Patents

Literature

40results about How to "Precise raise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle source device

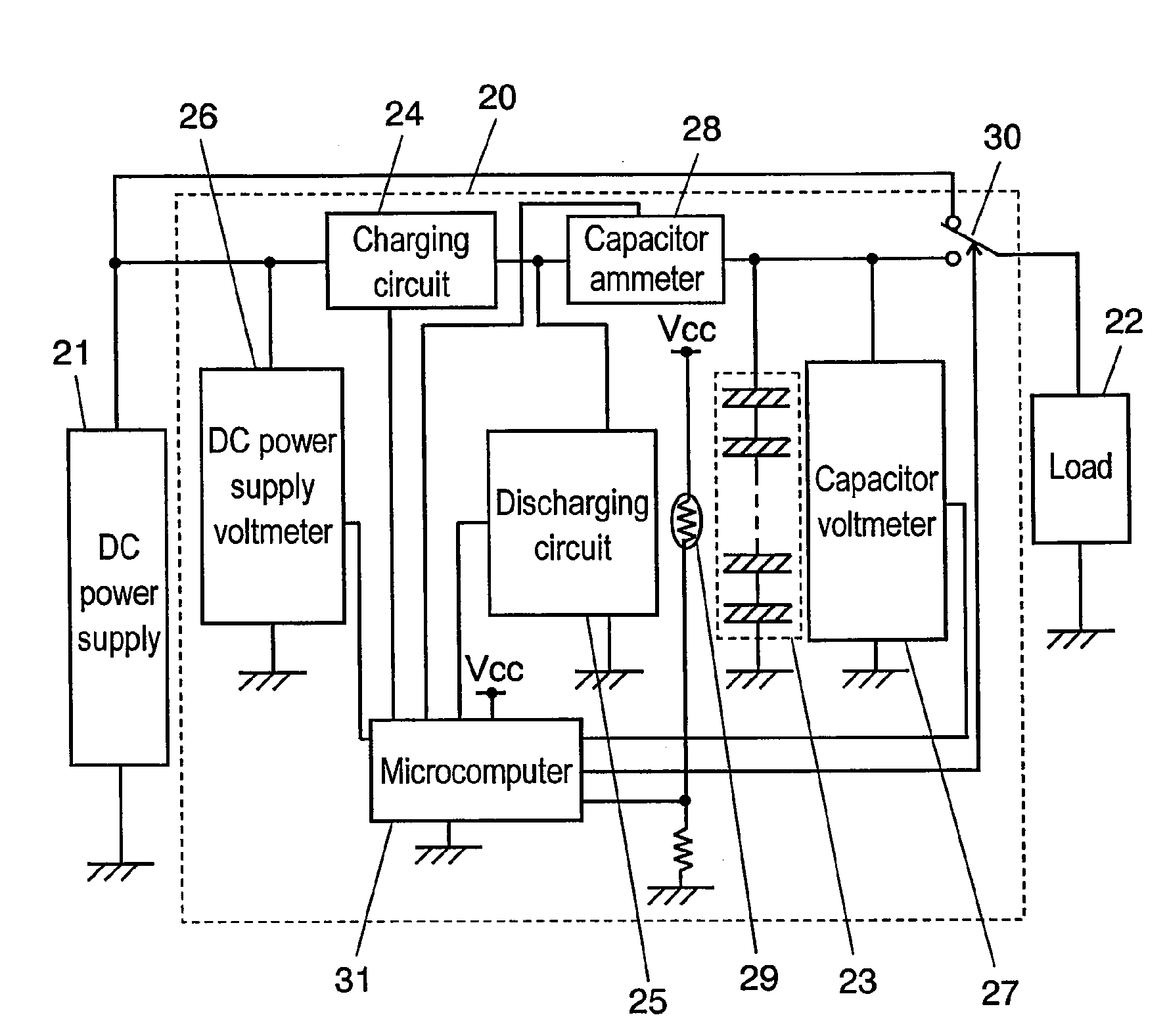

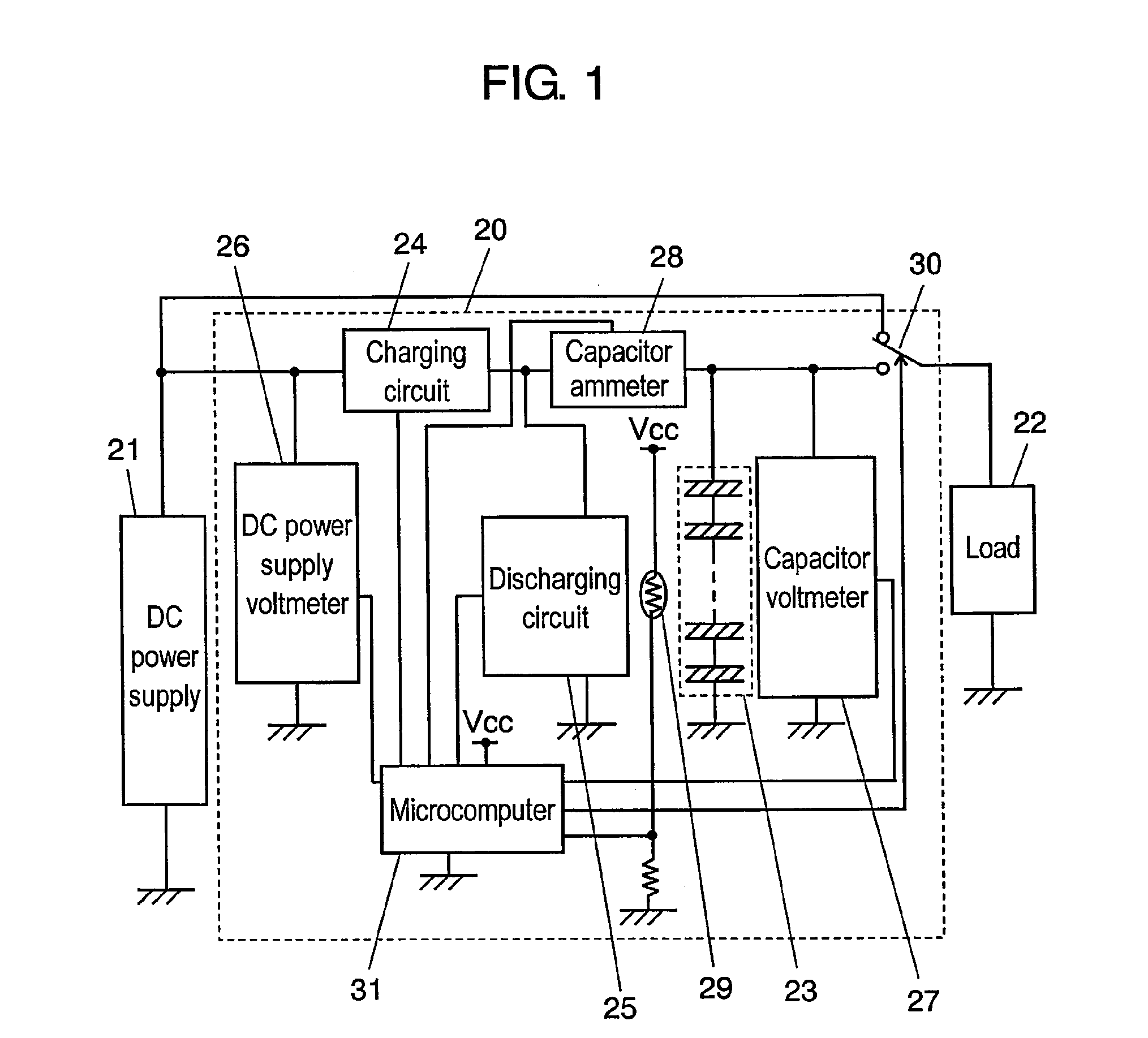

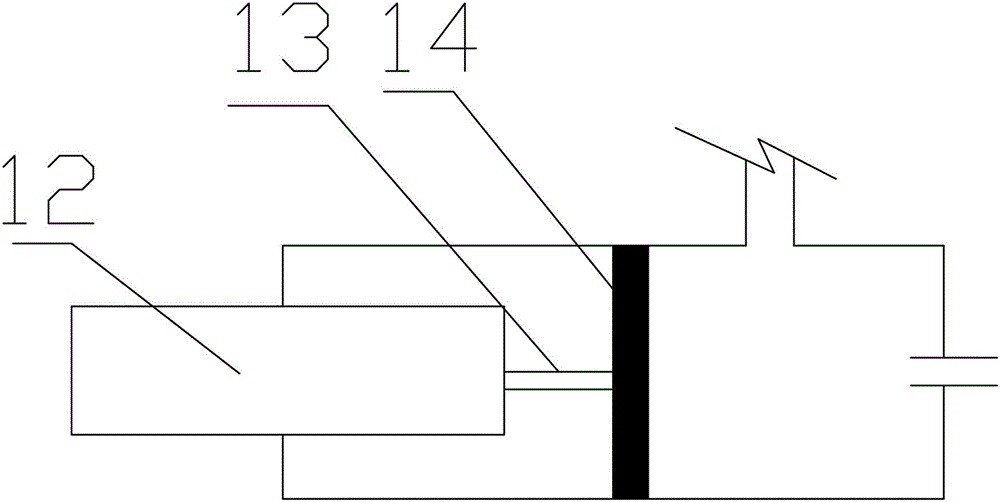

InactiveUS20090033294A1Accurate temperaturePrecise raiseOperating modesPropulsion by capacitorsInternal resistanceEngineering

A vehicle source device capable of performing a more accurate temperature-rise corresponding to the ability of the capacitor is provided. The correlation of the temperature and the internal resistance corresponding to the ability of the current capacitor in time of activation is obtained in advance, the internal resistance is obtained for every repetition of charge / discharge, and the temperature of the inside of the capacitor is obtained from the correlation. Since the accurate temperature of the inside of the capacitor is obtained, the capacitor is accurately temperature-raised to the target temperature.

Owner:PANASONIC CORP

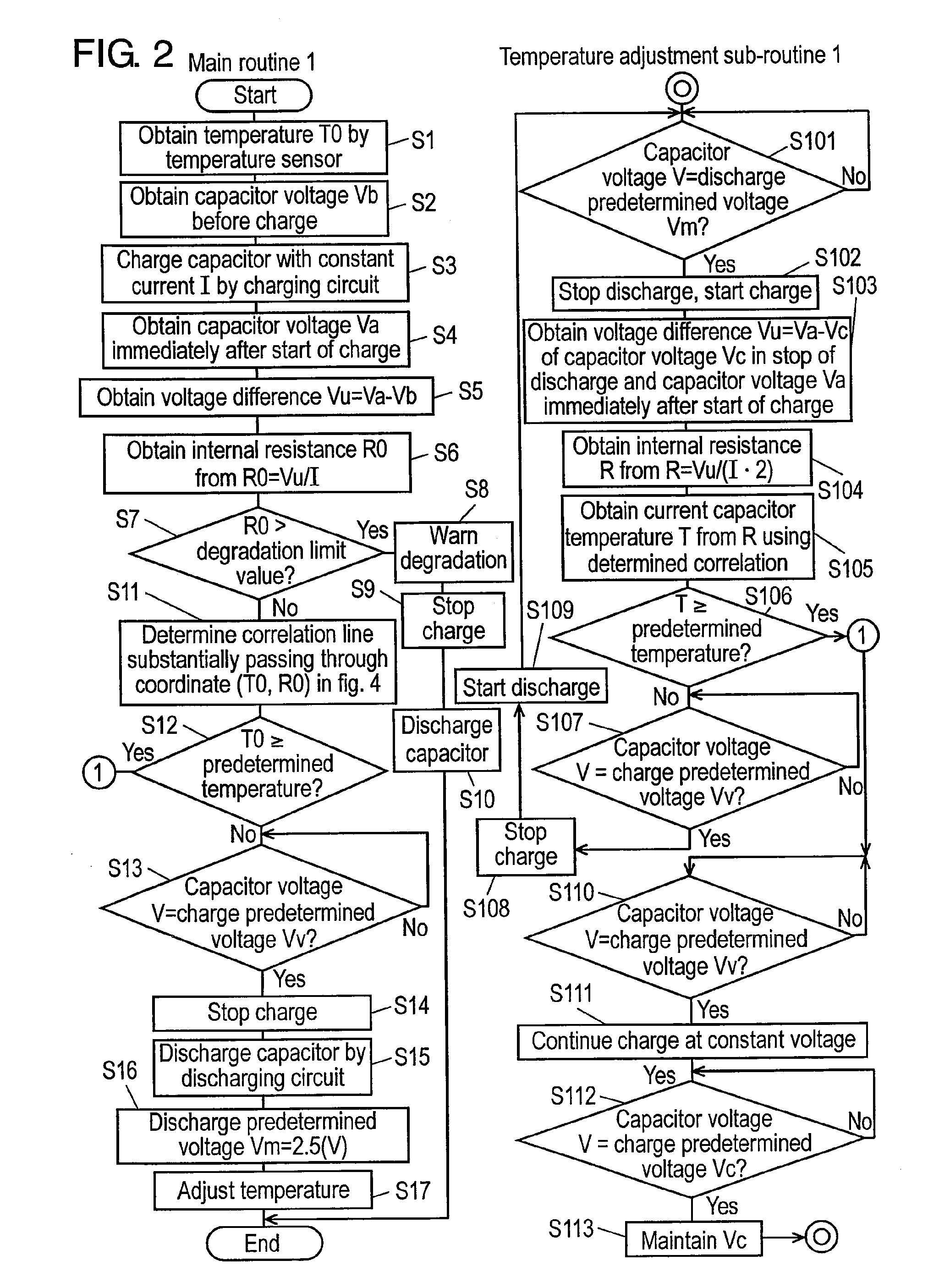

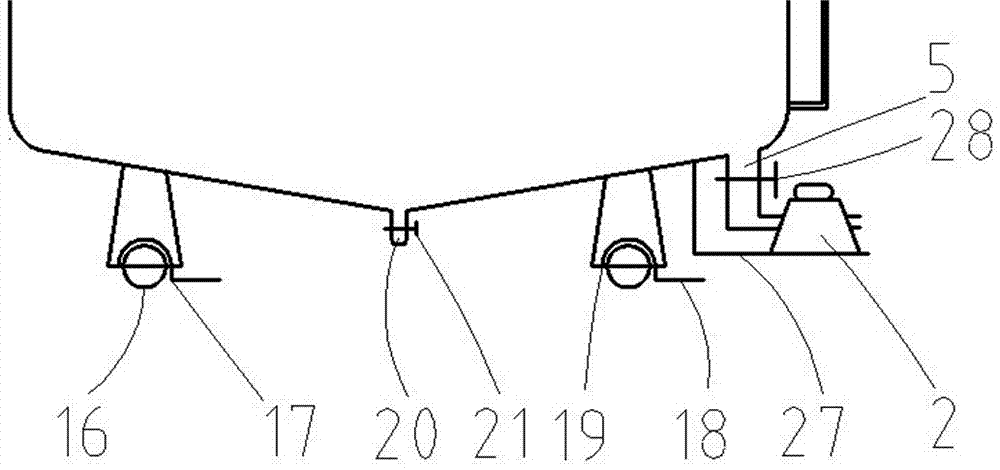

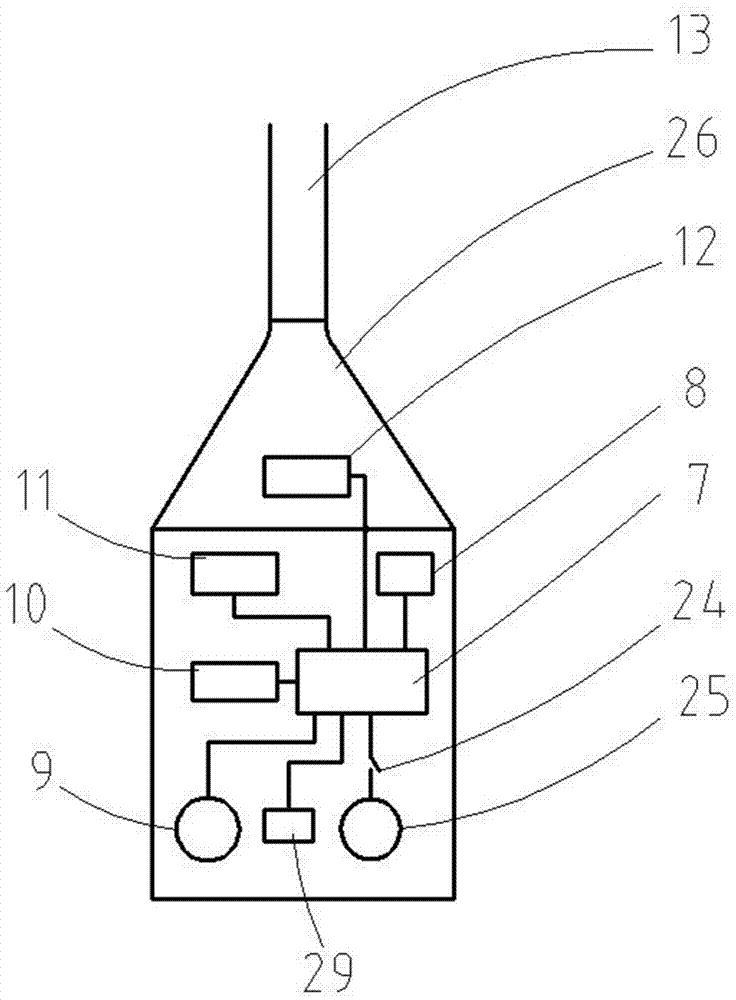

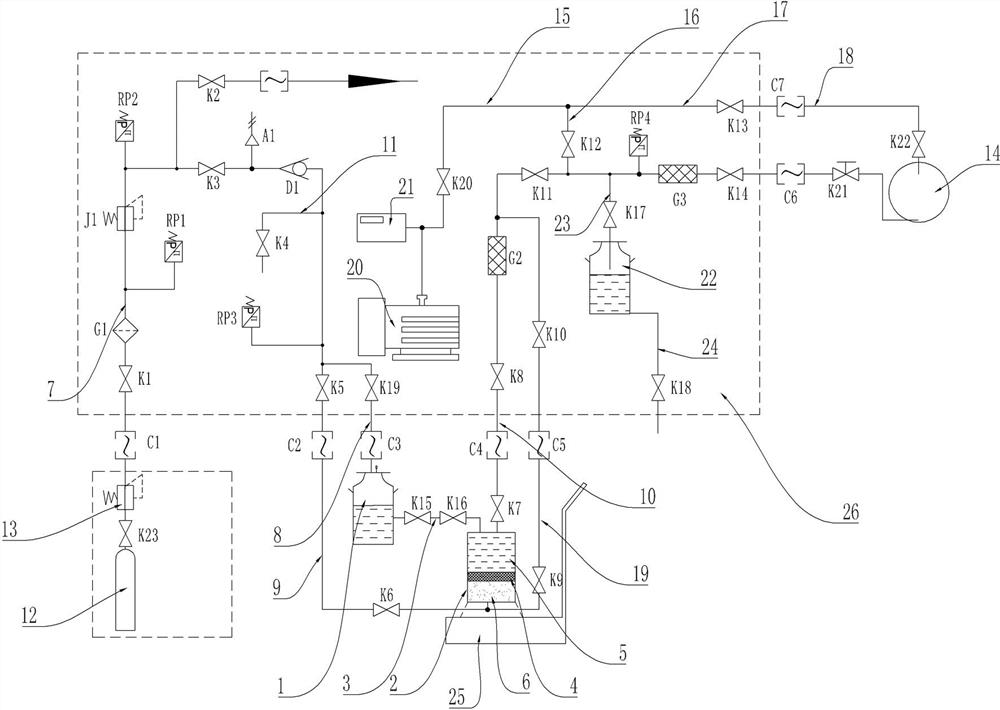

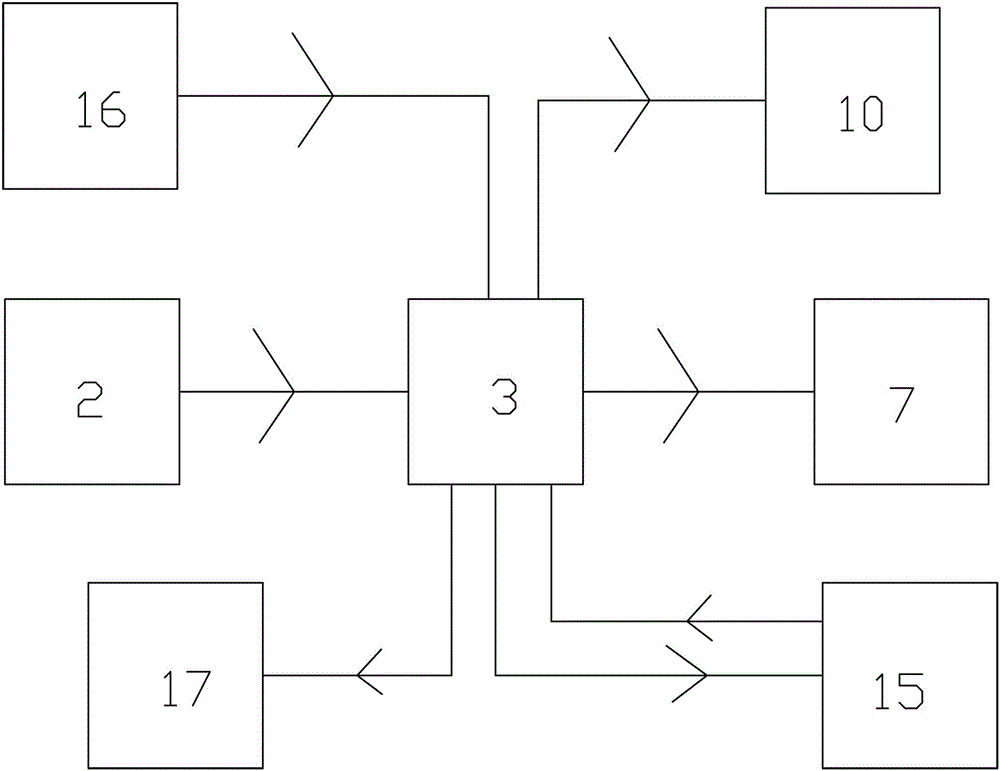

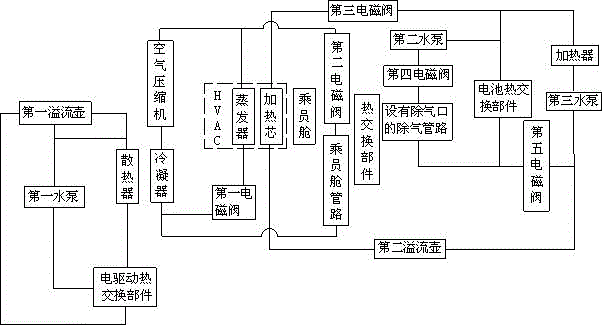

BEV (battery electric vehicle) thermal management system and cooling liquid filling method thereof

ActiveCN104477024AGuaranteed uptimeGood thermal managementAir-treating devicesVehicle heating/cooling devicesElectricityElectrical battery

The invention aims to provide a BEV (battery electric vehicle) thermal management system and a cooling liquid filling method thereof. The BEV thermal management system comprises an electric drive part thermal management sub-system and a passenger bin and battery thermal management sub-system. The electric drive part thermal management sub-system comprises a first overflow kettle, a first water pump, a radiator and an electric drive heat exchanging part, wherein one end of the radiator is connected with the first port of the electric drive heat exchanging part, the other end of the radiator is respectively connected with the first overflow kettle and the first port of the first water pump, and the second port of the electric drive heat exchanging part is respectively connected with the first overflow kettle and the second port of the first water pump. The BEV thermal management system and the cooling liquid filling method thereof have the advantages that effective thermal management of auto parts and accurate cooling liquid filling are achieved; the BEV thermal management system provides a good thermal management function for the electric drive part, a passenger bin and a battery, comfortableness of the passenger bin is guaranteed, and the electric drive part and the battery are enabled to be in an appropriate temperature range.

Owner:奇瑞新能源汽车股份有限公司

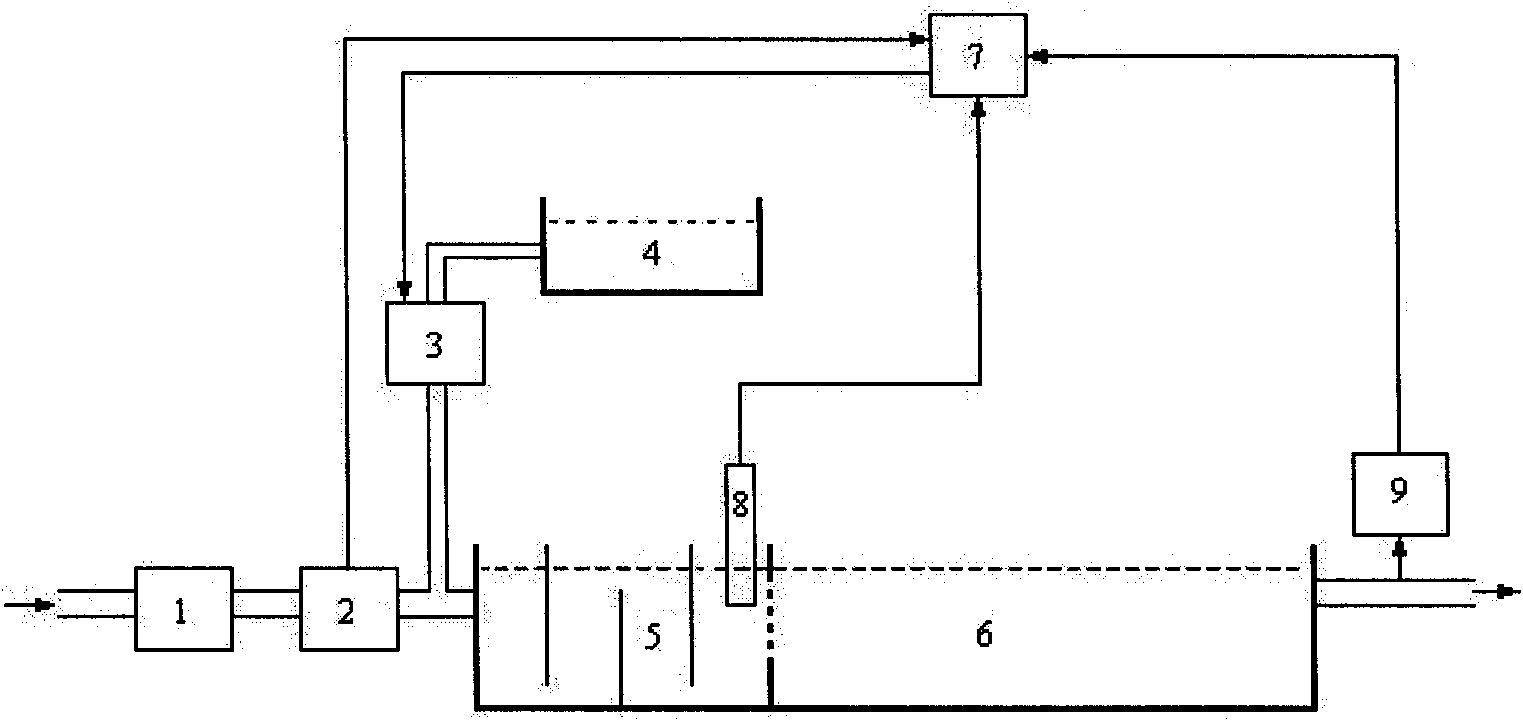

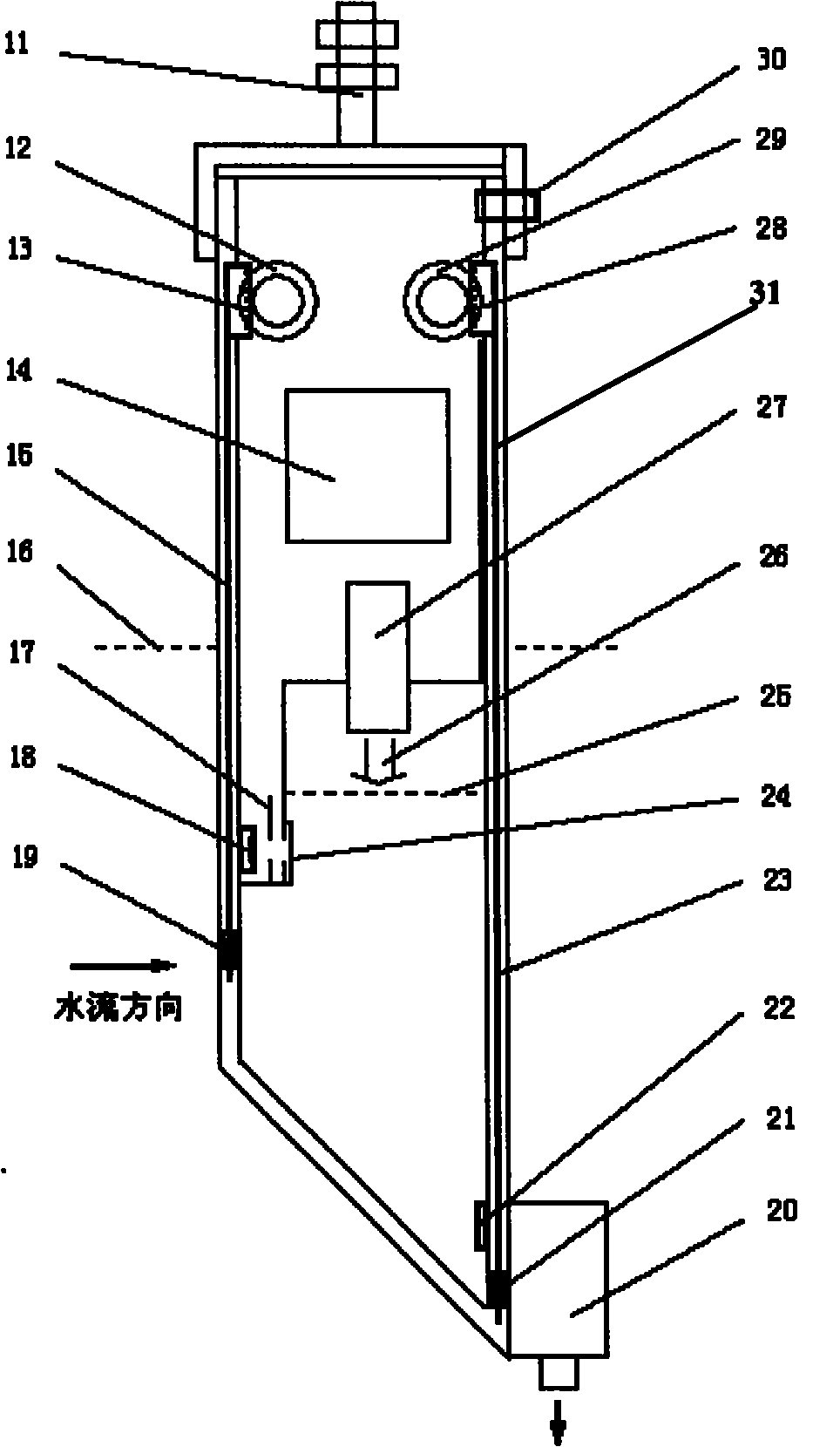

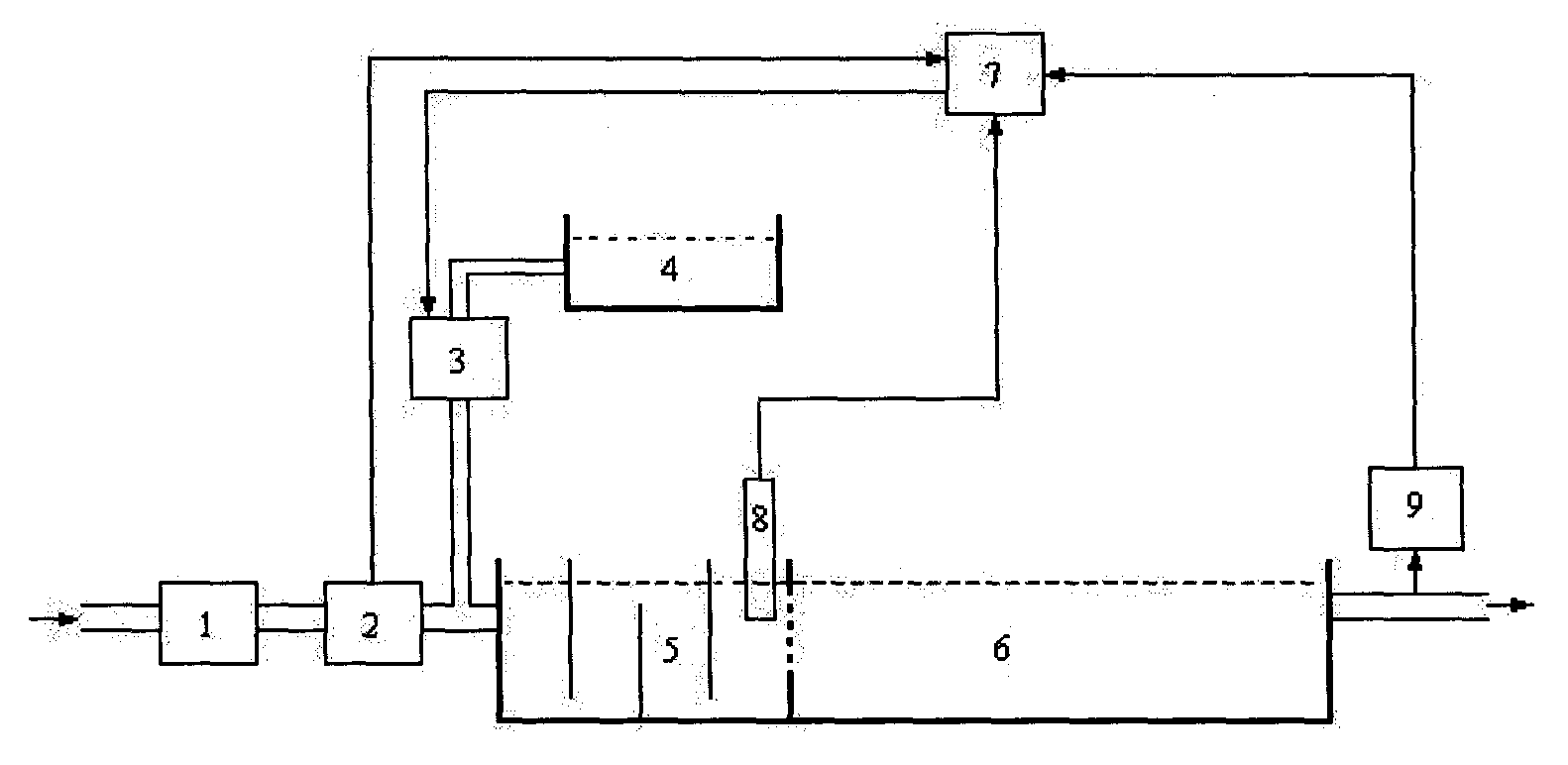

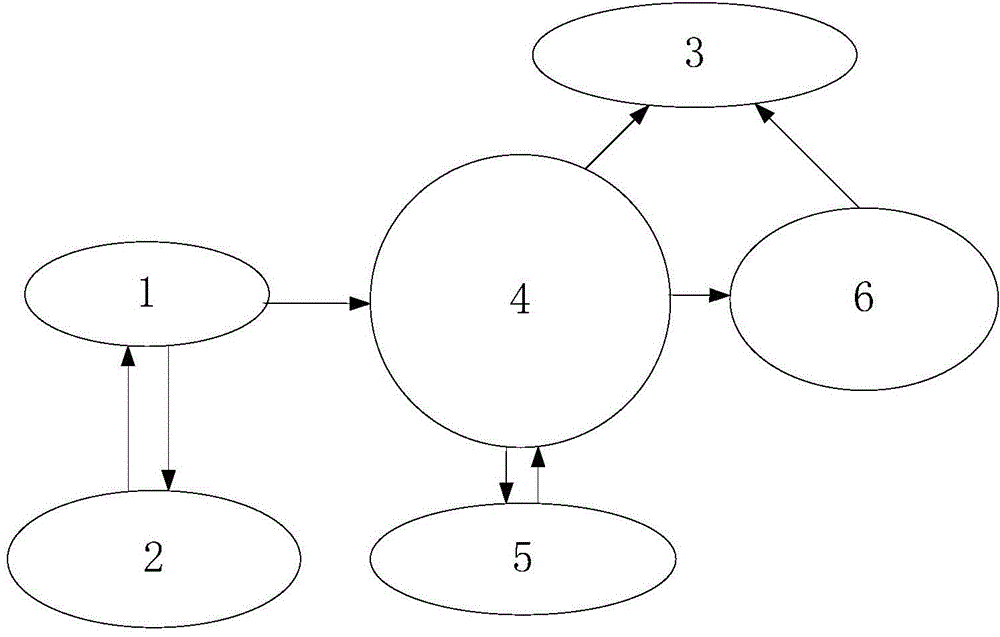

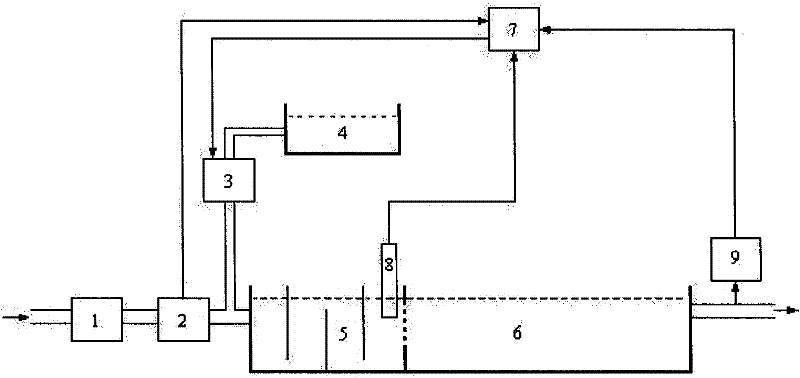

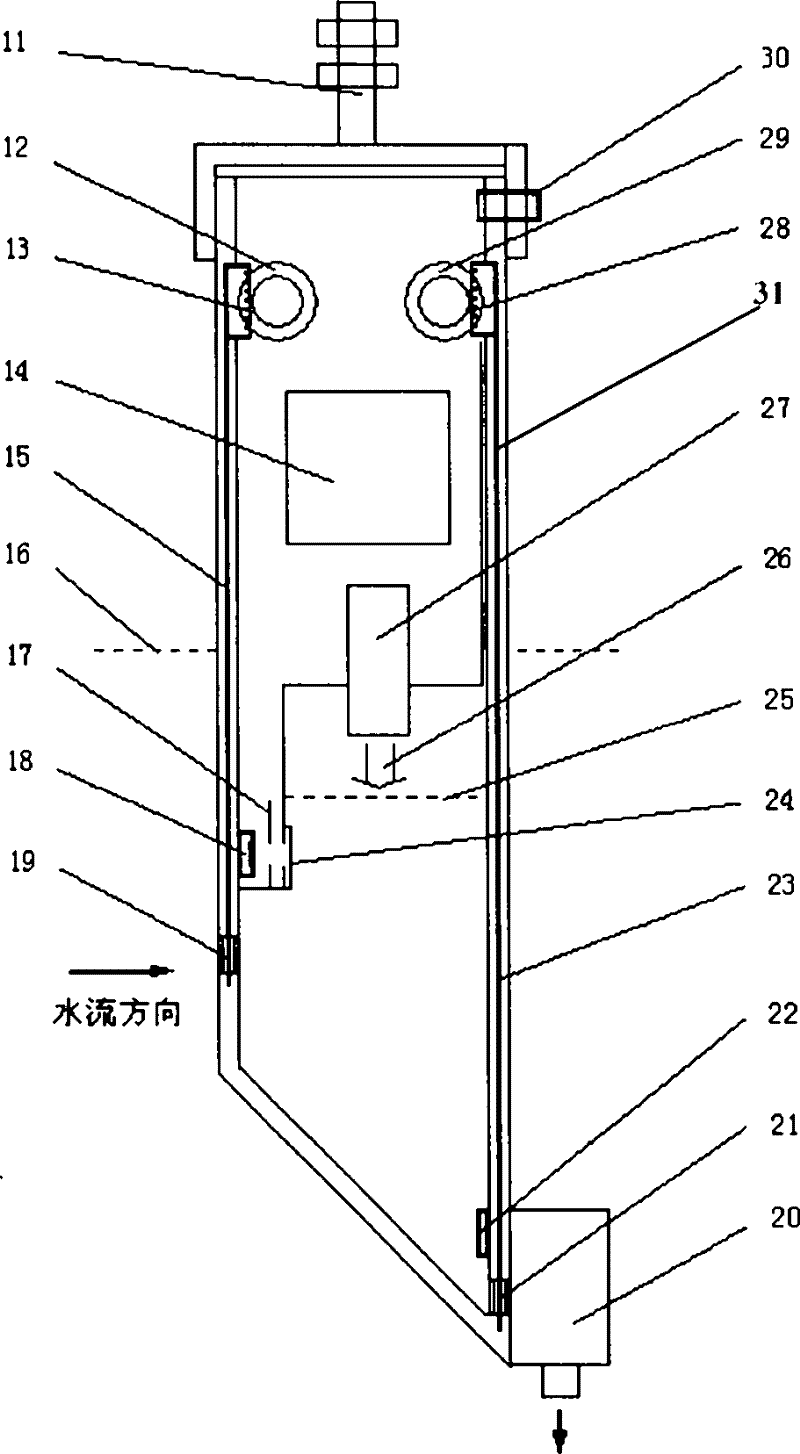

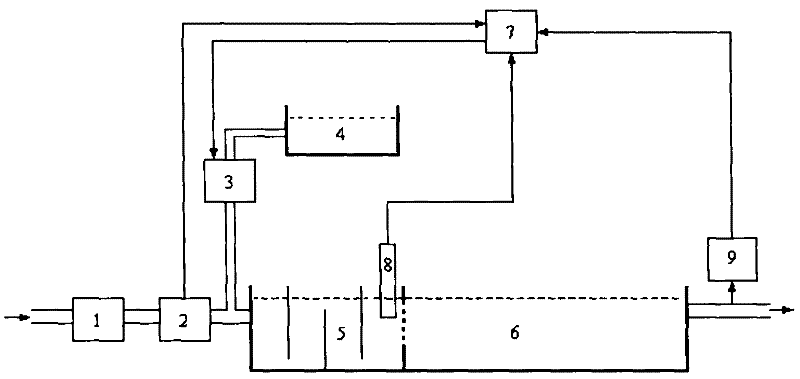

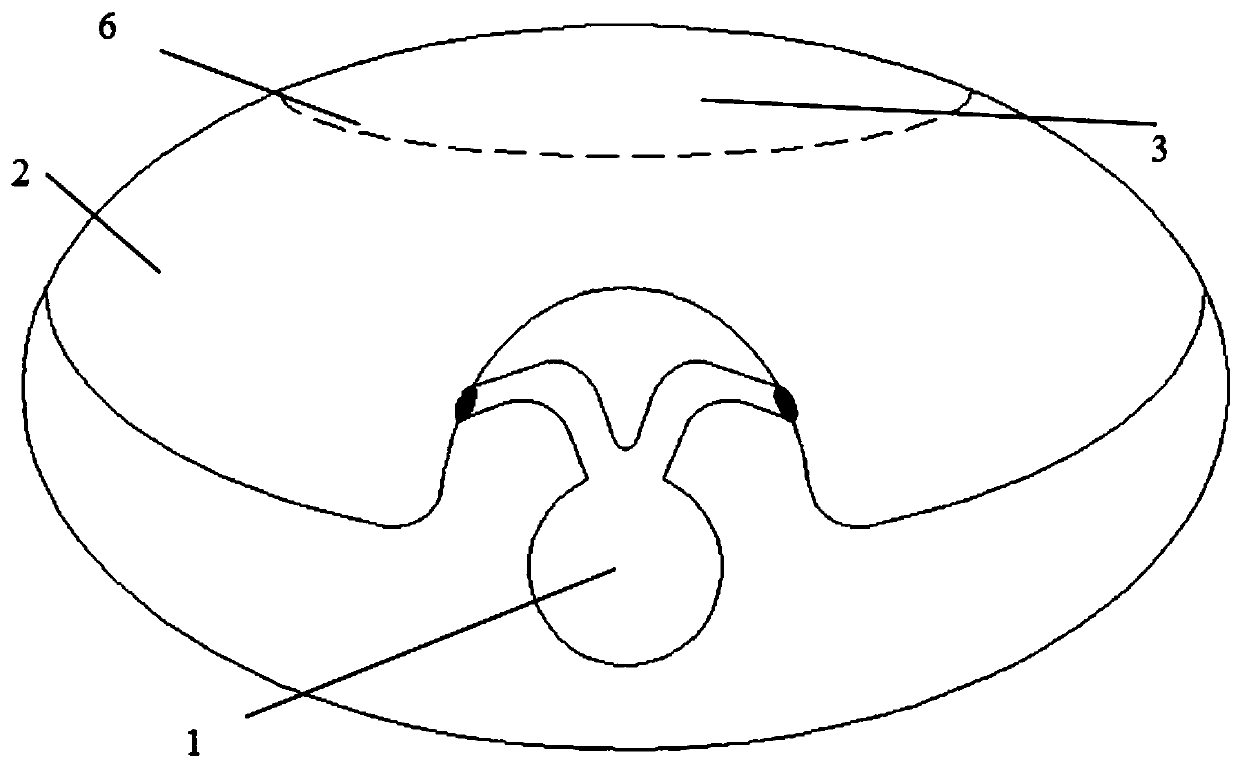

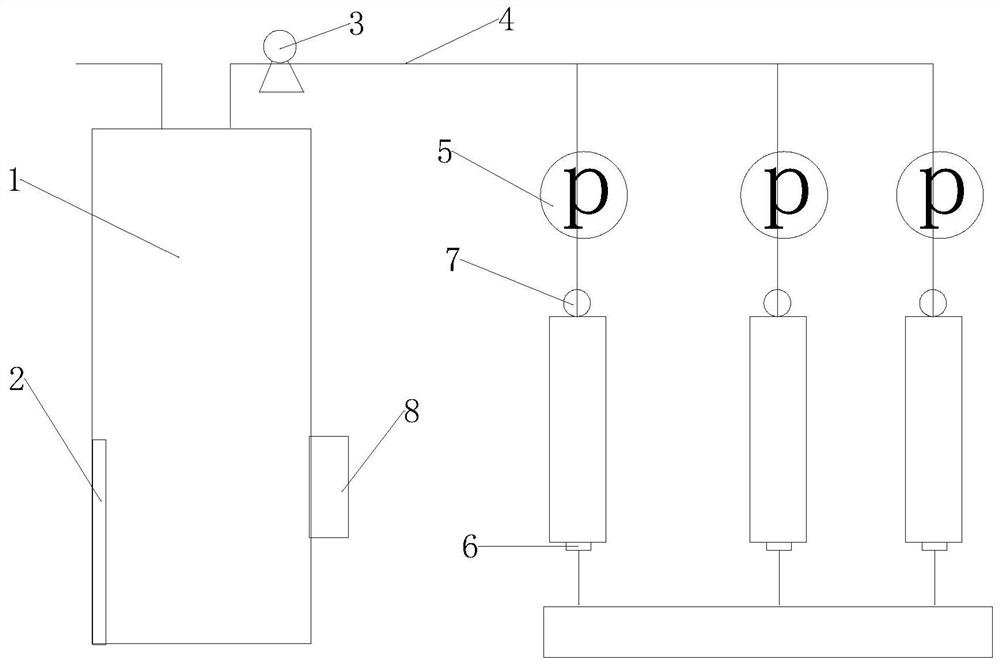

Method and system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation

InactiveCN101805050AReduce purification costsReduce fill volumeWater/sewage treatment by flocculation/precipitationFlocculationTurbidity

The invention relates to a method and a system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation. The method comprises the following steps of: making raw water enter a flocculation tank to mix, react and flocculate with the added coagulant so as to generate a flocculating substance; collecting the flocculation water in real time through a sensor for measuring the turbidity under the water at the tail end of the flocculation tank; sedimenting in the sensor in the given sedimentation time, and measuring the turbidity; comparing the measured value with the set value; and after the difference is subjected to PID operation, obtaining the needed dosing ratio, and multiplying the dosing ratio with the water inlet flow to obtain the dosing, converting the dosing into a standard current output signal to control the dosing of a dosing pump, and dosing the coagulant on line. The system consists of the flocculation tank, a sedimentation tank, the dosing pump, a coagulation tank, a microprocessor and a sensor 5 which is specially designed for measuring the turbidity. Due to adoption of the sensor for measuring the turbidity, the turbidity after flocculation water sedimentation can be accurately measured on line without being disturbed by other factors. Therefore, the on-line coagulant dosing can be accurately controlled, the coagulant dosing is reduced, the water purification quality is improved, and the water purification cost is lowered.

Owner:SHANGHAI UNIV

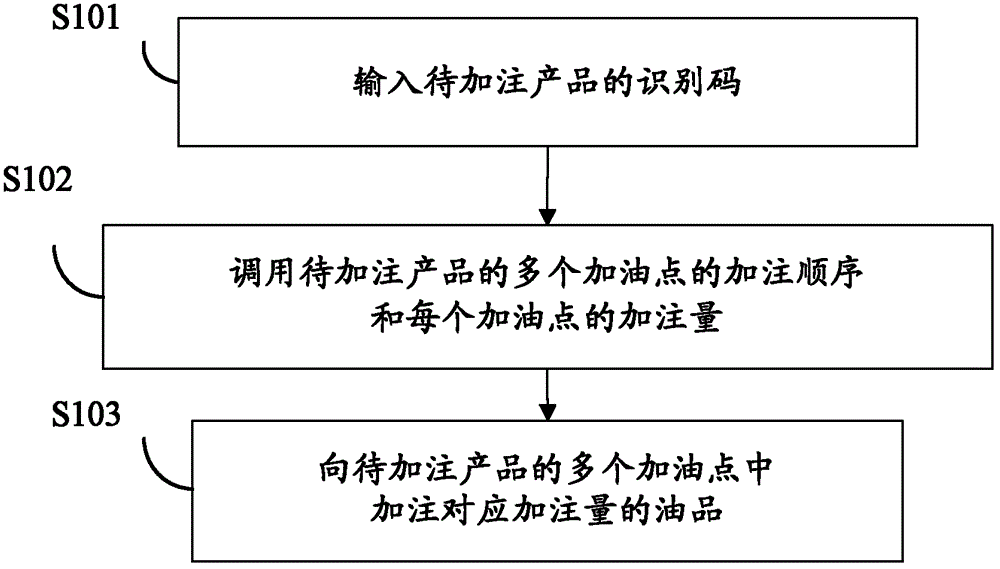

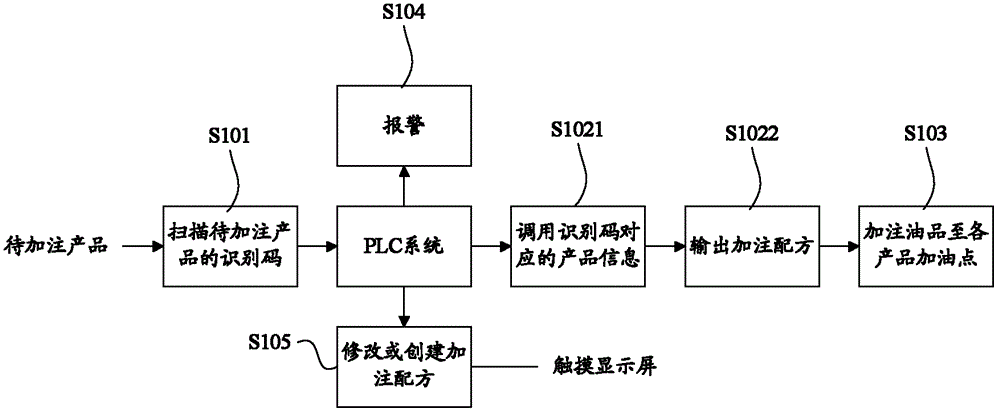

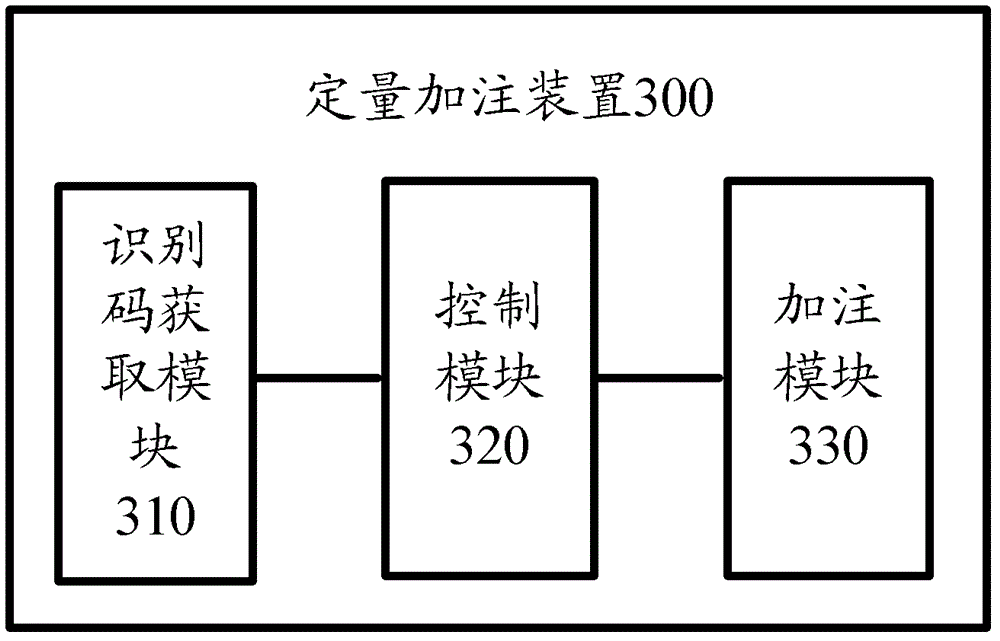

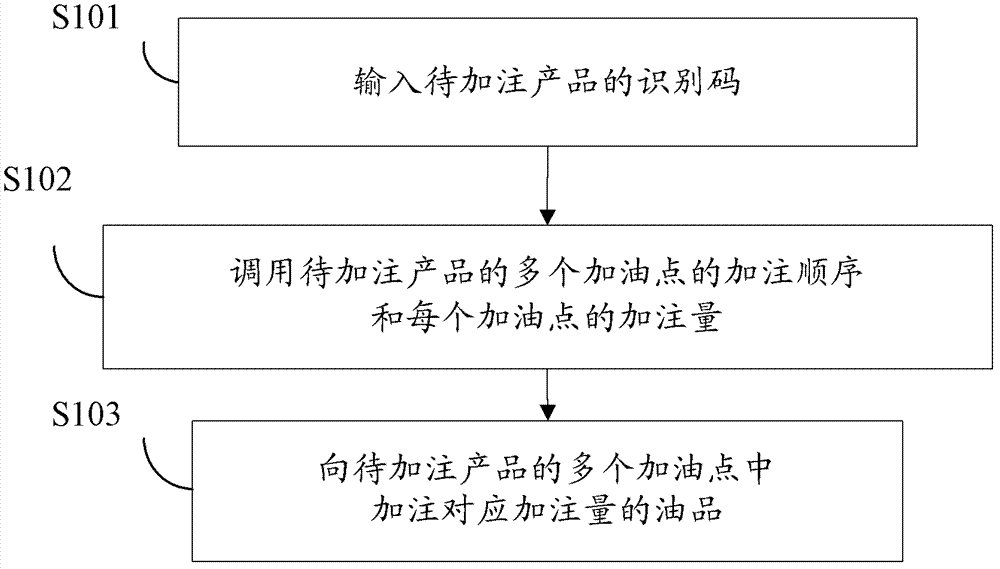

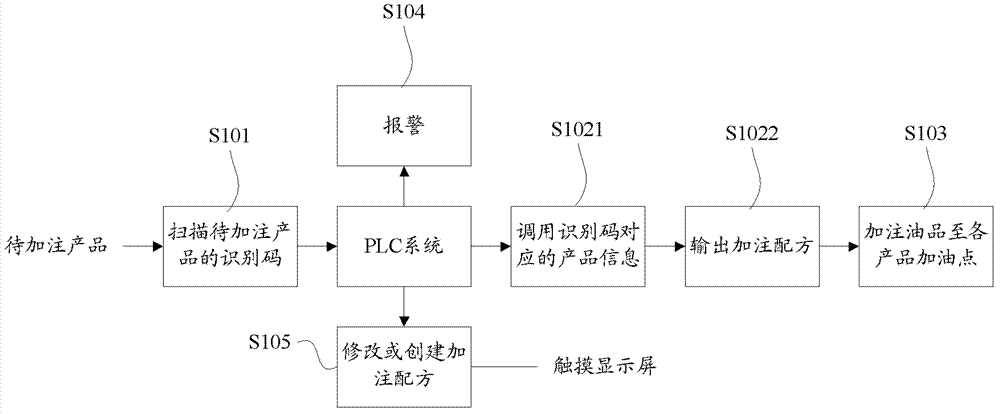

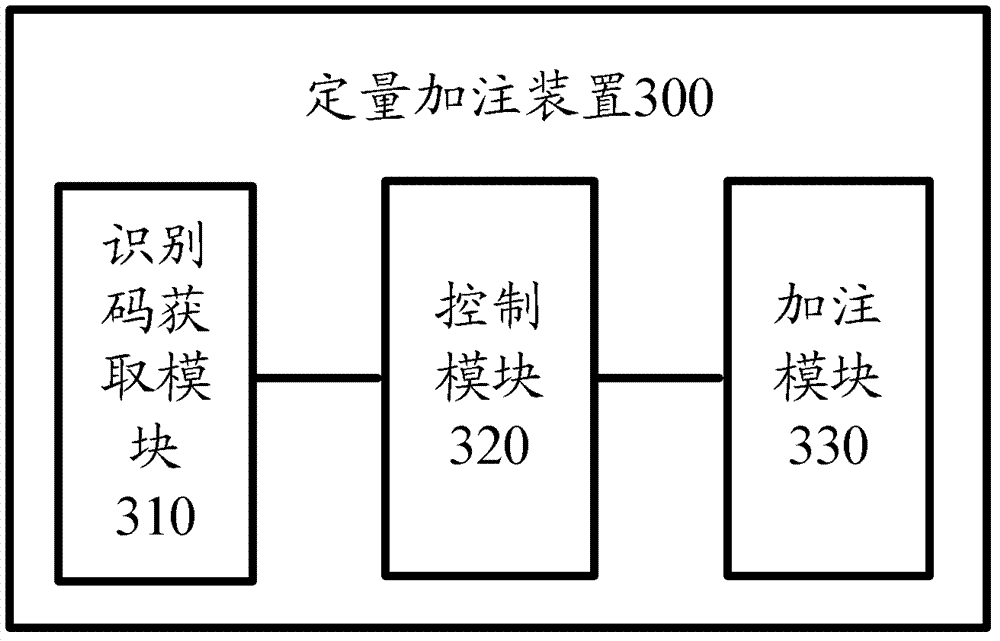

Quantitative filling method and device

ActiveCN102795203AGuaranteed filling qualitySimple and fast operationVehicle servicing/repairingProgramme control in sequence/logic controllersComputer moduleComputer science

The invention discloses a quantitative filling device. The device comprises an identification code acquisition module for acquiring the identification code of a product to be filled, a control module and a filling module, wherein the control module is used for receiving the identification code of the product to be filled from the identification code acquisition module and calling a filling formula of the product to be filled according to the identification code of the product to be filled; according to the filling formula, the filling sequence of a plurality of oil filling points of the product to be filled and the filling quantity corresponding to each oil filling point are provided; and the filling module fills oil into a plurality of oil filling points of the product to be filled in corresponding quantities according to the filling sequence. The invention also discloses a quantitative filling method. By the quantitative filling device and the quantitative filling method, problems such as wrong filling and missed filling of the oil in the process of manufacturing automobiles are solved; the oil filling quality of the automobiles is guaranteed; the quantitative filling device is easy and convenient to operate, and the oil can be filled accurately, so that the on-site assembly efficiency is improved.

Owner:BEIQI FOTON MOTOR CO LTD

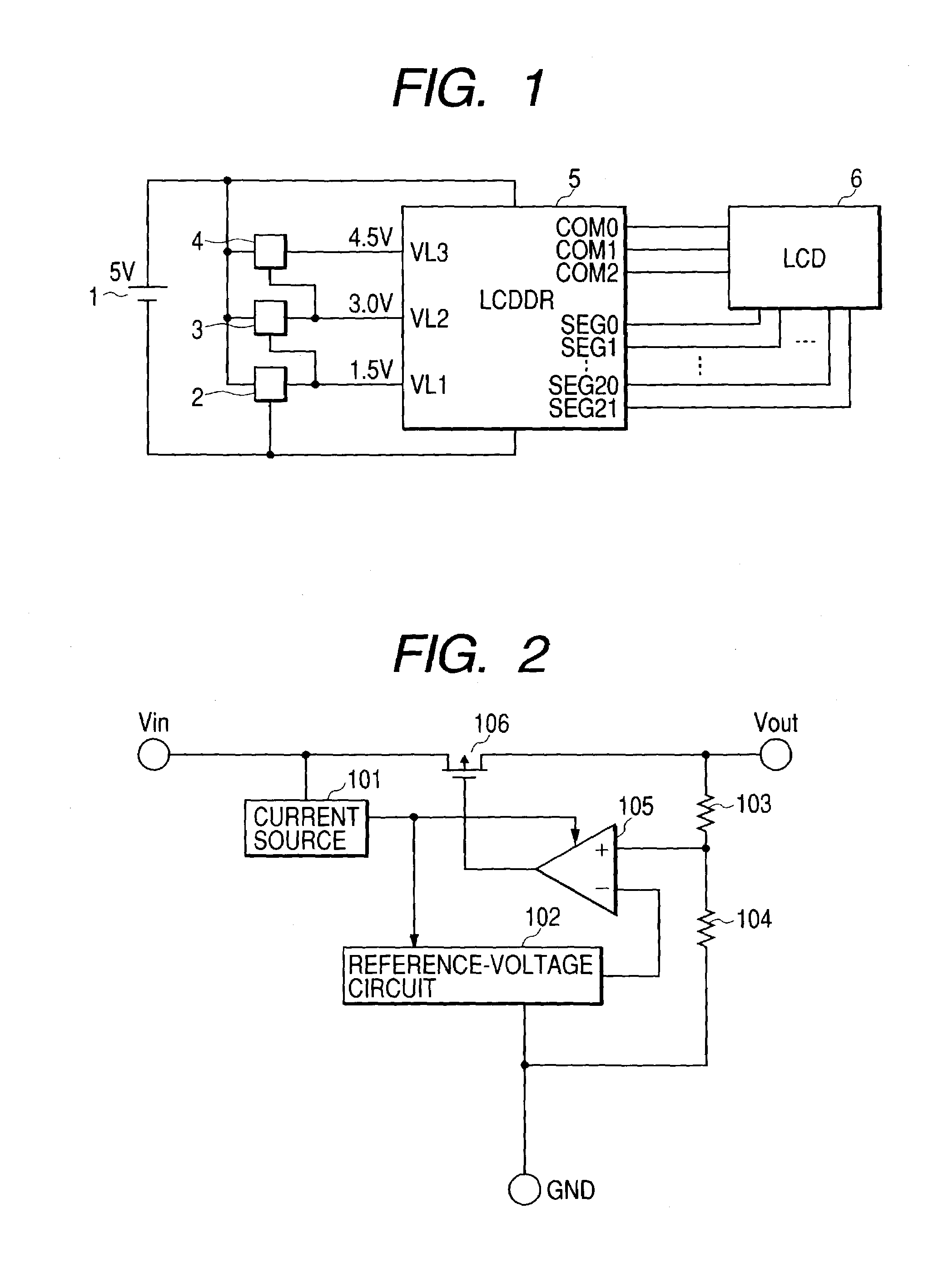

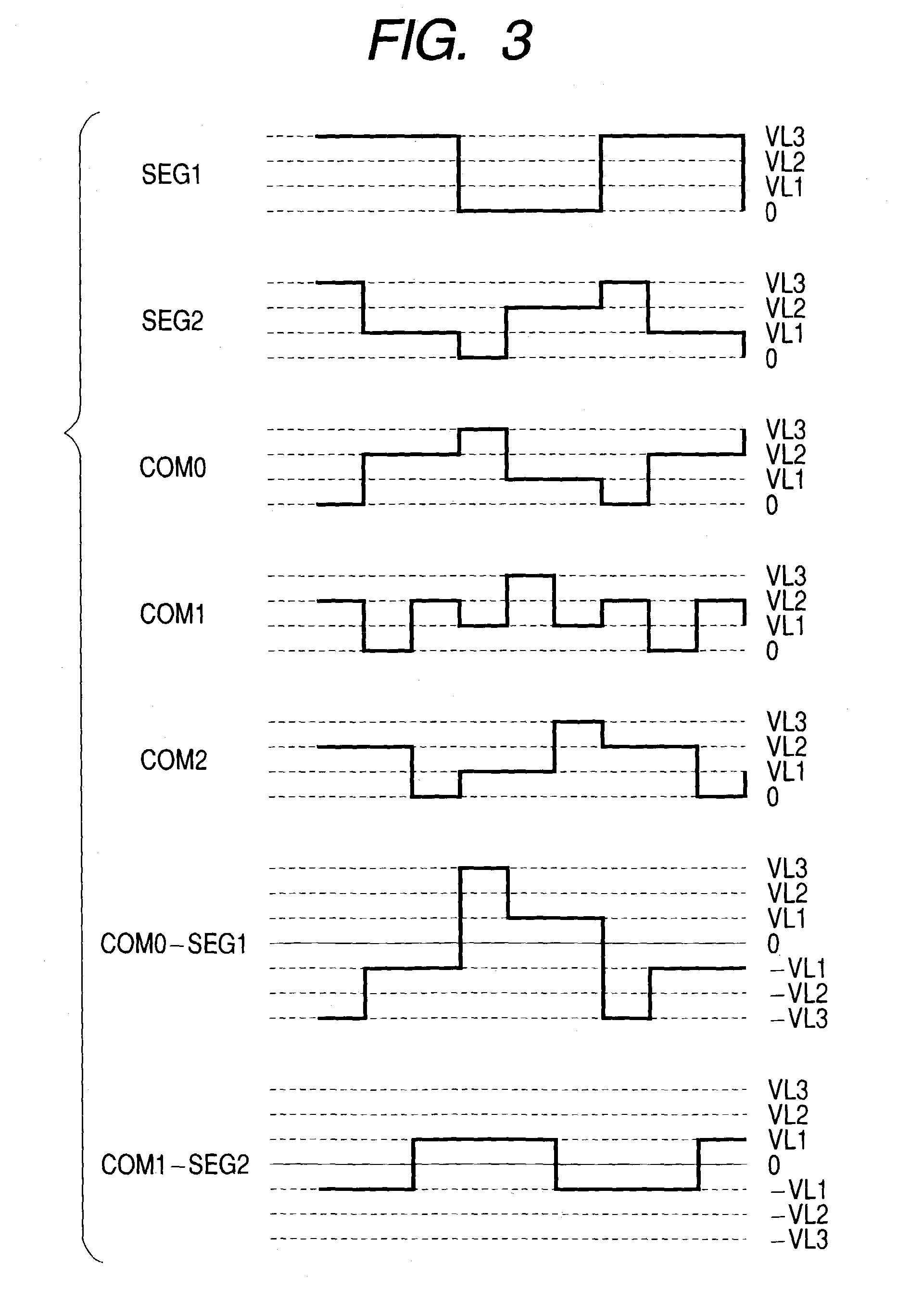

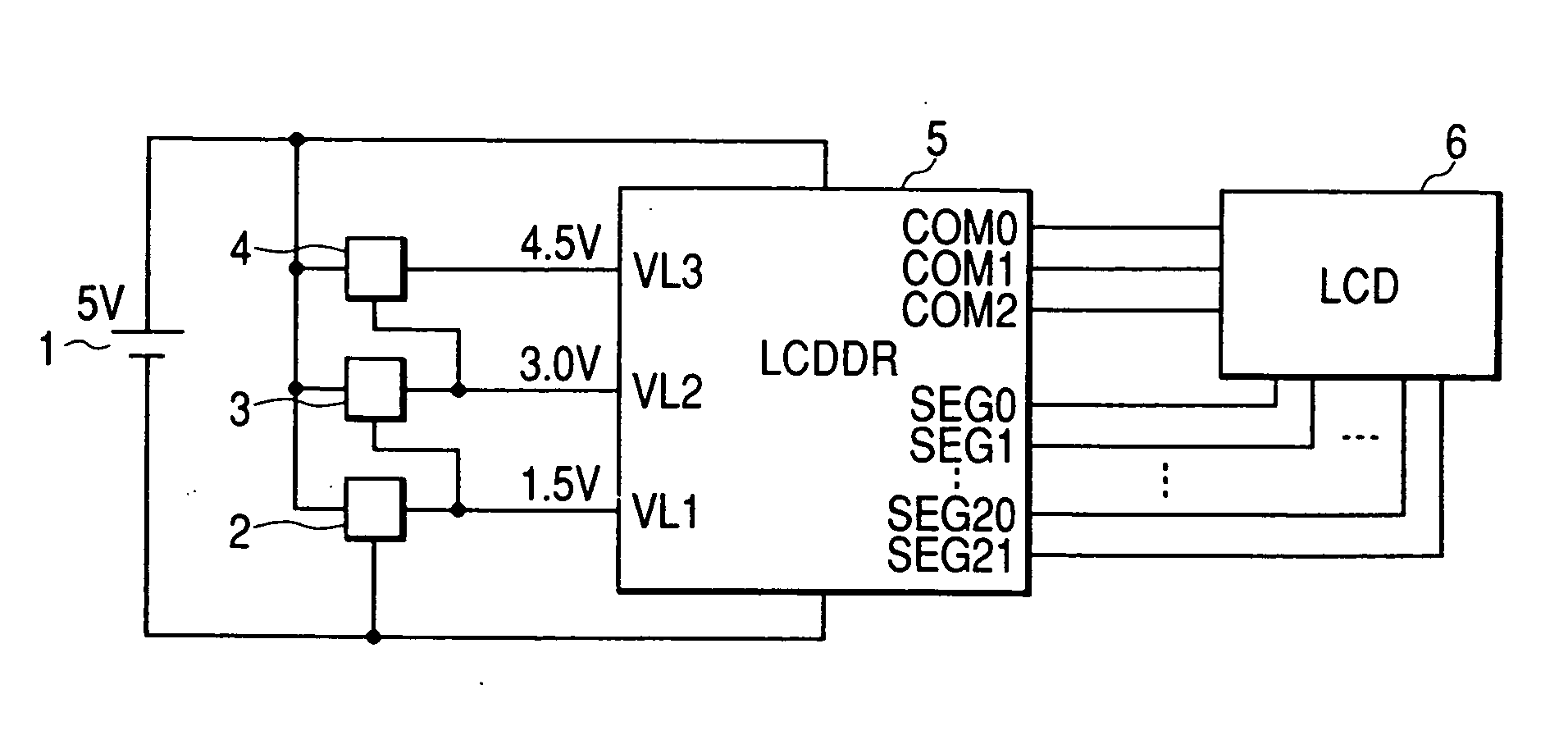

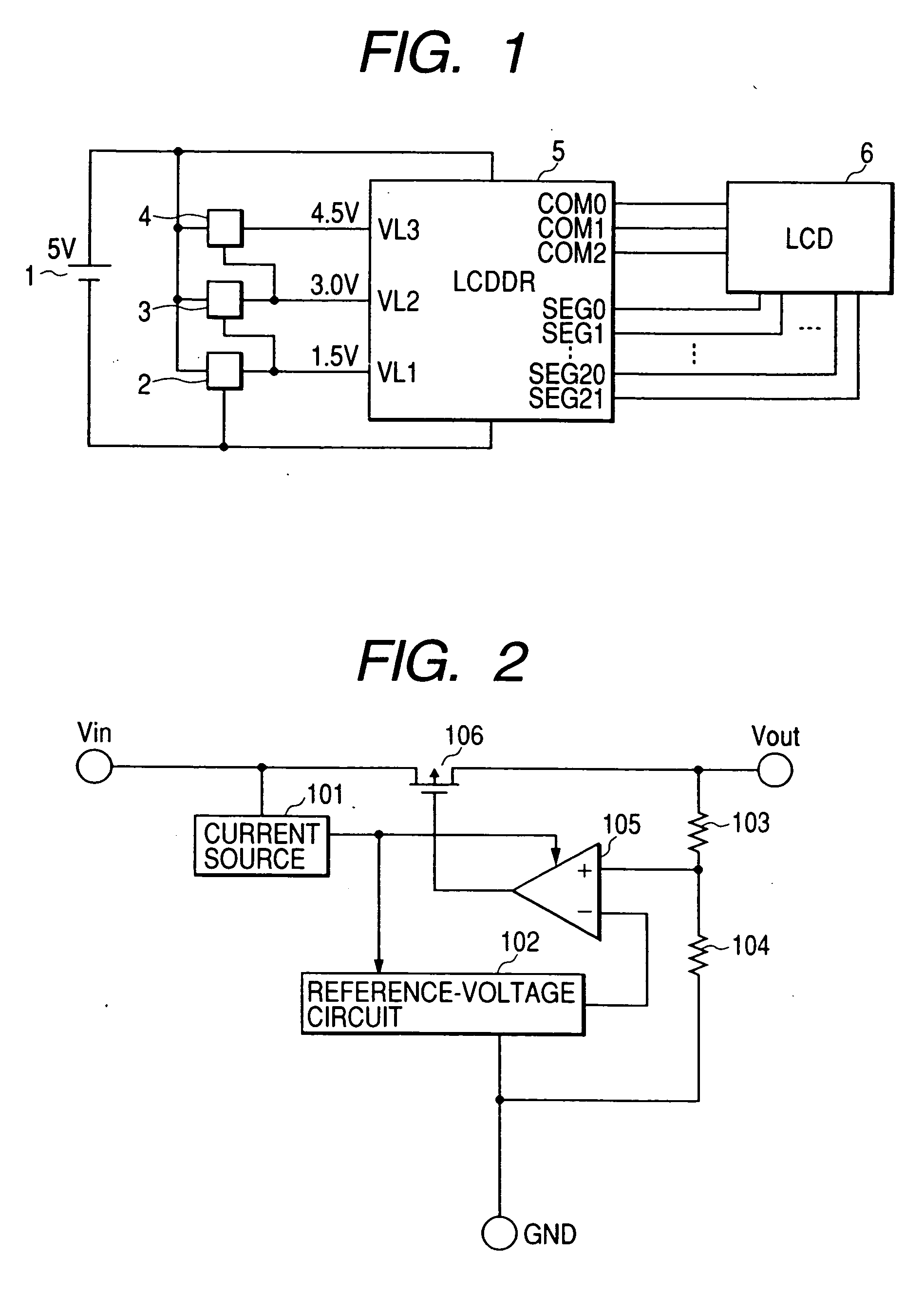

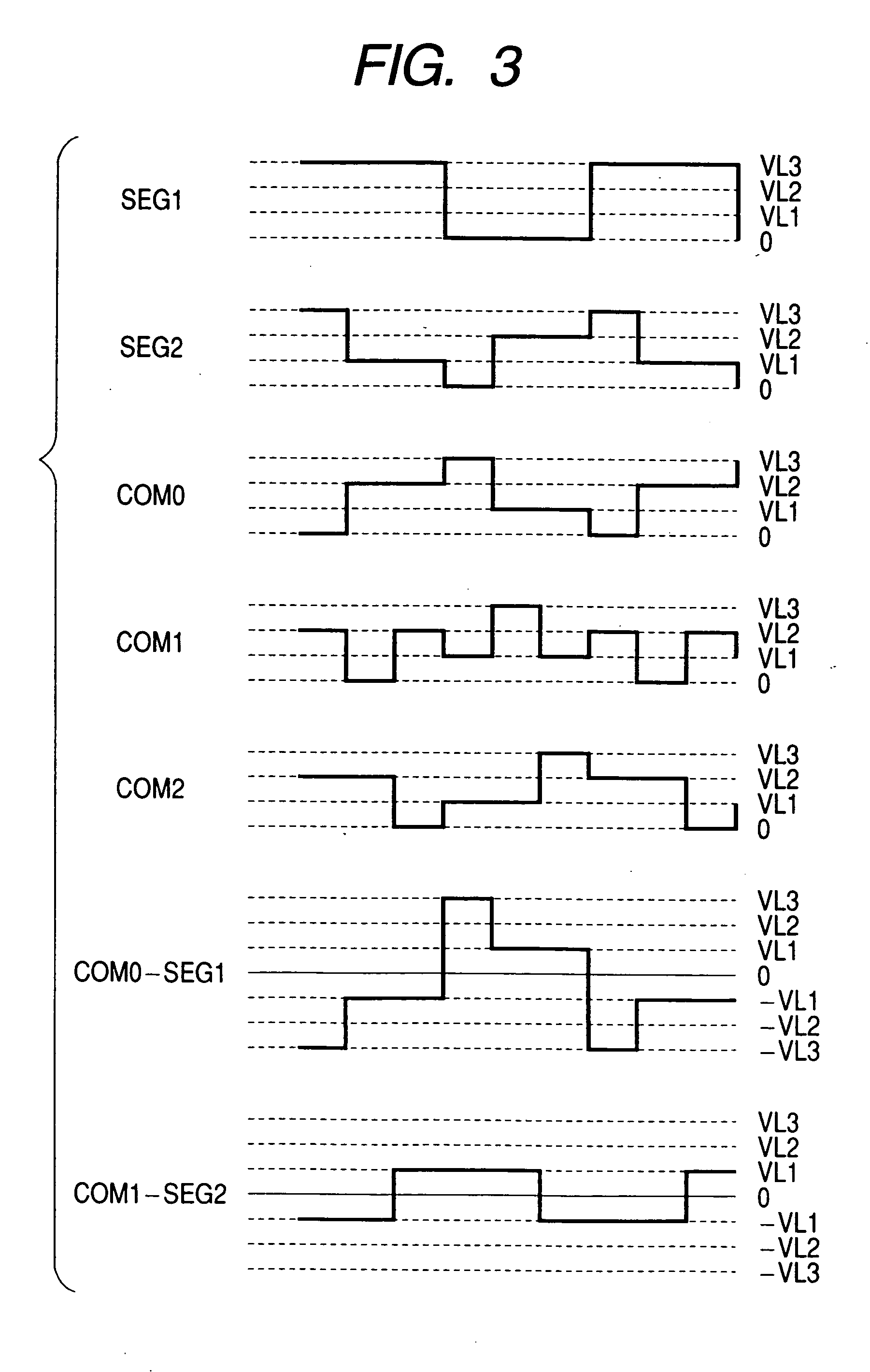

Power circuit for display driver, display device, and camera

InactiveUS6975314B2Precise raisePower supply linesCathode-ray tube indicatorsDriver circuitEngineering

Owner:CANON KK

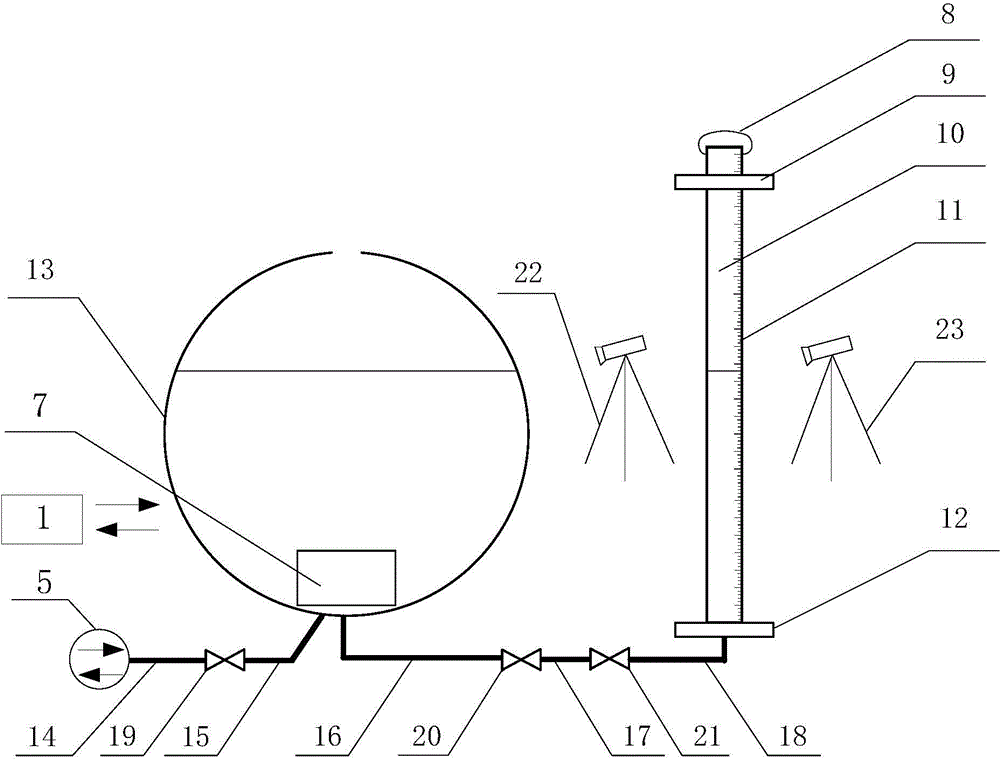

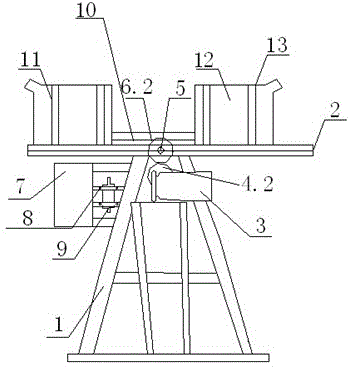

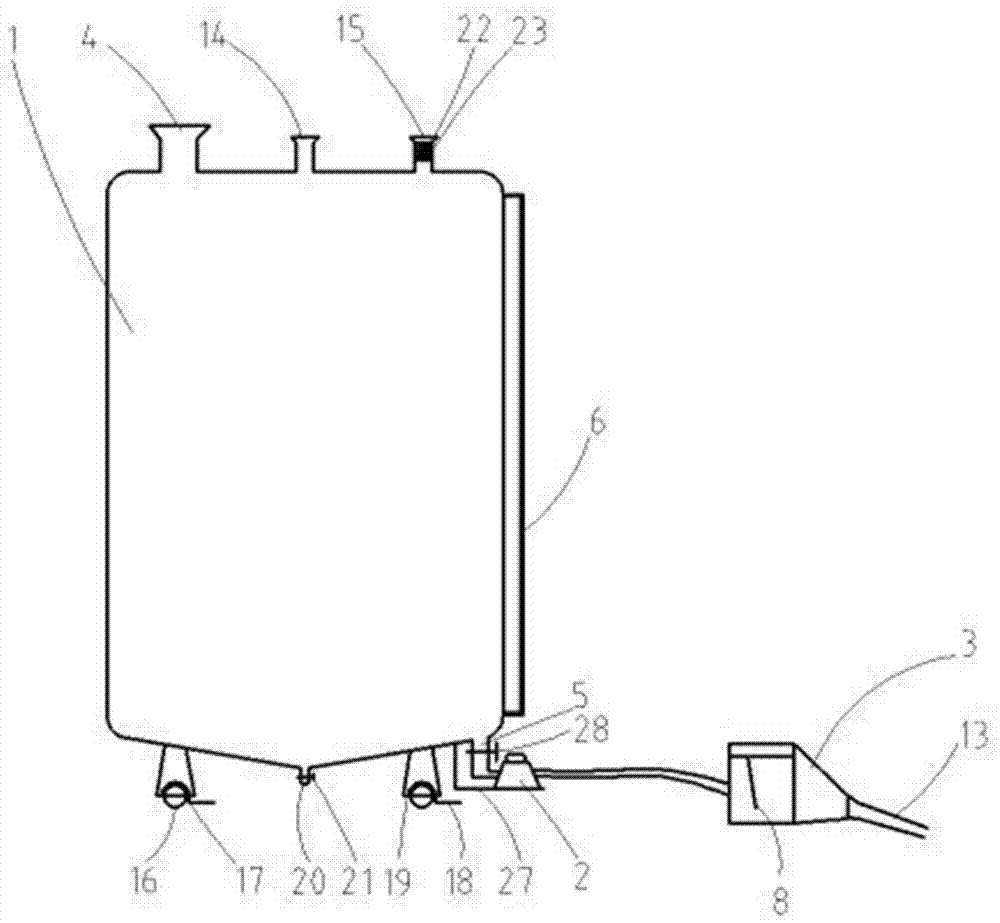

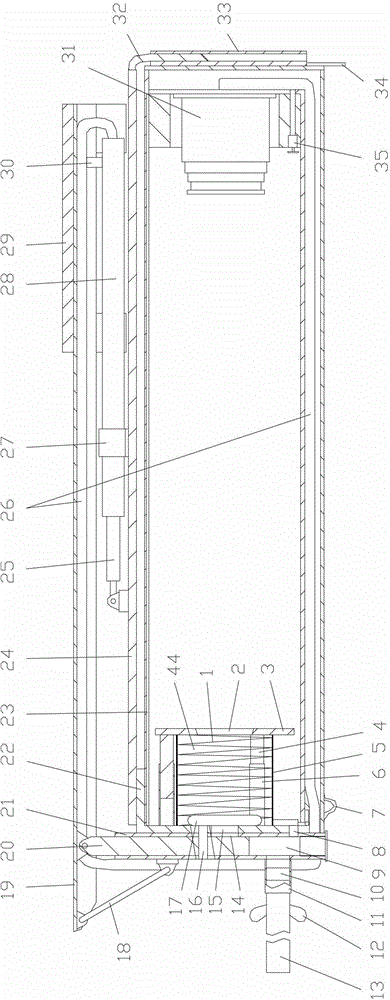

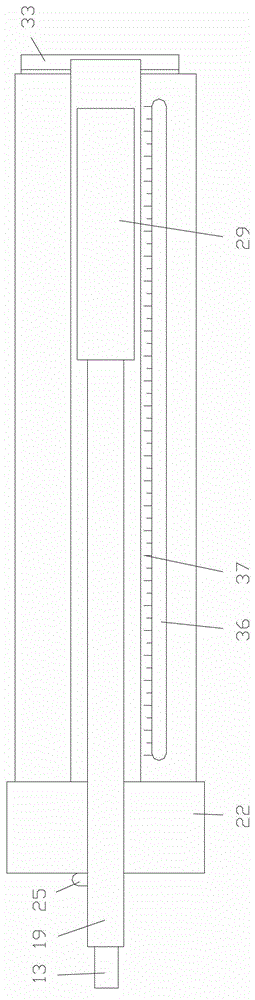

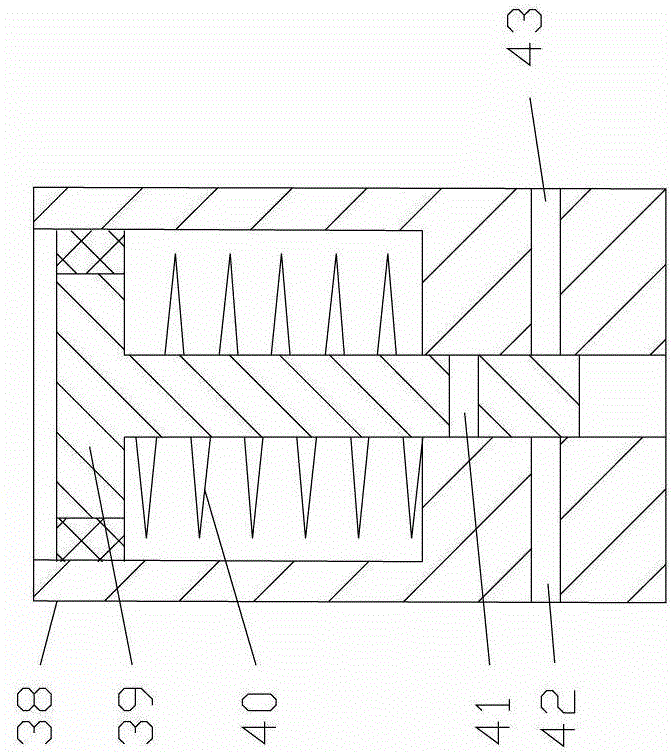

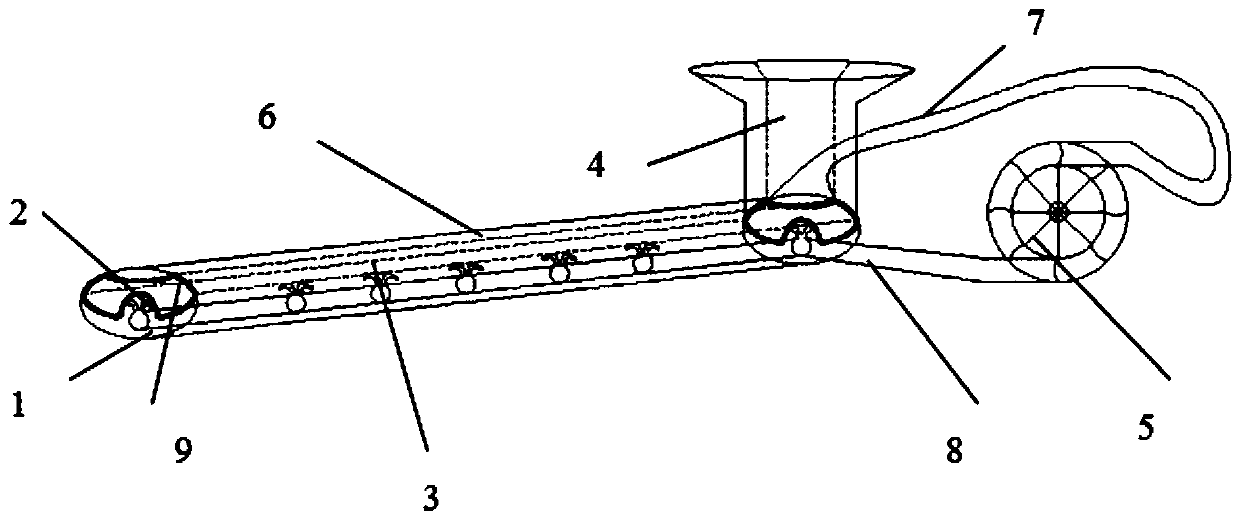

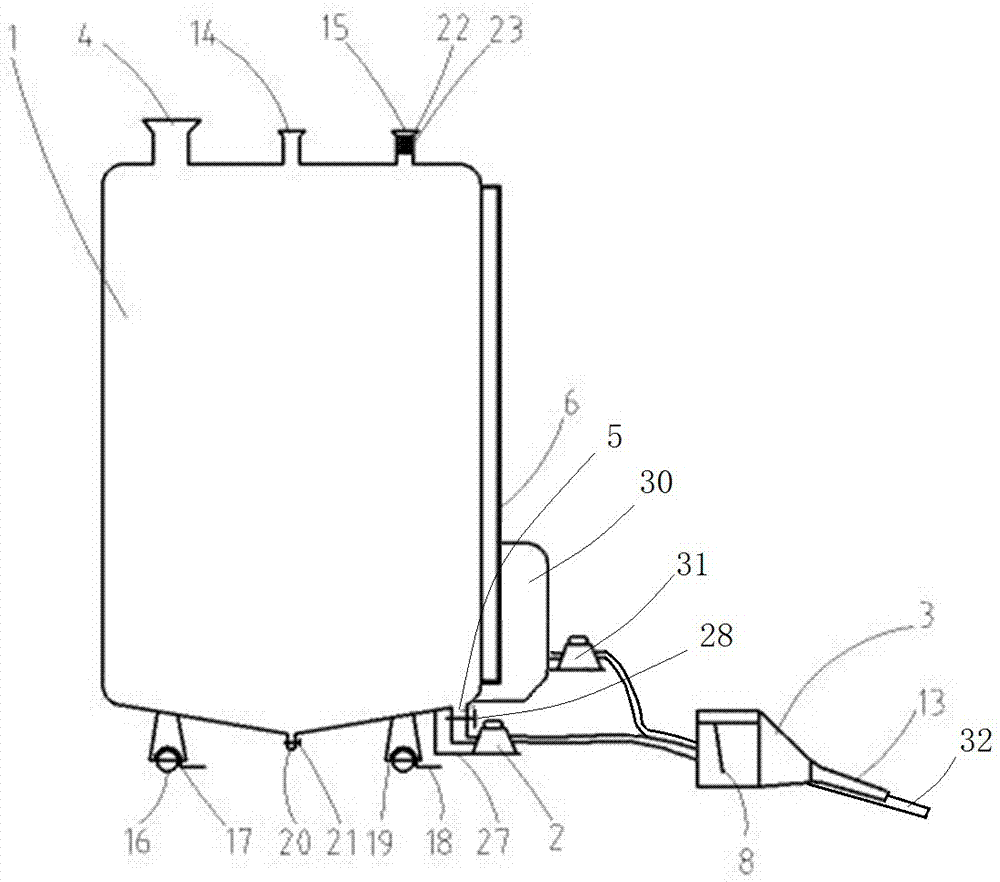

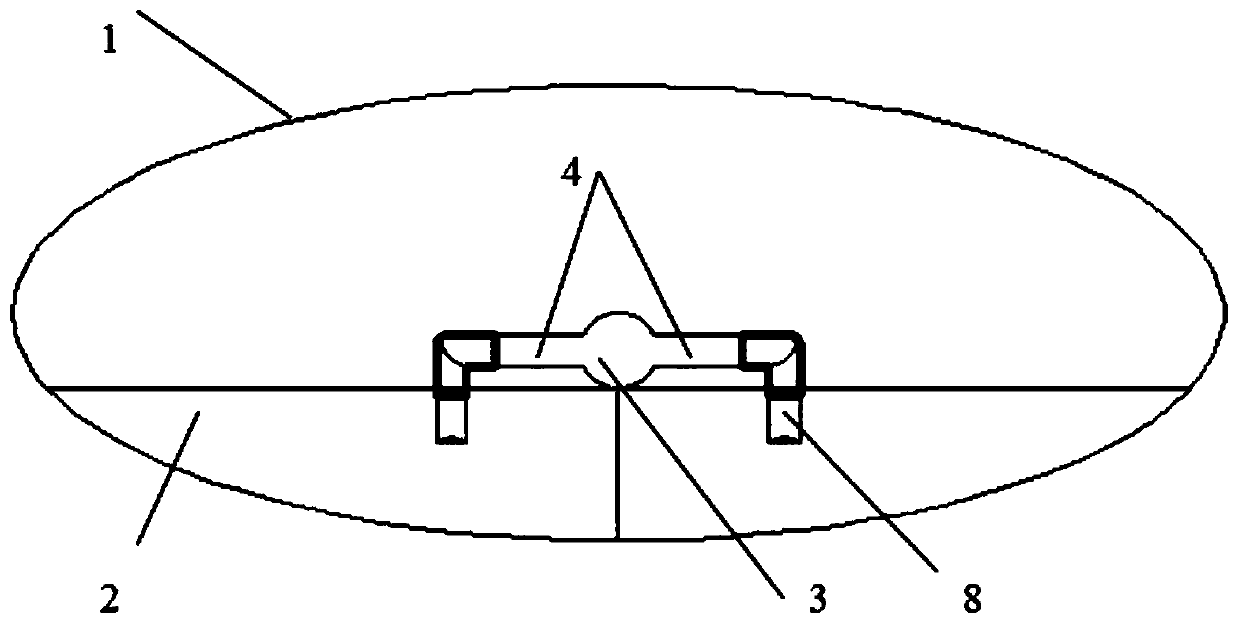

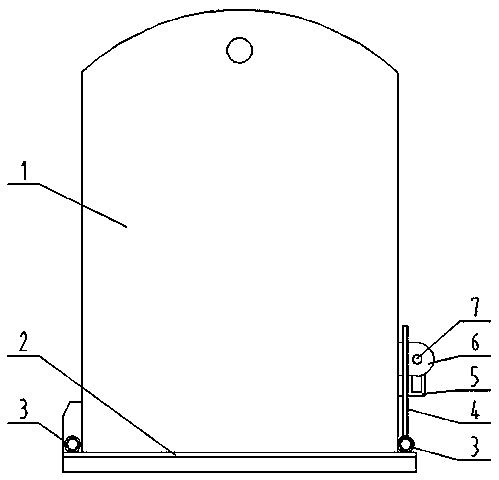

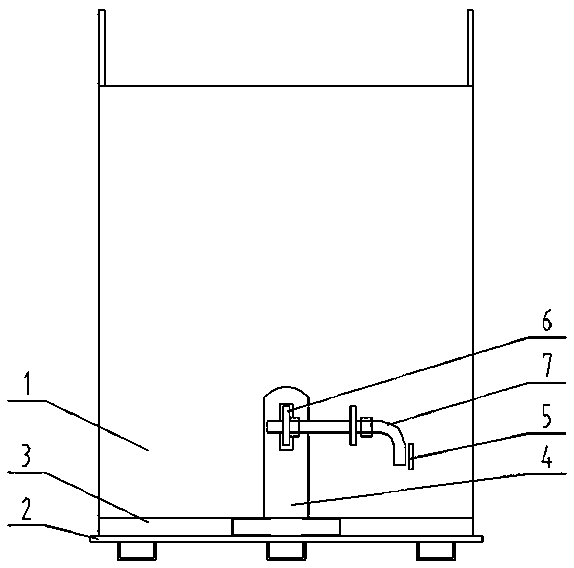

Waggle test storage tank liquid level measuring system

ActiveCN105806443APrecise raiseReduce measurement errorMachines/enginesLevel indicatorsAtmospheric airLevel measurement

The invention discloses a waggle test storage tank liquid level measuring system. A first branch pipe is connected with a filling and discharge unit and the bottom of a test storage tank. A second branch pipe is connected with the bottom end of the test storage tank and a communication pipe. The communication pipe is connected with the second branch pipe and a liquid level measuring organic glass pipe. An air outlet in the upper end of the test storage tank is communicated with an upper port of the liquid level measuring organic glass pipe, or the air outlet in the upper end of the test storage tank and the upper port of the liquid level measuring organic glass pipe are communicated with atmosphere. A first clamp is installed between the filling and discharge unit and the test storage tank. A second clamp is installed between the second branch pipe and the communication pipe. By means of the communicator principle, the liquid level in the storage tank is accurately measured through the liquid level measuring organic glass pipe, and accurate filling of propellant simulation liquid at different levels in the test storage tank is achieved; the clamps capable of being rapidly disassembled and assembled are adopted for connecting the pipes, the pipes can be rapidly assembled to and disassembled from the test storage tank, the state transition efficiency is greatly improved, and meanwhile negative influences caused by additional pipes on waggle test results are reduced.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Chemical agent adding method and device

PendingCN110953483APromote safe productionAvoid risk of damagePipeline systemsLiquid storage tankProcess engineering

The invention discloses a chemical agent adding method and device. The chemical agent adding method comprises the following steps of a, maintaining the pressure in a storage container of the chemicalagent to be between 1.0 MPa and 1.5 MPa; b, supplementing chemical agents into the storage container of the chemical agent; and c, accurately pressing out the chemical agent outside the storage container of the chemical agent. According to the chemical agent adding device, a pipeline is connected to the tank top of a liquid storage tank through a liquid inlet pump; a pipeline is connected to thetank top of the liquid storage tank through a self-operated regulating valve group of a sealing gas feed pipeline; the tank top of the liquid storage tank extends out of a pipeline, the pipeline is divided into two paths, one path passes through the self-operated regulating valve group of a sealed gas discharge pipeline, and the other path is provided with a safety valve, and the two paths finallymerge into one path and lead to the outside of the device; and the tank bottom of the liquid storage tank extends out of a pipeline which is sequentially connected with a mass flowmeter and a micro-flow regulating valve, and the tank body of the liquid storage tank is provided with a tank body liquid level meter. The chemical agent adding method and device is safe and has low failure rate.

Owner:青岛博纳德机械科技有限公司

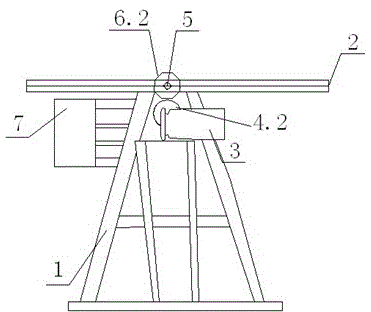

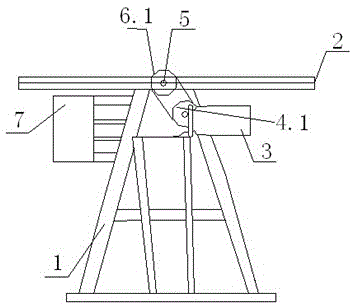

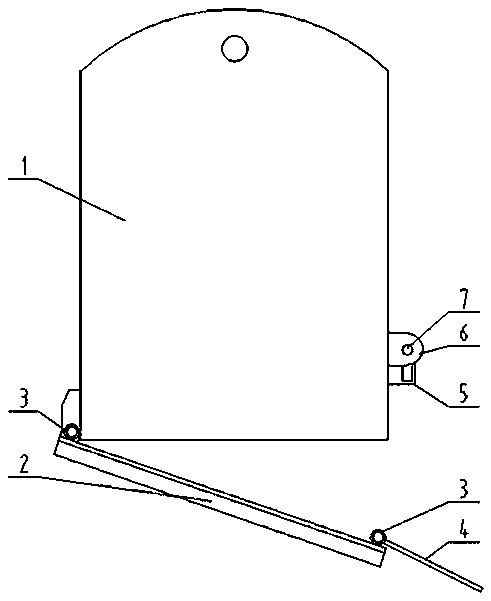

Test method used for overturning test of oil tank

ActiveCN102829937BImprove the efficiency of flip testingPrecise raiseMeasurement of fluid loss/gain rateFrequency changerMarine engineering

The invention provides an overturning bench used for an overturning test of an oil tank. The overturning bench comprises an overturning platform bracket, an overturning platform, an asynchronous motor and a worm and gear decelerator, wherein the overturning platform is arranged on the overturning platform bracket, the decelerator is fixedly arranged on the overturning platform bracket, an input shaft of the decelerator is connected with an output shaft of the asynchronous motor, a shaft of the overturning platform is provided with an overturning gear used for driving the overturning platform to overturn, and an output shaft gear of the decelerator is meshed with the overturning gear. The invention also provides a test method for the overturning test of the oil tank by using the overturning bench, the rotation speed of the asynchronous motor is controlled by a frequency changer in a control cabinet according to needs, the overturning of the oil tank can be automatically controlled, and a self-lock hold state can be realized and the test is carried out when the oil tank is overturned to a special position, so that the time and the labor are saved, the overturning test efficiency of the oil tank is greatly improved.

Owner:ANHUI ANKAI AUTOMOBILE

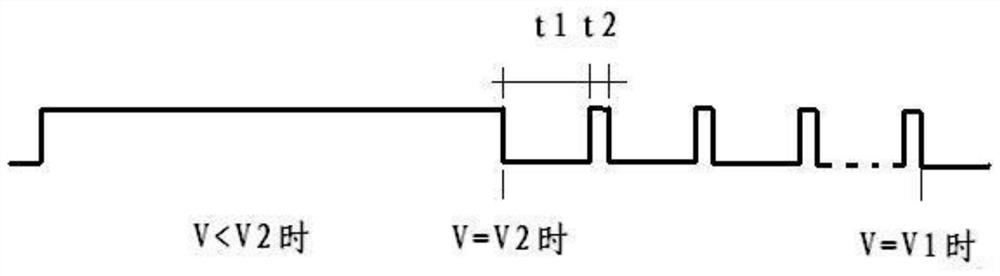

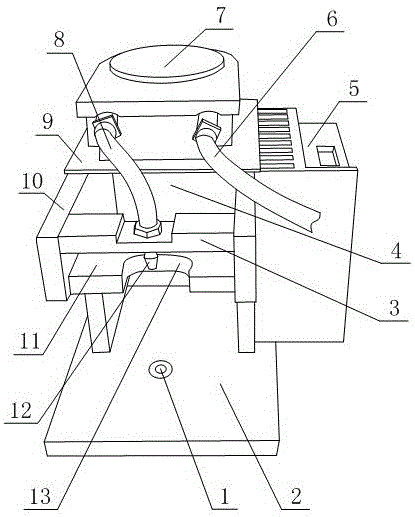

Control method of automatic vehicle engine oil injection equipment

InactiveCN107352498AWide range of usesEliminates manual oiling operationsLiquid transferring devicesInjection pressureElectricity

The invention discloses a control method of automatic vehicle engine oil injection equipment. The control method comprises the following steps that a lever is pulled down, a mechanical signal is formed, the mechanical signal is converted into a first electric signal through a control module, and the first electric signal controls the lever to reset automatically after oil injection is ended; a flow signal is formed through a flow meter according to the oil injection amount and the flow magnitude, and the flow signal is converted into a second electric signal through the control module, so that the oil injection amount and the flow are controlled; a first pressure signal is formed through a pressure valve according to the pressure formed in the oil injection process, and the first pressure signal is converted into a third electric signal through the control module, so that the oil injection pressure is monitored; a second pressure signal is formed through an air inlet valve when oil injection is ended, the second pressure signal is converted into a fourth electric signal through the control module, and the pressure valve is controlled to be switched on through the fourth electric signal, so that the air pressure is balanced; and after the control module is powered on, a fifth electric signal is formed, and an oil pump switch is controlled to be on and off through the fifth electric signal. By means of the control method of the vehicle automobile engine oil injection equipment, one-time quantitative automatic injection of engine oil for any vehicle model can be achieved, leakage of the engine oil is avoided, and cleanliness, convenience and fastness are achieved.

Owner:赛埃孚汽车保修设备(太仓)有限公司

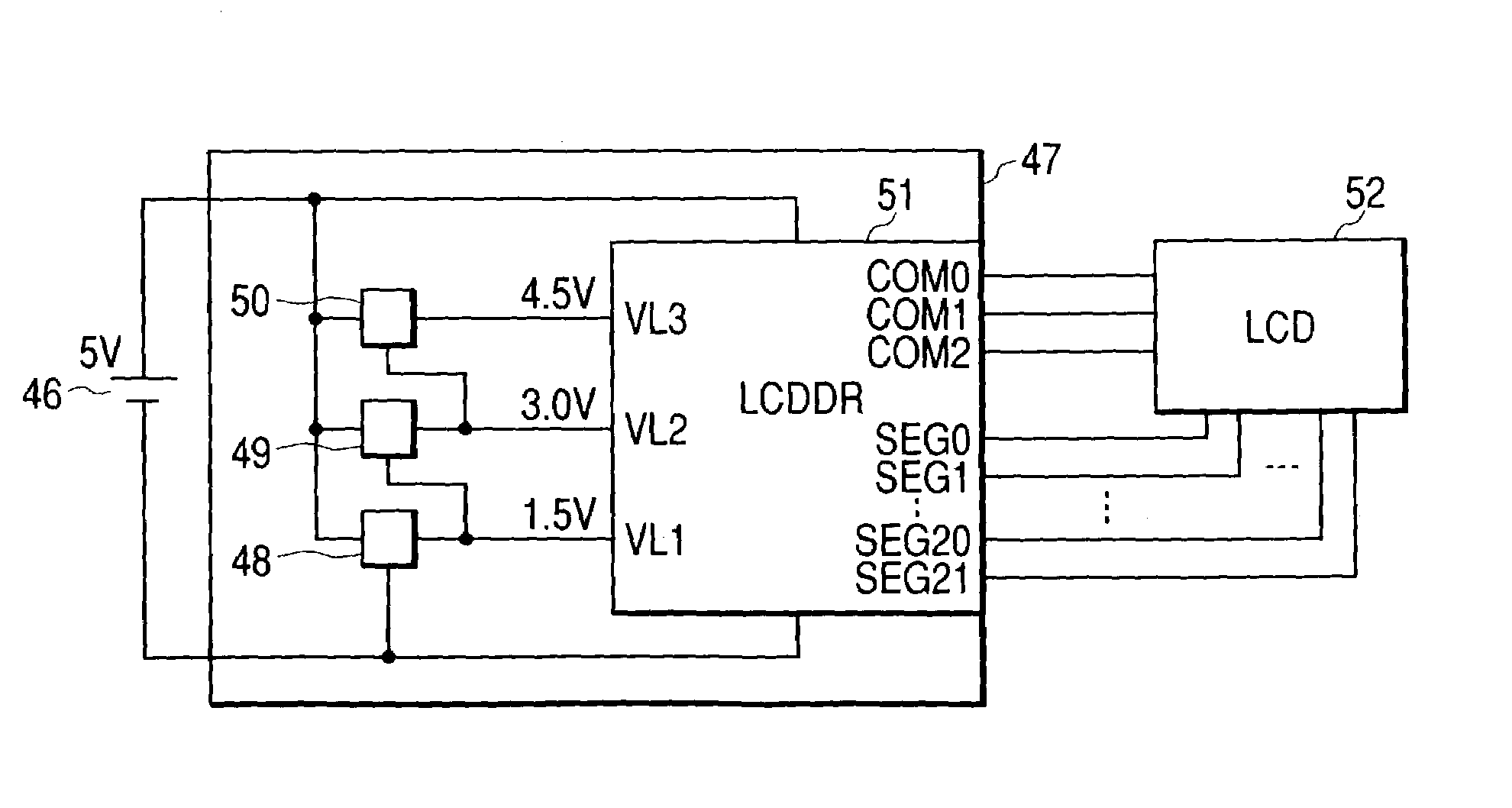

Power circuit for display driver, display device, and camera

InactiveUS20050237290A1Small currentPrecise raisePower supply linesCathode-ray tube indicatorsPower circuitsVoltage regulator

There is provided a power circuit for a display-device-driving circuit for supplying a plurality of voltages to a driving circuit for time-division-driving a display device, wherein each of the plurality of voltages are output via a constant-voltage circuit constituted by a regulator for dividing a voltage supplied from a power source and keeping divided voltages at a certain voltage level, whereby a stable power source consuming a small power to a driving circuit as a power source for a display device to be time-division-driven can be obtained.

Owner:CANON KK

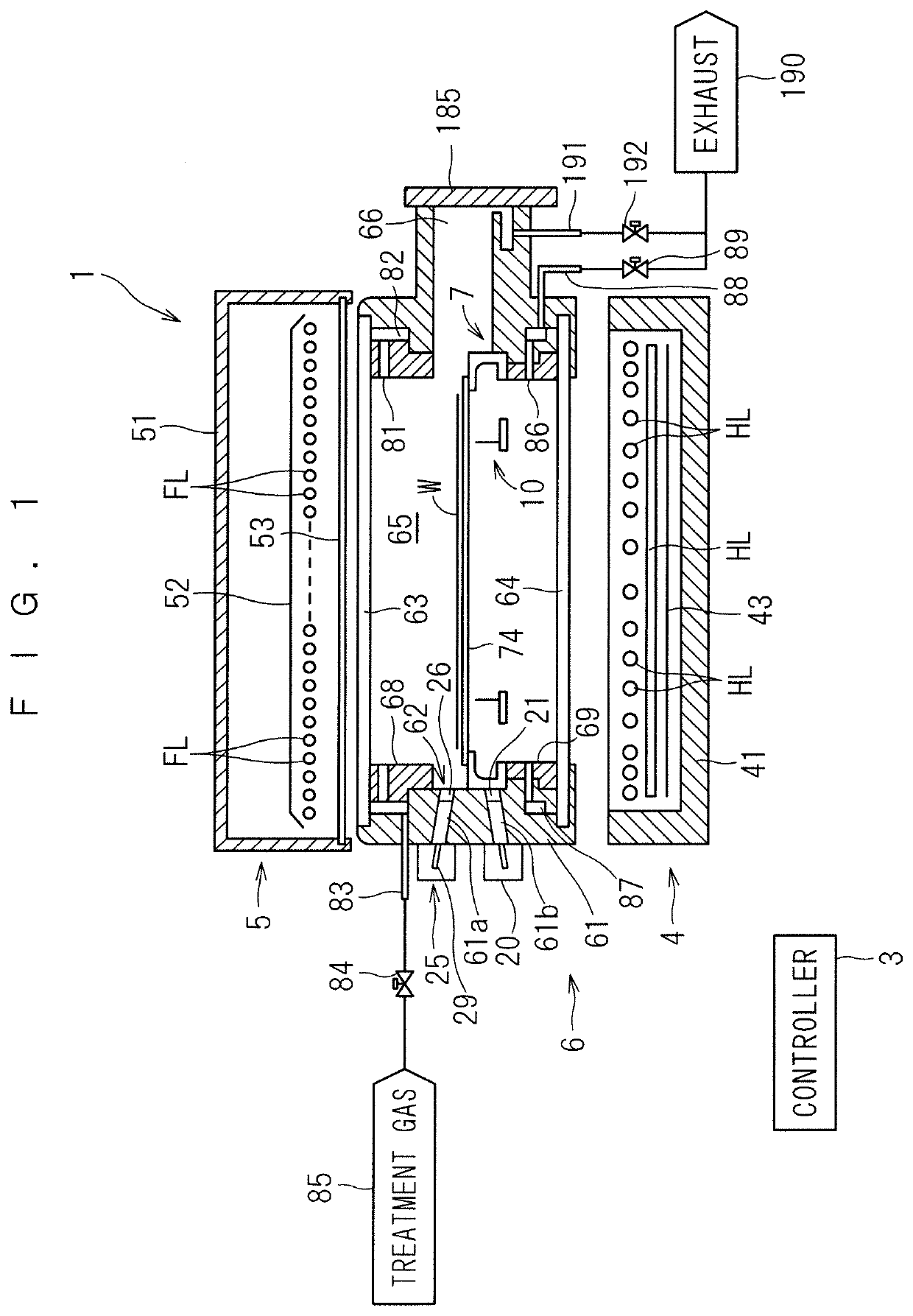

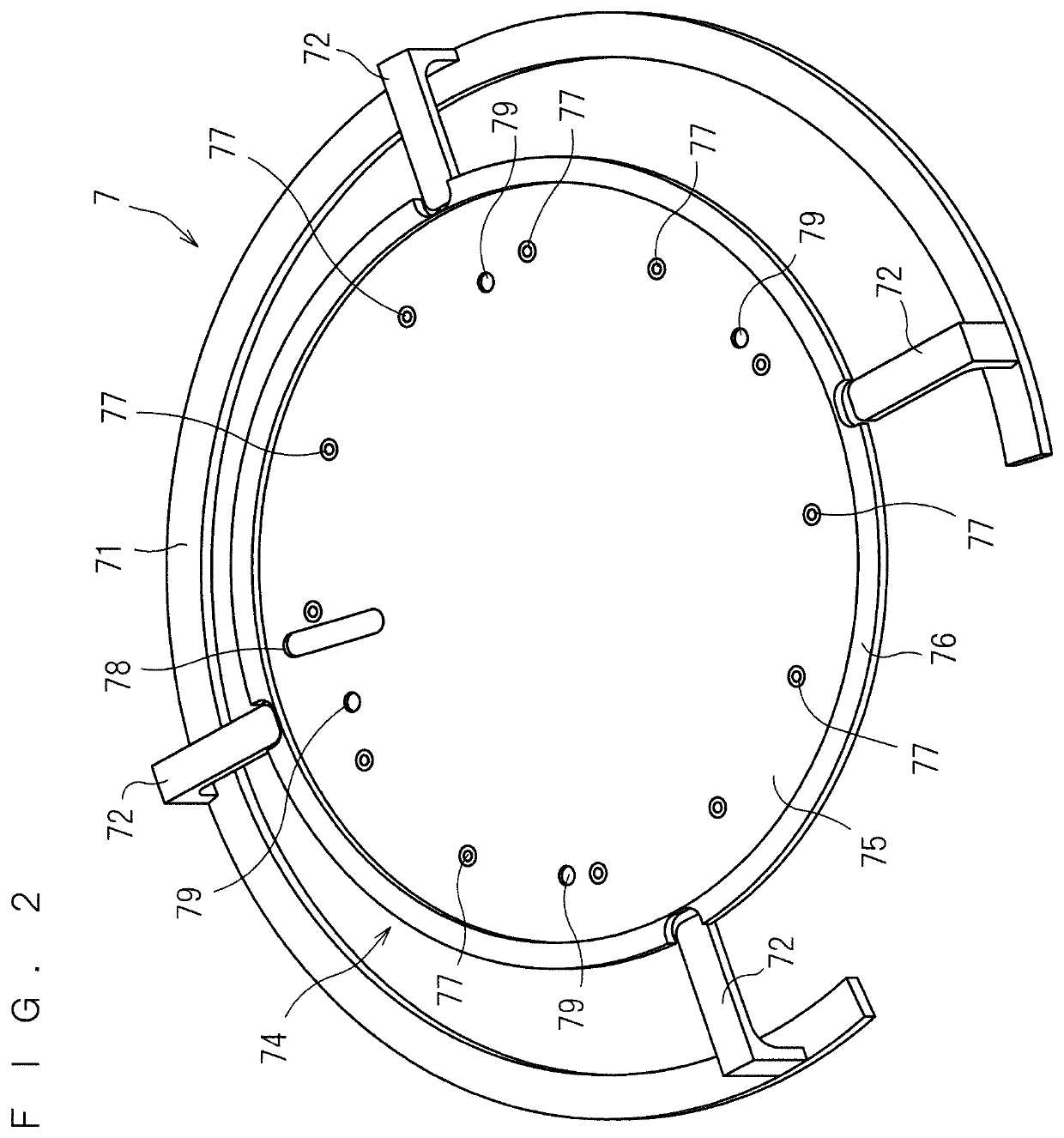

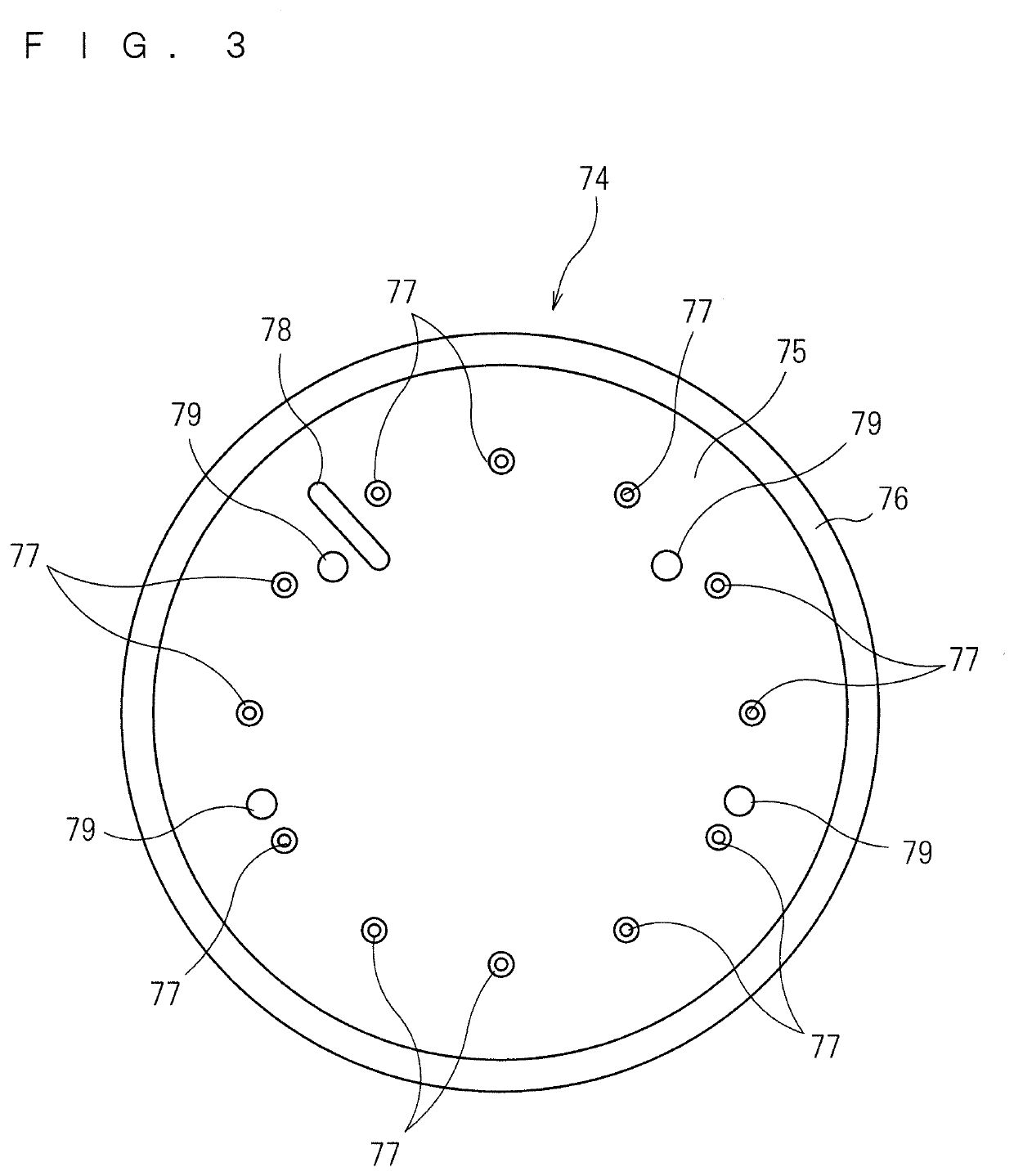

Heat treatment method and heat treatment apparatus

PendingUS20220172951A1Precise raiseLower substrate temperatureRadiation pyrometryTemperature control using digital meansWaferingRadiation thermometer

The semiconductor wafer is preheated at a preheating temperature, and then irradiated with a flash of light from a flash lamp. The upper radiation thermometer measures a temperature of a front-surface of a semiconductor wafer which is raised by irradiation with a flash of light. When the front-surface temperature of the semiconductor wafer measured by the upper radiation thermometer reaches the target temperature, the supply of a current to the flash lamps is stopped to lower the front-surface temperature of the semiconductor wafer. Since the supply of a current to the flash lamps is stopped when the measured temperature of the front-surface of the semiconductor wafer reaches the target temperature, the front-surface temperature of the semiconductor wafer can be accurately raised to the target temperature regardless of the front-surface state and reflectance of the semiconductor wafer.

Owner:DAINIPPON SCREEN MTG CO LTD

Method and system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation

InactiveCN101805050BReduce purification costsReduce fill volumeControlling ratio of multiple fluid flowsChemical variable controlFlocculationTurbidity

The invention relates to a method and a system for controlling coagulant dosing through on-line prediction of turbidity after flocculation water sedimentation. The method comprises the following steps of: making raw water enter a flocculation tank to mix, react and flocculate with the added coagulant so as to generate a flocculating substance; collecting the flocculation water in real time through a sensor for measuring the turbidity under the water at the tail end of the flocculation tank; sedimenting in the sensor in the given sedimentation time, and measuring the turbidity; comparing the measured value with the set value; and after the difference is subjected to PID operation, obtaining the needed dosing ratio, and multiplying the dosing ratio with the water inlet flow to obtain the dosing, converting the dosing into a standard current output signal to control the dosing of a dosing pump, and dosing the coagulant on line. The system consists of the flocculation tank, a sedimentation tank, the dosing pump, a coagulation tank, a microprocessor and a sensor 5 which is specially designed for measuring the turbidity. Due to adoption of the sensor for measuring the turbidity, the turbidity after flocculation water sedimentation can be accurately measured on line without being disturbed by other factors. Therefore, the on-line coagulant dosing can be accurately controlled, the coagulant dosing is reduced, the water purification quality is improved, and the water purification cost is lowered.

Owner:SHANGHAI UNIV

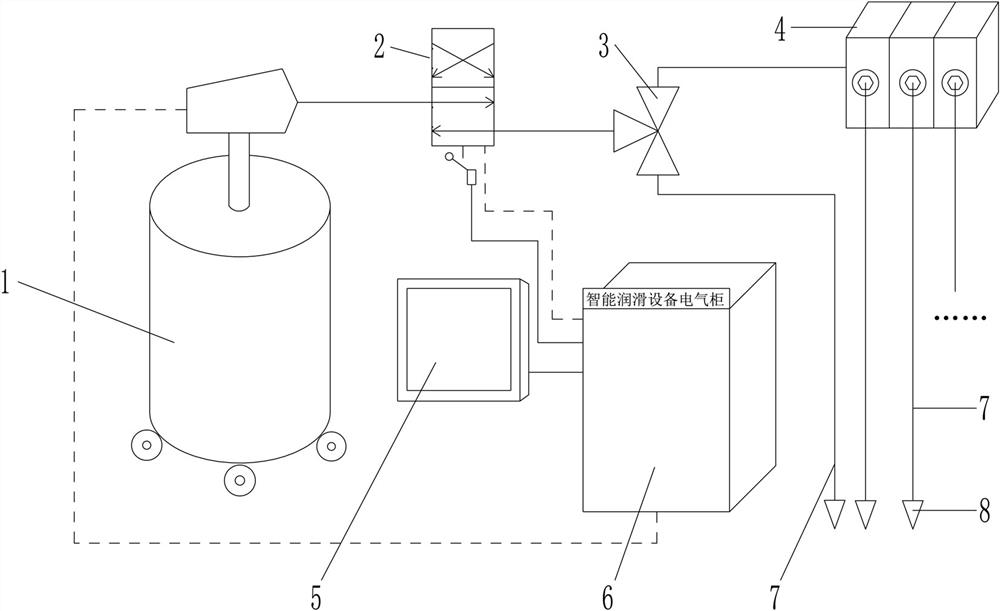

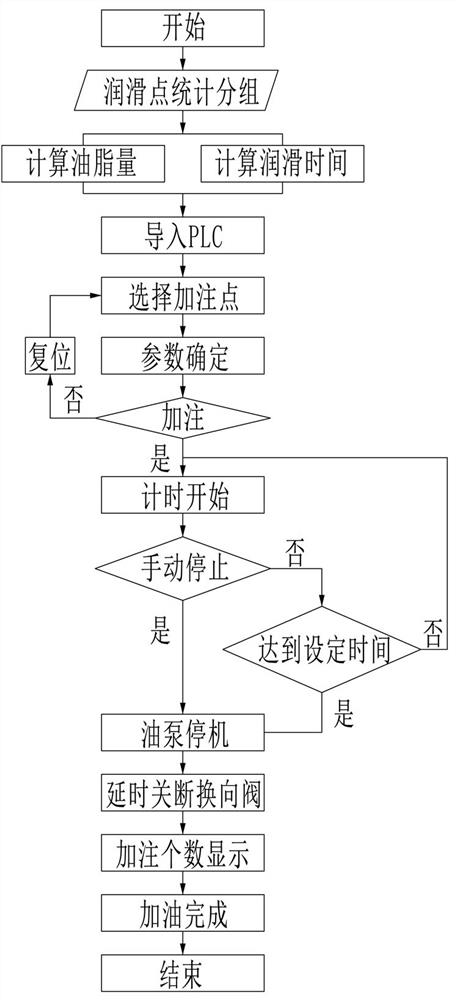

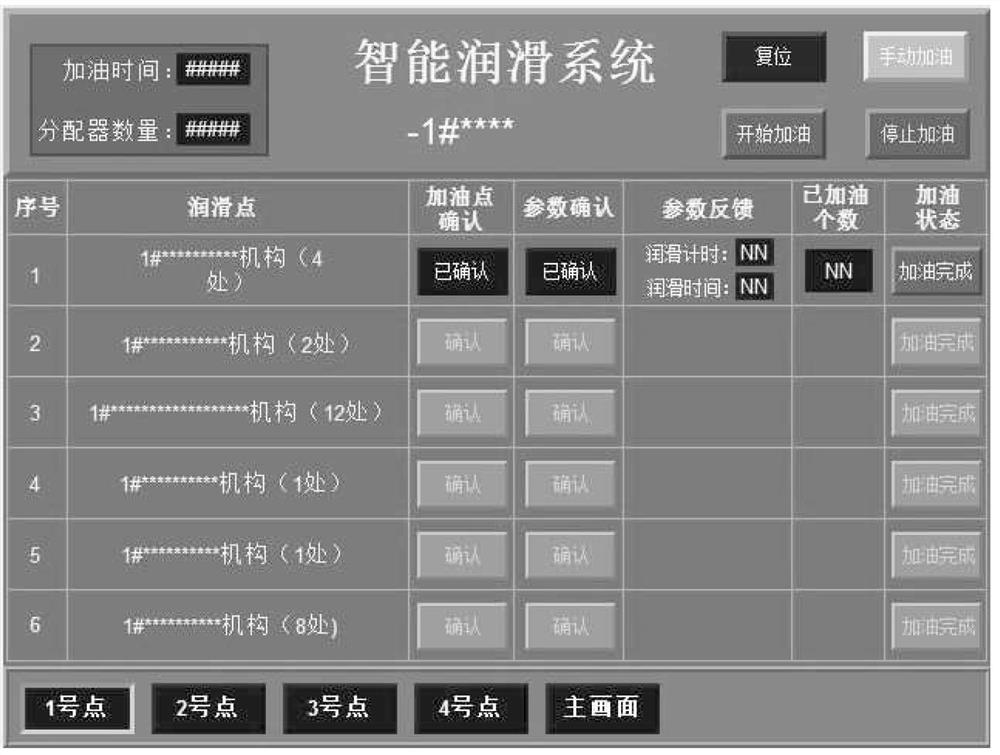

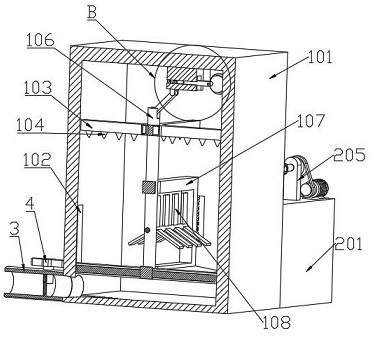

Industrial intelligent lubricating system and control method

PendingCN113790377AAvoid Manual Logging ErrorsAvoid wastingSignal processingProportioning devicesProcess engineeringOil and grease

The invention relates to an industrial intelligent lubricating system and a control method. The industrial intelligent lubricating system comprises oiling equipment, a grease reversing valve, a three-way switching valve, a grease distributor, an industrial touch screen and an electric panel cabinet; the oiling equipment is sequentially communicated with the grease reversing valve, the three-way switching valve and the grease distributor; a plurality of output ports in the grease distributor are respectively connected with a plurality of high-pressure oil pipes; oil filling nozzles connected with the ends of the high-pressure oil pipes are connected with lubricating points of an equipment mechanism to form a plurality of oil filling loops; the electrical panel cabinet is electrically connected with the oiling equipment, the grease reversing valve and the industrial touch screen to form a control system; oil is filled into the lubricating points of the equipment mechanism in a fixed-point, quantitative and timed mode by controlling opening and closing of the oil filling loops; centralized control is achieved; grease filling recording errors and filling omission or repetition are avoided; and the operation stability of large-scale complex equipment machinery can be improved.

Owner:CHINA YANGTZE POWER

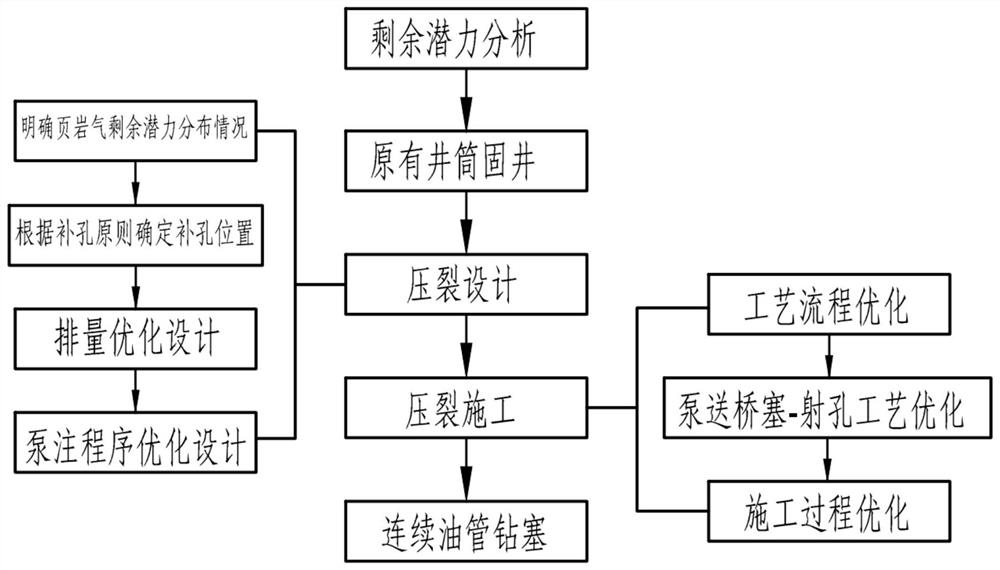

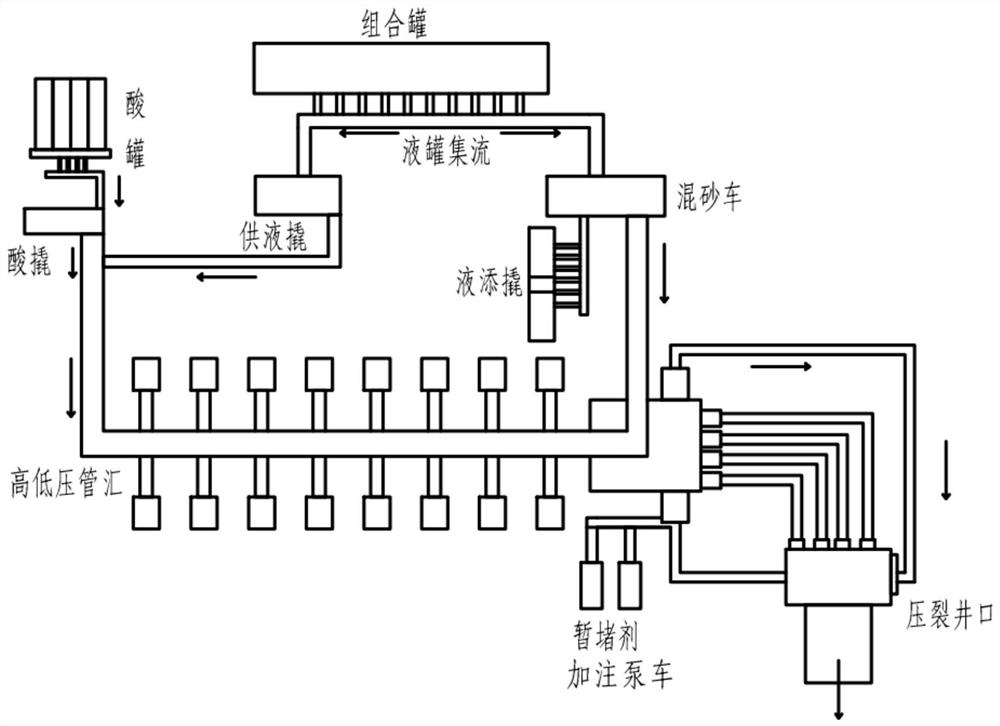

Shale gas horizontal well casing-fixation-in-casing refracturing method

ActiveCN113073966AImprove efficiencyImprove the transformation effectFluid removalThermodynamicsHorizontal wells

The invention relates to the technical field of shale gas repeated development, and particularly discloses a shale gas horizontal well casing-fixation-in-casing refracturing method. The method comprises the following steps of 1, performing residual potential analysis, and carrying out a gas production profile test to obtain the gas production contribution percentage of each cluster of primary fracturing; 2, performing well cementation of an original shaft, and installing a small casing pipe in the original shaft to form a new shaft; 3, performing fracturing design, analyzing the recovery degree of each section and each cluster in the original shaft according to the gas production contribution percentage, clearly determining the shale gas residual potential distribution condition in combination with the transformation effect of the original shaft during primary fracturing, determining the perforation position of refracturing according to the residual potential distribution condition, and performing displacement optimization and pump injection program optimization design; and 4, performing fracturing construction. The shale gas horizontal well casing-fixation-in-casing refracturing method solves the technical problems of high construction difficulty and low adaptability in a long horizontal section shale gas well in an existing technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel liquid filling device

ActiveCN111777027AInhibition of dissolutionReduce solubilityLiquid transferring devicesEngineeringLiquid piston

The invention relates to a novel liquid filling device. The novel liquid filling device comprises a liquid storage container and an extrusion container internally provided with a piston, the piston divides an inner cavity of the extrusion container into a liquid injection cavity and an extrusion cavity, the liquid injection cavity is used for communicating with the liquid storage container, the extrusion cavity is used for allowing an extrusion power medium to enter to exert pressure on the piston so as to extrude a liquid within the liquid injection cavity, the piston is assembled in the extrusion container in a sliding sealing mode, a liquid injection pipeline is connected to the liquid injection cavity, and a liquid injection vacuumizing pipeline is used for vacuumizing the liquid injection pipeline, the liquid injection cavity and a cavity to be injected with the liquid. The novel liquid filling device is provided with the extrusion container, the liquid can be injected into the extrusion container through the liquid storage container, the piston is arranged in the extrusion container, the piston is pressed to extrude the liquid injection cavity, so that the condition that airis dissolved in the liquid due to the air directly extrudes the liquid is avoided, and the technical problem that during filling of an existing liquid filling device, air is prone to mix, and much mixed air is caused is solved.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

Grease filling gun

InactiveCN103148331BQuick loading and unloadingReduce weightPressure lubricationLubrication check valvesPistonPetroleum engineering

Owner:张付成

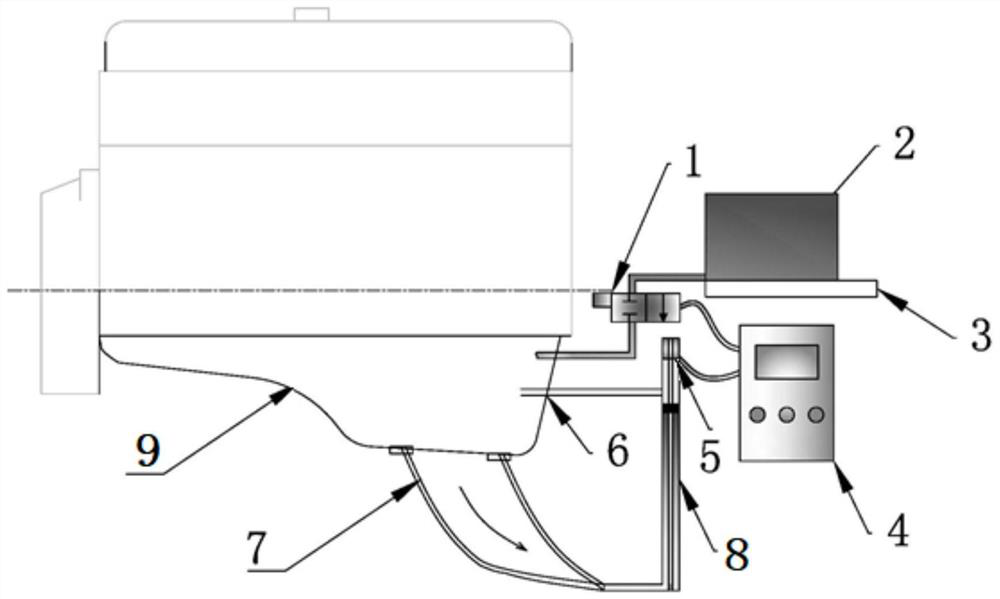

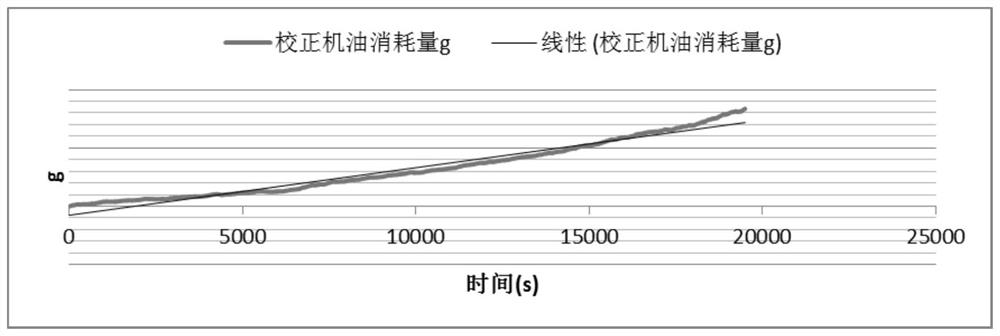

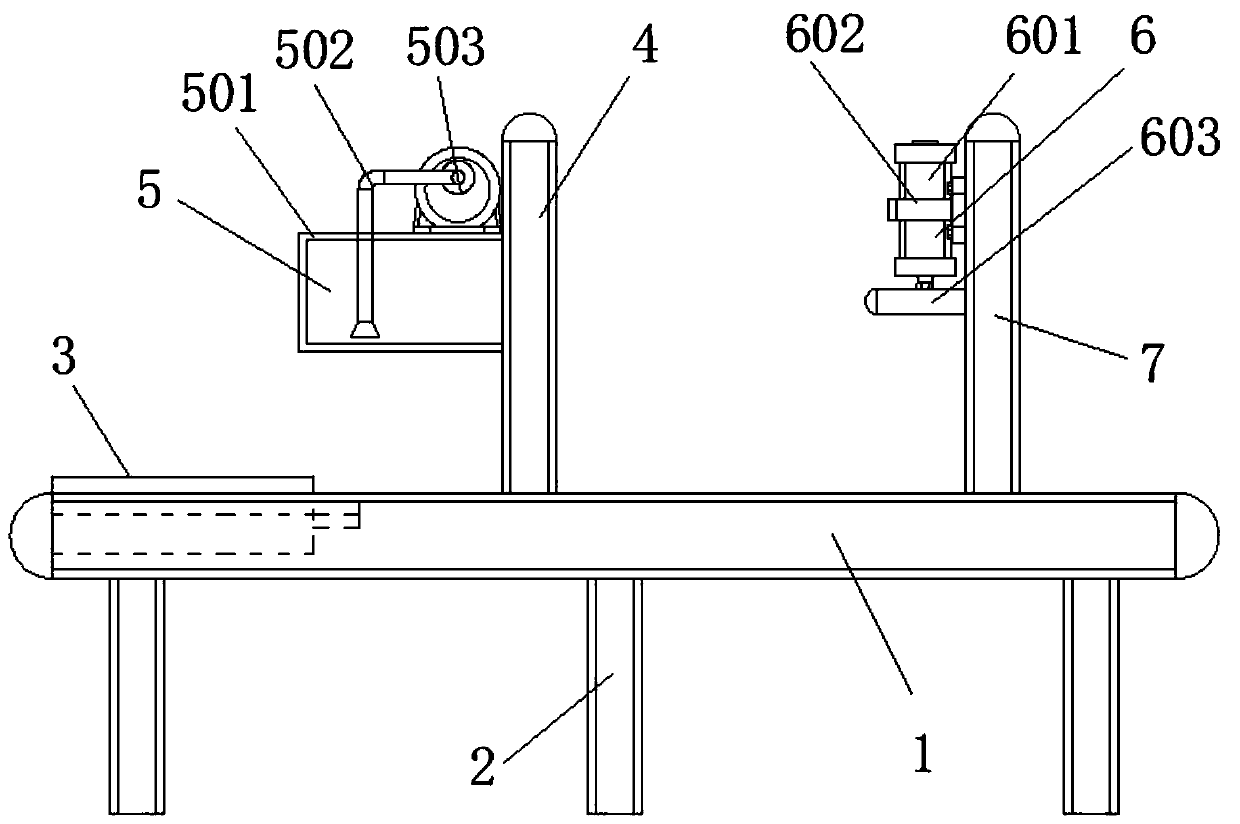

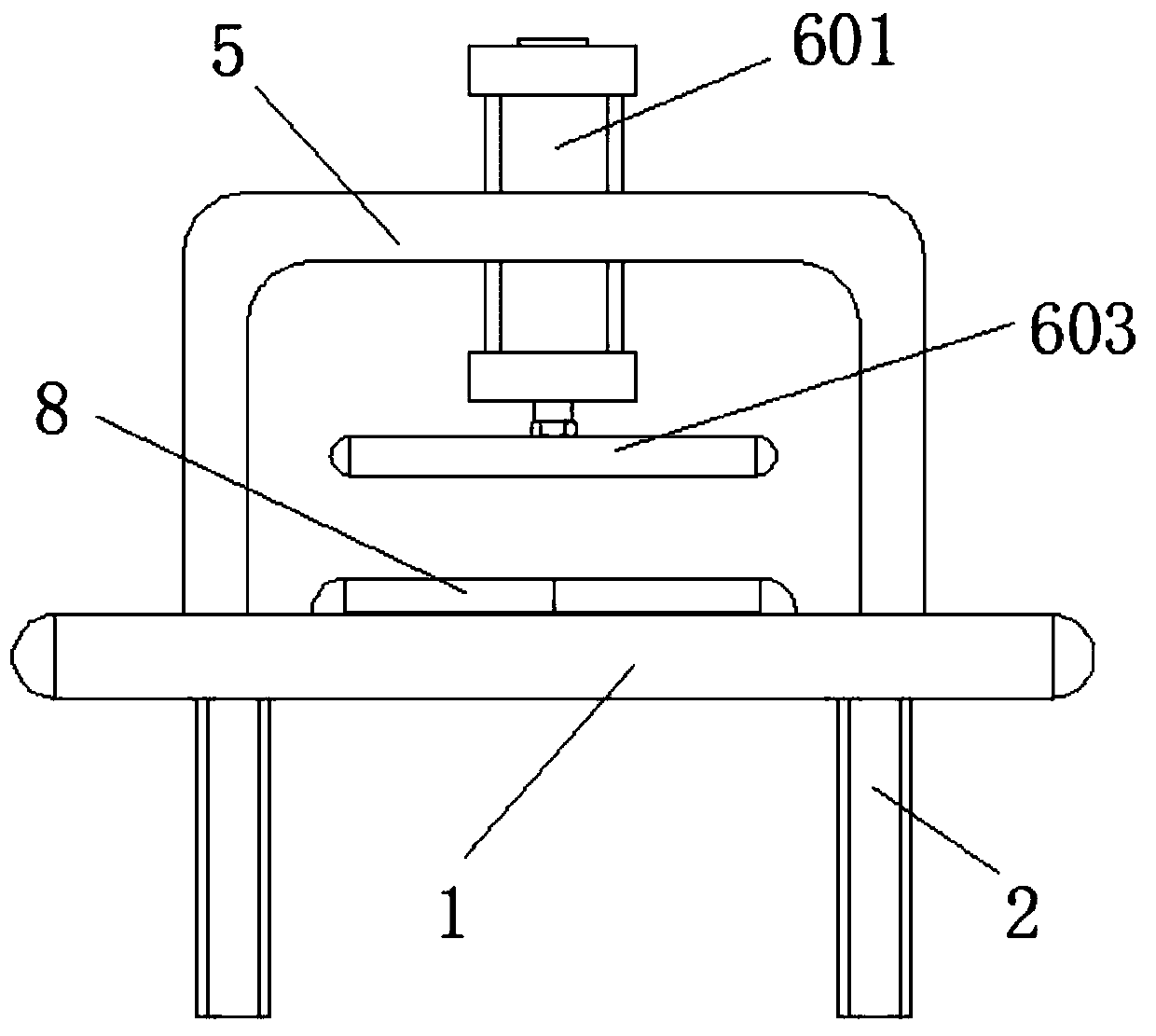

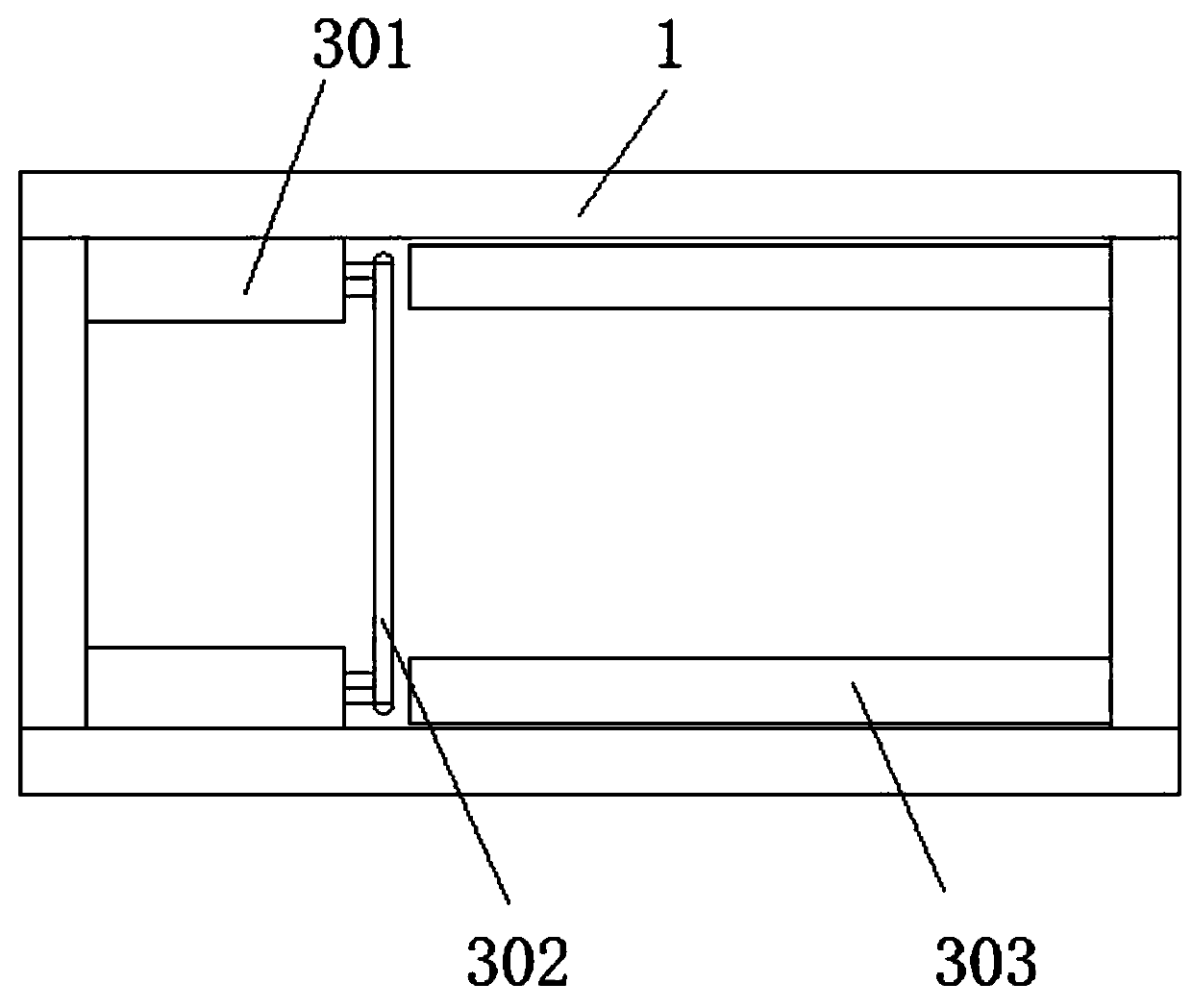

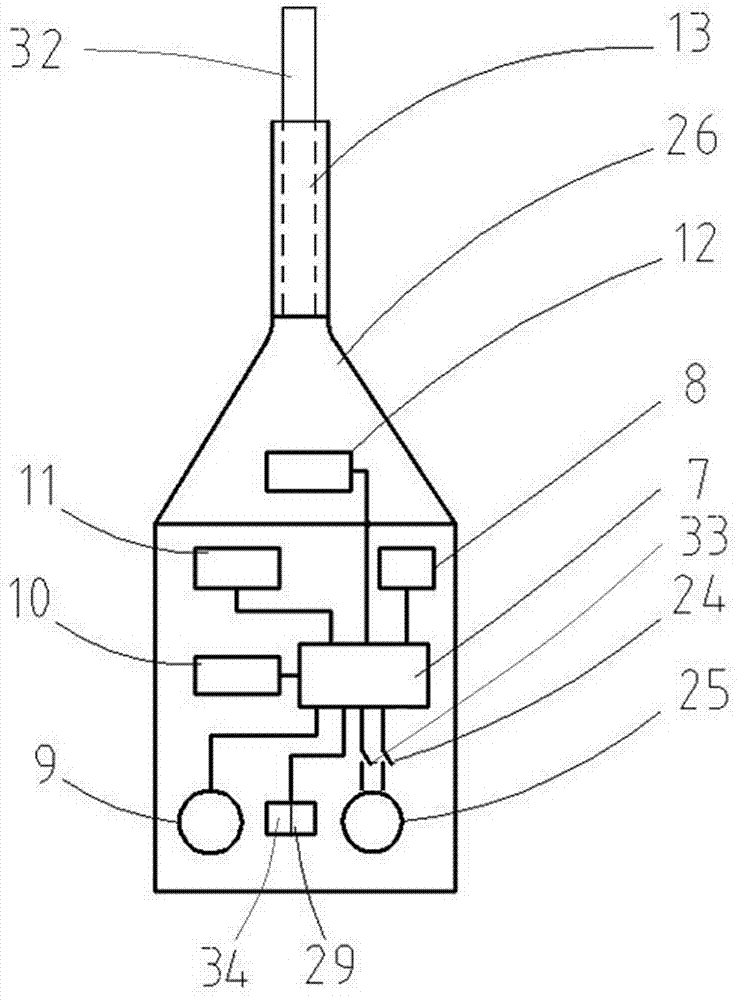

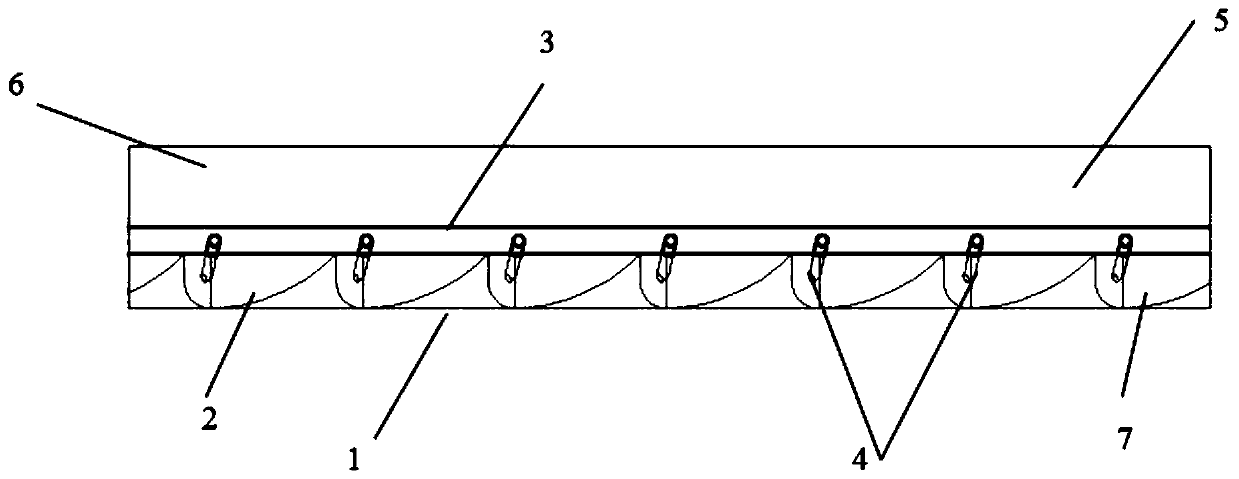

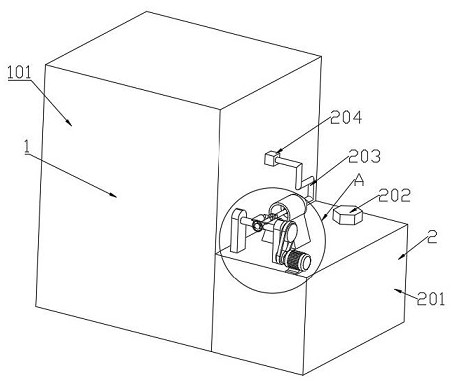

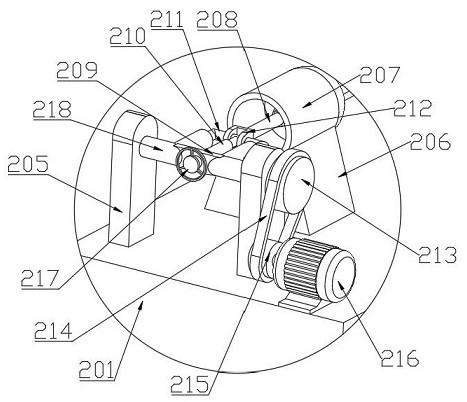

Accurate engine oil filling mechanism of engine and filling method of accurate engine oil filling mechanism

ActiveCN112761753APrecise raiseGuaranteed filling speedMachines/enginesLubricant filling/drainingFuel tankLiquid level sensor

The invention relates to the technical field of engine oil filling, in particular to an accurate engine oil filling mechanism of an engine and a filling method of the accurate engine oil filling mechanism. The accurate engine oil filling mechanism comprises an engine oil pan and an oil tank, and further comprises an electromagnetic valve, an engine oil supplementing measurement and control device, a liquid level sensor and a vertical pipe, the oil tank is connected with a liquid inlet of the engine oil pan through the electromagnetic valve, the vertical pipe communicates with the bottom of the engine oil pan, and the liquid level sensor is arranged in the vertical pipe. The liquid level signal output end of the liquid level sensor is electrically connected with the liquid level signal input end of the engine oil liquid supplementing measurement and control device, and the control signal output end of the engine oil liquid supplementing measurement and control device is electrically connected with the control signal input end of the electromagnetic valve. The filling liquid level is monitored in real time through the liquid level sensor, opening and closing of the electromagnetic valve are controlled through the engine oil liquid supplementing measurement and control device, and accurate filling of engine oil is achieved.

Owner:DONGFENG COMML VEHICLE CO LTD

Quantitative filling method and quantitative filling device

ActiveCN102795203BGuaranteed filling qualitySimple and fast operationVehicle servicing/repairingProgramme control in sequence/logic controllersComputer scienceCode acquisition

The invention discloses a quantitative filling device. The device comprises an identification code acquisition module for acquiring the identification code of a product to be filled, a control module and a filling module, wherein the control module is used for receiving the identification code of the product to be filled from the identification code acquisition module and calling a filling formula of the product to be filled according to the identification code of the product to be filled; according to the filling formula, the filling sequence of a plurality of oil filling points of the product to be filled and the filling quantity corresponding to each oil filling point are provided; and the filling module fills oil into a plurality of oil filling points of the product to be filled in corresponding quantities according to the filling sequence. The invention also discloses a quantitative filling method. By the quantitative filling device and the quantitative filling method, problems such as wrong filling and missed filling of the oil in the process of manufacturing automobiles are solved; the oil filling quality of the automobiles is guaranteed; the quantitative filling device is easy and convenient to operate, and the oil can be filled accurately, so that the on-site assembly efficiency is improved.

Owner:BEIQI FOTON MOTOR CO LTD

A self-gravity fluidized bed piping system for powder curing agent transportation and its application method

The invention provides a pipeline system of a gravity fluidized bed for transportation of a powder curing agent and a using method thereof. The pipeline system of the gravity fluidized bed is composedof a fluidized bed pipeline, a feeding hopper and air circulating compressor, wherein the fluidized bed pipeline is internally divided into three independent channels: an air inlet channel, a mediumtransportation channel and a gas recovery channel. The pipeline system of the gravity fluidized bed is used for cured construction of soil masses in geotechnical engineering and primarily solves the problem that the feeding channel is easily blocked in the injecting and mixing processes of the powder curing agent. By means of the principle of the fluidized bed, a proper amount of air is blown intothe powder, so that the powder has the characteristic of liquid flowing. The powder is transported forward obliquely under the action of gravity, so that the workload of manual feeding in the mechanical mixing process is reduced, the mixing uniformity and controllability are improved, the powder curing can be precisely injected according to a design demand, and the mechanical degree and the production efficiency are improved.

Owner:HOHAI UNIV

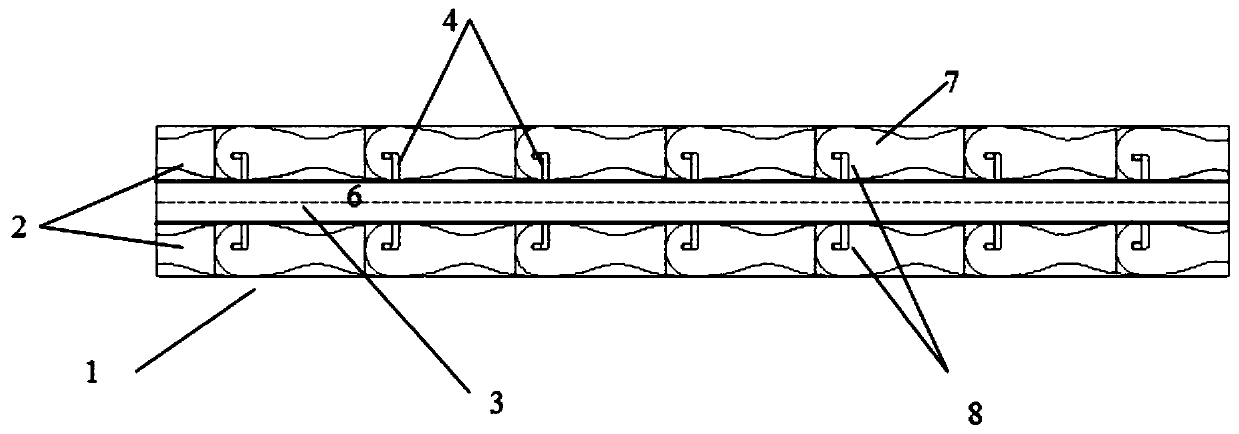

Novel processing method and mould for railway cushion plate

PendingCN111391393AFast shapingConducive to solidificationShaping pressAutomatic controlStructural engineering

The invention discloses a novel processing method and mould for a railway cushion plate. A processing platform and the processing mould are included, a bearing support is fixed to the lower end of theprocessing platform, and a mould position adjusting structure is fixed to the upper end face of the processing platform. A first bearing frame is arranged on the right side of the mould position adjusting structure, a processing raw material filling structure is installed on the outer side of the first bearing frame, a second bearing frame is arranged on the right side of the first bearing frame,a pressurized shaping structure is installed on the outer side of the second bearing frame, and the processing mould is arranged below the pressurized shaping structure. According to the novel processing method and mould for the railway cushion plate, different moulds can be conveniently replaced by the processing method, the railway cushion plate with suitable structure size can be obtained, andthe processing efficiency of the railway cushion plate is improved by quick feeding and pressing shaping; and at the same time, through automatic control, the production quality of the railway cushion plate can further be improved, and the practicability of the novel processing method and mould of the railway cushion plate is greatly improved.

Owner:江苏海迅铁路器材集团股份有限公司

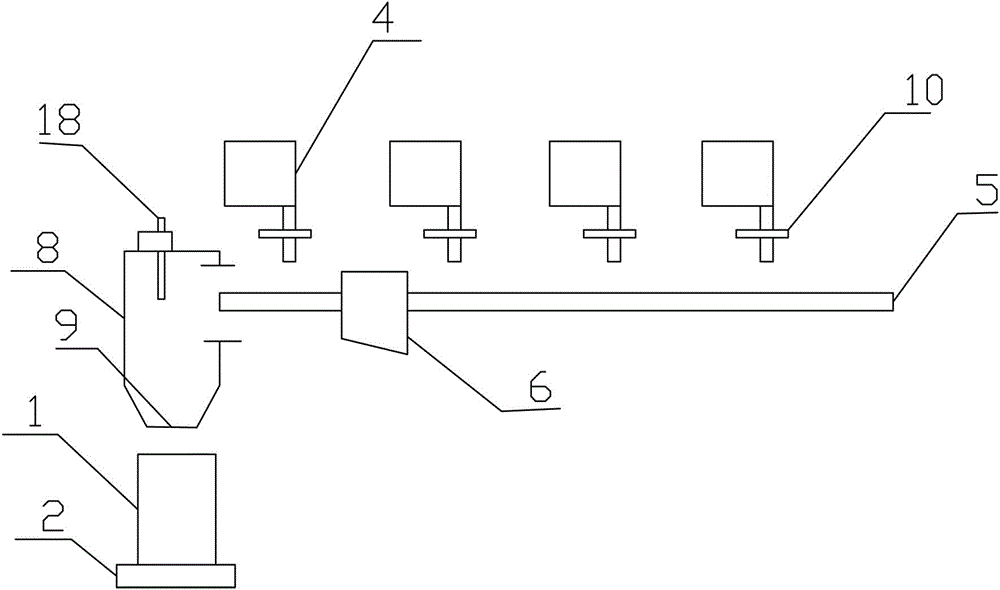

Automatic seasoning allocation device for production of pickled vegetable

The invention provides an automatic seasoning allocation device for production of pickled vegetable. The automatic seasoning allocation device comprises a seasoning adding component and a major ingredient cavity arranged below a discharge port of the seasoning adding component, wherein the major ingredient cavity is arranged on a first electronic scale; the first electronic scale is electrically connected with a controller; the seasoning adding component comprises a plurality of seasoning bins; the seasoning bins are arranged above a guide rail; a batching cavity is arranged on the guide rail and moves on the guide rail under driving by a driving device; a discharge bin is arranged at one end of the guide rail; a discharge port is formed at the lower end of the discharge bin; the batching cavity moves to the discharge bin and is communicated with the discharge bin, and the discharge port of the discharge bin is opened; an electric control valve is arranged at an outlet of each seasoning bin; and the electric control valves and the driving device are electrically connected with the controller. The device has the advantages that the device can add seasoning precisely, which enables the taste of pickled vegetable to maintain consistent; and a single production line is suitable for production of different kinds of pickled vegetables with different tastes.

Owner:HUBEI ZHONGSHU AGRI TECH

Automatic oil absorbing and oil changing equipment

InactiveCN107399708AWide range of usesEasy to operateLiquid transferring devicesChanging equipmentInjection pump

The invention discloses automatic oil absorbing and oil changing equipment which comprises an oil storage tank, an oil injection pump, an oil gun, a waste oil tank and an oil absorbing pump. The oil storage tank comprises an oil inlet and an oil outlet; one end of the oil injection pump is connected with oil outlet while the other end is connected with the oil gun; one end of the oil absorbing pump is connected with the waste oil tank while the other end is connected with the oil gun; the oil gun comprises a control module, an oil injection gun nozzle connected with the oil injection pump and an oil absorbing gun nozzle connected with the oil absorbing pump, and the oil absorbing gun nozzle is convex to the oil injection gun nozzle. By the arrangement that used lubricating oil is absorbed out before injection of new machine oil, simple operation is achieved; injection quantity of the machine oil is set according to different vehicle types, and one-time, quantitative and automatic injection of the machine oil is realized; leakage of the machine oil is avoided, and cleanliness and convenience are achieved.

Owner:赛埃孚汽车保修设备(太仓)有限公司

Active washboard fluidized bed pipeline for powder material transportation and method of use thereof

The invention provides a driving washboard type fluidized bed pipe for powder material transportation and an application method thereof. The fluidized bed pipe consists of a pipe outer wall, a wave washboard separation layer, a gas pipe and a reverse flushing nozzle. The fluidized bed pipe system is used for curing construction of soil in geotechnical engineering, mainly solves the problem of easyblockage of a charging channel in the injecting and mixing process of a powder curing agent, uses a fluidized bed principle for blowing a proper amount of air into powder through the reverse flushingnozzle to enable the powder to present the liquid flowing characteristic, in particular, uses eddy currents formed by reverse flushing air currents on the arc wave washboard separation layer for forwards transporting powder materials, and can transport split materials to the other end of the pipe when the pipe is horizontal or even upwards inclined by a small angle. The manual charging workload is reduced in the mechanical mixing process; the mixing uniformity and controllability are improved; the powder curing agent can be precisely injected according to design demands; and the mechanical degree and the production efficiency are improved.

Owner:HOHAI UNIV

Device for filling reagent tubes with liquid medicine

The invention discloses a method for filling a reagent tube with liquid medicine. Two supporting plates parallel to each other are arranged on a bottom plate; the supporting plates are vertically fixed with the bottom plate; a liquid withdrawing pump is arranged between the supporting plates; a metering pump is arranged at the top end of the liquid withdrawing pump; the liquid withdrawing pump is communicated with the metering pump; a motor is arranged on the bottom plate; the motor is contacted with the side walls of the supporting plates; the liquid withdrawing pump and the metering pump are connected with the motor; a liquid inlet pipe communicated with the liquid withdrawing pump is arranged on the liquid withdrawing pump; a liquid collection tank is connected to one end, which is far away from the liquid withdrawing pump, of the liquid inlet pipe; a liquid outlet pipe communicated with the metering pump is arranged on the metering pump; a liquid outlet nozzle is connected with one end, which is far away from the liquid withdrawing pump, of the liquid outlet pipe; the liquid outlet nozzle is arranged between the supporting plates; a liquid outlet of the liquid outlet nozzle faces the bottom plate; an axis of the liquid outlet nozzle is parallel to a plumb line. According to the device, the reagent tube is automatically and quantitatively filled with the liquid medicine through the machine, and the filling volume can be unified each time, so that the filling operation is accurate, the labor intensity of an operator is reduced, and the filling efficiency is improved.

Owner:SICHUAN ORIENTER BIOLOGICAL TECH

A pure electric vehicle thermal management system and coolant filling method thereof

ActiveCN104477024BGuaranteed uptimeGood thermal managementAir-treating devicesVehicle heating/cooling devicesElectricityElectrical battery

Owner:奇瑞新能源汽车股份有限公司

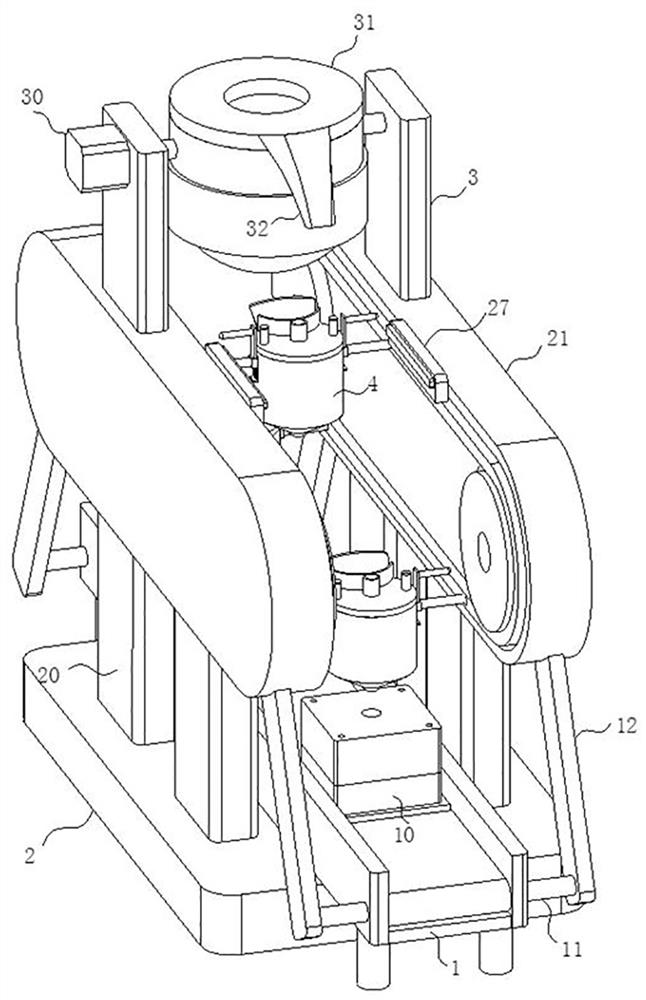

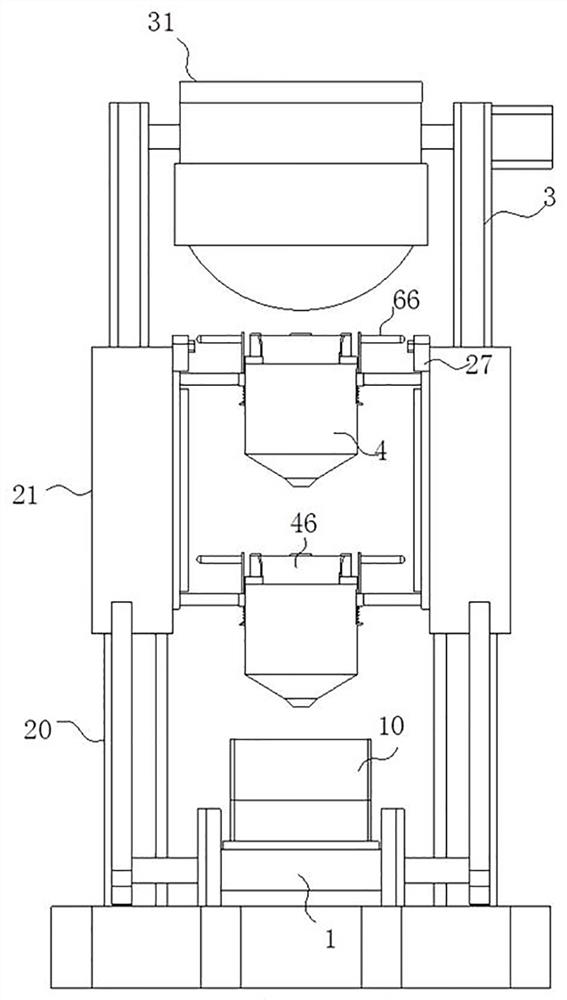

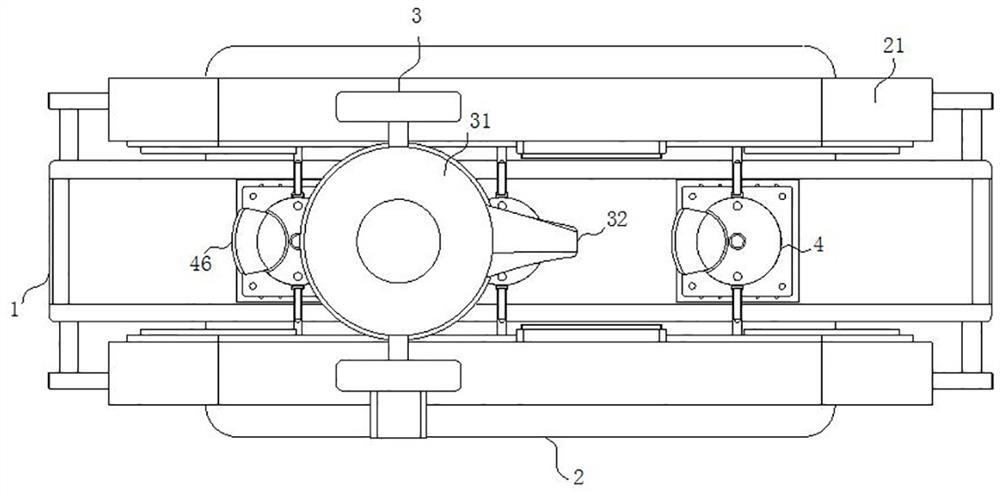

Semi-autogenous mill steel ball hoisting and charging device capable of effectively preventing steel balls from falling

The invention discloses a semi-autogenous mill steel ball hoisting and charging device capable of effectively preventing steel balls from falling. The device comprises a hopper body, a bottom plate, hinges, a lock catch, a baffle, a lock catch base and a lock pin. The baffle and the lock catch base are arranged in the positions, close to the lower end port, of the right side of the hopper body correspondingly. The lock pin is arranged on the lock catch base. Hoisting holes are formed in the upper ends of the front face and the back face of the hopper body correspondingly. The bottom plate is arranged at the lower end port of the hopper body. One hinge is arranged between the left end of the bottom plate and the hopper body. The lock catch is arranged at the right end of the bottom plate. The other hinge is arranged between the bottom plate and the lock catch. The lock catch and the lock catch base are connected in a matched mode. According to the semi-autogenous mill steel ball hoisting and charging device provided by the invention, the hoisting holes are formed in the upper end of the hopper body, so that the steel ball hoisting and charging device is quite safe during hoisting; and a ruler is arranged on the hopper body, so that steel ball charging is quite precise. Meanwhile, the steel ball charging mode is high in charging efficiency. The semi-autogenous mill steel ball hoisting and charging device is simple in structure, easy and convenient to operate, safe to use, and capable of effectively preventing the steel balls from falling.

Owner:YUXI DAHONGSHAN MINING

Centralized automatic lubricating device for coal mine belt conveyor

ActiveCN113753531AReduce manual labor intensityPrecise raiseConveyorsCleaningProcess engineeringLiquid level sensor

The invention relates to a centralized automatic lubricating device for a coal mine belt conveyor. The centralized automatic lubricating device comprises a lubricating oil tank, a lubricating pipeline, a temperature sensor and a central control unit, wherein a liquid level sensor is arranged in the lubricating oil tank and used for detecting the oil level height of lubricating oil in the lubricating oil tank, and the lubricating oil in the lubricating oil tank is conveyed into a bearing chamber through the lubricating pipeline by a pump arranged on the lubricating oil tank; the lubricating pipeline comprises a plurality of lubricating pipelines, pressure changes in the lubricating pipeline are detected through pressure sensors arranged on the lubricating pipelines, and a flow meter is arranged at the tail end of each lubricating pipeline and used for detecting the lubricating oil flowing out of the lubricating pipeline; the temperature sensor is arranged on one side of a bearing and used for detecting the real-time temperature of the bearing; and the central control unit is connected with the liquid level sensor, the pump, the pressure sensors, the flow meters and the temperature sensor and controls working parameters of the pump. By gradually adjusting the filling speed, the labor intensity of work can be well relieved, accurate filling is conducted, and the filling efficiency of the device is improved.

Owner:内蒙古双欣矿业有限公司

Energy-saving and environment-friendly chemical waste treatment equipment

InactiveCN113083122AReduce labor intensityAchieve their goalsRotary stirring mixersSolid waste disposalEngineeringProcess engineering

The invention discloses energy-saving and environment-friendly chemical waste treatment equipment, and belongs to the technical field of chemical waste treatment. The equipemnt comprises a stirring device and a dosing device, the stirring device comprises a stirring box, a fixing frame is fixedly connected in the stirring box, a moving rod is slidably connected in the fixing frame, and a fixing frame is fixedly connected to the circumferential surface of the moving rod; a rotating shaft is rotatably connected in the fixing frame, the circumferential surface of the rotating shaft is fixedly connected with stirring blades, and the side end of the rotating shaft is fixedly connected with a gear; a base and a fixing strip are fixedly connected into the stirring box, a sliding groove is formed in the front end face of the fixing strip, a sliding block is slidably connected in the sliding groove, a first connecting block is fixedly connected to the front end of the sliding block, a rocker is rotatably connected to the front end of the first connecting block, a fixing shaft is rotatably connected in the rocker, a rotating disc is fixedly connected to the side end of the fixing shaft, and a first motor is fixedly connected to the rear end of the rotating disc. The equipment is simple in structure and low in manufacturing cost, liquid medicine and chemical waste liquid can be mixed only through simple operation, and the liquid medicine can be accurately injected.

Owner:屈秋蓉

An automatic casting device and casting method for valve body production and manufacturing

ActiveCN114309566BPrecise bottom injection casting processPrecision Casting ProcessMelt-holding vesselsMould handling equipmentsProduction lineProcess engineering

The invention discloses an automatic casting device and a casting method used in the production and manufacture of valve bodies in the field of casting technology. There is a trigger component that triggers the action of the liquid replenishment opening and closing mechanism. The trigger component automatically changes the height following the overall gravity of the bottom injection transfer cylinder. Shaft drive mechanism, the bottom pouring transfer cylinder is provided with a material receiving part that follows the rotation of the main ladle; on the basis of uninterrupted conveying of the casting mold, the present invention uses multiple bottom pouring transfers that can reciprocate, automatically refill liquid and automatically open and close casting The cylinder realizes a more accurate bottom pouring casting process, which solves the problem of unsuitability in the market and safe casting of large-volume ladles in the production line.

Owner:蓬莱金创精密铸造有限公司

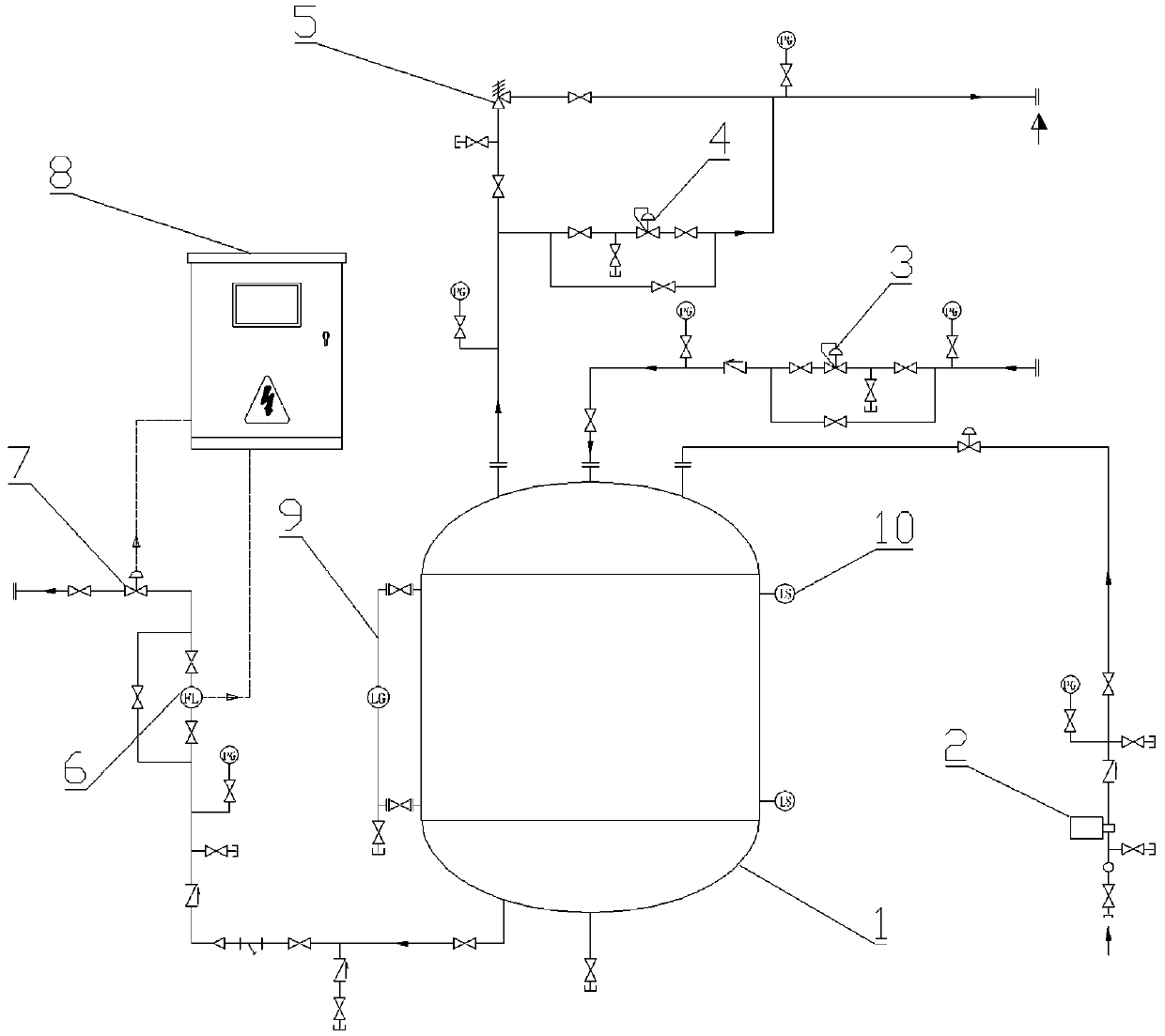

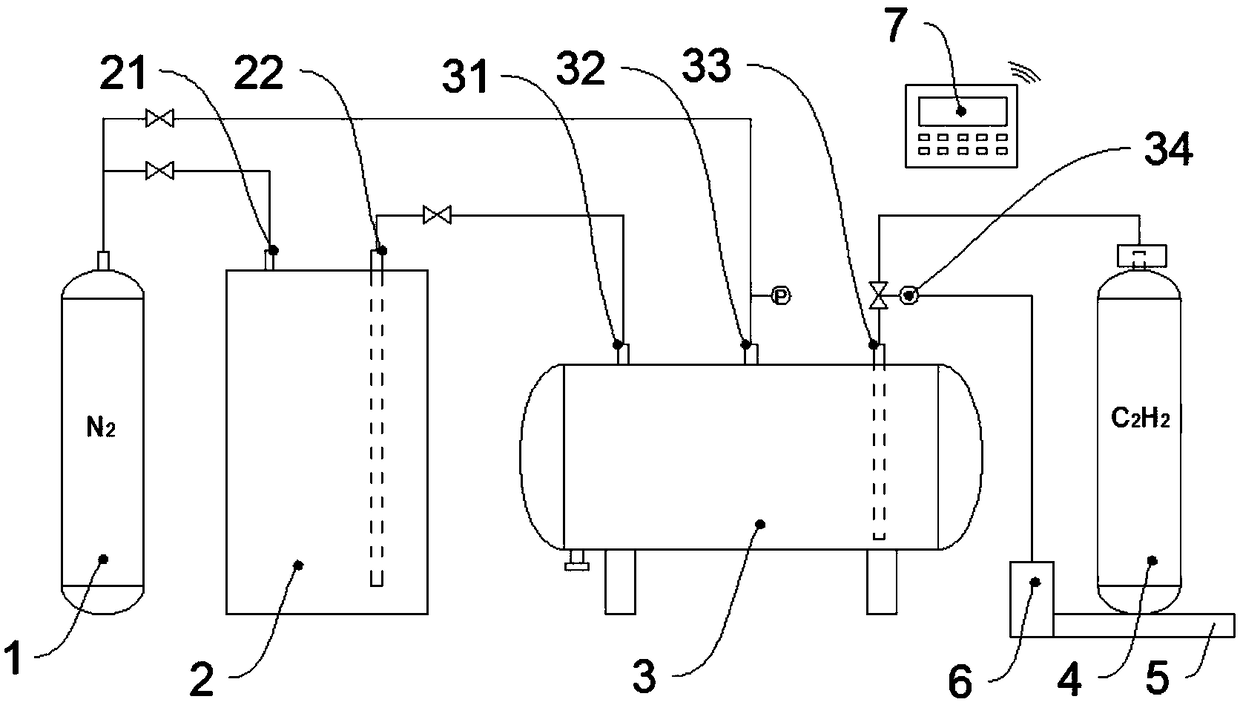

Acetylene gas cylinder acetone supplementing device

InactiveCN108488618APrecise raiseVessel geometry/arrangement/sizeContainer filling methodsGas cylinderNitrogen gas

The invention relates to an acetylene gas cylinder acetone supplementing device, and belongs to the technical field of gas production and split charging. By aiming at the problem that the acetone supplementing of the existing acetylene gas cylinder is not precise enough, the invention provides the acetylene gas cylinder acetone supplementing device, which can realize precise filling. The acetylenegas cylinder acetone supplementing device comprises a nitrogen gas cylinder, an acetone raw material tank, an acetone supplementing tank, a weighbridge and a controller, wherein the nitrogen gas cylinder is respectively connected with a first gas inlet of the acetone raw material tank and a second gas inlet of the acetone supplementing tank; an acetone outlet of the acetone raw material tank is connected with an acetone inlet of the acetone supplementing tank through a hose; an supplementing outlet extends to the bottom of the acetone raw material tank through a pipeline; an acetone filling opening is formed in the acetone supplementing tank; the acetone filling opening extends to the bottom of the acetylene supplementing tank through a pipeline; the acetone filling opening is connected with the gas cylinder through a hose; an electromagnetic valve is arranged between the acetone filling opening and the gas cylinder; the weighbridge is arranged at the bottom of the gas cylinder and isconnected with the controller; the controller is connected with the electromagnetic valve.

Owner:CHIZHOU SENDA LIGHT IND PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com