Patents

Literature

154results about How to "Guaranteed filling quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

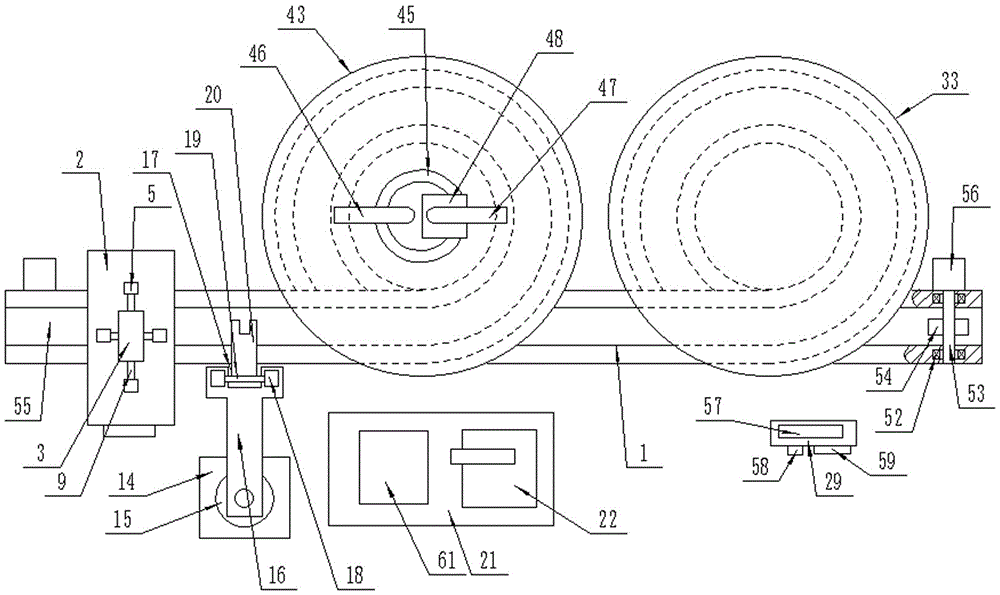

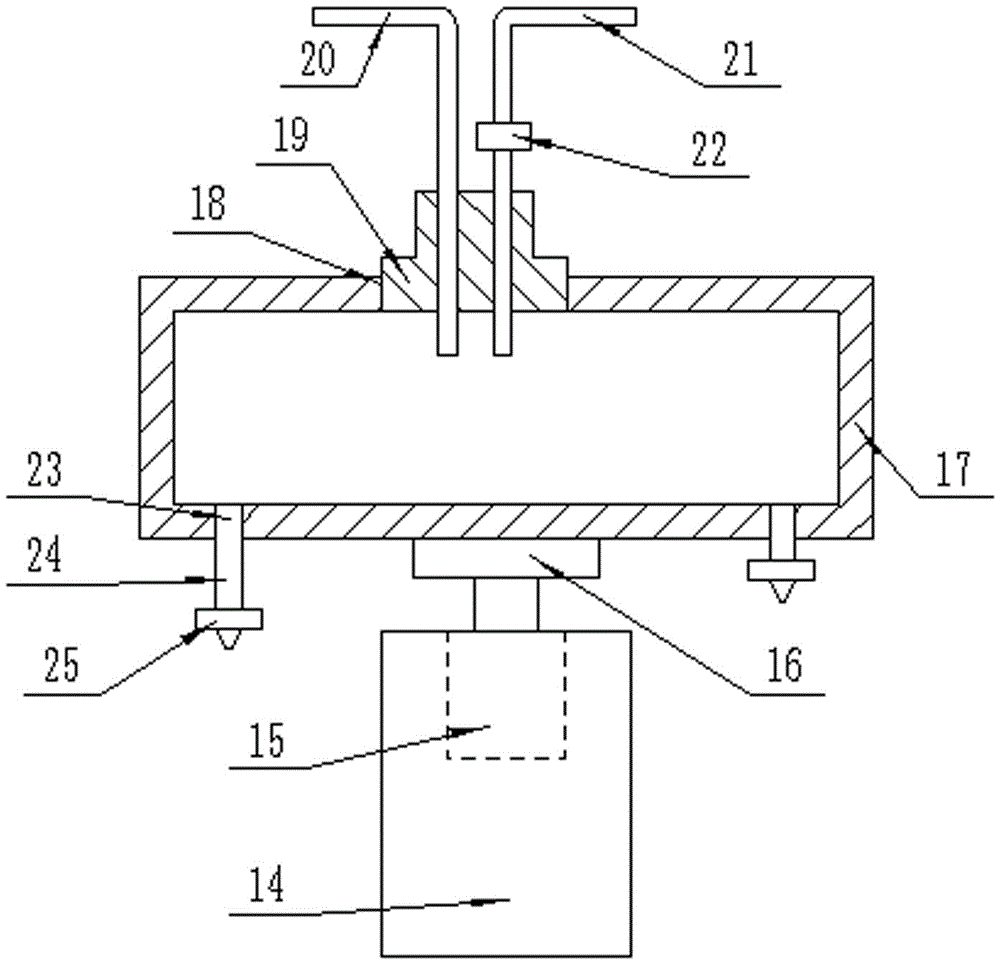

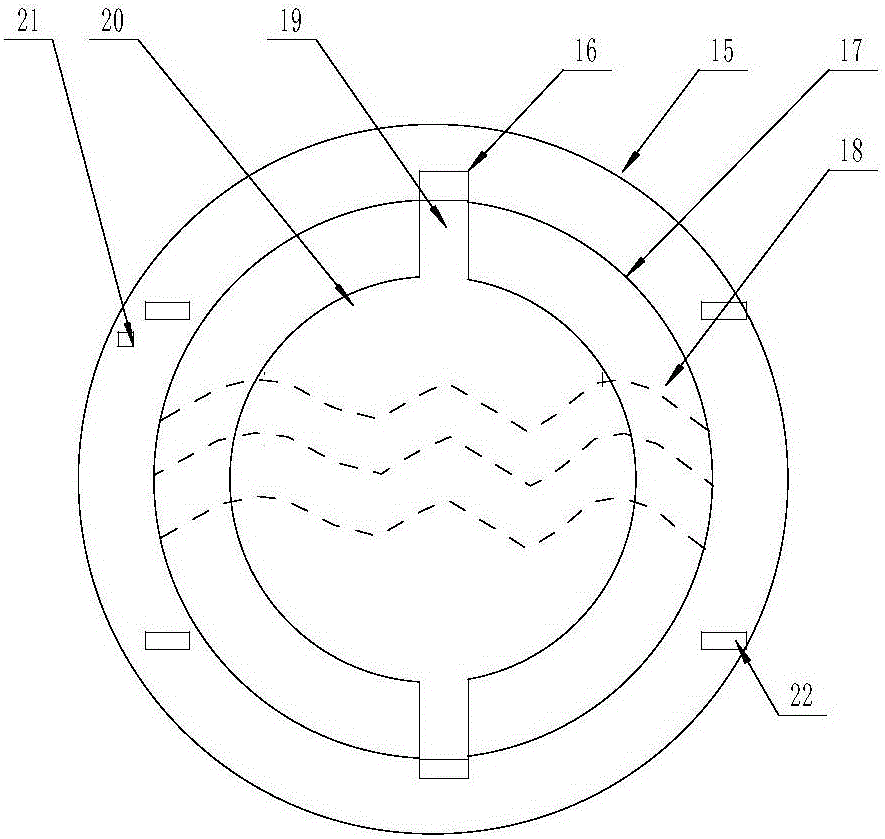

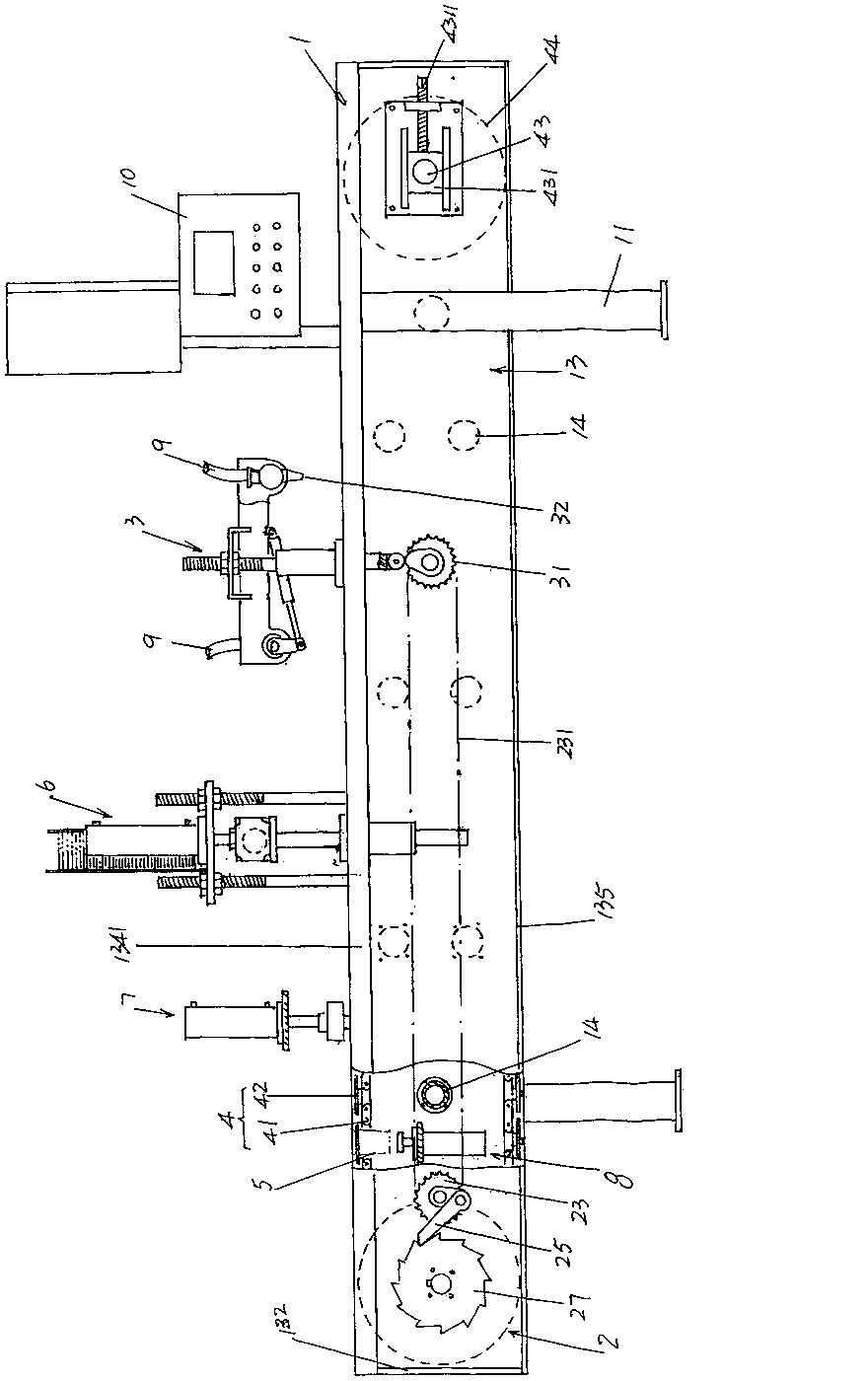

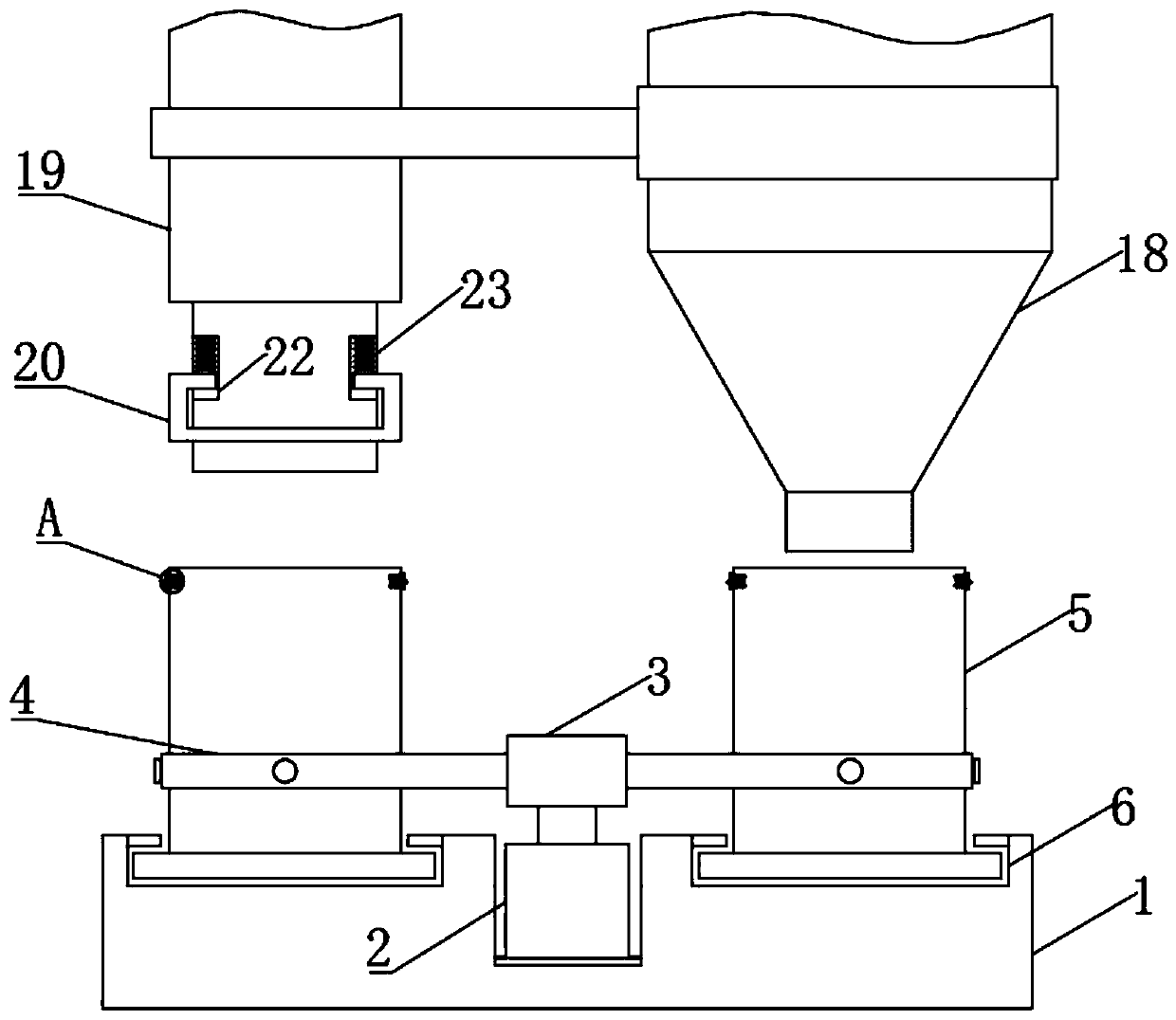

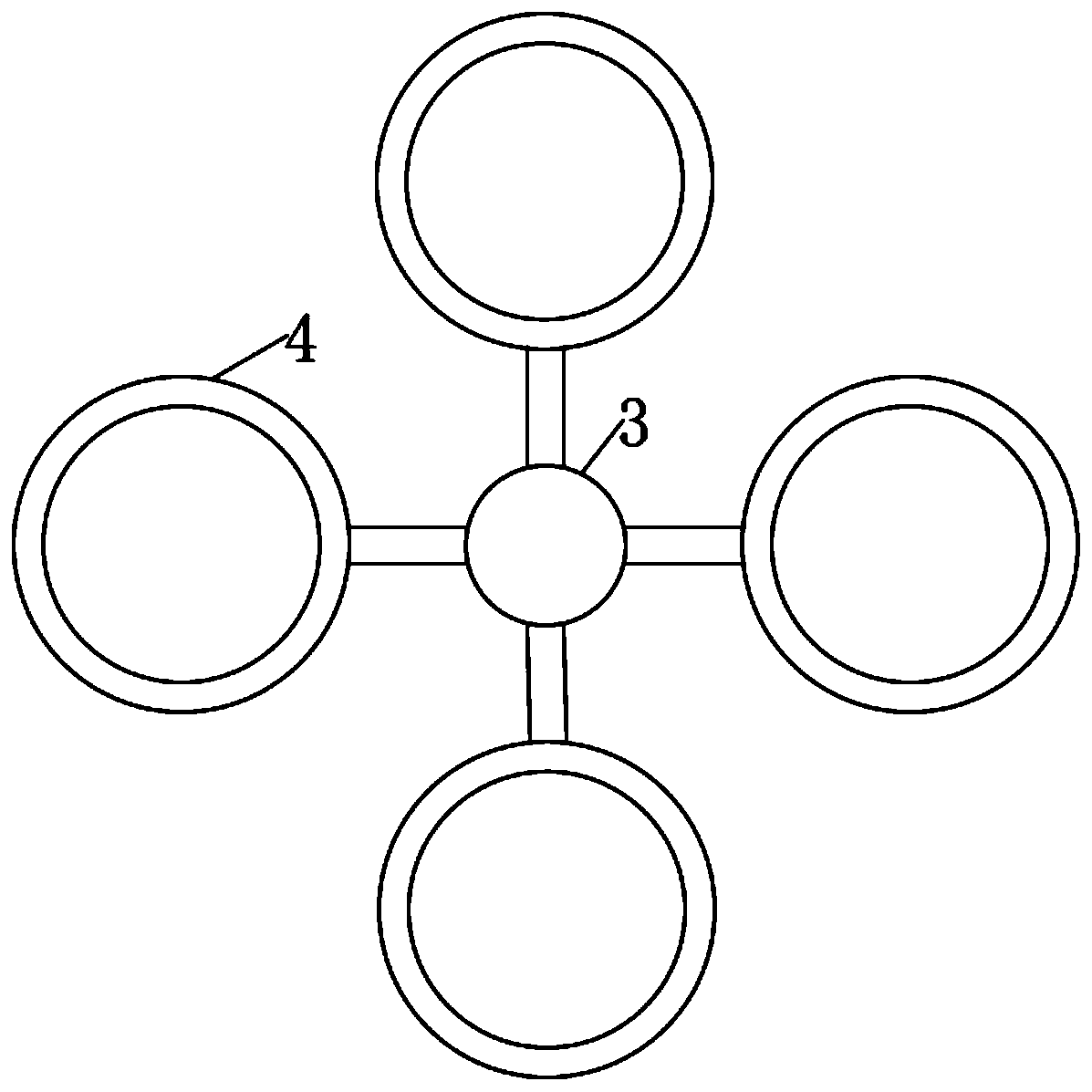

Novel contraction type sterilizing and detecting pharmacy assembly line

InactiveCN105668492AGuaranteed filling qualityAvoid pollutionSynchronising machinesFlanged caps applicationChain typeEngineering

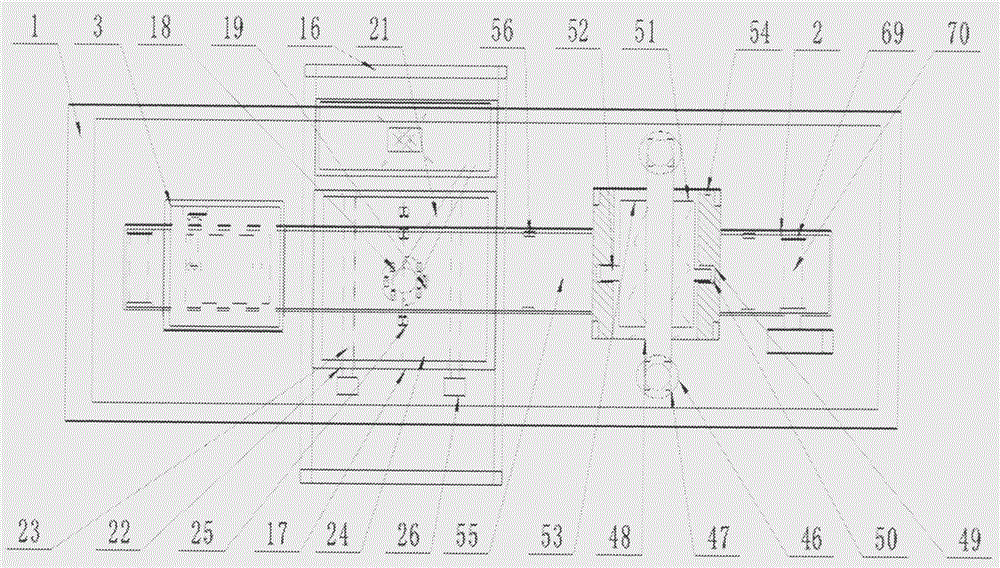

The invention discloses a novel contraction type sterilizing and detecting pharmacy assembly line. The novel contraction type sterilizing and detecting pharmacy assembly line comprises a double-ring-shaped support fixed to the ground. A chain type double-ring-shaped conveying belt mechanism is arranged in the double-ring-shaped support. An ozone sterilizing mechanism and a medicine bottle detecting device are arranged at the front end of the double-ring-shaped support. A multifunctional liquid medicine filling mechanism is arranged at the position of one center ring of the double-ring-shaped support, an annular bottle cap hot-pressing sealing mechanism is arranged at the position of the other center ring of the double-ring-shaped support, and a control box is arranged on the ground. The novel contraction type sterilizing and detecting pharmacy assembly line has the beneficial effects of being simple in structure and high in practicability.

Owner:廖淑梅

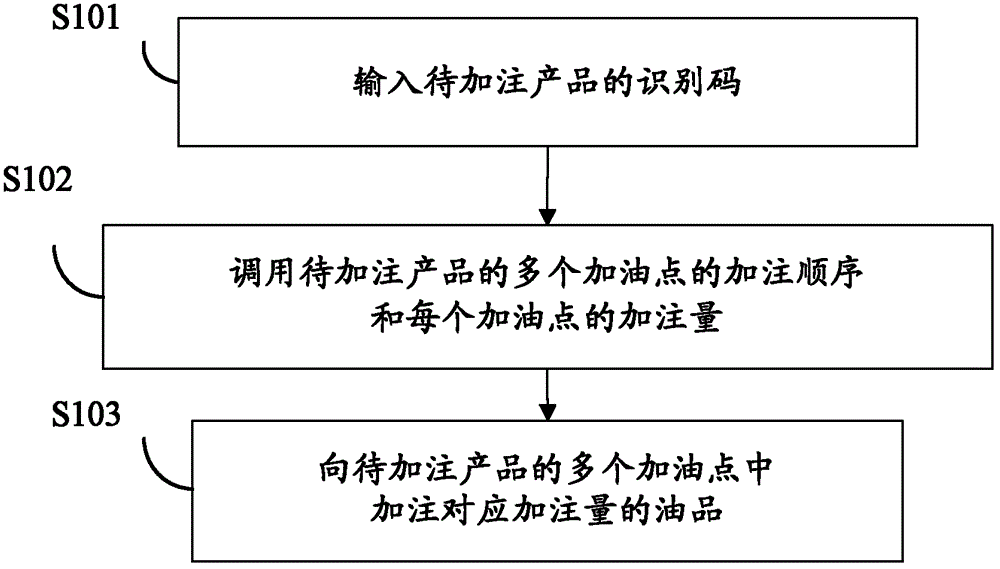

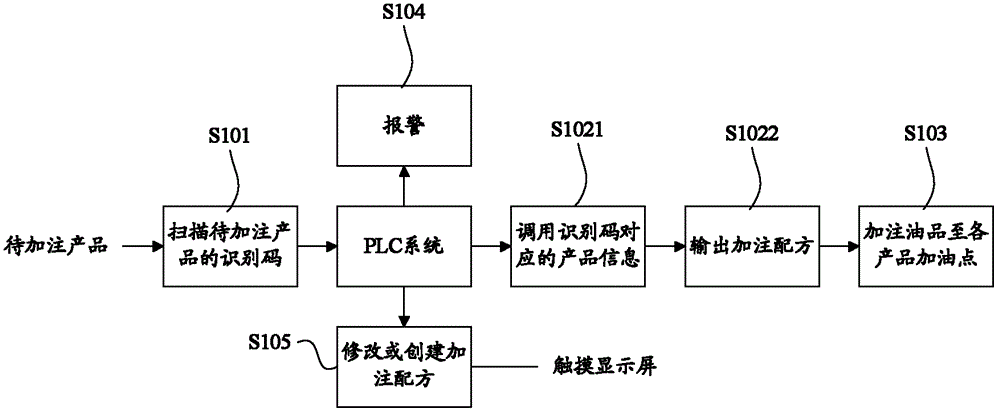

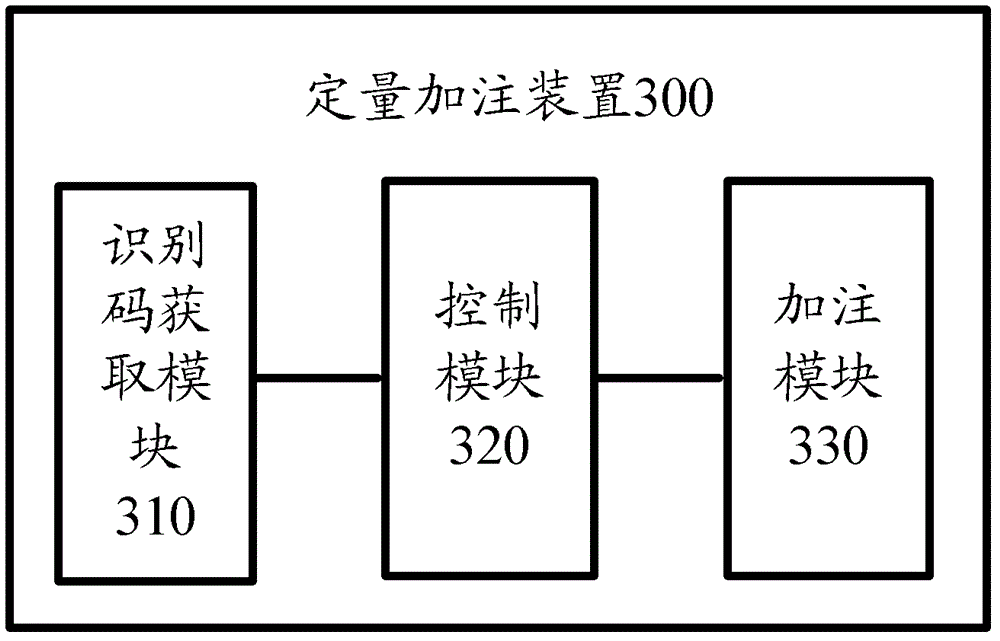

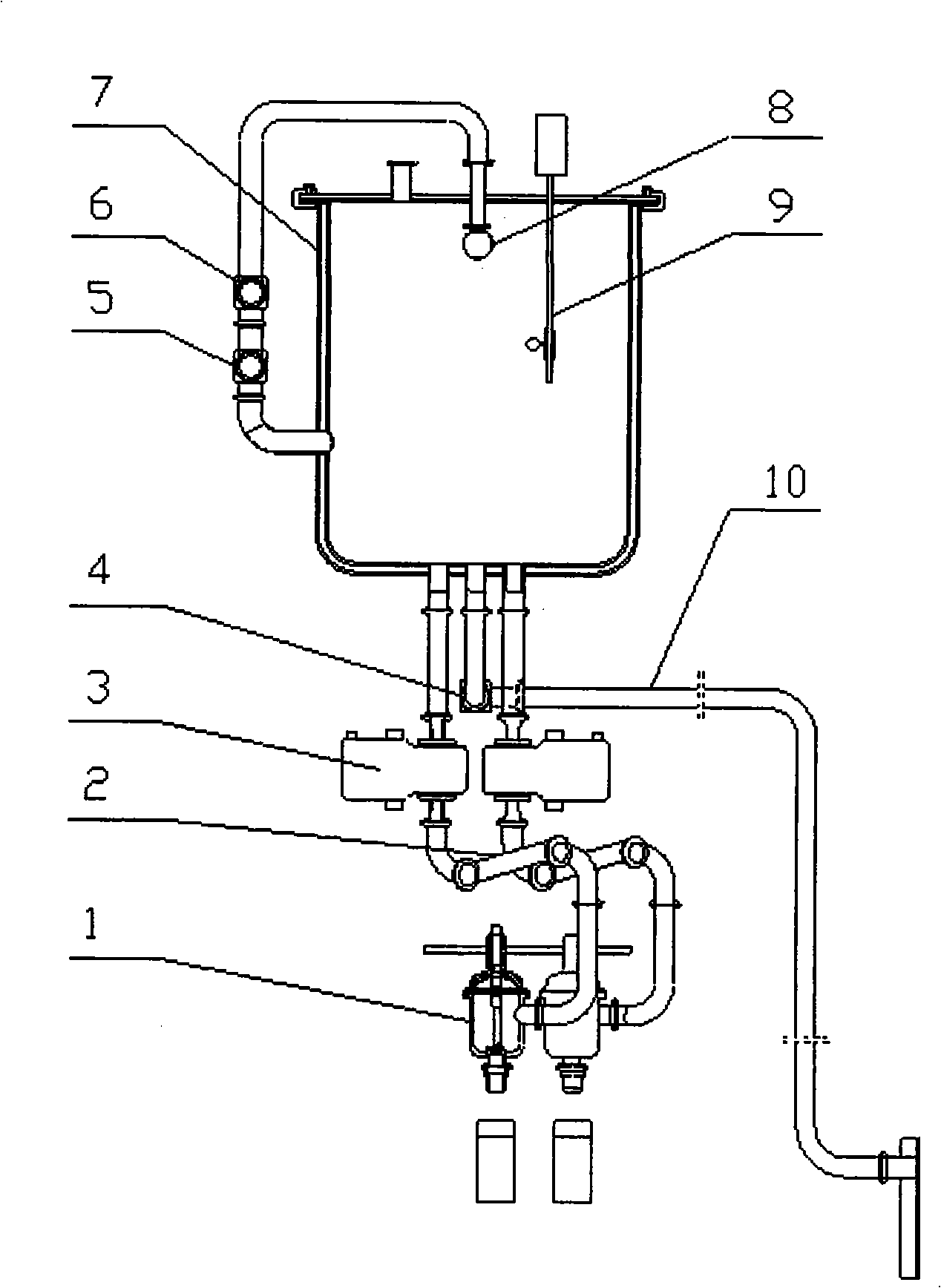

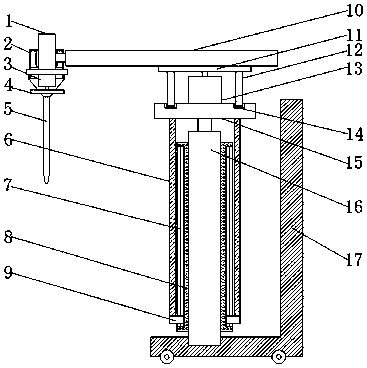

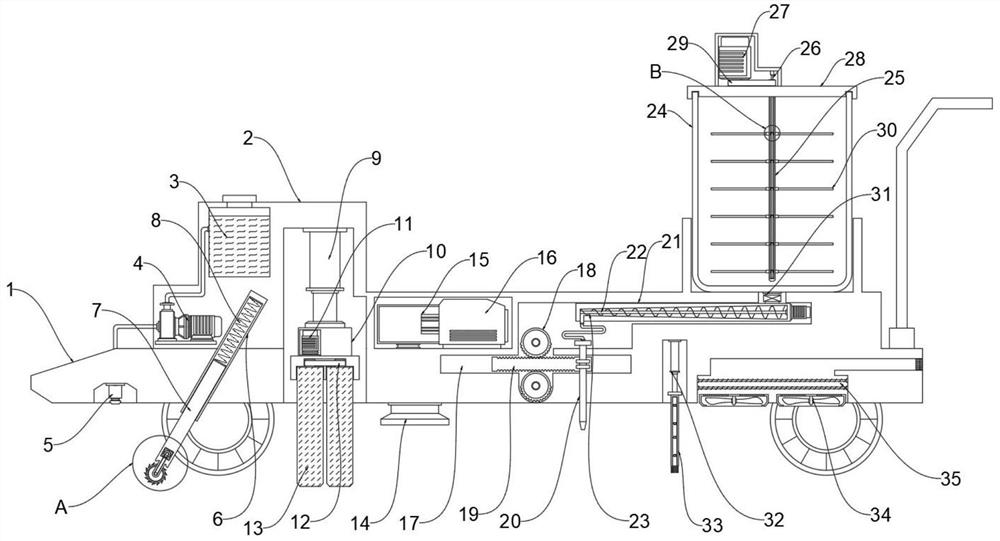

Quantitative filling method and device

ActiveCN102795203AGuaranteed filling qualitySimple and fast operationVehicle servicing/repairingProgramme control in sequence/logic controllersComputer moduleComputer science

The invention discloses a quantitative filling device. The device comprises an identification code acquisition module for acquiring the identification code of a product to be filled, a control module and a filling module, wherein the control module is used for receiving the identification code of the product to be filled from the identification code acquisition module and calling a filling formula of the product to be filled according to the identification code of the product to be filled; according to the filling formula, the filling sequence of a plurality of oil filling points of the product to be filled and the filling quantity corresponding to each oil filling point are provided; and the filling module fills oil into a plurality of oil filling points of the product to be filled in corresponding quantities according to the filling sequence. The invention also discloses a quantitative filling method. By the quantitative filling device and the quantitative filling method, problems such as wrong filling and missed filling of the oil in the process of manufacturing automobiles are solved; the oil filling quality of the automobiles is guaranteed; the quantitative filling device is easy and convenient to operate, and the oil can be filled accurately, so that the on-site assembly efficiency is improved.

Owner:BEIQI FOTON MOTOR CO LTD

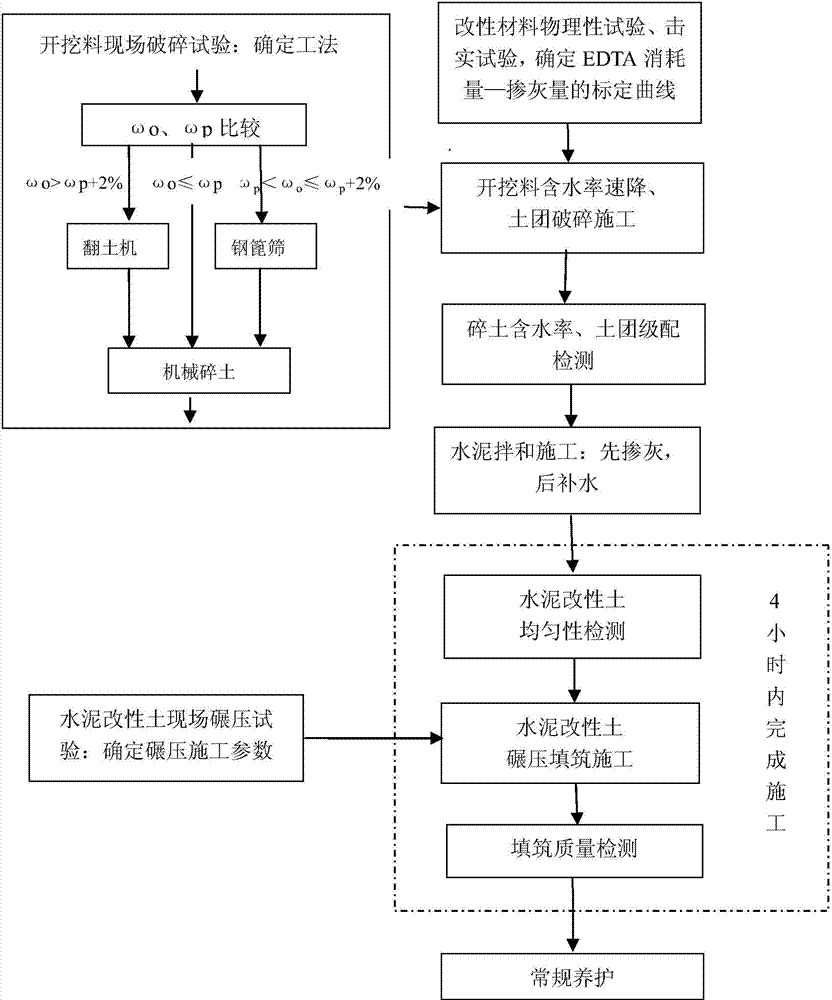

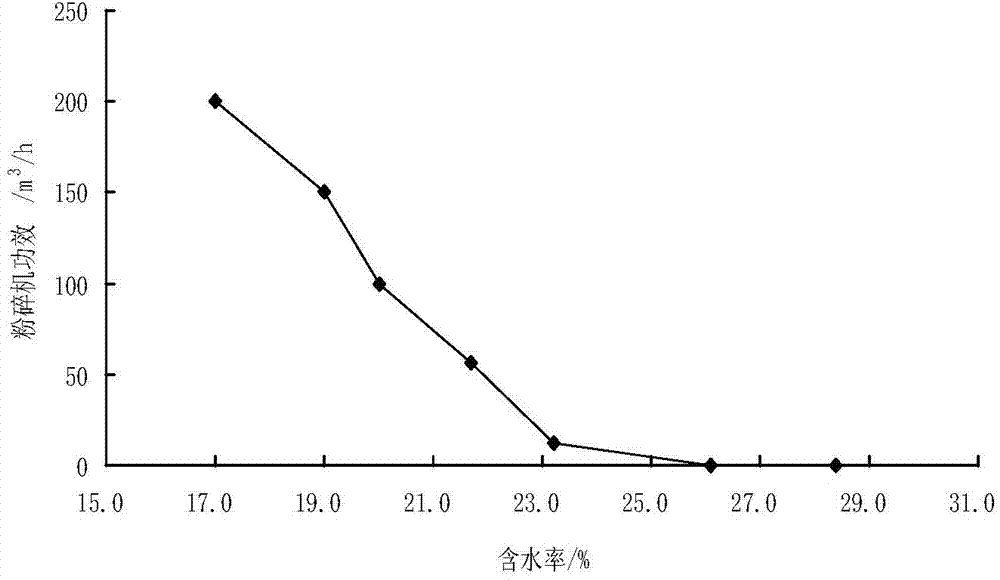

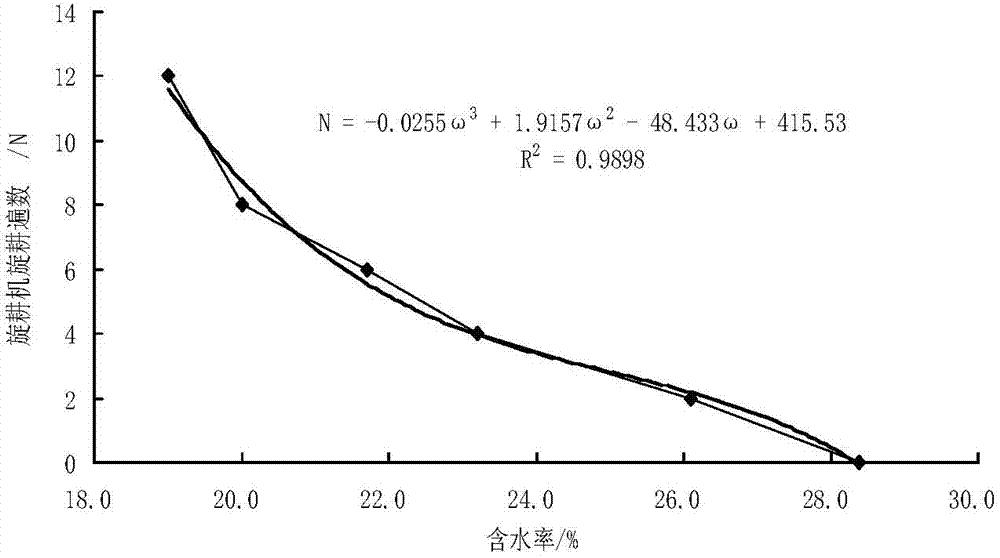

Expansive soil cement modifying and filling construction method

An expansive soil cement modifying and filling construction method includes the following steps of (1) carrying out a modified material general characteristic test; (2) carrying out excavated material moisture content prompt drop and soil mass breaking construction; (3) carrying out broken soil moisture content and soil mass graded construction quality inspection; (4) carrying out cement mixing construction; (5) carrying out modified cement soil uniformity construction quality inspection; (6) carrying out modified cement soil grinding and filling construction; (7) carrying out modified cement soil filling construction quality inspection; (8) carrying out conventional maintenance. Different breaking construction methods are selected according to the measured natural moisture content omega o for soil mass breaking construction, the requirements for soil mass grades and moisture content of cement mixing uniformity can be met, cement is uniformly mixed at first and then 3-5 percent of water is supplemented in cement mixing and construction, it is guaranteed that the moisture content is approximate to the optimum moisture content during modified cement soil grinding and filling, meanwhile the requirement for time of modified cement soil grinding and filling construction is put forward, and modified cement soil filling quality is guaranteed.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

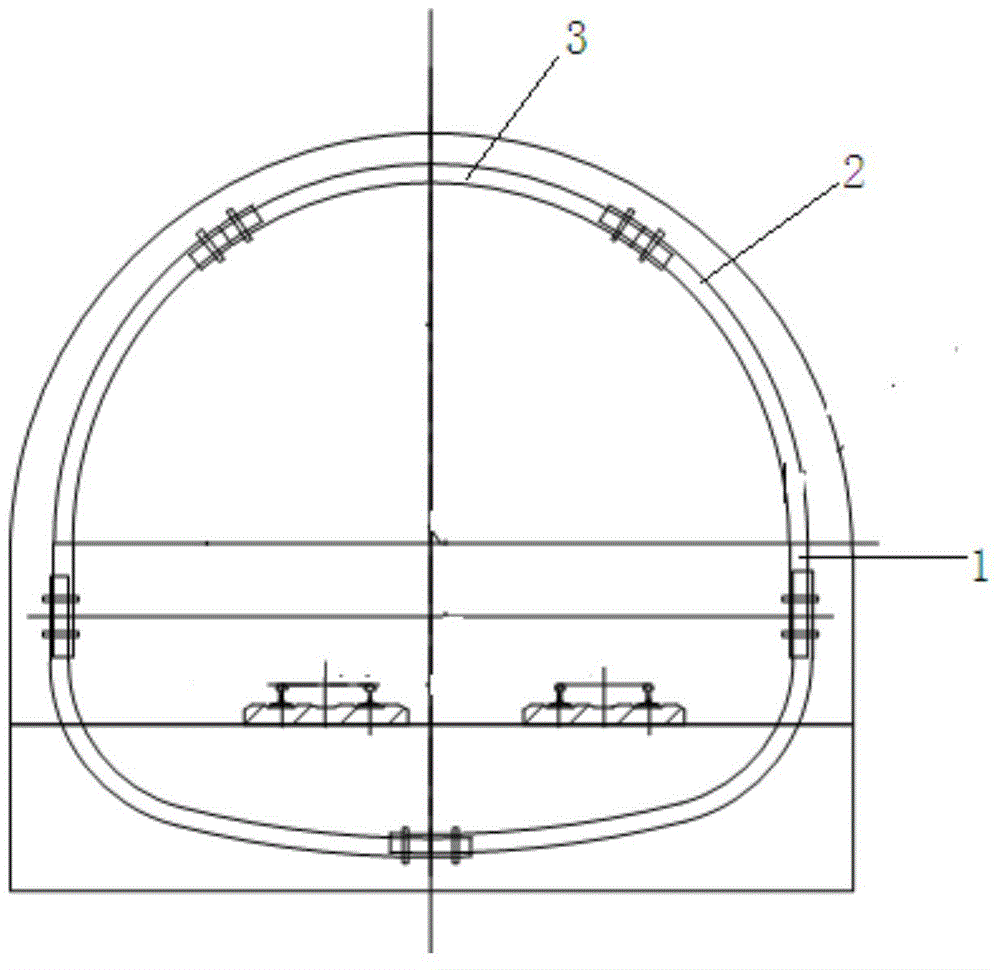

Method for filling and constructing foam concrete in coal mine soft rock largely-deformed roadway supporter

ActiveCN104653198APromote absorptionFully contactedUnderground chambersTunnel liningFoam concreteRock bolt

The invention relates to a method for filling and constructing foam concrete in a coal mine soft rock largely-deformed roadway supporter. The method comprises the following steps of paving and filling foam concrete from outside to inside along the roadway direction after an arched shed body is built completely; sequentially paving double-layer plastic nets and air tubing cloth at the outer side of the shed body; sectionally paving each unit from bottom to top, and binding the plastic nets with the shed body; arranging wood back plates and revivified anchor rods between the shed body and the plastic nets along the roadway direction so as to reinforce the shed body; filling a gap between the shed body and the roadway with wood plates or transverse braces; sealing two ends of the gap of each unit; conveying the foam concrete to the gap between the shed body and the roadway, and filling the gap with the foam concrete from bottom to top, wherein the filling height every time is 1-1.5 m; filling once every 2-3 m in the process of filling the middle top; performing guniting treatment at the inner side of the shed body from bottom to top, and paving and filling the next unit after the guniting treatment is finished. According to the method for filling and constructing the foam concrete in the coal mine soft rock largely-deformed roadway supporter, the filling operation, the double-layer plastic net and air tubing cloth operation and the guniting operation are performed alternately, so that the filling process is visualized, and the filling quality is effectively guaranteed.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

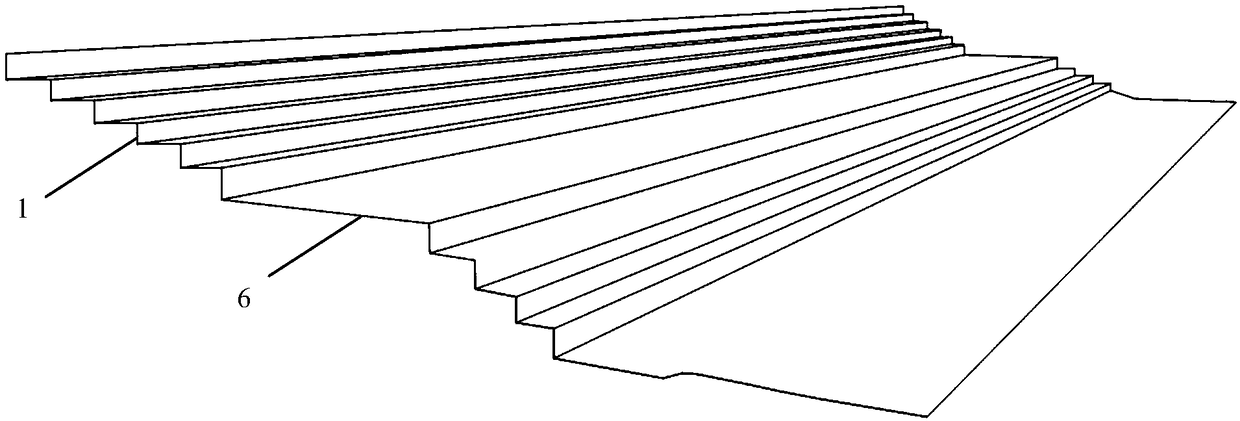

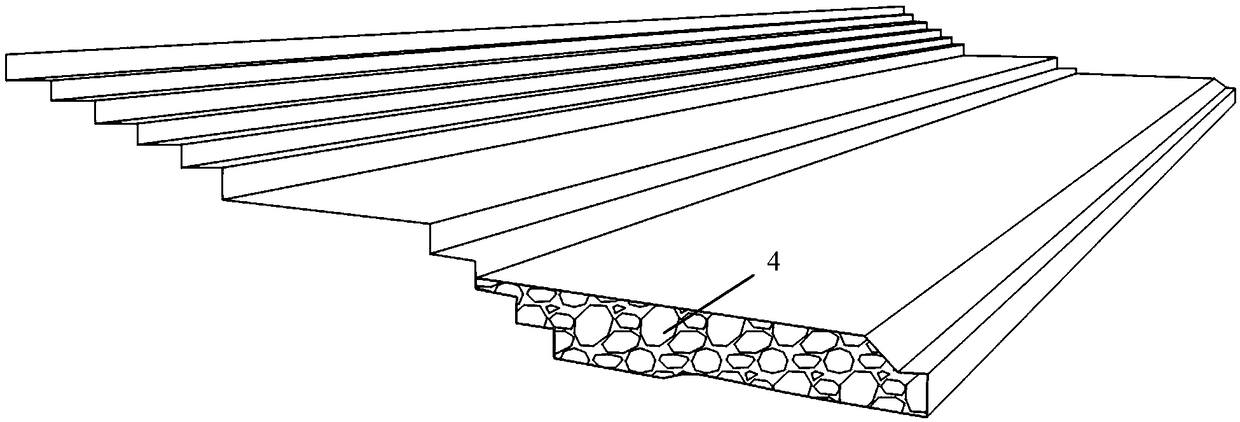

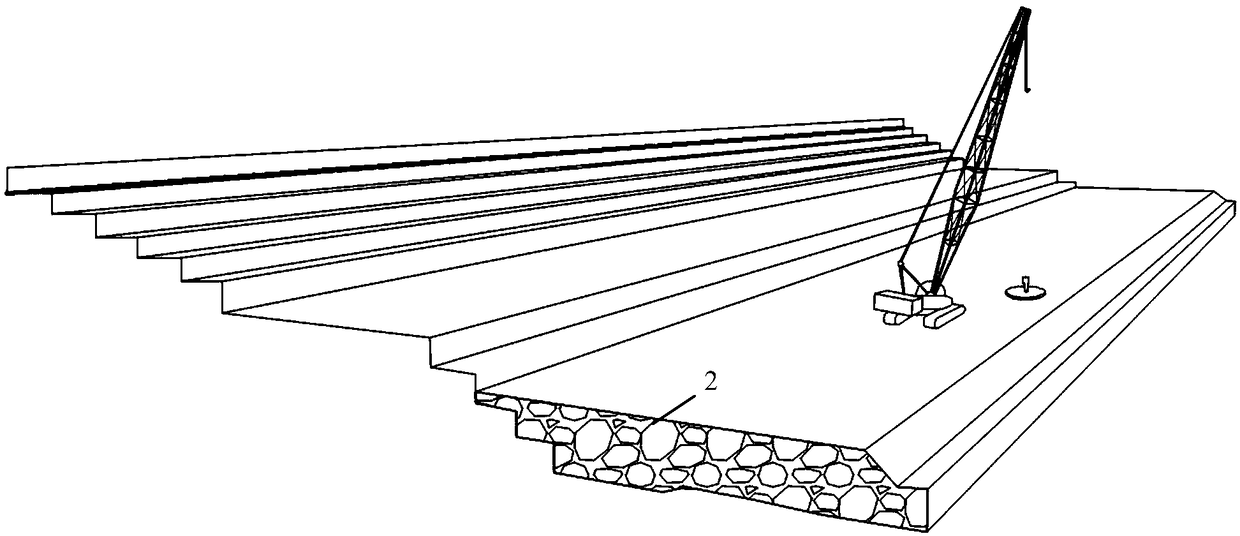

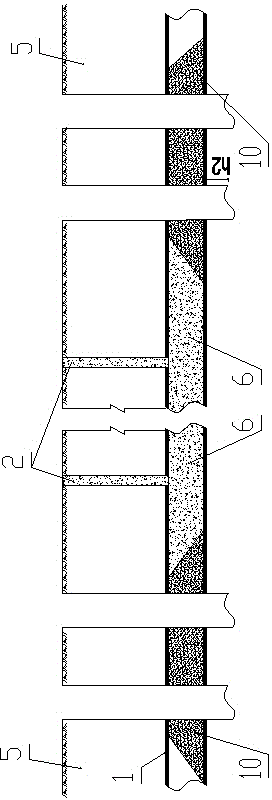

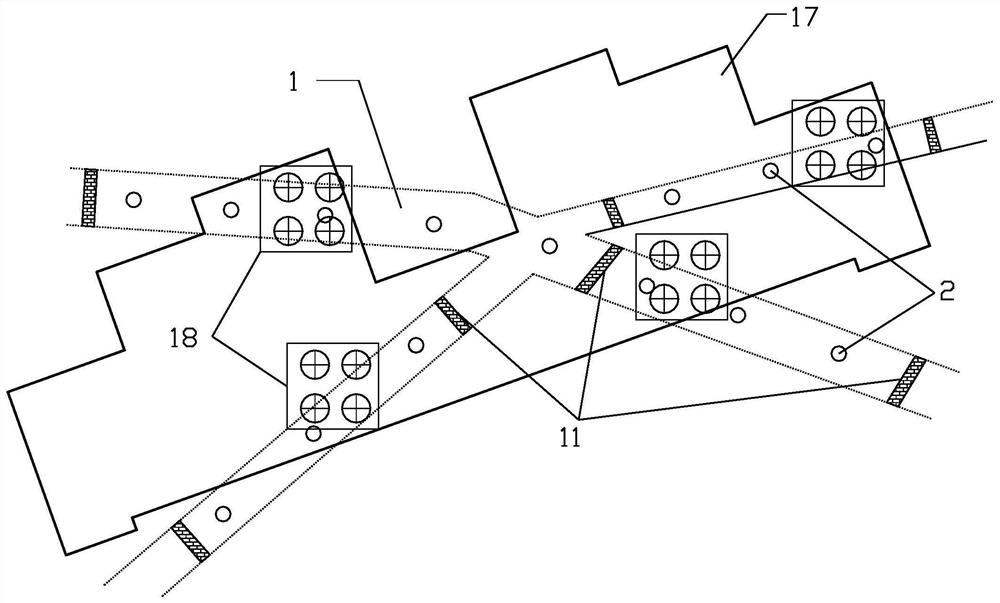

Multi-layered structure and construction method of high embankment near mountains

PendingCN109056439AGuaranteed filling qualityDelay uneven settlementRoadwaysEmbankmentsEngineeringSlope ratio

The invention relates to a multi-layered structure of a high fill roadbed alongside a mountain, comprising a mountain body, a rockfill embankment, a drainage canal, a block stone, a soil-stone mixture, a mountain platform, a platform and a cross slope, wherein the multi-layered structure comprises a mountain body, a rockfill embankment, a drainage canal, a block stone, a soil-stone mixture, a platform and a cross slope. The hill is excavated into a stepped structure, and the hill is provided with a hill platform; The subgrade of Shanao road section in the lower part of the stepped mountain body is filled with a rock-filled embankment, the thickness of the pavement layer of the rock-filled embankment is not more than 60cm, and the filling stones are blocks of different sizes of 20-30cm, andcrevices are left between the blocks; and the rock-filled embankment is filled with the rock-filled embankment. Non-woven geotextiles are laid on the top surface of the rockfill embankment; The rockfill embankment consists of graded slopes with platforms between each grade, and the slope ratio is consistent. An inverted trapezoidal drainage channel is arranged at the bottom of the slope of the rockfill embankment; Earth-rock mixture fills from the top surface of the rockfill embankment to the bottom of the roadbed in stages. The invention has the beneficial effects that the subgrade stratum is filled with a block stone, and can be used as a surface drainage water permeable layer, thus ensuring the smooth drainage of the subgrade after the subgrade is filled, and reducing the influence ofsurface water on the stability of the subgrade during the operation period.

Owner:杭州市交通规划设计研究院有限公司

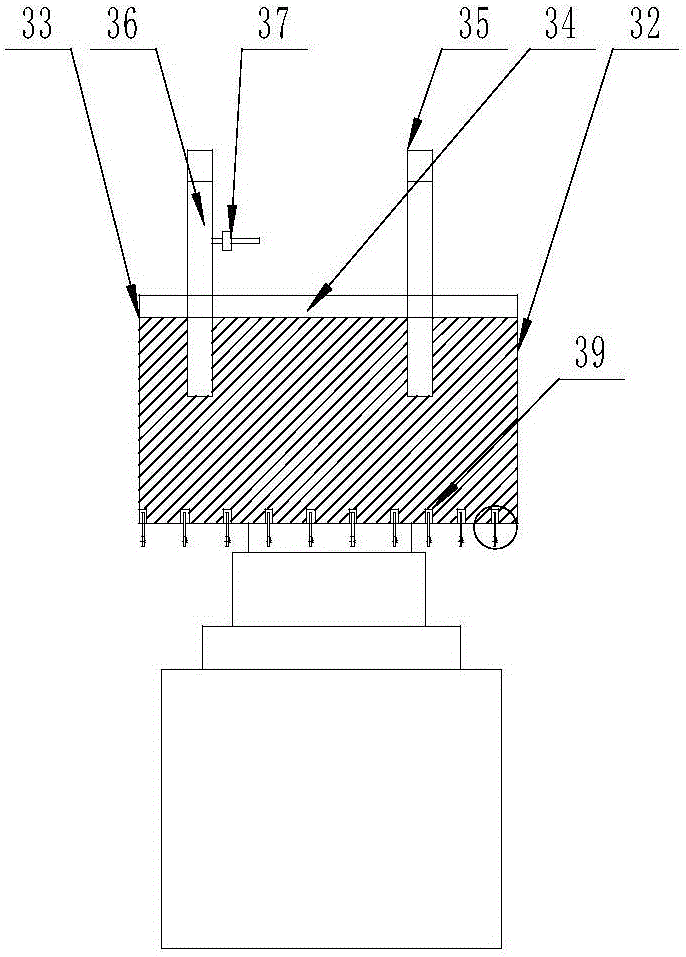

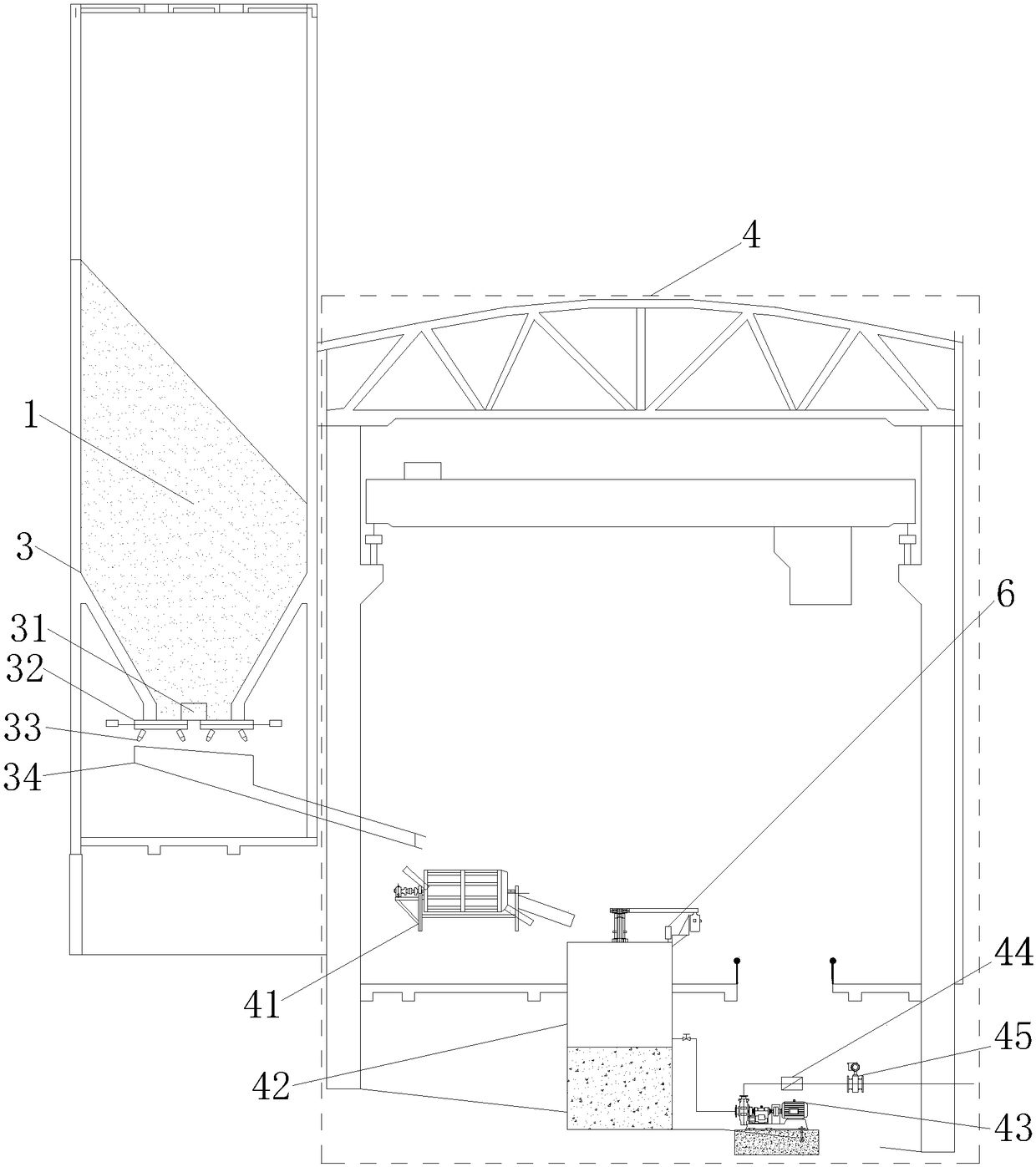

Tailing slurry filling system and technology

PendingCN108547659AWon't be lostRapid sedimentation concentrationMaterial fill-upHigh concentrationSlurry

The invention provides a tailing slurry filling system and technology, and belongs to the technical field of tailing treatment. The tailing slurry filling system utilizes a deep-cone thickener to perform thickening and dehydration on low-concentration tailing slurry, the low-concentration tailing slurry can quickly settled and thickened after being pumped to the thickener, fine-fraction tailing cannot be lost, the upper overflow water is clearer, and the overflow clear water can be transferred to a production pool for storage; and tailing chambers serve as high-concentration slurry storage andtailing placement devices and are specially responsible for the storage, slurry making and tailing placement of the tailing. The tailing slurry filling system and technology have the advantages thatrespective merits of the deep-cone thickener and tailing chamber are fully utilized, tailing slurry treatment is carried out, so that the loss of the tailing is reduced, the utilization rate is improved, the filling quality is guaranteed, and the reliability of the filling system is improved; the tailing slurry filling technology can achieve the 24-hour tailing intake and 24-hour tailing supply optimal working system of the deep-cone thickener, alternative tailing intake and alternative filling of the two tailing chambers are carried out, thereby improving the working efficiency.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

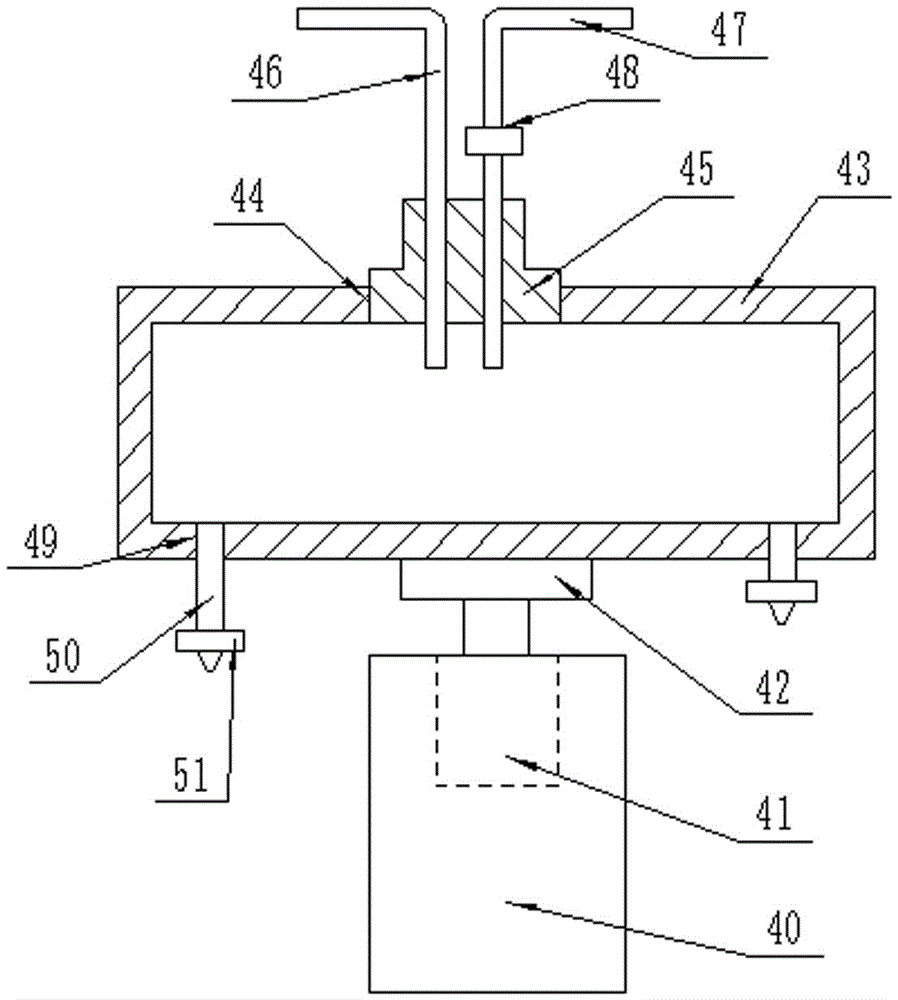

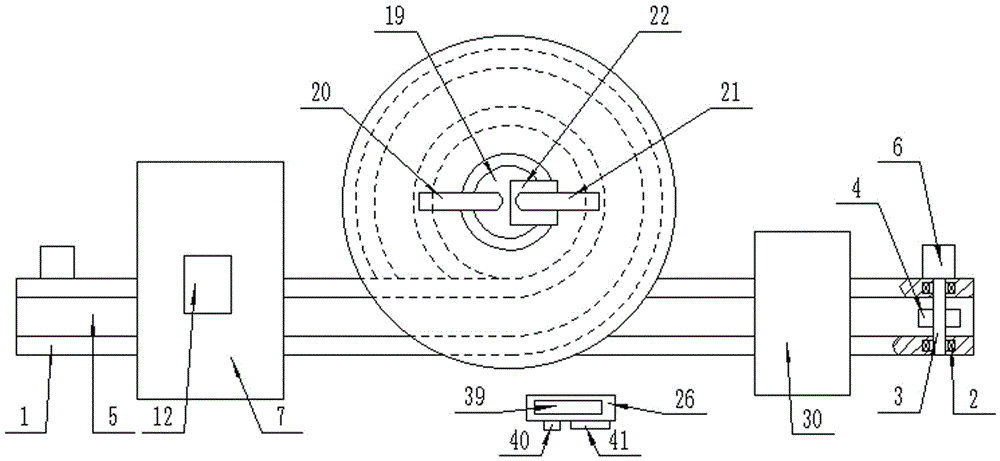

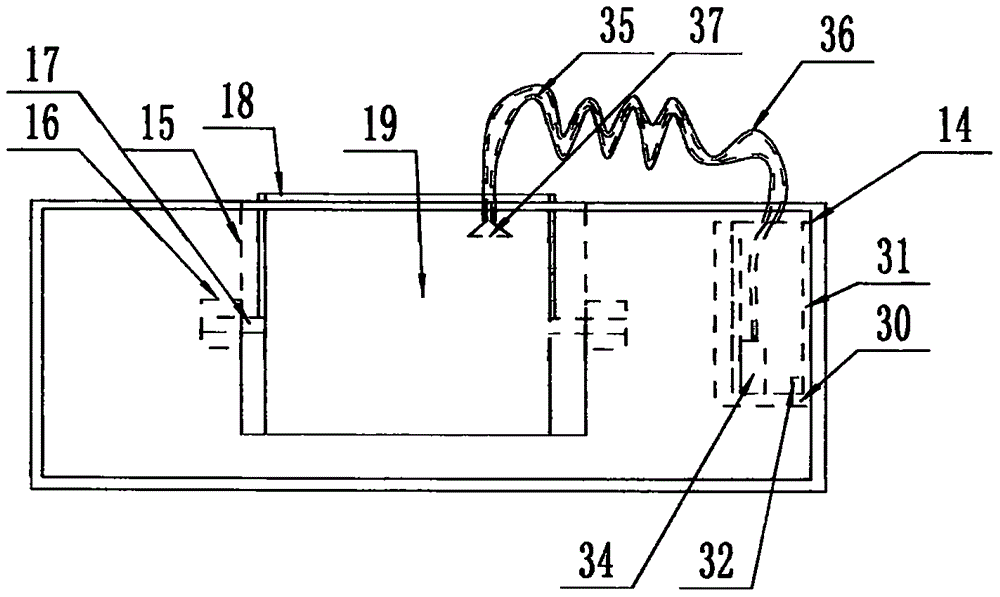

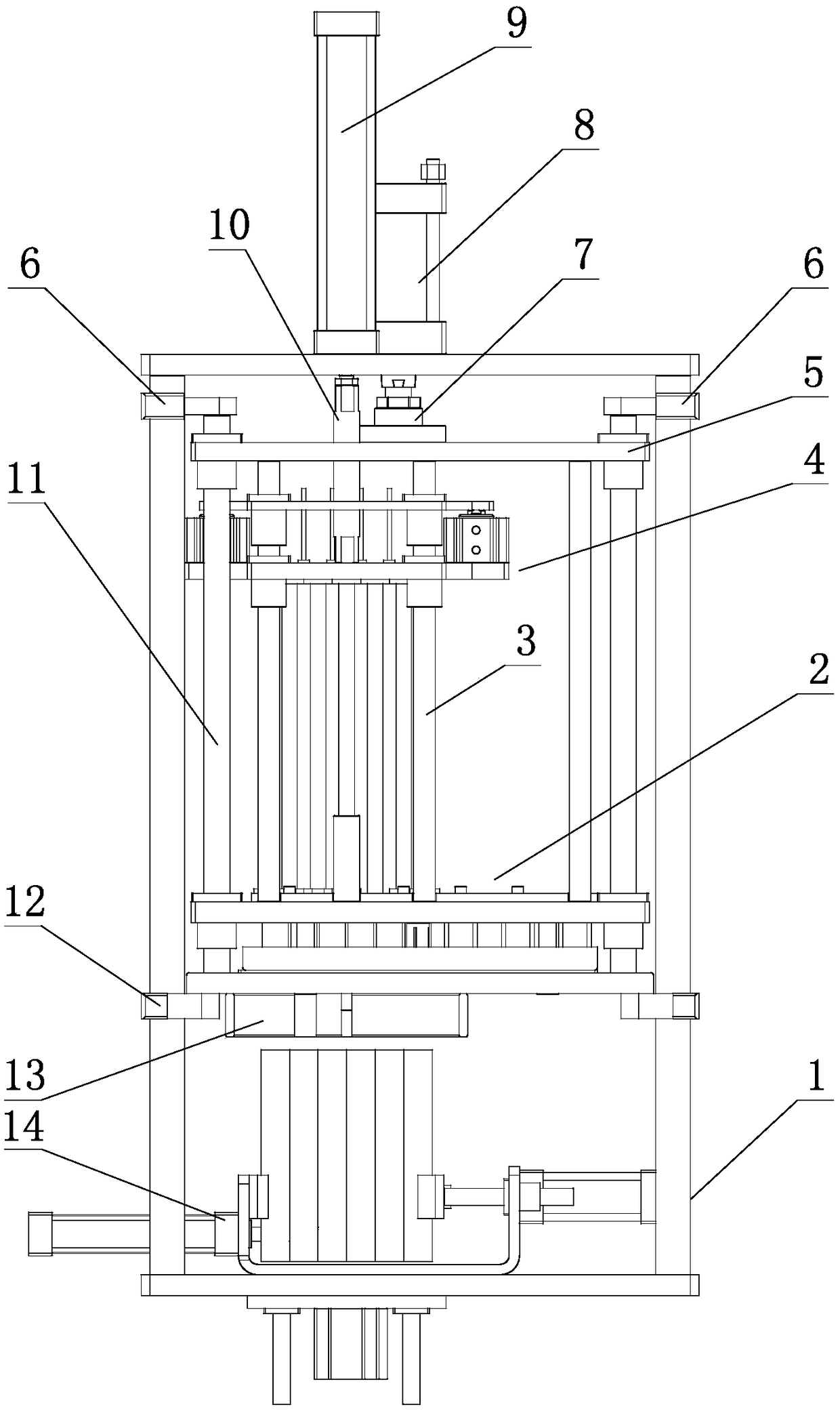

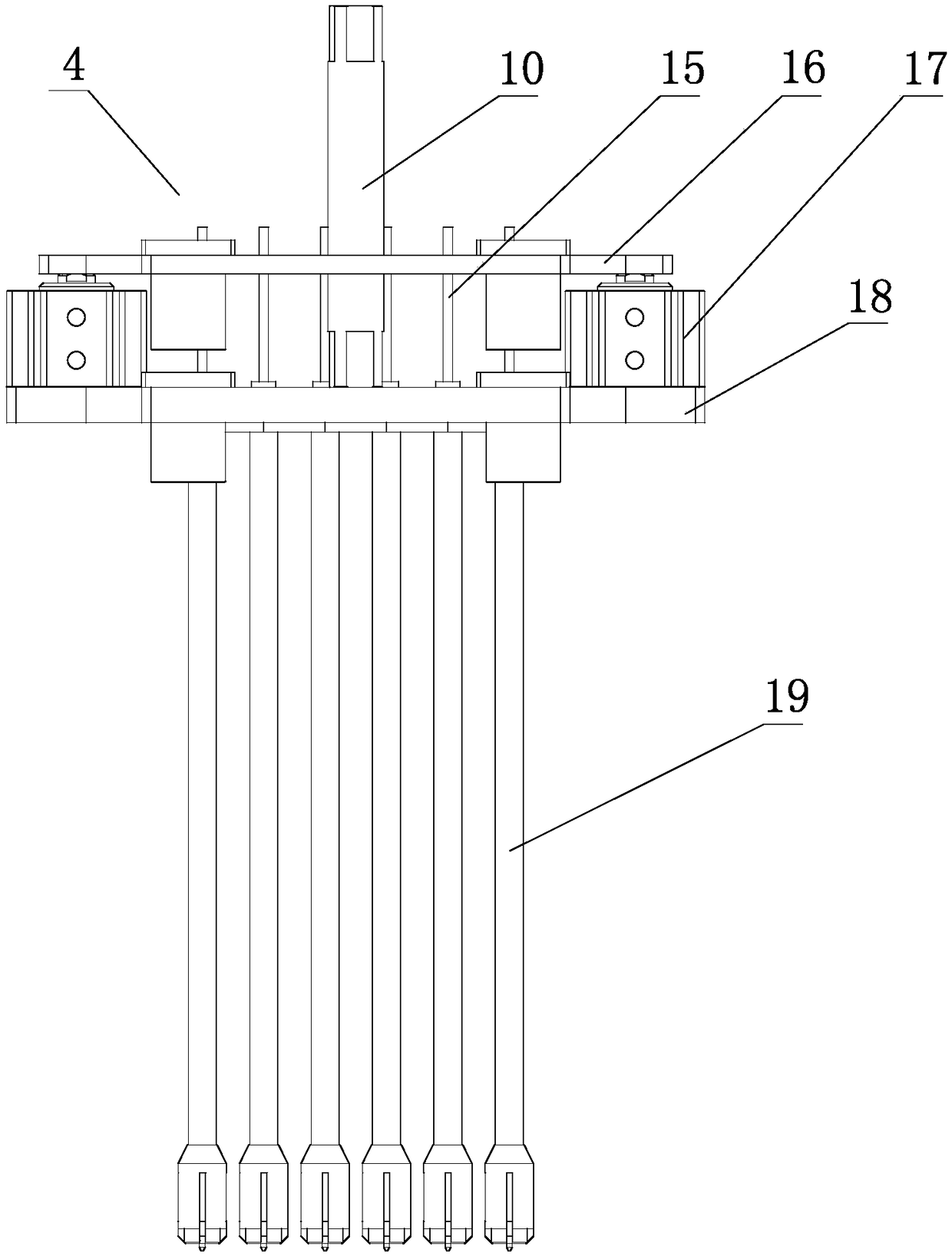

Novel high-temperature heating disinfecting anti-bacteria pharmacy production line

InactiveCN105584975AShorten the timeGuaranteed filling qualitySynchronising machinesLiquid bottlingProduction linePharmacy

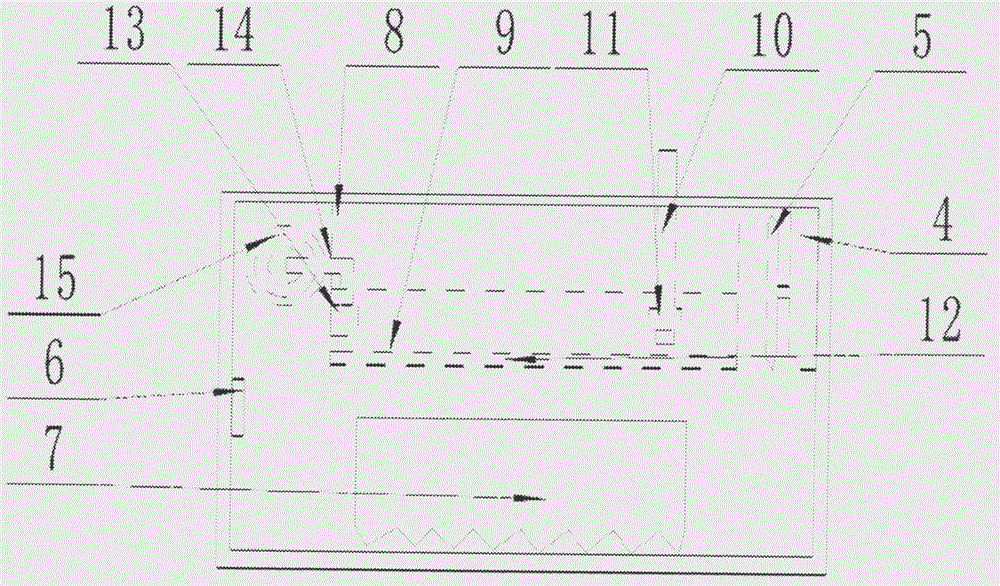

The invention discloses a novel high-temperature heating disinfecting anti-bacteria pharmacy production line. The novel high-temperature heating disinfecting anti-bacteria pharmacy production line comprises an annular support which is fixedly installed on the ground, and a chained annular conveying belt mechanism is arranged in the annular support and is jointly formed by a plurality of bearings located on the inner side wall of the annular support, rotating shafts inserted into the bearings, gears fixedly installed on the rotating shafts in a sleeving manner, annular wide type conveying chains meshed with all gears and two driving motors fixedly installed at the two ends of the annular support and fixedly connected with the rotating shafts at the two ends; a bottle cover hot pressing sealing mechanism is arranged at the other end of the chained annular conveying belt mechanism; and a control box is arranged on the ground. The novel high-temperature heating disinfecting anti-bacteria pharmacy production line has the beneficial effects of being simple in structure and high in practicability.

Owner:廖淑梅

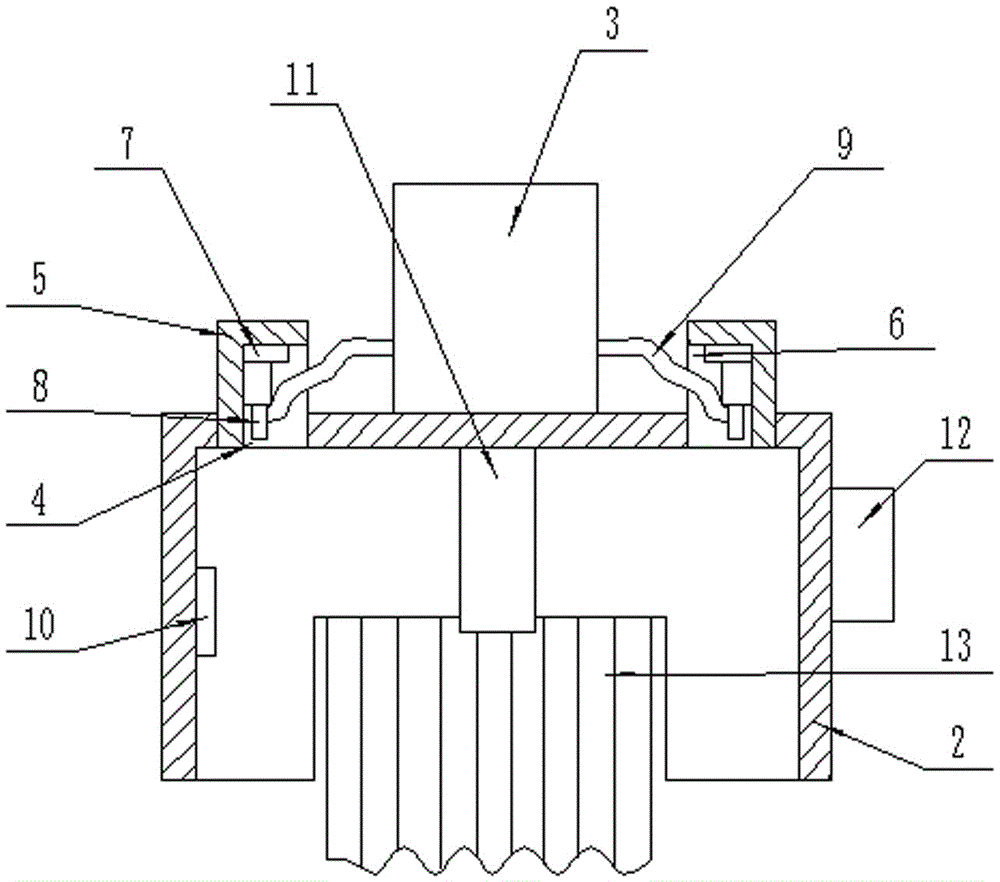

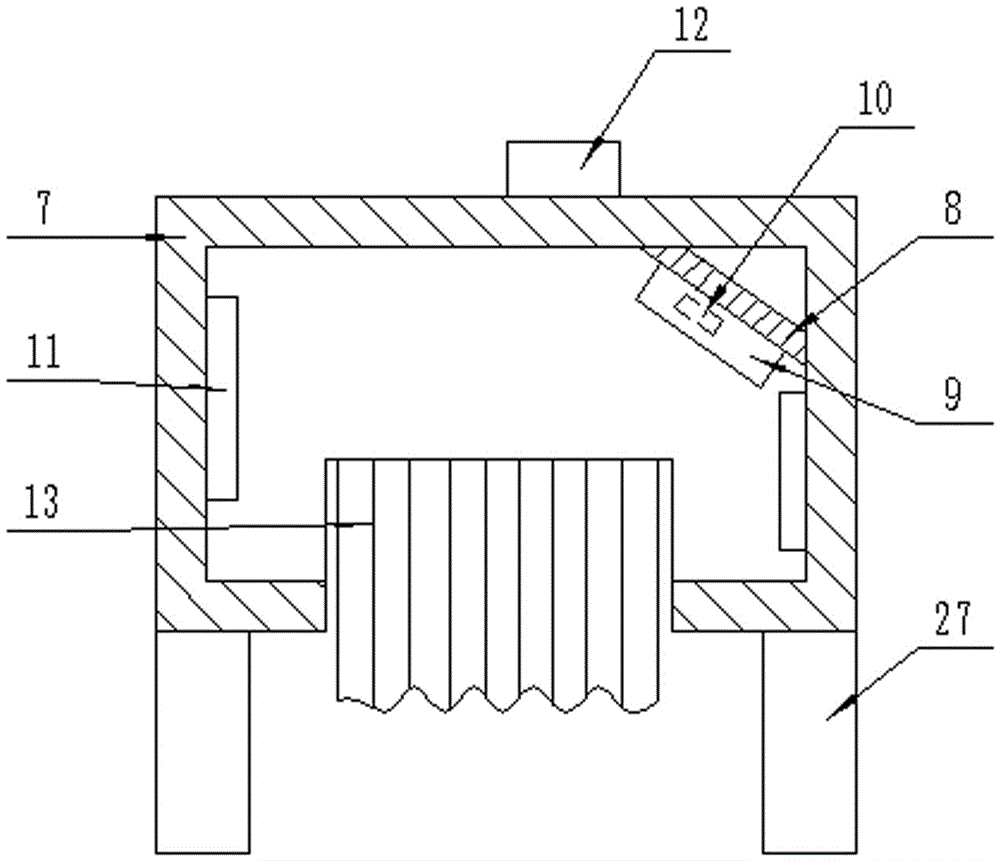

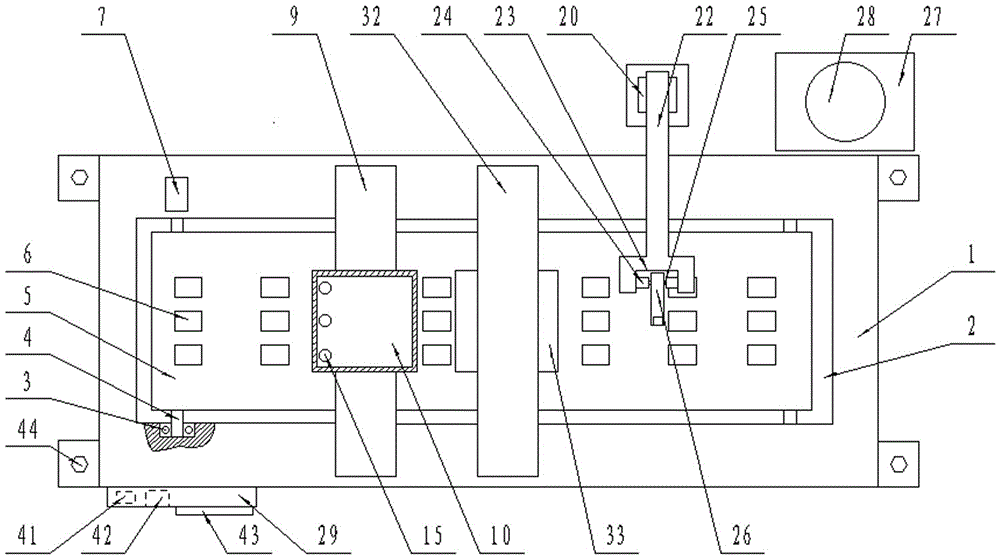

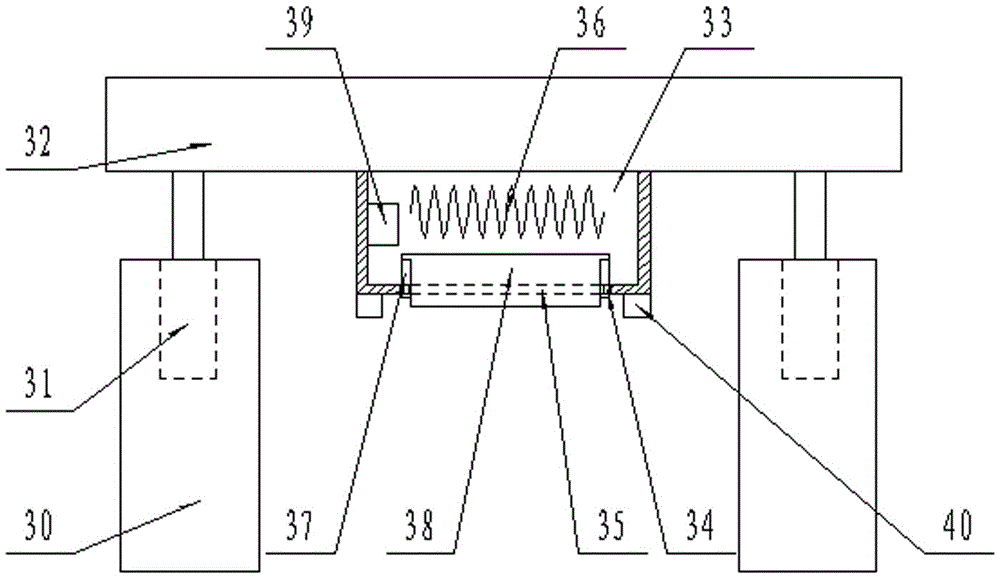

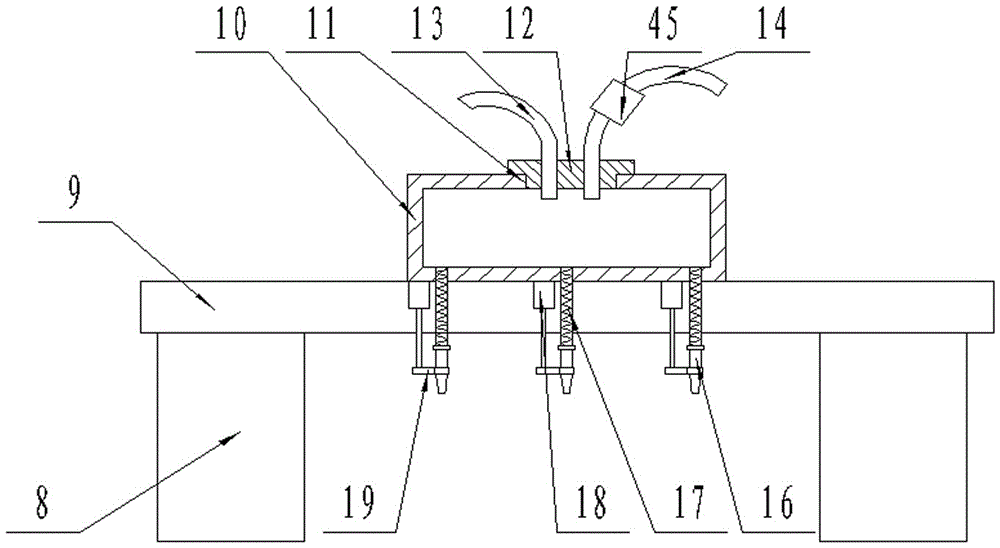

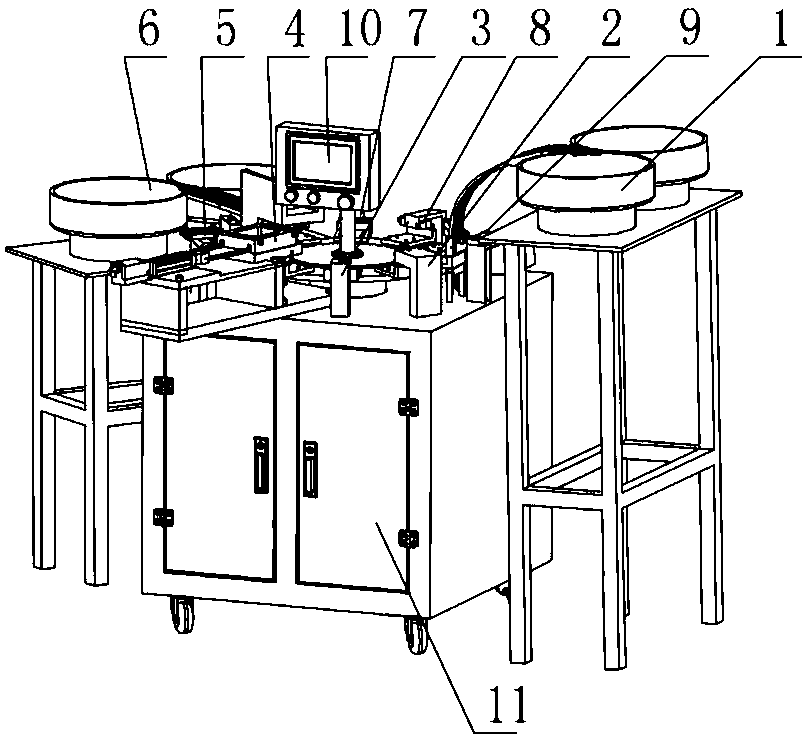

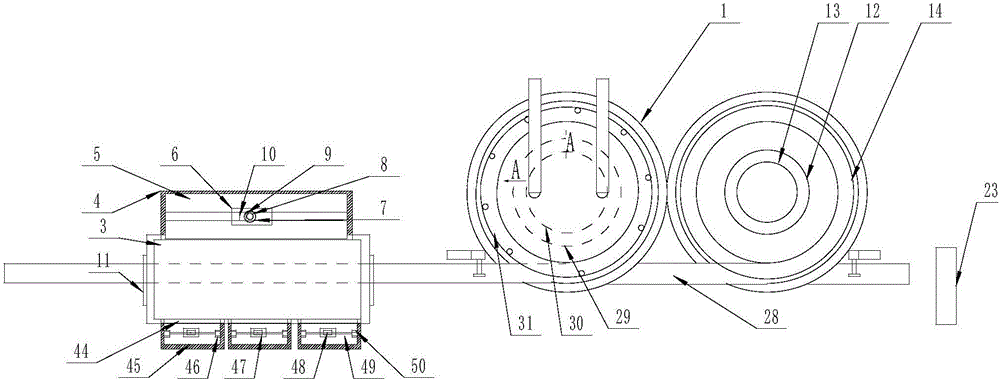

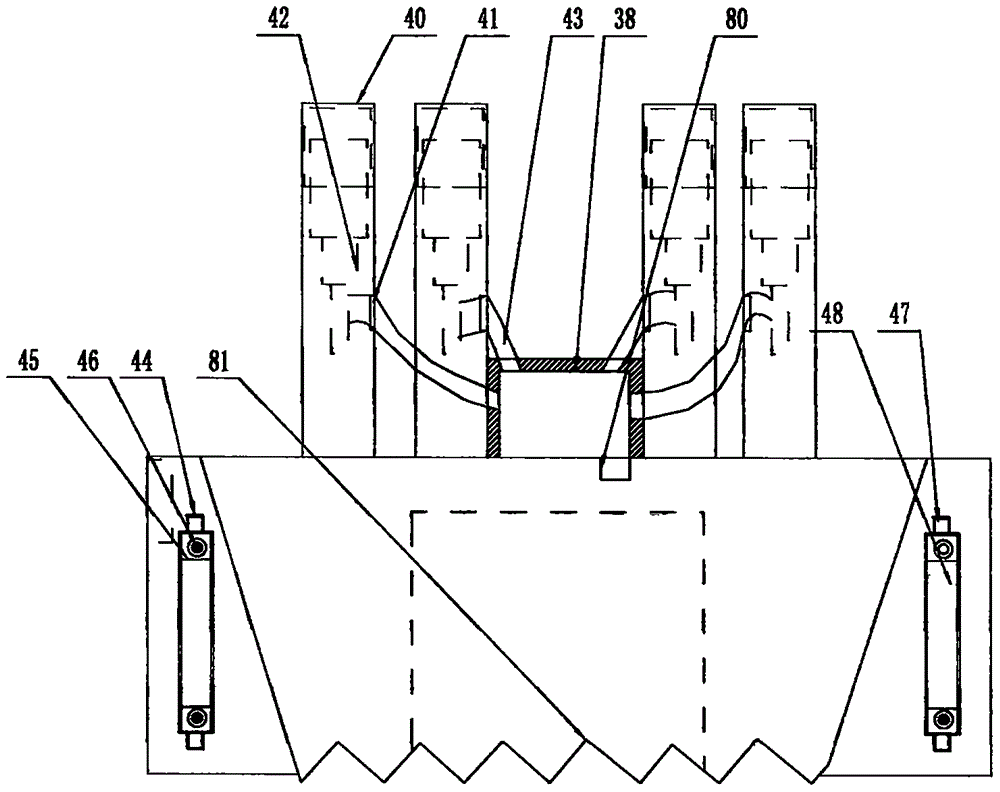

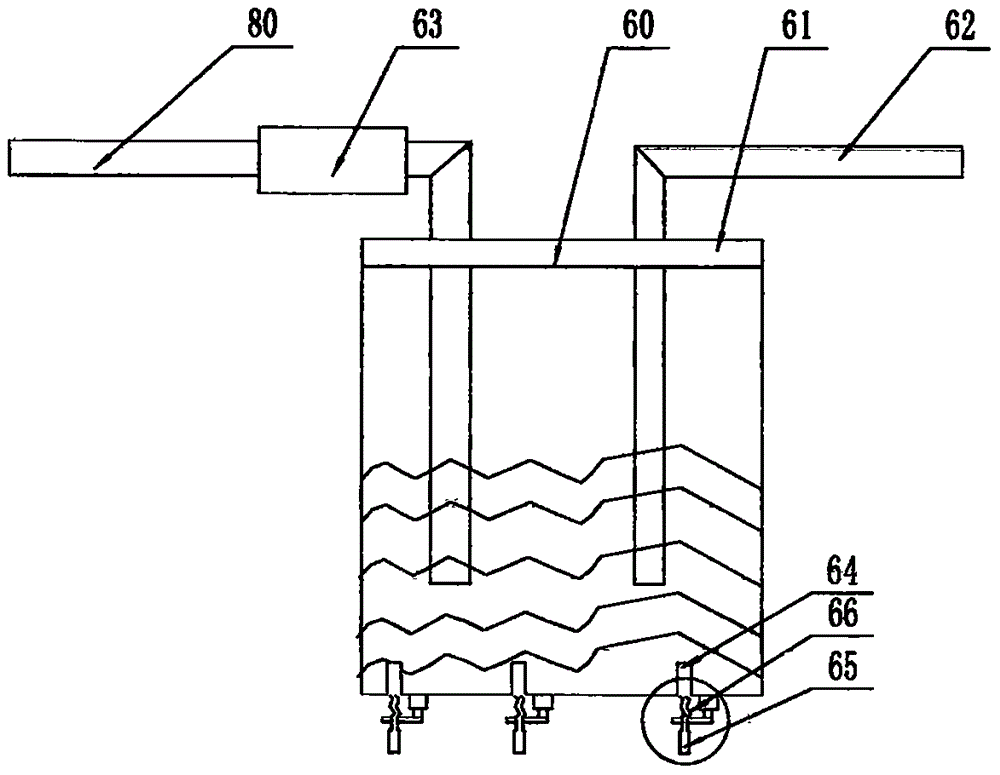

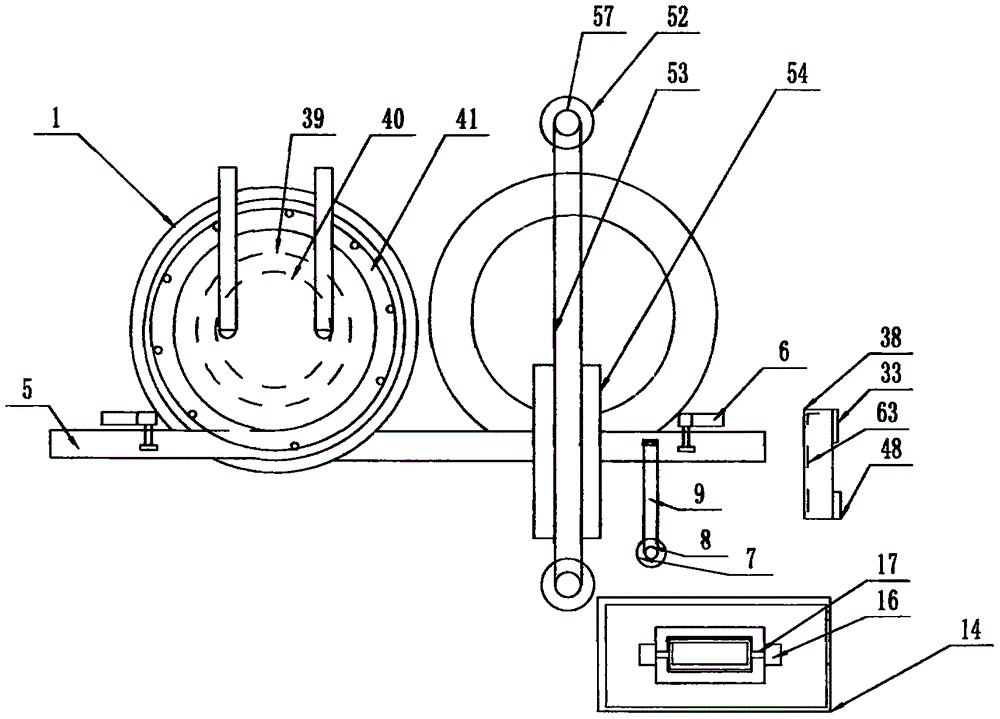

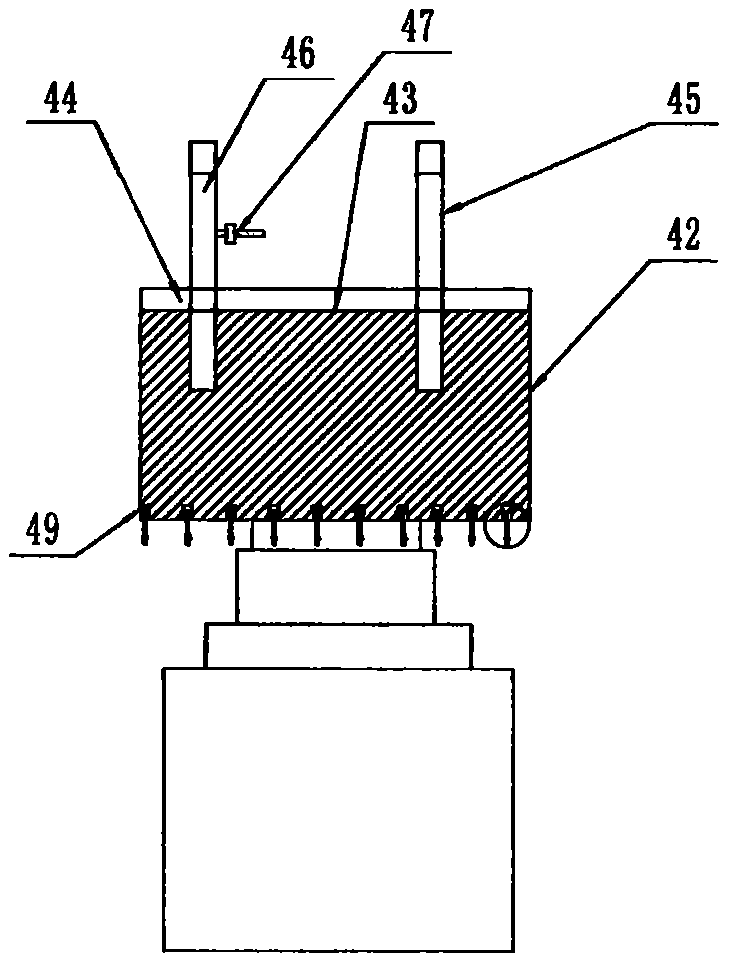

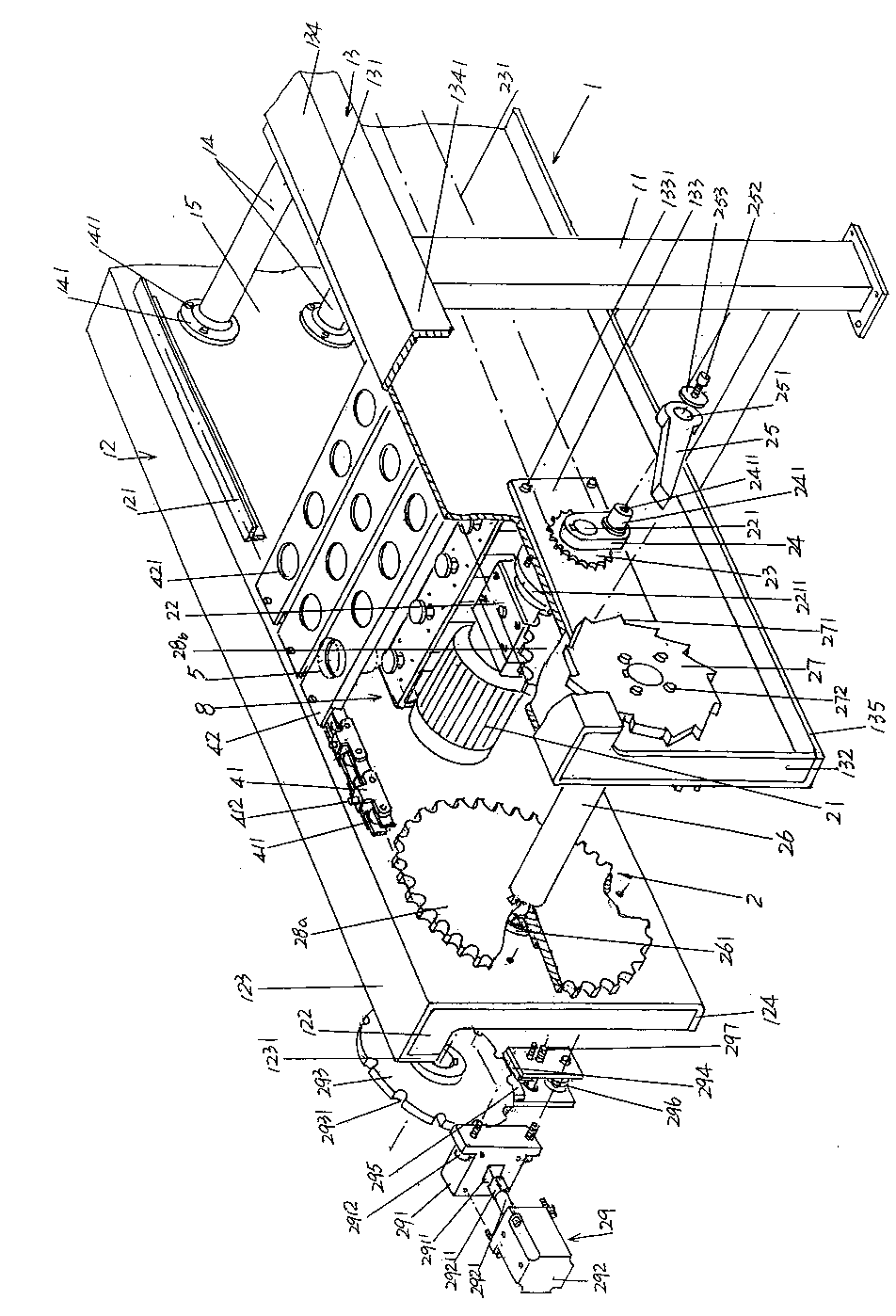

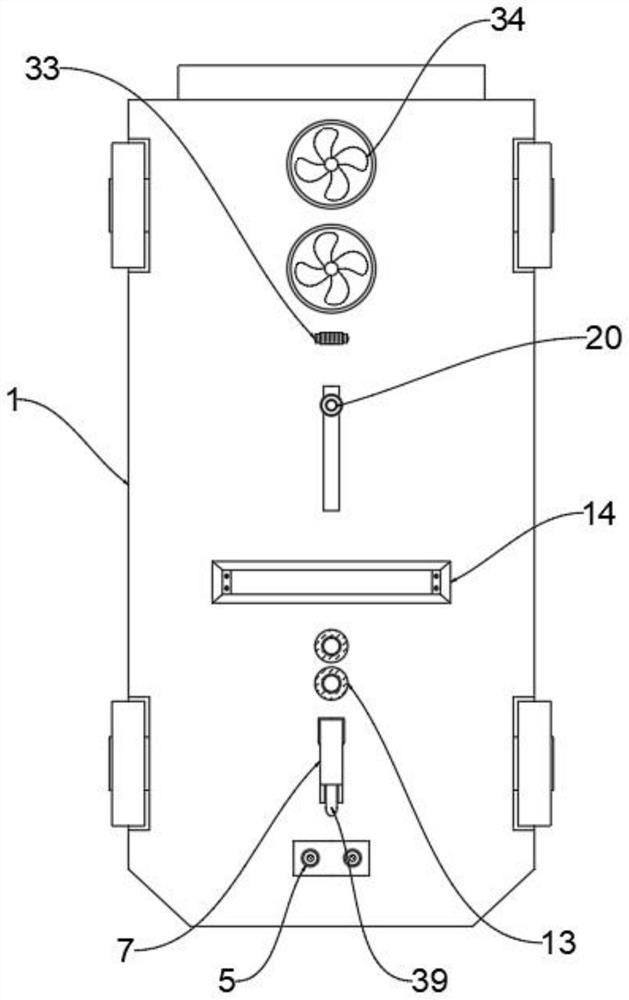

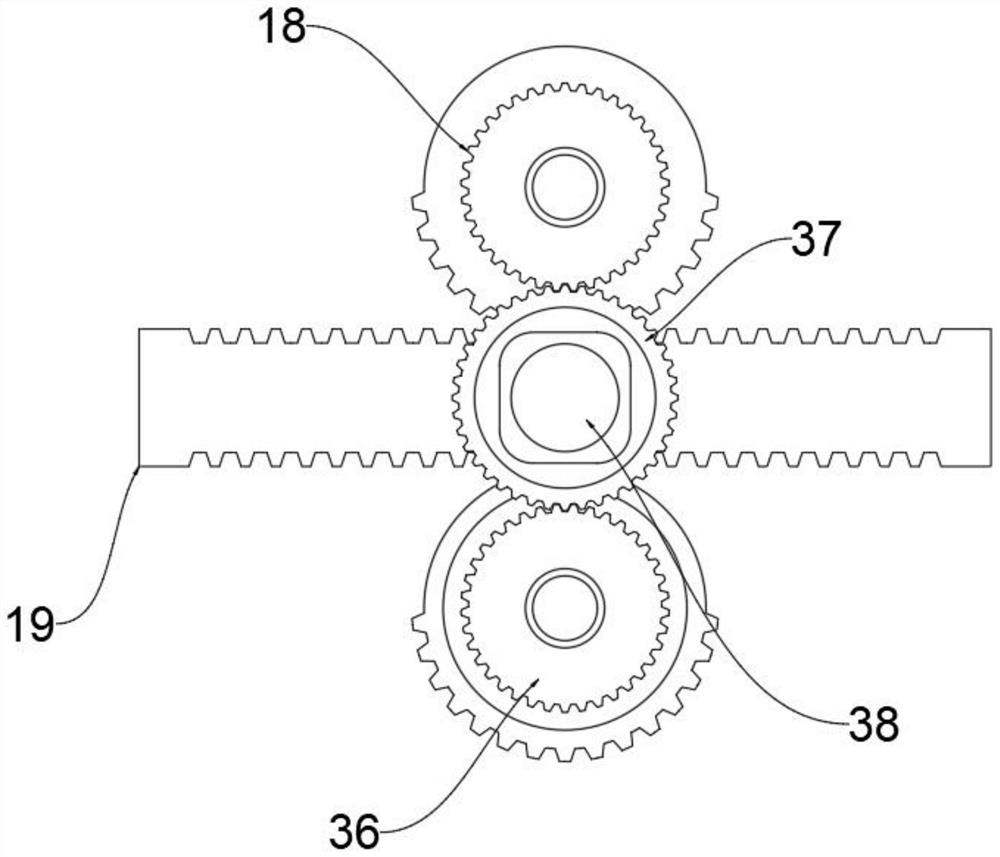

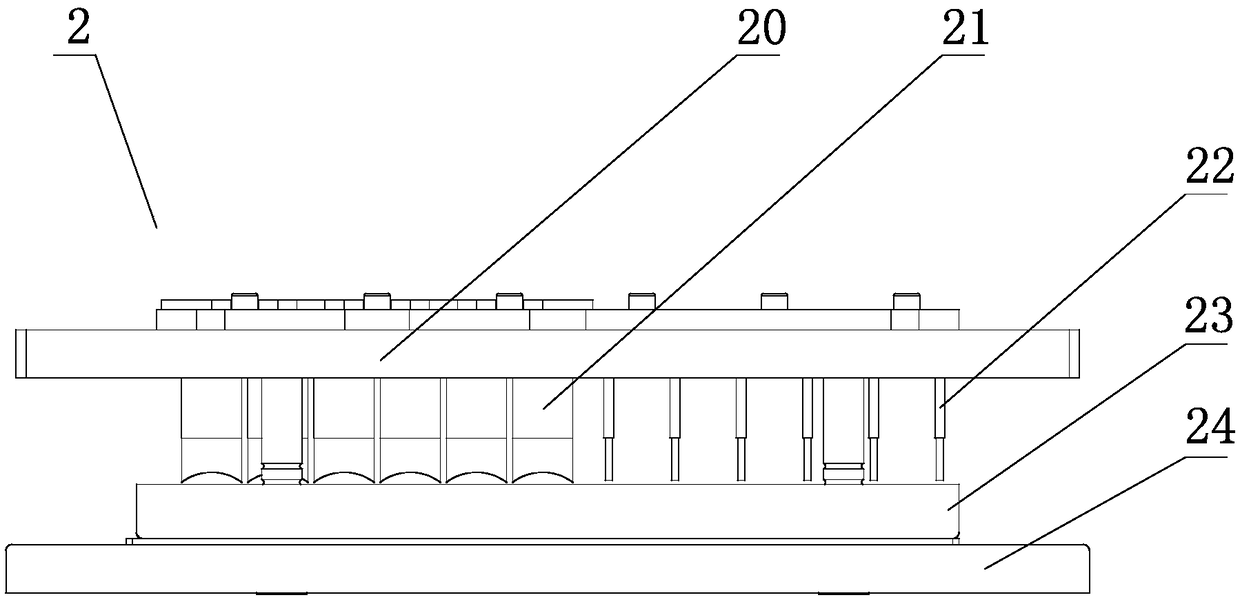

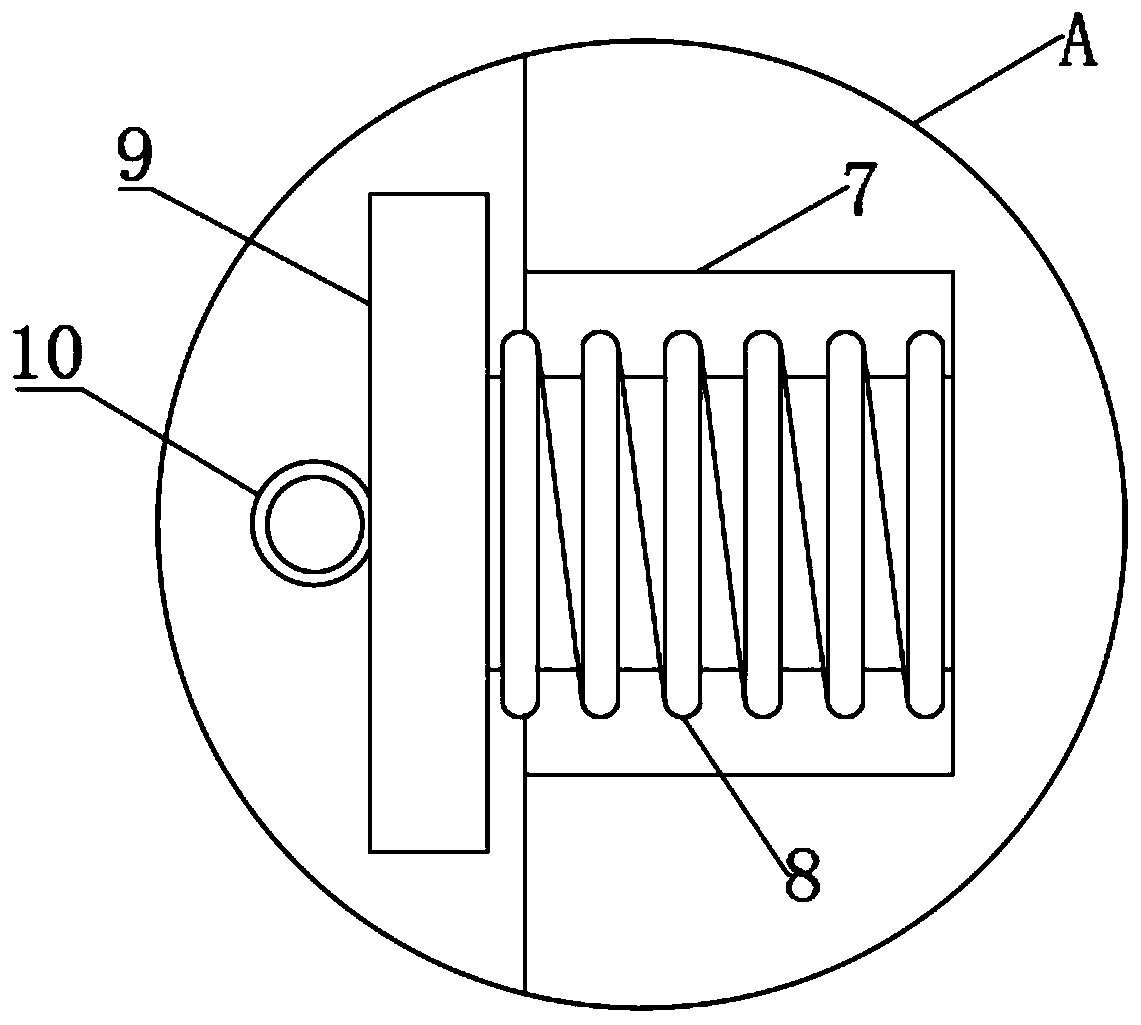

Novel drug filling and sampling production machine

InactiveCN105600719AGuaranteed filling qualityCompact structureFilling using counterpressureBottle-handling machinesElectric machineryBottle cap

The invention discloses a novel drug filling and sampling production machine which comprises a base. The upper surface of the base is provided with a through groove in the length direction of the base, and a conveying mechanism is arranged in the through groove and composed of two sets of bearings which are located on the two sides inside the through groove, two rotation shafts which are inserted into one corresponding set of the bearings, a conveyor belt arranged on the rotation shafts in a sleeving mode, flexible LED luminous bodies embedded into the surface of the conveyor belt and a motor located in the base, wherein the rotating end of the motor is connected with one of the rotation shafts; the upper surface of the base is sequentially provided with a liquid drug filling mechanism, a bottle cap hot-press sealing mechanism and a sampling and detecting device in the length direction of the base, and the side surface of the base is provided with control box which is electrically connected with the conveying mechanism, the liquid drug filling mechanism, the bottle cap hot-press sealing mechanism and the sampling and detecting device. The novel drug filling and sampling production machine has the advantages of being simple in structure and high in practicability.

Owner:张丽凤

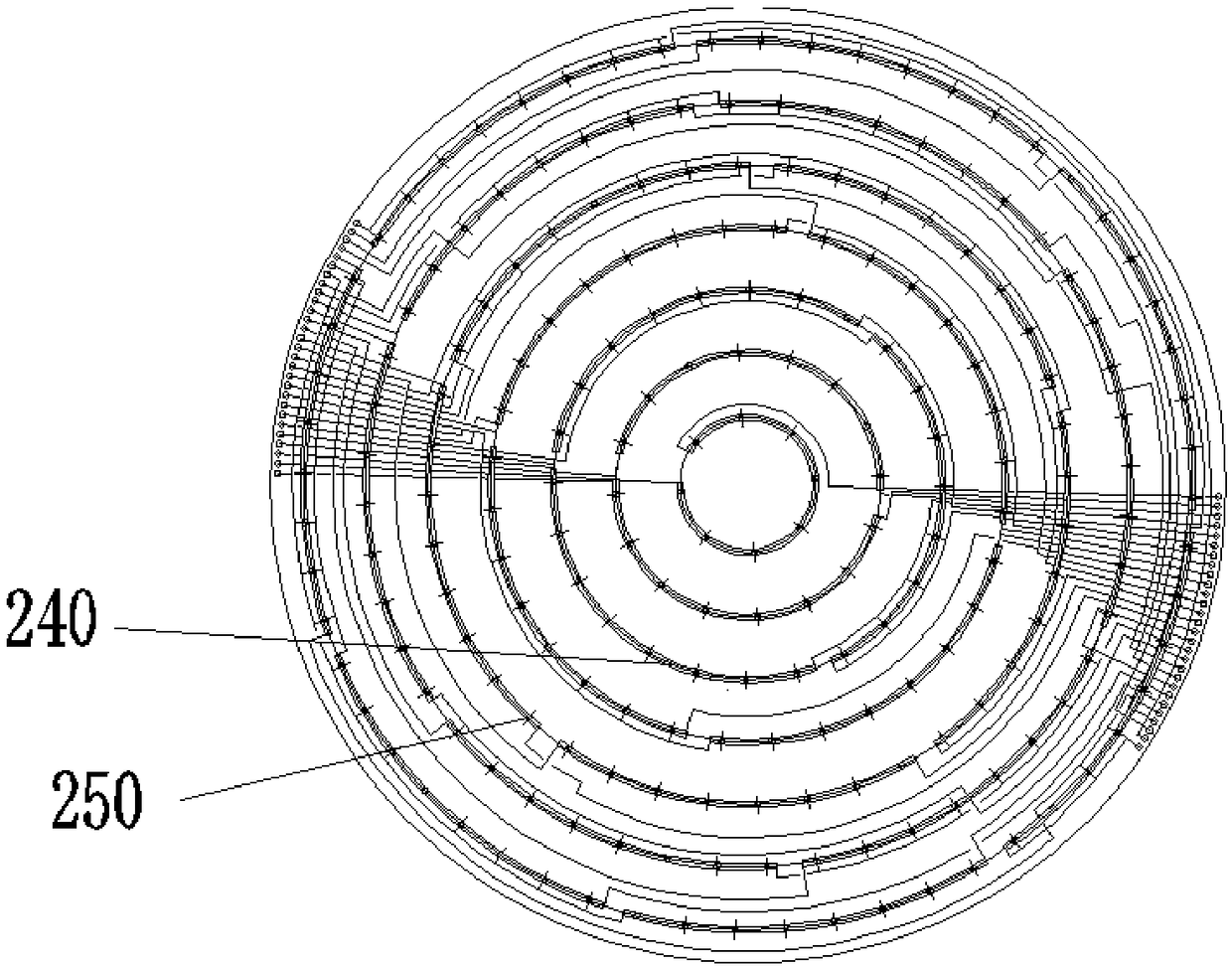

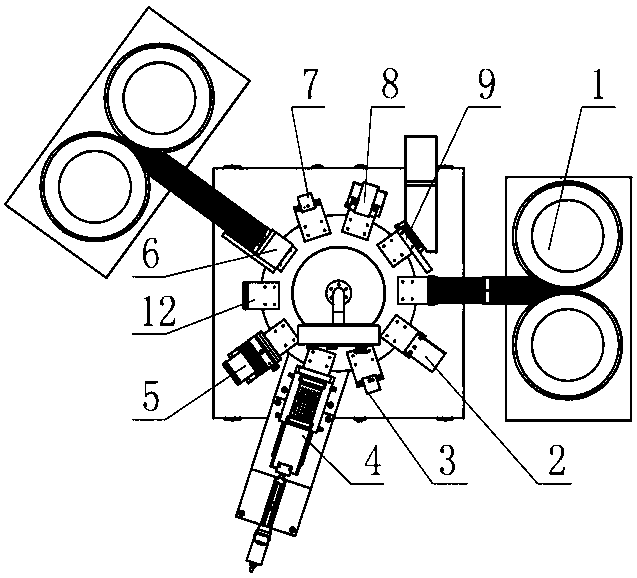

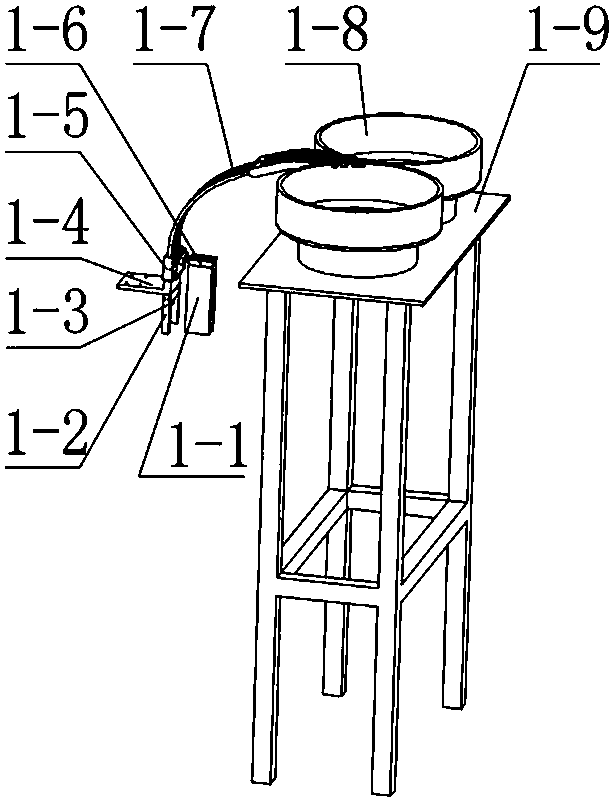

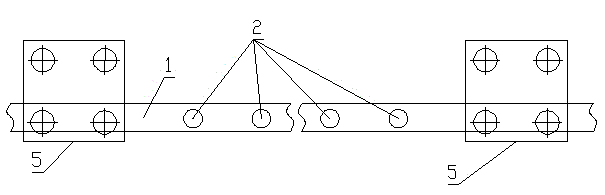

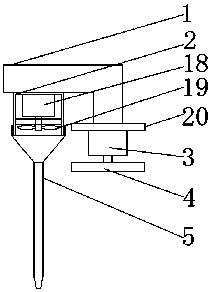

Full-automatic disc type pill filling machine

PendingCN109927978ACompact structureExtended service lifePackaging automatic controlIndividual articlesEngineeringRotating disc

The invention discloses a full-automatic disc type pill filling machine, and relates to the field of automatic filling / packaging machinery. The full-automatic disc type pill filling machine comprisesa workbench, wherein a circular rotating disc is arranged on the workbench, a bottle arranging mechanism, a dust removing and bottle arranging mechanism, a bottle checking and static removing mechanism, a pill filling mechanism, a pill supplementing mechanism, a cap arranging and capping mechanism, a cap detecting mechanism, a waste removing mechanism and a finished product collecting mechanism are sequentially distributed on the periphery of the circular rotating disc, the circular rotating disc is driven by the transmission device to sequentially finish corresponding procedures, and finally,filled medicine bottles are output through the finished product collecting mechanism. According to the full-automatic disc type pill filling machine, the circular rotating disc is used for replacinga traditional conveying belt structure, a plurality of bottle fixing seats are fixedly installed on the circular rotating disc, the medicine bottles pass through the bottle arranging mechanism and enter the bottle fixing seats, the bottle fixing seats rotate along with the circular rotating disc to reach a dust removing and bottling arranging station, a bottle checking and static removing mechanism, a pill filling station, a pill supplementing station, a cap arranging and capping station, a cap checking station, a waste removing station and a finished product collecting station in sequence, and the advantages of being compact in structure, accurate in positioning, long in service life, low in maintenance cost and the like are achieved.

Owner:成都伟爻科技有限公司

Construction technology for foam concrete treatment of abandoned sewage pipeline at urban overpass foundation

InactiveCN104452793AGuaranteed filling qualityEliminate potential safety hazardsSoil preservationOpen waterFoam concrete

The invention discloses a construction technology for foam concrete treatment of an abandoned sewage pipeline at an urban overpass foundation. The construction technology comprises the following steps that first, measuring and paying off are conducted for pile foundation construction, and dry drilling is carried out to the top of the abandoned sewage pipeline to be treated; second, the abandoned sewage pipeline is removed; third, a percussion drill is used for refilling cohesive soil layer by layer, the cohesive soil is compacted into the abandoned sewage pipeline, and after extrusion cannot be conducted, filling compaction is conducted continuously to be the position above the pipeline top; fourth, dado mud is matched with the drill for conducting pile foundation drilling construction; fifth, grouting is performed; before the fifth step, a plurality of holes are directly drilled from the current situation ground to the abandoned sewage pipeline to be treated along the abandoned sewage pipeline, so that injection holes are formed. By the adoption of the construction technology, the filling quality of the pipeline can be guaranteed, potential safety hazards are eliminated, the filling amount of grouting fluid is reduced, the degree of fullness of the abandoned sewage pipeline is improved, the filling compaction of the abandoned sewage pipeline is guaranteed, and open water at the crossed position of the abandoned sewage pipeline and the pile foundation is avoided.

Owner:ZHENGZHOU MUNICIPAL ENG CORP

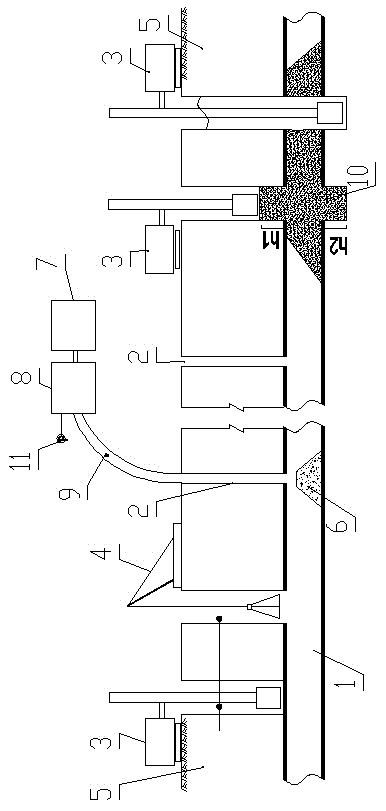

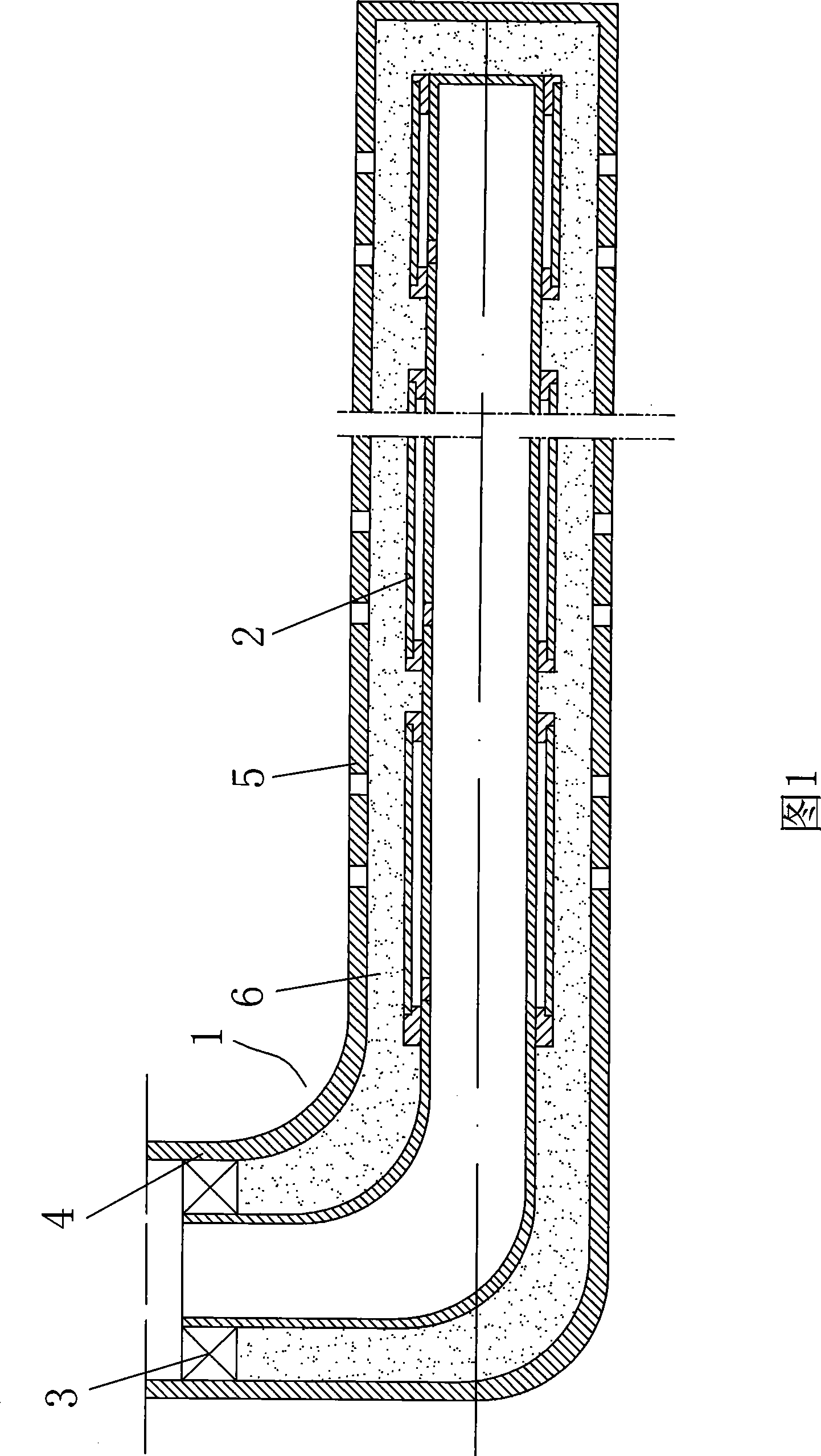

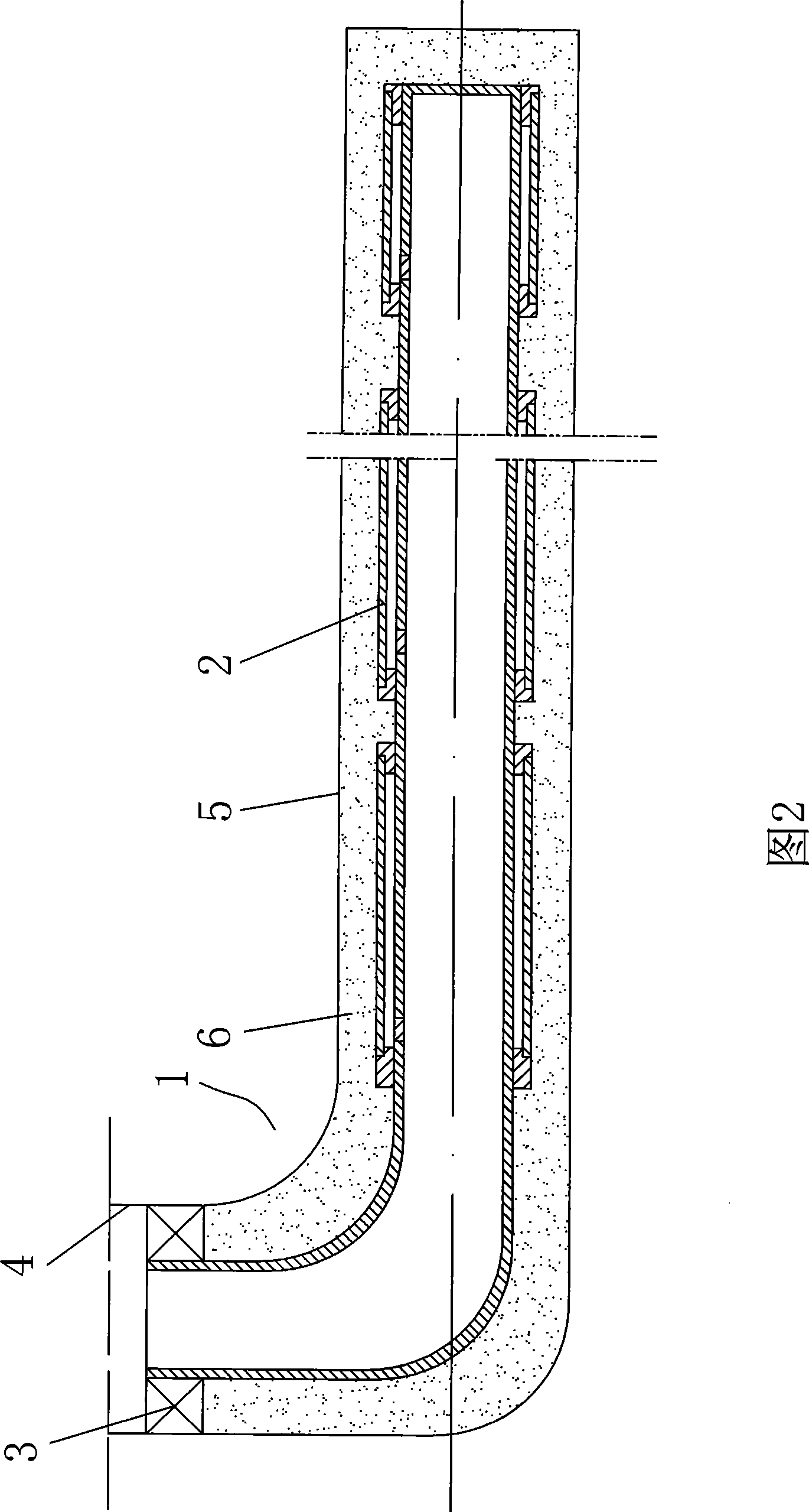

Slide ultraviolet sterilization pharmacy production line

InactiveCN105668494AGuaranteed filling qualityImprove balanceBottle-handling machinesPharmacyProduction line

The invention discloses a slide ultraviolet sterilization pharmacy production line. The slide ultraviolet sterilization pharmacy production line comprises annular supports, the dual annular supports are fixedly installed on the ground, and dual chain type annular conveying belt mechanisms are arranged in the dual annular supports; and a slide infrared sterilization mechanism is arranged at the front end of each annular support, a control box is arranged on the ground, and the control box is electrically connected with the dual chain type annular conveying belt mechanisms, the slide infrared sterilization mechanisms, a multifunctional medicine liquid filling mechanism and an annular bottom cover hot pressing sealing mechanism. The slide ultraviolet sterilization pharmacy production line has the beneficial effects that the structure is simple, and the practicability is high.

Owner:万潇熠

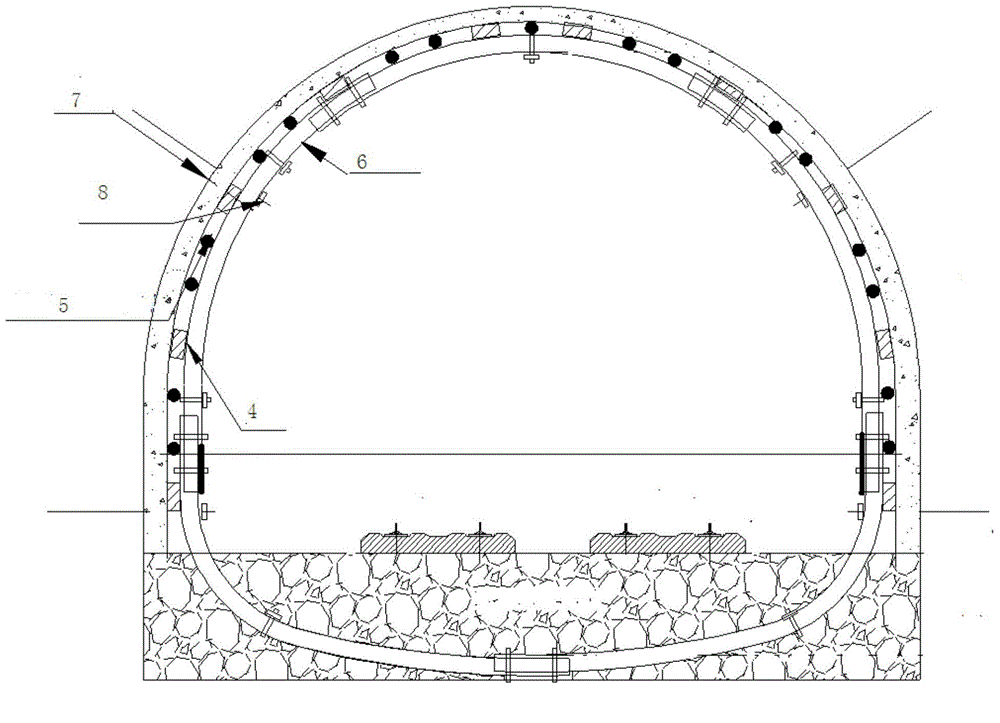

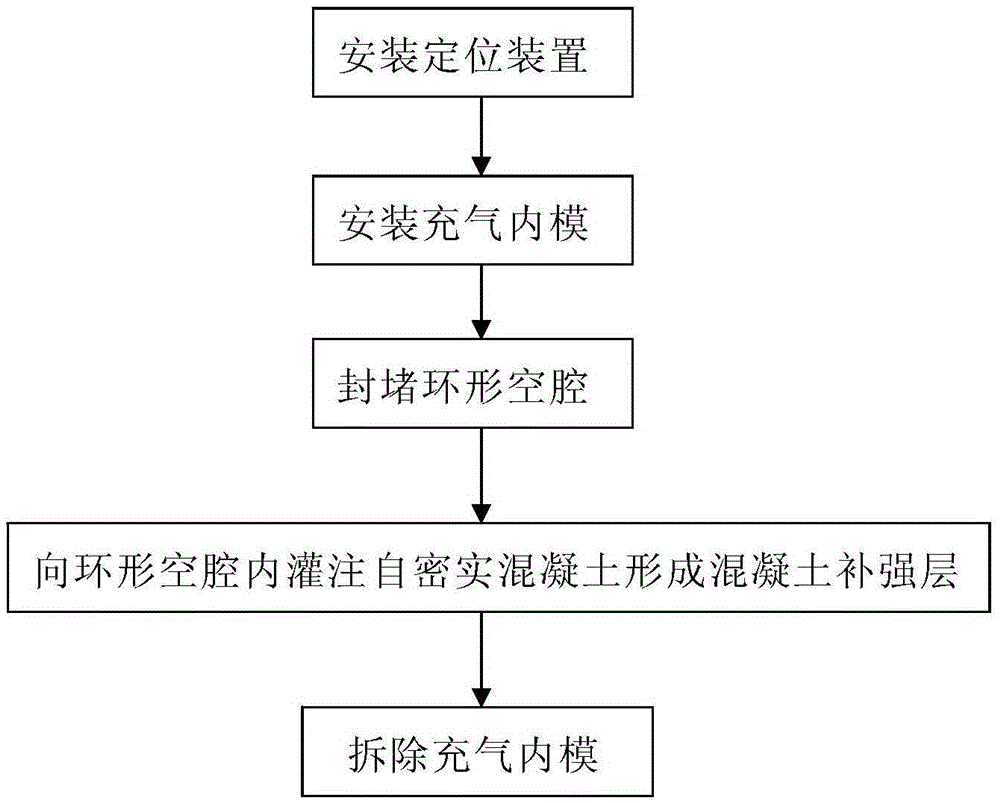

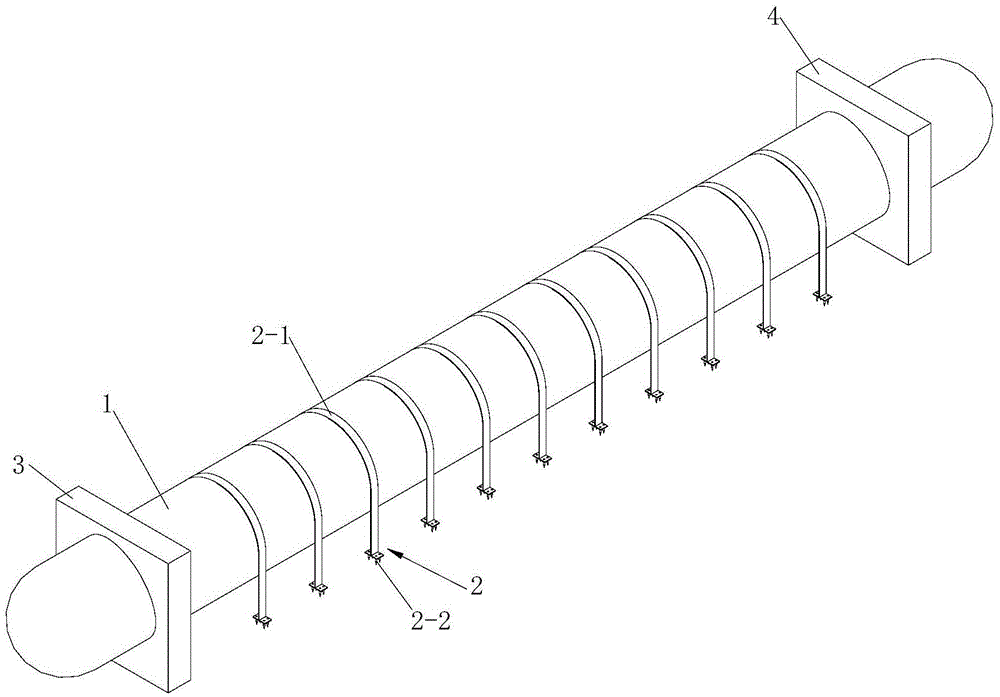

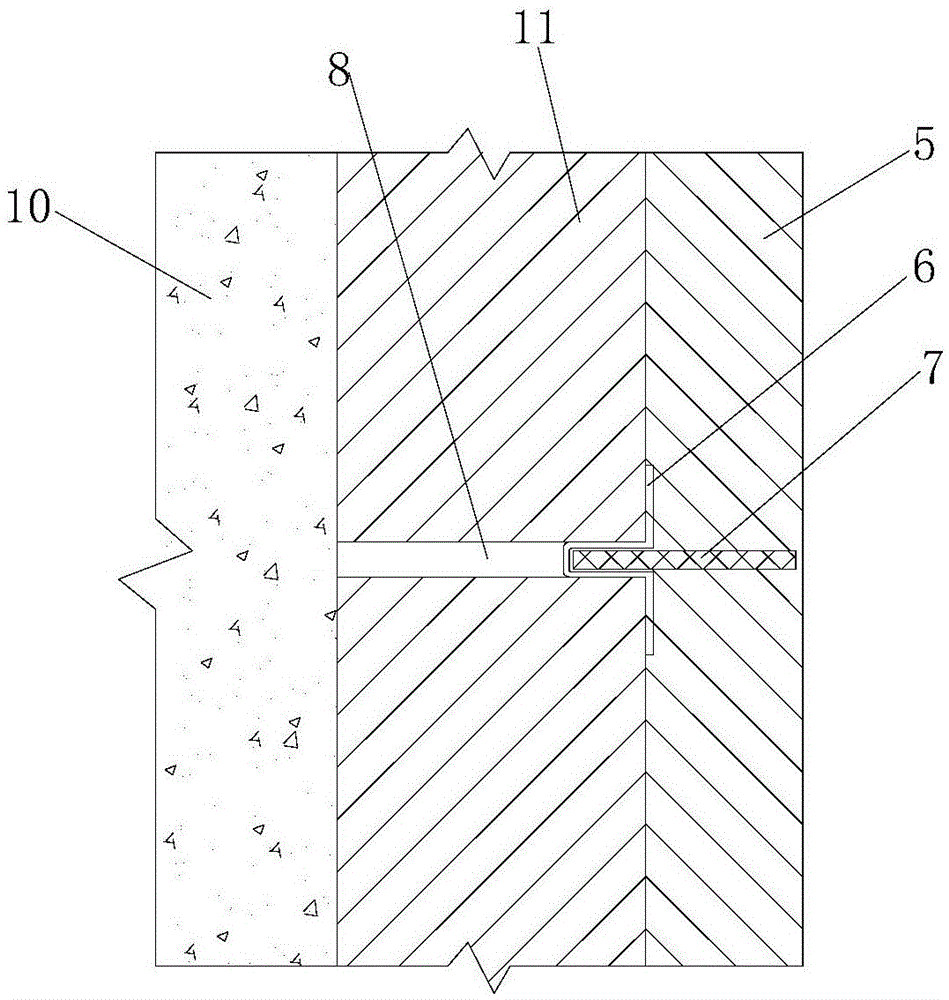

Method for reinforcing culvert through inflatable internal mold and self-compacting concrete

ActiveCN105625201AImprove liquidityGuaranteed filling qualityGround-workFoundation repairCooperative workMaterials science

The invention discloses a method for reinforcing a culvert through an inflatable internal mold and self-compacting concrete. The method comprises the following steps: firstly, positioning devices are mounted; secondly, the inflatable internal mold is mounted; thirdly, an annular cavity is blocked; fourthly, the self-compacting concrete is poured into the annular cavity to form a concrete strengthening layer; and fifthly, the inflatable internal mold is dismounted. A rubber air bag is adopted in the method for reinforcing the culvert for serving as the inflatable internal mold, the self-compacting concrete is poured into the position between the inflatable internal mold and an existing culvert, and the concrete strengthening layer formed by the self-compacting concrete which has certain bearing capacity and is uniform and dense serves as a reinforcing body of the existing culvert; the concrete strengthening layer and a culvert structure jointly bear load action and carry out cooperative work; and the bearing force of the existing structure is effectively improved.

Owner:CHANGAN UNIV

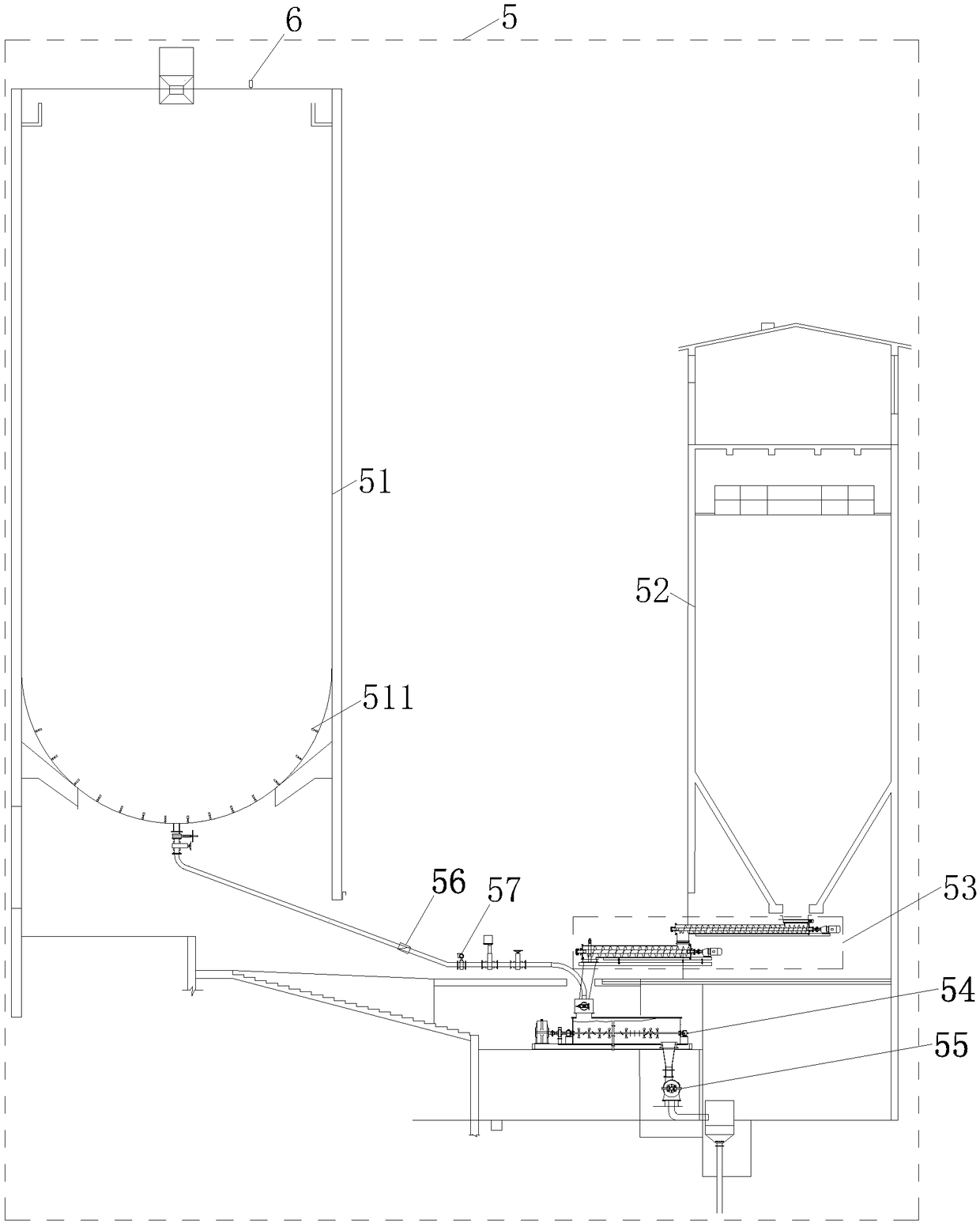

Tailing slurry recycling filling system and technology

PendingCN108590748AControl ratioControl concentrationMaterial fill-upIngredients weighing apparatusHigh concentrationSlurry

The invention provides a tailing slurry recycling filling system. The tailing slurry recycling filling system comprises a conveying vehicle, a filter cake storage bin, a tailing slurry recycling device and a filling slurry preparing device; the conveying vehicle is used for conveying high-concentration tailing filter cakes generated in a dressing plant and formed through filter pressing to a filling station; the filter cake storage bin is used for storing the high-concentration tailings filter cakes in a concentrated mode and impacting and diluting the high-concentration tailings filter cakesthrough high-pressure water so as to output tailing slurry in a flowing mode; the tailing slurry recycling device is used for filtering and stirring the tailing slurry output by the filter cake storage bin to obtain the tailing slurry with the stable concentration; and the filling slurry preparing device is used for preparing and forming filling slurry through the tailing slurry, with the stable concentration, output by the tailing slurry recycling device and outputting the filling slurry to fill a goaf. The filter cake storage bin disperses the high-concentration tailing filter cakes throughthe high-pressure water, so that tailings and water are mixed and diluted to obtain the tailings slurry. The tailings slurry recycling device filters and stirs the tailing slurry output by the filtercake storage bin to remove coarse-particle impurities in the tailing slurry to enable the tailings and water to be mixed evenly so as to obtain the tailing slurry with the stable concentration.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

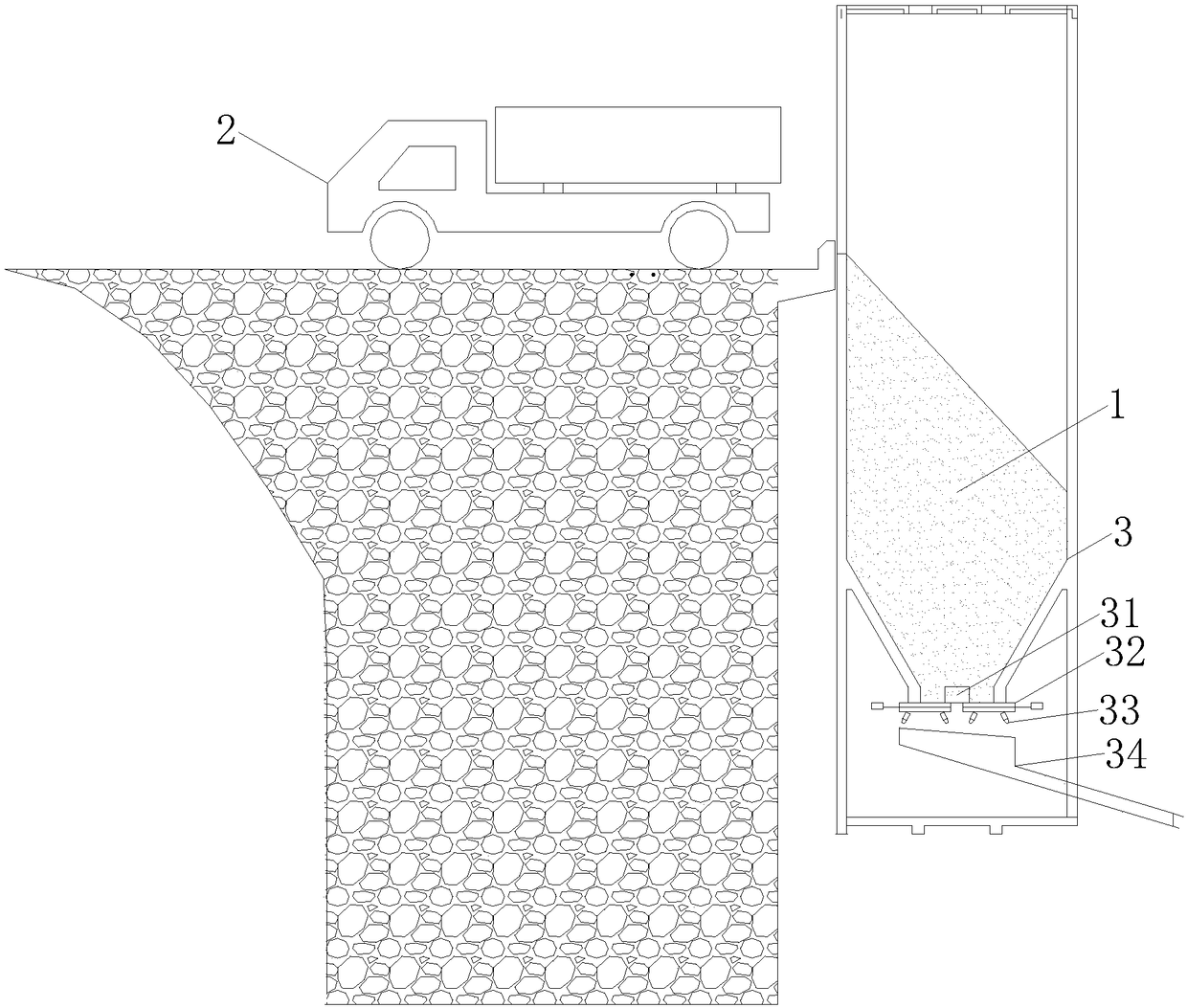

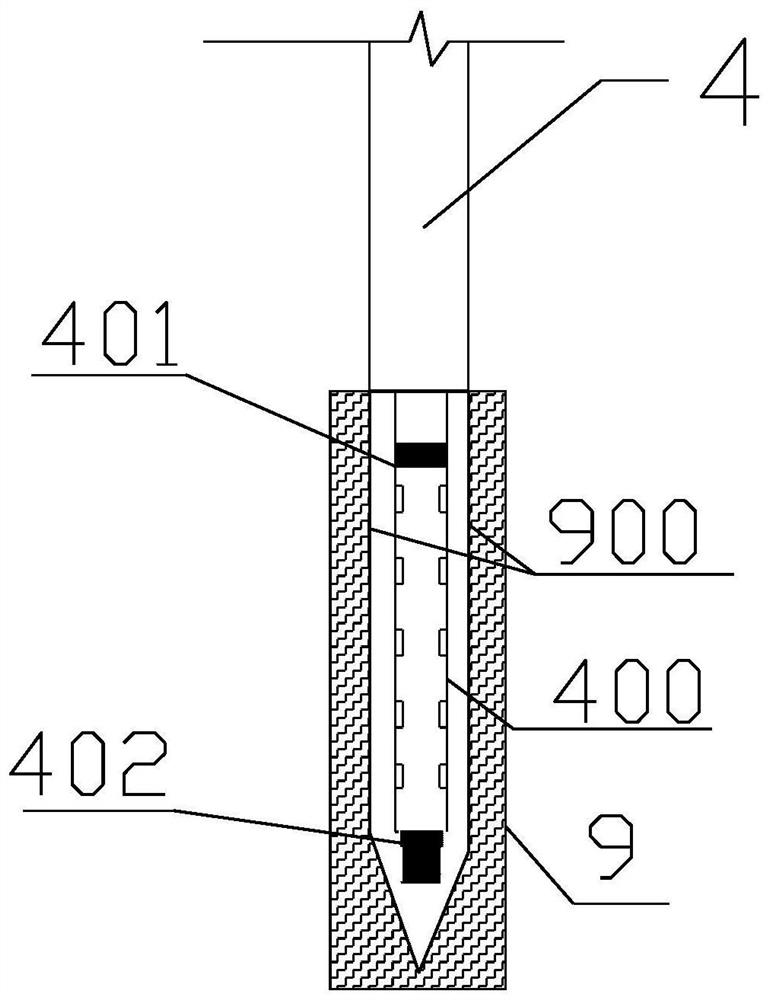

Filling device and method for waste air-raid shelter of pile foundation construction site

ActiveCN112323823ASmooth Construction MeasuresGuaranteed cycleEmbankmentsFoam concreteArchitectural engineering

The invention provides a filling device and method for a waste air-raid shelter of a pile foundation construction site. The filling method comprises the steps that a grouting drill hole is drilled above a waste air-raid shelter to be filled, a primary grouting pipe, a secondary grouting pipe, an air supply pipe and an air exhaust pipe are installed in the drill hole, the primary grouting pipe andthe air supply pipe vertically extend into the bottom of the air-raid shelter, the secondary grouting pipe and the air exhaust pipe vertically extend to the top of the air-raid shelter, firstly, the primary grouting pipe is connected with a grouting pump, the air supply pipe is connected with an air compressor, foam concrete grouting slurry is injected in a layered mode, the primary grouting pipeand the air supply pipe are pulled up all the way to the top of the air-raid shelter after grouting of each layer is completed, then the secondary grouting pipe is connected to inject the foam concrete grouting slurry for the second time, and air is not supplied during secondary grouting. The filling problem of the deep-buried air-raid shelter can be solved under the condition that excavation is not conducted, normal construction of a cast-in-situ bored pile can be guaranteed on a filled construction site, and the problems that when a rotary drilling rig constructs a cast-in-situ pile foundation, normal construction cannot be conducted on the deep-buried air-raid shelter, the site collapses and the like are solved.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

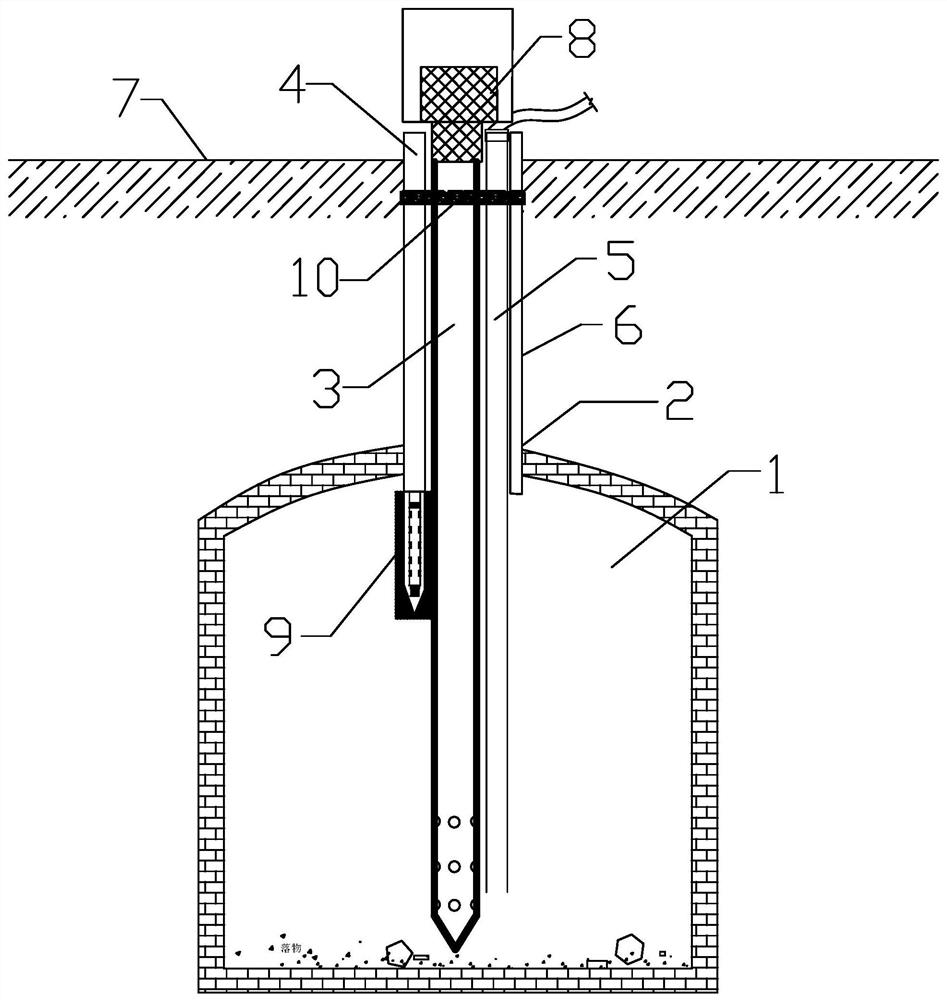

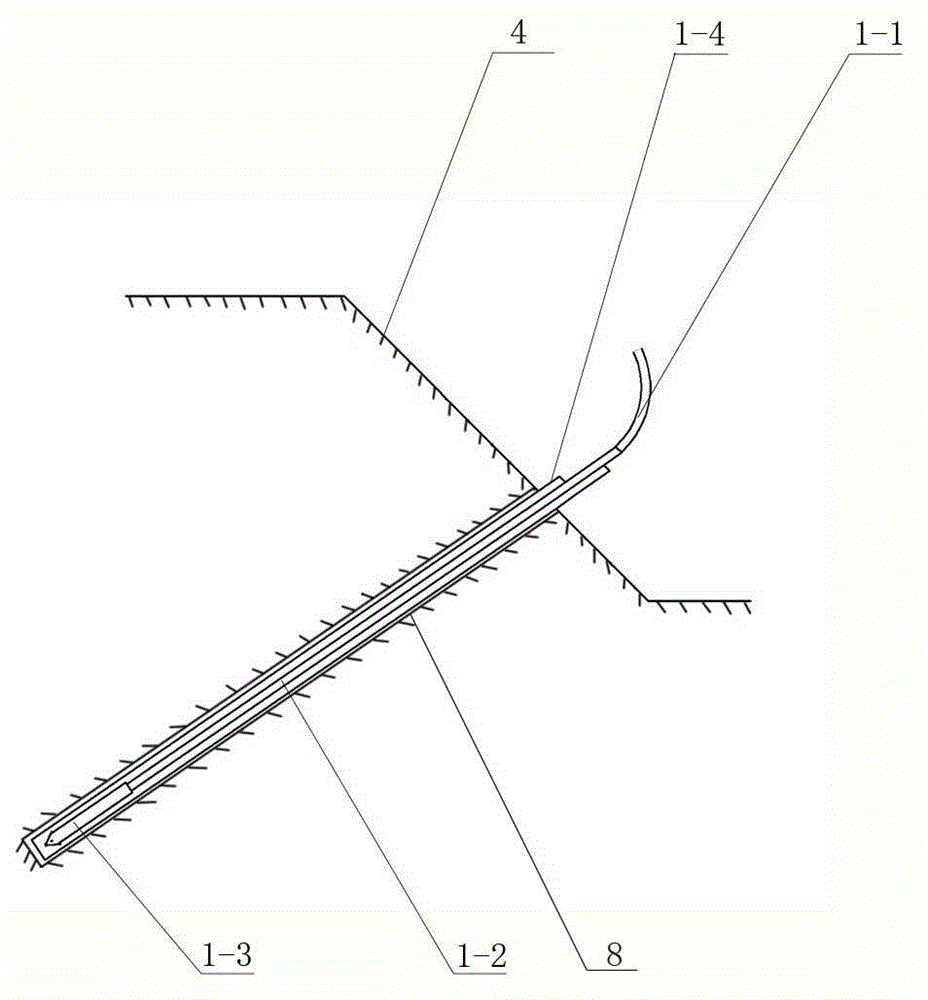

Sinking device and method for well point drawdown pipe of liquid soil layer

ActiveCN104975611AReduce resistanceNot subject to wear and tearFoundation engineeringPunchingEngineering

The invention relates to a sinking device and method for a well point drawdown pipe of a liquid soil layer. The sinking device comprises a punching device and a pipe burying device. According to the punching device, a punching gun head is connected to the front end of a punching gun, a water hose used for being connected with a high-pressure water pump is connected to the rear end of the punching gun, and a protective cylindrical pipe is arranged outside the punching gun in a sleeving mode. The pipe burying device comprises a push rod and a push plate. According to the push rod, a handle is connected to one end of a connecting rod, and a push rod end socket is connected to the connecting rod in a sleeving mode. According to the push plate, a push plate head is connected to one end of a linkage rod, a push handle is connected to the other end of the linkage rod, and the push plate head is of a semicircular plate like structure provided with an arc-shaped groove so that filler materials placed in a well pit can be compacted. The sinking device is simple in structure, convenient to operate and practical; the punching device, the push plate and a push gun are used in cooperation, and thus the problem that the wall of the well pit deforms due to retraction of sand and stones is effectively solved. By the adoption of the sinking device and method, the working efficiency of sinking of the well point drawdown pipe can be effectively improved.

Owner:河北二十冶建设有限公司

Steam type antivirus fine-adjustment screening production line

InactiveCN105667845AGuaranteed filling qualityCompact structureCapsCaps pretreatmentProduction lineEngineering

The invention discloses a steam type antivirus fine-adjustment screening production line. The steam type antivirus fine-adjustment screening production line comprises a base. A through groove is formed in the upper surface of the base in the length direction of the base. A transmission mechanism is arranged in the through groove. The upper surface of the base is sequentially provided with a steam sterilization mechanism, a dropping pill filling mechanism and a bottle cap hot-pressing sealing mechanism in the length direction of the base. A control box is arranged on the lateral surface of the base and electrically connected with the transmission mechanism, the steam sterilization mechanism, the dropping pill filling mechanism and the bottle cap hot-pressing sealing mechanism. The steam type antivirus fine-adjustment screening production line has the beneficial effects of being simple in structure and high in practicability.

Owner:CHINA JILIANG UNIV

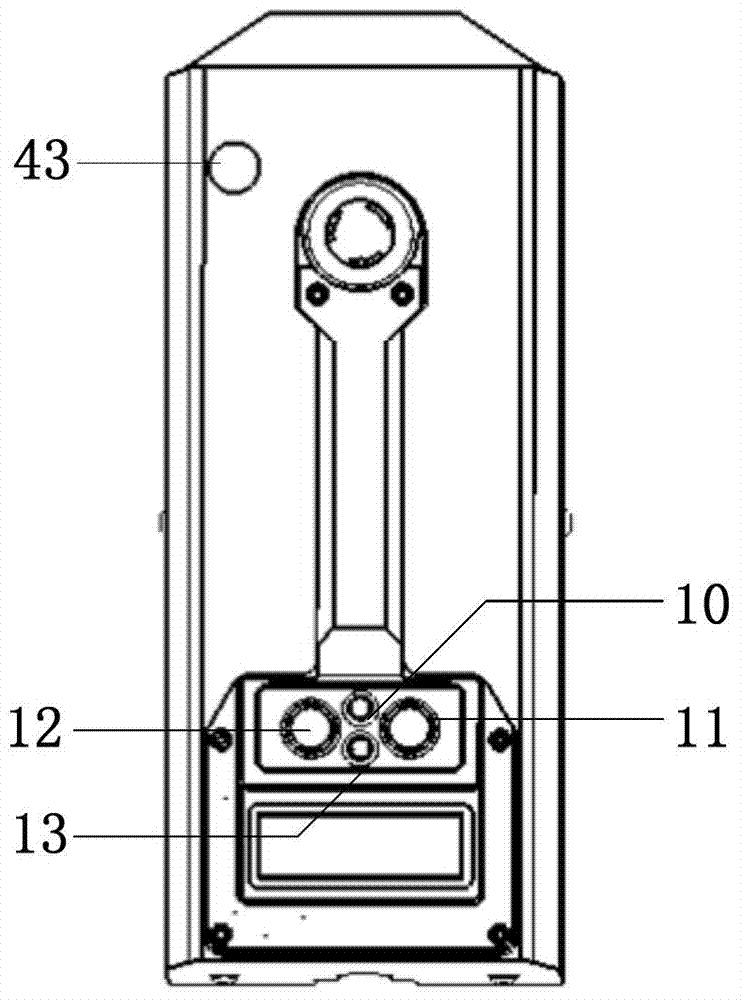

Novel waste sampling detection device

InactiveCN106248419ACompact structureLow costWithdrawing sample devicesElectrical connectionEngineering

The invention discloses a new type of waste product sampling detection device, which comprises a new type of waste product sampling detection device, including a base, the upper surface of the base is provided with a through groove along its length direction, and a transmission mechanism is arranged in the through groove , the upper surface of the base is sequentially provided with an ozone sterilizing device, a liquid medicine filling mechanism, and a bottle cap hot-press sealing mechanism along its length direction, and an infrared photoelectric detection mechanism is arranged on the side of the bottle cap hot-press sealing mechanism , the side of the infrared photoelectric detection mechanism is provided with a waste product sampling device, and a control box is provided on the side surface of the base, and the control box is respectively connected with the transmission mechanism, the ozone sterilizing device, the liquid medicine filling mechanism, the bottle cap heating The pressure sealing mechanism, the infrared photoelectric detection mechanism, and the waste product sampling device are electrically connected. The invention has the advantages of simple structure and strong practicability.

Owner:蒋清校

Sampling, dissolving and detecting integrated pharmaceutical device

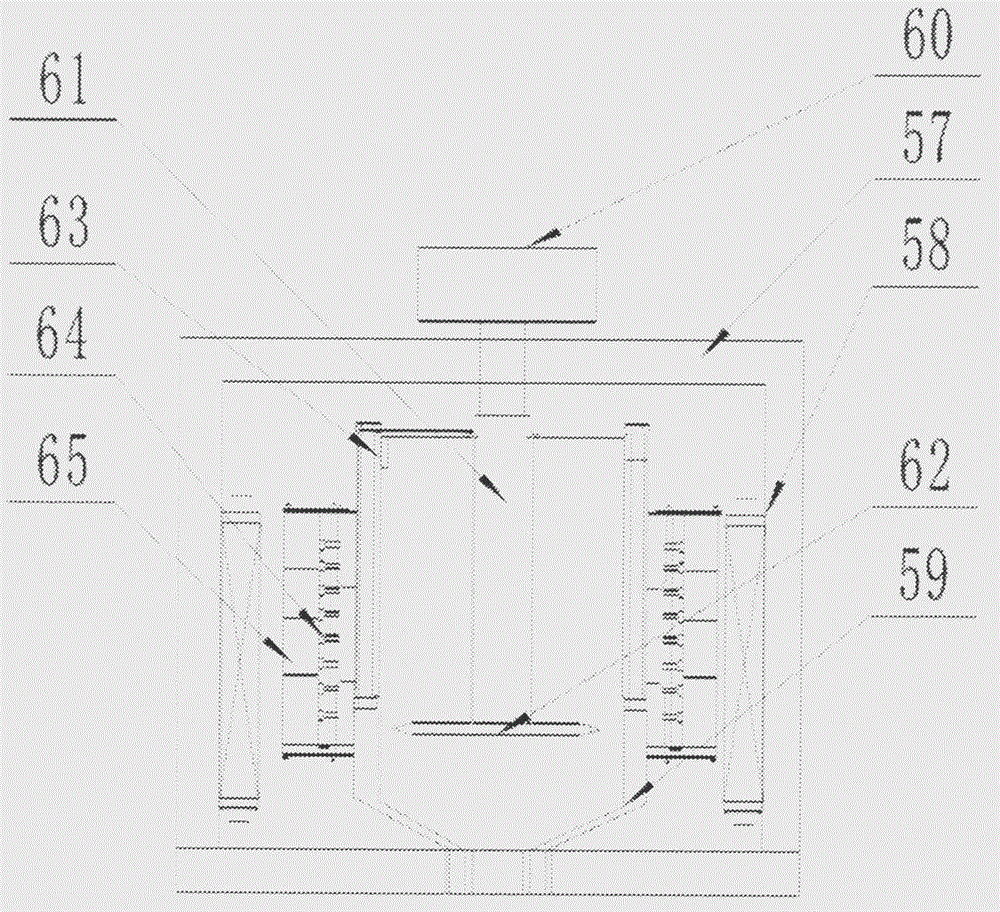

InactiveCN106198106AGuaranteed filling qualityCompact structureCapsSynchronising machinesBiochemical engineeringHot press

The invention discloses a sampling, dissolving and detecting integrated pharmaceutical device. The pharmaceutical device comprises an annular supporting frame which is fixedly mounted on the ground, a chained annular conveying belt mechanism is arranged in the annular supporting frame, and a control box is arranged on the ground and electrically connected with the chained annular conveying belt mechanism, a multifunctional liquid medicine filling mechanism, a bottle cap hot-pressing sealing mechanism and a sampling detector respectively. The sampling, dissolving and detecting integrated pharmaceutical device has advantages of simple structure and high practicality.

Owner:蒋清校

Regenerated type road cold-repairing material

The invention relates to a regenerated road cold feeding material, which comprises 56-87% milling material, 0.08-0.34% cold feeding additive, 0.87-1.6% diesel, and stones. The invention adds stone, feeding liquid, diesel, and macromolecule activate modified additive into the milling waste of highway, to be heated and mixed, to save material and reduce the pollution, while the added macromolecule activate modified additive can resolve the aging problem of pitch. And the invention uses the milling waste as material to avoid damaging the continuity of road, while the regenerated cold feeding material has high strength.

Owner:河南交投交通建设集团有限公司 +4

Sterile filling device

The invention discloses an aseptic filling device, comprising a filling valve, a feed valve, a material tank, and a liquid level meter. The liquid level meter comprises a buoy arranged inside the material tank; a sliding bar with one end connected with the buoy and the other end sliding on a thin plate arranged inside the liquid level meter; a magnetic loop arranged at the upper end of the sliding bar; and two magnetic switches arranged outside the thin plate and connected with a stop valve of a feed tank via a signal wire. The filling valve is provided with a separation gasket for separating material from the outside and preventing bacteria from polluting the material, and a silk screen is arranged for filtering and preventing drip leakage. The aseptic filling device is made from stainless steel, so as to remarkably improve the reliability of aseptic production; and a self-designed liquid level meter is installed, so as to overcome the influence of foaming materials, remarkably improve the metering precision and ensure the filling quality. The liquid level meter can be used in coordination with a high-precision flow meter to achieve the best filling precision.

Owner:温州天龙包装材料有限公司

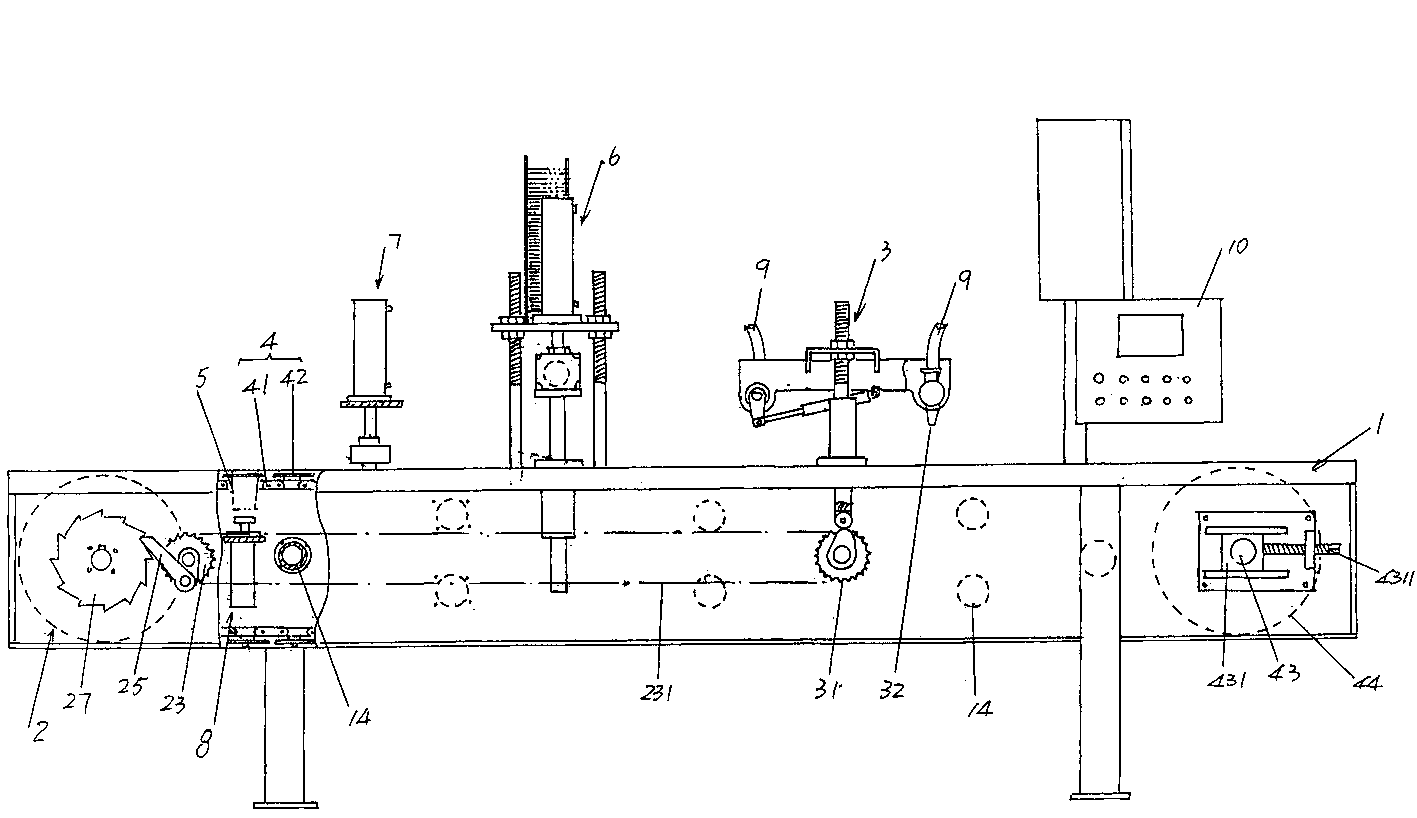

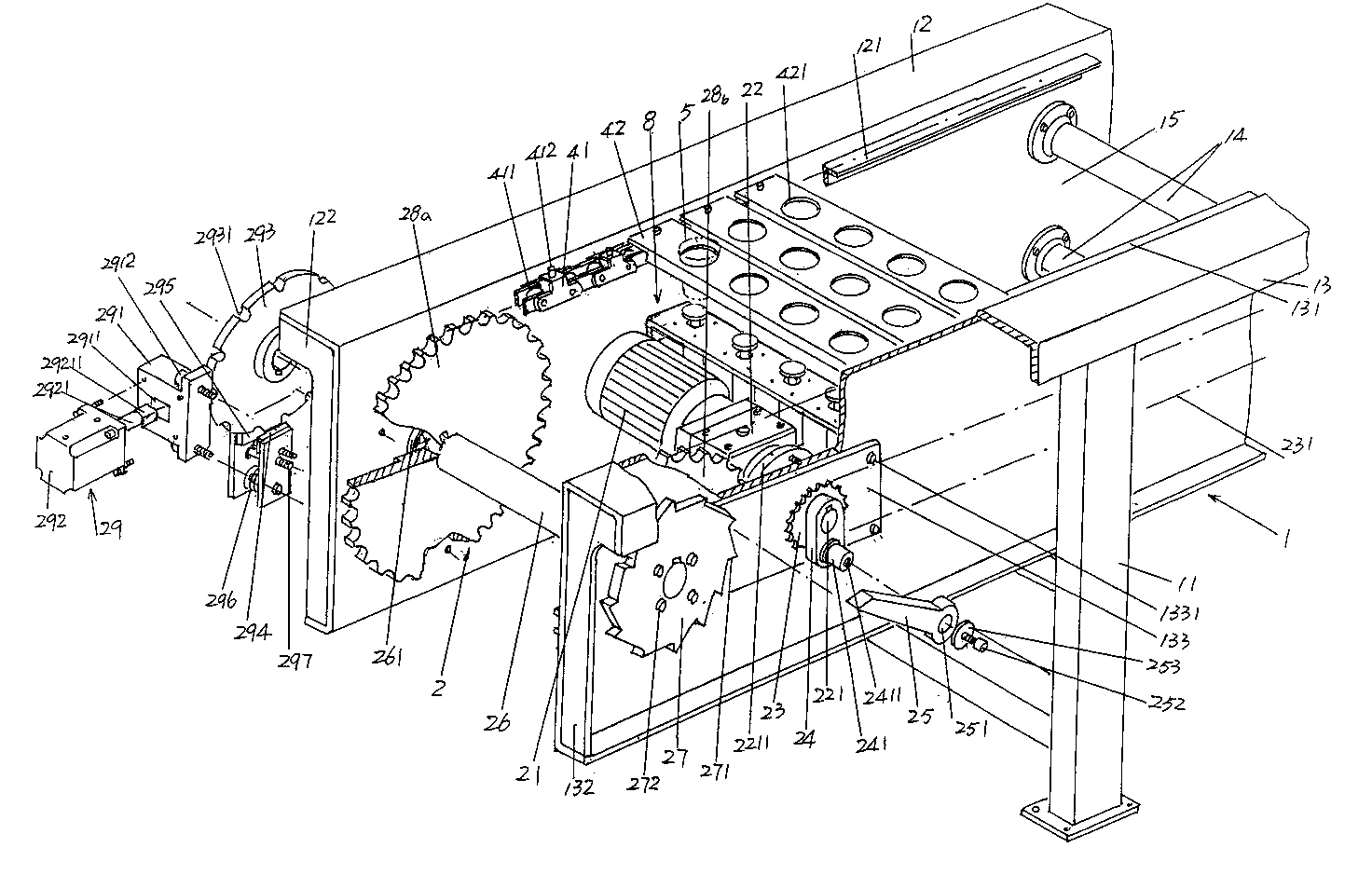

Automatic paper-cup ice cream filling machine

The invention discloses an automatic paper-cup ice cream filling machine belonging to food filling machinery. The automatic paper-cup ice cream filling machine comprises a rack, a power mechanism, a filling mechanism and a caterpillar mechanism, wherein the rack consists of a cross beam support, a first cross beam, a second cross beam and a group of cross beam supports; the power mechanism is arranged at one end of the rack; the filling mechanism is arranged at the other end of the rack; the caterpillar mechanism is arranged between the first cross beam and the second cross beam; a first horizontal folding edge is formed at the upper part of the first cross beam, a first vertical folding edge is formed on the first horizontal flange, a second horizontal folding edge is formed at the lower part of the first cross beam, a third horizontal folding edge is formed at the upper part of the second cross beam, a second vertical folding edge is formed on the third horizontal folding edge, and a fourth horizontal folding edge is formed at the lower part of the second cross beam; fixed flange seats are respectively fixed at the two ends of the group of cross beam supports; and the power mechanism comprises a motor, a reduction gearbox, a main transmission wheel, a cam, a pawl, a large sprocket shaft, a ratchet wheel disc, a first large sprocket, a second large sprocket and an inertia elimination device. The intensity of the cross beams is ensured, the safety is ensured, and the reliability of movement and pause of paper cups carried by the caterpillar mechanism is ensured.

Owner:常熟威玛乳品机械有限公司

Wood board polishing device used before wood board putty construction

PendingCN108356660AFlexible position adjustmentAvoid cleaningGrinding carriagesGrinding drivesHydraulic cylinderFixed frame

The invention discloses a wood board polishing device used before wood board putty construction. The device comprises a fixing frame, an installation box, a first motor, a grinding wheel, an air guidepipe, a connection rod, a first hydraulic cylinder, a rotary plate, a movable rod, a second motor, a second guide rail, a third motor, a fan body, an installation plate and a connection pipe. The rotary plate is stably fixed through the second guide rail and the movable rod, the grinding wheel is driven by the first motor to rotate, and therefore a wood board is polished. The fan body is driven by the third motor to rotate, so that chippings produced in polishing are blown away, follow-up wood board cleaning is avoided, and working efficiency is improved. The connection pipe and the installation box are in threaded connection to control the air guide pipe to blow away wood flour in grooves in the surface of the wood board, and the putty construction quality is ensured. The height and position of the grinding wheel can be flexibly adjusted, the work intensity of workers is lowered, the wood board surface is cleaned during polishing, the working efficiency is improved, polishing and cleaning are integrated, and the cost is reduced.

Owner:庞乐民

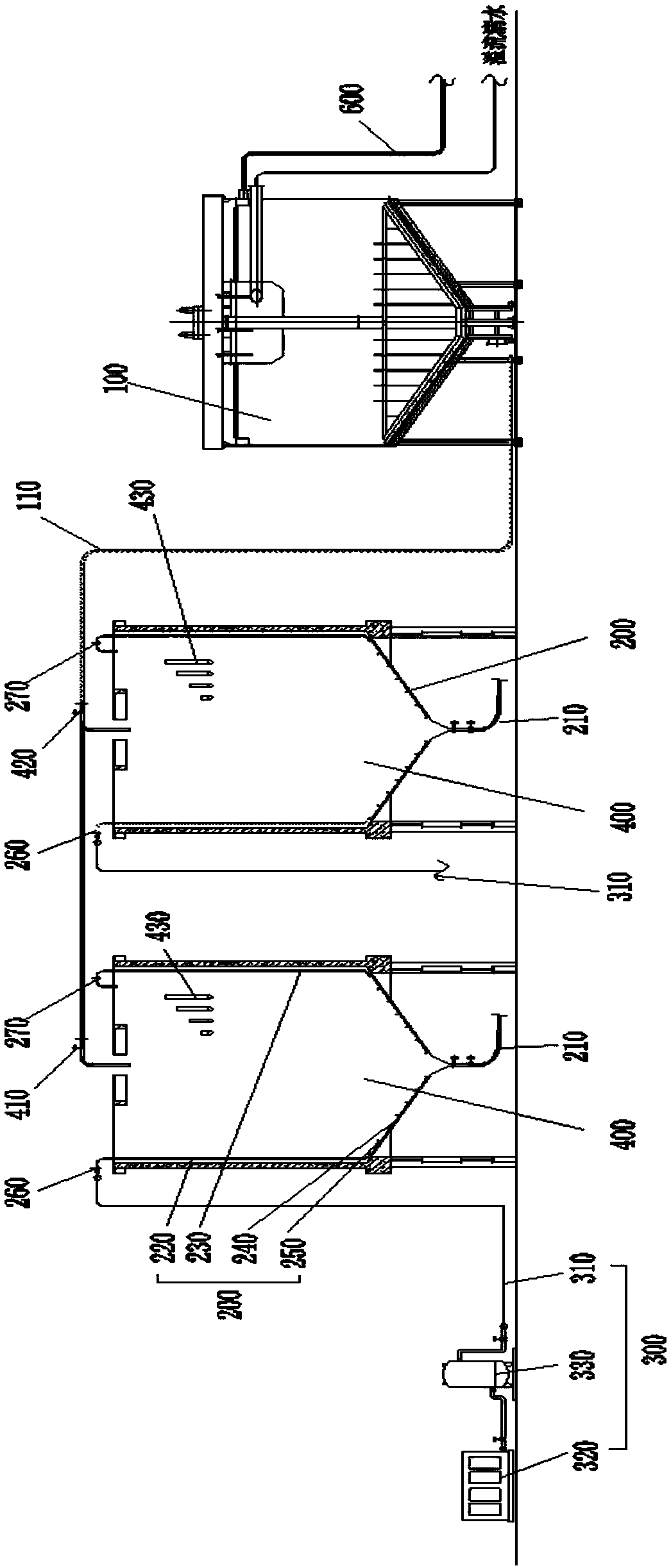

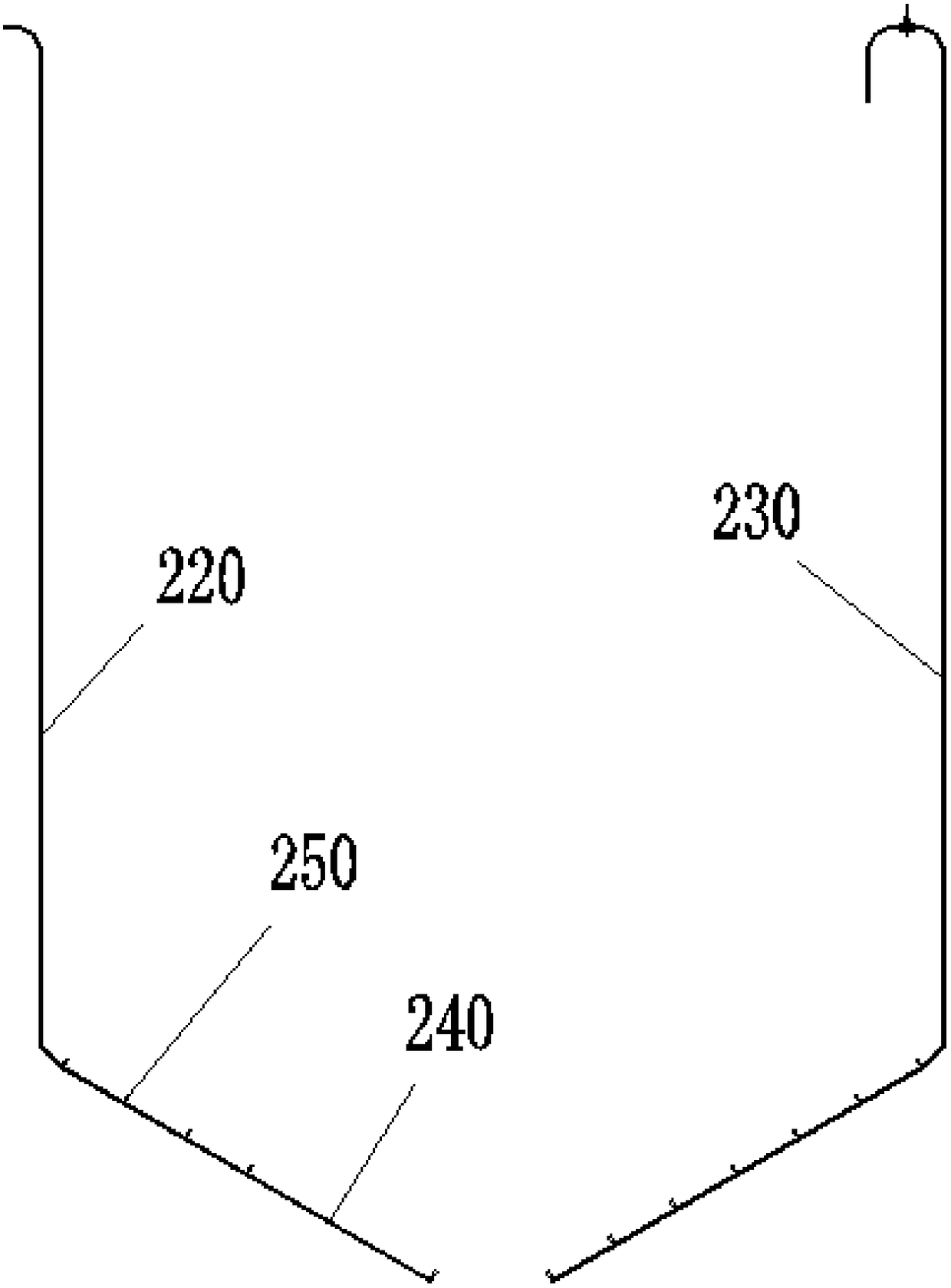

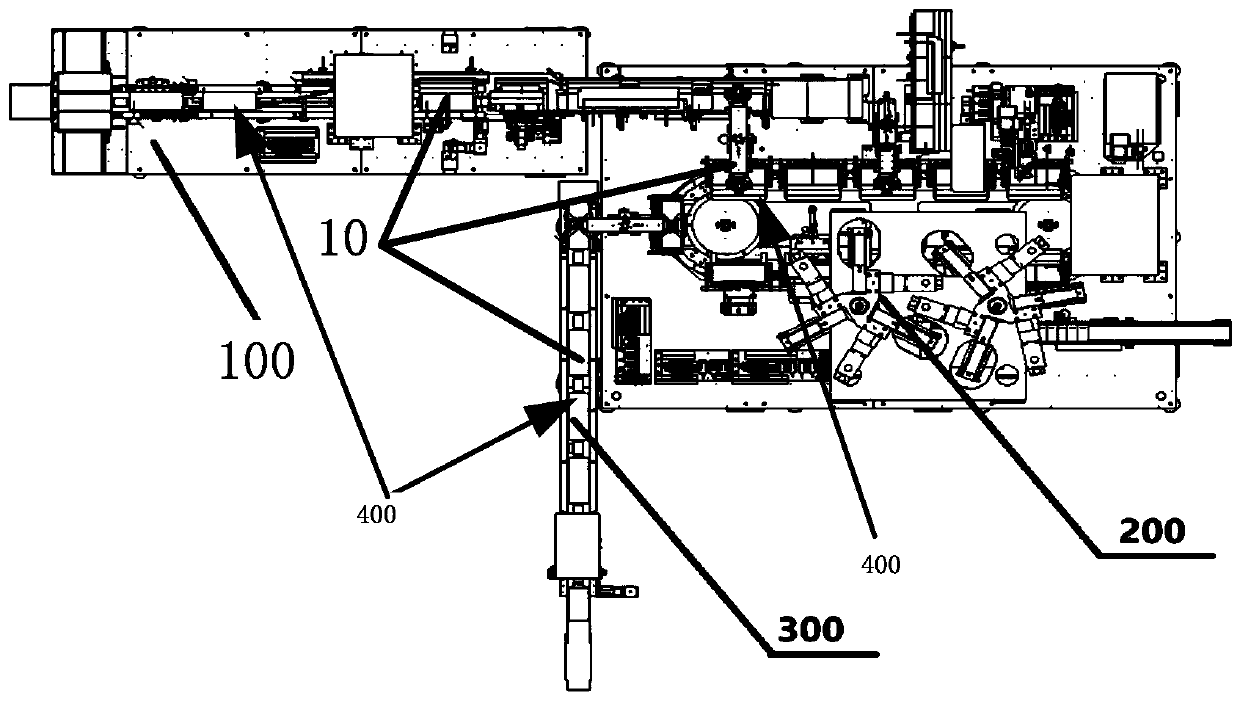

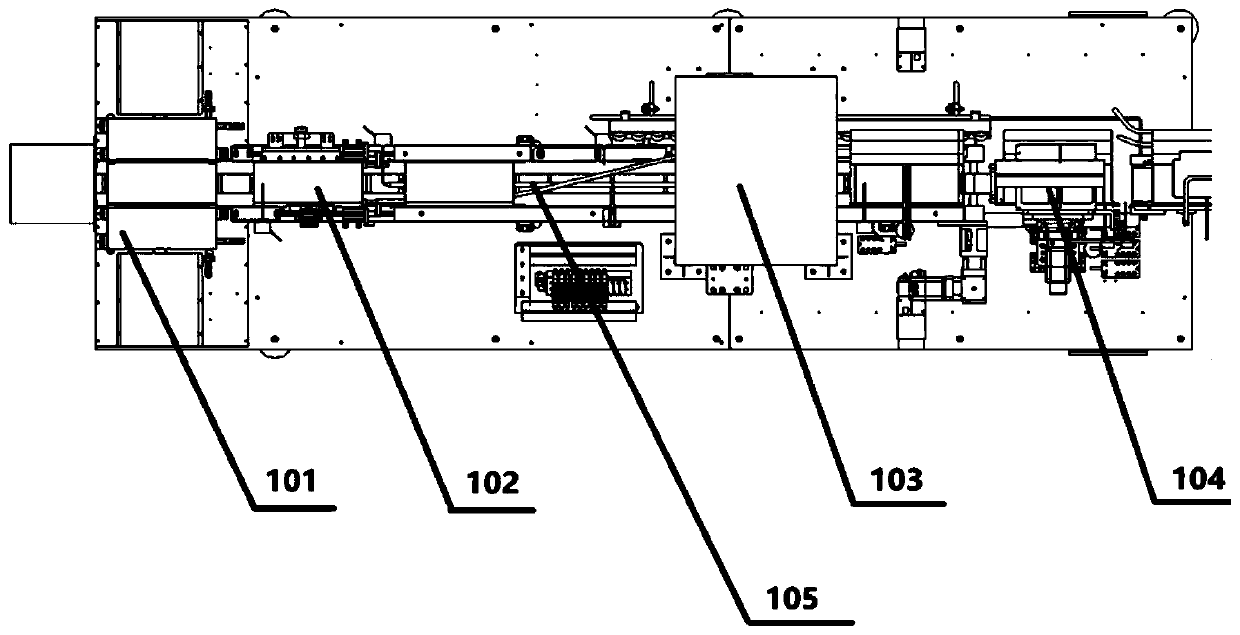

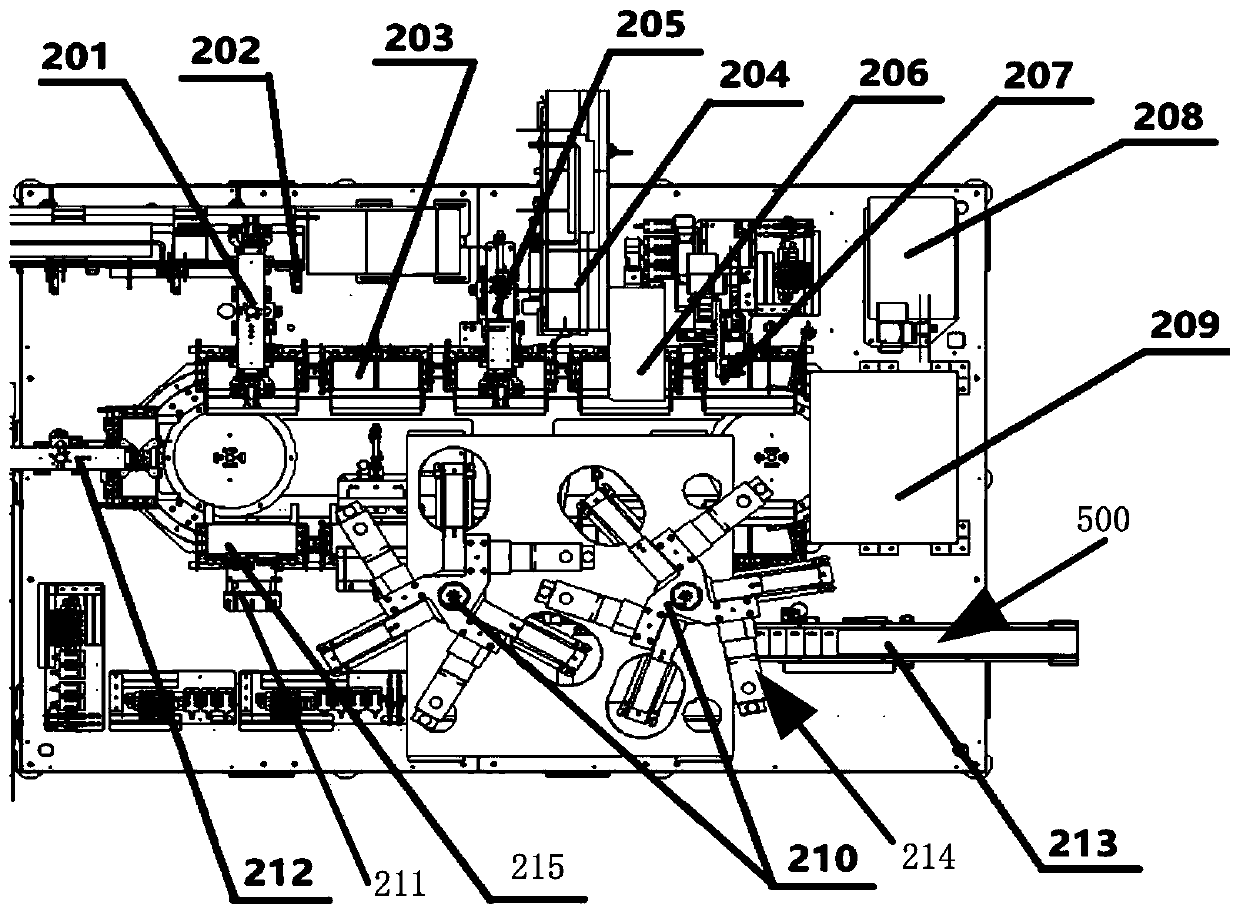

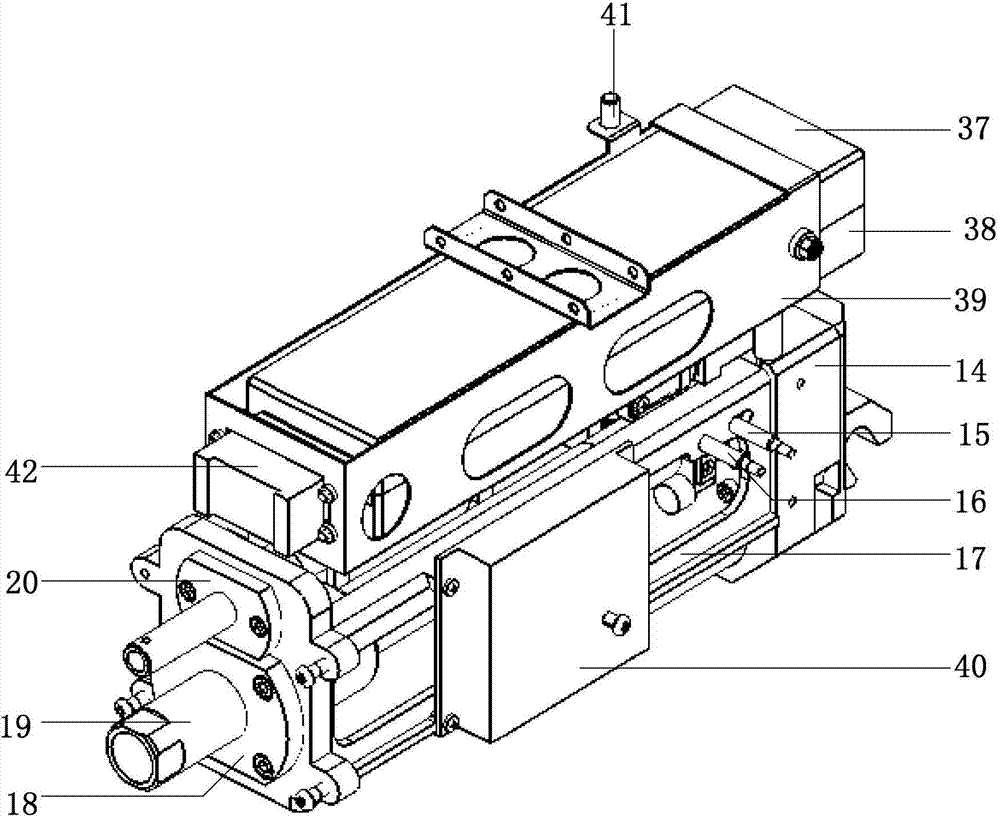

Strip-box filling packing machine and filling method of gift-box cigarette

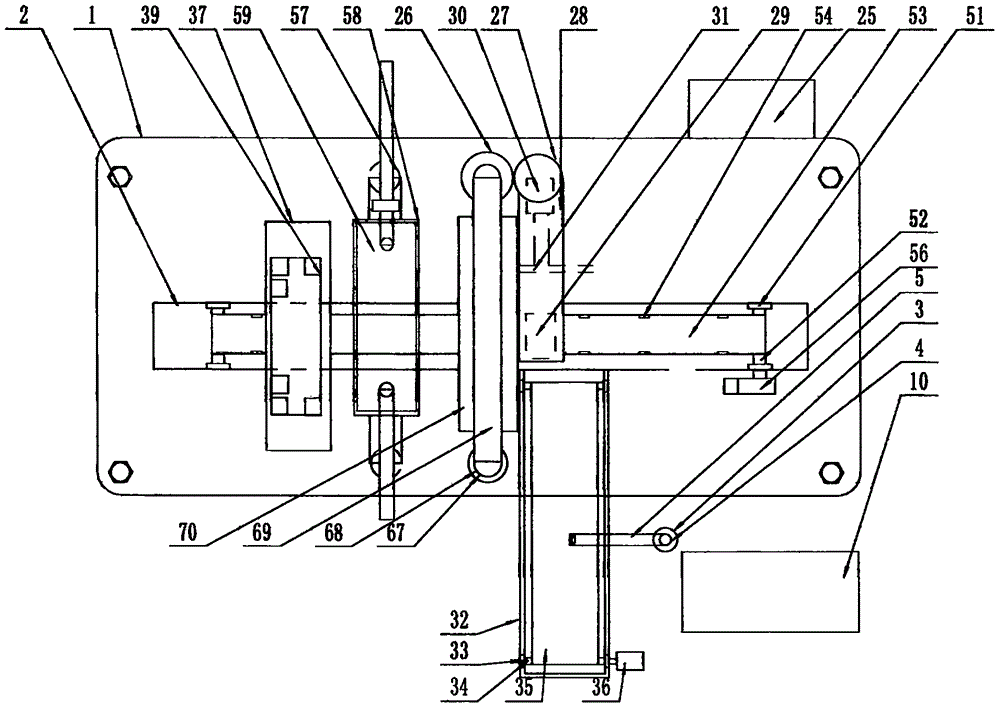

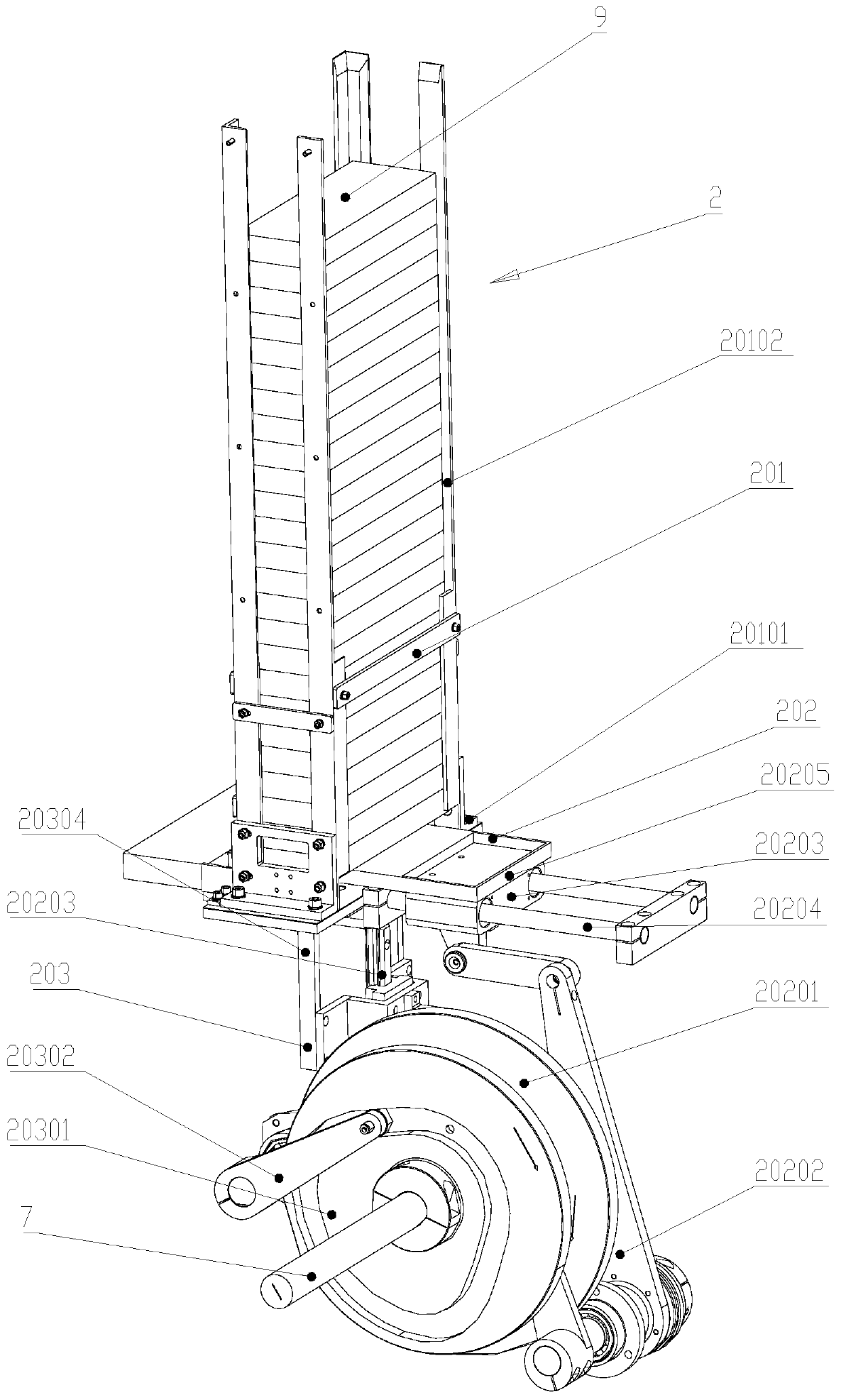

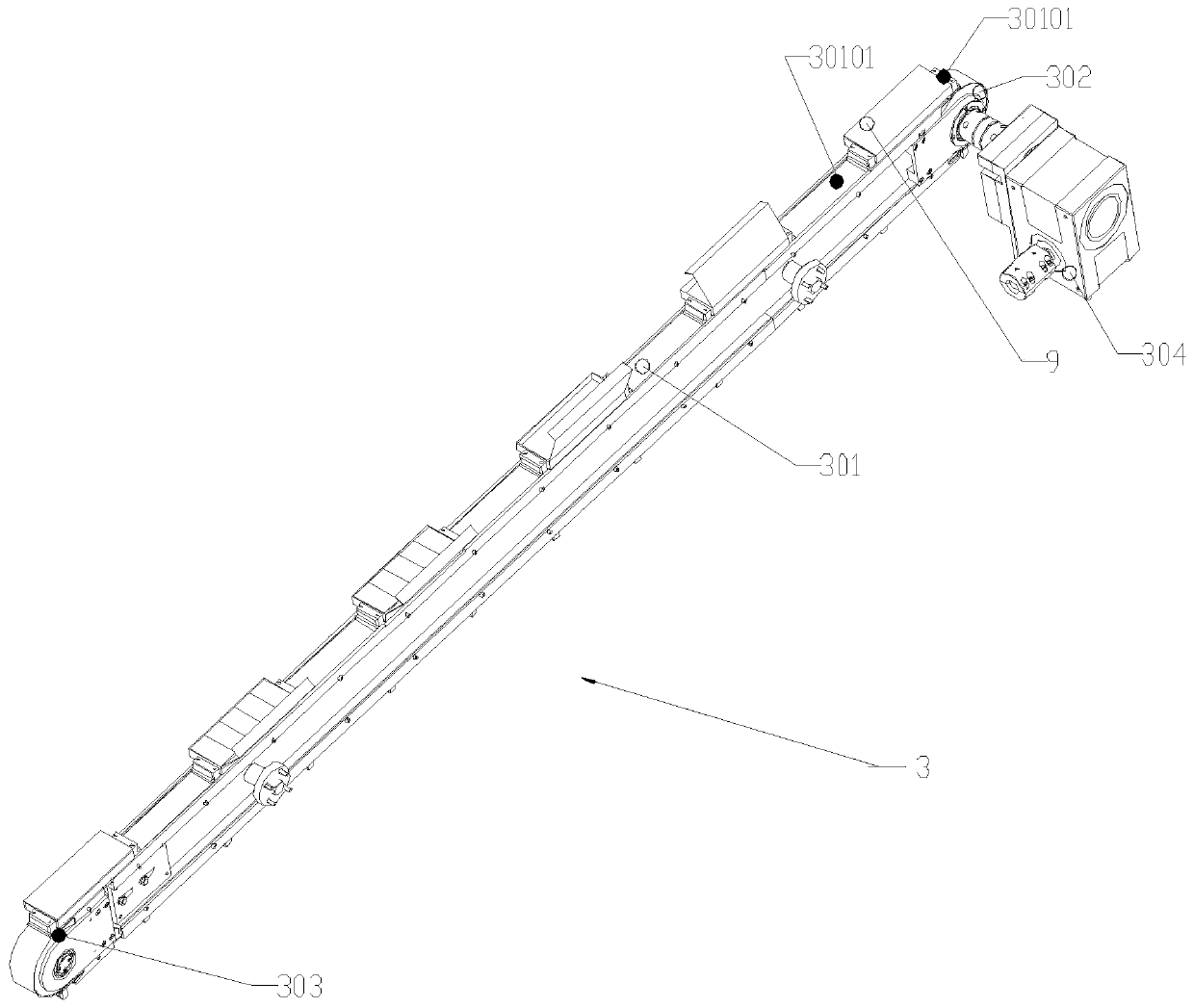

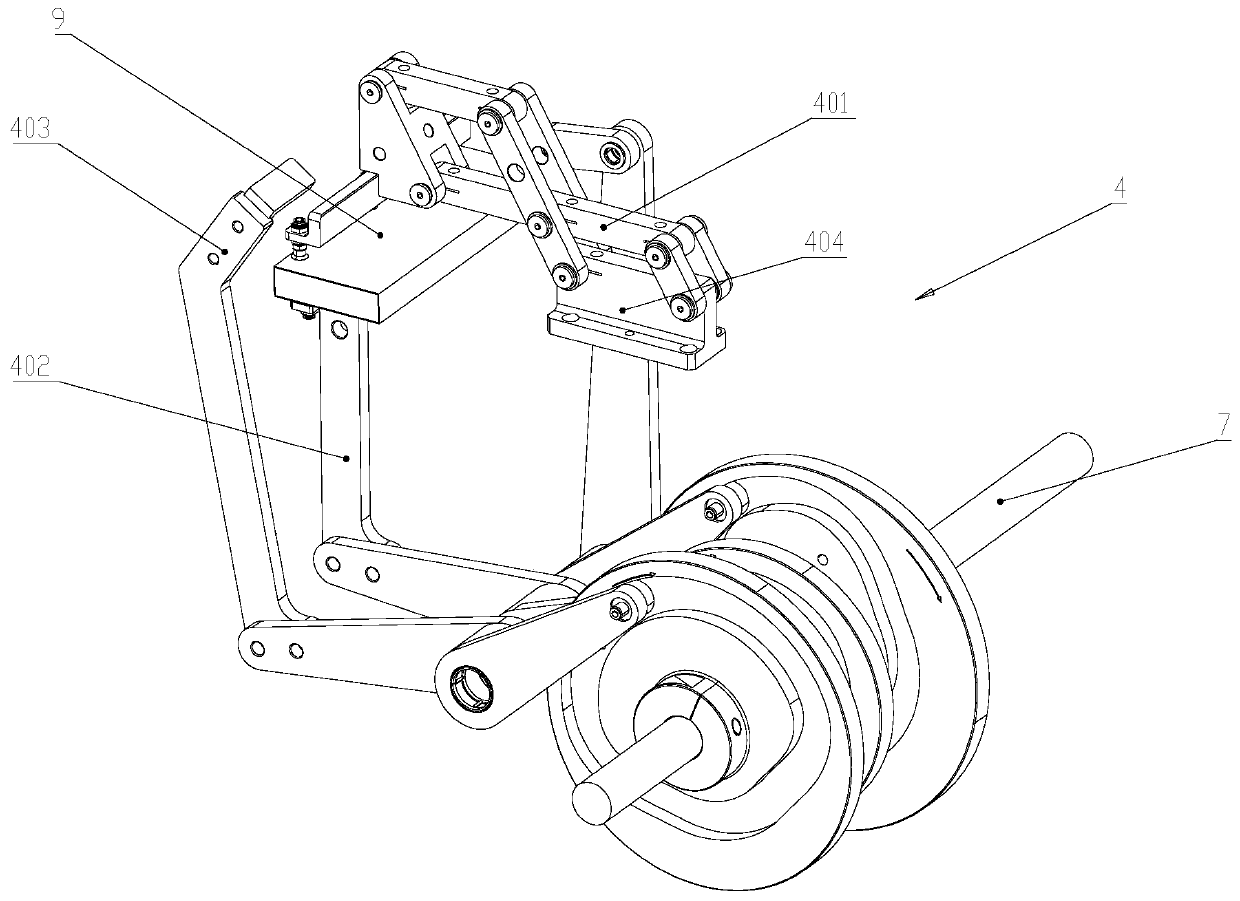

ActiveCN110641787AImprove work efficiencyPracticalPackaging automatic controlIndividual articlesAssembly lineConveyor belt

The invention provides a strip-box filling packing machine and filling method of gift-box cigarette. The strip-box filling packing machine comprises a feeding worktable (100), a main body worktable (200) and a blanking conveyor belt (300); automatic assembly line work is adopted by a packing machine (10), the feeding worktable (100), the main body worktable (200) and the blanking conveyor belt (300) are sequentially the upstream, the midstream and the downstream of the automatic assembly line work, the conveying of a gift box (400) in the whole assembly line is achieved by adopting a conveyorbelt and a mechanical arm, and the quality detection of the gift box (400) in the filling process of a cigarette pack (500) is achieved by arranging a dimension detection mechanism (103), a pre-filling detection mechanism (209), a pack lacking detection mechanism (302) and a PLC (11). According to the strip-box filling packing machine, a plurality of detection mechanisms are arranged, the qualityof filling operation is improved, automation degree is high, the operation efficiency is high, and the practicability is high.

Owner:CHINA SOUTH IND GRP SHANGHAI ELECTRIC CONTROL RES INST

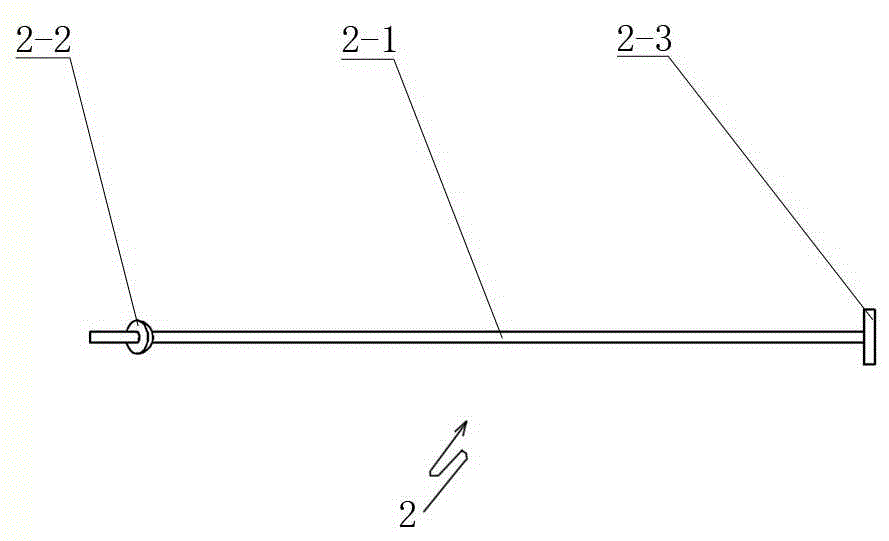

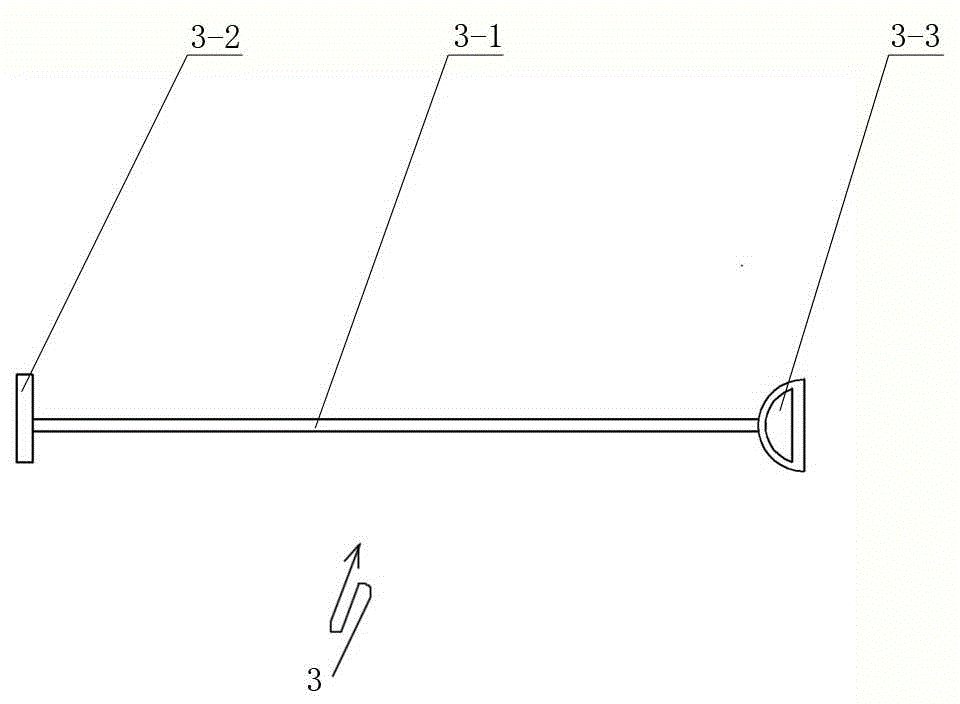

Novel horizontal well sand preventing well completion structure

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Ice cream filling machine

The invention discloses an ice cream filling machine, which belongs to the technical field of food packaging machines. The ice cream filling machine comprises a rack, a filling mechanism and a chain track mechanism, wherein the rack is composed of a crossbeam bracket, first and second crossbeams and a set of crossbeam supports; the filling mechanism is arranged at the other end of the rack; the chain track mechanism is arranged between the first and second crossbeams; and the ice cream filling machine is characterized in that a power mechanism comprises a motor, a reduction gearbox, a main driving wheel, a cam, a pawl, a large sprocket shaft, a ratchet wheel plate, a first large sprocket and a second large sprocket. The ice cream filling machine has the advantages that the security is embodied, and the concise effect of the whole machine can also be improved; as the power mechanism adopts a structure that the pawl is matched with the ratchet wheel plate, the first and second large sprockets do not produce an inertia motion in the process of pausing, and the reliability of moving and pausing of the chain track mechanism carrying paper cups is ensured, so that the filling quality of the filling mechanism is ensured, and the occurrence of unqualified filling products or the waste of frozen ice cream raw materials is avoided.

Owner:常熟威玛乳品机械有限公司

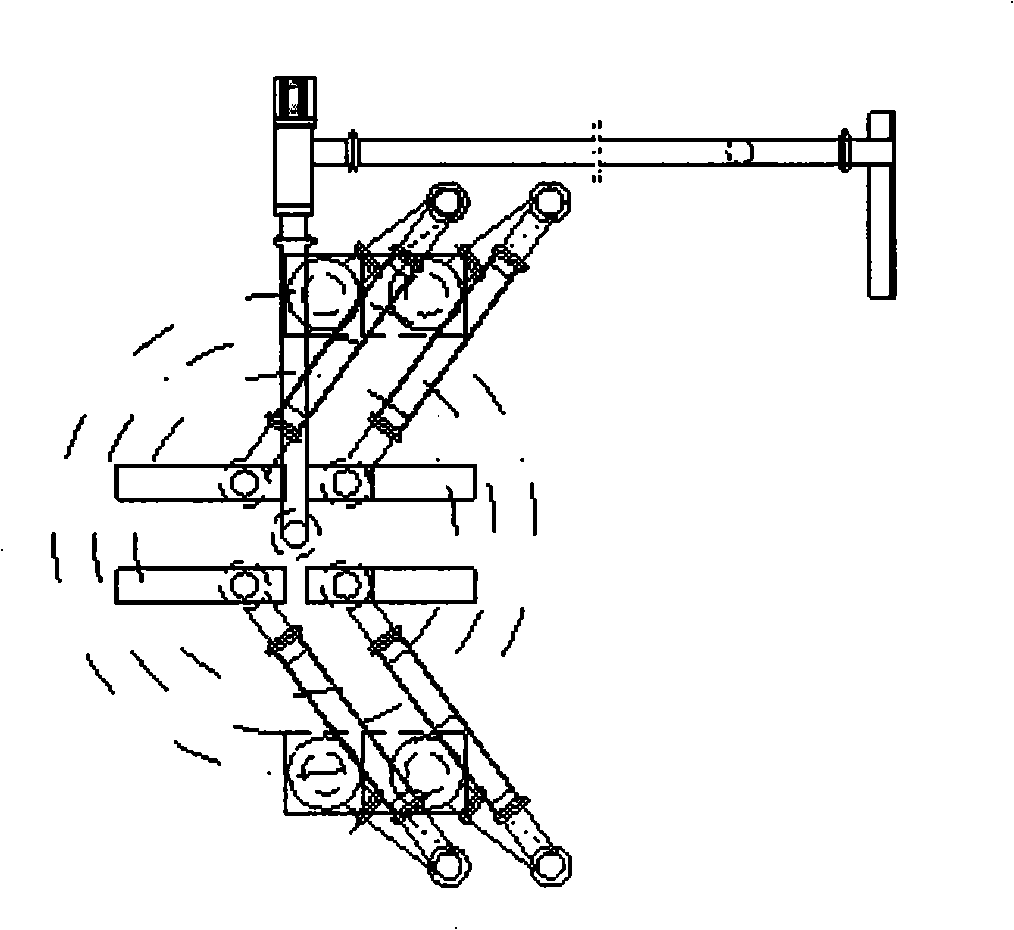

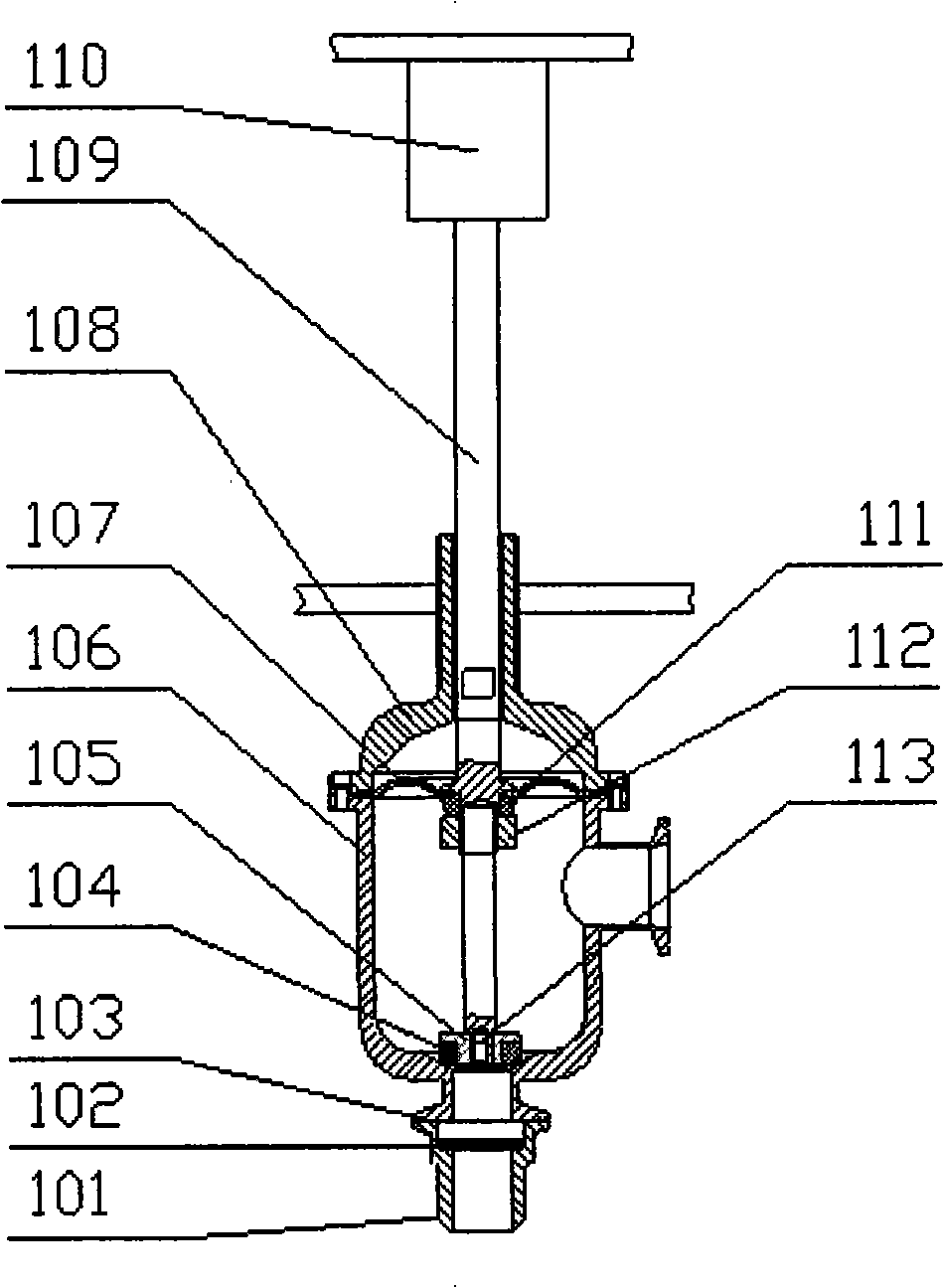

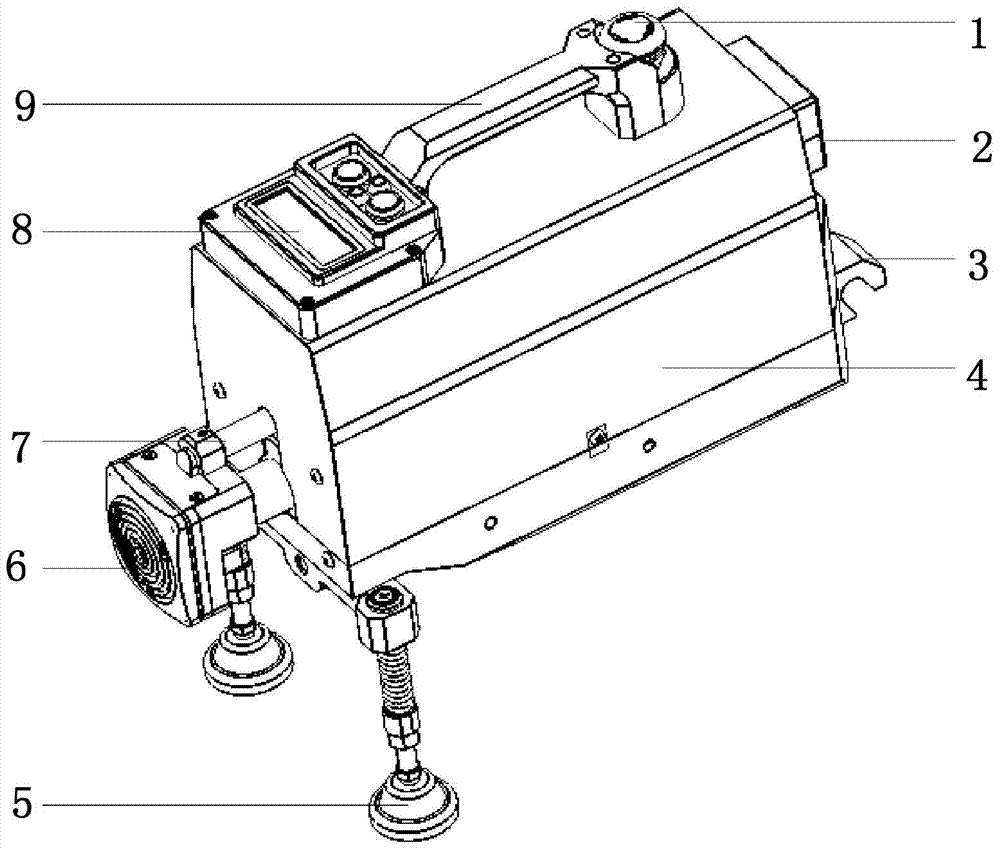

Pedal effort detector

ActiveCN104266785AAccurate measurement dataSimple and efficient operationVehicle testingTransmission systemsEngineeringVehicle brake

A pedal effort detector comprises a shell, a transmission device and a detection mechanism. The transmission device is arranged inside the shell. The detection mechanism is arranged at the front end of the shell and connected with the transmission device. The transmission device comprises a main frame, an auxiliary sliding shaft, a main sliding shaft and a slippage mechanism. The slippage mechanism is installed on the main frame. Both the auxiliary sliding shaft and the main sliding shaft are connected to the slippage mechanism. The detection mechanism comprises a front end base, a front end top plate, a force sensor and a microswitch, wherein the front end base is connected with the main sliding shaft and the auxiliary sliding shaft, the front end top plate is installed on the front end base, a spring is arranged between the front end top plate and the front end base, the force sensor, a floating shaft and the microswitch are installed inside the front end base, and the floating shaft is connected with the front end top plate. According to the detector, parameters such as force applied to a vehicle braking system pedal, displacement generated on the vehicle braking system pedal, and time spent by operating the vehicle braking system pedal are collected in real time through the force sensor, the safe quality performance of the vehicle braking system is reflected, the measured data are accurate, and operation is easy and convenient.

Owner:济南易恒技术有限公司

Material filling device for bridge expansion joint settlement repair and using method thereof

InactiveCN113026582AClean high speedBreak up quicklyDirt cleaningBridge structural detailsVehicle frameRepair material

The invention discloses a material filling device for bridge expansion joint settlement repair and a using method thereof. The material filling device comprises a frame and a cleaning box arranged above the front end of the frame; a sleeve rod is arranged below a water tank, a movable rod is mounted in the sleeve rod, and a crushing wheel is rotationally mounted at the lower end of the movable rod; a mounting sleeve is mounted at the rear end of the interior of the cleaning box, and a nylon roller is mounted below the mounting sleeve; a sliding groove is formed in the middle of the interior of the frame, and a filling head is fixedly arranged on one side of a transmission toothed plate; and a trowelling mechanism is arranged at the rear end of the filling head, and extension plates are arranged on the two sides of the trowelling mechanism. On one hand, it can be guaranteed that the area is kept in a clean state in the process of filling the area to be repaired, floating dust generated by cleaning of soil impurities can be avoided, and on the other hand, it can be guaranteed that repairing materials can be evenly attached to the surface of the expansion joint when the area to be repaired is filled.

Owner:马超

Modular combined firework paper mold filling equipment

The invention discloses modular combined firework paper mold filling equipment. The modular combined firework paper mold filling equipment is characterized in that a paper mold forming pressing plateis arranged above a filling and stamping assembly, the upper end of the paper mold forming pressing plate and a paper mold forming driving mechanism arranged at the top of a rack are in connecting driving through a detachable connecting seat, and the paper mold forming pressing plate and the paper mold forming assembly are fixedly connected through a fixed column. The paper mold forming pressing plate is connected with an auxiliary column through a linear bearing sliding sleeve, one end of the auxiliary column is fixedly connected with the rack through a detachable connecting plate I, the other end of the auxiliary column is fixed to the paper mold forming assembly, and the paper mold forming assembly is fixedly connected with the rack through a detachable connecting plate II. The fillingand stamping assembly is connected to a fixed column through a linear bearing sliding sleeve, and the upper end of the filling and stamping assembly and a filling and stamping driving mechanism arranged at the top of the rack are in connecting driving through a detachable connecting plate III. The modular combined firework paper mold filling equipment has the advantages of being simple in structure, easy and convenient to assemble and disassemble, good in paper mold filling effect, high in product quality and the like.

Owner:LIUYANG WUYI TECH MACHINERY CO LTD

Multi-stage compression feed packaging device pressing mechanism

The invention relates to the technical field related to feed packaging, in particular to a multi-stage compression feed packaging device pressing mechanism. The multi-stage compression feed packagingdevice pressing mechanism comprises a mounting seat, a vibration plate is connected inside a connecting groove in a sliding manner, the surface of the vibration plate is in screw joint with a vibration motor, a positioning slider is welded to the surface of the vibration plate, a positioning sliding slot is formed inside of a fixing frame, and the positioning slider is connected inside the positioning sliding slot in a sliding manner. The multi-stage compression feed packaging device pressing mechanism has the beneficial effects that when feed in a packaging bag is pressed, a pneumatic cylinder is started, the pneumatic cylinder drives a pressing plate to extrude the surface of the feed, the feed is pressed through the pressing plate, meanwhile, in the process of pressing the feed, an external pressing frame slides on the surface of the pneumatic cylinder through a sliding block and a sliding slot under the elastic effect of a third spring, the external pressing frame extrudes the surface of the packaging bag, restriction to the packaging bag is achieved, the compaction quality and efficiency of the feed are ensured, the structure is simple, and the multi-stage compression feed packaging device pressing mechanism is suitable for popularization.

Owner:黄颖

Equipment for filling small box with middle box and process method of equipment

The invention discloses equipment for filling a small box with a middle box and a process method of the equipment. The equipment comprises a machine frame, a box discharging device, a box conveying device, a box opening device, a box filling device and a cover closing device, the machine frame is a bearing body of the whole equipment, all the devices are installed on the machine frame and share amain driving shaft, and strip boxes to be filled with cigarette packets are stored in a box library of the box discharging device; the equipment can automatically and continuously carry out all operation actions of filling cigarette packages into strip boxes, manual participation is not needed, the labor cost is saved, the filling quality is guaranteed, and meanwhile the production efficiency is greatly improved.

Owner:湖南中南高创机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com