Novel room-temperature vulcanized silicon rubber and cross-linking agent thereof

A technology of room temperature vulcanization and silicone rubber, which is applied in organic chemistry, chemical instruments and methods, compounds of group 5/15 elements of the periodic table, etc., and can solve the problem of damage to the mechanical properties of silicone rubber, decrease in tensile strength, and affect performance, etc. problem, to achieve the effect of improving flame retardancy, preventing burning, and increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

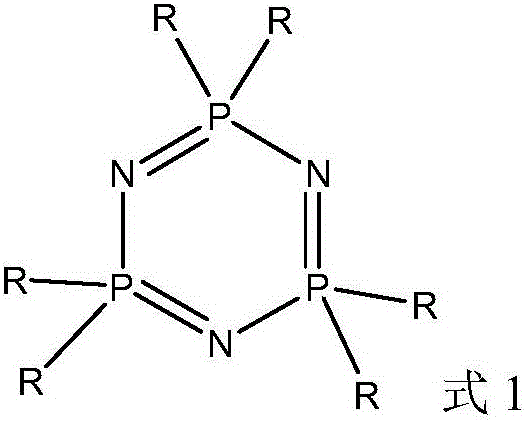

[0040] The application of hexachlorocyclotriphosphazene modified product in room temperature vulcanized silicone rubber as crosslinking agent, the structural formula of described hexachlorocyclotriphosphazene modified product is as follows:

[0041]

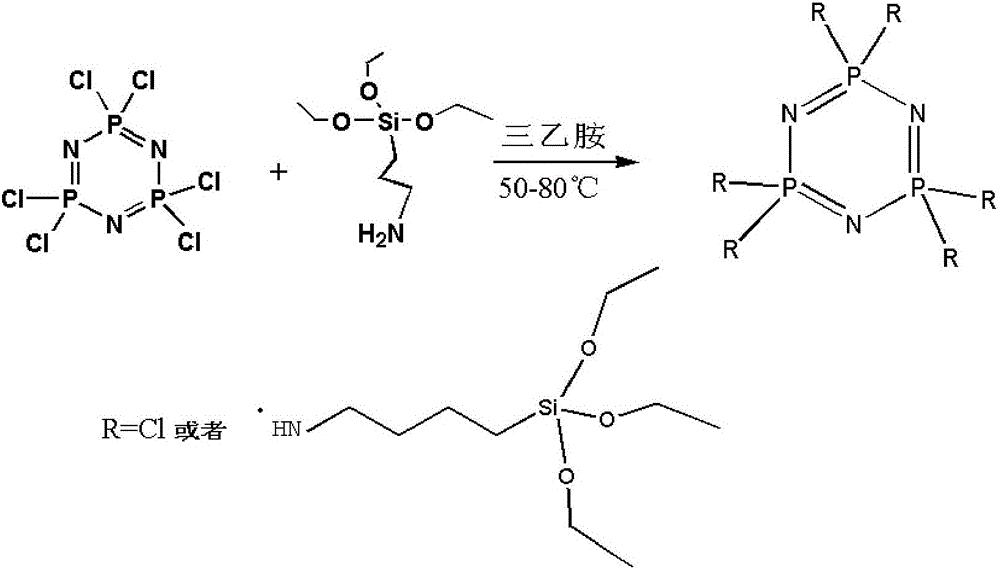

[0042] The preparation method of the above-mentioned hexachlorocyclotriphosphazene modified product, the main steps are: 210g hexachlorocyclotriphosphazene and 421g triethylamine are added in batches to 810g of aminopropyltriethoxysilane, 2L of acetonitrile, After stirring for 0.5-1h, heat up to 60-70°C, react for 12-14 hours, cool down, vacuum filter to remove the precipitate, and distill the solvent under reduced pressure at 80-90°C to obtain hexachlorocyclotriphosphazene-type modified things. The reaction equation is as follows:

[0043]

[0044] This embodiment also provides a novel room temperature vulcanized silicone rubber, using a modified hexachlorocyclotriphosphazene as a crosslinking agent, and its preparation m...

Embodiment 2

[0048] The difference between this example and Example 1 is that the amount of the modified hexachlorocyclotriphosphazene is 100 g.

Embodiment 3

[0050] The difference between this example and Example 1 is that the amount of the modified hexachlorocyclotriphosphazene is 150 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com