Integrated optical waveguide gyroscope based on optical microcavity

A technology that integrates optical waveguides and optical microcavities, which is applied in the coupling of optical waveguides, Sagnac effect gyroscopes, etc., can solve the problems of fiber optic gyroscope performance, fiber ring quality limitation, and unfavorable fiber optic gyroscope applications. Light, reasonable structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

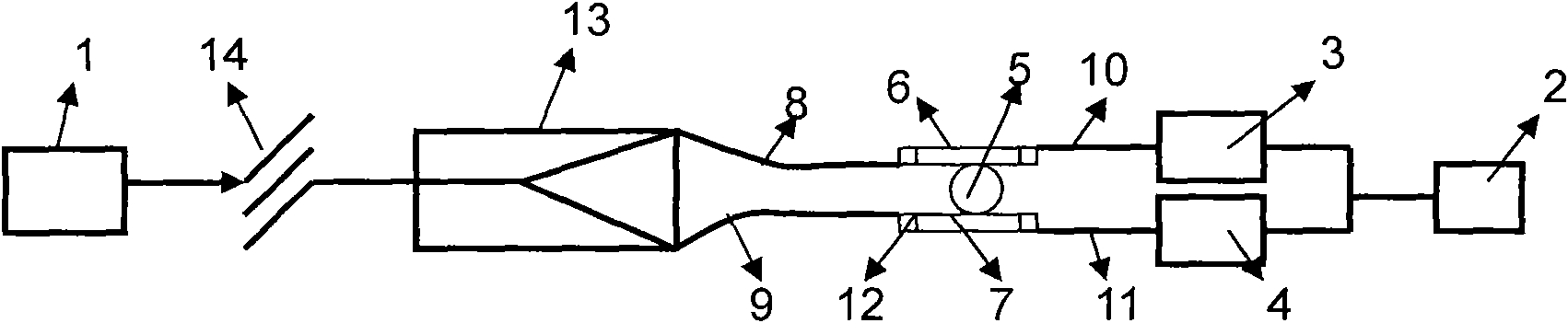

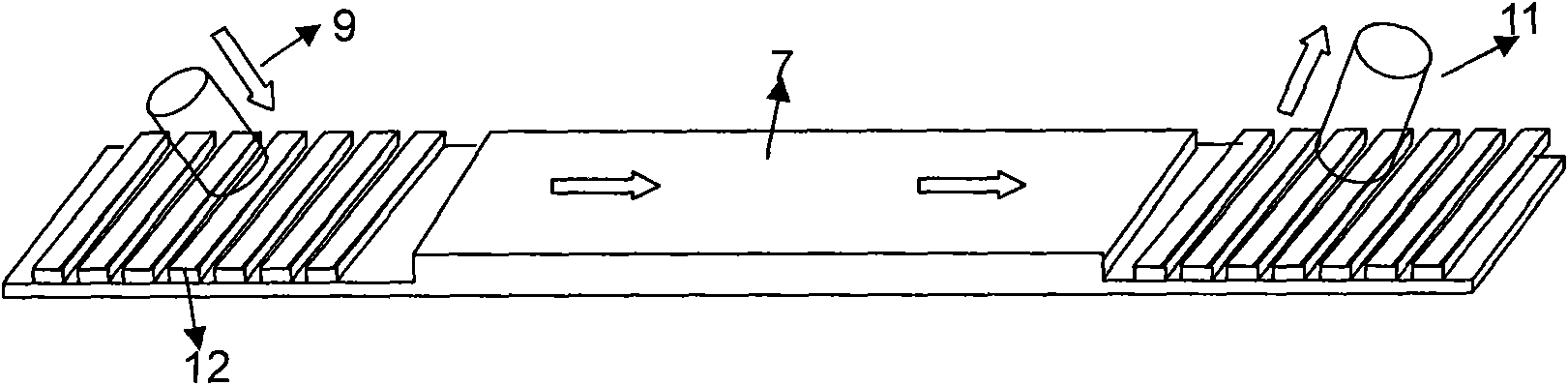

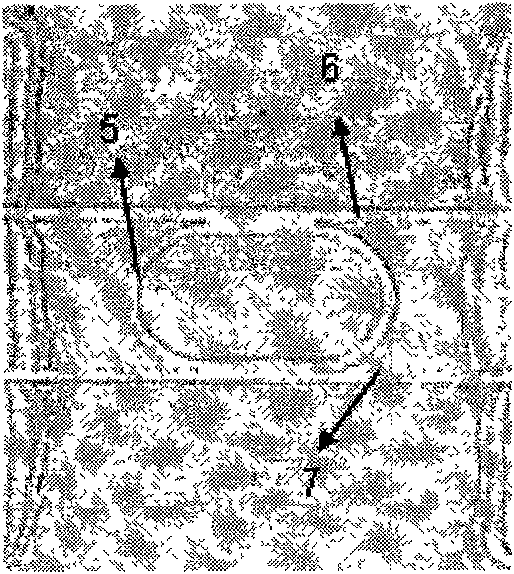

[0016] Such as figure 1 , 3 As shown, the integrated optical waveguide gyro based on the optical microcavity includes a light source 1, a beam splitter and a light detection device composed of a signal processing unit 2 and two photodetectors 3 and 4. The light source 1 is directly incident on the beam splitter The output port of the two photodetectors 3 and 4 is connected to the signal acquisition end of the signal processing unit 2, and includes an optical microcavity 5 processed on a semiconductor substrate by using MEMS processing technology, and an optical microcavity 5 arranged in parallel and symmetrically on the optical microcavity. The optical waveguides 6 and 7 on both sides of the cavity 5, and the two optical waveguides 6 and 7 respectively form an optical waveguide-microcavity coupling structure with the optical microcavity 5, and the optical microcavity 5 and the optical waveguides 6 and 7 are arranged between the beam splitter and the optical cavity. Between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com