Control method of automatic vehicle engine oil injection equipment

An automatic filling and control method technology, which is applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of dust adhered to the outer wall of the oil filling port, inaccurate oil filling, and oil leakage and adhesion, etc., to achieve Eliminate manual oiling operations, save manpower, and intelligentize troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

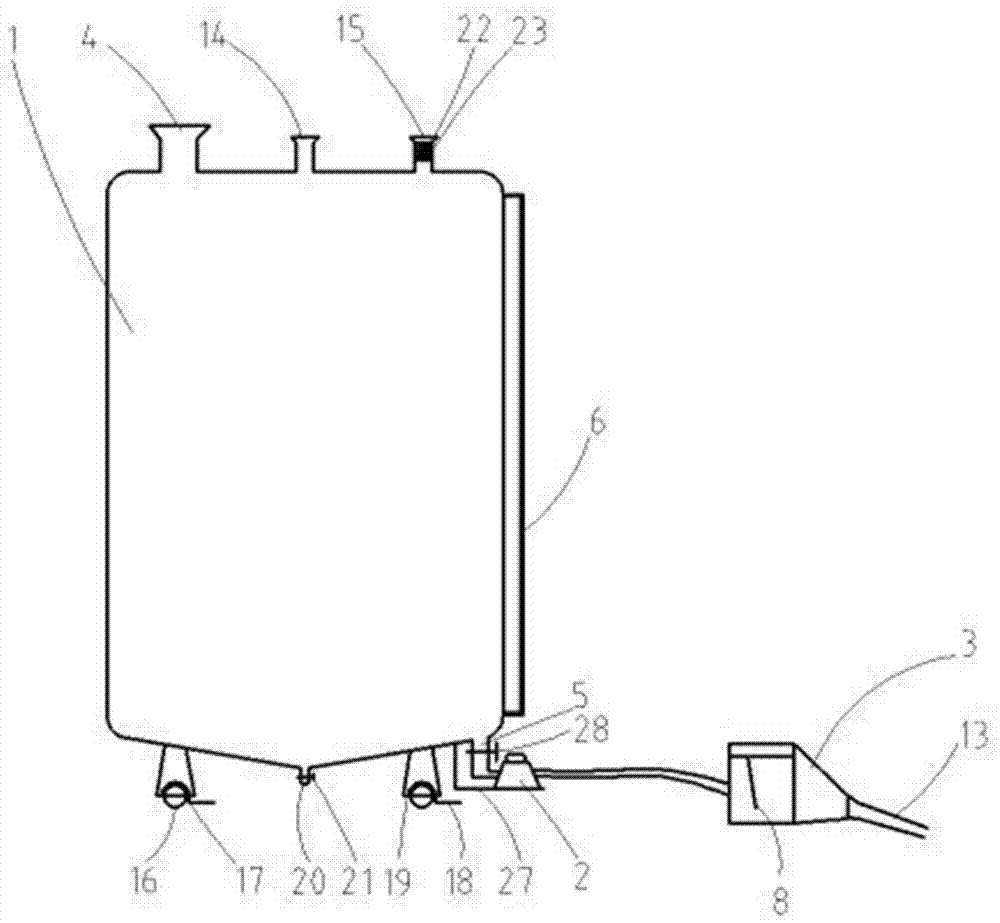

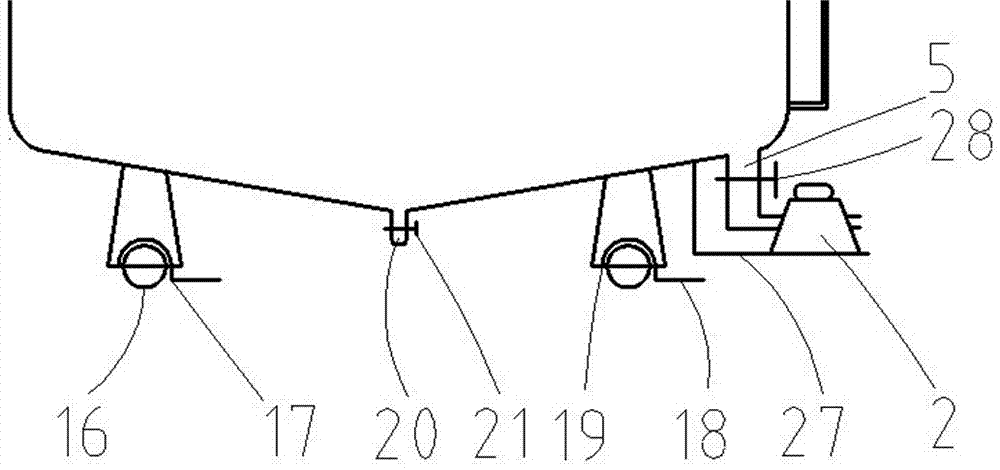

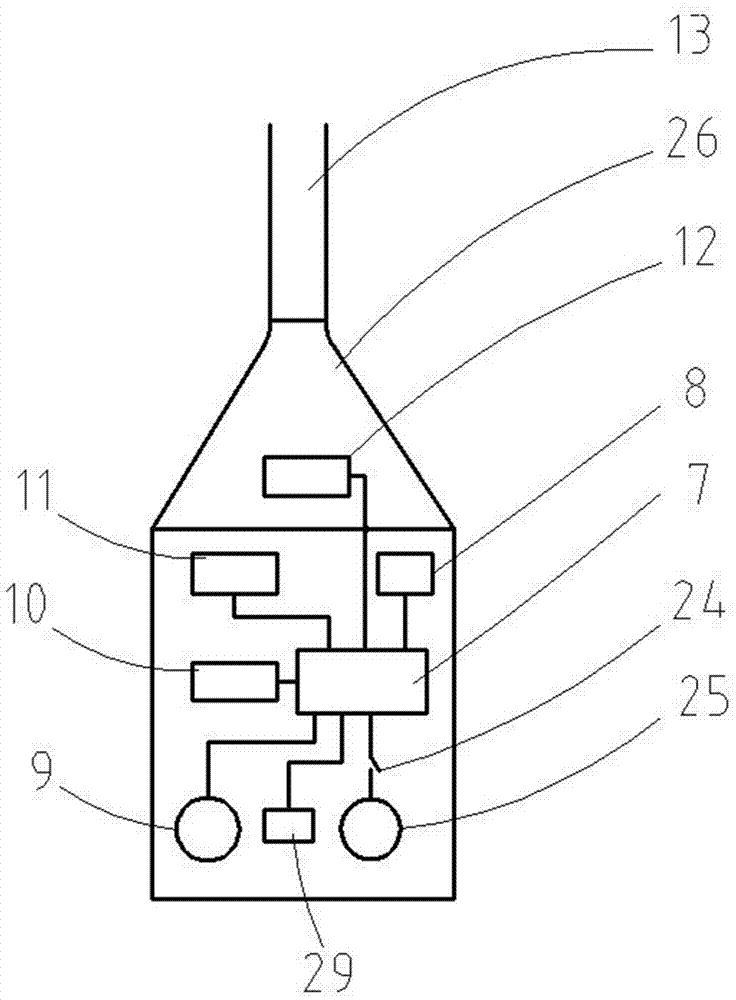

[0032] The invention discloses a control method for automatic filling equipment of automobile engine oil, such as Figure 1 to Figure 4 shown, including the following steps:

[0033] 1) The lever 8 connected to the grease gun 3 has an automatic reset function. The user pulls down the lever 8 at the beginning of fuel injection, and forms a mechanical signal and sends it to the control module 7 connected to the grease gun 3. The control module 7 forms a first reset according to the mechanical signal. Electric signal, the lever 8 is always pulled down during the oil filling process, after the oil filling is completed, the first electric signal controls the lever 8 to reset automatically;

[0034] 2) The flow meter 9 connected to the oil injection gun 3 has the function of setting the oil injection volume and flow adjustment. It can set the oil injection volume and adjust the flow rate of the flow meter 9 according to the different oil injection volumes of different models, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com