCS;—A pin mounted under the perforator with possible axial movements is introduced;—A cylindrical retainer washer is put on the upper part of the perforator above nozzles; the washer is fixed so as to permit axial movement;—PCS indexing mechanism, step rings and a tripping muff are mounted bottom up and in alignment on the lower tube of PCS which is in series connected with the perforator;—At the same time the pin is connected with the cylindrical washer situated on the upper part of the perforator by control-rods with possible axial movement;—The indexing mechanism is put on PCS with the possibility of fixed coupling of its body with the casing pipe wall and split engagement of its body by step rings. Step rings are to be rigidly fixed on the lower PCS tube, and the tripping muff-on the PPS with its skirt down. At least a couple of rotary fluke-claws, with one end of each hingedly connected with the body of indexing mechanism, and the other end clasped to the casing pipe wall by spacer springs mounted between the indexing mechanism body and the fluke-flaw end, can be a variant of engagement of the indexing mechanism body with the casing pipe wall. At least a couple of spring-mounted pins installed on the interior surface of the indexing device body can be a variant of split engagement of the indexing mechanism by step rings. At that the pin heads are of round shape at the contacting end set against PCS. A muff with conical inside surface and the exterior of streamlined form can be a variant of tripping muff for forced tripping of the indexing mechanism from the casing pipe wall. The optimum distance between the step rings equals to one drain port diameter D±5%, and the number of rings has to amount to prescribed length of the slot-shaped seat divided by the drain port diameter D. At the same time adjacent drainage canals will unite and form a single slot-shaped seat. The recommended force for coupling of the split pin heads with PCS lies within the limits of 10-20% of PCS weight. The recommended force for coupling of the indexing device body with the casing pipe wall is in the range from 30% of PCS weight up to breaking strength point of the casing pipe.

Owner:DAVIDSON DRILLING

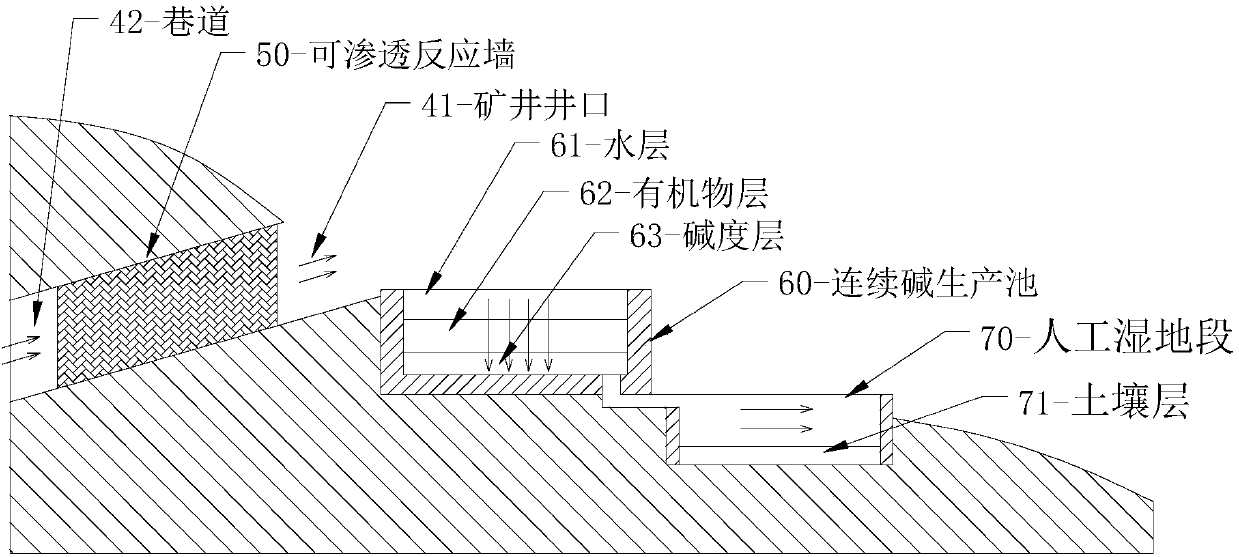

Comprehensive treatment method for acid mine water of small abandoned coal mines

InactiveCN107935301AReduce supplyReduce excretionWaste water treatment from quariesWater treatment parameter controlConstructed wetlandSurface layer

The invention provides a comprehensive treatment method for acid mine water of small abandoned coal mines. A slurry is injected into a grouting filling layer, a plugging surface layer is formed afterthe slurry is solidified, the underground water supplementary amount of atmospheric precipitation to underground mined-out areas of the abandoned mines in a target area is reduced, and a permeable reactive barrier, a continuous alkali production pool and a constructed wetland section are continuously arranged at mine wellheads of the small abandoned coal mines with relatively good maintenance conditions; a drainage canal collection system is built around surface rivers in the target area; coal gangue piles in the target area are subjected to closed treatment. The integrated technical scheme realizes comprehensive treatment of the acid mine water in a number of small abandoned coal mines distributed in the target area, and has the advantages of high practicability, low cost and good effect.

Owner:中国煤炭地质总局水文地质局

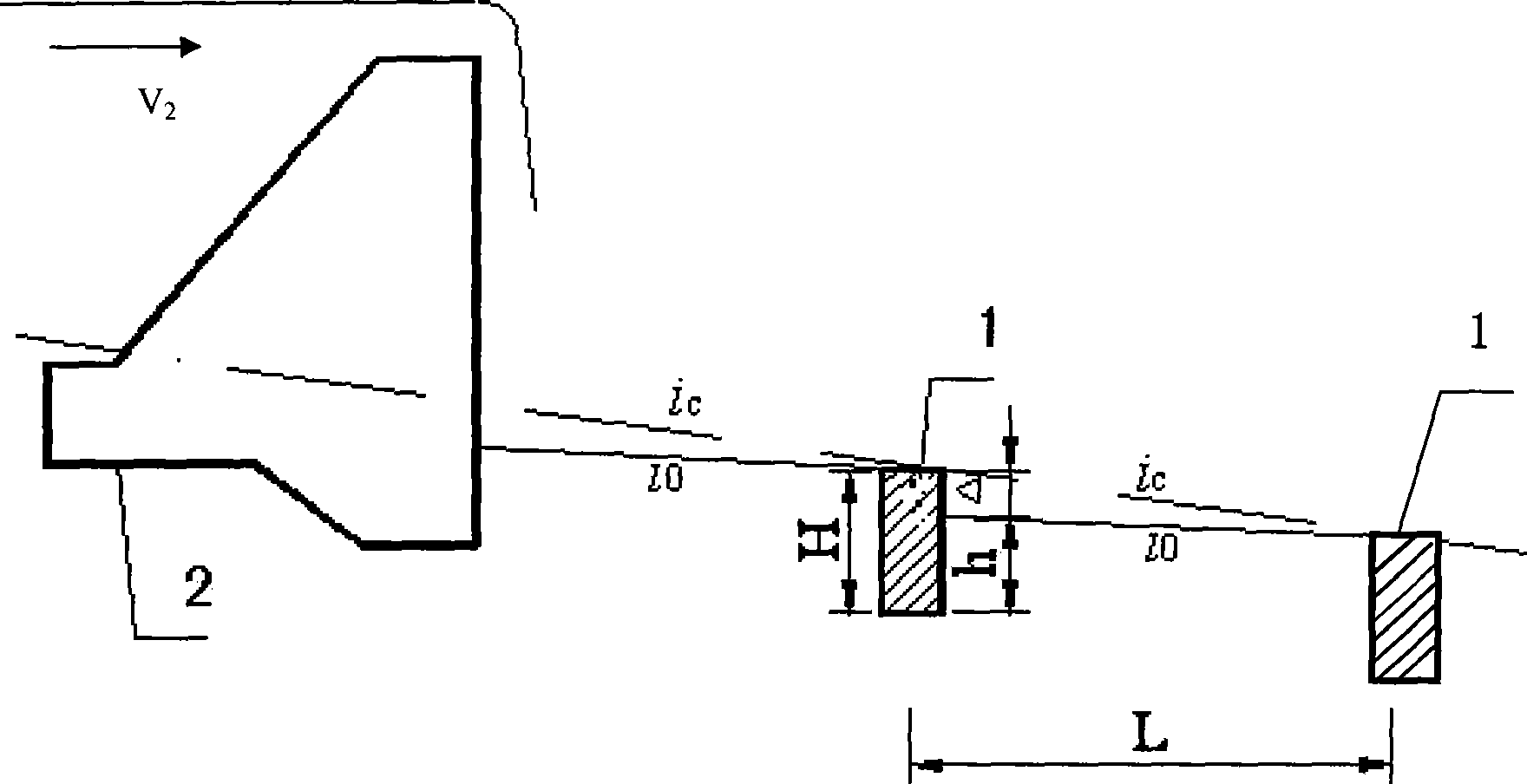

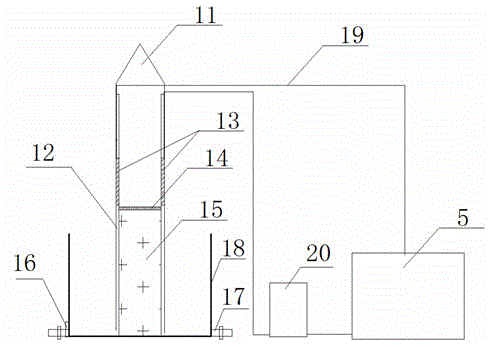

Design method and use of transversal dentated sill embedded depth of foundation based on debris flow soft foundation energy dissipating

InactiveCN101463593AAchieving a dynamic balance of scour-sedimentationLong-term safe operationClimate change adaptationMarine site engineeringEngineeringDrainage canal

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

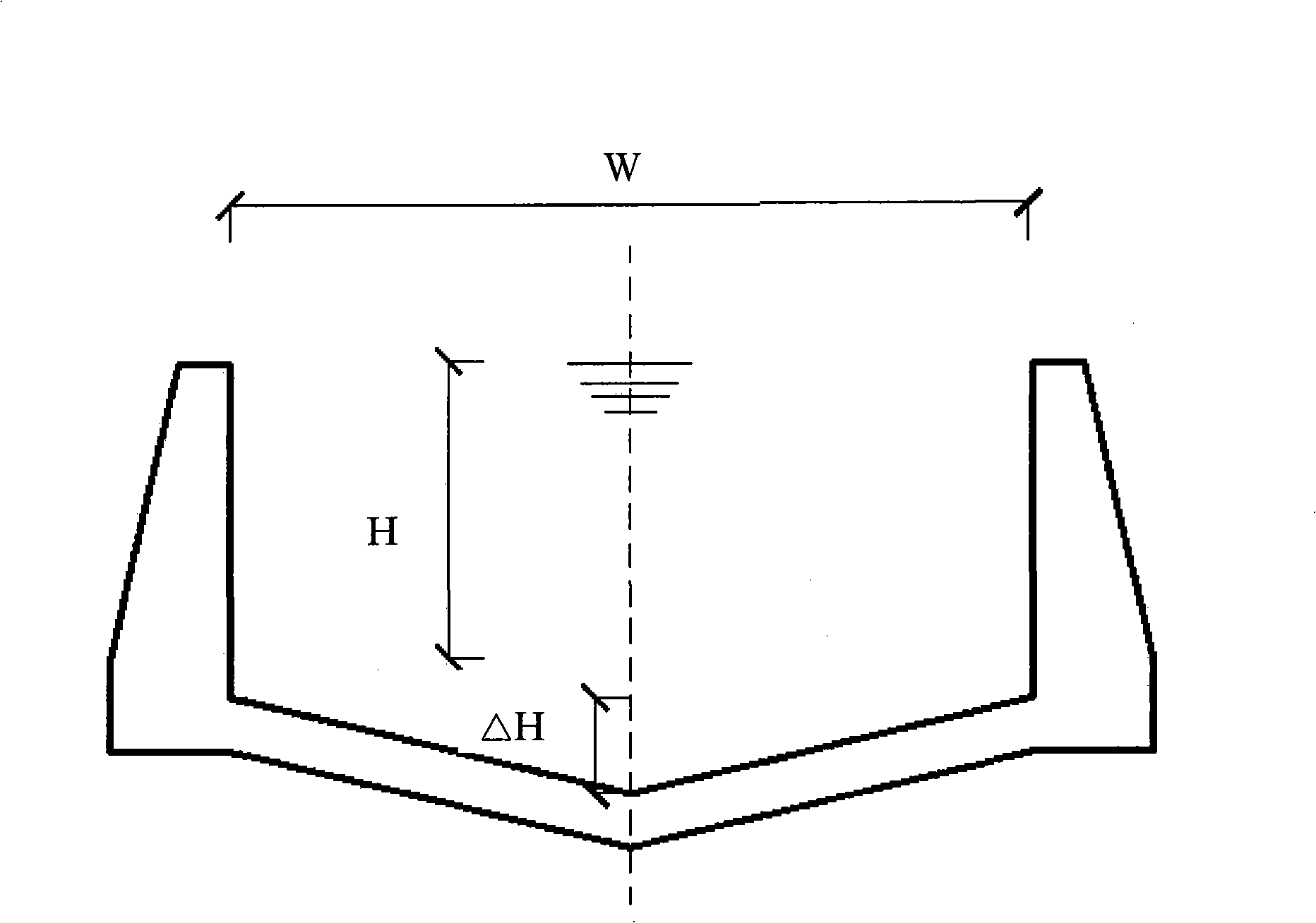

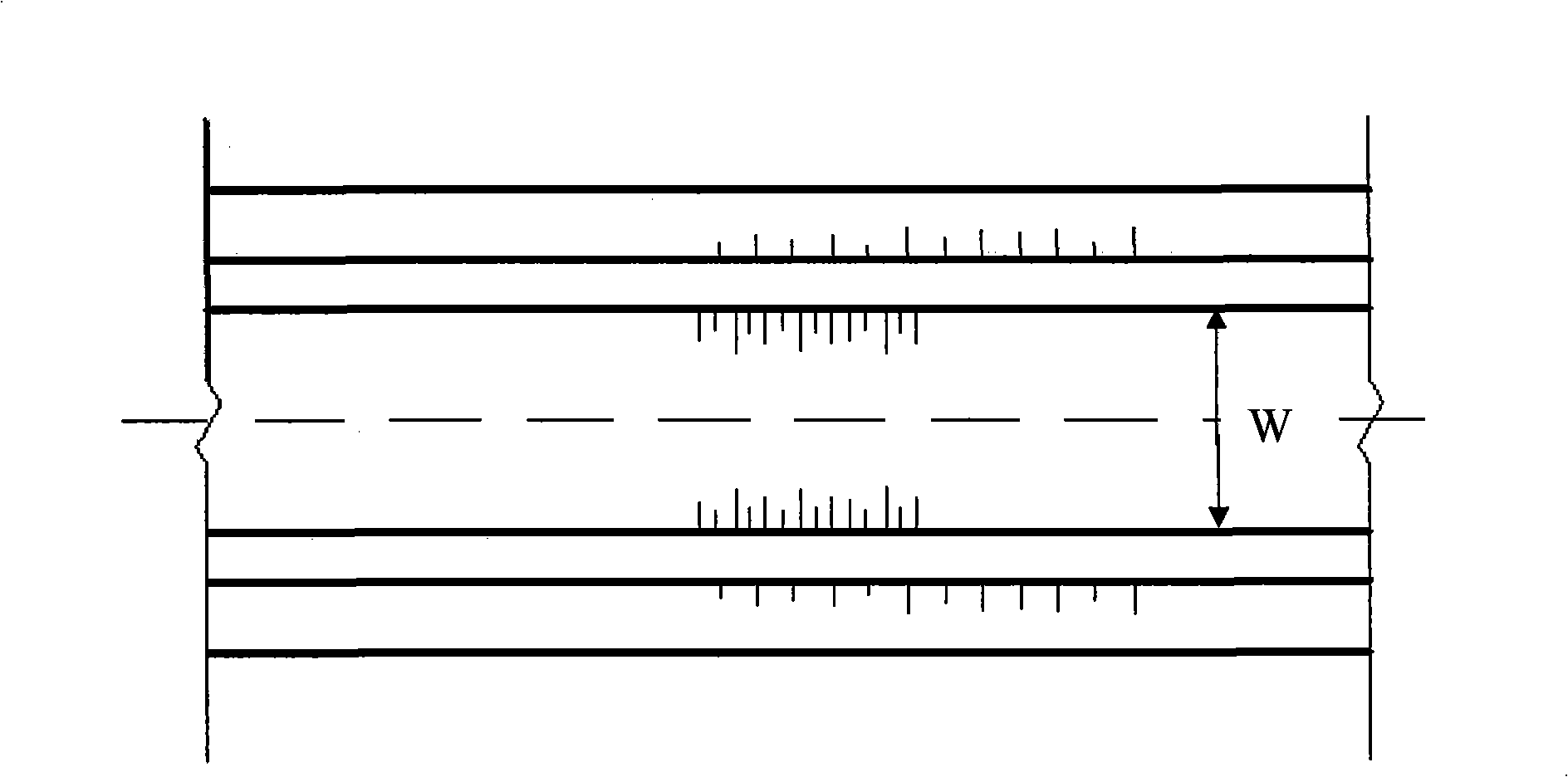

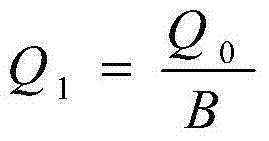

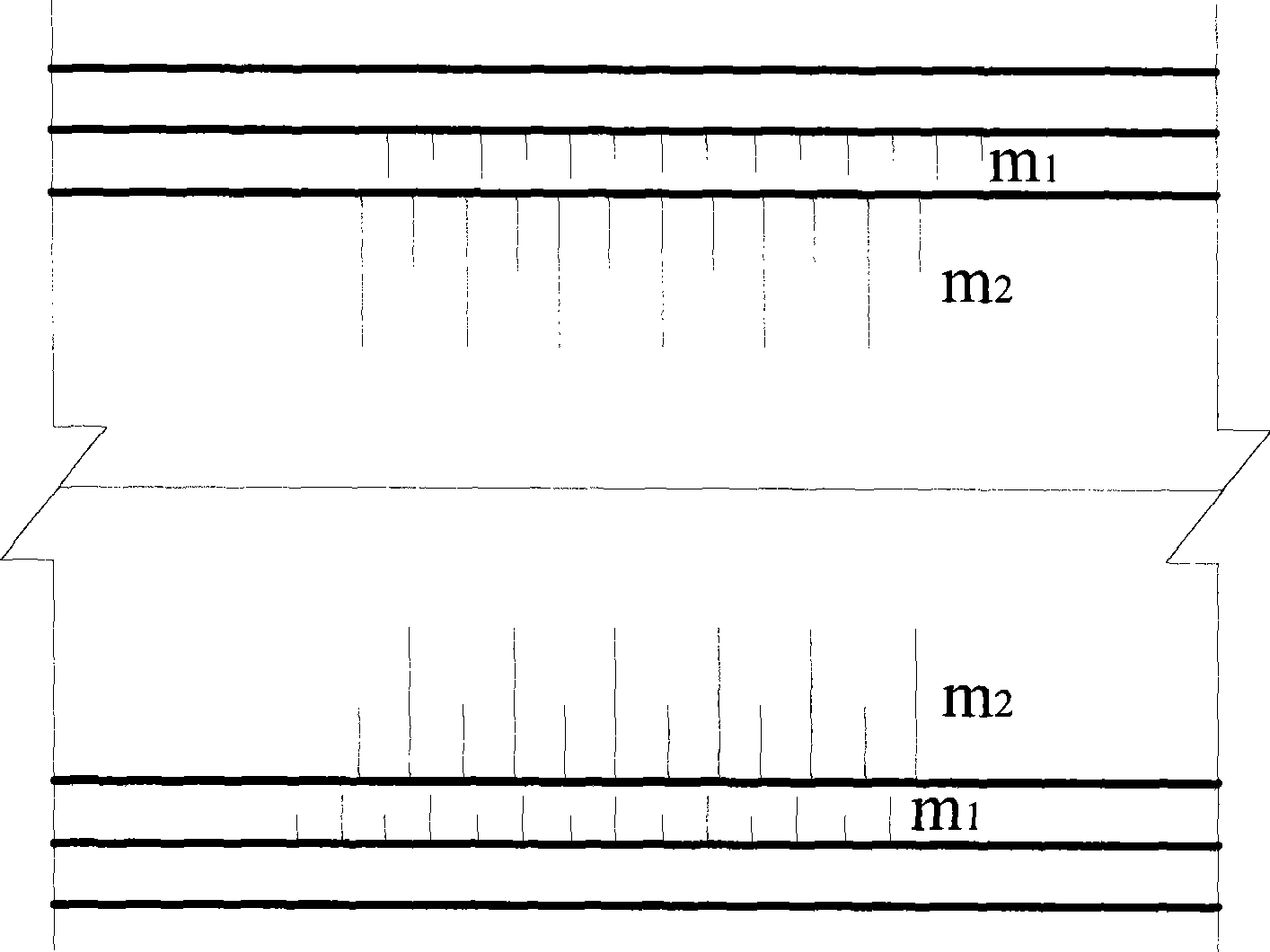

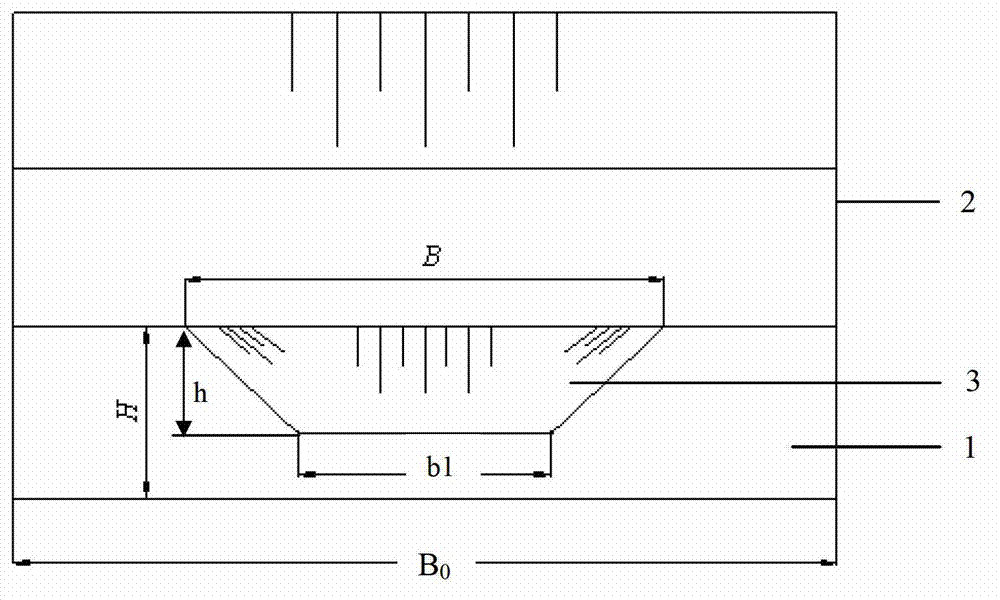

Viscous mud-stone flow triangle bottom guide groove hydraulic optimum section design method and its uses

InactiveCN101265699AImprove discharge capacityCalculation method is simpleDamsProtective constructionEngineeringDrainage canal

The invention discloses a design method of a viscous mud-flow triangle base drainage canal optimum hydraulic section and the application thereof. The invention aims at the disadvantages in the prior art that the calculation method of the drainage canal optimum hydraulic section in the triangle base drainage canal design is complicated and no unique definite value can be obtained. The invention provides the design method of the viscous mud-flow triangle base drainage canal optimum hydraulic section. The method includes the following steps: calculating the size parameter F and the characteristic parameter S of the drainage canal optimum hydraulic section; then calculating the drainage canal hydraulic radius R; and finally the width W and the depth H of the optimum hydraulic section. The method is applicable to the control of the viscous mud-flow and coordinate use with other backbone type blocking projects. Compared with the prior art, the method can reasonably determine the shape and the size of the triangle base drainage canal optimum hydraulic section with unique definite value of the calculation result, effective, rapid and convenient calculation, thereby being applicable to the practical engineering.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

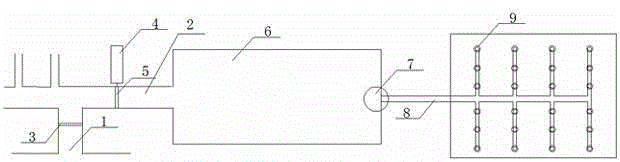

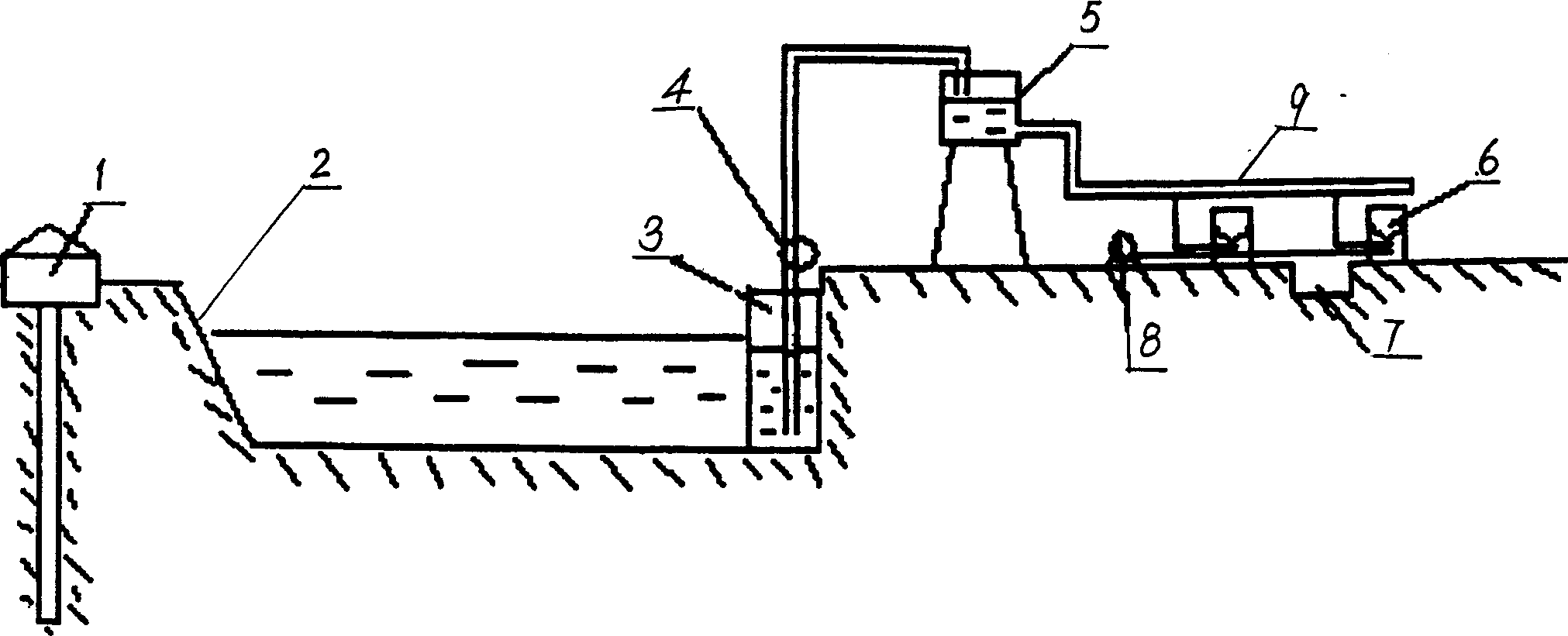

Agricultural land initial stage runoff collection irrigation system and method thereof

ActiveCN104782447AReduce pollutionReduce construction costsConstructionsWatering devicesEngineeringLoad following power plant

The invention discloses an agricultural land initial stage runoff collection irrigation system and a method thereof. The agricultural land initial stage runoff collection irrigation system comprises a drainage canal, a diversion canal, a drainage canal flow blocking weir, an initial stage runoff sensor, an electric water collection valve, a water collection tank, a lift pump, an agricultural irrigation pipeline and farmland irrigation spray nozzles. Square non-flush-period drainage exits are dug in the drainage canal flow blocking weir, and the electric water collection valve controlled by the initial stage runoff sensor is arranged on the diversion canal and is used for collecting initial stage runoff for daily farming irrigation. The agricultural land initial stage runoff collection irrigation system and the method thereof start from the perspective of reducing the pollution of agricultural initial stage runoff with high nitrogen and phosphorus load to water and utilizing agricultural crops to absorb the nitrogen and phosphorus load, an original canal system is utilized, the functions of collecting the initial stage runoff and ensuring smooth drainage of rainfall are achieved, and meanwhile the water resources are used for non-flush-period farmland irrigation. According to the agricultural land initial stage runoff collection irrigation system and the method thereof, the structure is simple, the implementation is easy, and flexible application can be achieved according to existing conditions of an application place.

Owner:ZHEJIANG UNIV

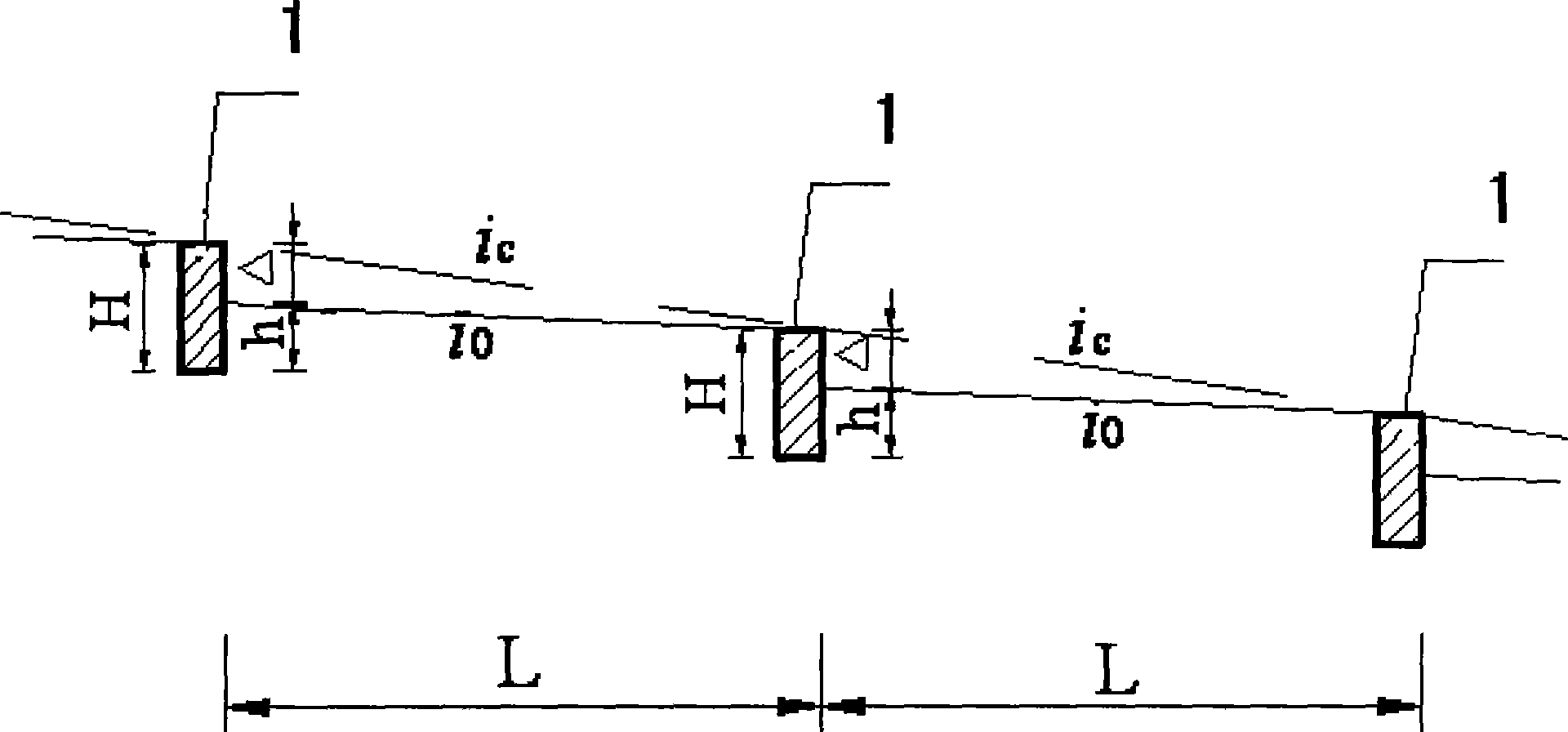

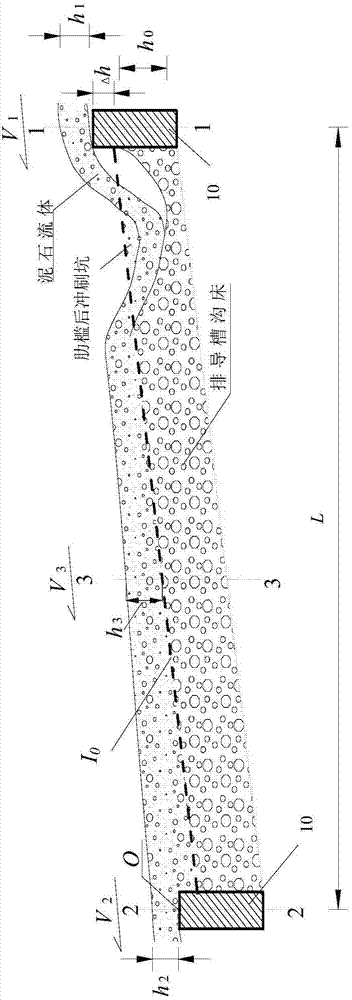

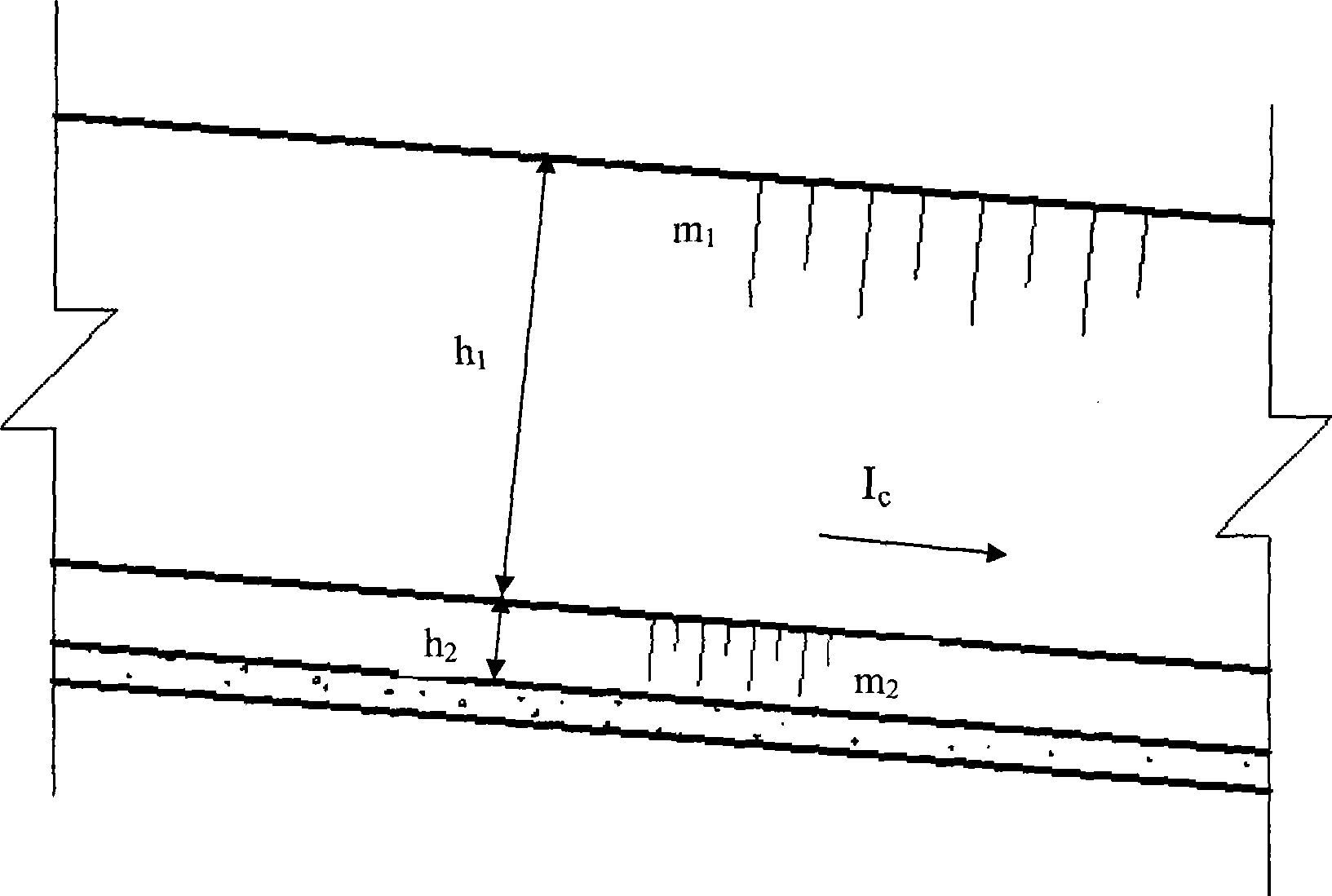

Method of calculating maximum scour depth of rear part of debris flow drainage canal transverse sill and applications

InactiveCN104848825AEasy to calculateAdapt to engineering needsMeasurement devicesBody weightSediment

The invention discloses a method of calculating the maximum scour depth of a rear part of a debris flow drainage canal transverse sill and applications. The calculation method comprises steps: a designed longitudinal slope for the drainage canal, a designed distance between transverse sills, a designed height of the transverse sill over a gully bed, and a designed width for the drainage canal are firstly determined; a debris flow body weight, a gully bed sediment weight, a debris flow viscosity coefficient and a debris flow yield stress are then determined; a debris flow depth and a debris flow velocity are then determined; and finally, according to the maximum scour depth calculation formula for the gully bed at the rear part of the transverse sill, the maximum scour depth of the gully bed at the rear part of the soft foundation energy dissipative-type debris flow drainage canal transverse sill is determined. The method comprehensively considers the gully bed condition and debris flow features, rear transverse sill scour features are also combined, the maximum scour depth calculation formula for the rear part of the drainage canal transverse sill is obtained through theoretical derivation, the maximum scour depth of the gully bed at the rear part of the transverse sill in different conditions can be reasonably determined, a scientific basis is provided for the debris flow disaster prevention engineering design, and the calculation method is simple and convenient and can meet engineering needs.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

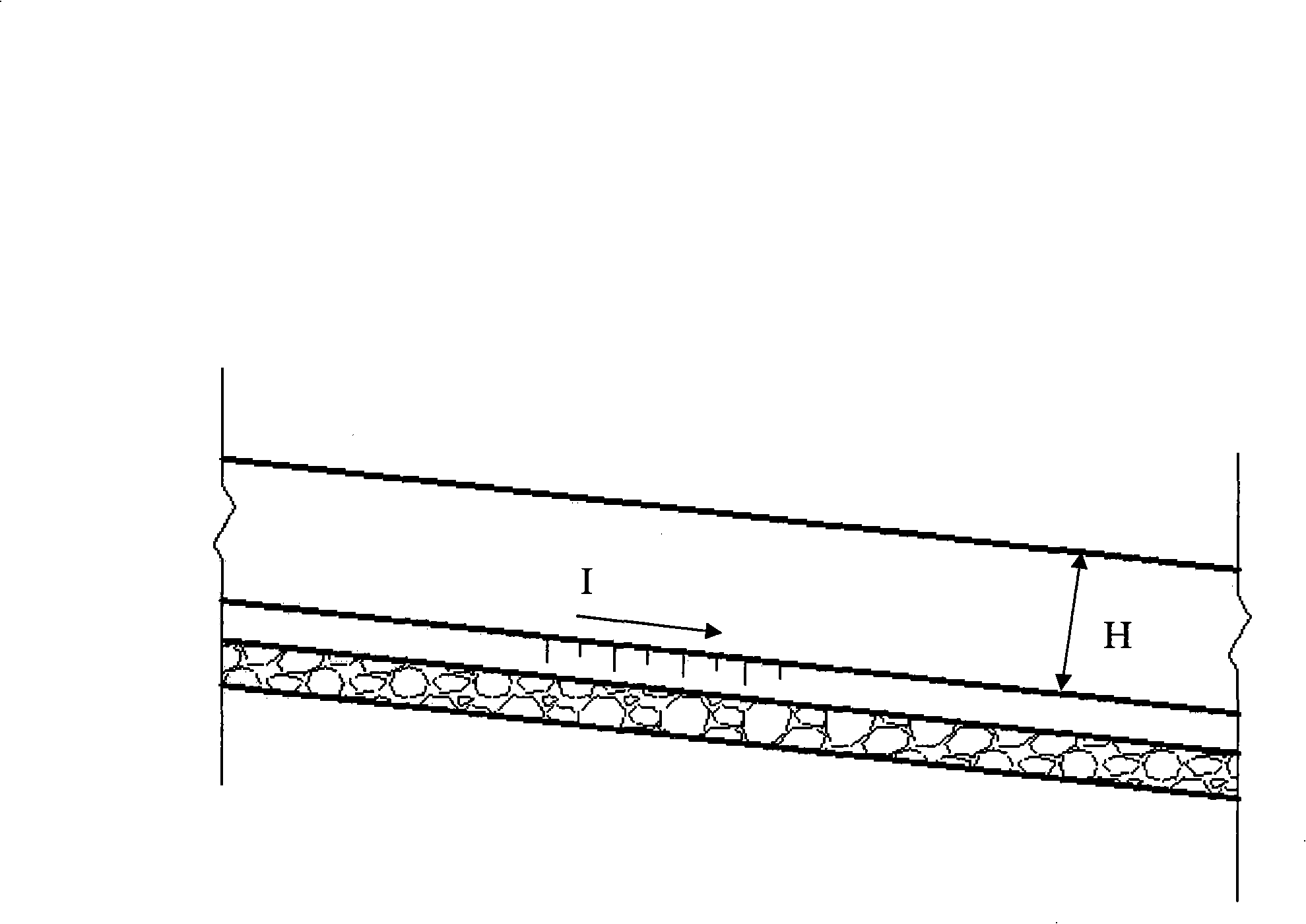

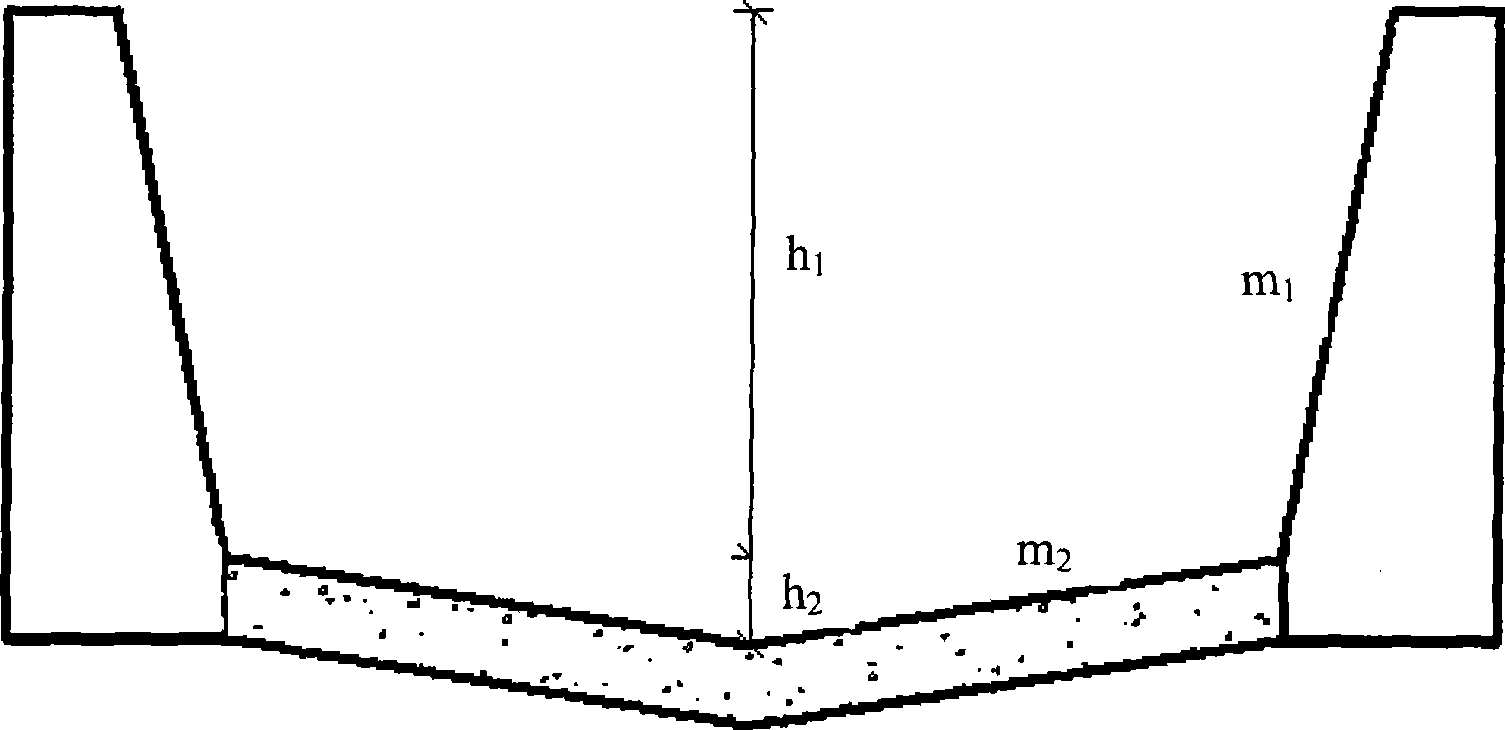

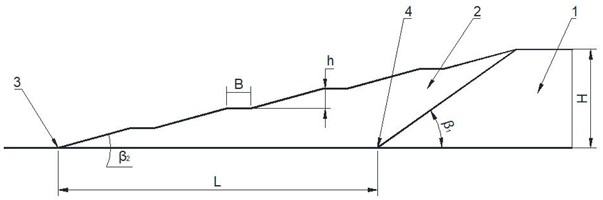

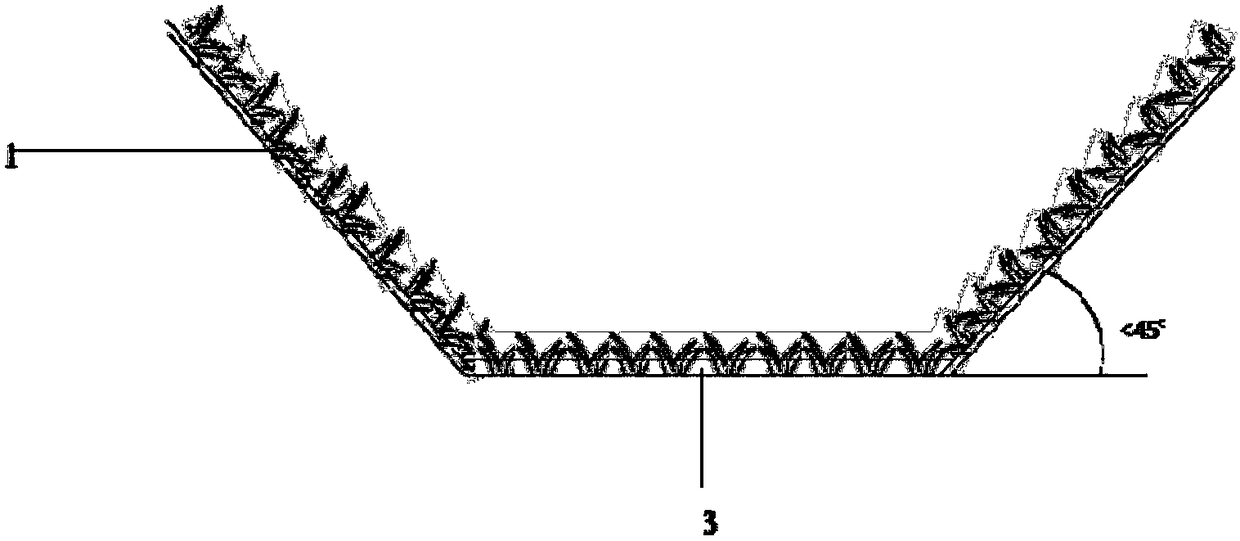

V type discharging and guiding slot water power optimum section design method of viscous debris flow and application thereof

InactiveCN101435191AImprove discharge capacityCalculation method is simpleDamsProtective constructionGreek letter betaEngineering

The invention discloses a method for designing hydraulic optimum section of V-shaped drainage canal for viscous debris flow inclined wall and application thereof. Aiming at the default that the hydraulic optimum section can not be determined because the section form and size of the V-shaped drainage canal of the inclined wall are generally designed based on personal experience in the prior art, the invention discloses the method for designing hydraulic optimum section of V-shaped drainage canal for viscous debris flow inclined wall. The method first calculates the hydraulic optimum section size parameter Beta for the drainage canal; then calculates the hydraulic optimum section characteristic parameter S; then calculates the corresponding hydraulic diameter R of the hydraulic optimum section for the drainage canal; and finally calculates the slope depth h1 and canal bottom depth h2 of the hydraulic optimum section. The method is suitable for the control of viscous debris flow and can be used matching with other mainstay block engineering. Compared with the prior art, The method of the invention can reasonably determine the shape and size of the hydraulic optimum section of V-shaped drainage canal of inclined wall to obtain maximum flow discharge ability, has effective, fast, and simple calculation methods, and is adapted to the requirement of practical engineering.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

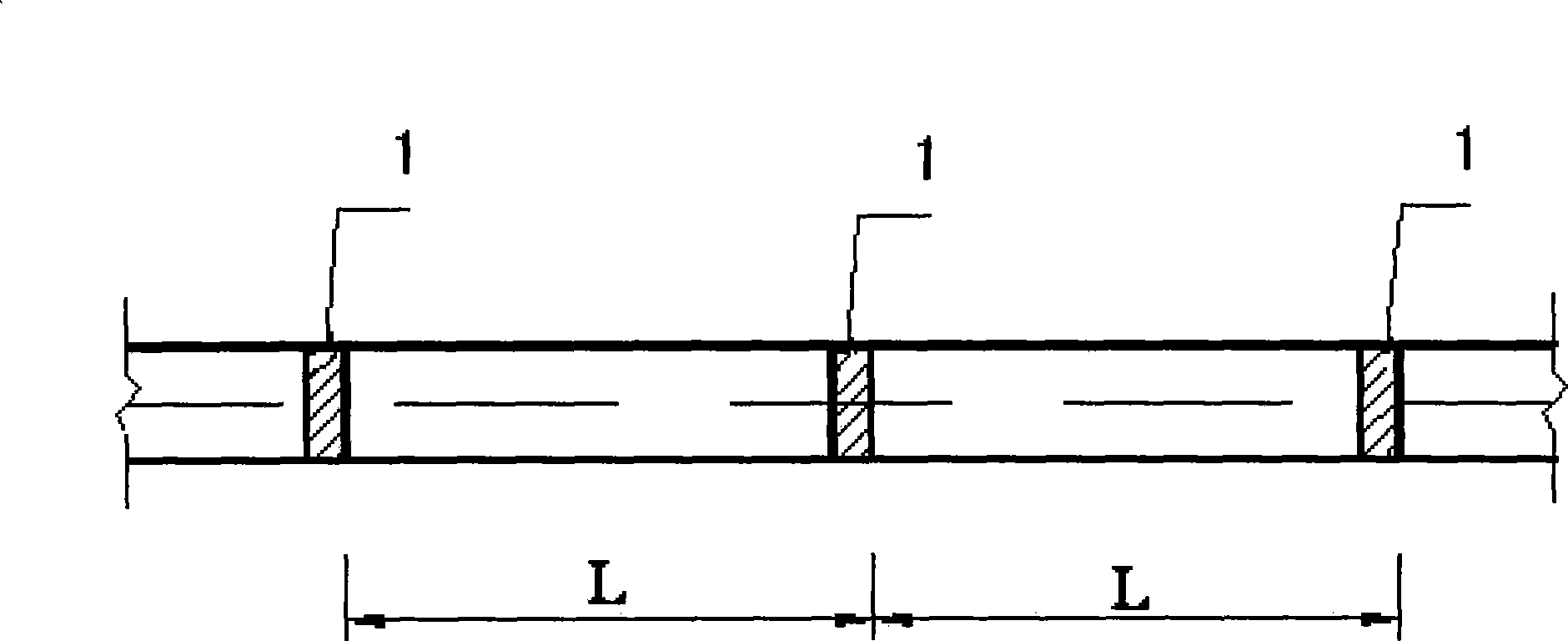

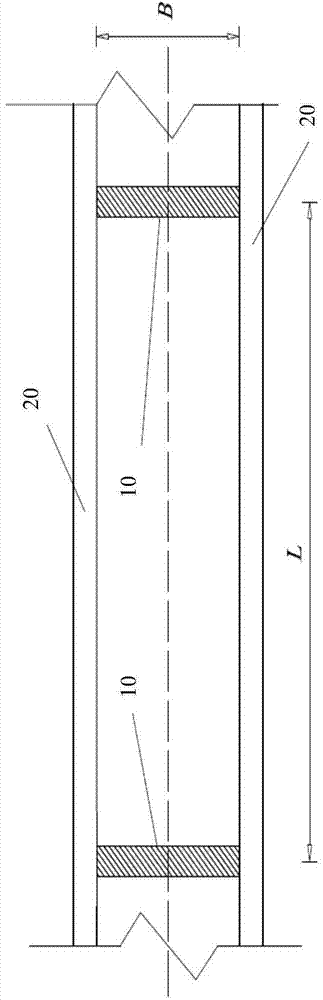

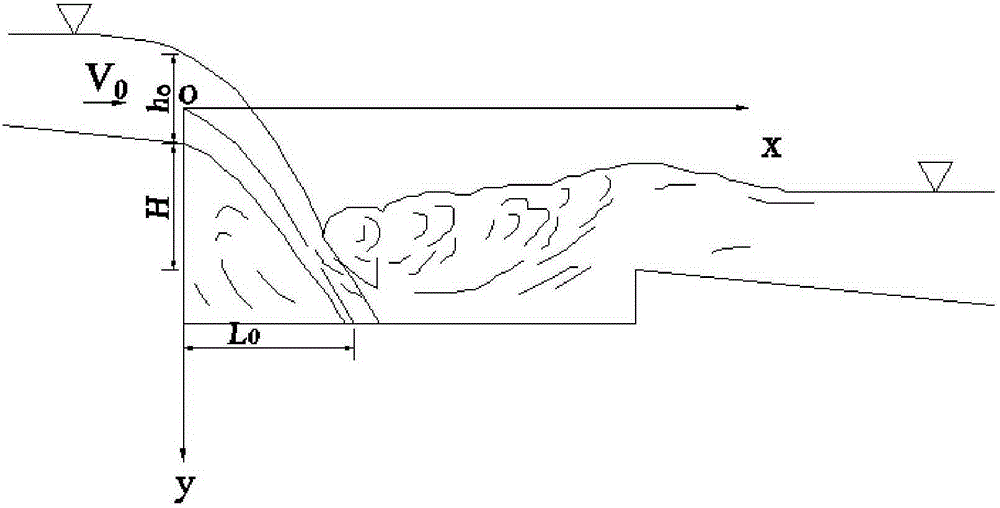

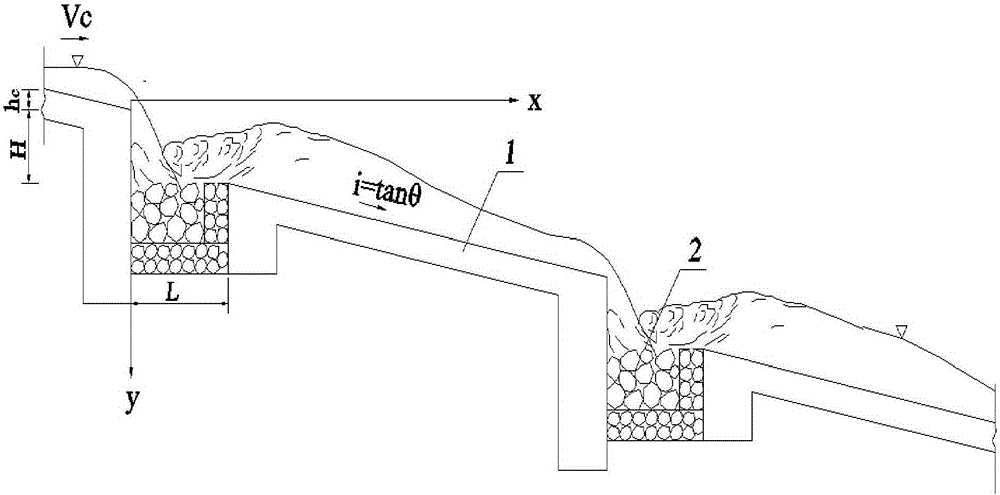

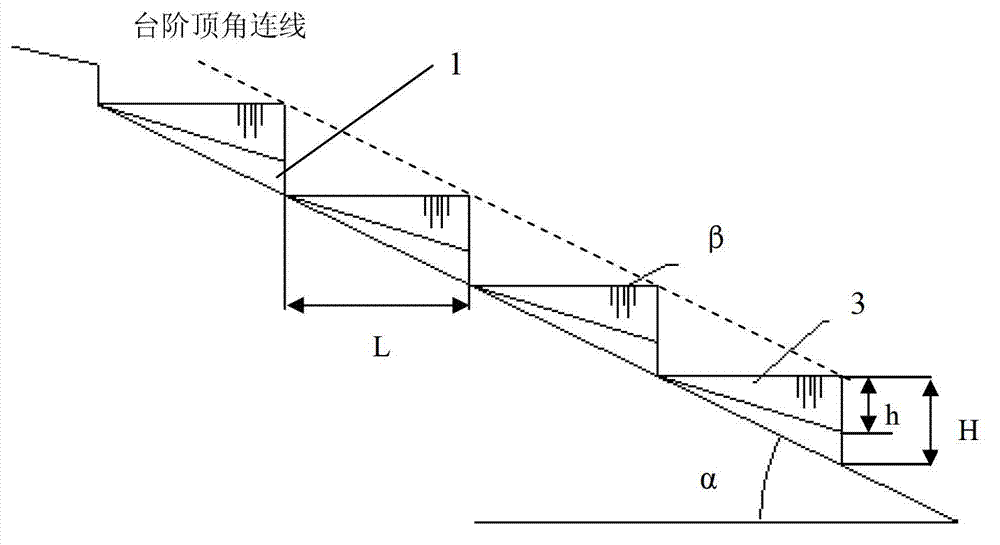

Measuring and calculating method for length of deep pool segment of step-deep pool type debris flow drainage canal

ActiveCN105178255ABalanced excretion without flushing or siltingAvoid direct impactArtificial water canalsDrainage canalDebris flow

The invention discloses a measuring and calculating method for the length of a deep pool segment of a step-deep pool type debris flow drainage canal. According to the measuring and calculating method, firstly, the unit weight of a debris flow body, the designed longitudinal slope of the drainage canal, the casting angle of debris flow, the designed suspension height of a step segment, the designed width of the drainage canal and the designed peak flow of the drainage canal are determined; then the roughness factor of the drainage canal, the permissible velocity and the overflowing mud depth of the debris flow are determined; afterwards, the average velocity of a debris flow cross section is determined, and the permissible velocity is compared with the average velocity of the debris flow cross section; and finally, the length of the deep pool segment of the step-deep pool type debris flow drainage canal is determined through a measuring and calculating formula of the deep pool segment. Proceeding from the complete movement process of fluid in the canal, the method is based on strict theoretical derivation, and the influence of the properties of the debris flow on the casting range is considered in combination with experiments, so that the length of the deep pool segment of the step-deep pool type debris flow drainage canal is determined reasonably, and a basis is provided for the design of the step-deep pool type drainage canal; the precision of a calculated result is high; the method is adapted to the actual requirement of engineering.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

River way type sewage treatment system

InactiveCN1562826AEasy to handleCan change the situationMultistage water/sewage treatmentSustainable biological treatmentSewageEngineering

The invention relates to sewage processing system in natural river or artificial drainage canal. Super water gate, under water gate, sewage pump and sewage pipe are built in river or drainage canal. Sewage in river or drainage canal is pumped by sewage pump from upper reaches of super water gate to sewage processing area between super water gate and under water gate. There are some water gates are built between said super water gate and under water gate to form several sewage processing function areas.

Owner:甄建伟

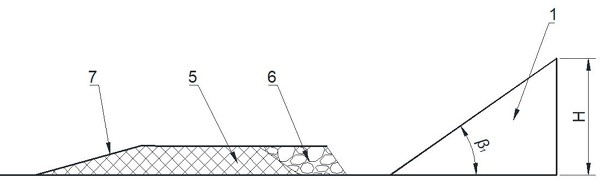

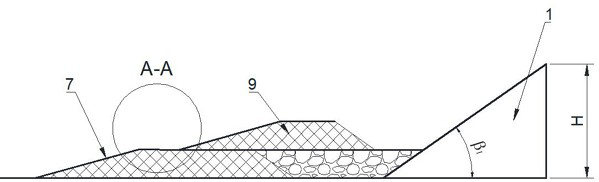

Multi-layered structure and construction method of high embankment near mountains

PendingCN109056439AGuaranteed filling qualityDelay uneven settlementRoadwaysEmbankmentsEngineeringSlope ratio

The invention relates to a multi-layered structure of a high fill roadbed alongside a mountain, comprising a mountain body, a rockfill embankment, a drainage canal, a block stone, a soil-stone mixture, a mountain platform, a platform and a cross slope, wherein the multi-layered structure comprises a mountain body, a rockfill embankment, a drainage canal, a block stone, a soil-stone mixture, a platform and a cross slope. The hill is excavated into a stepped structure, and the hill is provided with a hill platform; The subgrade of Shanao road section in the lower part of the stepped mountain body is filled with a rock-filled embankment, the thickness of the pavement layer of the rock-filled embankment is not more than 60cm, and the filling stones are blocks of different sizes of 20-30cm, andcrevices are left between the blocks; and the rock-filled embankment is filled with the rock-filled embankment. Non-woven geotextiles are laid on the top surface of the rockfill embankment; The rockfill embankment consists of graded slopes with platforms between each grade, and the slope ratio is consistent. An inverted trapezoidal drainage channel is arranged at the bottom of the slope of the rockfill embankment; Earth-rock mixture fills from the top surface of the rockfill embankment to the bottom of the roadbed in stages. The invention has the beneficial effects that the subgrade stratum is filled with a block stone, and can be used as a surface drainage water permeable layer, thus ensuring the smooth drainage of the subgrade after the subgrade is filled, and reducing the influence ofsurface water on the stability of the subgrade during the operation period.

Owner:杭州市交通规划设计研究院有限公司

Method for increasing ammonium nitrogen in river water

ActiveCN106044919ALow costEasy to prepareWater contaminantsWater/sewage treatment by ion-exchangeSteam pressureIon exchange

The invention discloses a method for increasing ammonium nitrogen in river water. The method is characterized by including: using natural zeolite powder as a raw material, cement as a binder and aluminum powder, quicklime and surfactantt as foamers; obtaining an aerated concrete building block through blending, mixing, forming, cutting and steaming pressure maintaining. The zeolite aerated concrete building block is used to build a drainage canal or a seepage dam of a small brook, and river water containing ammonia nitrogen flows through the canal or the seepage dam; the zeolite aerated concrete building block has a function of selectively adsorbing ammonia nitrogen in water and is an efficient microorganism carrier material; on one hand, ammonia nitrogen in the water is adsorbed and removed through ion exchange during drainage or during a drainage peak, and on the other hand, loaded microorganisms convert ammonia nitrogen into nitrate during drainage intermission or drainage valley to realize zeolite regeneration.

Owner:ANHUI MEIZIRAN ENVIRONMENTAL TECH

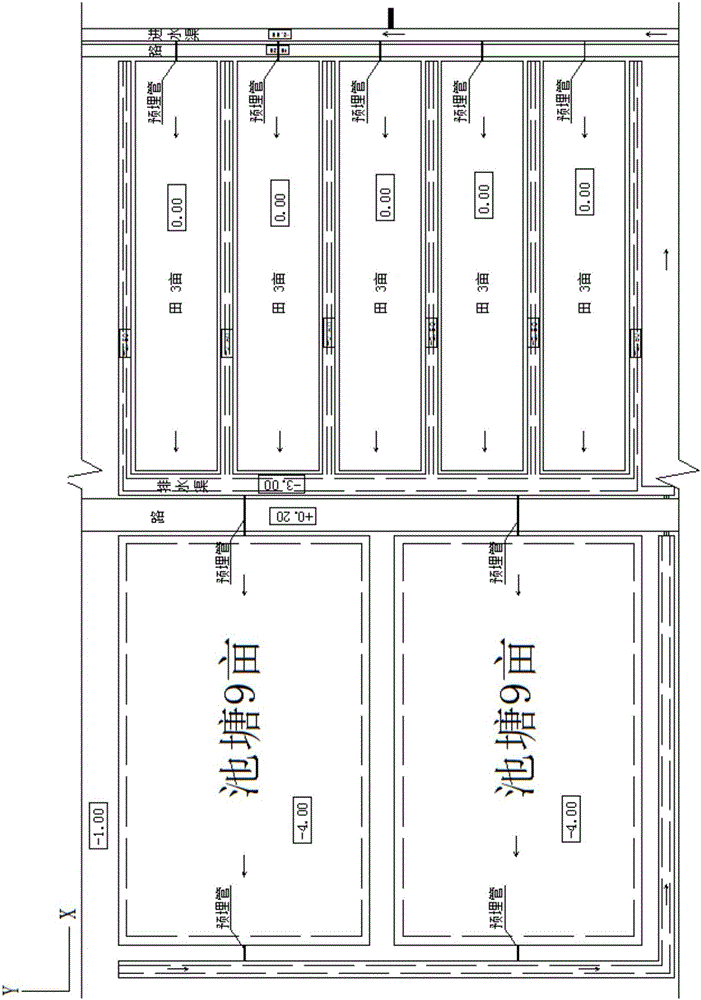

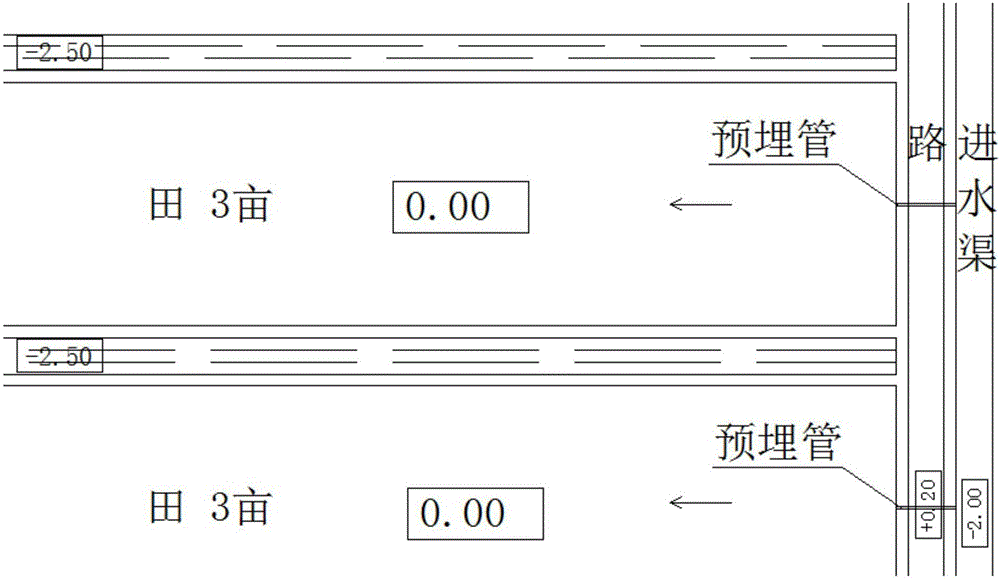

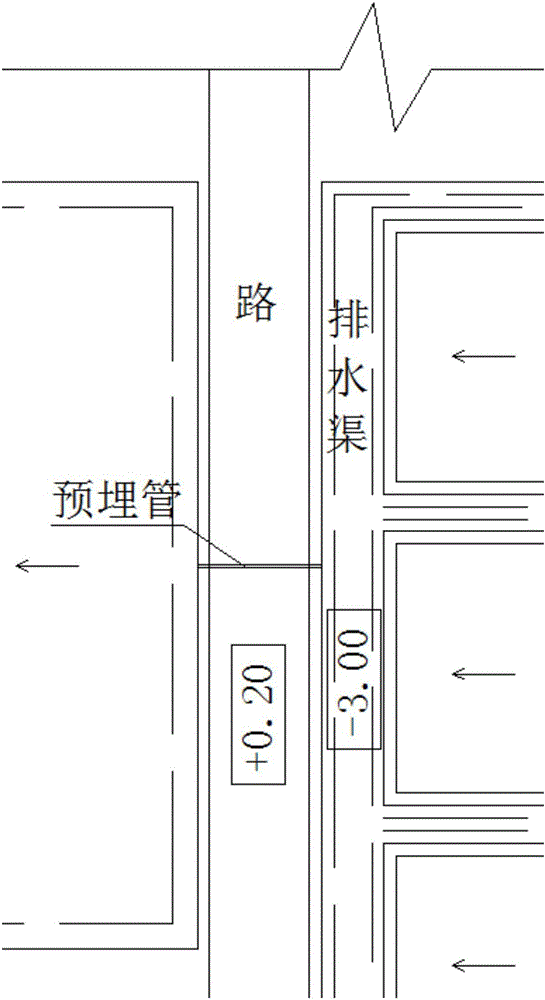

Saline-alkaline pond construction structure

ActiveCN106719258ARealize comprehensive utilizationIncrease economic valuePisciculture and aquariaSoil-working methodsEcological environmentEngineering

The invention relates to a saline-alkaline pond construction structure. The saline-alkaline pond construction structure comprises a culture pond area and a strip field area which are adjacent, wherein a plurality of strip fields are arranged in the strip field area in parallel along the X direction, an inflow channel is arranged at one end of each strip field, the inflow channel is communicated with each strip field through an embedded pipeline, the liquid level of the inflow channel is higher than the upper surface of the each strip field, two lateral drainage channels are arranged on two sides of each strip field, a main drainage channel is arranged at the other end of each strip field, the bottom of the main drainage channel is lower than each lateral drainage channel, and communicated with each lateral drainage channel, one end of each pond in the culture pond area is communicated with the main drainage channel through an embedded pipe, the bottom of the main drainage channel is higher than the bottom of each pond, the other end of each pond is communicated with a main drainage canal through an embedded tube, the main drainage canal is communicated with an outer river alkali discharge channel, and by lifting water through a water pump, the main drainage canal is further communicated with the inflow channel for recycling a part of water. The saline-alkaline pond construction structure achieves comprehensive utilization of water bodies in the soil improvement process, improves economical value of soil, and improves an ecological environment.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

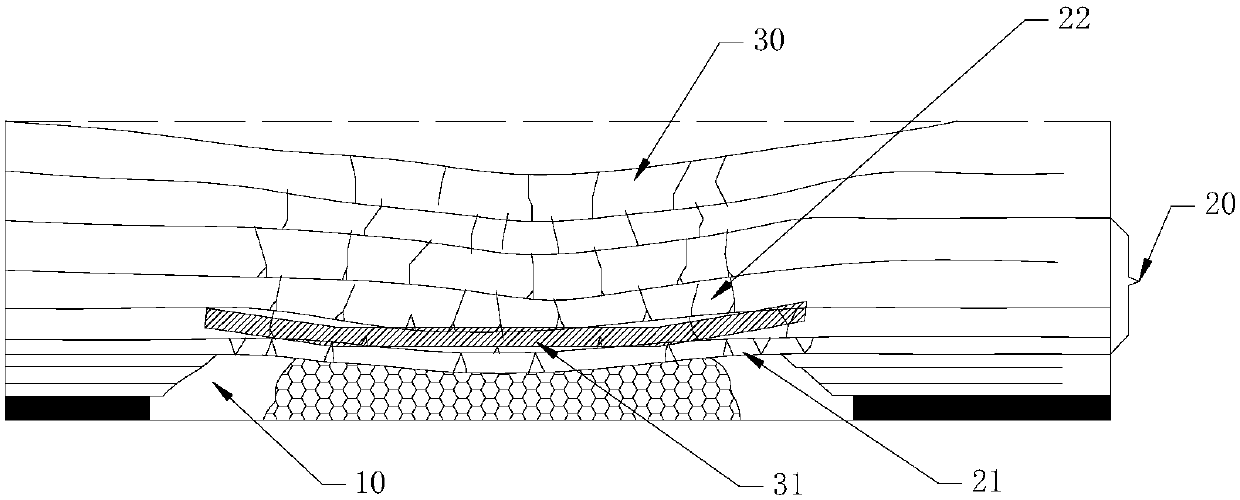

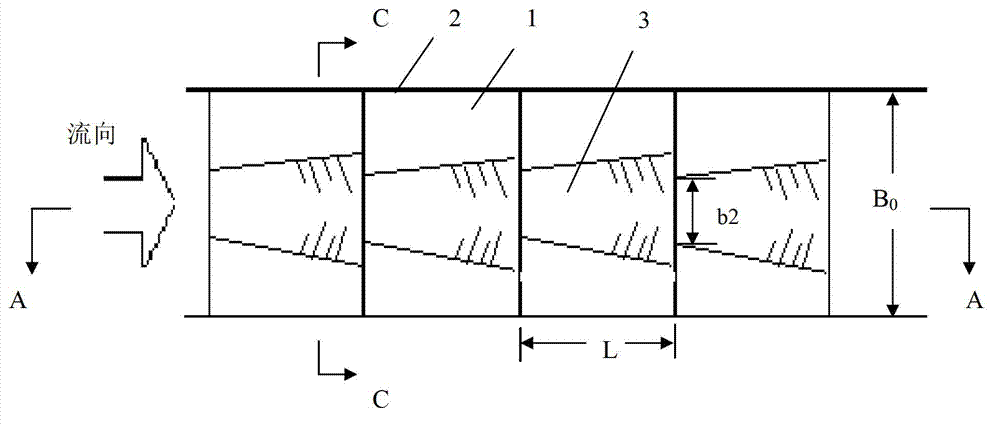

Debris-flow drainage canal with energy dissipation and drainage functions and application thereof

The invention discloses a debris-flow drainage canal with energy dissipation and drainage functions and an application of the debris-flow drainage canal with energy dissipation and drainage functions. The drainage canal comprises a fully-lining drainage canal bottom plate and drainage canal side walls on two sides of the drainage canal bottom plate; the drainage canal bottom plate is in the shape of continuously-connected multiple-stage steps, the steps are provided with grooves; the width of the grooves on the top surfaces of the steps increases gradually along the flow direction of the debris flow, and the width of the grooves on the vertical surfaces of the steps decreases gradually; and the maximum width of the grooves on the top surfaces of the steps coincide with the maximum width B on the vertical surfaces of the steps. Compared wit the prior art, the step shape design is adopted to dissipate the energy of the debris flow all the way and the groove design is adopted to drain the debris flow, so the debris-flow drainage canal disclosed by the invention has high efficiency and good drainage capacity. By adjusting the height and the length of the steps and the size and the shape of grooves, the debris-flow drainagedrainage canal can be used for preventing the debris flow with any gradient and any nature.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Energy and water-saving fry hatching system

InactiveCN1817115AIncrease dissolved oxygenImprove developmentClimate change adaptationPisciculture and aquariaWater savingWater well

An energy- and water-saving fish fry incubating system based on the combination of aerodynamics with fluid mechanics is composed of water well, water sunning pool, filter pool, water tower, drainage canal, fish fry collecting pool, incubator, deposition pool, adsorption pool, aerating pool, and water returning canal. It can save water by 60% or more and electric energy by 50% or more.

Owner:泰安市水产研究所

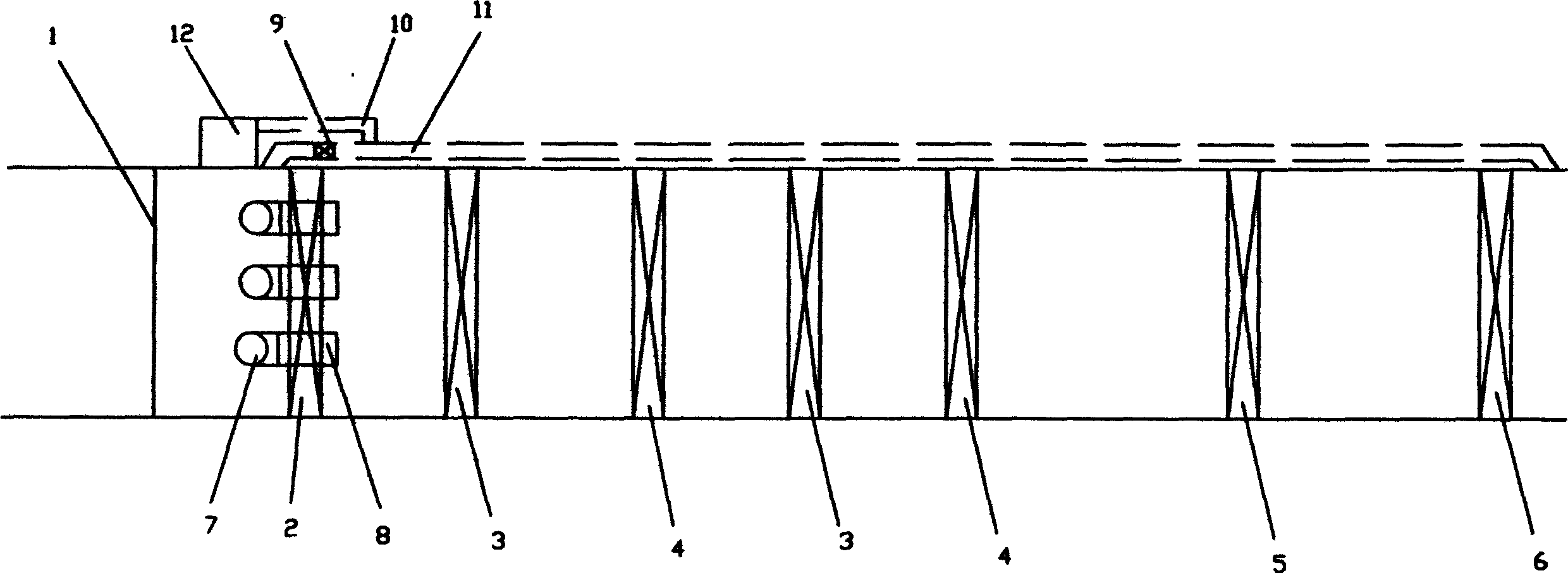

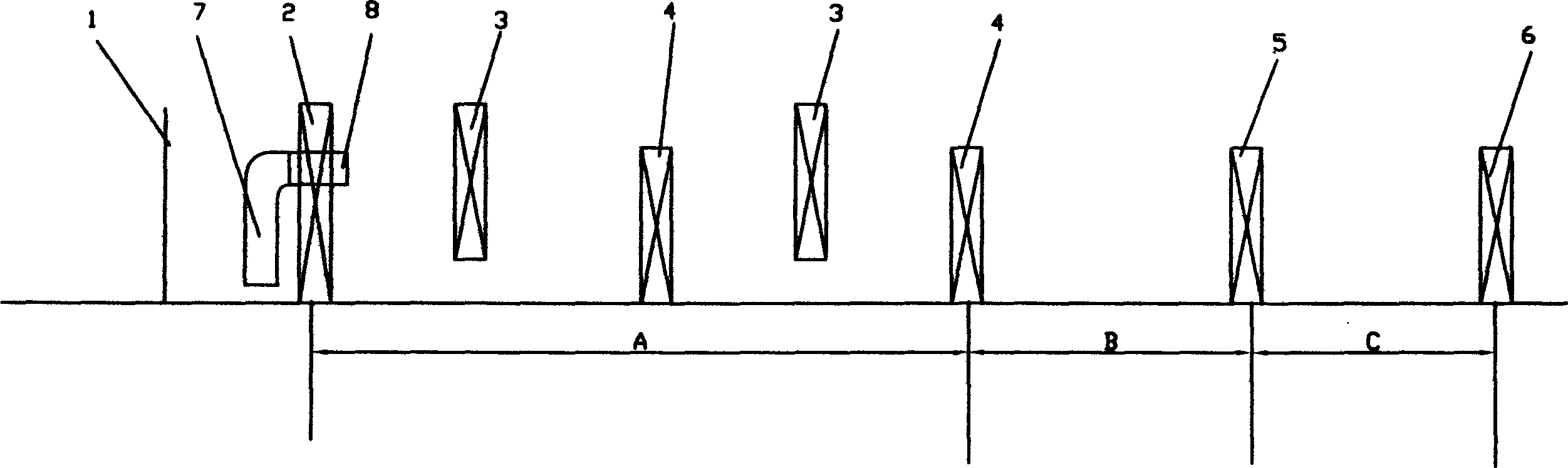

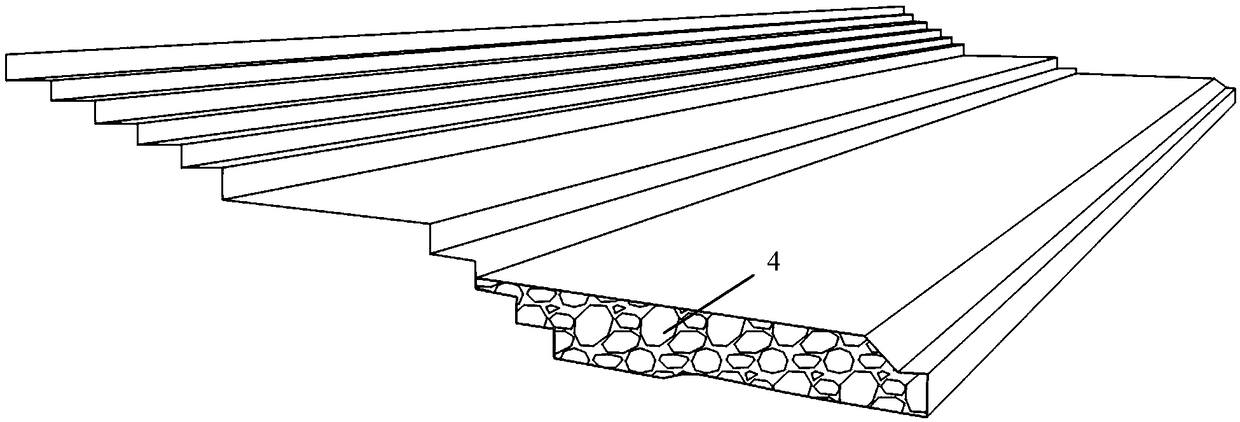

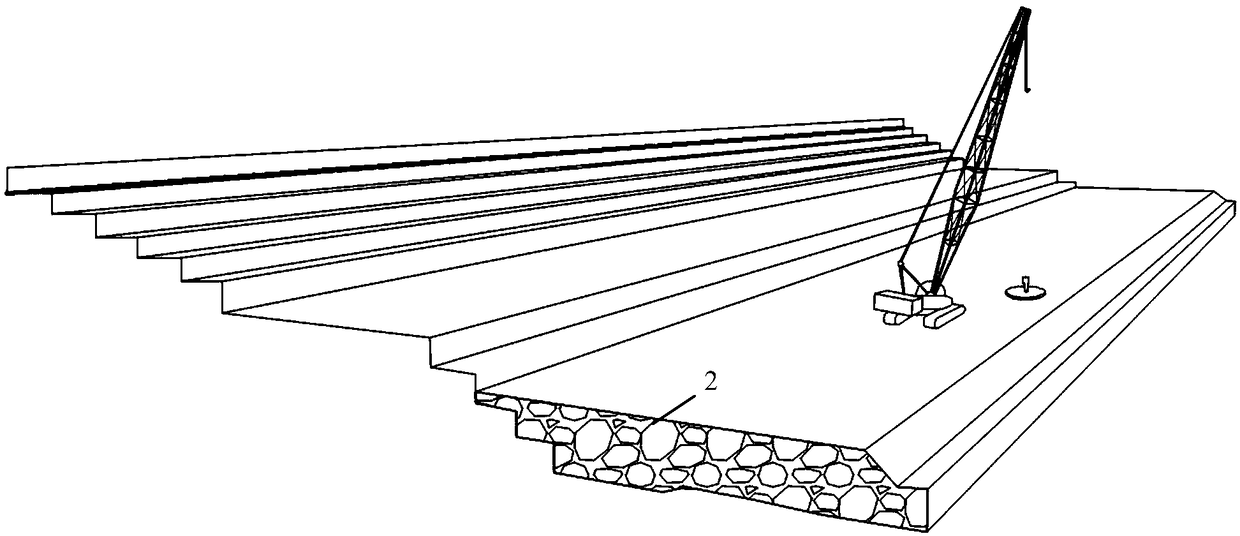

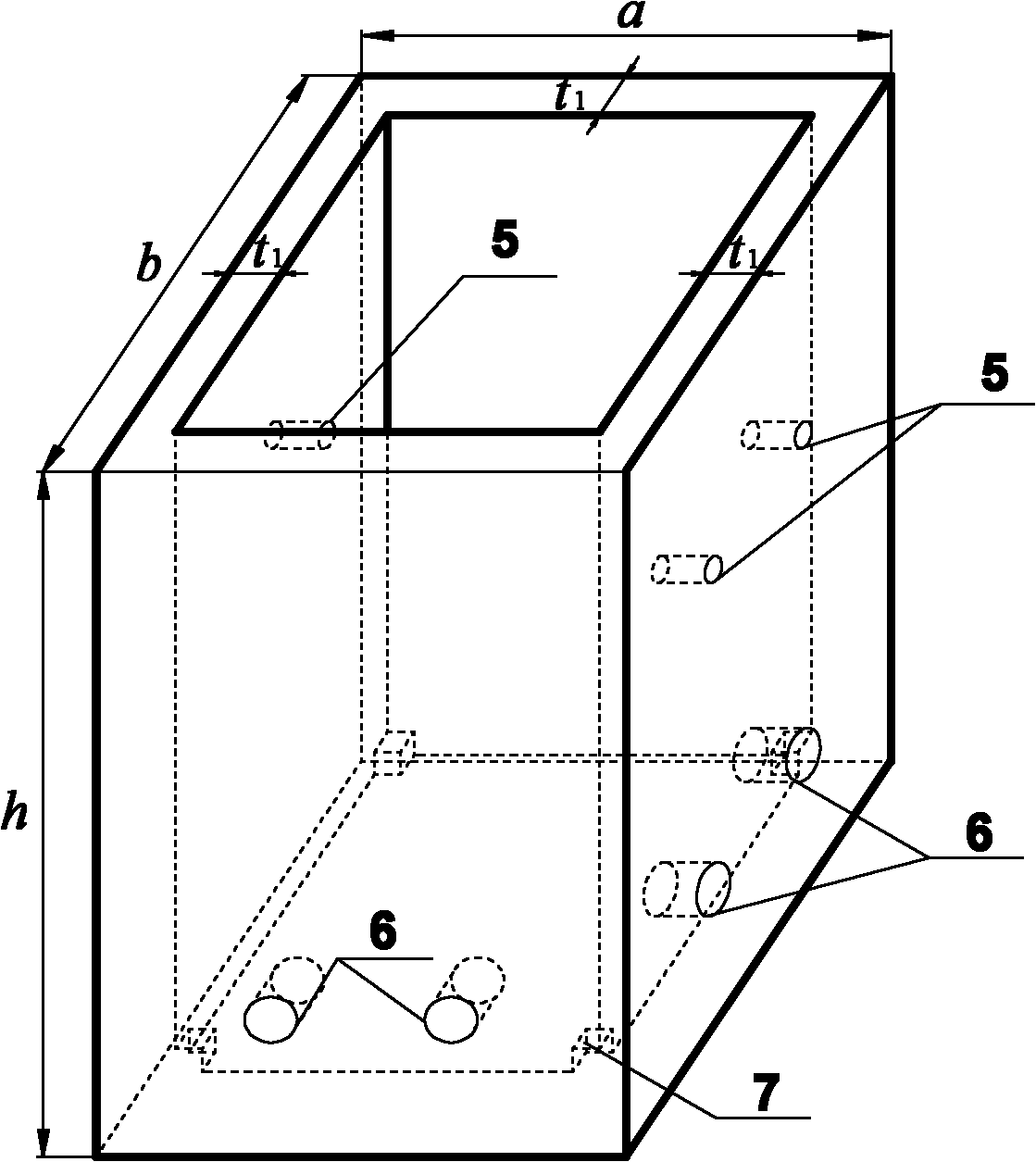

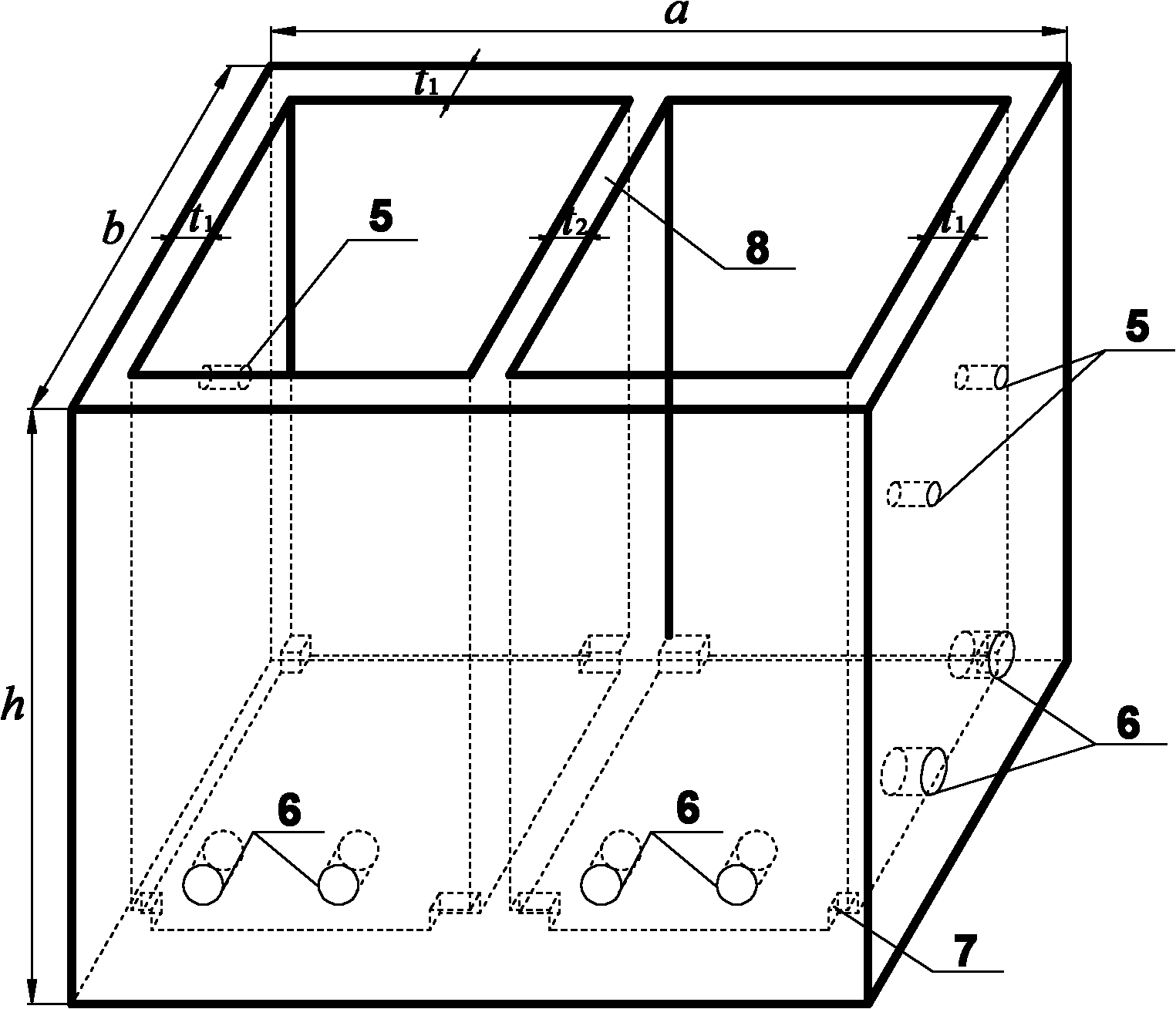

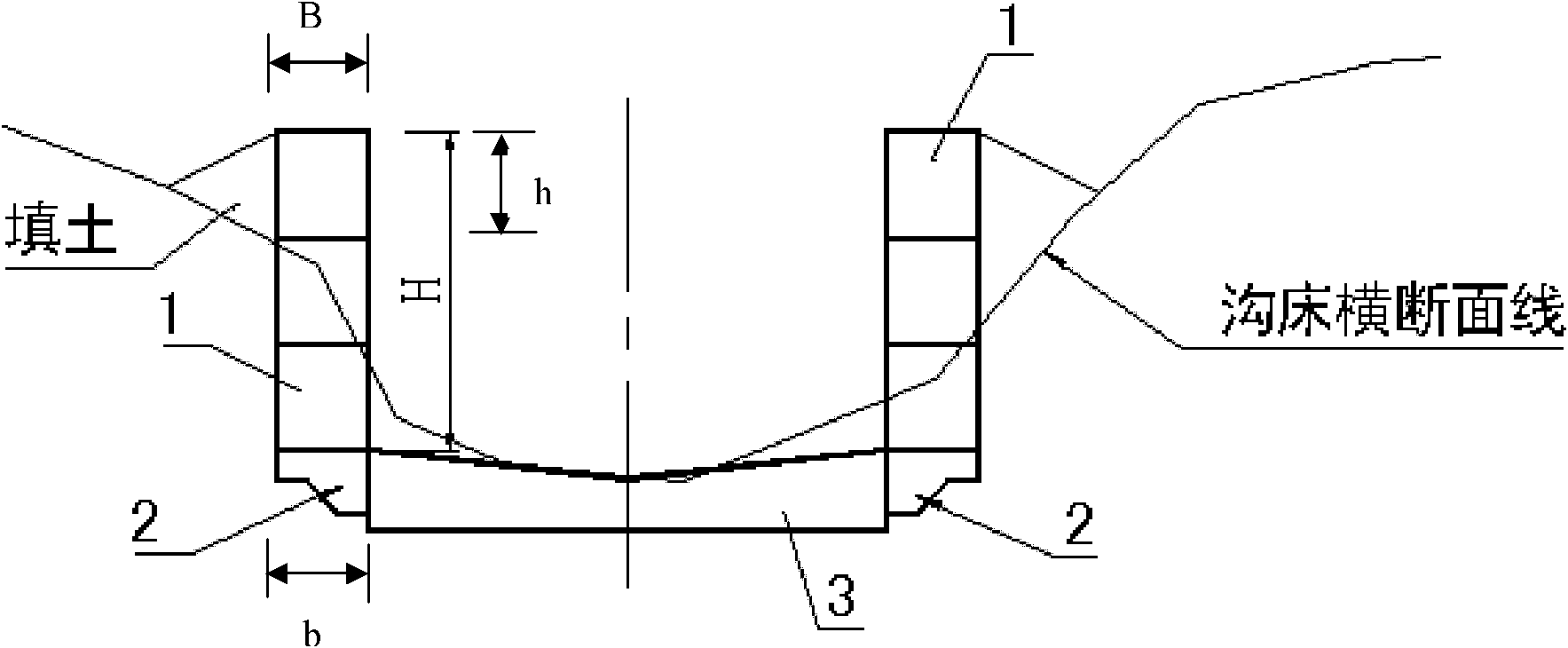

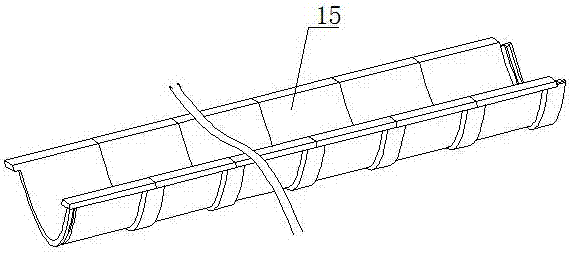

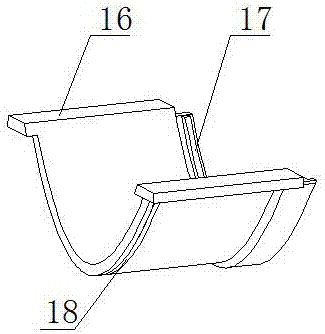

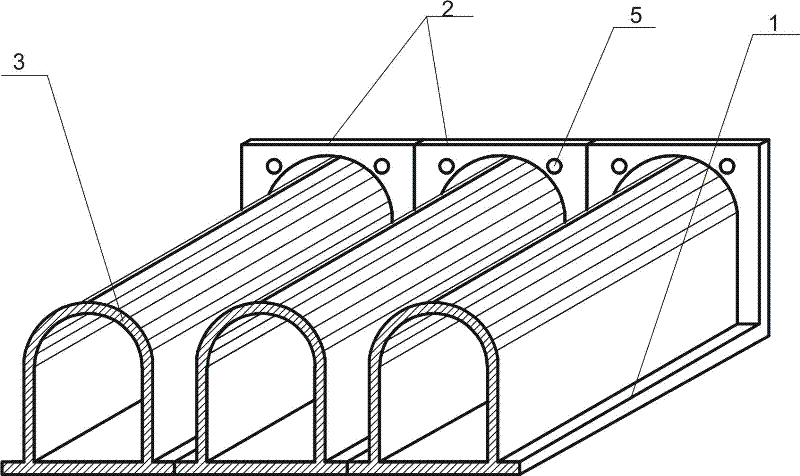

Assembled drainage canal of debris flows and construction method thereof

InactiveCN102174803AReduce the impactSolve mass transportationDamsProtective constructionReinforced concreteEngineering

The invention discloses an assembled drainage canal of debris flows and a construction method thereof. The drainage canal comprises a drainage canal bottom and drainage canal side walls at two sides of the drainage canal, wherein the drainage canal side walls respectively comprise a side-wall foundation and a side-wall main body on the side-wall foundation; a plurality of prefabricated rectangular reinforced concrete rectangular boxes are connected vertically and horizontally and distributed in a single row along the direction of the drainage canal, thus forming the side-wall main body; and the top surface of each rectangular box is opened, the other five surfaces of each rectangular box are closed, and the inside of each rectangular box is filled with soils. Compared with the prior art, the quick assembly characteristic of the rectangular boxes is utilized, so that the rectangular boxes can be prefabricated in an area which is far away from the drainage canal, which is conducted together with the construction of the side-wall foundation of the drainage canal and the drainage canal bottom synchronously, thereby shortening the construction period and reducing the influences on environments around the drainage canal scene. The soils existing in channels can be loaded in the rectangular boxes directly, thereby solving the problem that construction materials are transmitted massively. Compared with the traditional drainage canal, the assembled drainage canal has the advantages that the project investment can be saved by 20-50% and the construction period can be saved by 20-80%.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

Intelligent farmland irrigation management system

PendingCN106933166AAvoid wastingPromote growthProgramme controlComputer controlWater savingAgricultural engineering

The invention relates to an intelligent farmland irrigation management system and belongs to the technical field of farmland irrigation. The irrigation management system comprises a farmland, an irrigation pump station, a water delivery main pipe, irrigation branch pipes, irrigation water outlet pipes, an irrigation control device and farmland soil monitors. The plurality of irrigation branch pipes are embedded under the farmland soil in parallel at intervals; one end of each irrigation branch pipe is provided with the water delivery main pipe; the water delivery main pipe is communicated with the irrigation pump station and the plurality of irrigation branch pipes; the joint of each irrigation branch pipe and the water delivery main pipe is provided with a control valve; one side of the farmland at the other end of each irrigation branch pipe is provided with a drainage channel; and the farmland is communicated with the drainage channel through drainage pipes. The irrigation management system realizes water level refinement management, creates an optimum growth environment for crops, can promote crop growth and improve output of the crops; and the system strengthens scientific management of water resources, realizes real full and reasonable utilization of the water resources, achieves a water saving purpose, and meanwhile, reduces labor cost.

Owner:湖北楚峰水电工程有限公司

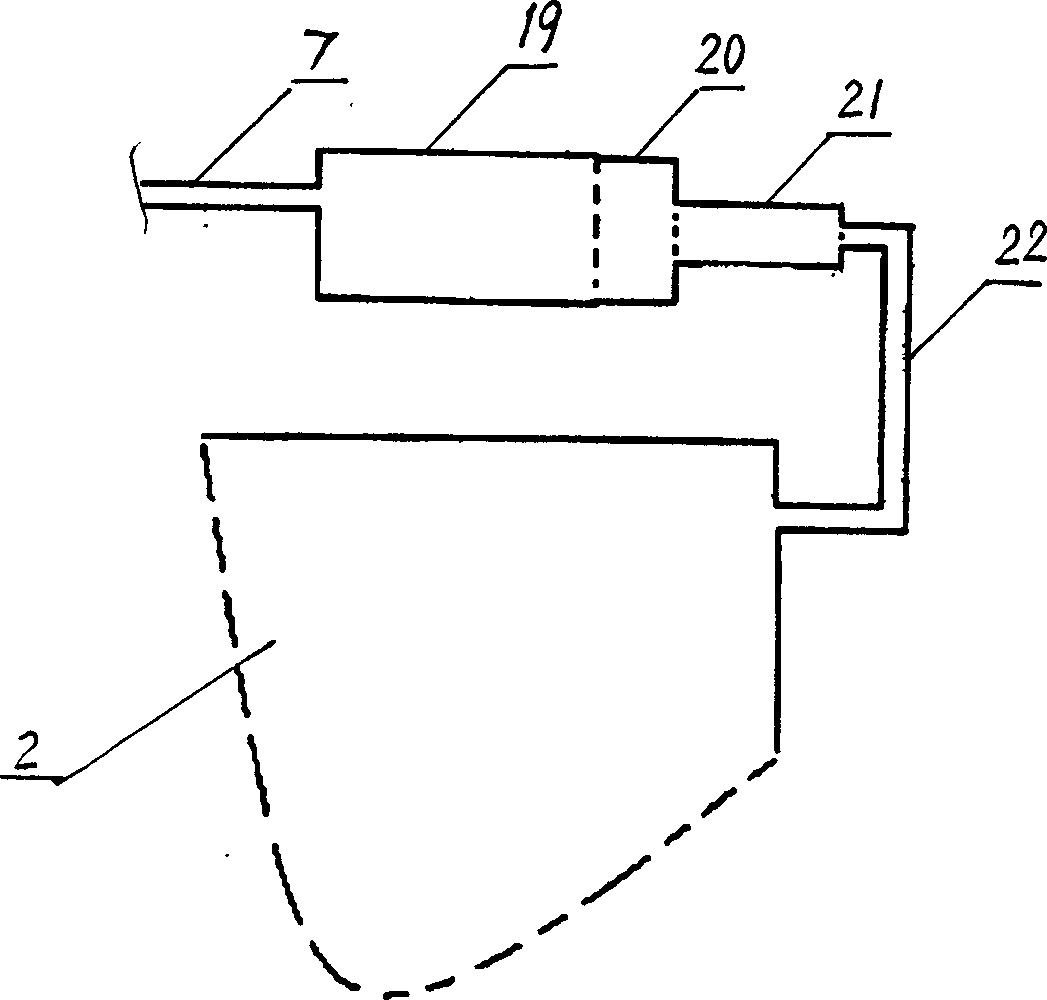

Control case for controlling water drainage and pollution discharge in farmland and automatic control system for water in farmland

InactiveCN1970891AIncrease profitEasy to recycleConstructionsSoil drainageAutomatic controlRiver network

The invention discloses a control box for drainage and drainage floodwater in farmland, comprising main box body and side box body. Drainage hole is set on the back-side surface of main box body and side box bodies are set on the outer bottom position of two left-right side surfaces of main body box. The side box body is connected with main body box by guiding hole. On the upper end of side and left-right sides several drainage notches are set and floodwater drainage hole is set on the top of side box body. Cover boards are set on the top of main and side box bodies respectively. Automatic control system for soil surface water in farmland in the invention is formed as said control box for drainage and drainage floodwater in farmland is buried in the ridge of field near the drainage canal, the back-side face of main box body is towards the drainage canal, meanwhile drainage holes set on the back-side face is are connected with the drainage canal. The design and arrangement of reasonable structure can decrease the load of N, P nutrient elements in drainage. It is provided with extending and applying value widely in pollution control for national river network area.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

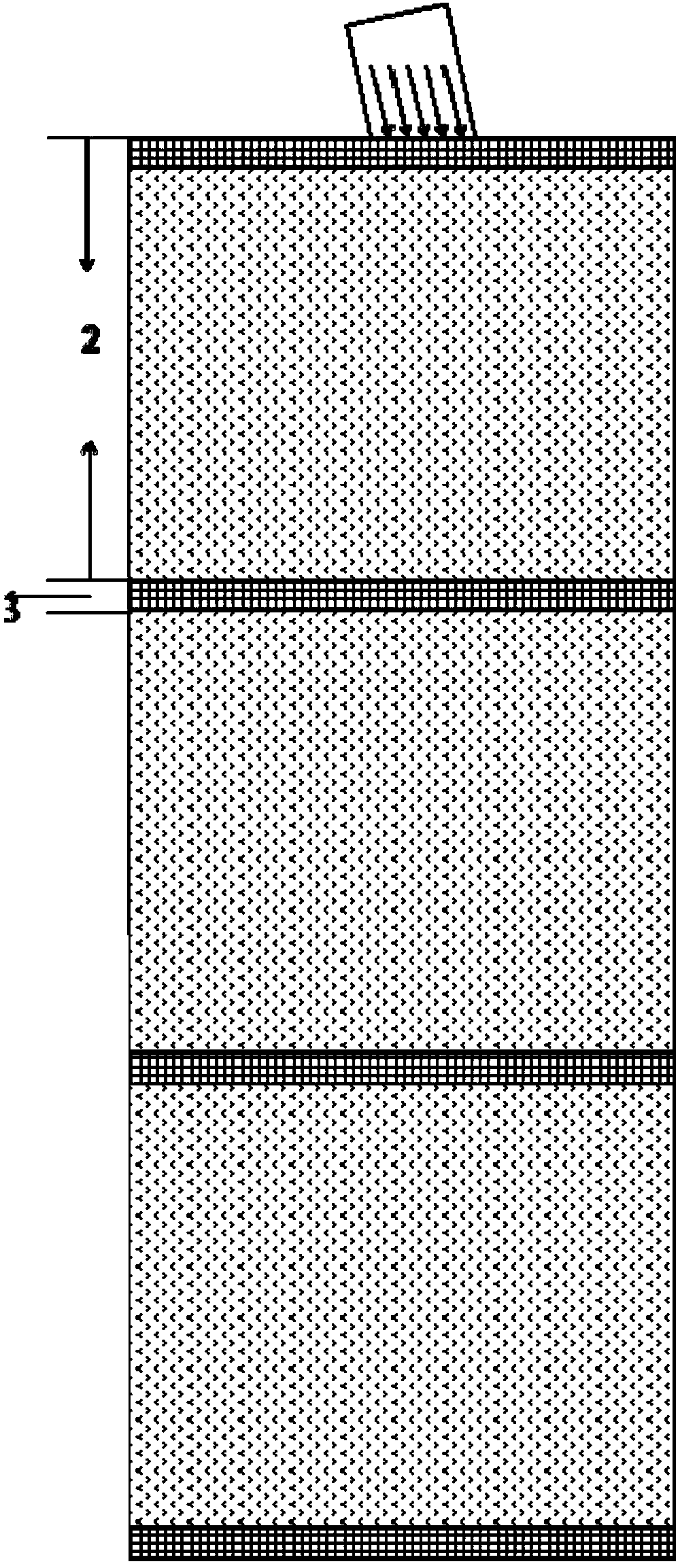

Saline-alkali land improvement system and method

ActiveCN110521322AReduce water accumulationReduce evaporationOrganic fertilisersSoil-working methodsLand improvementSalt resistance

The invention discloses a saline-alkali land improvement system. The system comprises a drainage channel, a subsoil layer and a planting layer, wherein the drainage channel is arranged above the subsoil layer, and the side face of the drainage channel is provided with the planting layer containing to-be-improved saline-alkali soil; an impermeable interlayer is arranged between the subsoil layer and the planting layer, the bottom of the drainage channel is configured to be impermeable, and the impermeable interlayer is connected with the upper edge of the bottom of the drainage channel; the impermeable interlayer is configured to be gradient from the end away from the drainage channel to the drainage channel; a first planting area to an Nth (N is greater than or equal to 2) planting area are sequentially arranged on the planting layer, from the end away from the drainage channel to the drainage channel, at the same side of the drainage channel, and the Nth planting area is next to the side wall of the drainage channel; the end, away from the drainage channel, of the first planting area is provided with a first-level infiltrating irrigation channel, and the end, away from the drainage channel, of the Nth planting area is provided with an N-level infiltrating irrigation channel; the side wall of the first-level infiltrating irrigation channel and the side wall of the N-level infiltrating irrigation channel are configured to be permeable; the side wall of the drainage channel is configured to be permeable; the first planting area to an Nth planting area are used for planting plants with salt resistance from weak to strong in sequence.

Owner:MEILIGUOTU BEIJING ECOLOGICAL ENVIRONMENT ENG TECH RES INST CO LTD

Treatment method for moderate stony desertification in karst mountain area

InactiveCN103891573AGood governancePlay the role of comprehensive managementClimate change adaptationAfforestationGrasslandControl area

The invention relates to a treatment method for moderate stony desertification in a karst mountain area. The treatment method includes the steps that a land terracing technology is popularized in a slope cropland, a forest for water and soil conservation is constructed on the periphery, high-yield commercial fruit-bearing forest-crystal grapes are developed on the lower portion of a peak cluster slope and part of depressions, and gold pears are developed between grasslands which are good in condition on the upper middle portion of a slope body and a sparse forestland. Through a grassland construction technology, a grassland improvement technology and a high-quality forage planting and managing technology, by the utilization of the mode of combining an intercepting ditch, a desilting basin and a small reservoir and the mode of combining a floodwater drainage canal, a water inlet ditch, a desilting basin and a reservoir, water resources are developed and utilized. An ecological medicine industry base and an ecological grape industry base are established. A machine is used for digging a well, underground water is taken, a high-position water pool is constructed at the high point of a control area, the water pool and slope surface water pool field pipelines form an irrigating net, and by the adoption of an irrigation technology, an early vegetable base is established. Through the treatment method, moderate stony desertification of the karst mountain area is effectively treated, water and soil loss is weakened, the rock exposing trend is restrained, and society and economy are coordinately developed.

Owner:GUIZHOU NORMAL UNIVERSITY

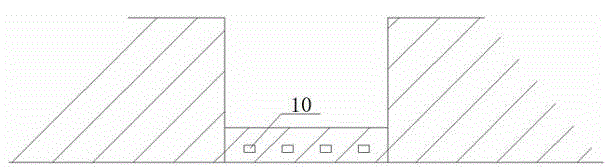

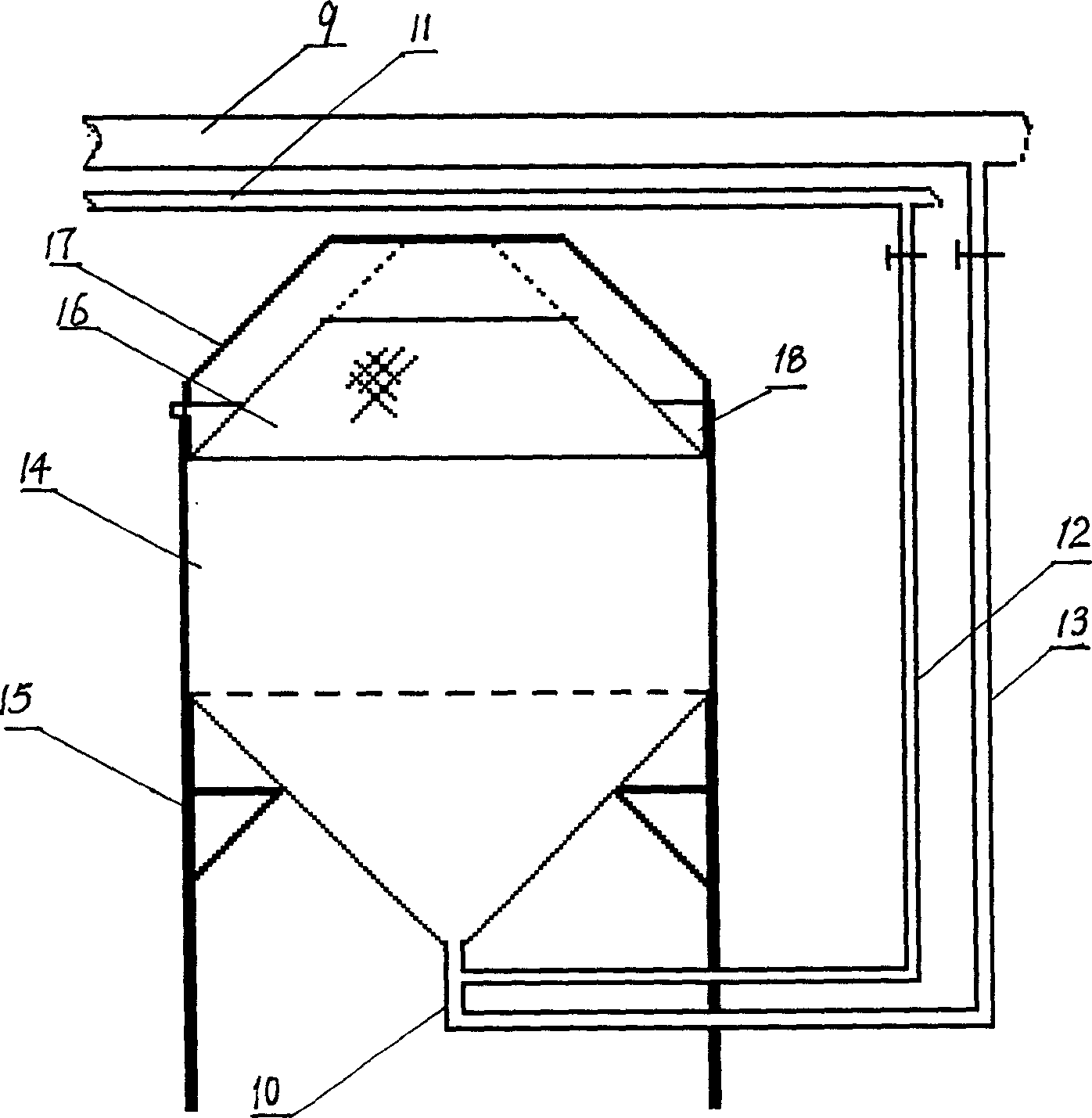

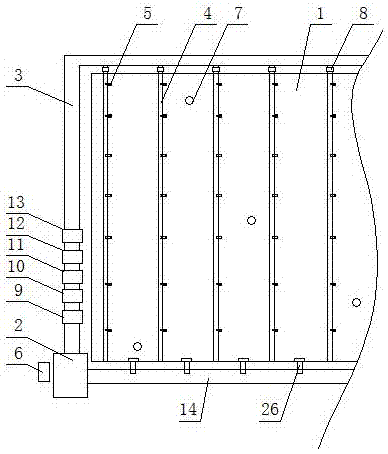

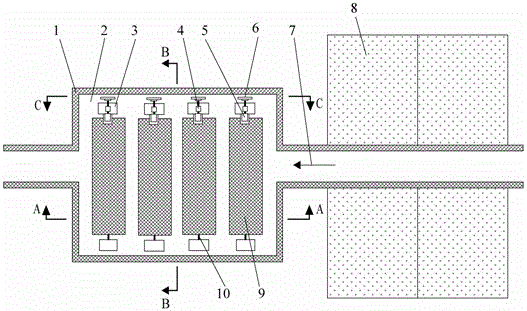

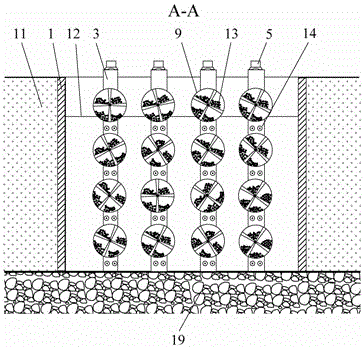

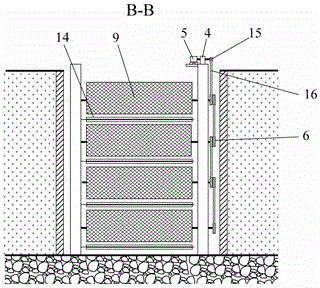

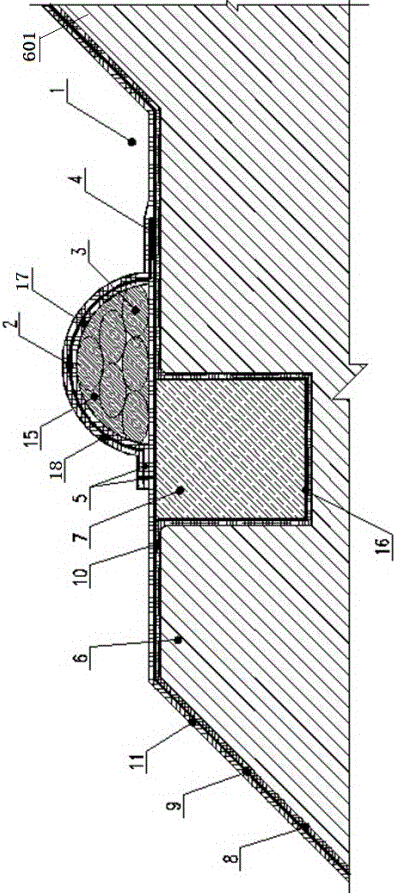

Multi-layer drum type photocatalysis purification tank applicable to farmland drainage canal

ActiveCN104973650ASimple structureImprove purification efficiencyWater/sewage treatment by irradiationEngineeringDrainage canal

The invention discloses a multi-layer drum type photocatalysis purification tank applicable to a farmland drainage canal. The structure of the photocatalysis purification tank comprises a purification tank, a support base, rotary purification cages, photocatalysis ceramic particles, quartz burners and a synchronous drive device, wherein the rotary purification cages are fixed on the support base in parallel through spindles, the photocatalysis ceramic particles are placed in the rotary purification cages, the quartz burners are fixed among the rotary purification cages, the top of the support base is 10-20cm higher than the top of the purification tank, and the rotary purification cages are connected with the synchronous drive device. The multi-layer drum photocatalysis purification tank applicable to the farmland drainage canal has the advantages of simple structure, high purification efficiency, no maintenance and the like, and can be used for treatment of farmland drainage which is seriously polluted.

Owner:HOHAI UNIV

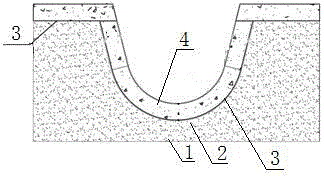

Construction method for slope support drainage canal

ActiveCN106759126AUniform flow rateUniform velocity distributionSoil drainageArtificial water canalsGeomembraneEngineering

The invention discloses a construction method for a slope support drainage canal. According to the method, a U-shaped canal is poured at the slope toe of a collapsible loess high-steep slope in the high-cold northwest district for drainage, and the non-uniformity of the expansive deformation distribution of the canal is improved, frost heaving is alleviated, the phenomena of cracks and slab staggering due to subsoil collapse are reduced through carrying out lime-soil replacement and tamping on a foundation trench, additionally arranging a gravel cushion at the bottom of the canal and laying a composite geomembrane at the bottom of a U-shaped soil model, so that deformation due to the frost heaving and leakage at a construction joint can be effectively prevented.

Owner:CHEM IND GEOTECHN ENG

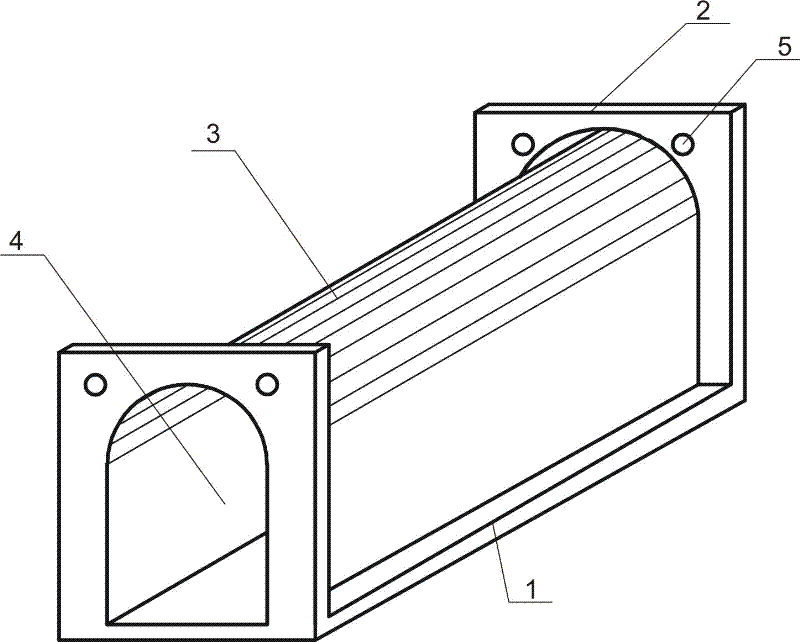

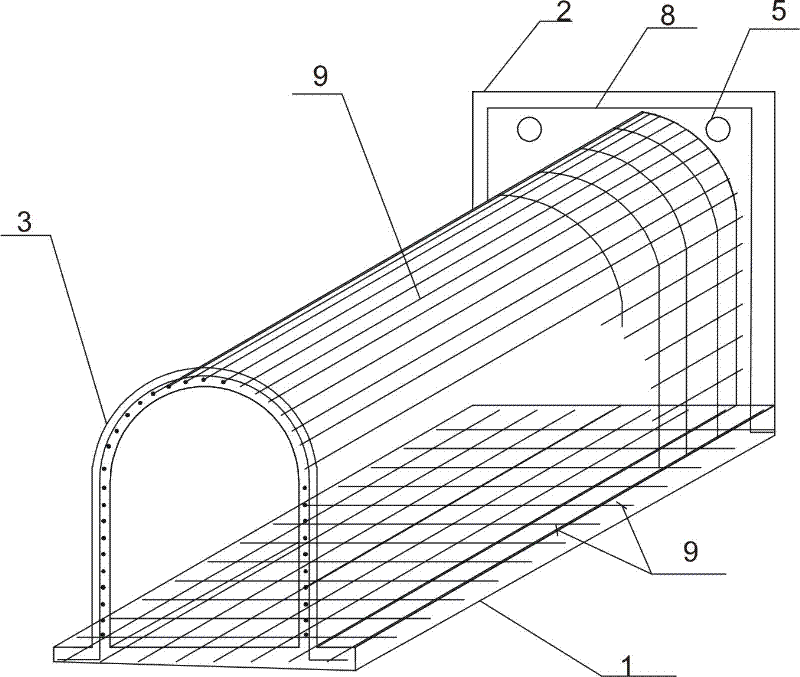

Fabricated culvert member and construction method thereof

ActiveCN102373675AImprove water delivery capacityReduce evaporationGround-workArchitectural engineeringMaterial resources

The invention relates to a fabricated culvert member and a construction method thereof. The fabricated culvert member comprises a base plate, a rib plate and an arc plate, wherein the rib plate is in a gantry shape and is fixed on both ends of the arc plate, the lower ends of the arc plate and the rib plate are fixed on the base plate, the three plates are integrated, and a space between the arc plate and the base plate is a drainage channel. The fabricated culvert member provided by the invention has the advantages of factory fabrication, field assembly, simple operation, guaranteed quality,quick construction speed, simple structure, reasonable force bearing, simple maintenance (installation, removal and replacement, good integrity, high strength, large adaptive deformation, no pollution, small environmental influence, practicability, economy and obvious effect, the maintenance of the culvert member saves 20-40% human resources, material resources and money less than that of common masonry pebble revetments, town bottom or buried circular pipe culverts, and the water utilization coefficient of the canal system can be greatly increased (evaporation and seepage are reduced).

Owner:余跃建 +1

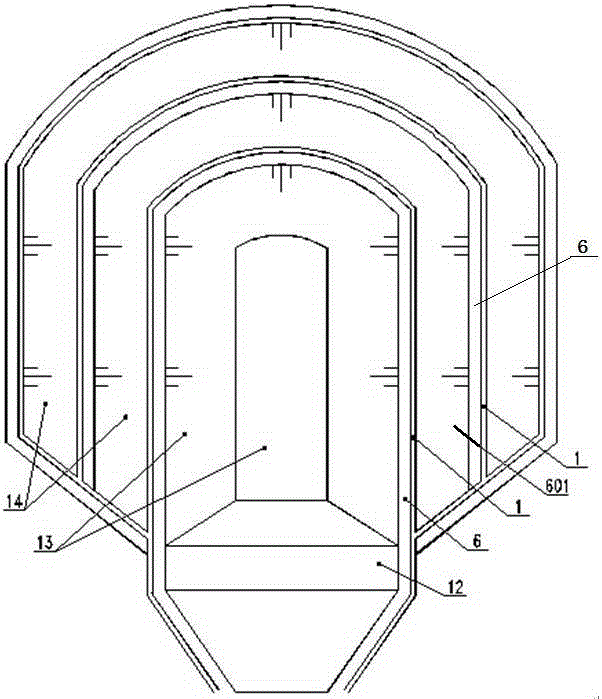

HDPE (High-Density PolyEthylene) membrane rain sewage diversion drainage canal for refuse landfill

ActiveCN105201024AEffective interceptionTroubleshoot technical issues with shuntingSewerage structuresClimate change adaptationSewageDrainage canal

The invention discloses an HDPE (High-Density PolyEthylene) membrane rain sewage diversion drainage canal for a refuse landfill. The HDPE membrane rain sewage diversion drainage canal for the refuse landfill comprises the refuse landfill, a seepage prevention layer laid on a slope around a field area of the refuse landfill and a retaining wall, wherein a reservoir area of the refuse landfill is divided into different blocks by each stage of annular anchoring platforms with different elevations; an area below the elevation of the top of the retaining wall is taken as a leachate area, and an area above the elevation of the top of the retaining wall is taken as a rain area; the rain area is divided into rain blocks with different elevations by each stage of anchoring platform with different elevations; HDPE membrane rain ridges are arranged on each stage of anchoring platform; an HDPE membrane rain sewage diversion drainage canal is formed between each HDPE membrane rain ridge and the sidewall of the higher stage of anchoring platform. According to the HDPE membrane rain sewage diversion drainage canal for the refuse landfill, the slope anchoring platforms are fully utilized, and the HDPE membrane rain sewage diversion drainage canals are constructed on each stage of anchoring platform, and are used for effectively intercepting rain in the blocks above the elevations of the HDPE membrane rain sewage diversion drainage canals and guiding and draining the rain out of the refuse landfill to fulfill the aim of rain sewage diversion; the HDPE membrane rain sewage diversion drainage canal for the refuse landfill has the advantages of simple structural form, convenience in construction and reliable effects.

Owner:中国市政工程西北设计研究院有限公司

Strip mine waste dump with ecological step slope structure

PendingCN112982447AImprove compactionReduce settlementFatty/oily/floating substances removal devicesSewerage structuresEnvironmental resource managementWaste dump

The invention discloses a strip mine waste dump with an ecological step slope structure. The strip mine waste dump comprises a designed waste dump and an ecological waste dump, wherein the ecological waste dump is divided into a plurality of layers of ecological steps; the first layer of ecological step is built firstly, then the width of a one-way road of a mining engineering vehicle and a drainage channel are built on the ecological step, and water is collected into water collecting wells built at intervals along the drainage channel by utilizing the set flowing water slope; and after the first layer of ecological step is built, the second layer of ecological step is continuously built on the first layer of ecological step along the inner edge of the drainage channel, and so on until the last layer of ecological step is built. The ecological steps are formed in a reverse dumping mode, the material compaction effect is good, the sedimentation is small, and the water retention effect is good; the ecological steps can be directly used for driving the vehicle, so that the surface soil layer coverage and ecological restoration construction are facilitated, and the water and soil conservation effect is good; and the drainage channel and the water collecting wells are matched to collect rainwater, so that on one hand, the erosion of rainfall to the waste dump is reduced, and on the other hand, the drainage channel and the water collecting wells can be used for subsequent reclamation irrigation of the waste dump, and the reclamation effect is improved.

Owner:CHINA UNIV OF MINING & TECH

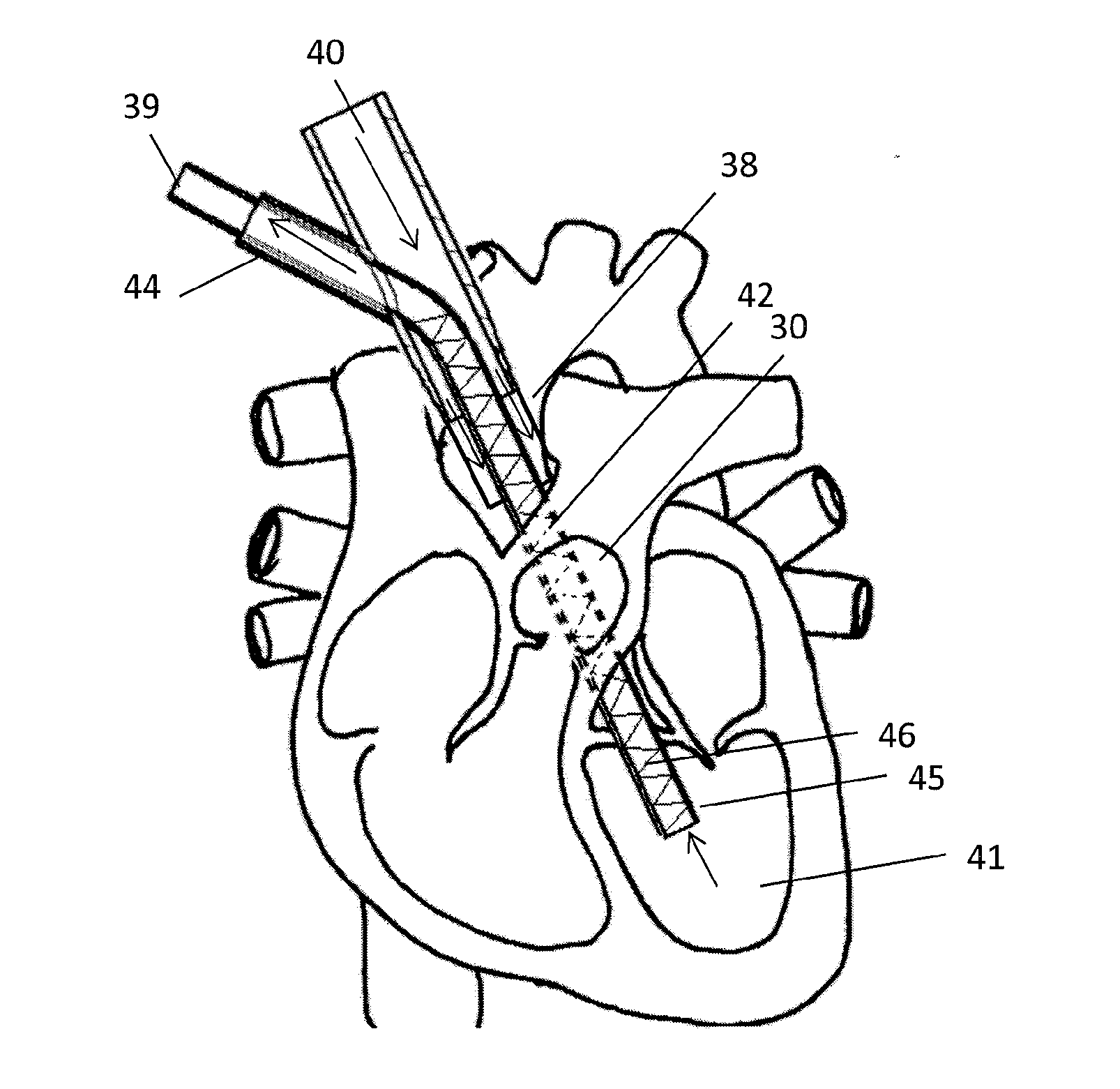

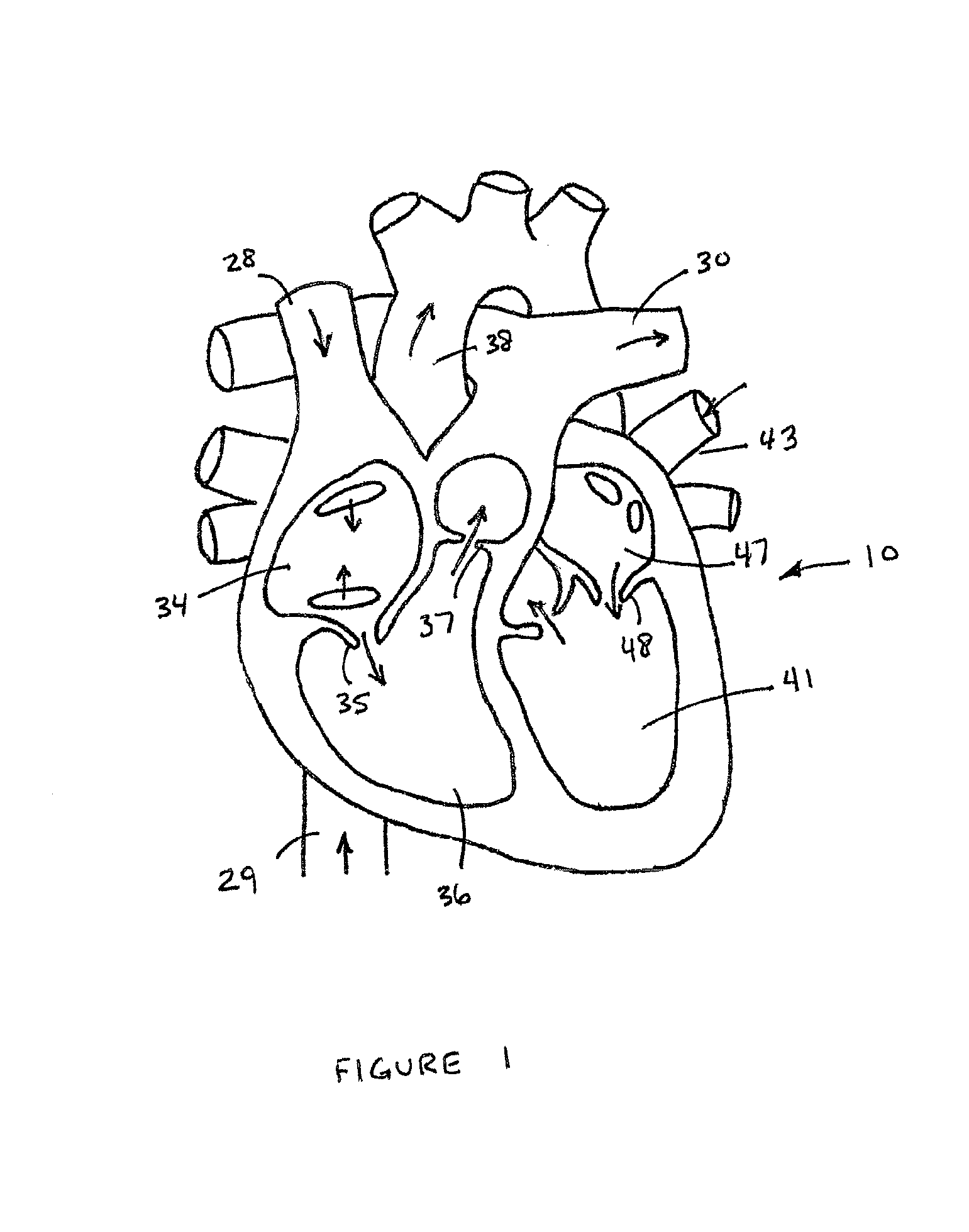

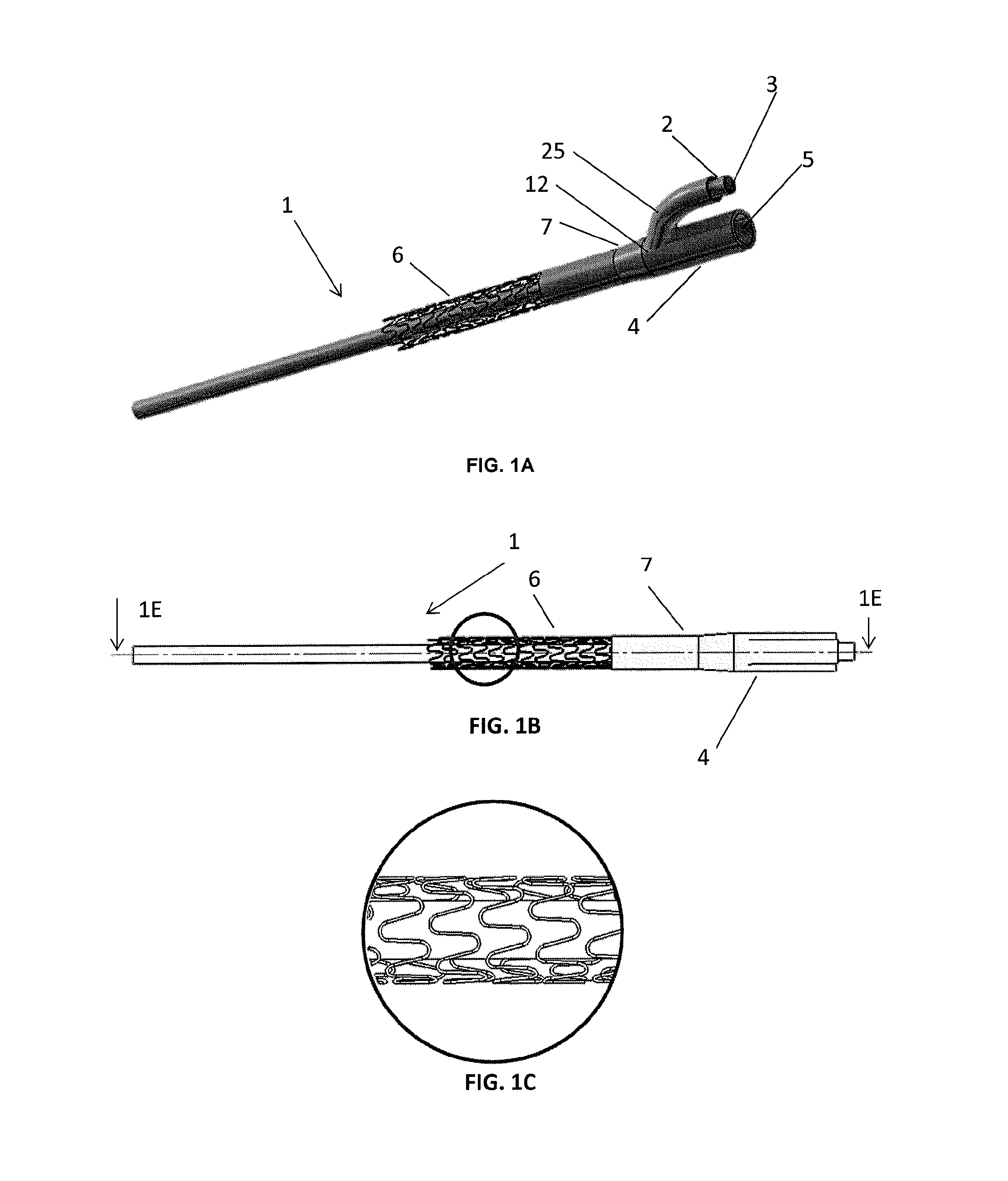

Self-expanding cannula

ActiveUS20160158489A1Sufficient flexibilityPrevent crashMulti-lumen catheterOther blood circulation devicesWire frameDrainage canal

Disclosed is a self-expanding cannula, systems using such cannulae, and methods of their use. The cannulae may comprise single lumen cannula (SLC) configurations and double lumen cannula (DLC) configurations, and include at least a first cannula and a self-expanding wire frame attached to the first cannula. Self-expanding wire frame is automatically expandable from a compressed state (providing a reduced cannula diameter as it is moved through a patients body to the site at which it is to be deployed) to an expanded state (which increases the diameter of the cannula to the diameter intended for its normal use). The expanded wire frame provides radial support to prevent a drainage canal (whether a patients blood vessel or a portion of the system inserted into the patients blood vessel) from collapsing as fluid is drained from the patient.

Owner:UNIV OF MARYLAND BALTIMORE

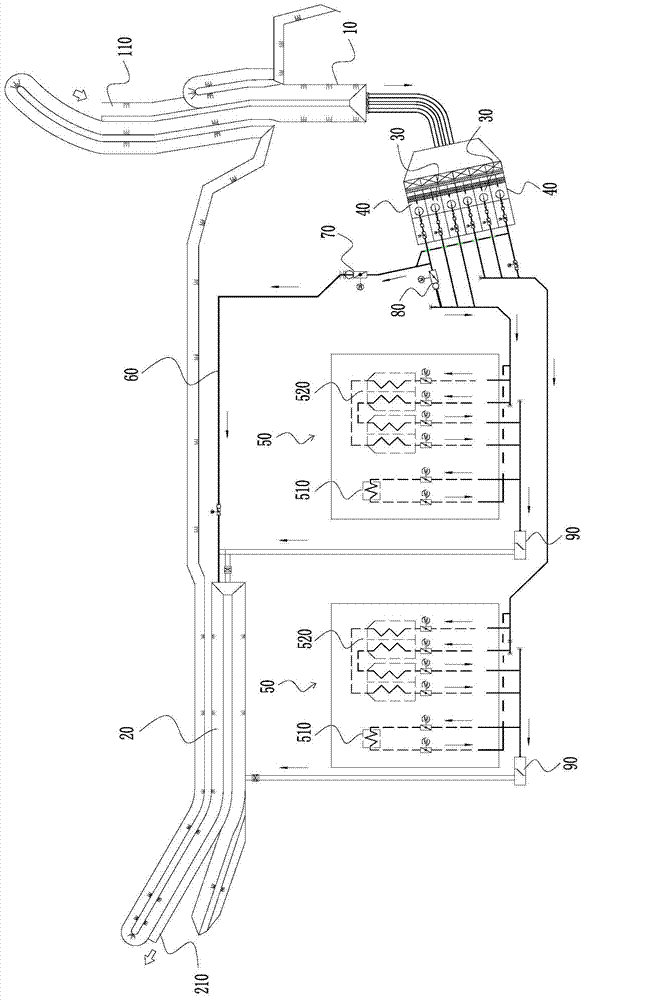

Power plant seawater once-through cooling system

ActiveCN104729178AReduce heat pollutionSave land areaLighting and heating apparatusCooling fluid circulationCooling towerEconomic benefits

The invention relates to a power plant seawater once-through cooling system. The power plant seawater once-through cooling system comprises an intake canal with a water inlet, a drainage canal with a water outlet, a circulating water pump, a mixing water pump, a heat exchange device and pipelines; the intake canal, the circulating water pump, the heat exchange device and the drainage canal are sequentially connected through the pipelines to form a main cooling system body, the intake canal, the mixing water pump and the drainage canal are sequentially connected through the pipelines to form a mixing cooling system body, and a first valve is connected between the mixing water pump and the drainage canal. According to the power plant seawater once-through cooling system, the main cooling system body and the mixing cooling system body are arranged, original seawater directly transported by the mixing cooling system body and thermal discharge water output by the main cooling system body are mixed in the drainage canal, and therefore the temperature, discharged to a sea, of the thermal discharge water is reduced; the temperature, entering the sea, of the thermal discharge water can be reduced without needing to arrange a cooling tower, the thermal pollution of the thermal discharge water of a power plant is reduced, the plant area is greatly decreased, the initial investment is reduced, the energy consumption is reduced, and the economic benefit is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

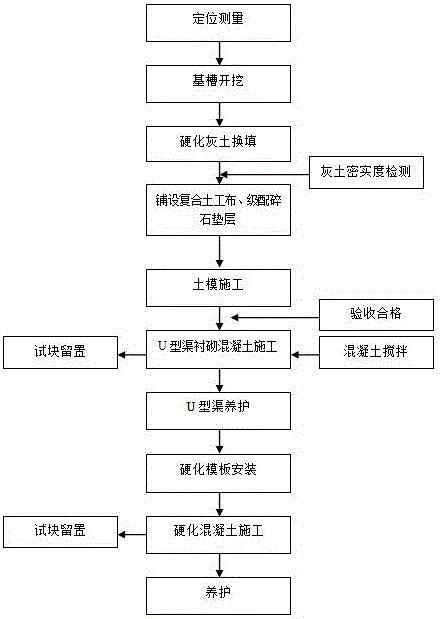

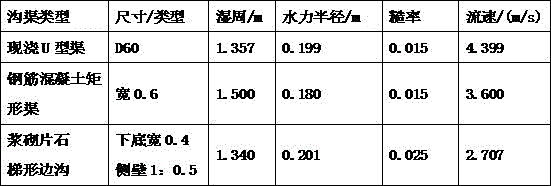

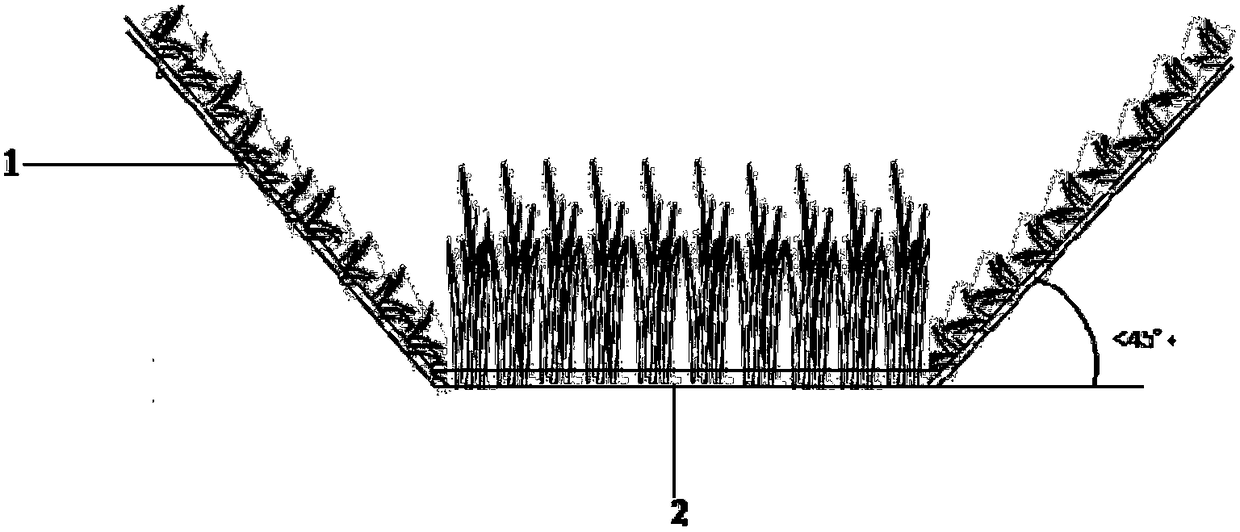

Ecological drainage canal construction method

The invention provides an ecological drainage canal construction method comprising the steps of flattening the bottom of a soil drainage canal; and growing slope protection plants on the side slops ofthe soil drainage canal, and growing bottom hedgerow plants and bottom cropping strip plants at the bottom of the soil drainage canal. According to the construction method, by flattening the bottom of the soil drainage canal according to a certain depth, an ecological drainage canal with a trapezoidal cross section and a trapezoidal or rectangular longitudinal section is constructed, and the gradient of the both side slops is 45 DEG; the slope protection plants, the bottom hedgerow plants and the bottom cropping strip plants are grown; nitrogen and phosphorus can be intercepted effectively, and the applicability is high; all plants are perennial plants, and can be used for many years after planting in next year, and the landscape effect is good; all plants are tolerant to drought, and applicable for arid regions in Northern China; the growth of worst weeds can be restrained effectively after the ground is covered completely, and the daily maintenance is easy, and the cost is low; andthe construction method is easy to popularize and apply.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com