Patents

Literature

115results about How to "Conducive to solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

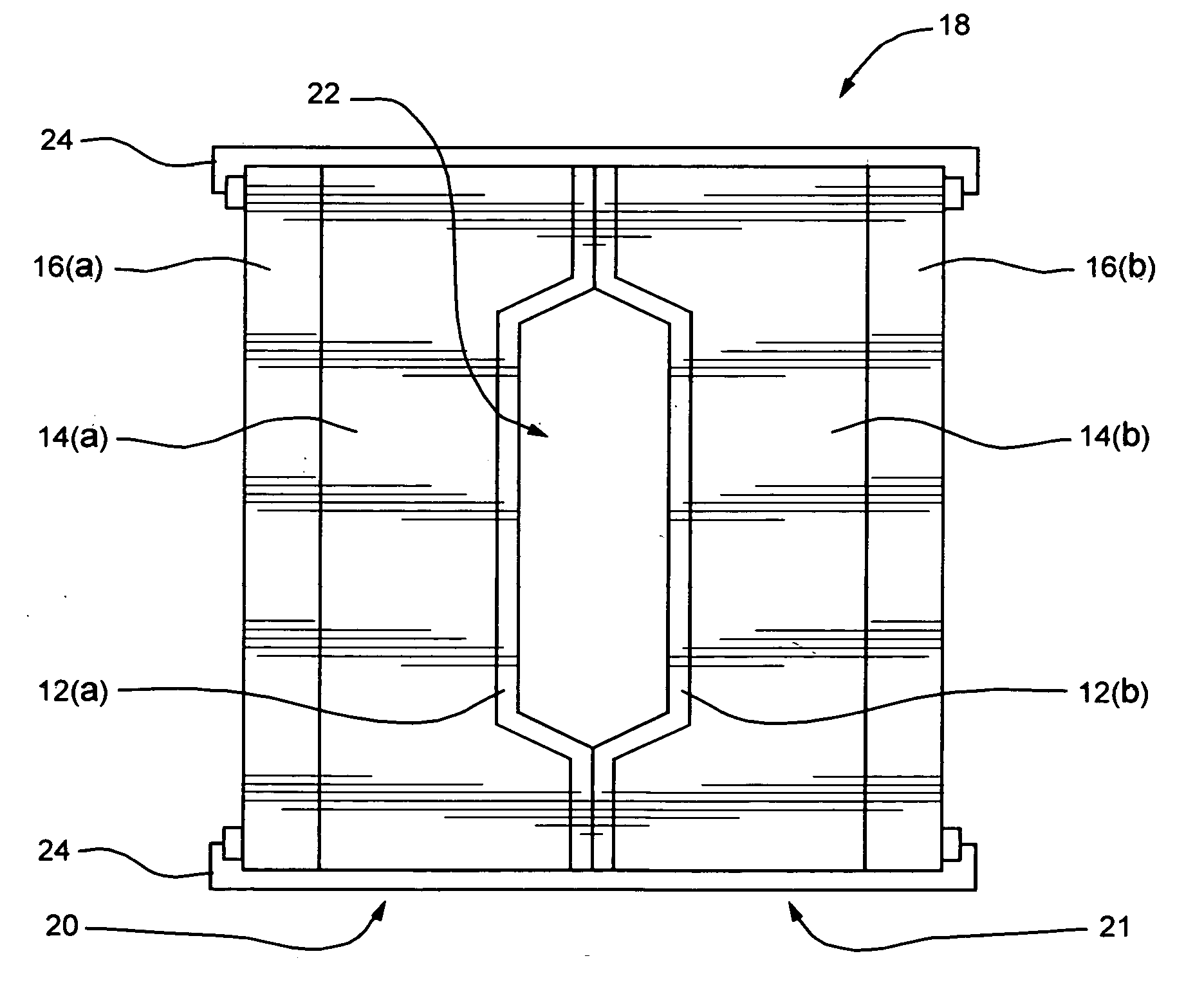

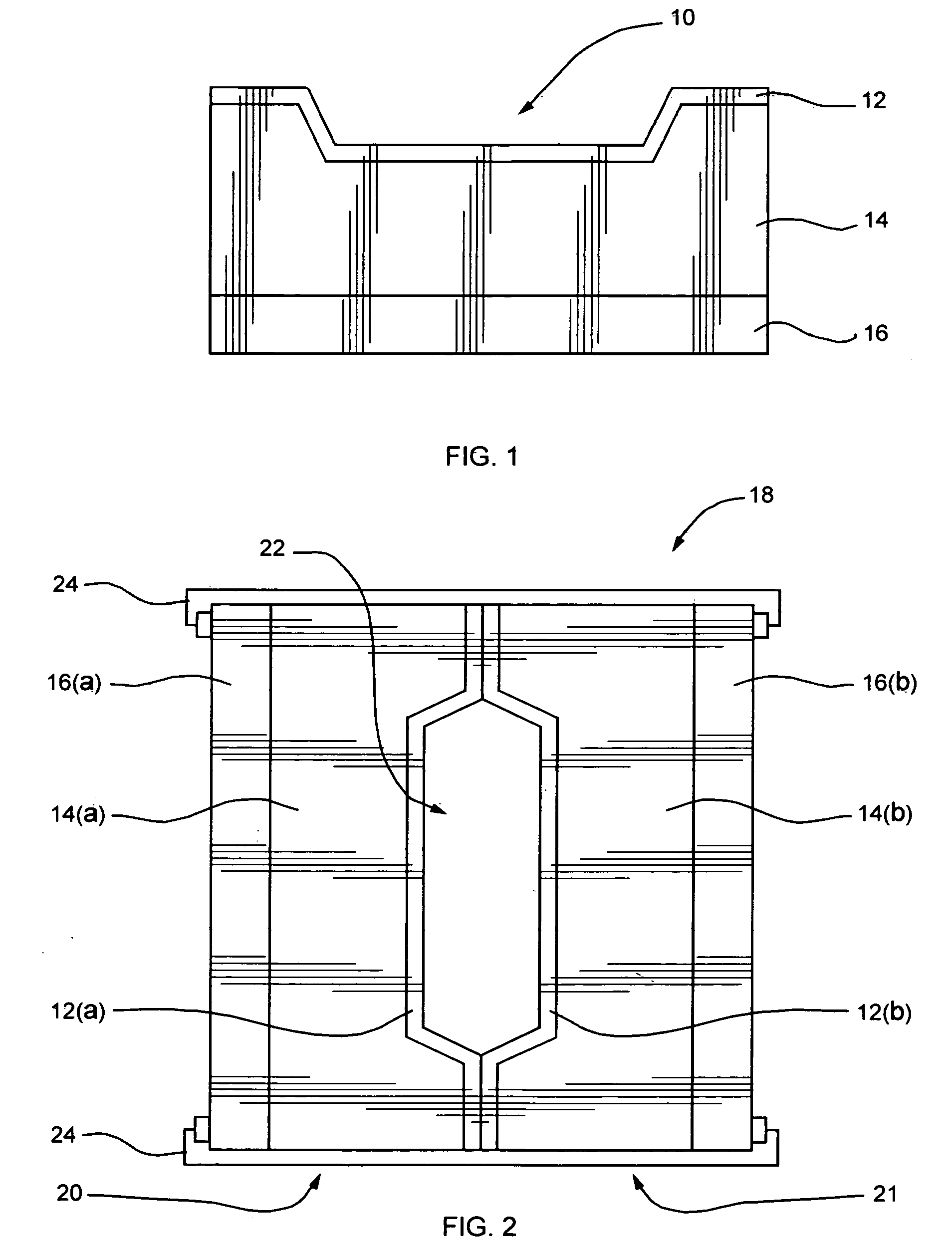

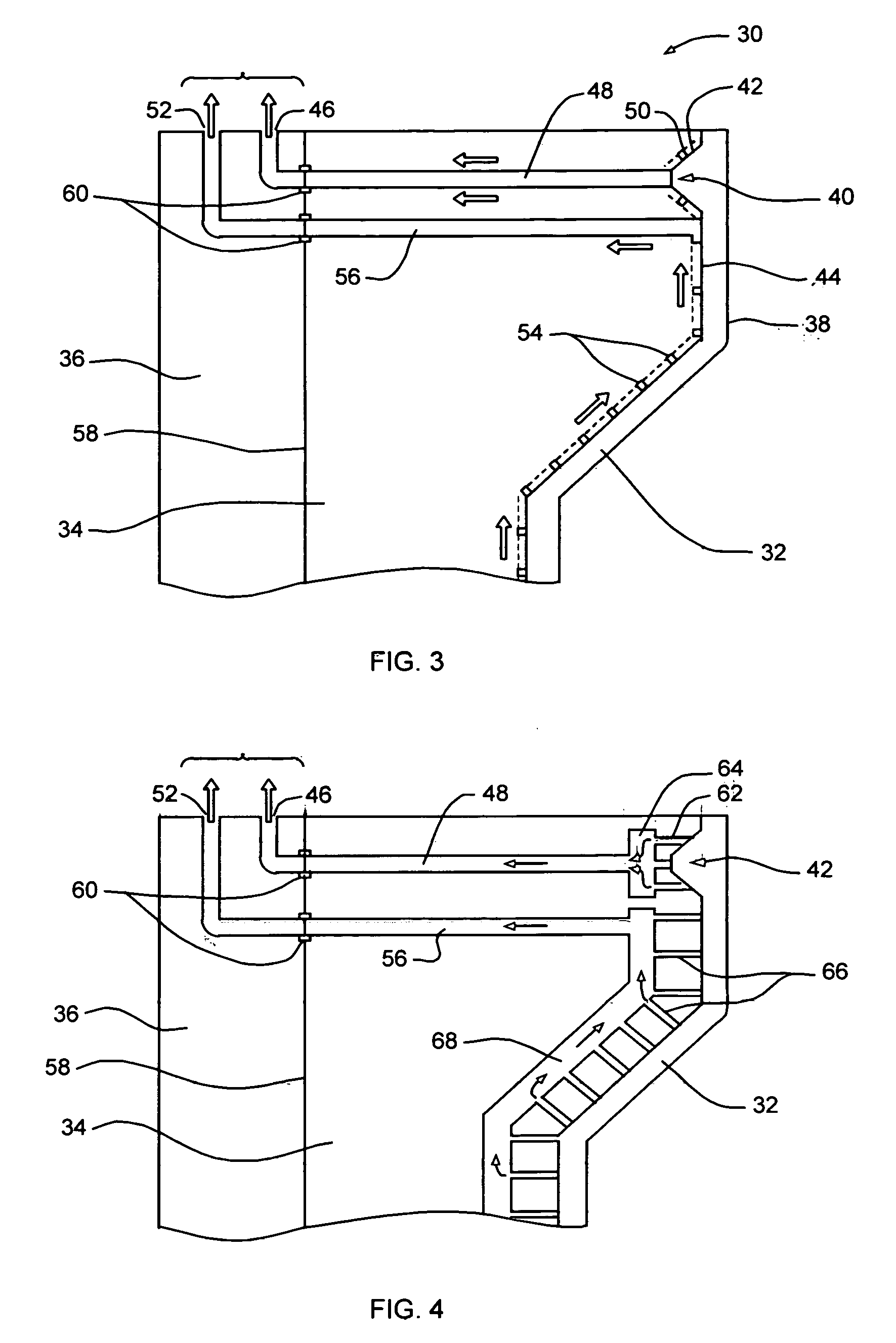

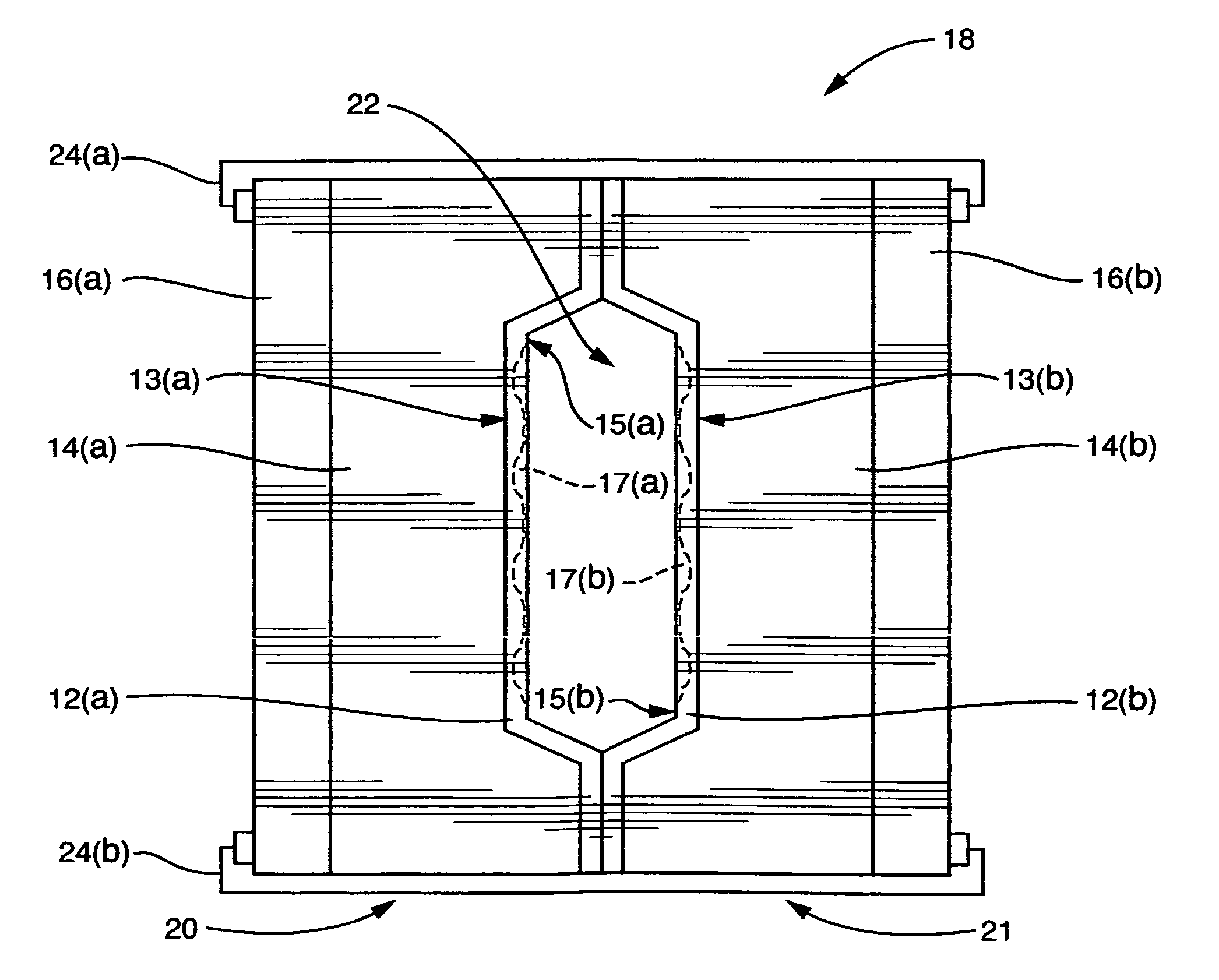

Compound tooling system for molding applications

ActiveUS20070063378A1Accurate operationFacilitate partial removalAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

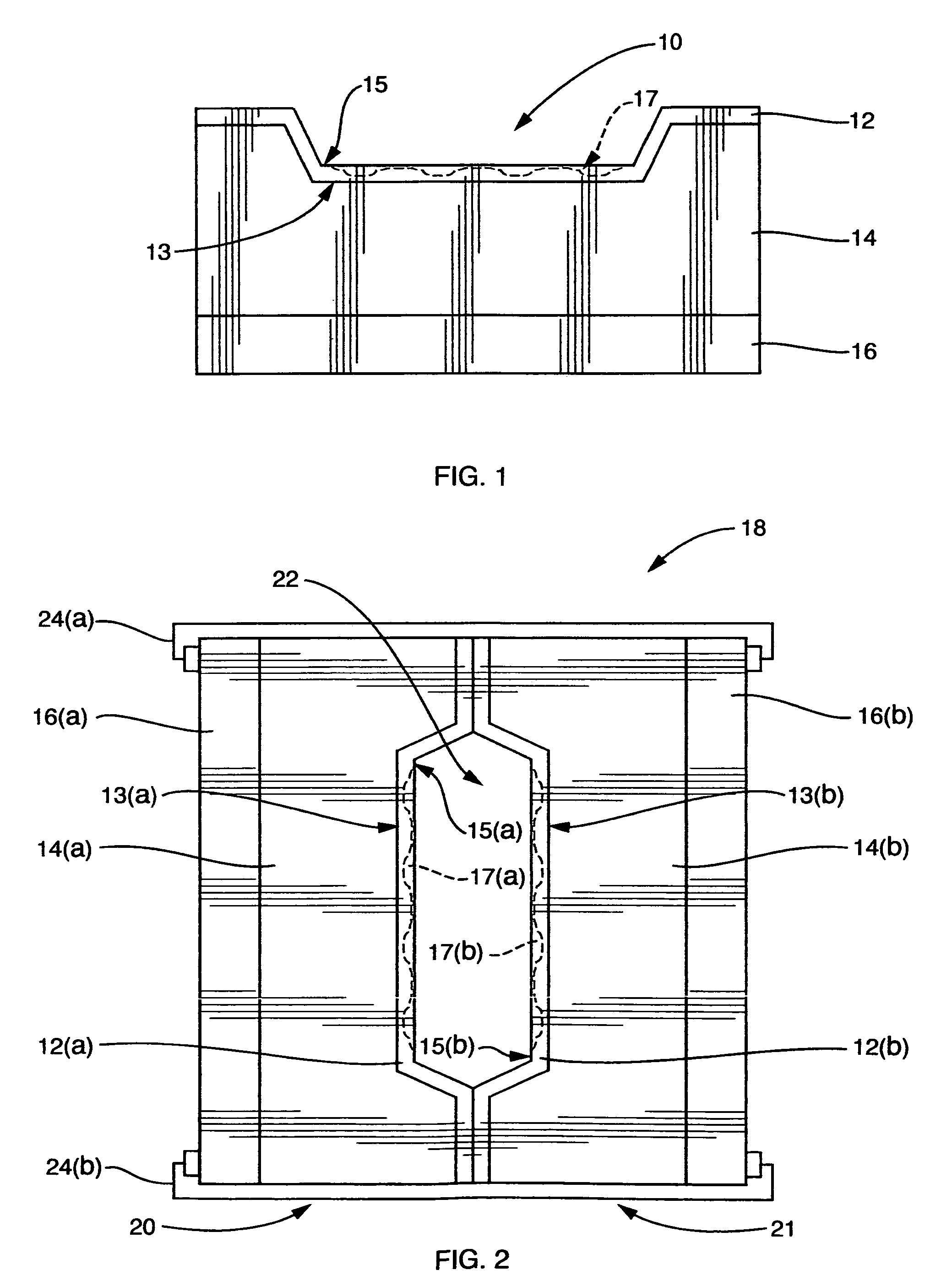

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

Compound tooling system for molding applications

ActiveUS7972129B2Easy to modifyEvenly heatedAdditive manufacturing apparatusConfectioneryShell moldingMetal mold

A compound mold or tooling system is designed to provide an alternative to conventional, expensive, metal molds for various plastics molding applications. The compound mold comprises a replaceable thin-walled liner, or skin-mold, defining the mold surface, temporarily bonded by vacuum means or mechanical means to a conforming backing-mold mold body supported by a rigid backing-plate. Both skin- and backing-molds are composed of suitable polymers with or without additives, fillers, reinforcements or other inclusions depending on mold requirements. The backing-plate contains standard features and fixtures common to all molds used in the particular process or of a particular geometry.

Owner:ODONOGHUE JOSEPH

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

Double-component silane-terminated sealing adhesive and preparation method thereof

InactiveCN102304340AFlexible ratio rangeFlexible dosageOther chemical processesPolyureas/polyurethane adhesivesEndcappingPolymer science

The invention discloses a double-component silane-terminated seal adhesive which comprises a component A and a component B, wherein the component A is prepared from silane-terminated prepolymer, plasticizer, thixotropic agent, ultraviolet absorbent, ultraviolet stabilizer, moisture remover, accelerator, curing agent, colorant, bulking filler and reinforcing filler; the component B is prepared from silane-terminated prepolymer, plasticizer, cocatalyst, surfactant and water absorbent; and the component A and the component B are mixed in a weight ratio of 5:1-49:1. In the invention, the proportioning range of the double-component system is more flexible, and the consumption of the component B is flexible and low, so that the properties of the double-component system are closer to and even superior to those of the single component A in the curing process after reducing the A\B mixture.

Owner:TONSAN ADHESIVES INC

Method for preparing Kefir sour milk

The invention discloses a method for preparing Kefir sour milk which comprises water, sugar and sour milk prepared from the fermentation of two different Kefir grains; the preparing method comprises the follow steps: 1. raw milk is sterilized and then cooled to the temperature of 20 DEG C to 30 DEG C; 2. the two different Kefir grains are activated and cultured separately; 3. the activated and cultured Kefir grains with inoculum size of 2 percent to 5 percen are respectively inoculated to the sterilized raw milk; 4. the raw milk is fermented for 15 hours to 24 hours at the temperature of 20 DEG C to 30 DEG C; 5. the Kefir grains are filtered out to obtain two filtrates which are fermentation agents; 6. the two fermentation agents are mixed; 7. the mixed fermentation agents with the inoculum size of 2 percent to 5 percent are inoculated to the sterilized original milks and then fermented at the variable temperature ranging from 20 DEG C to 45 DEG C for 4 hours to 6 hours; and 8. the fermented milk are blended, homogenized and canned. With the adoption of the fermentation agents for fermenting at the variable temperature, the flavor of Kefir milk is well improved. The ferment time of the product is short, the yeasts in the mixed fermentation agents are more stable and the difference between flavors of Kefir sour milk prepared in different batches is small. The product has health-care functions of regulating beneficial bacteria in intestinal canals, lowering blood lipids, resisting tumors and the like, thus being a low-cost functional beverage.

Owner:于岚 +2

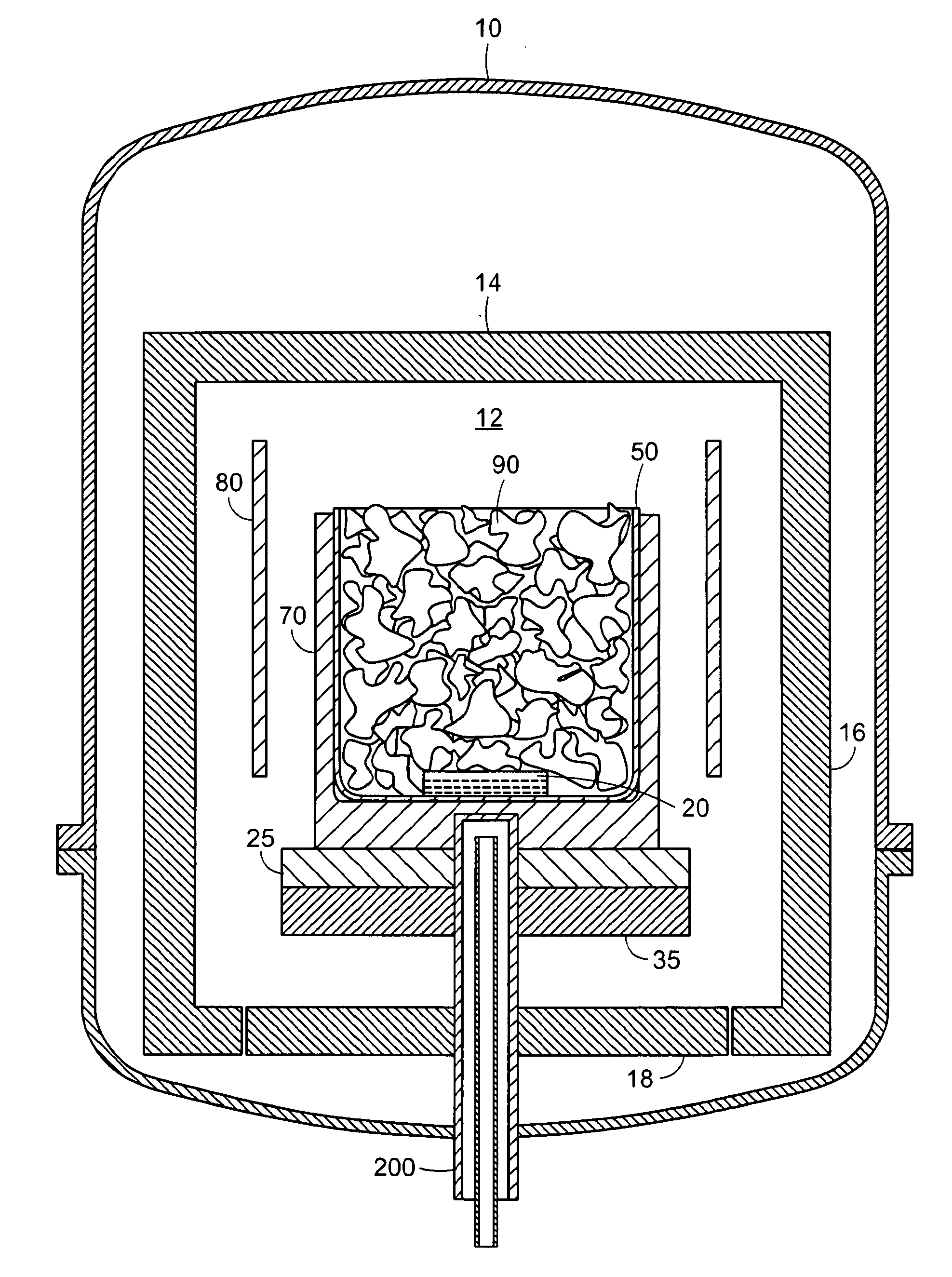

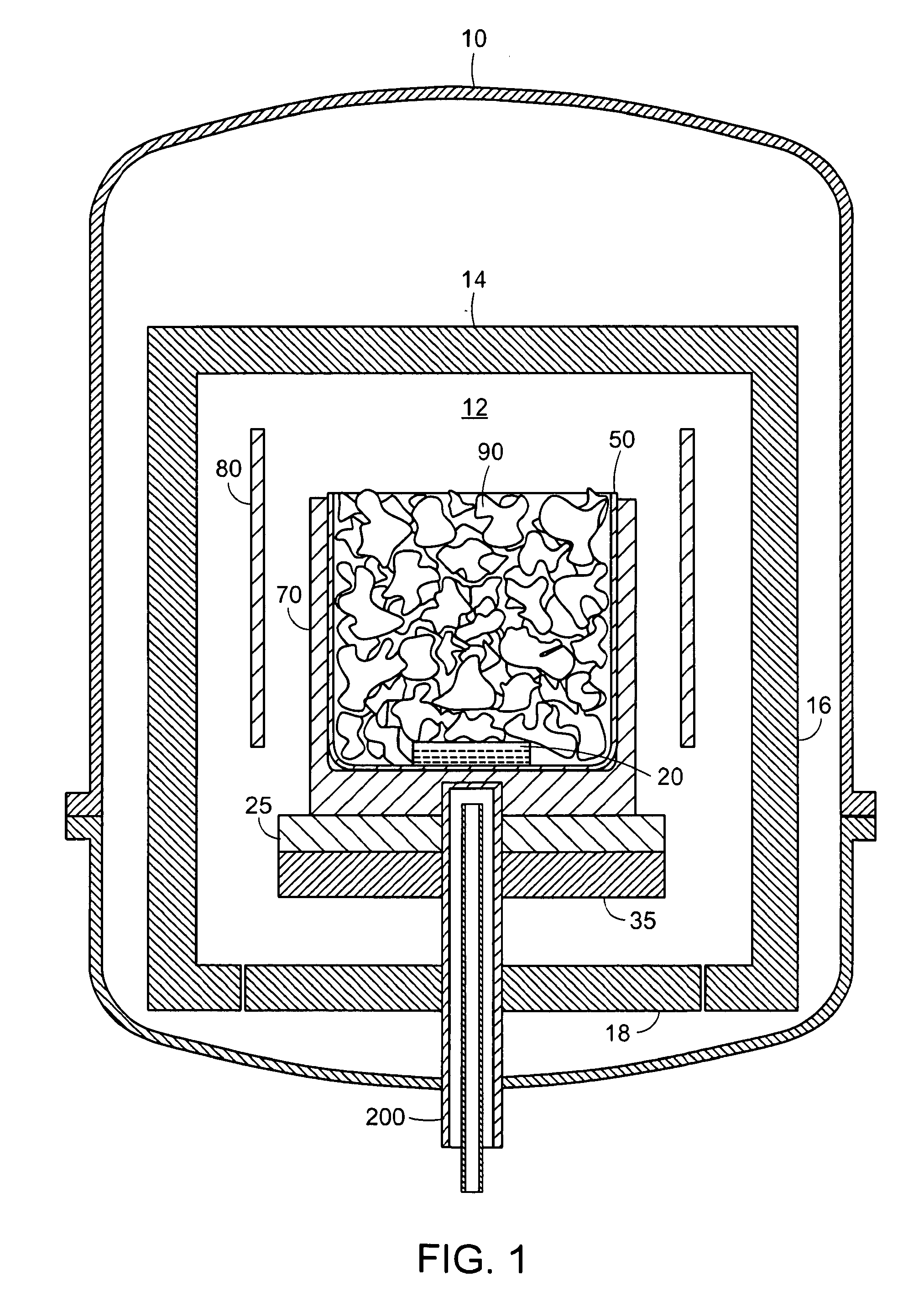

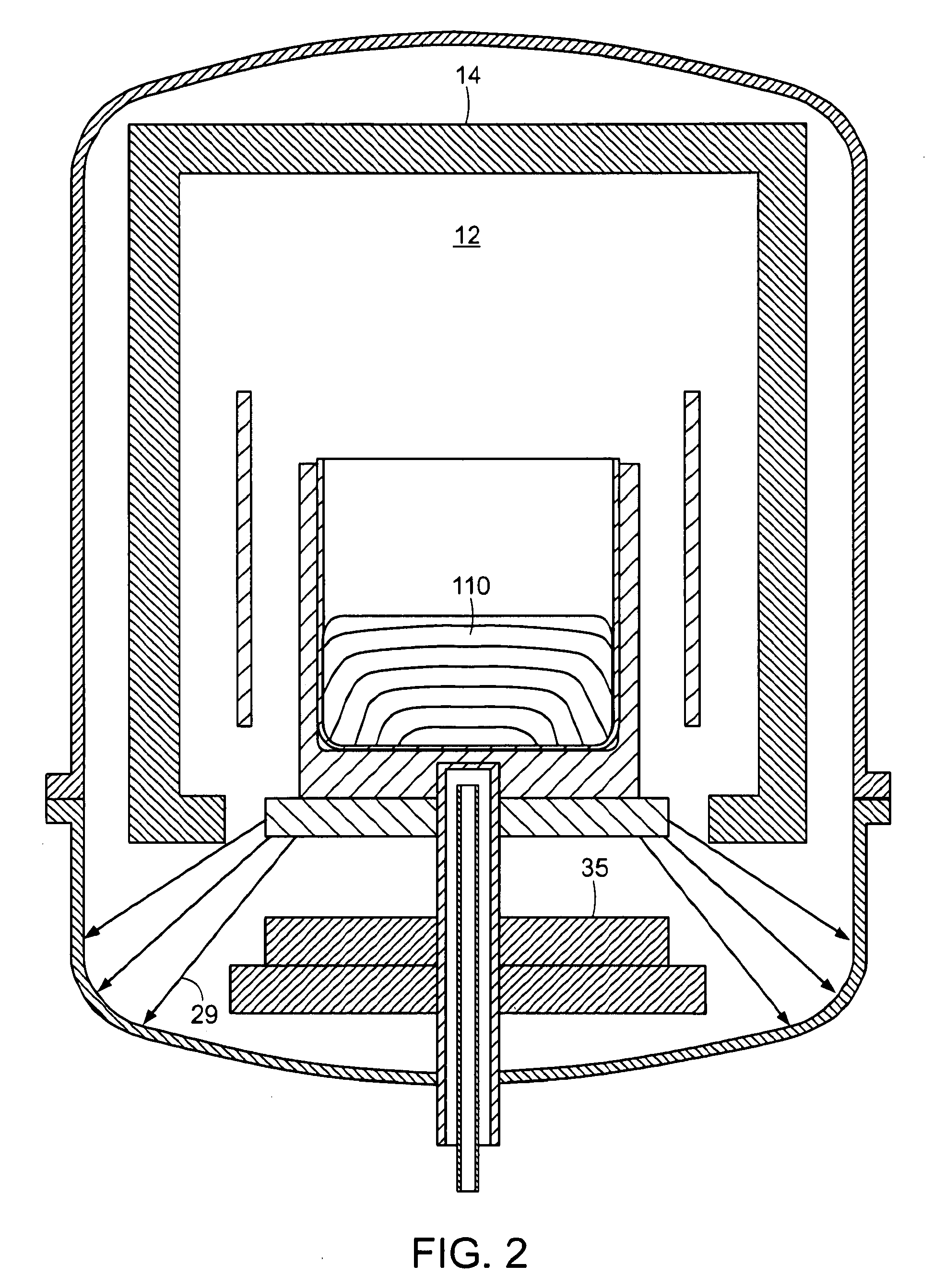

Systems and methods for growing monocrystalline silicon ingots by directional solidification

InactiveUS20110259262A1Quality improvementEfficiency savingPolycrystalline material growthBy zone-melting liquidsGrowth phaseCrucible

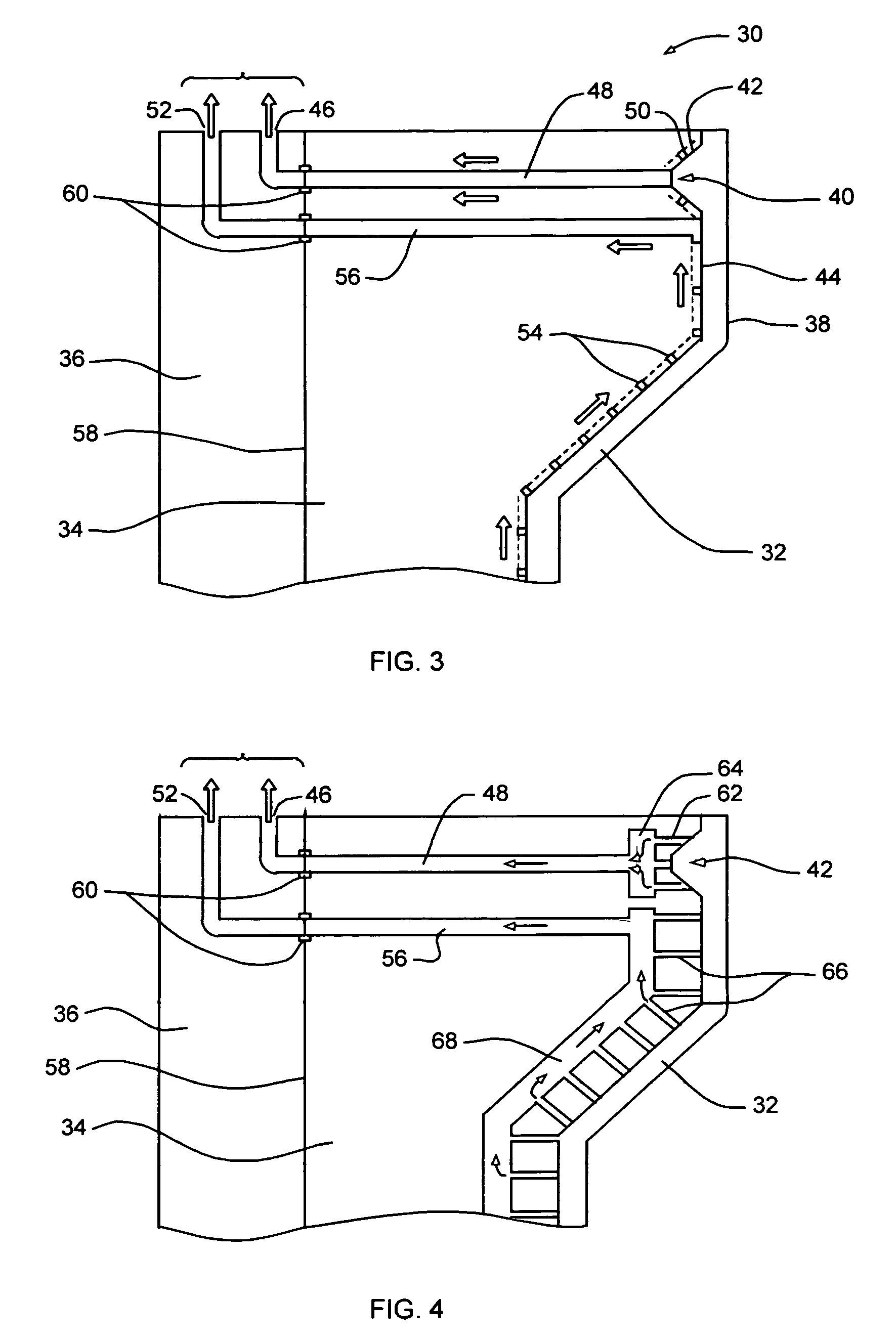

Systems and methods are provided for producing monocrystalline materials such as silicon, the monocrystalline materials being usable in semiconductor and photovoltaic applications. A crucible (50) is received in a furnace (10) for growing a monocrystalline ingot, the crucible (50) initially containing a single seed crystal (20) and feedstock material (90), where the seed crystal (20) is at least partially melted, and the feedstock material (90) is completely melted in the crucible (50), which is followed by a growth and solidification process. Growth of monocrystalline materials such as silicon ingots is achieved by directional solidification, in which heat extraction during growth phases is achieved using insulation (14) that is movable relative to a crucible (50) containing feedstock (90). A heat exchanger (200) also is provided to control heat extraction from the crucible (50) during the growth and solidification process to achieve monocrystalline growth.

Owner:GT SOLAR INC

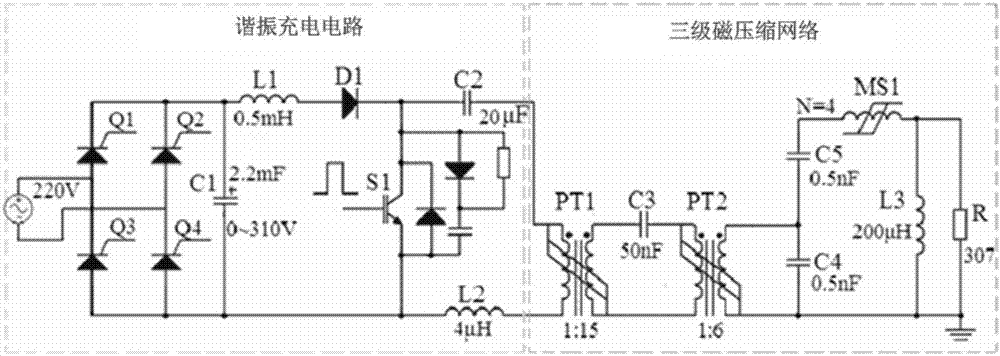

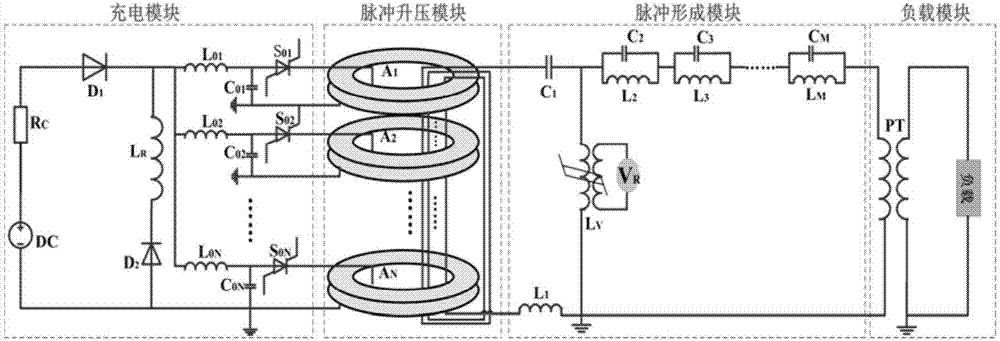

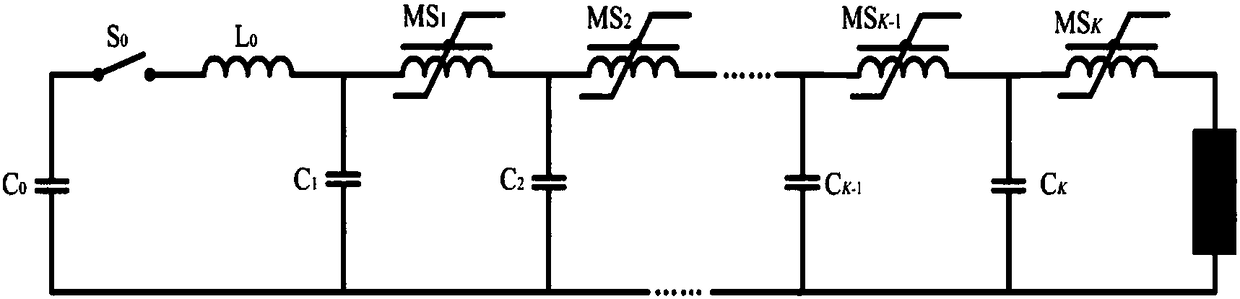

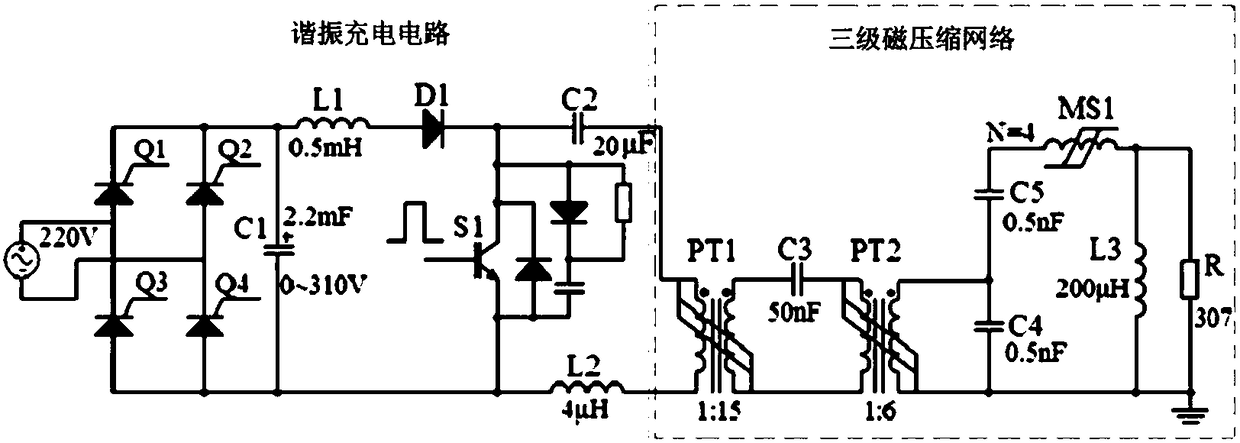

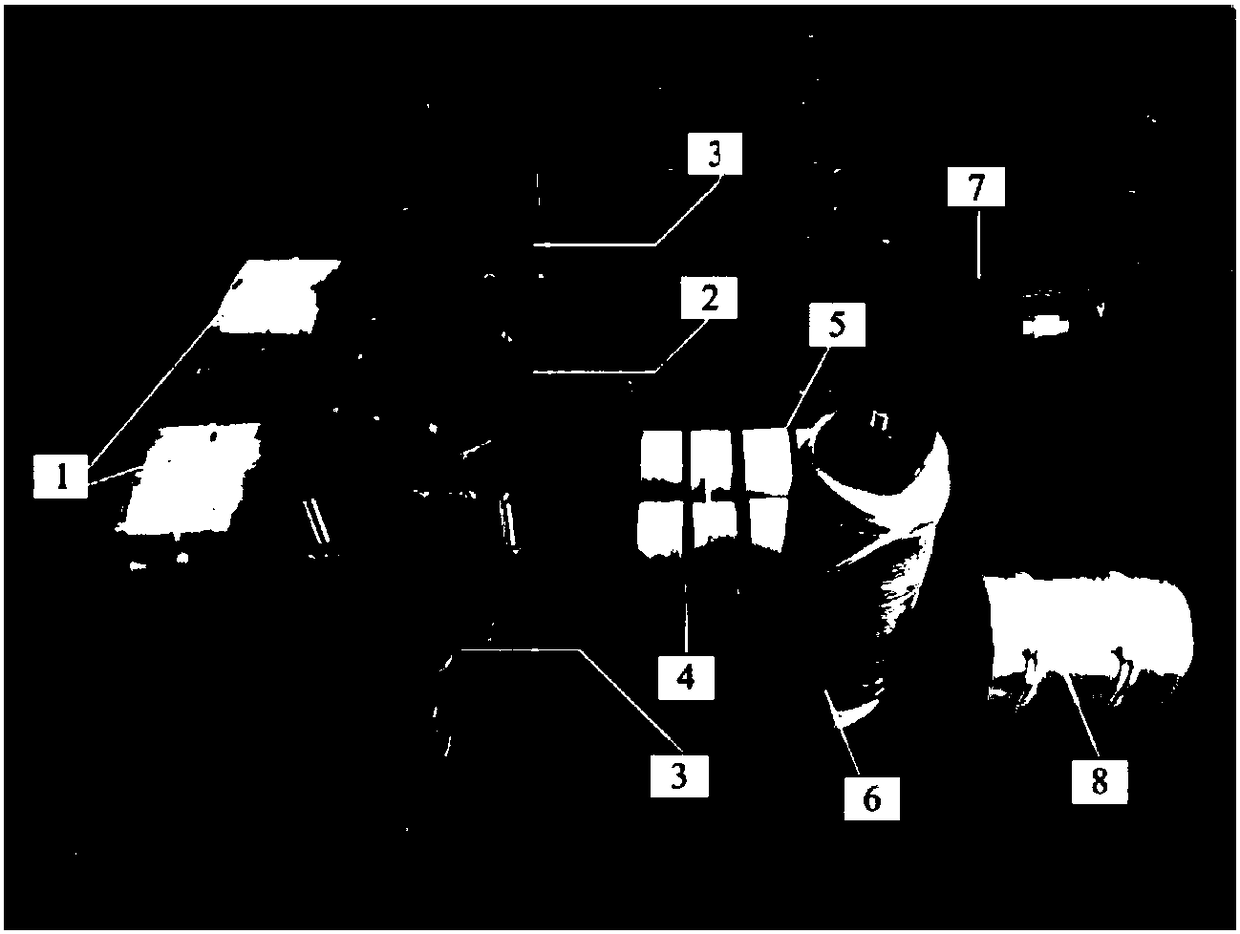

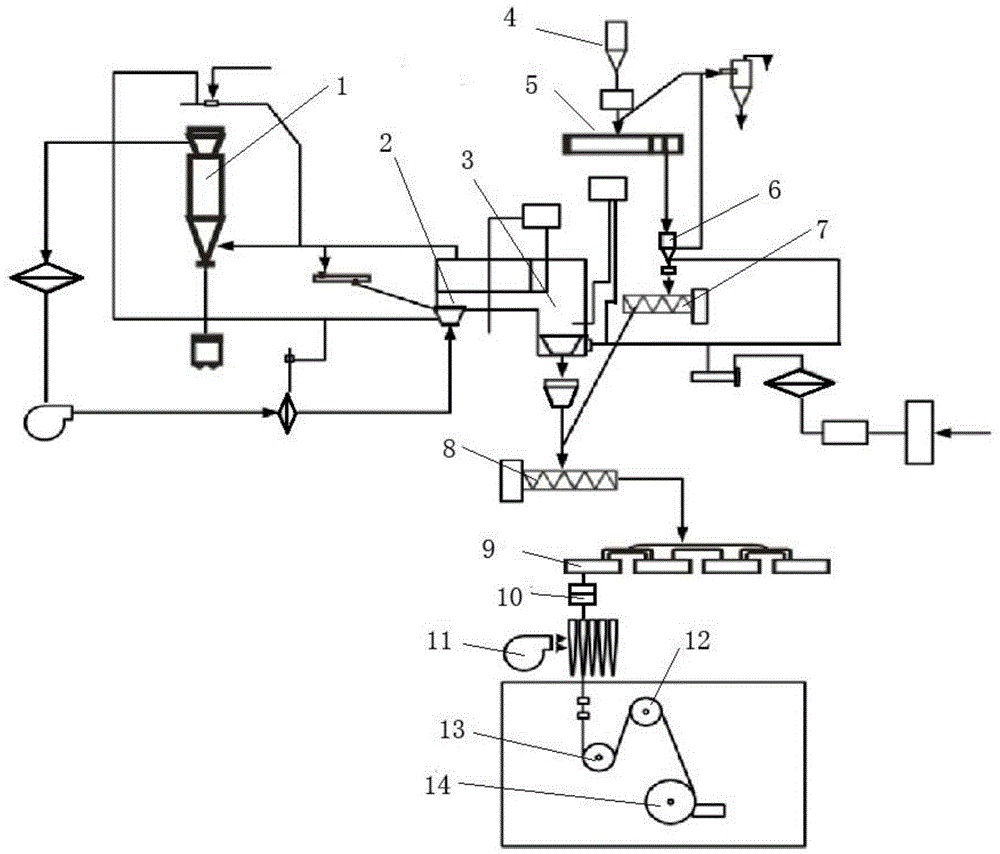

All-solid-state high-voltage microsecond pulse generator based on FRSPT (Fractional-turn Ratio Saturable Pulse Transformer) and anti-resonance network

ActiveCN107040244ACompact integrationAvoid the voltage equalization problem of the working voltagePulse generation by bulk negative resistance devicesAll solid stateMicrowave

The invention relates to a microsecond pulse generator, particularly relates to an all-solid-state high-voltage microsecond pulse generator based on a FRSPT (Fractional-turn Ratio Saturable Pulse Transformer) and an anti-resonance network, and belongs to the field of pulse power. The pulse generator consists of a charging module, a pulse boosting module, a pulse forming module and a load. The charging module is mainly used for charging the pulse generator, and charges the pulse forming module by the pulse boosting module; the pulse boosting module is the FRSPT; in one aspect, the FRSPT is used as a transformer of the pulse boosting module, and in the other aspect, the FRSPT is used as a switch of the pulse forming module; and the pulse forming module is used for forming a quasi-square wave pulse which is reasonable in leading and lagging edge time and good in flat top degree. The pulse generator is long in service life and stable to operate; all-solid-state compact integration of the pulse generator is implemented; an output square wave is high in quality; and the all-solid-state high-voltage microsecond pulse generator can be used for the fields of a high-power microwave source, foods, sterilization and disinfection, wastewater treatment and the like.

Owner:NAT UNIV OF DEFENSE TECH

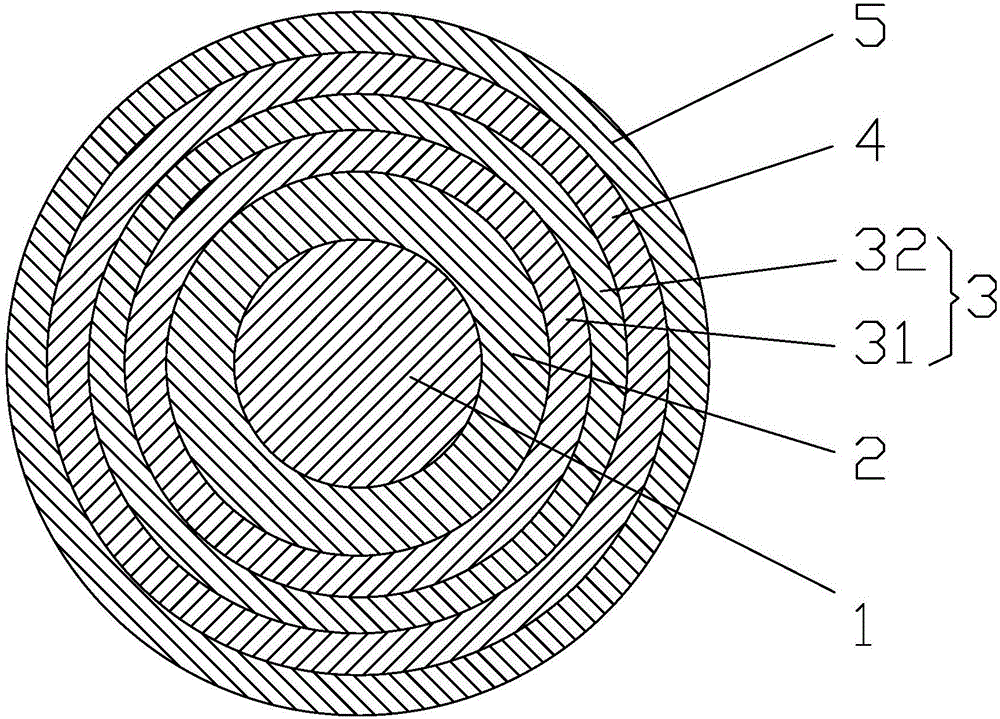

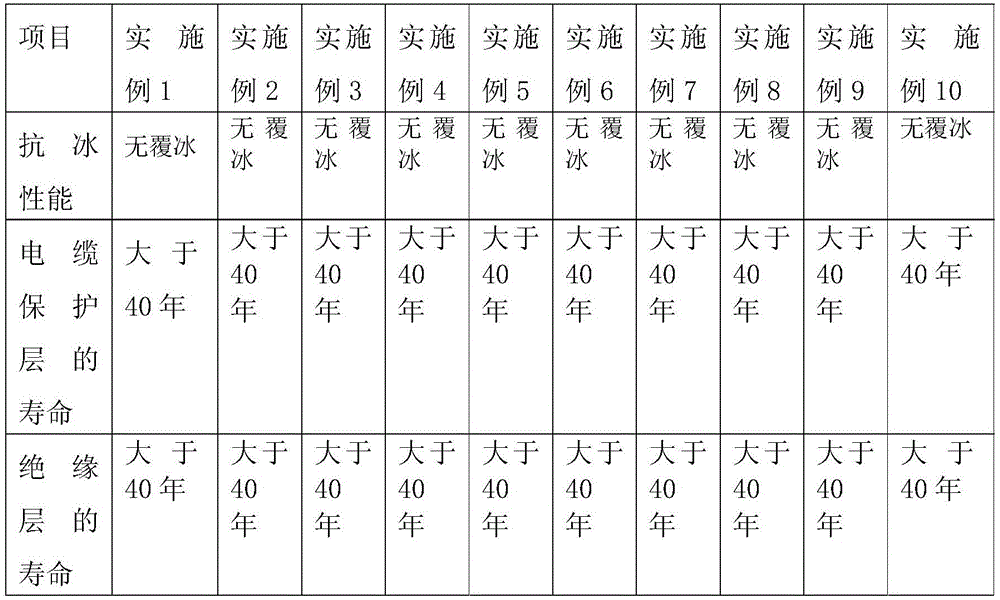

Power transmission cable with anti-icing function and preparation method of power transmission cable

ActiveCN106531335AReasonable structural designReduce escapePower cables with screens/conductive layersInsulated cablesSnow meltingCold weather

The invention relates to a power transmission cable with an anti-icing function. The power transmission cable sequentially comprises a power transmission cable inner core, an insulating layer sleeving the outside of the power transmission cable inner core, a cable shielding layer sleeving the outside of the insulating layer, and a cable sheath layer sleeving the outside of the cable shielding layer from inside to outside, wherein the power transmission cable is characterized in that an anti-icing function layer is also arranged in the middle of the insulating layer and the cable shielding layer and comprises an inner-layer high-temperature composite phase change material layer and an outer-layer low-temperature phase change material layer. The power transmission cable is reasonable in structure design and various parts are tightly combined and mutually isolated and insulated. In cold weather, the inner-layer high-temperature composite phase change material layer is capable of retarding heat escape and preventing overheat ageing of an outer-layer material; and the outer-layer low-temperature phase change material layer is capable of keeping the outer surface of the cable in a relatively low temperature state, preventing snow melting and icing, caused by heating of the inner core, of the outer surface of the power transmission cable, preventing cold shortness of the cable material and prolonging the life of the cable protection layer and the insulating layer.

Owner:FUJIAN REIDA PRECISION

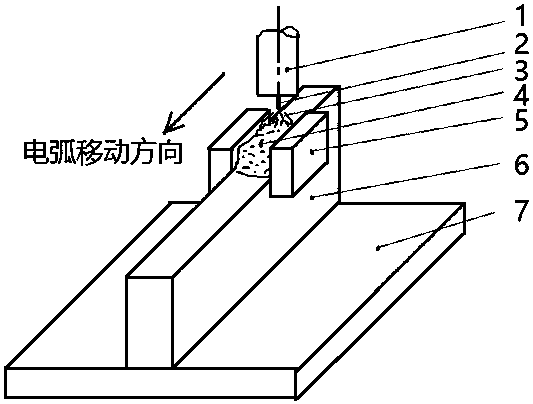

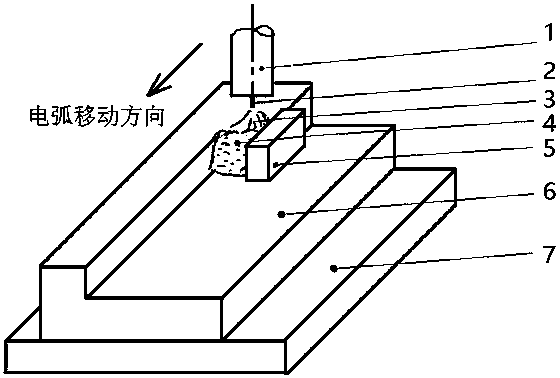

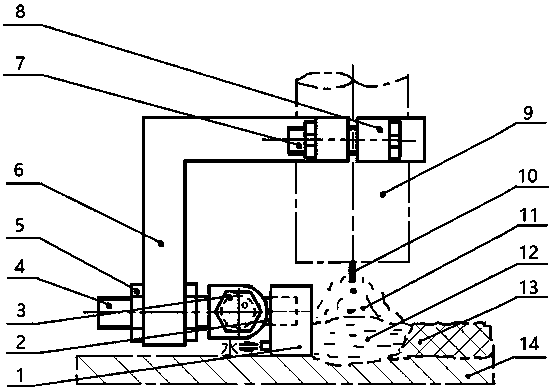

Method for improving arc additive manufacturing precision and forming efficiency of wire material

ActiveCN107803568AAvoid overall overheatingExtend your lifeWelding/cutting auxillary devicesAuxillary welding devicesAdvanced manufacturingWeld bead

The invention discloses a method for improving arc additive manufacturing precision and forming efficiency of a wire material and belongs to the technical field of advanced manufacturing. The problemsthat during arc additive manufacturing of a conventional wire material, the size precision and the surface quality of samples are poor, the heat inputting is limited, and the forming efficiency is not high are solved. According to the method, the relative positions of a forming mold and a welding gun are fixed, the mold forming face in the forming process is made to keep being in contact with theside face of a molten pool, the shape of the molten pool is restrained, the molten pool is made to be solidified under the mold restraint, micro casting of metal of the molten pool is achieved, and the consistency of the welding bead width and stable process parameters are guaranteed in the forming process, so that the size precision and the surface quality of the formed samples can be improved;and by means of water cooling on the mold, cooling on the molten pool is enhanced, changing of the cooling conditions is reduced, and the uniformity of the performance of the structures of the samplesis guaranteed. On the other hand, because the mold is adopted to restrain the metal of the molten pool, the linear energy can be increased, it is not needed to worry that because of free flowing of the molten pool, forming cannot be achieved, and therefore the forming efficiency is improved.

Owner:SHANDONG JIANZHU UNIV

Water-soluble polyvinyl alcohol chopped fiber as well as preparation method and application thereof

ActiveCN102433599ALow water dissolution temperatureEmission reductionSpinnerette packsArtificial filament heat treatmentPolymer scienceSpinning

The invention discloses a water-soluble polyvinyl alcohol chopped fiber of which the water dissolving temperature is 65-75 DEG C. The water-soluble polyvinyl alcohol chopped fiber is prepared by performing spinning and spinning after-treatment on polyvinyl alcohol and water serving as raw materials, wherein the polymerization degree of the polyvinyl alcohol is 1,400+ / -200, the alcoholysis degree is 98.3-99.9 percent, and the mass percentage concentration is 21.0-23.0 percent. The water-soluble polyvinyl alcohol chopped fiber has low water dissolving temperature, and has particularly prominent application effects in the fields of soluble embroidery base cloth, water-soluble paper and the like in the industries of spinning and non-woven fabrics; the water-soluble polyvinyl alcohol chopped fiber is free from salt, so that fiber adhesion is prevented during drying after desalination in the production process; and meanwhile, the strength of the water-soluble polyvinyl alcohol chopped fiber is more than or equal to 3.2 cN / dtex, and the crispation number is more than or equal to 4 / 25 millimeters. The preparation method contributes to industrial mass production, the dissolving temperature of the prepared water-soluble polyvinyl alcohol chopped fiber is 65-75 DEG C, and grading, packaging and transportation are easy.

Owner:CHINA PETROCHEMICAL CORP +1

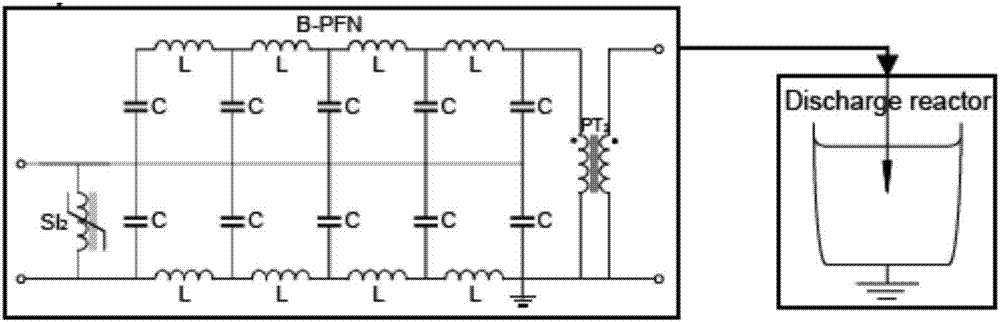

All-solid-state square-wave pulse generator

ActiveCN108390665ACompact integrationAvoid the voltage equalization problem of the working voltageElectric pulse generator circuitsHigh pressurePhysics

The invention relates to a square-wave pulse generator, and in particular relates to an all-solid-state square-wave pulse generator based on a fractional ratio saturable pulse transformer and a Marx generator, and belongs to the field of pulse power. The pulse generator is composed of a charging module, a pulse boosting module and a load module. According to the pulse generator provided by the invention, the primary working voltage and an auxiliary side saturable inductor of the pulse transformer can be reduced, and compact integration of the pulse transformer and the magnetic switch can be achieved; the magnetic switch is used for replacing an air switch in the traditional Marx generator, so that the service life of the whole system and the repeat frequency are greatly enhanced; a high voltage silicon rectifier stack is used for replacing an isolated inductor in the Marx generator, and the pre-pulse problem is effectively eliminated; meanwhile quasi-square-wave pulse with relatively high quality and good flattening degree can be output via an anti-resonant network, the system is all solidified and miniaturized, and is small in volume, light in weight, convenient in transport and practicability, avoids a multi-switch serial structure of the high voltage pulse generator, and can improve the service life.

Owner:NAT UNIV OF DEFENSE TECH

Cyanate resin composition and application for preparing high modulus carbon fiber prepreg by hot-melt method thereof

The invention provides a cyanate resin composition comprising at least one 70-90wt% of cyanate or cyanate prepolymer, 30-10wt% of epoxy resin and 100-500ppm of catalyst. In addition, the invention provides a high modulus carbon fiber prepreg which is prepared by soaking the carbon fiber in the cyanate resin composition without solvent, the prepreg has good operability and long-life property at room temperature, and the mechanical property of the cyanate / high modulus carbon fiber composite material which is through the hot-press forming with a press or through the autoclave forming is greatly increased compared with that of the corresponding epoxy / high modulus carbon fiber.

Owner:EAST CHINA UNIV OF SCI & TECH

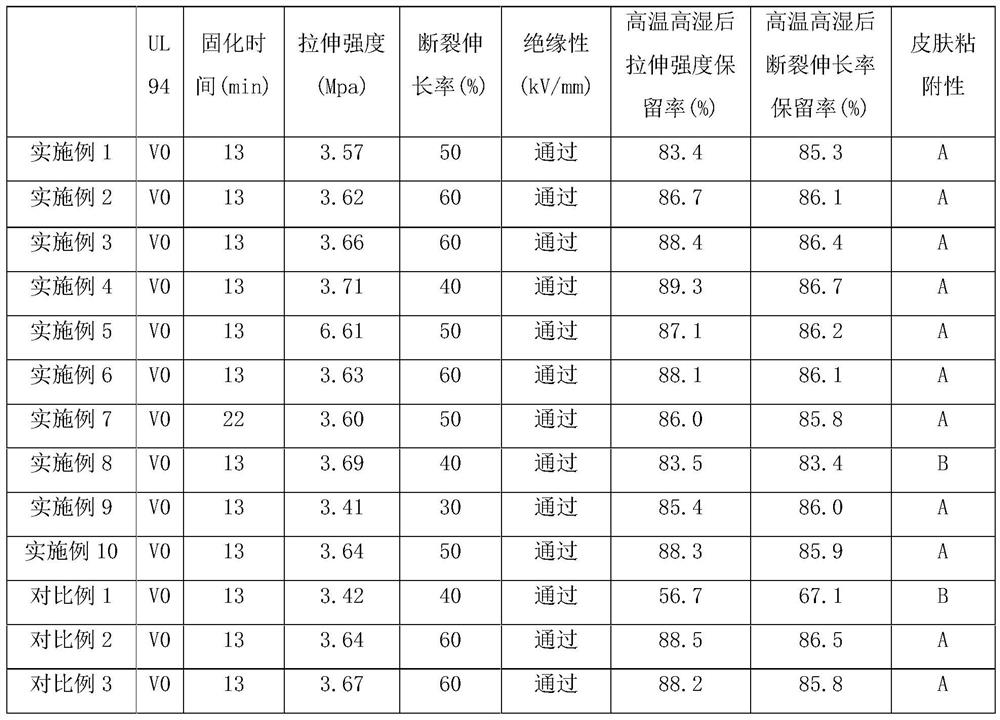

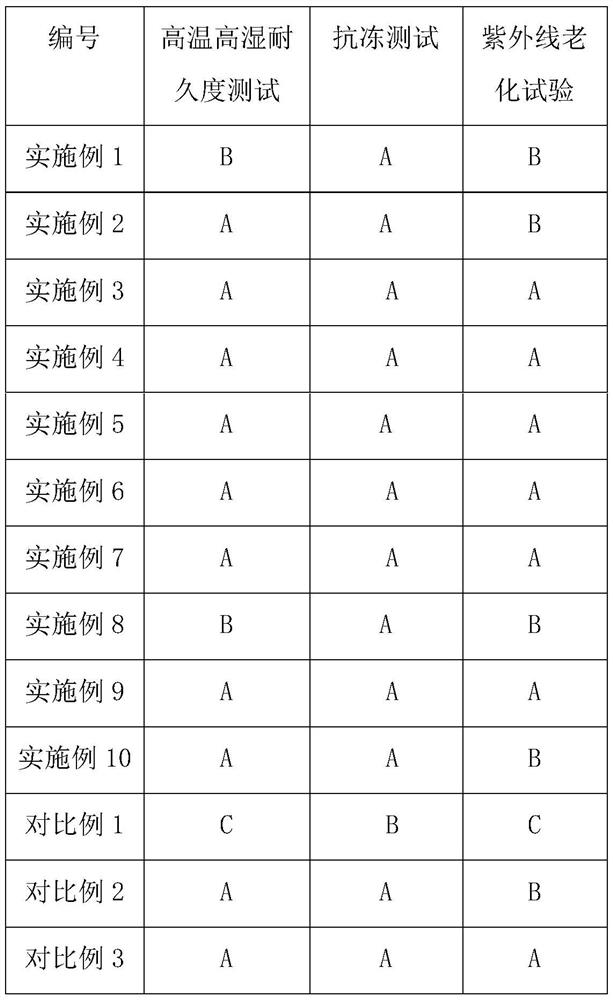

Fast cured moist-heat aging resistant double-component sealing adhesive and preparation process thereof

InactiveCN102391819AWide range of weight ratiosReduce the amount of mixingNon-macromolecular adhesive additivesOther chemical processesEndcappingPolymer science

The invention discloses a fast cured moist-heat aging resistant double-component sealing adhesive consisting of components A and B and a preparation process thereof. The component A comprises silane-containing blocking prepolymer, plasticizer, thixotropic agent, ultraviolet absorbent, ultraviolet stabilizer, moisture scavenging agent which is easily hydrolyzed silane coupling agent or oxazolidine moisture scavenging agent, accelerant, curing agent, colorant, incremental filler which is superfine calcium carbonate, superfine talcpowder, surface treated calcium carbonate or silicon micro powder, and reinforcing filler; and the component B comprises silane-containing blocking prepolymer, plasticizer, thixotropic agent, cocatalyst, surfactant and water absorbent material. The weight ratio range of the component A and the component B of the double-component system is relatively wide, and certain mixing error and metering error are allowed during mixing. Moreover, the mixing quantity of the component B is relatively low, the performance of the component B is furthest kept equivalent to that when the component B and the component A are separately cured, and the adhesive influence is reduced to minimum.

Owner:TONSAN ADHESIVES INC

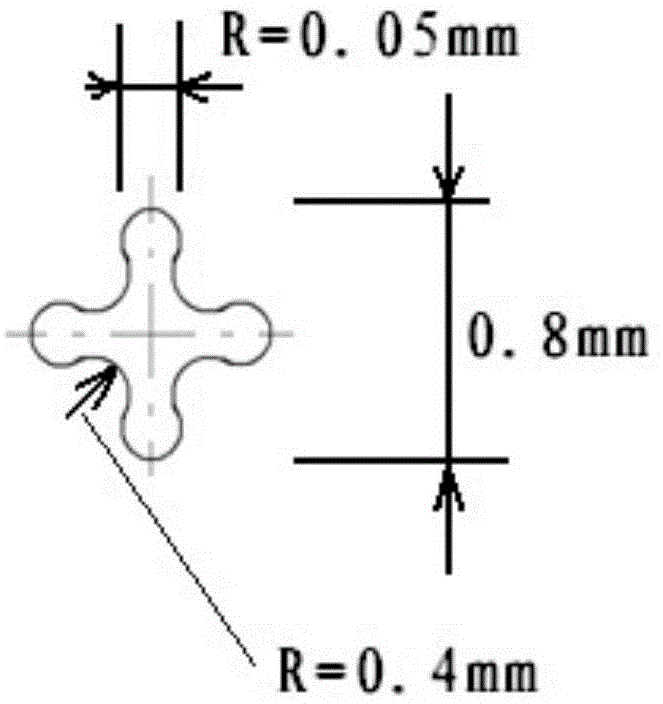

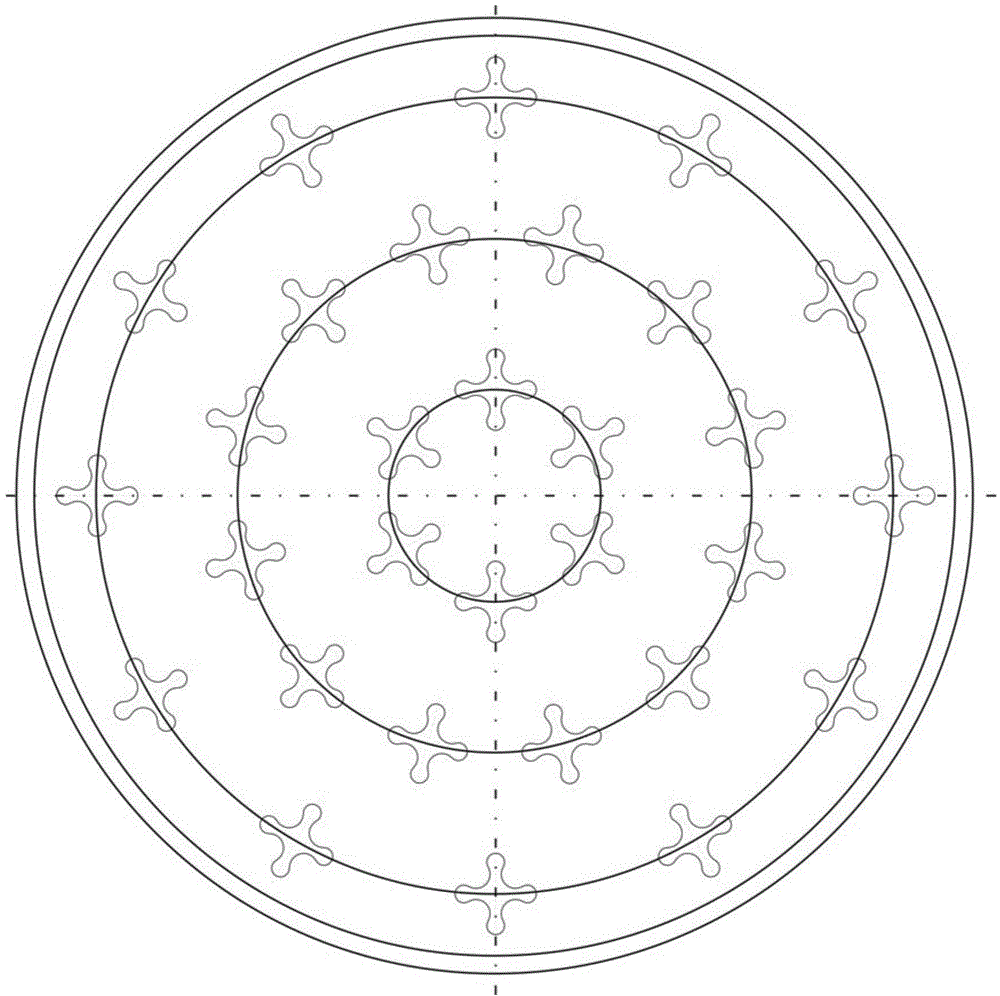

Special-shaped spinneret plate and method for producing square-section colored FDY through special-shaped spinneret plate

InactiveCN104451922ASquareness GuaranteedGuaranteed squarenessArtificial thread manufacturing machinesMelt spinning methodsYarnEngineering

The invention provides a special-shaped spinneret plate and a method for producing square-section colored FDY through the special-shaped spinneret plate. Spinneret holes in the spinneret plate are in an approximate rhombus shape of circular arc vertex angles and inward concave arc edges. Each edge of the rhombus is in an inward concave circular arc shape. Each angle is in an outward convex circular arc shape. The spinneret holes are distributed on the plane of the spinneret plate in the shape of concentric circles in a layered mode. Each layer of spinneret holes are distributed on the spinneret plate in a regular rhombus radial diagonal mode. The spinneret hole layers are arranged in a staggered mode. Sections of filament fibers spun by the spinneret plate are tightly stacked, the fibers are not likely to roll between yarn and fabric, the arrangement stacking density of the filament fibers in the fabric can be improved, and the strength, wind-proof performance and water-proof performance of the fabric can be improved.

Owner:ZHEJIANG HUAXIN ADVANCED MATERIALS

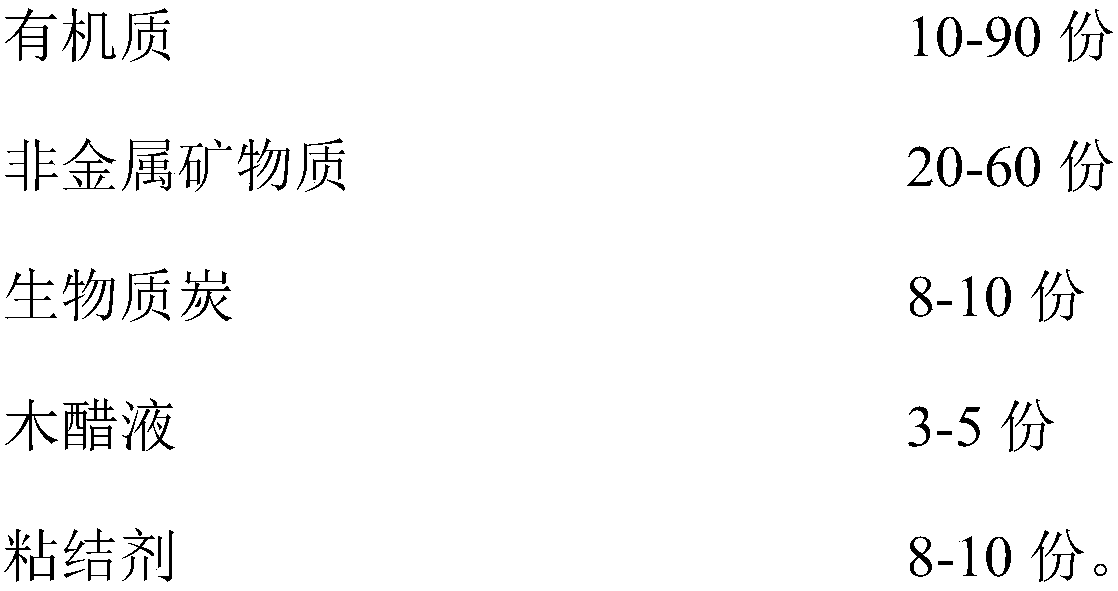

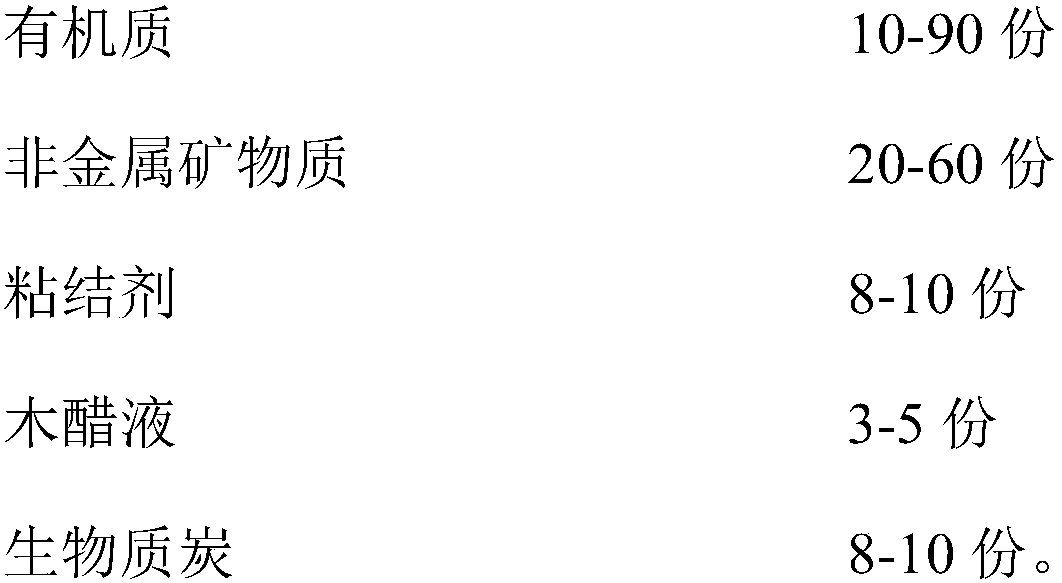

Culture substrate and preparation method thereof

InactiveCN107581023AImprove water retention and breathabilityReduce cloggingGrowth substratesCulture mediaParticulatesOxygen

The invention discloses a culture substrate and a preparation method thereof. According to the culture substrate, an organic matter, non-metallic minerals, an adhesive, pyroligneous liquor and biomasscharcoal with special proportion are adopted and are matched with one another; in the blending process, the ingredients and aggregations between the ingredients grow up through the binding effect ofa binder, and the blockage for holes of small particulate matters is reduced; holes of the culture substrate are balanced by utilizing biomass charcoal; the pyroligneous liquor is sprayed to the culture substrate, and penetrates into the culture substrate, the culture substrate is loosened, the ventilation and water retaining capability of the culture substrate can be enhanced, the condition thatroots have sufficient oxygen and water can be guaranteed, and the growth of crops is promoted. In addition, the culture substrate contains rich organic matters and microelements, so that nutrients needed by the crops can be provided, and the germination rate is increased due to sufficient oxygen and water.

Owner:BEIJING SANJU GREEN ENERGY TECH CO LTD

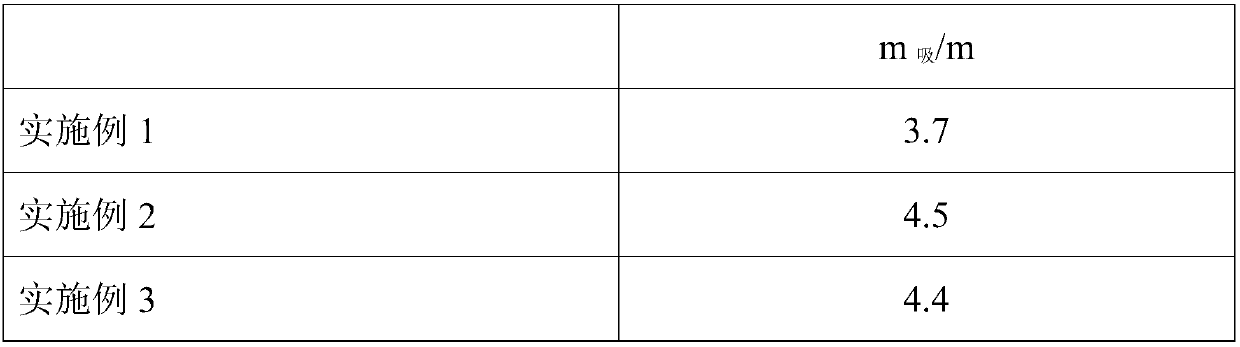

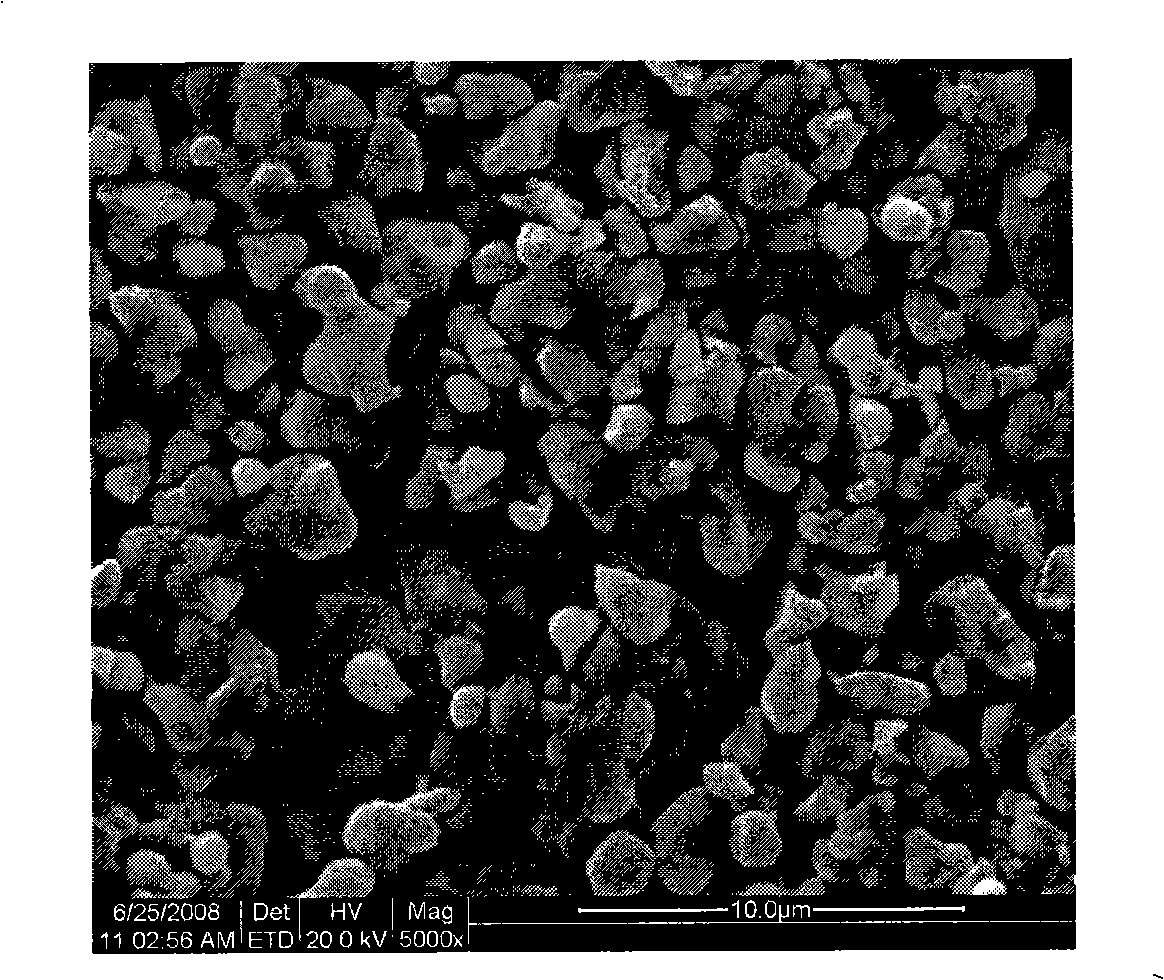

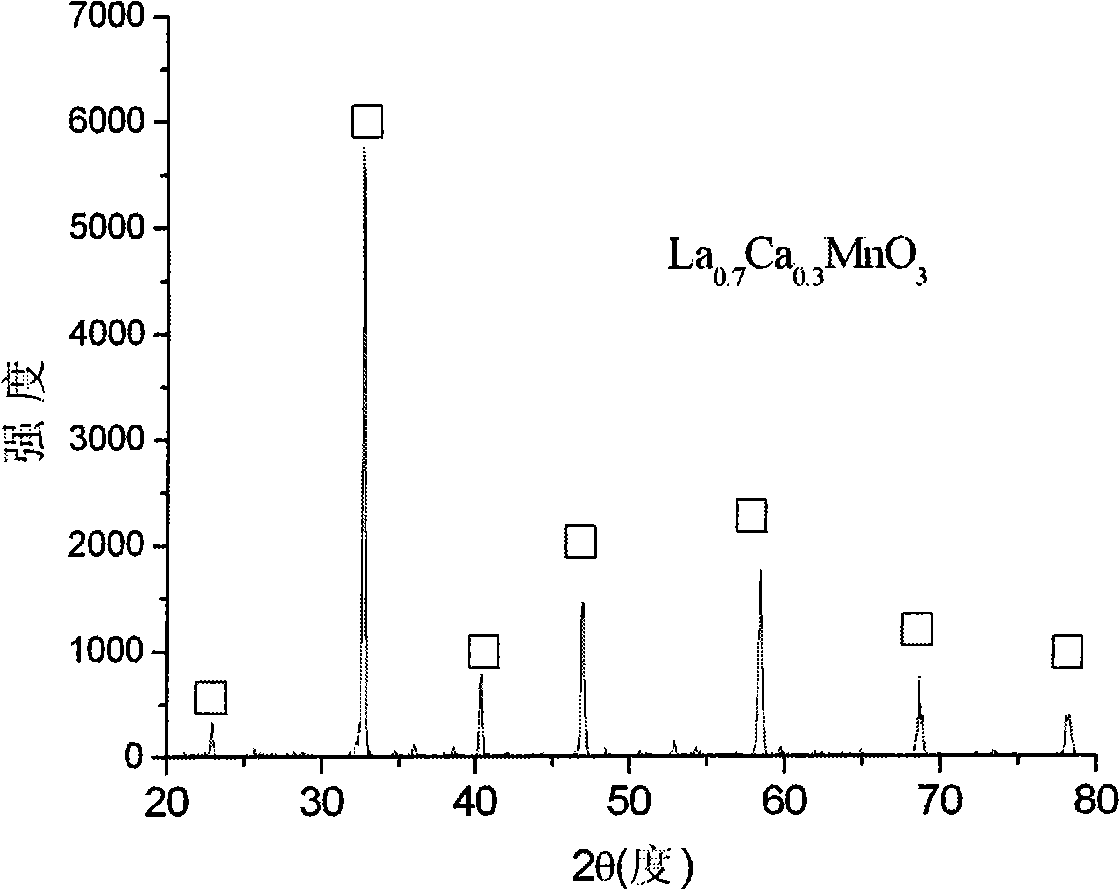

Adhesive joint type perovskite manganese oxide material

InactiveCN101337818AHigh bonding strengthImprove mechanical propertiesManganese oxideMechanical property

The invention provides an adhesive perovskite manganese oxide material. The adhesive perovskite manganese oxide material is prepared by adopting the following method: preparing precursor powder: La2O3, CaCO3 or SrCO3 or Pr6O11 or Co2O3, MnO2 are mixed according to the atomic ratio of La1-xMxMnO3, thereinto, La<1-x>MxMnO3, x is more than 0 but less than 1 and M is either Sr, Ca, Pr or Co; after the raw materials are milled, the milled materials are calcined at the temperature of 1100 to 1300 DEG C for 5 to 20 hours twice to three times before the calcined materials are milled again; b. packaging a coupling agent: the coupling agent of 0.5 to 1.5 percent of the precursor powder by weight is added to the precursor powder and is beaten uniformly; c. adhesion: an adhesive agent of 1 to 6 percent of the precursor powder by weight and a curing agent corresponding to the adhesive agent are dissolved in acetone; subsequently, the precursor powder in the step b is added; the mixture is mixed uniformly and baked before the mixture is pressed under the pressure of 10 to 800MPa. The adhesive perovskite manganese oxide material has good mechanical property and is tough to some extent, which is unbreakable. The adhesive perovskite manganese oxide material can be manufactured into components of various complicated shapes.

Owner:SOUTHWEST JIAOTONG UNIV

Integrated optical waveguide gyroscope based on optical microcavity

InactiveCN101793520AHigh quality factorImprove qualitySagnac effect gyrometersCoupling light guidesBeam splitterWaveguide

The invention relates to the optical field and the micro electromechanical field, in particular to an integrated optical waveguide gyroscope based on an optical microcavity, which solves the problems that the performance improvement of a traditional optical fiber gyroscope is restricted by the quality of an optical fiber ring, the optical fiber gyroscope is not beneficial to being applied to the high precision fields and the like. The integrated optical waveguide gyroscope comprises a light source, a beam splitter, an optical detection device as well as an optical microcavity and optical waveguides, wherein the optical detection device consists of a signal processing unit and two photo detectors, the optical microcavity is obtained through processing on a semiconductor substrate by using an MEMS (Micro-Electro-Mechanical System) processing technique, the optical waveguides are symmetrically arranged at two sides of the optical microcavity in parallel, the two optical waveguides and the optical microcavity respectively form an optical waveguide-microcavity coupling structure, two exit ports of the beam splitter respectively establish two incident light paths in one-to-one correspondence through an incident optical fiber and incident ends of the two optical waveguides and exit ends of the two optical waveguides respectively establish two exit light paths in one-to-one correspondence through an exit optical fiber and the input ends of the two photo detectors in the optical detection device. The invention has simple and reasonable structure, high flexibility and wide application range and can be suitably applied to the field of high precision measurement.

Owner:ZHONGBEI UNIV

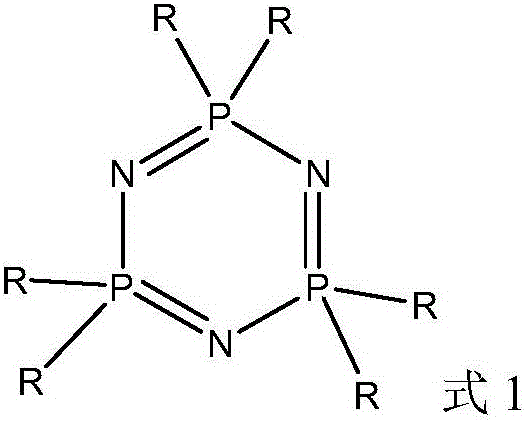

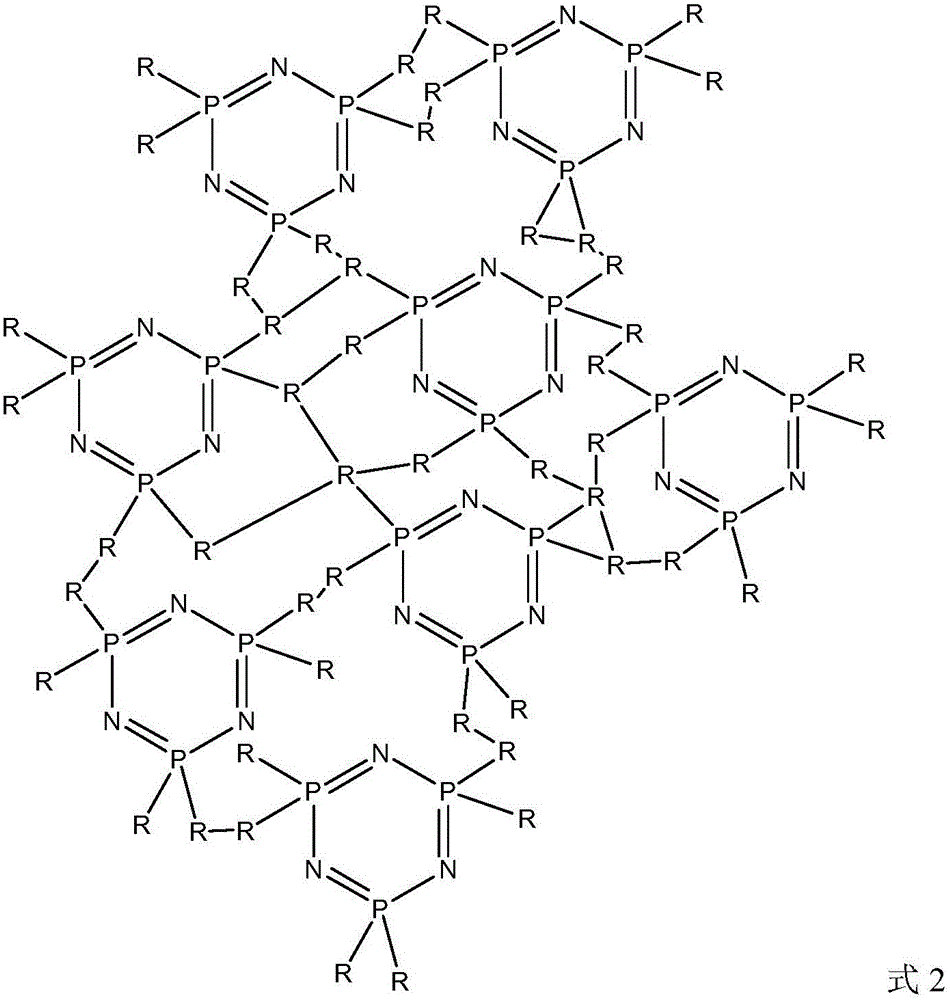

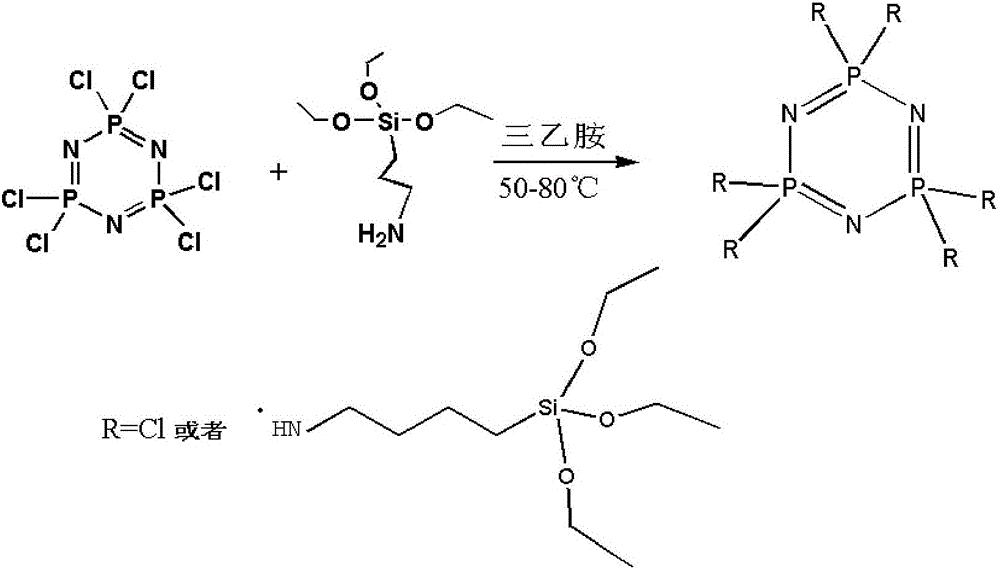

Novel room-temperature vulcanized silicon rubber and cross-linking agent thereof

InactiveCN106084236AImprove mechanical propertiesImprove flame retardant performanceGroup 5/15 element organic compoundsCross-linkPolymer science

The invention relates to novel room-temperature vulcanized silicon rubber and a cross-linking agent thereof, and discloses application of a phosphonitrilic chloride trimer modifier and a hydrolytic condensation product of the phosphonitrilic chloride trimer modifier as a cross-linking agent in the room-temperature vulcanized silicon rubber. The phosphonitrilic chloride trimer modifier and the hydrolytic condensation product of the phosphonitrilic chloride trimer modifier comprise siloxane structures and phosphonitrile groups, wherein the weight ratio of siloxane groups to phosphonitrile groups is 100:(10-60) along with different hydrolytic condensation degrees of the phosphonitrilic chloride trimer modifier and the hydrolytic condensation product of the phosphonitrilic chloride trimer modifier. The novel room-temperature vulcanized silicon rubber provided by the invention is stable in property, the use environment of the novel room-temperature vulcanized silicon rubber is widened, particularly compared with a similar product, prepared flame-retardant silicon rubber is good in mechanical property, and the mechanical strength of a product can be well improved; the prepared silicon rubber is good in flame retardancy, and the limit oxygen index of the silicon rubber is increased.

Owner:WUHAN UNIV

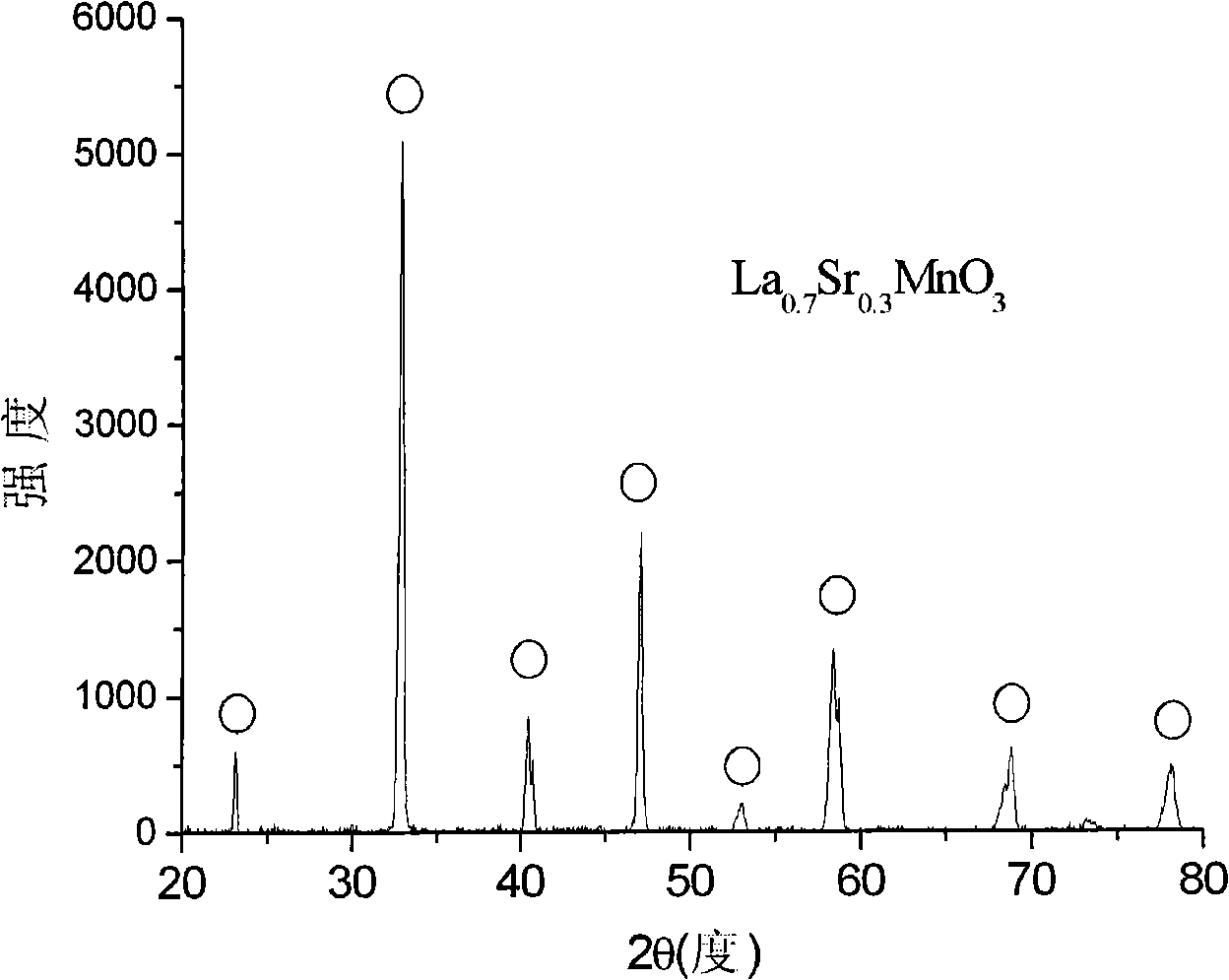

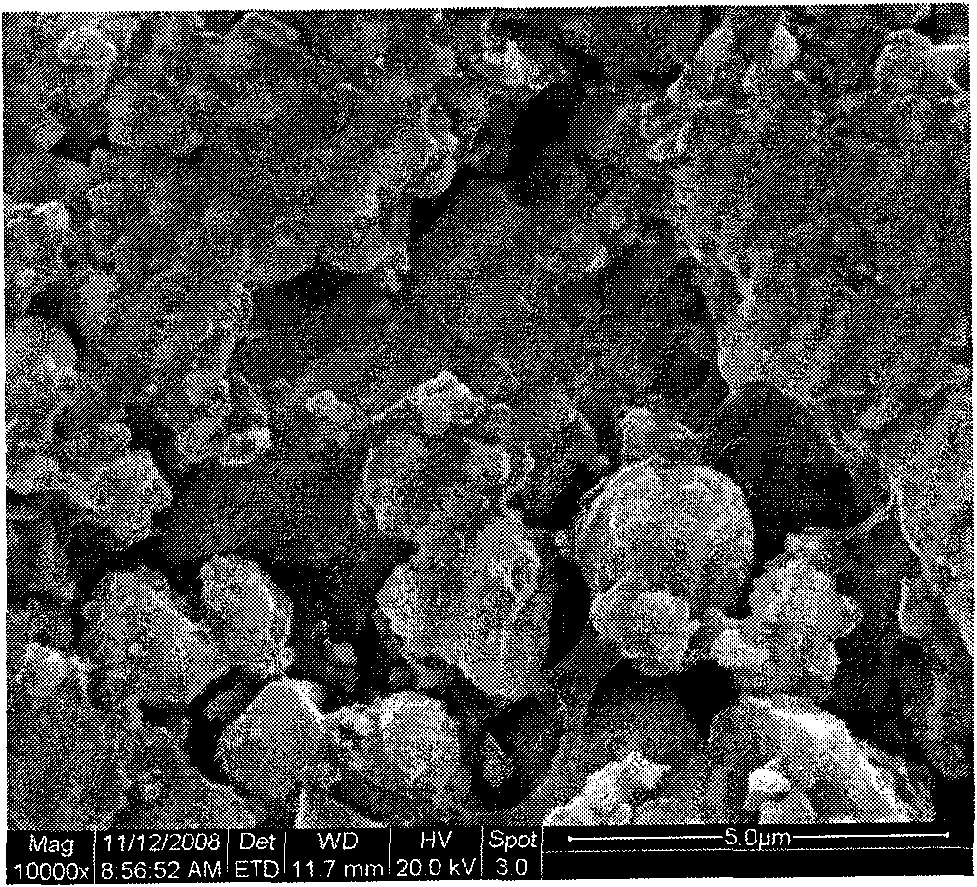

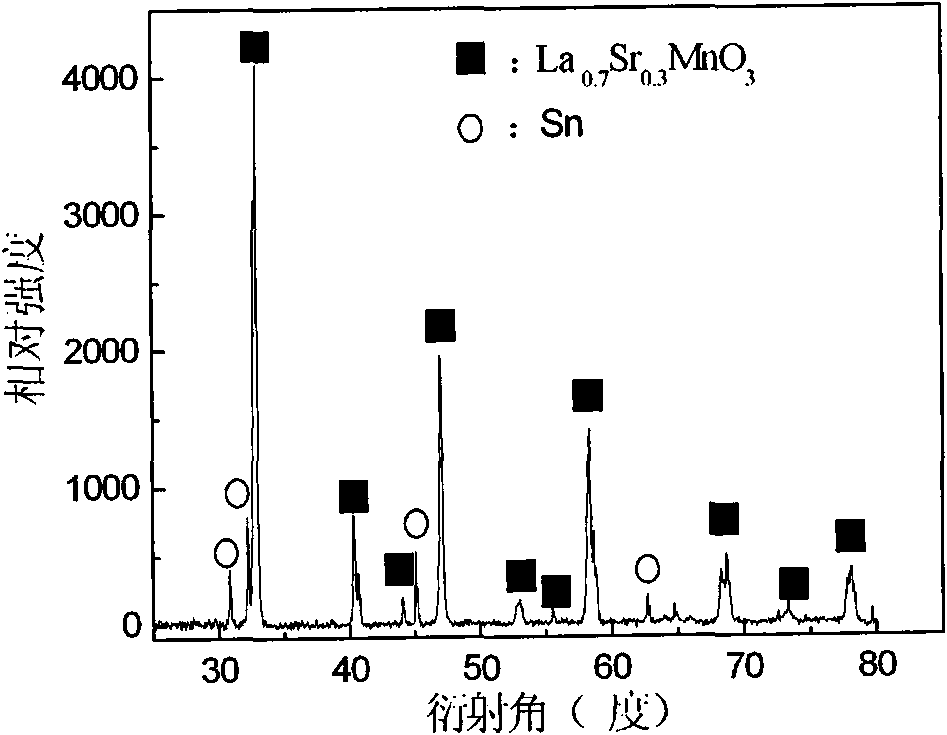

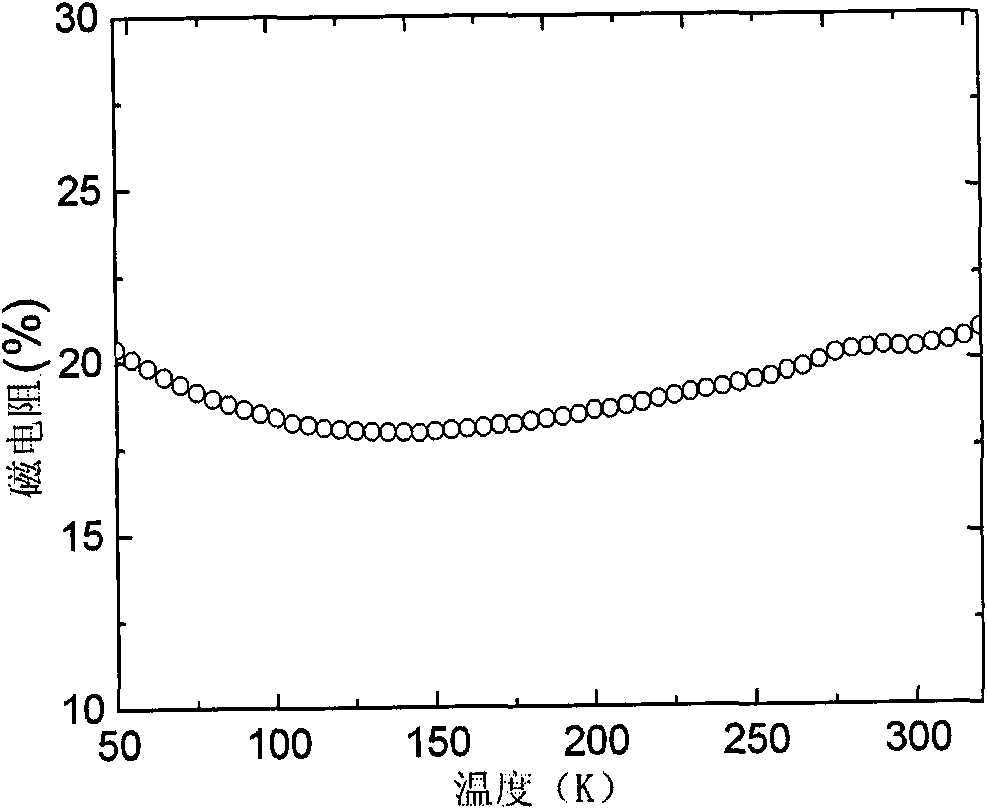

Preparation method of non temperature-sensibility manganese oxide magneto-resistor material

The invention relates to a preparation method of non temperature-sensibility manganese oxide magneto-resistor material, the specific steps are as follows: a. La2O3, SrCO3 and MnO2 are prepared according to atomic ratio of La0.7Sr0.3MnO3, the raw material is ground, three-time calcination and the grinding after calcination are carried out to obtain precursor powder; b. 5-15 percent of metal tin powder is added in the precursor powder to obtain mixed powder; c. the mixed powder is mixed with coupling agents of which the weight is 1 percent of the precursor powder; d. binding material which is 4 percent of the precursor powder by weight and curing agents are sequentially dissolved in acetone, the mixed powder is added, evenly mixed and then the mixture is dried and is formed by pressing at 100-800MPa, and is solidified at 120-160 DEG C. The preparation method has simple preparation process, low energy consumption and low cost, and the prepared manganese oxide magneto-resistor material has high magneto-electricity resistance in the wide temperature range and downfield, and the magneto-electricity resistance is insensitive to the temperature.

Owner:SOUTHWEST JIAOTONG UNIV

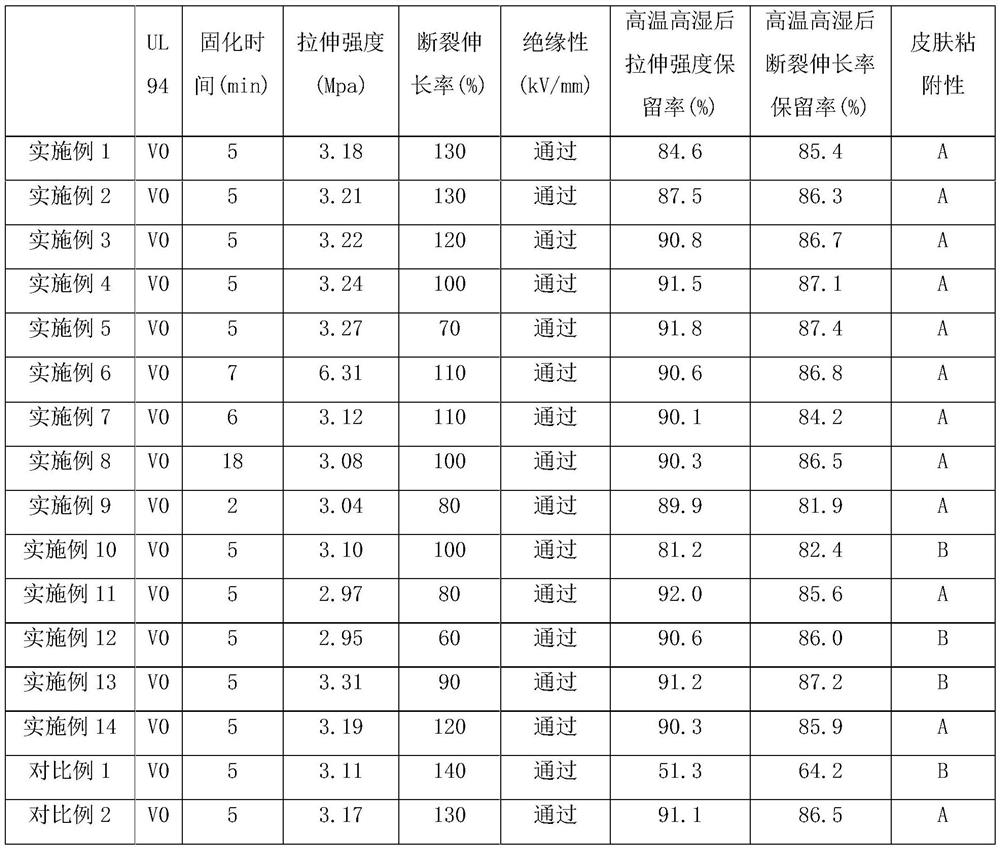

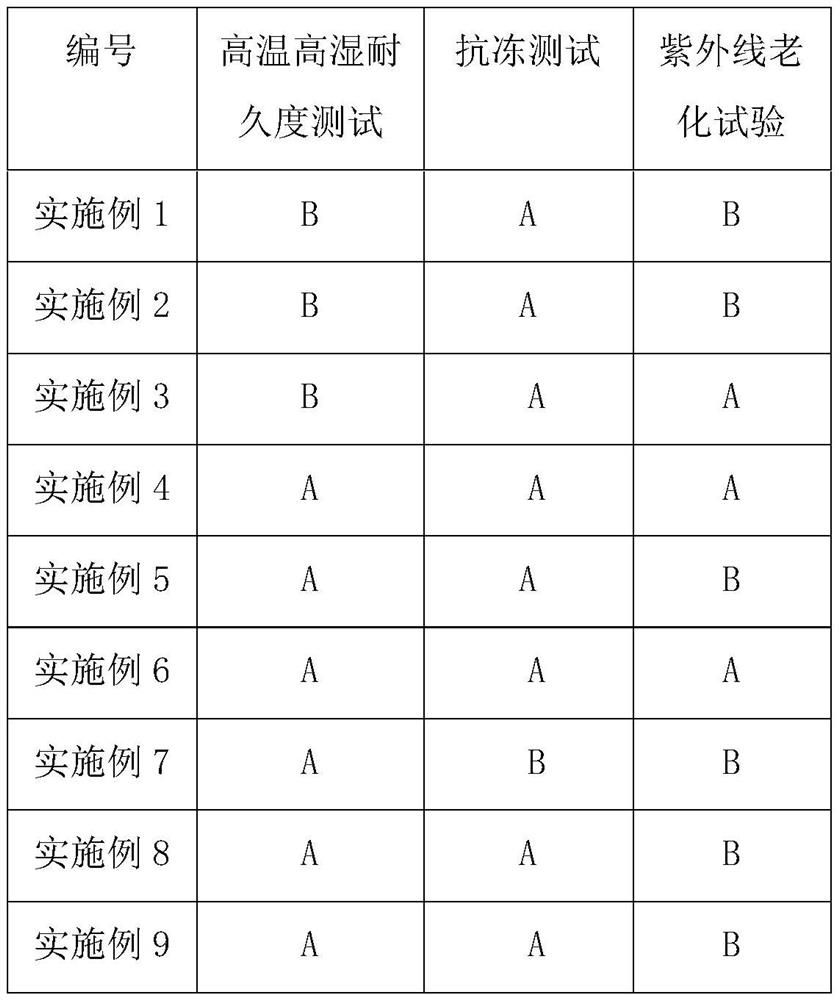

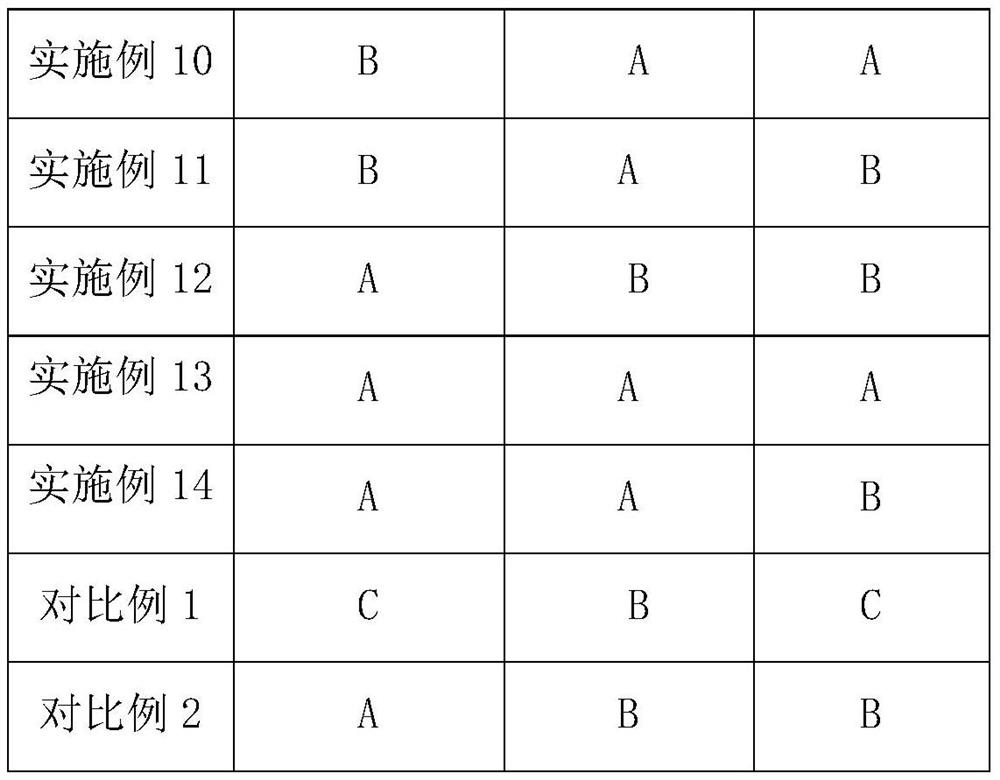

Double-component peelable cement gum and preparation method thereof

ActiveCN111944473AGood weather resistanceNot stickyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention provides double-component peelable cement gum, which is composed of a component A and a component B. The component A comprises polyether polyol, isocyanate, surface hydroxyl modified paraffin, a thickener and a solid filler. The component B comprises polyether polyol, a catalyst, a chain extender, surface hydroxyl modified paraffin, a thickener and a solid filler; and the chain extender comprises castor oil. According to the invention, paraffin with hydroxyl on the surface is introduced into two components, so that a product does not stick to hands of operators during kneading; meanwhile, due to the fact that hydroxyl on the surface can react with the isocyanate, the cement gum has good compatibility after being cured, material cracking, pulverization and deformation caused by migration are avoided, meanwhile, the cement gum obtained after curing has good weather resistance in high-temperature, high-humidity, high-salt and other environments, and the cement gum can play arole in protection and plugging for a long time in severe environments. Meanwhile, the chain extender contains a certain amount of castor oil, so that during stripping, the cement gum can be used forforming whole glass and basically has no residue on a protected device.

Owner:中电保力(北京)科技有限公司

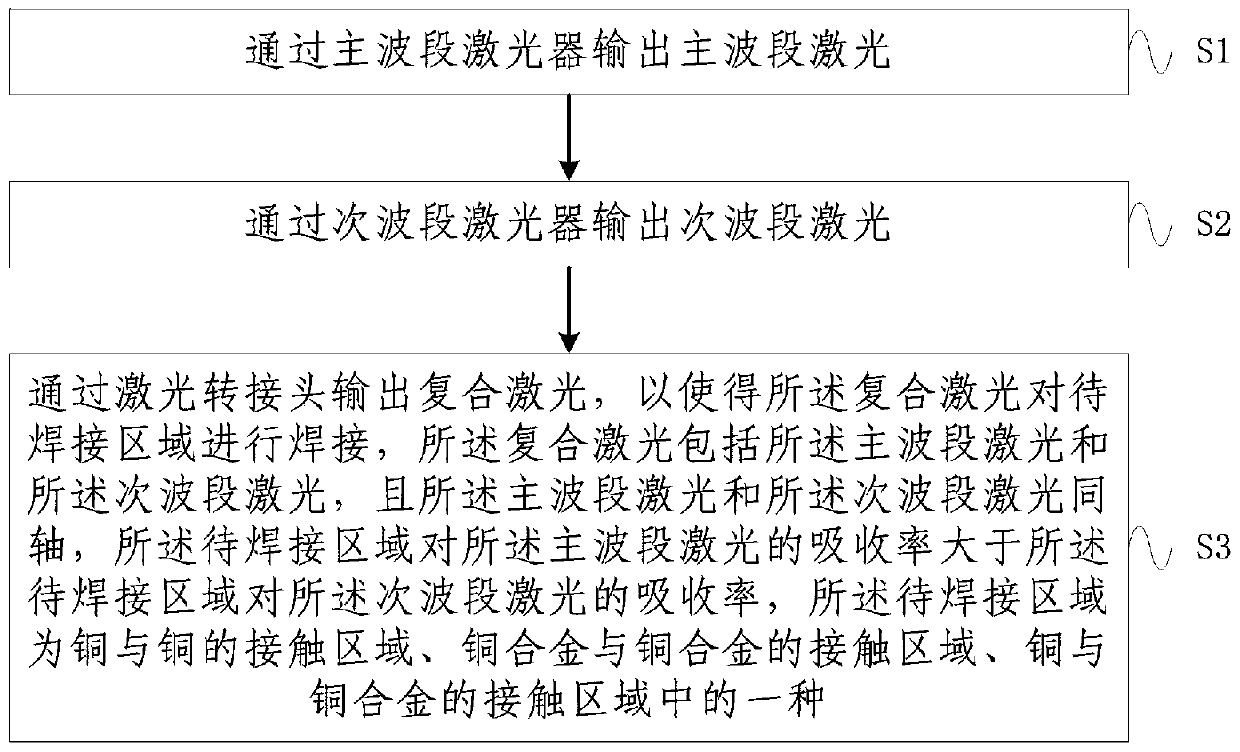

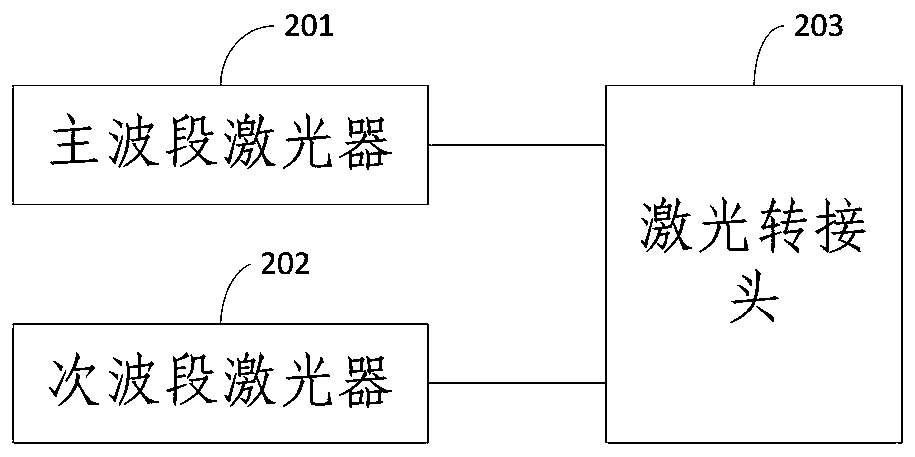

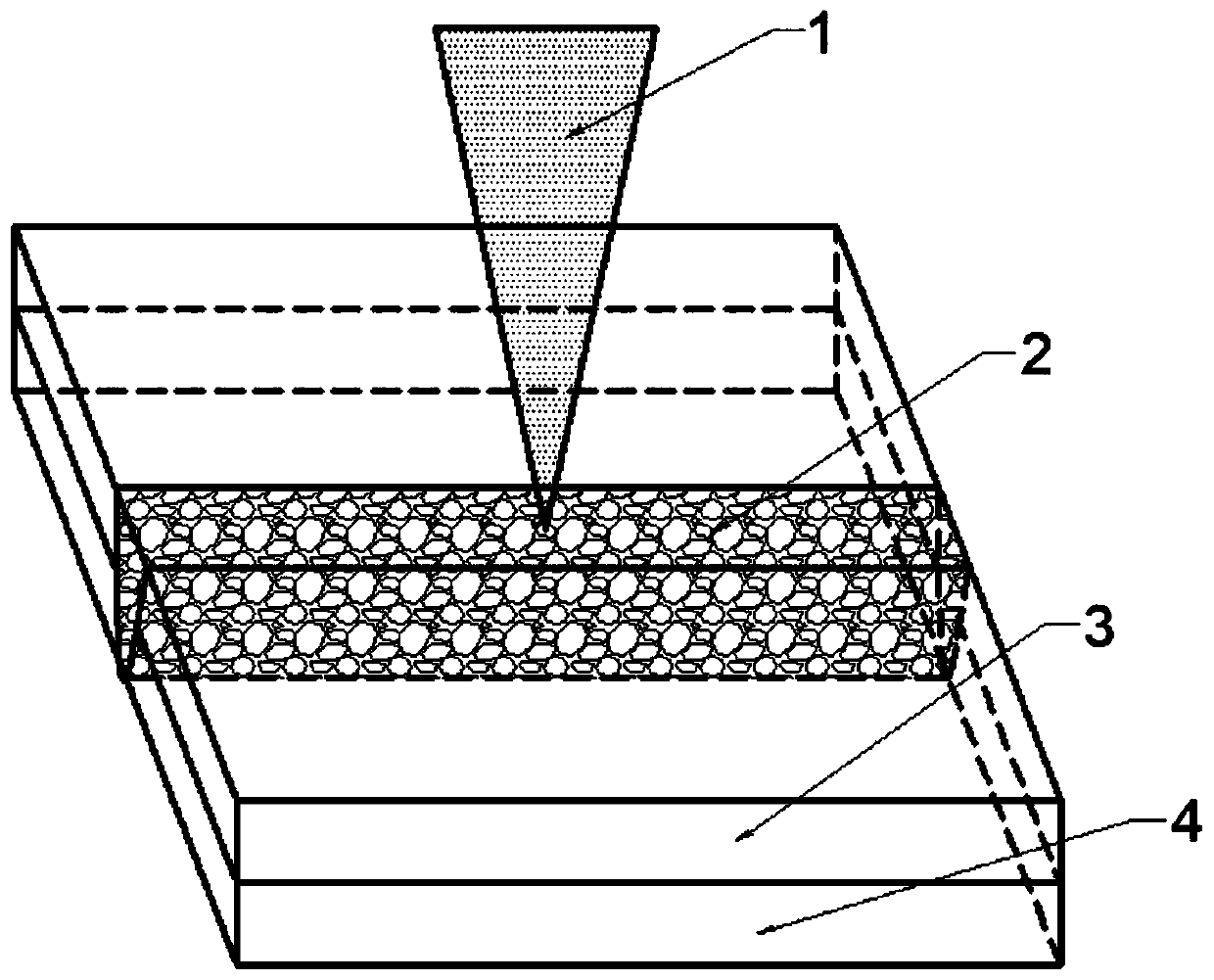

Welding method and device of copper and copper alloy material

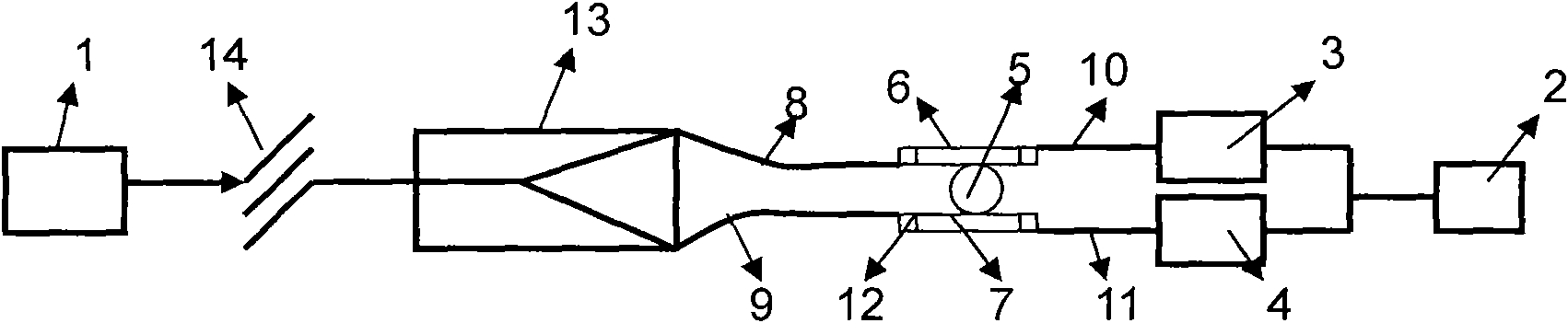

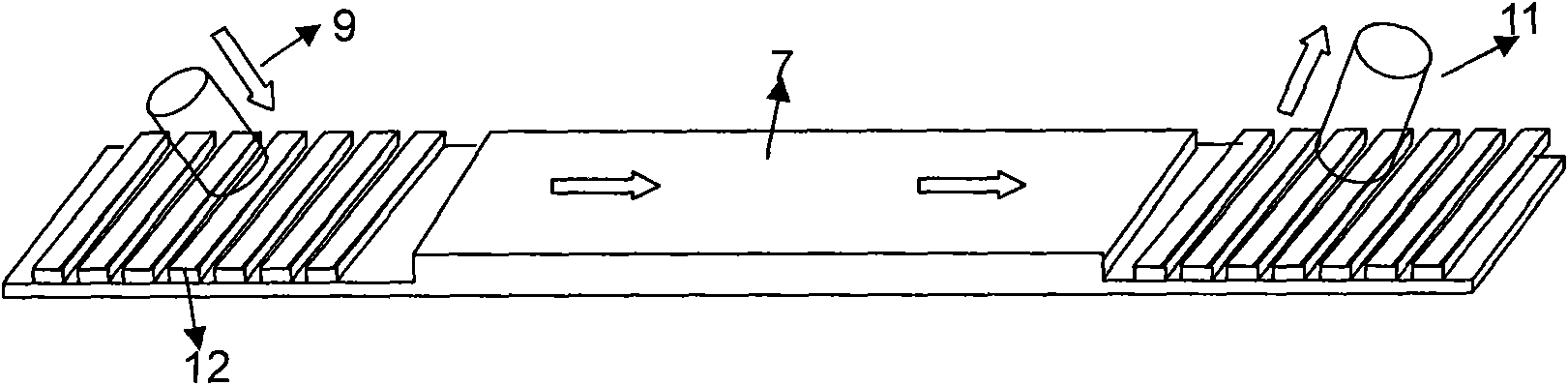

ActiveCN109926719AImprove absorption ratePromote escapeWelding/soldering/cutting articlesLaser beam welding apparatusOptoelectronicsLaser beams

The embodiment of the invention provides a welding method and device of copper and a copper alloy material. The method comprises the steps that through a main waveband laser device, main waveband laser is output; through a second waveband laser device, second waveband laser is output; through a laser adapter, composite laser is output, the composite laser carries out welding on the area to be welded, the composite laser comprises the main waveband laser and the second waveband laser which are coaxial, and the absorbing rate of the area to be welded for the main waveband laser is larger than the absorbing rate of the area to be welded for the second waveband laser. The energy use rate of the laser beam is improved, under the same laser power level, the higher-speed welding can be achieved,due to the high-speed welding, condensing forming of copper and copper alloy can be facilitated, the composite welding method is used for achieving high-speed stable welding of the copper and the copper alloy, and welding line forming and welding line quality can be ensured.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

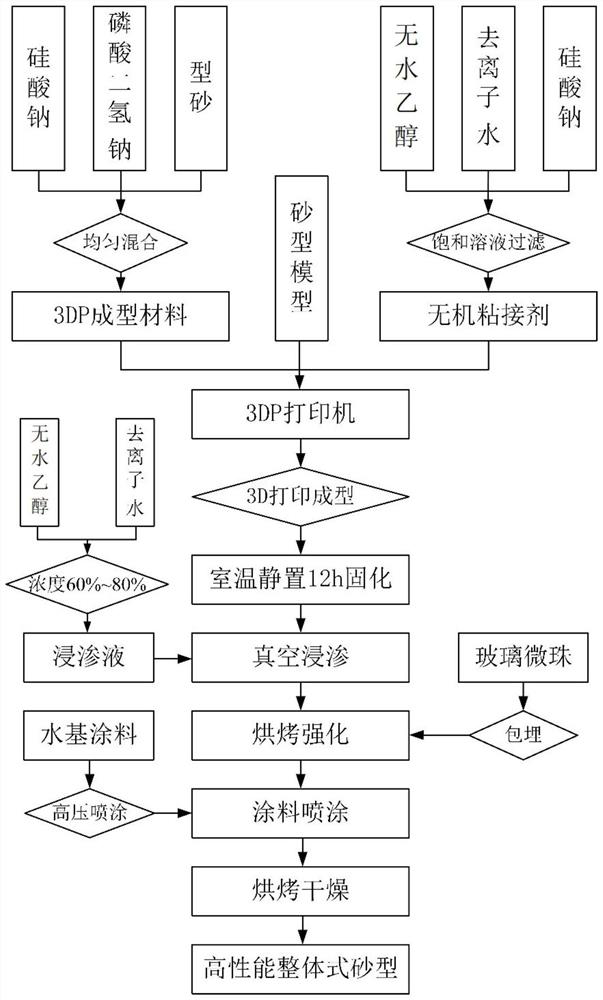

Method for preparing 3DP of integral sand mold

ActiveCN114054673AAvoid the problem of sharp drop in accuracyHigh strengthAdditive manufacturing apparatusSolid waste managementAlcoholPhysical chemistry

The invention discloses a 3DP preparation method of an integral sand mold, which comprises the following processes: 3DP molding is carried out by using a 3DP molding material and an inorganic binder, the obtained integral sand mold is subjected to standing curing, and the 3DP molding material is obtained by uniformly mixing sodium silicate powder, disodium hydrogen phosphate powder and 3D printing molding sand; the inorganic binder is obtained by adding sodium silicate powder into a mixed solution of absolute ethyl alcohol and deionized water until the sodium silicate powder is dissolved to be saturated and then filtering; the cured integral sand mold is subjected to vacuum infiltration, so that the integral sand mold fully absorbs the infiltration liquid; the integral sand mold is subjected to reinforced baking and then cooled, and coating spraying treatment is conducted on the surface of the integral sand mold; and the integral sand mold of which the surface is subjected to coating spraying treatment is dried so as to obtain the high-performance integral sand mold. According to the invention, sodium silicate can be used as a binder to carry out 3DP molding of the integral sand mold, and the high-performance integral sand mold with good performance is obtained through an adaptive post-treatment process.

Owner:XI AN JIAOTONG UNIV

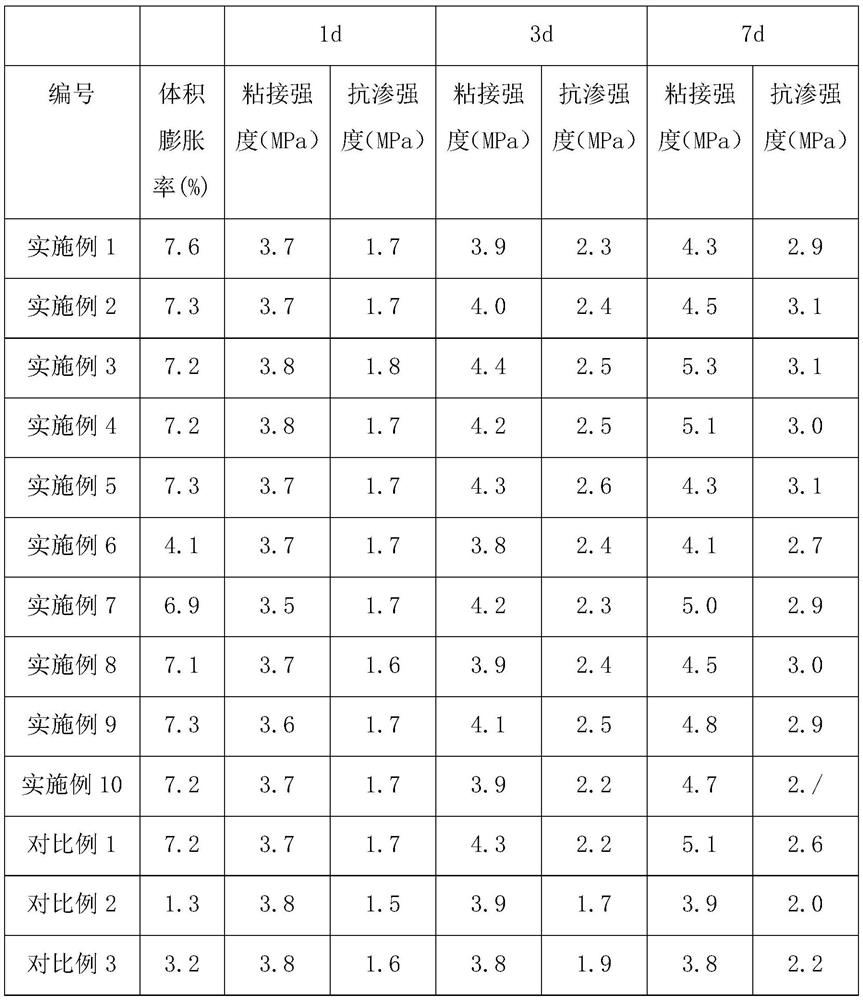

Double-componentwater-swelling cement gum and application thereof

ActiveCN111944470AGood weather resistanceNot stickyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention provides double-component water-swelling cement gum, which is composed of a component A and a component B. The component A comprises the following raw materials: polyether polyol, isocyanate, surface hydroxyl modified paraffin, epoxy resin, an epoxy diluent, a thickener and a solid filler. The component B is prepared from the following raw materials: polyether polyol, water-absorbentresin, a catalyst, a chain extender, surface hydroxyl modified paraffin, a thickener and a solid filler; wherein the solid filler comprises bentonite modified by a silane coupling agent. According tothe invention, paraffin with certain hydroxyl on the surface is introduced into the two components, so that certain surface lubricity is provided, and a product does not stick to hands of operators during kneading; good weather resistance is realized in various environments. The water-absorbent resin and the silane coupling agent modified bentonite synergistically play a role, so that the bondingstrength between the cement gum and a wall surface is enhanced, and a three-dimensional waterproof sealing effect is formed on a bonding interface, and waterproof and moistureproof effects are betterfacilitated.

Owner:中电保力(北京)科技有限公司

Bi-component fast-curing plastic cement and preparation method thereof

The invention provides double-component fast-curing plastic cement which is composed of a component A and a component B. The component A comprises polyether polyol, a curing agent, surface hydroxyl modified paraffin, a thickening agent and solid filler. The component B comprises polyether polyol, a catalyst, a cross-linking agent, surface hydroxyl modified paraffin, a thickening agent and a solidfiller. Paraffin with a certain hydroxyl on the surface is introduced into the two components so that certain surface lubricity is provided, and hands of an operator cannot be stuck during kneading; meanwhile, hydroxyl on the surface can react with isocyanate so that the compatibility is good after curing and the material is prevented from cracking, powdering and deforming due to migration. In addition, due to good compatibility, the cement obtained after curing has very good weather resistance in high-temperature, high-humidity, high-salt and other environments, and can play a role in protecting and plugging electrical equipment for a long time in a severe environment.

Owner:中电保力(北京)科技有限公司

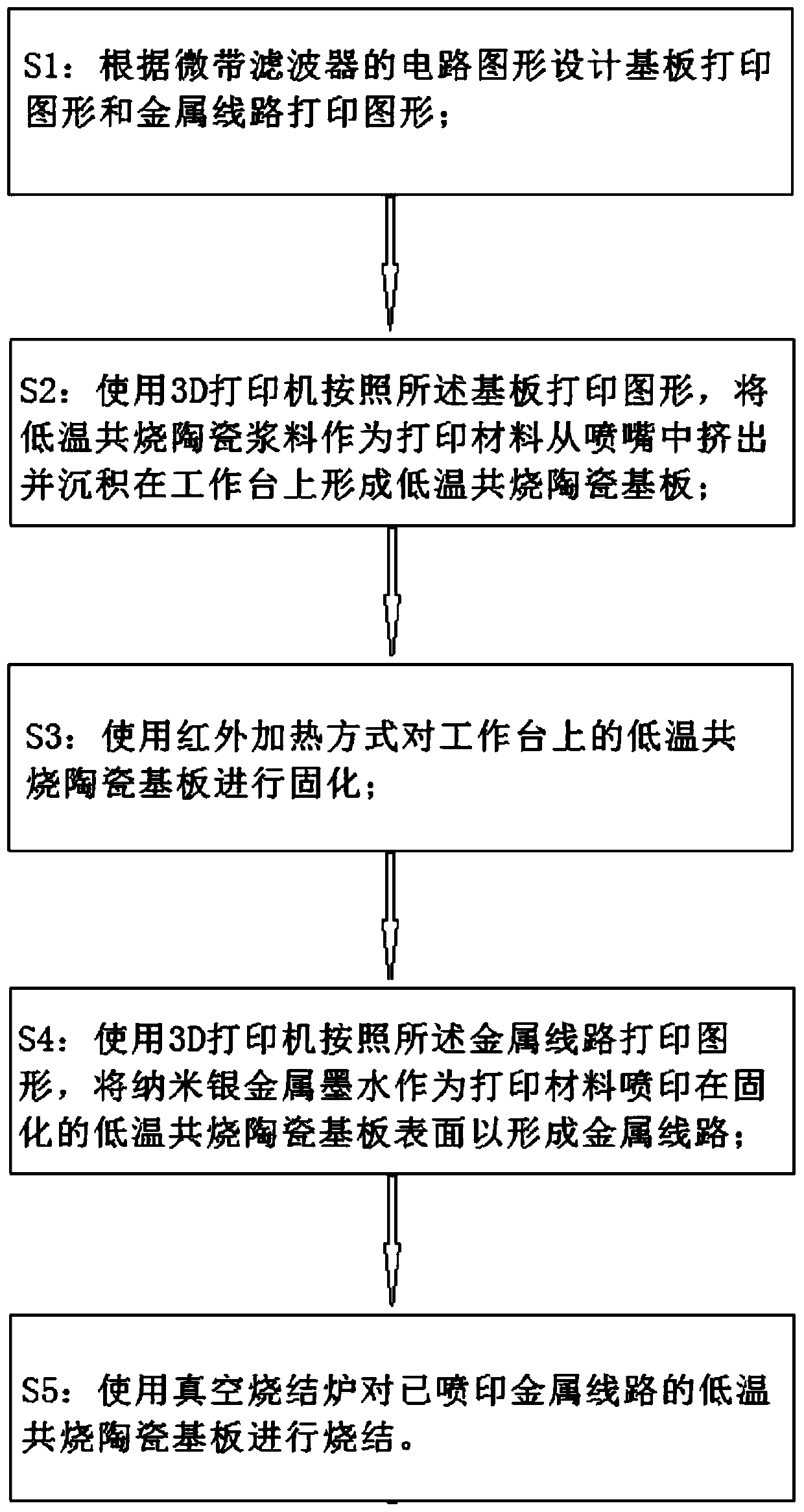

Micro-strip filter 3D printing manufacturing method

PendingCN111065211ARealize personalized creationConducive to solidificationConductive pattern formationComputer printingMicroribbon

The invention discloses a micro-strip filter 3D printing manufacturing method. The method comprises the following steps: S1, designing a substrate printing pattern and a metal circuit printing patternaccording to a circuit pattern of a micro-strip filter; S2, extruding low-temperature co-fired ceramic slurry serving as a printing material out of a nozzle and depositing the slurry on a workbench to form a low-temperature co-fired ceramic substrate by using a 3D printer according to the substrate printing pattern; S3, curing the low-temperature co-fired ceramic substrate on the workbench in aninfrared heating mode; S4, spray-printing nano-silver metal ink serving as a printing material on the surface of the cured low-temperature co-fired ceramic substrate to form a metal circuit by using the 3D printer according to the metal circuit printing pattern; and S5, sintering the low-temperature co-fired ceramic substrate printed with the metal circuit by using a vacuum sintering furnace. Themethod is simple and easy to master, the production cost can be reduced, and a solution is provided for rapid manufacturing and individuation of the micro-strip filter.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

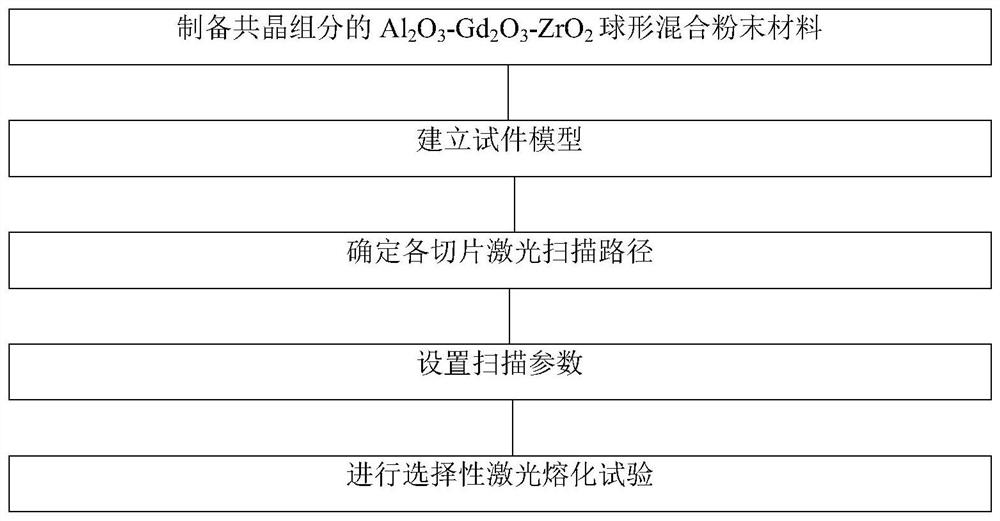

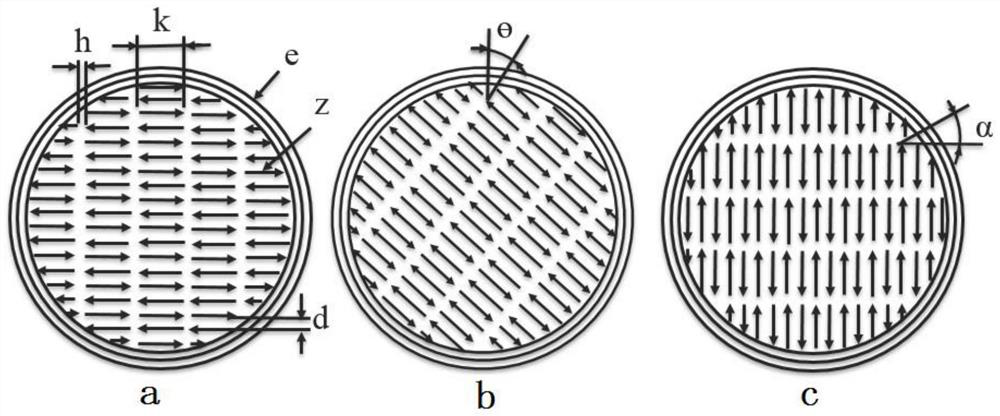

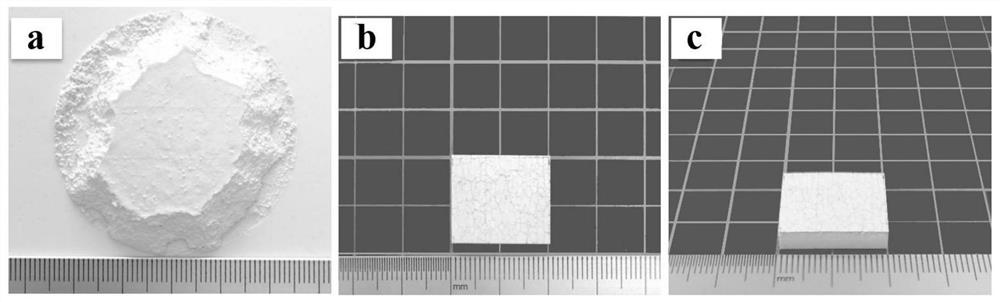

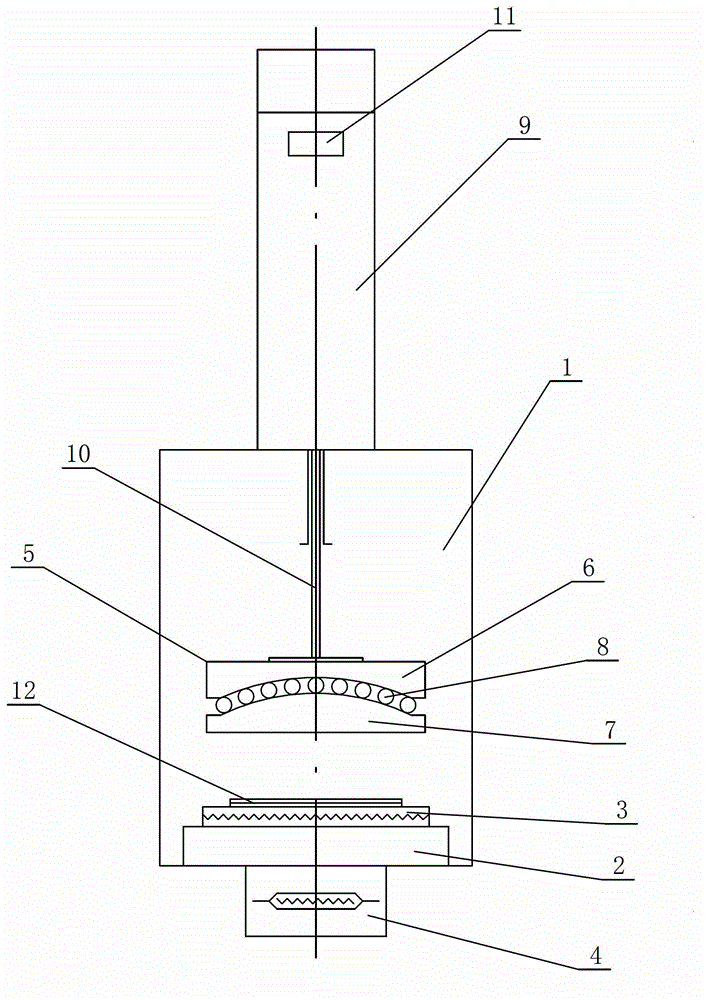

Method for preparing Al2O3-GdAlO3-ZrO2 ternary eutectic ceramic by selective laser melting

A selective laser melting method of blocky ternary eutectic oxide ceramic adopts a CO2 laser selective melting method, the scanning rate and the laser power of the CO2 laser selective melting method are controlled within ranges shown in the specification, and a melt material in a laser scanning area obtains higher supercooling degree, the nucleation rate is increased, so that the eutectic structure is refined, and the mechanical properties of a sample is improved. The large-size blocky Al2O3-GdAlO3-ZrO2 eutectic ceramic is obtained through preparation, and the size of the prepared Al2O3-GdAlO3-ZrO2 eutectic ceramic reaches 20*18*3.5 mm<3> after the Al2O3-GdAlO3-ZrO2 eutectic ceramic is subjected to linear cutting. The scanning rate can reach 5000 mm / s at most, the energy absorption rate ofthe ceramic material to a CO2 laser is high, and complete melting and solidification forming of the oxide ceramic material are better facilitated. Meanwhile, a laser beam selectively melts and solidifies a powder layer according to a path and parameters set by a computer, layer-by-layer stacking is carried out, and a solidified eutectic ceramic sample with a large size and a complex shape can beprepared.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

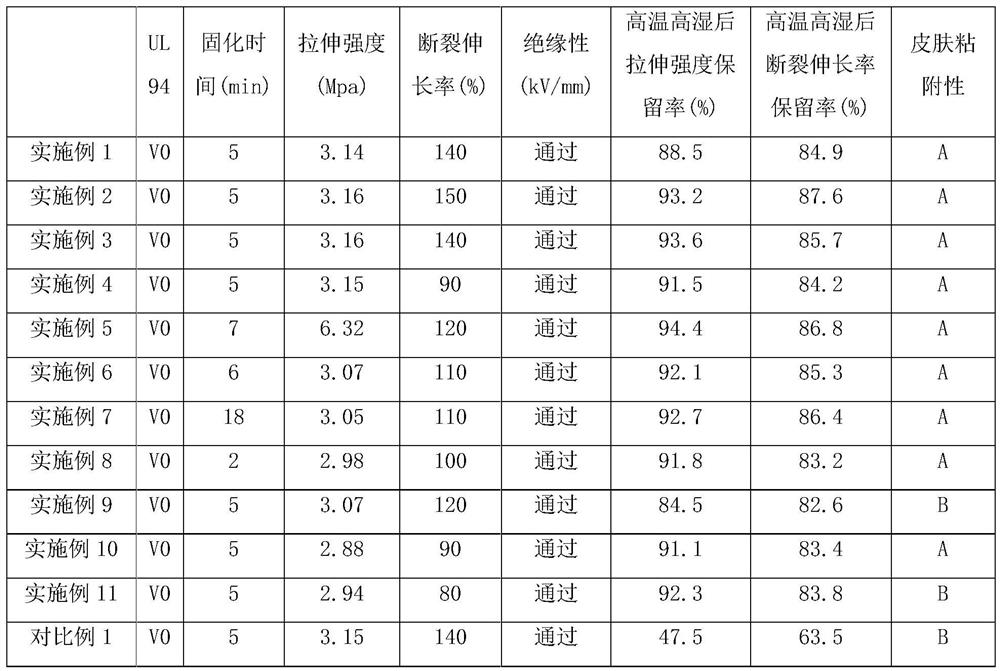

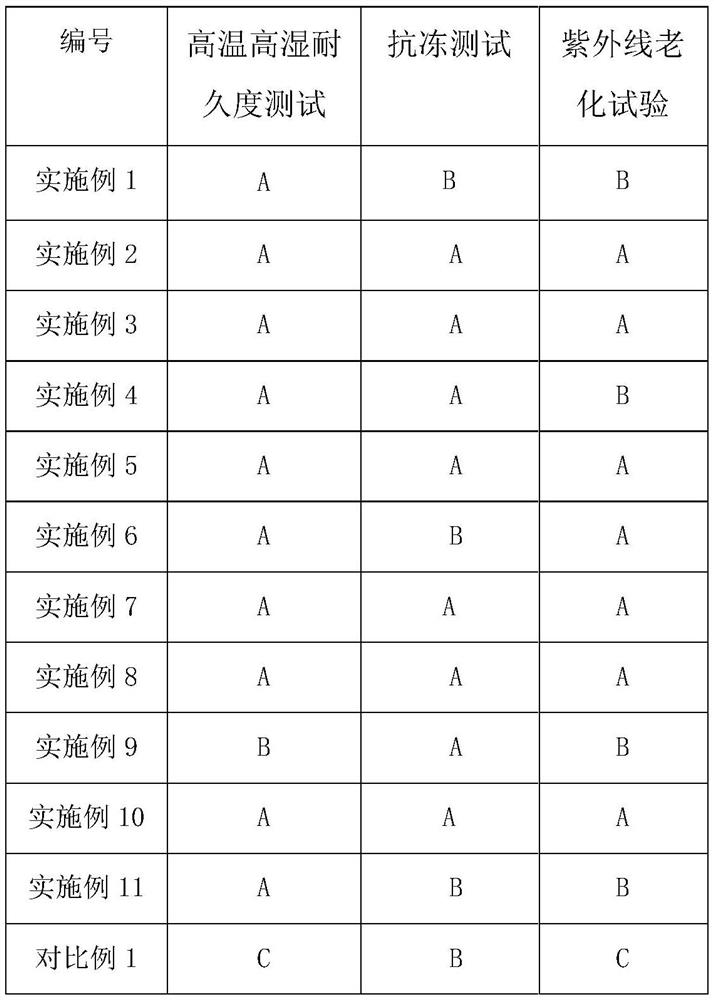

Graphene modified resin packaging material and preparation method thereof

InactiveCN111533486AHigh strengthImprove cooling effectEncapsulation/impregnationCoils manufacturePolymer scienceFirming agent

The invention relates to a graphene modified resin packaging material and a preparation method thereof. The invention discloses a graphene modified resin packaging material. The graphene modified resin packaging material is formed by combining a component A and a component B according to the mass ratio of 1: (0.9-1.4), wherein the component A is prepared from 18 to 25 parts by weight of bisphenolA type epoxy resin, 0.5 to 2 parts by weight of a toughening agent, 1 to 10 parts by weight of a graphene resin dispersion liquid and 48 to 52 parts by weight of silica powder; and the component B comprises the following components in parts by weight: 15-25 parts of a curing agent, 0.05-0.15 part of an accelerant and 1-5 parts of a toughening agent. The invention relates to a graphene modified resin packaging material and a preparation method thereof. Through graphene pre-dispersion treatment, controllable graphene layer number and sheet diameter, and components, a formula and a preparation method of the graphene modified resin packaging material for a dry-type transformer, the graphene modified resin packaging material has a good heat dissipation effect while meeting the electrical performance.

Owner:新疆烯金石墨烯科技有限公司

Fermented bean curd and making method thereof

InactiveCN106135446AConducive to solidificationGrowth inhibitionCheese manufactureFood scienceBiotechnologyGypsum

The invention discloses fermented bean curd and a making method thereof. The fermented bean curd is made from raw materials including, by weight, 100-160 parts of soybeans, 10-16 parts of wine, 7-11.2 parts of table salt, 5-8 parts of pepper, 2-3 parts of spice, 40-64 part of soup, 400-640 parts of water and 0.6-0.96 part of gypsum water via process of raw material selecting, washing, pulping, boiling, solidifying, forming, fermenting, pickling and the like. The fermented bean curd is healthy and delicious, special in taste, safe without additives, easy to take and long in shelf life.

Owner:贞丰县马氏丰味食品有限责任公司

Nanoimprint machine and pressurizing method thereof

ActiveCN103149797AUniform pressure distributionNo embossing defectsPhotomechanical apparatusRolling resistanceBall screw

The invention discloses a nanoimprint machine and a pressurizing method thereof. The nanoimprint machine comprises a vacuum chamber, a drive unit, a pressurizing disc, a bearing platform and a curing forming device, the bearing platform is arranged at the bottom in the vacuum chamber, the pressurizing disc is arranged above the bearing platform in the vacuum chamber and is connected with the drive unit, the drive unit comprises a direct-driven servo electric cylinder composed of a servo motor and a ball screw, a high-sensitivity pressure sensor is arranged in the cylinder body of the servo electric cylinder, the pressurizing disc comprises an upper pressurizing disc and a lower pressurizing disc, the upper pressurizing disc is connected with the ball screw, rolling friction balls are arranged between the upper pressurizing disc and the lower pressurizing disc, the bearing platform is provided with a heater, and the bottom of the bearing platform is provided with an ultraviolet light source. The nanoimprint machine has the advantages of uniform pressure distribution, self control and arrangement of an imprint pressure, a dwelling time and an imprint speed, and suitableness for the thermocuring formation and ultraviolet curing formation.

Owner:无锡市正先自动化设备有限公司

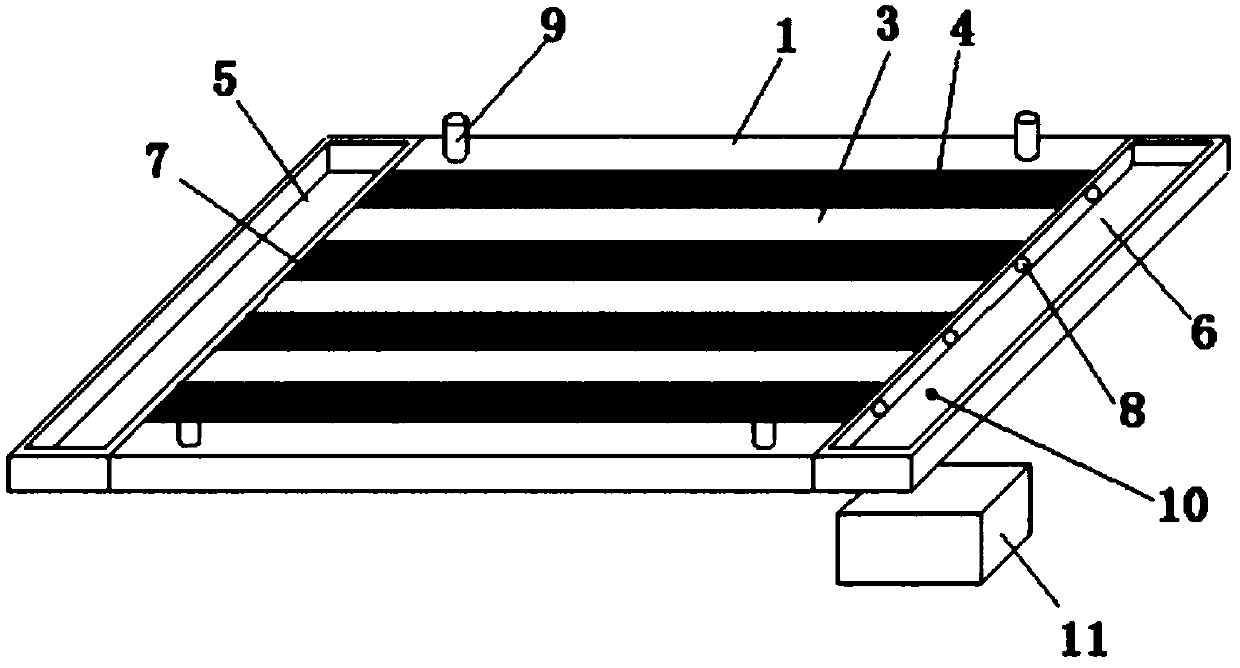

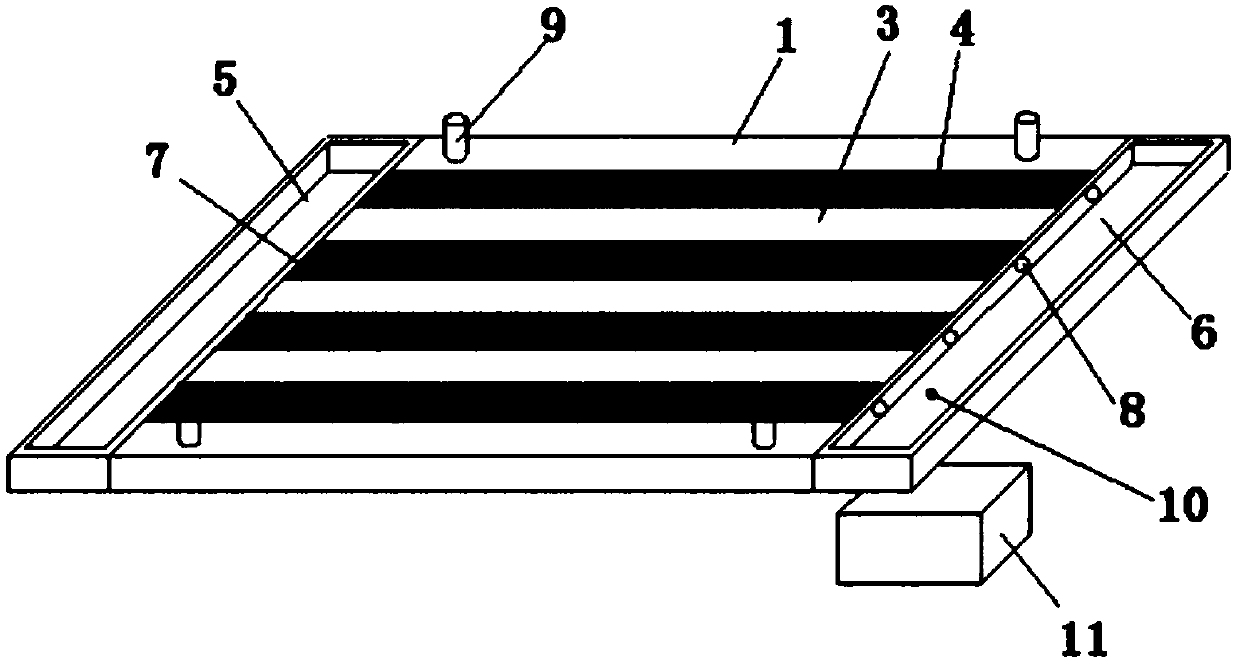

Vacuum circuit chip packaging mould

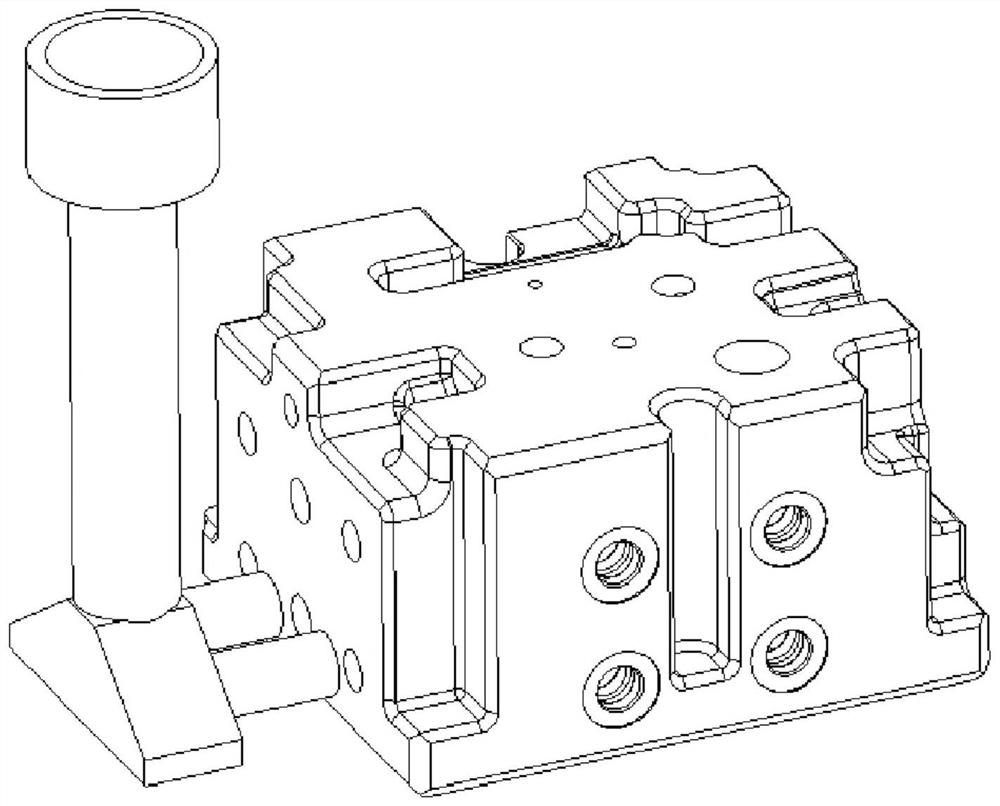

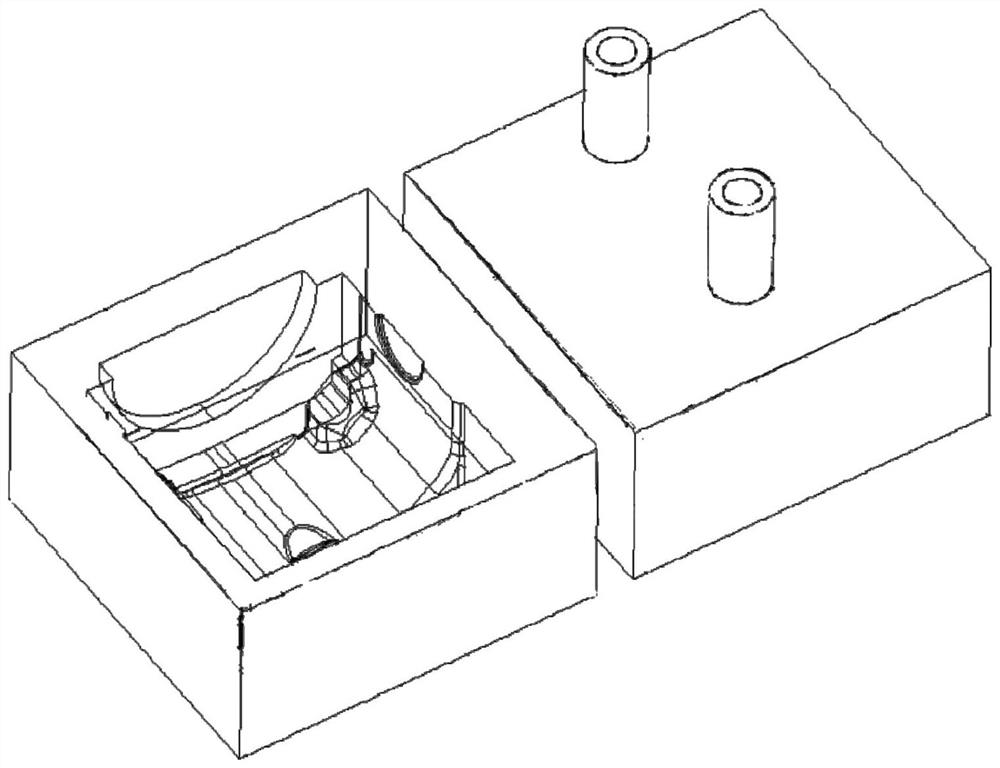

InactiveCN109834895AFast installationFlat surfaceSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringElectron

The invention discloses a vacuum circuit chip packaging mould. The vacuum circuit chip packaging mould is characterized in that the vacuum circuit chip packaging mould comprises a lower mould(1) and an upper mould (2), the lower mould (1) comprises a plurality of platforms (3) and a mold cavity (4), wherein the platforms are horizontally arranged at intervals, the mold cavity (4) is used for placing electron components, feeding grooves (5) and residual material discharging grooves (6) are correspondingly formed in the two ends of the platforms (3) and the mold cavity (4), feeding holes (7) areformed in the connecting ends of the mold cavity (4) and the feeding grooves (5), and discharging holes (8) are formed in the connecting ends of the mold cavity (4) and the residual material discharging grooves (6); and vacuum holes (10) are formed in the bottom ends of the residual material discharging grooves (6), and the vacuum holes (10) are connected with a vacuum pump (11). According to thevacuum circuit chip packaging mould, the degassing effect is great, and the vacuum circuit chip packaging mould is particularly suitable for degassing and packaging of packaging materials with largestickiness and bad mobility.

Owner:湖南正美光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com