Patents

Literature

43 results about "Microribbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

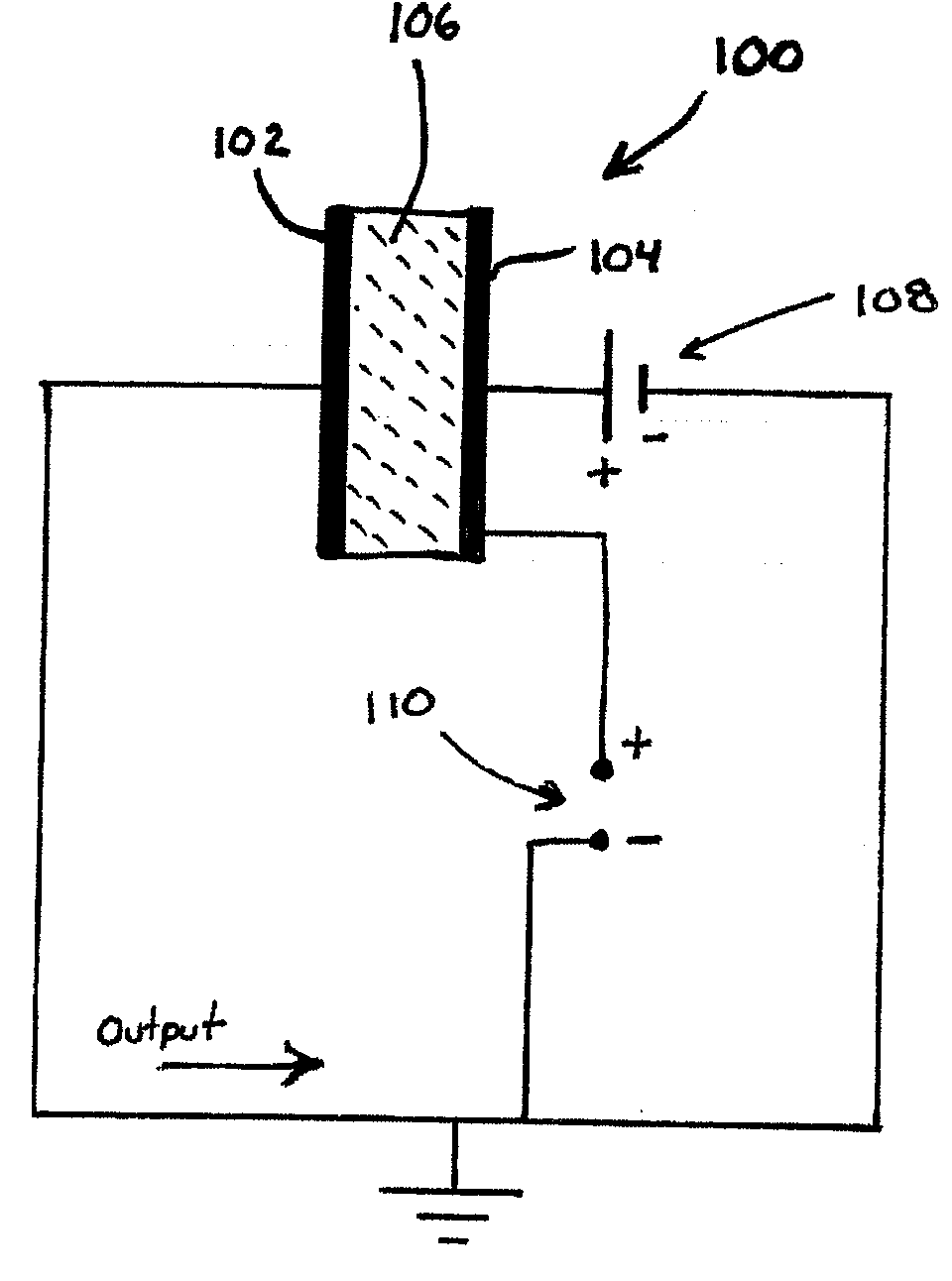

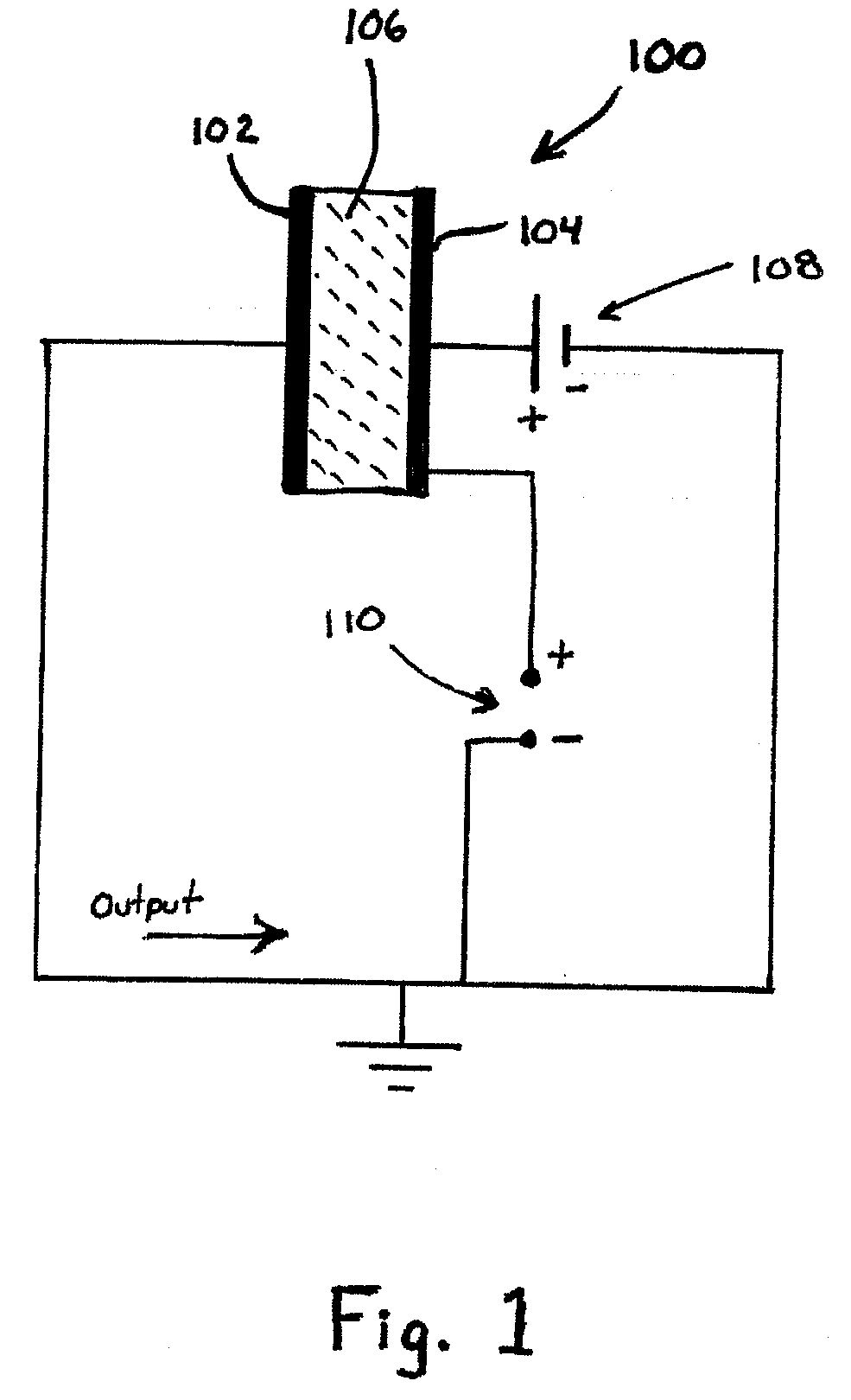

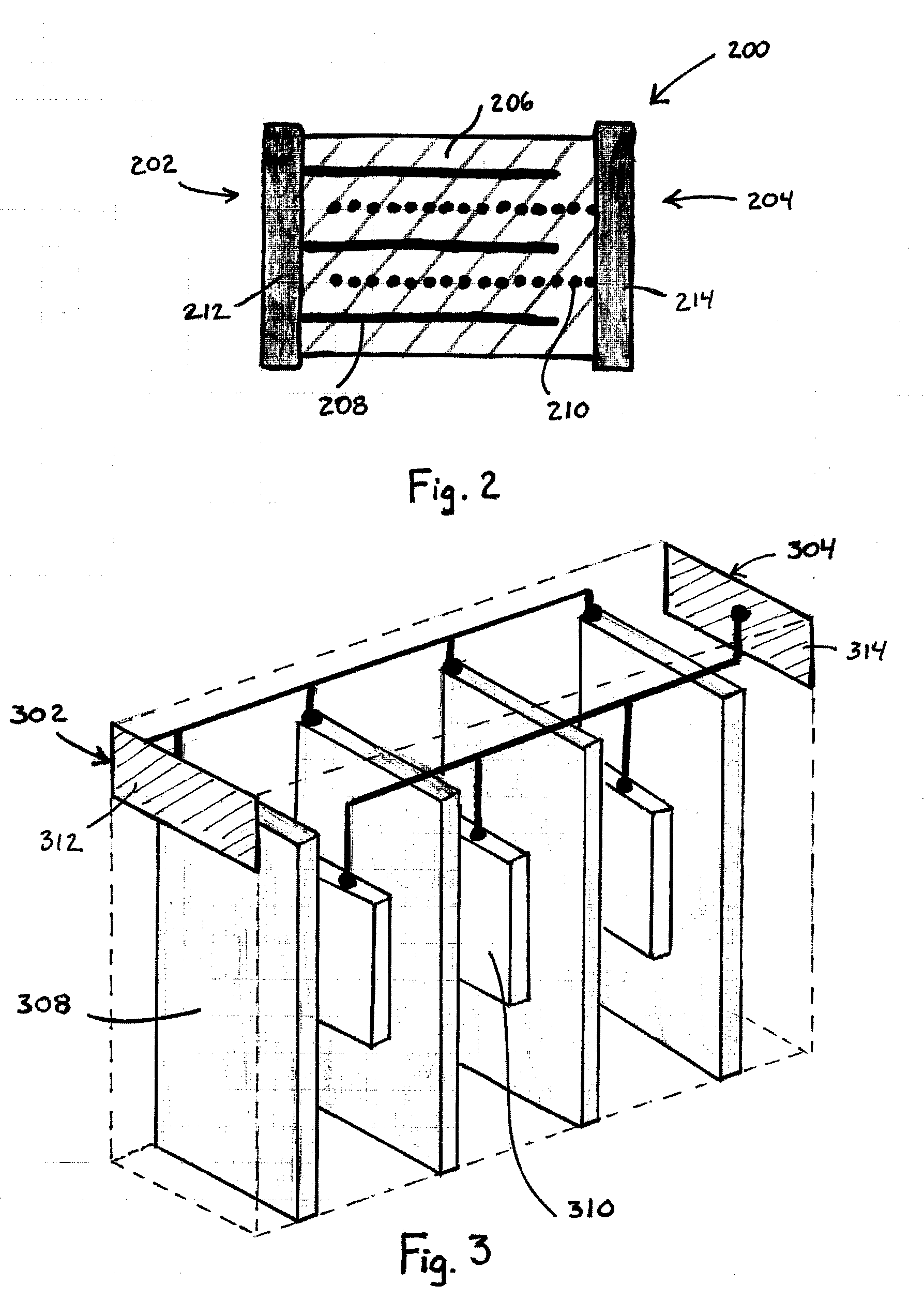

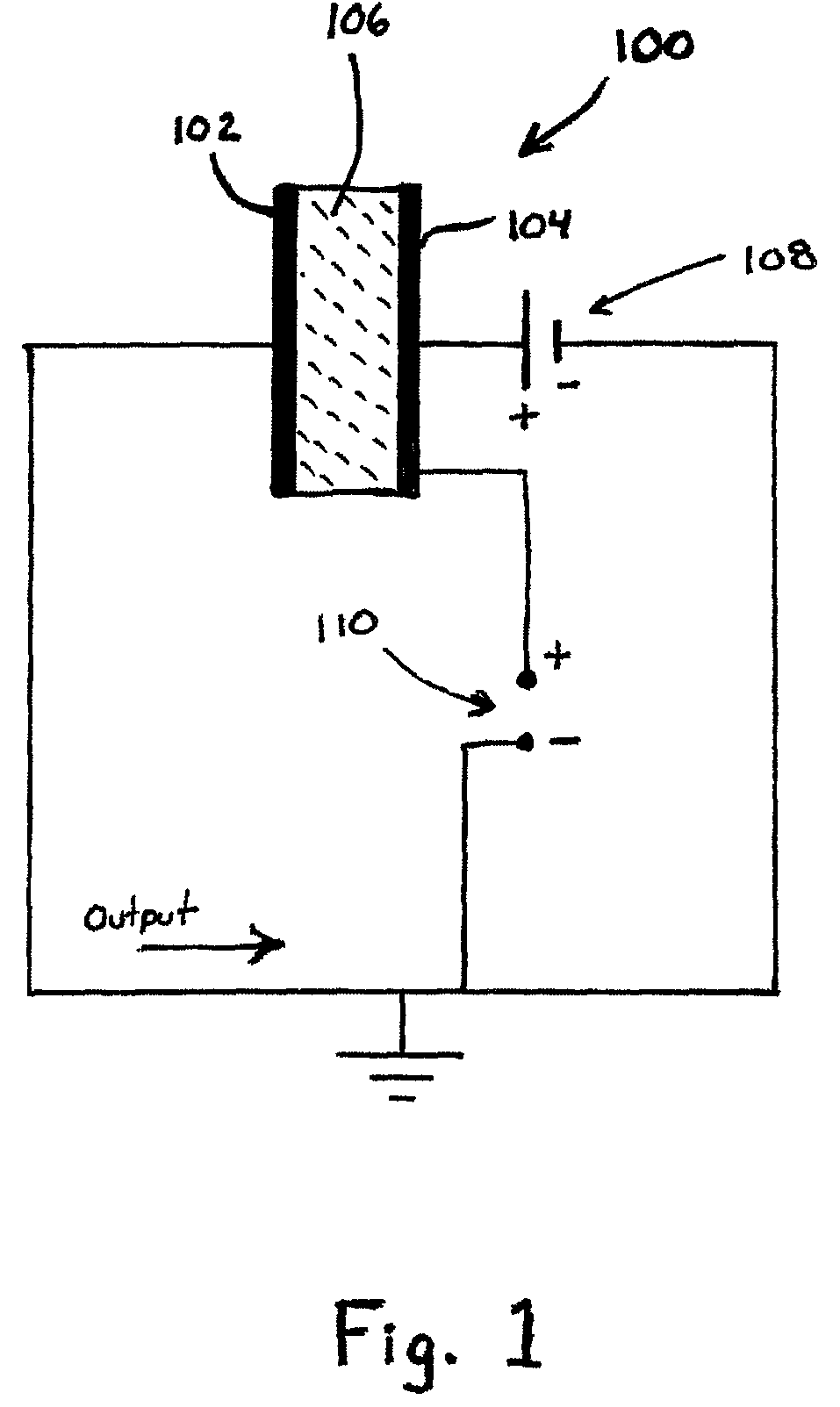

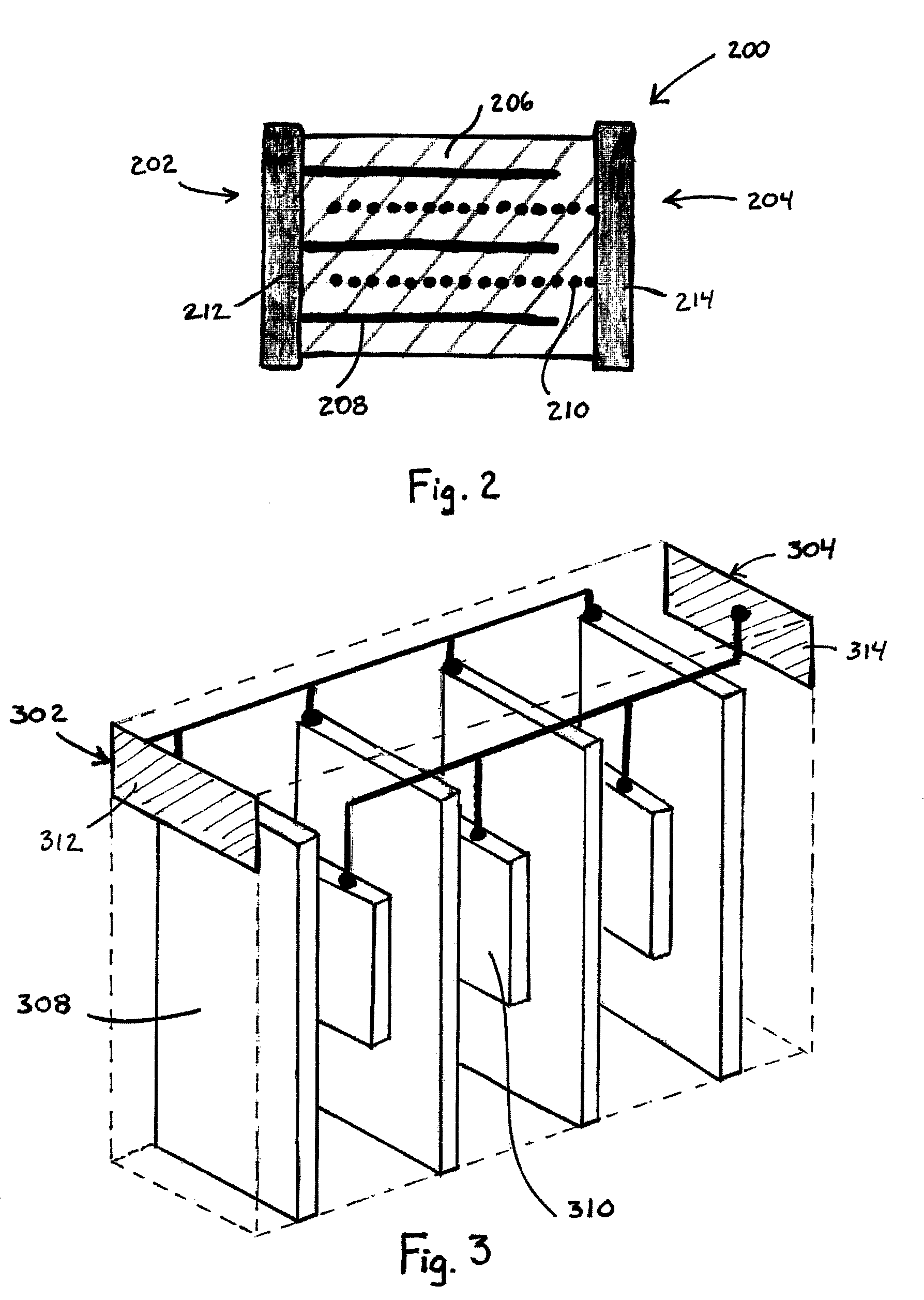

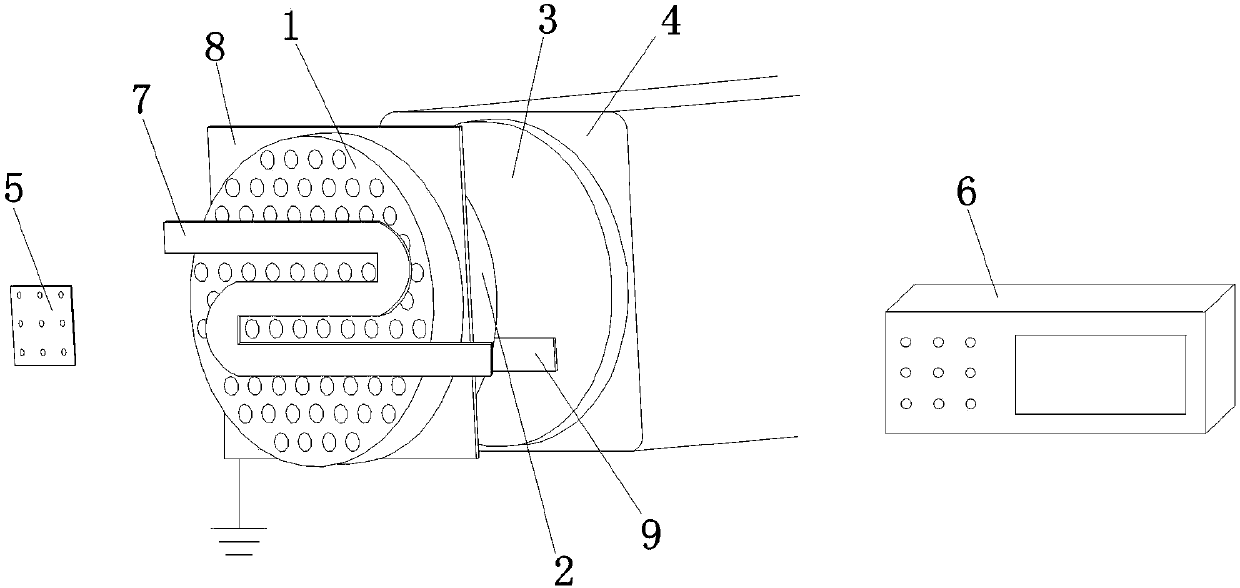

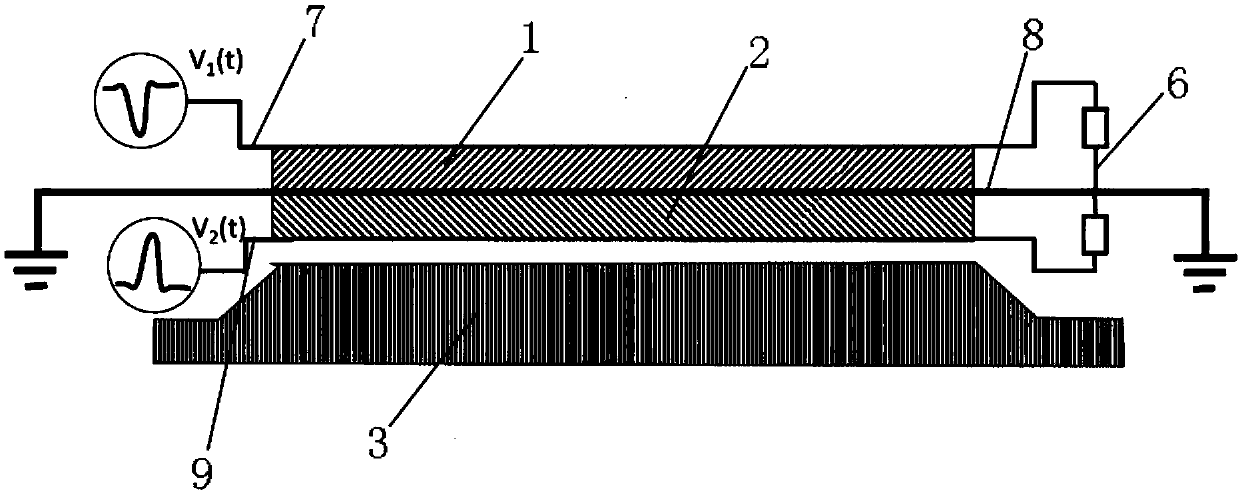

Solid state electrochemical gas sensor and method for fabricating same

InactiveUS20070102294A1Small sizeWeather/light/corrosion resistanceVolume/mass flow measurementPolymer electrolytesElectrochemical gas sensor

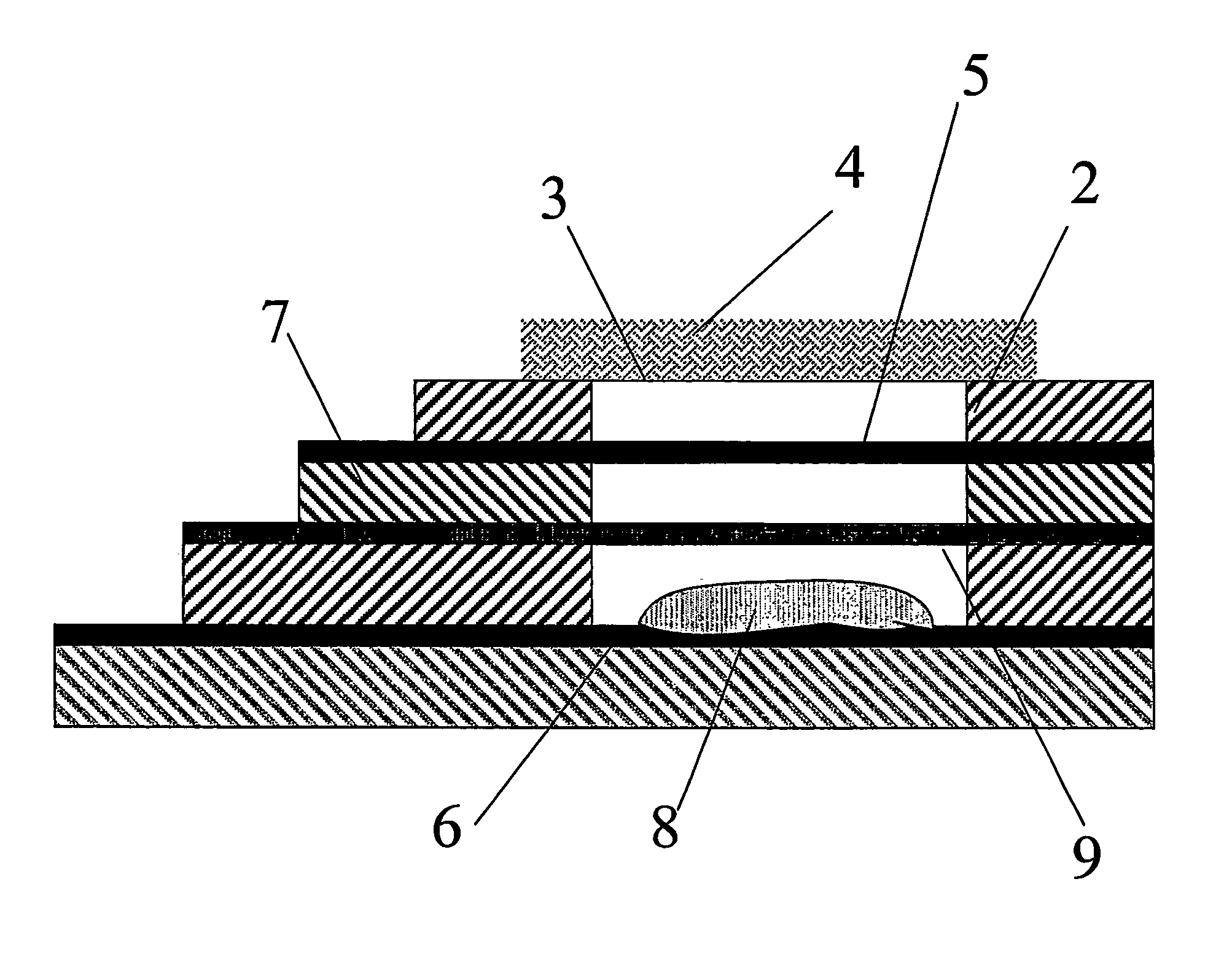

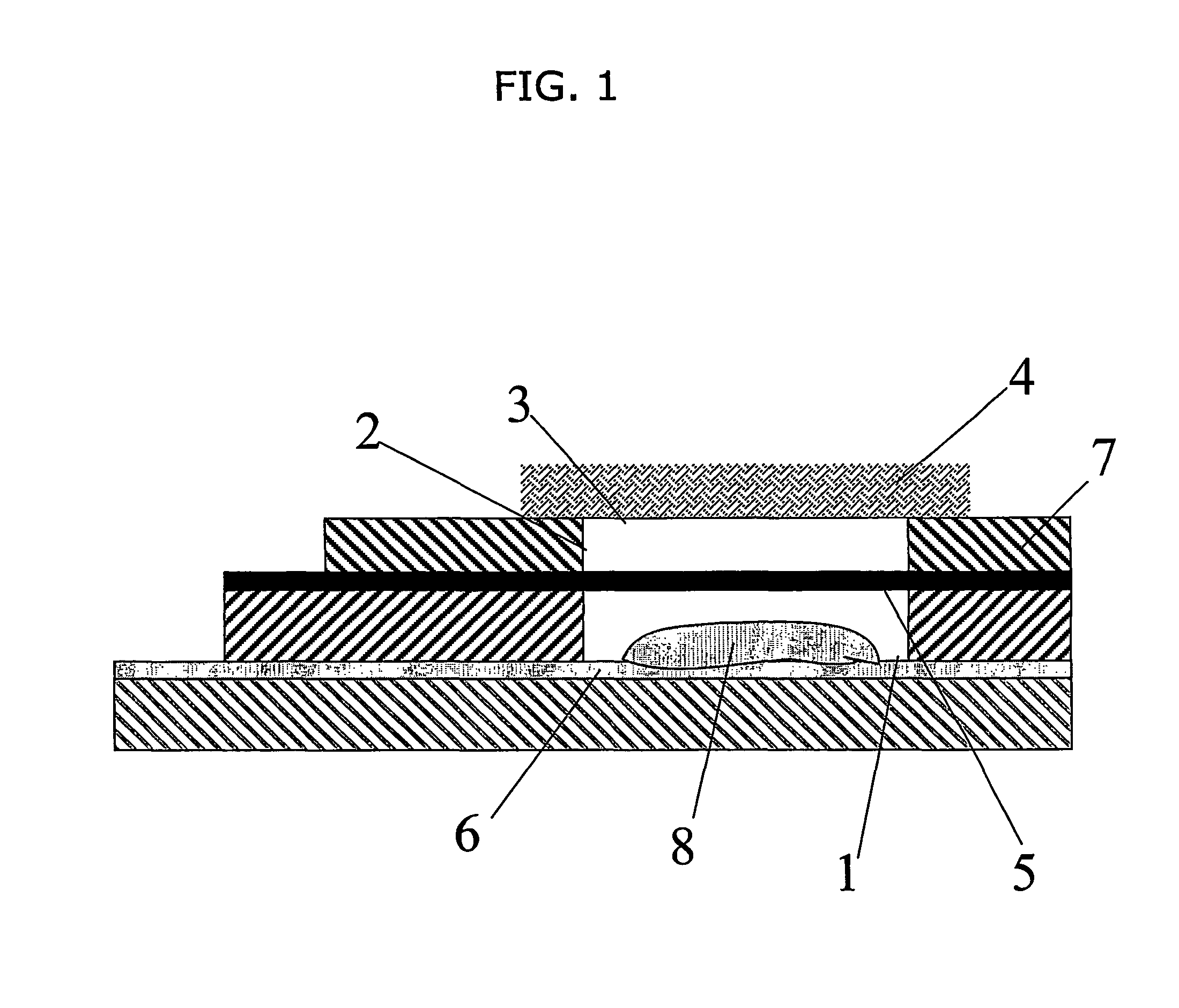

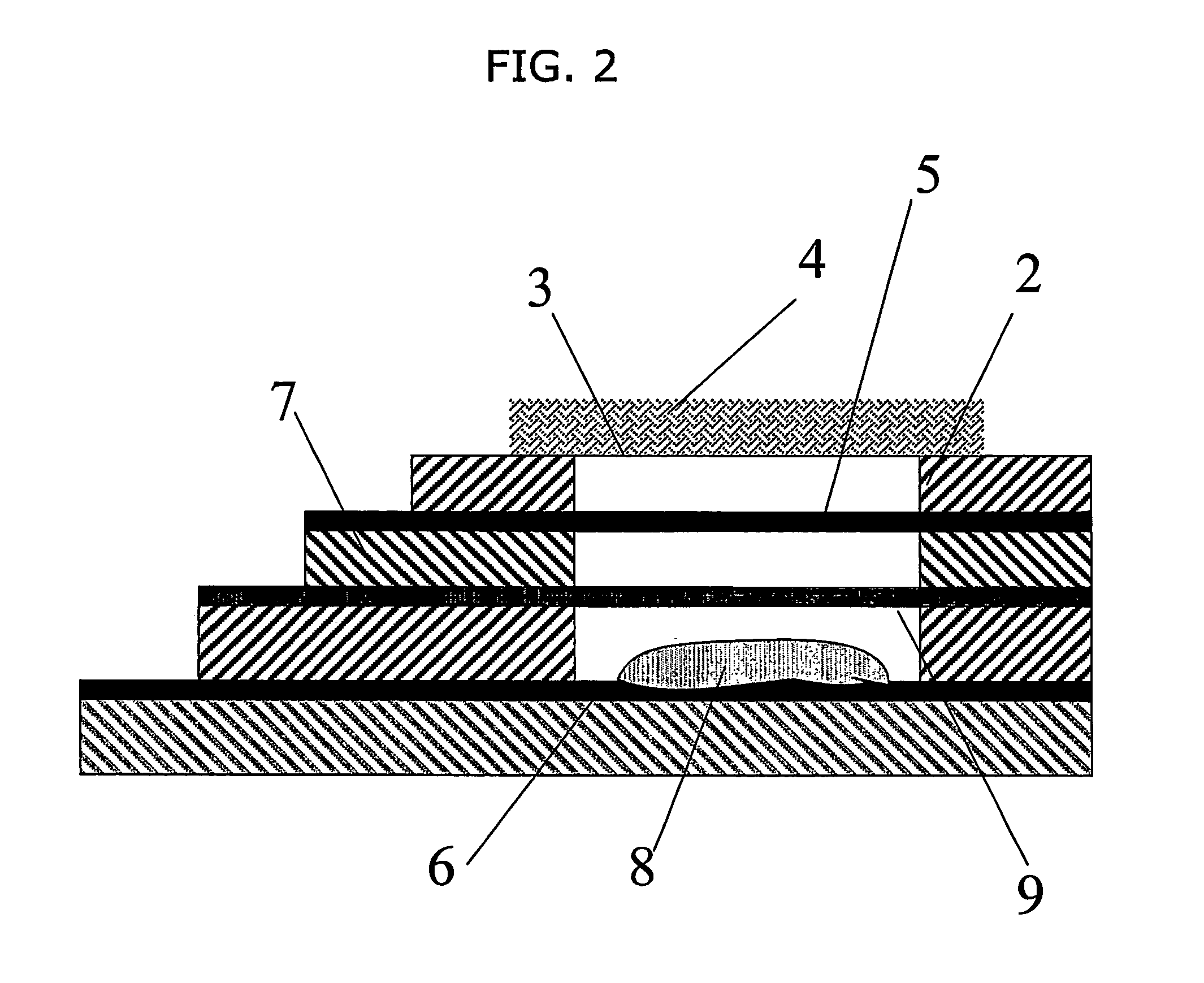

An electrochemical gas sensor, a method for making the sensor and methods for the detection of a gaseous species. The electrochemical gas sensor is a solid-state gas sensor that includes a solid polymer electrolyte. A working electrode is separated from a counter electrode by the solid polymer electrolyte. The sensor can include a multilaminate structure for improved detection properties, where electrode microbands are disposed within the solid polymer electrolyte.

Owner:INTEGRATED DEVICE TECH INC

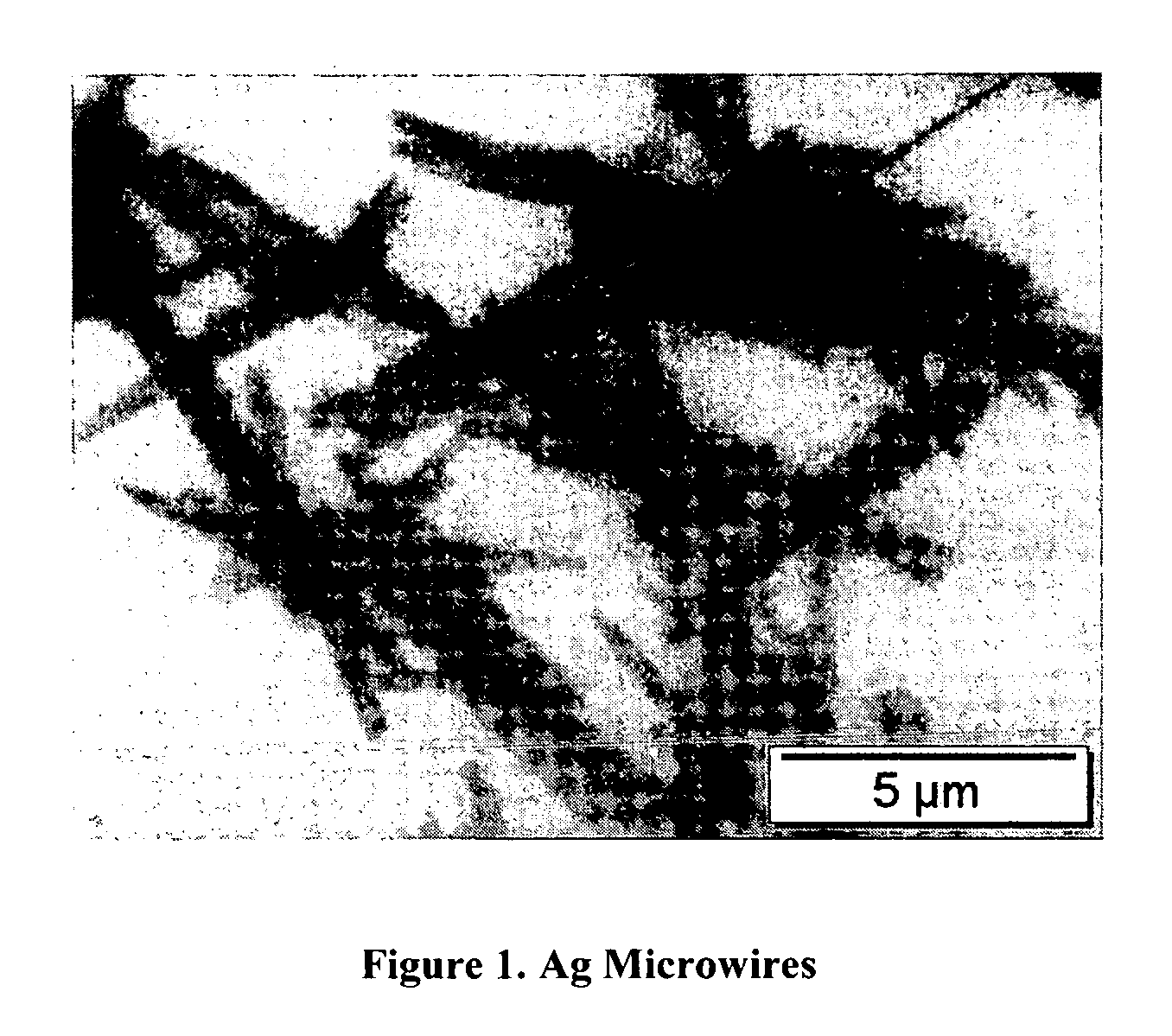

Silver microribbon composition and method of making

InactiveUS20060068025A1Simple and cost-effectiveSmall sizeBiocideInorganic active ingredientsFiberLatent image

This invention relates to a composition of matter comprising predominantly silver metal microribbons, wherein the microribbons are at least 1 micron in length×0.1 to 0.5 microns in width×0.05 to 0.5 microns in height. It further relates to a method of making predominantly silver microribbons comprising providing a reducible silver salt, contacting the reducible silver salt with a fogging agent to form latent image silver centers; reducing the reducible silver salt into silver metal using a reducing agent, supplying a polymer that is soluble in a non-aqueous solvent, and a non-aqueous solvent; allowing the growth of the microribbons in the presence of the polymer and non-aqueous solvent

Owner:EASTMAN KODAK CO

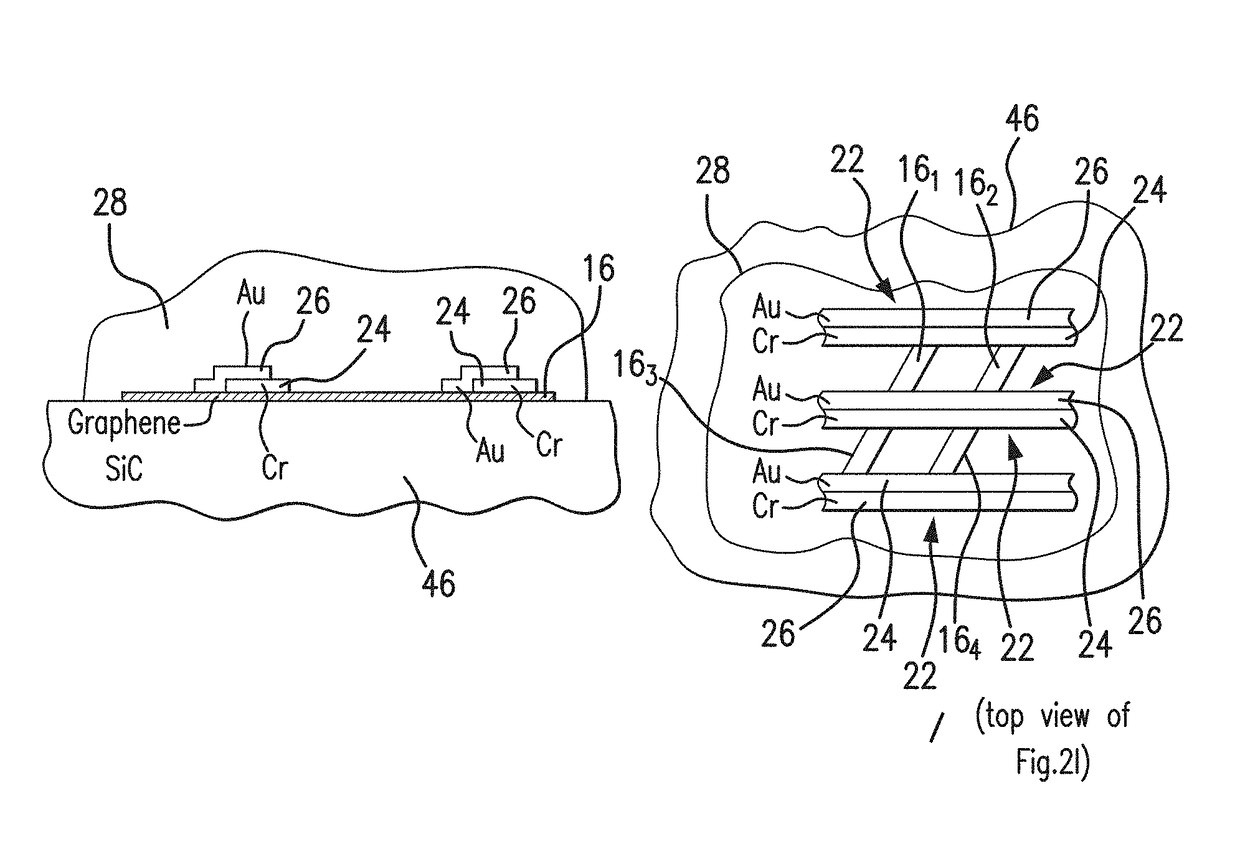

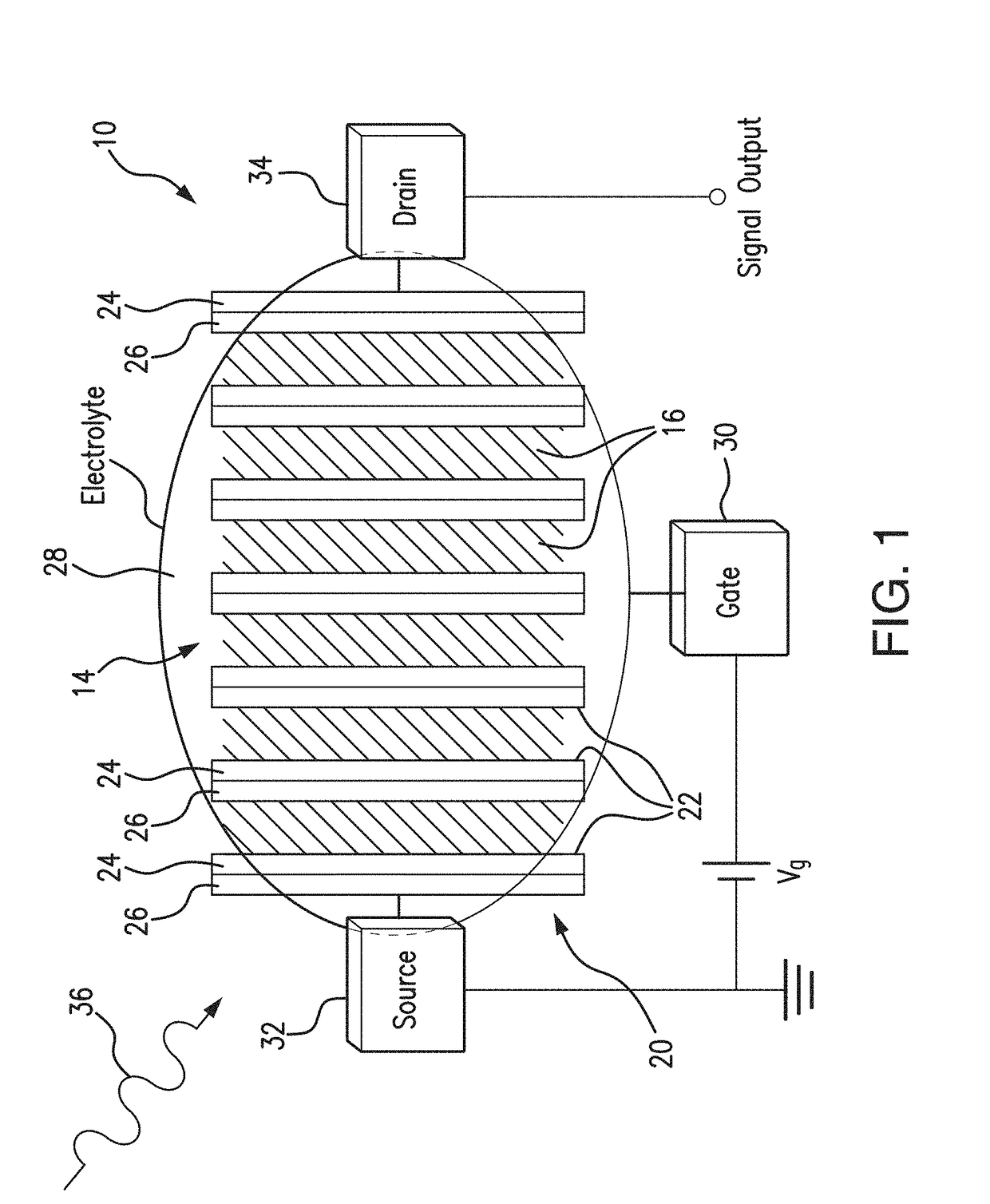

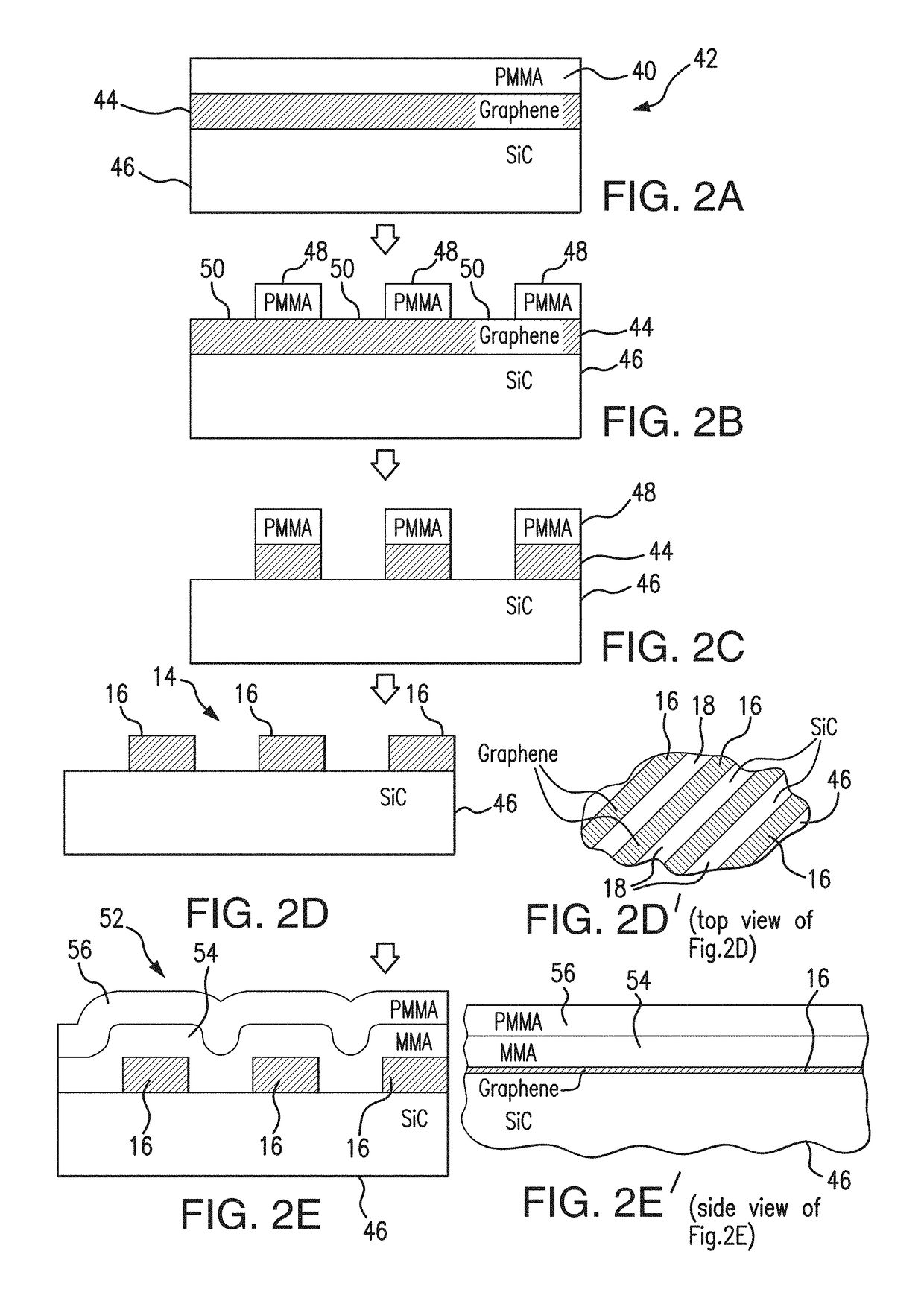

Plasmon-enhanced terahertz graphene-based photodetector and method of fabrication

ActiveUS20180047856A1Improve responsePromote absorptionMaterial nanotechnologyWave amplification devicesMetallic electrodePhotodetector

A plasmon-enhanced terahertz graphene-based photodetector exhibits an increased absorption efficiency attained by utilizing a tunable plasmonic resonance in sub-wavelengths graphene micro-ribbons formed on SiC substrate in contact with an array of bi-metallic electrode lines. The orientation of the graphene micro-ribbons is tailored with respect to the array of sub-wavelengths bi-metallic electrode lines. The graphene micro-ribbons extend at the angle of approximately 45 degrees with respect to the electrode lines in the bi-metal electrodes array. The plasmonic mode is efficiently excited by an incident wave polarized perpendicular to the electrode lines, and / or to the graphene micro-ribbons. The absorption of radiation by graphene is enhanced through tunable geometric parameters (such as, for example, the width of the graphene micro-ribbons) and control of a carrier density in graphene achieved through tuning the gate voltage applied to the photodetector.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

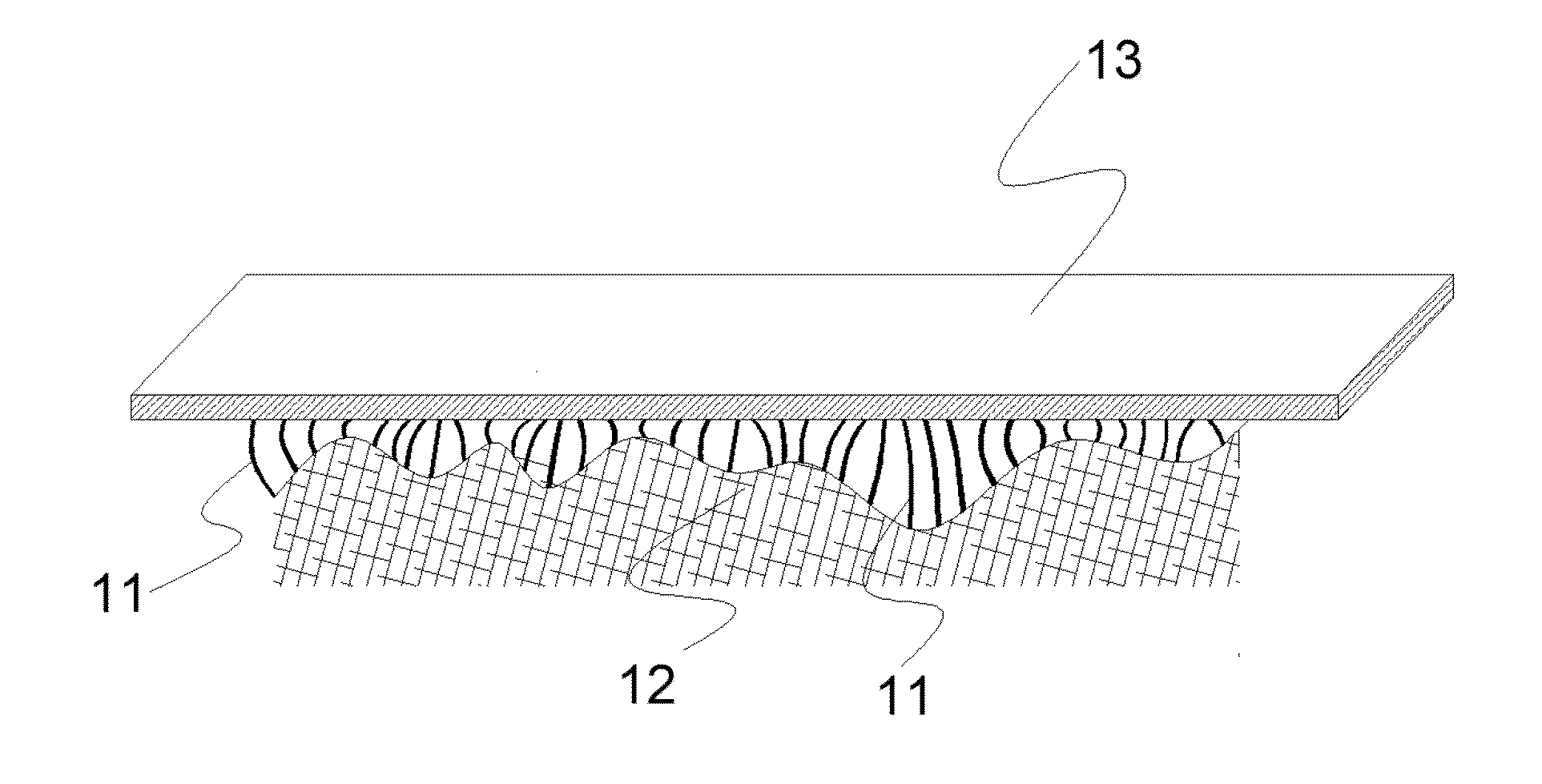

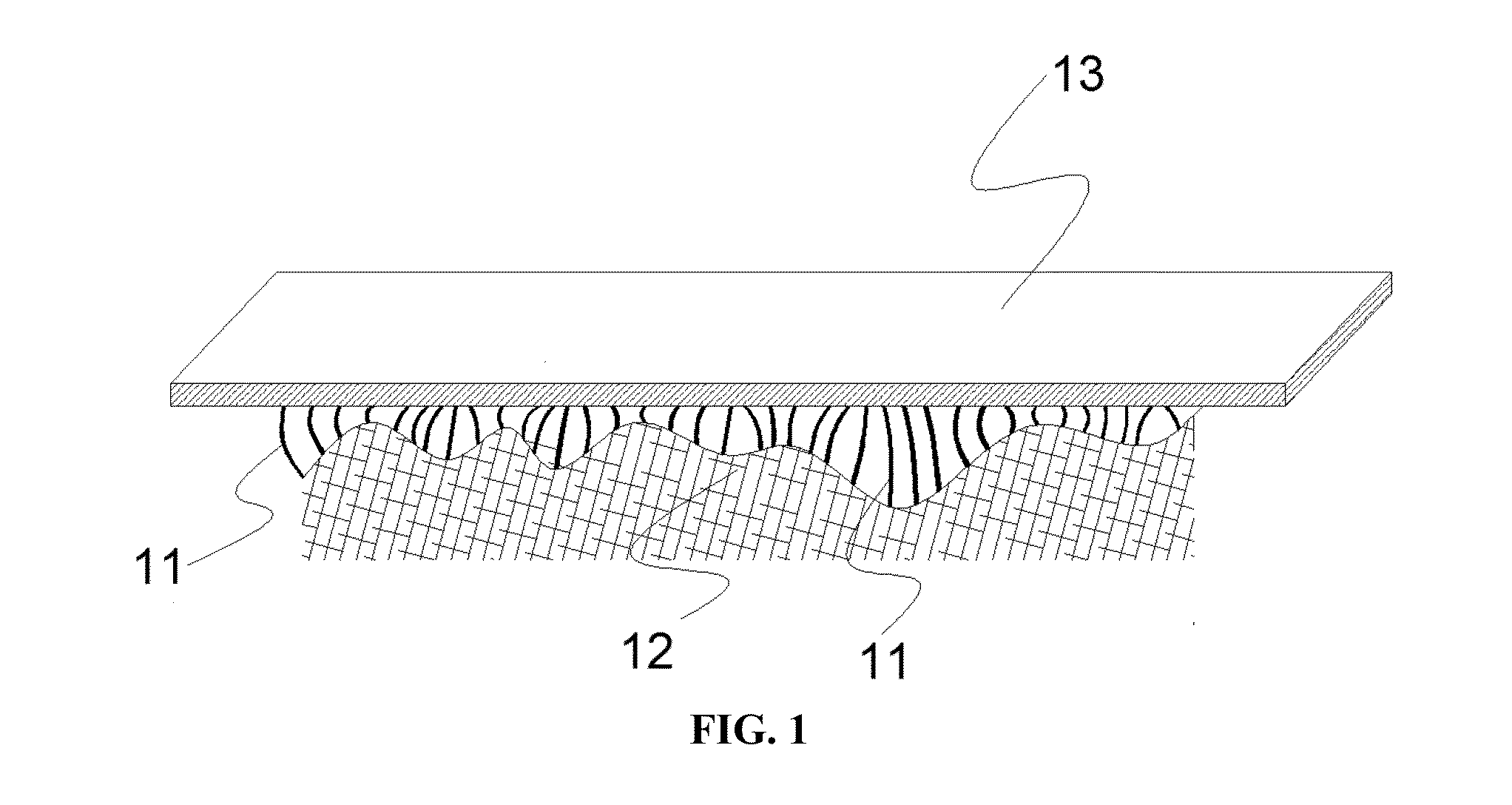

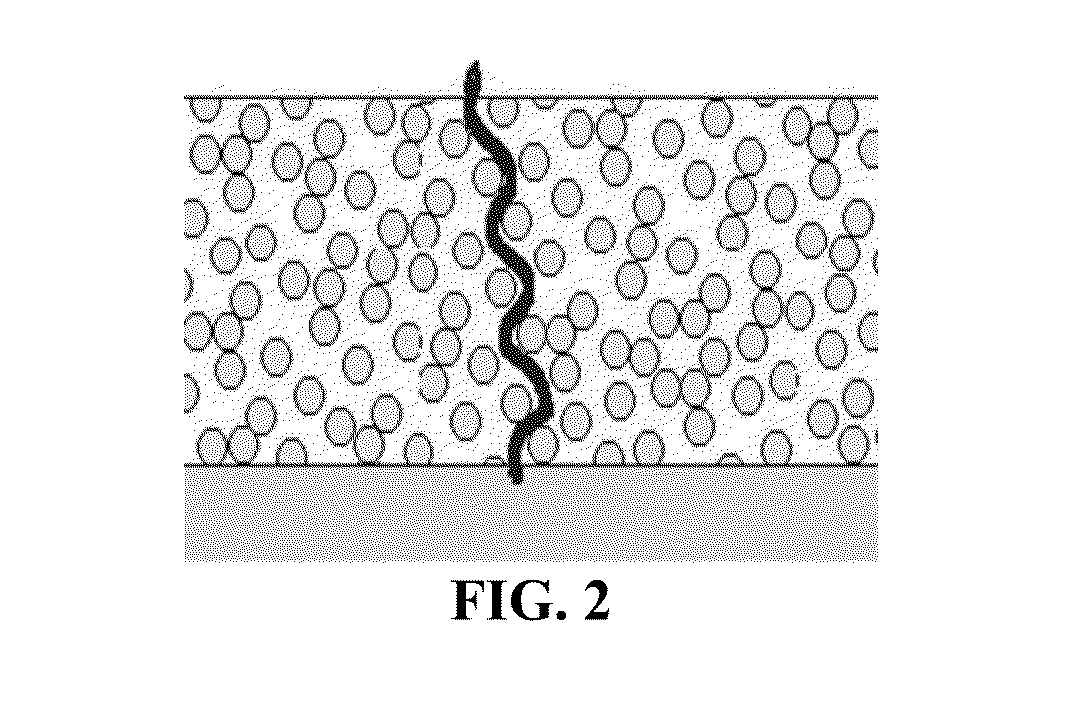

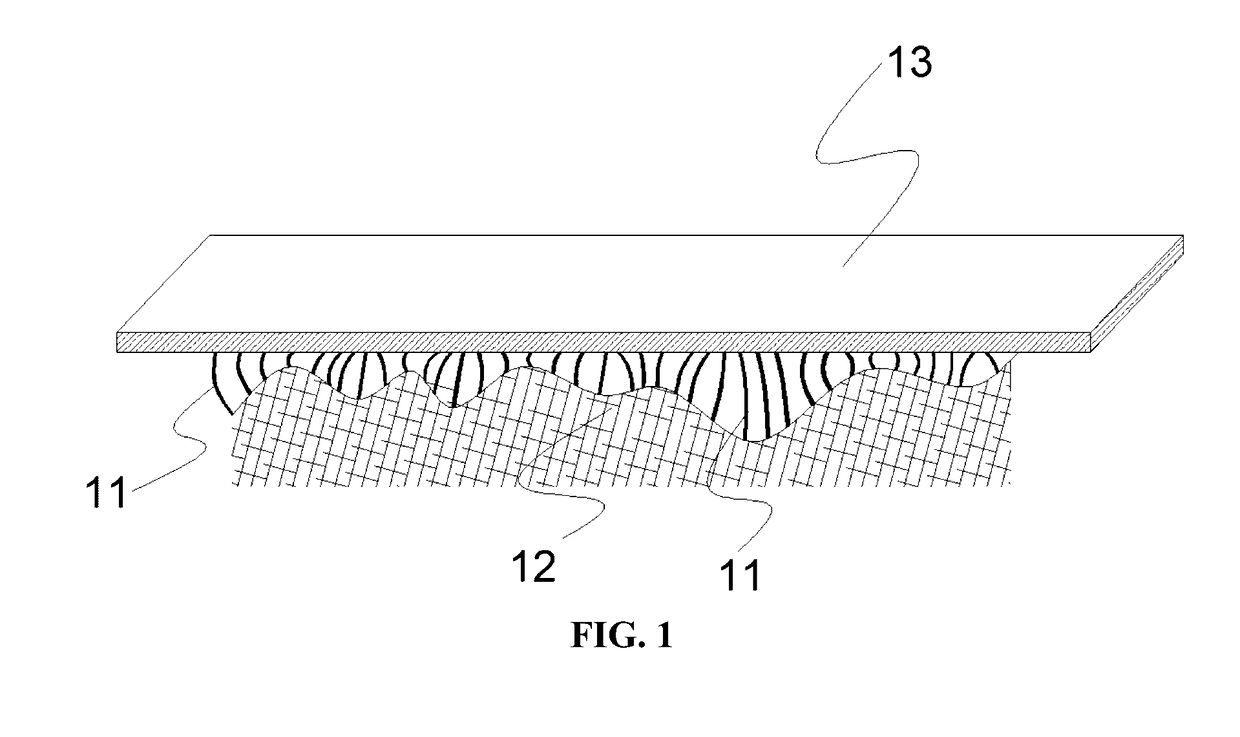

Micropatterned structures for forming a seal with the face skin and other surfaces and method of make

ActiveUS20150329743A1Good contact/sealIncrease frictionFilm/foil adhesivesSynthetic resin layered productsFiberAdhesive

The present invention is directed towards an article suitable for attachment to facial skin or other surfaces, which comprises microfibrils and continuous microribbons. The article provides good sealing when used on a regular skin, and on a challenge skin surface with facial hair, sweat and acnes. The article also provides good adhesion and sealing on any other rough surfaces, and can be used repeatedly against different surfaces. These dry adhesives can be used for improving sealing of mask respirators, swimming goggles, or for other applications such as medical bandage, working gloves, and protective clothing seal.

Owner:METNA

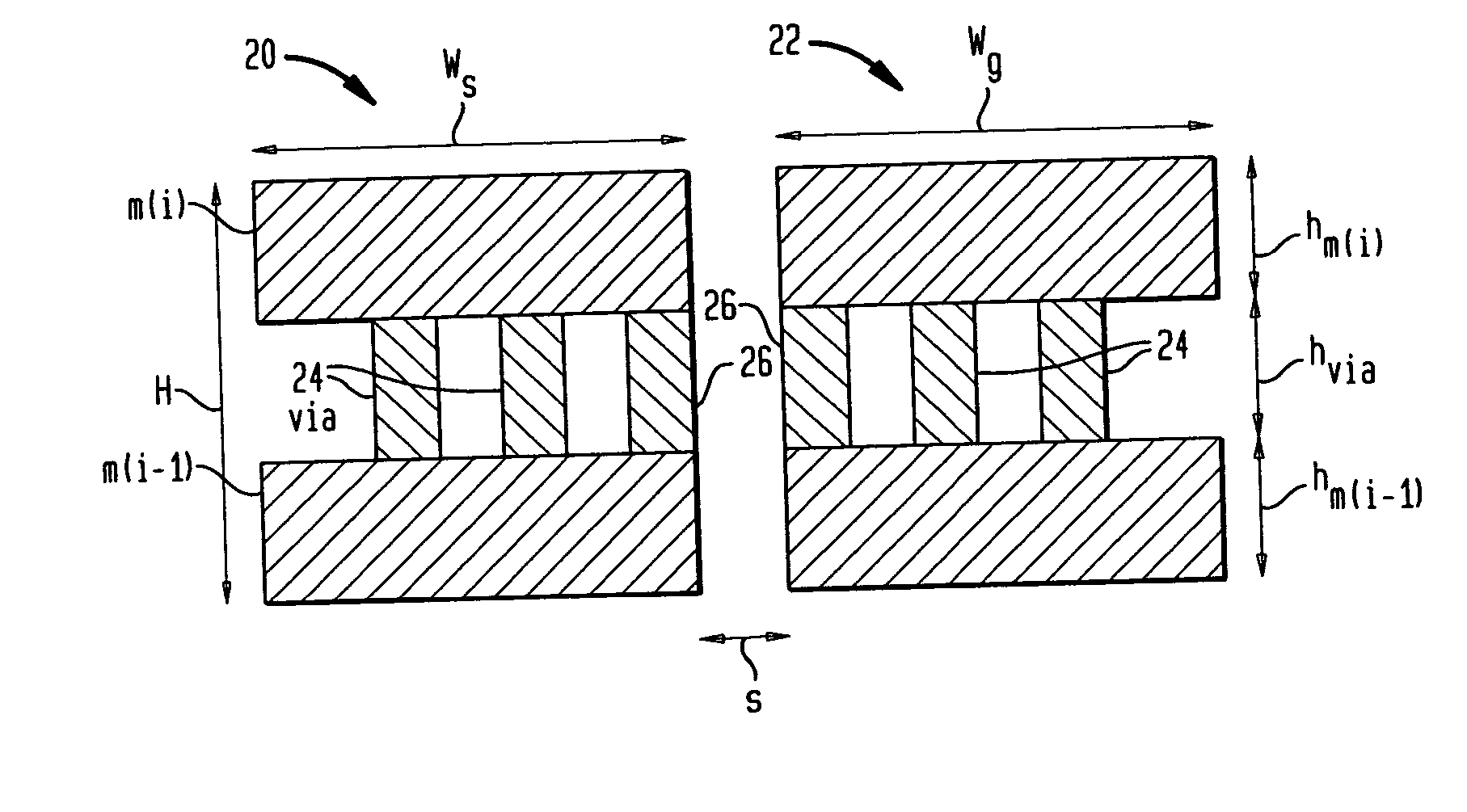

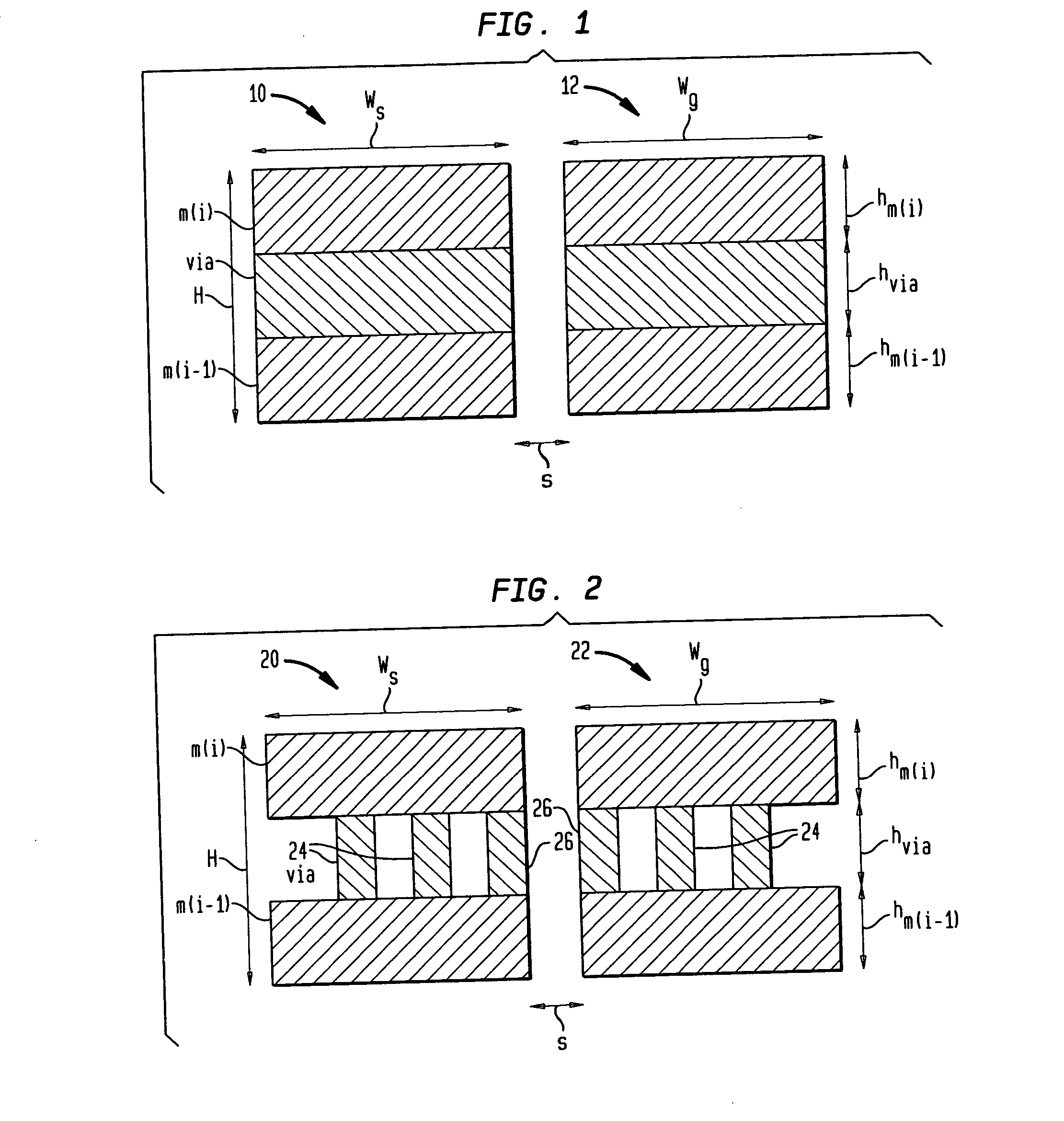

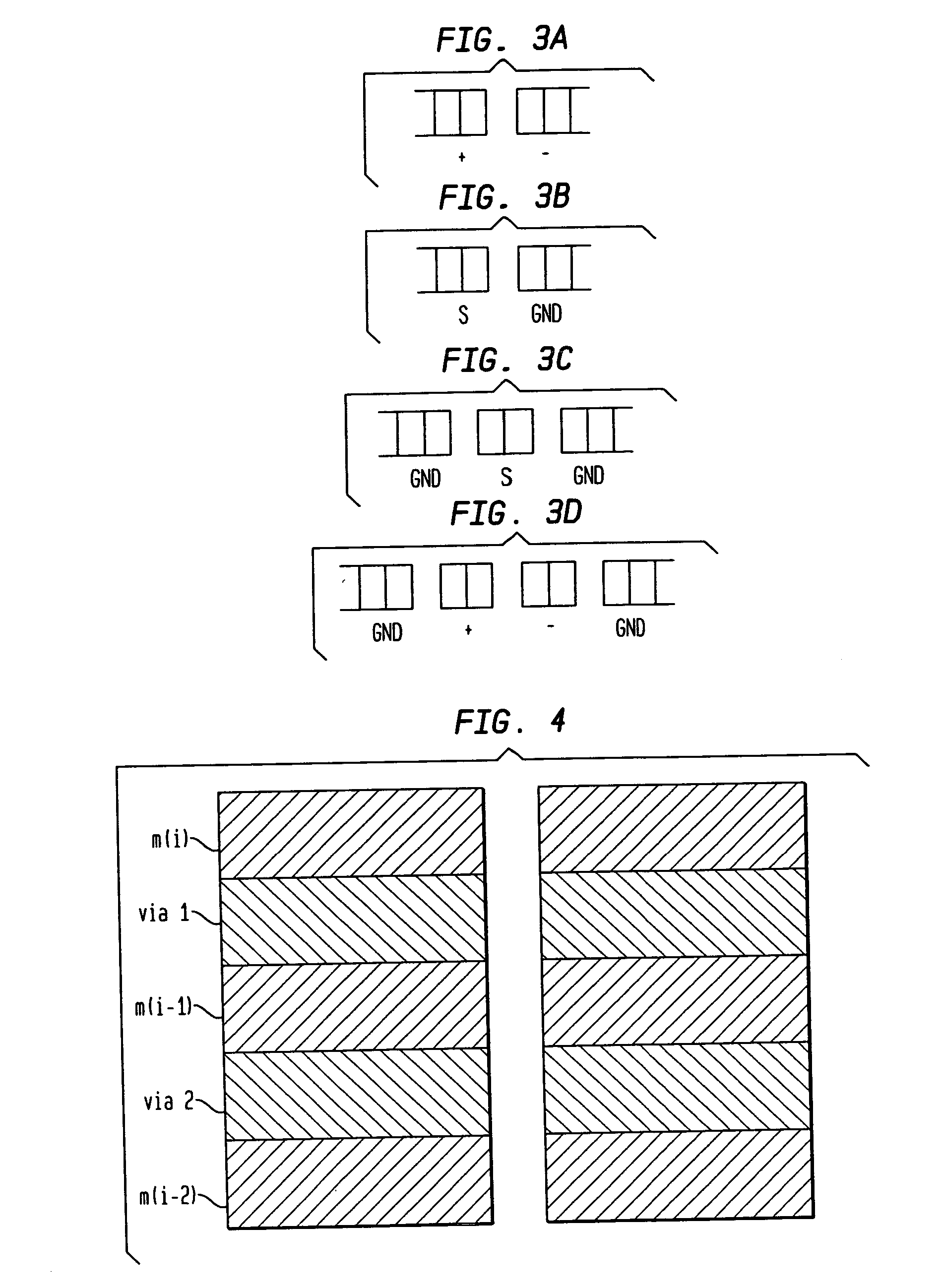

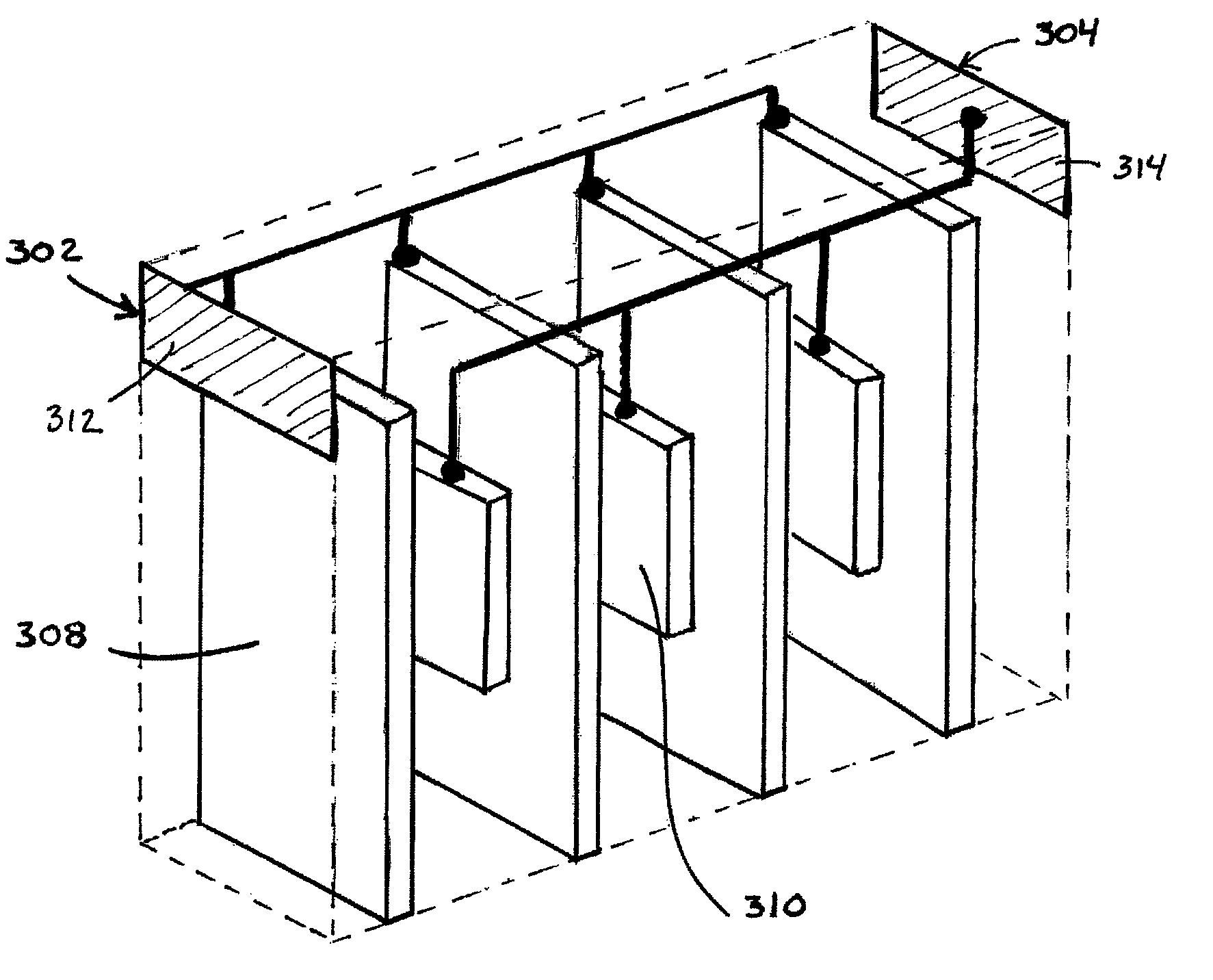

Vertically-stacked co-planar transmission line structure for IC design

InactiveUS20050062137A1Improve performanceWide rangeSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorPlanar transmission lines

A vertically stacked coplanar transmission line structure for an IC (integrated circuit) is provided which has superior loss and reflection characteristics relative to conventional on-chip transmission line designs. A simple embodiment of the vertically stacked coplanar transmission line structure comprises a micro-strip pair of first and second vertically stacked coplanar conductors, each comprising a metal layer, a next metal layer down, and an intermediate connecting via layer in between the metal layer and the next metal layer down.

Owner:IBM CORP

Solid state electrochemical gas sensor and method for fabricating same

InactiveUS7918977B2Weather/light/corrosion resistanceVolume/mass flow measurementElectricityPolymer electrolytes

An electrochemical gas sensor, a method for making the sensor and methods for the detection of a gaseous species. The electrochemical gas sensor is a solid-state gas sensor that includes a solid polymer electrolyte. A working electrode is separated from a counter electrode by the solid polymer electrolyte. The sensor can include a multilaminate structure for improved detection properties, where electrode microbands are disposed within the solid polymer electrolyte.

Owner:INTEGRATED DEVICE TECH INC

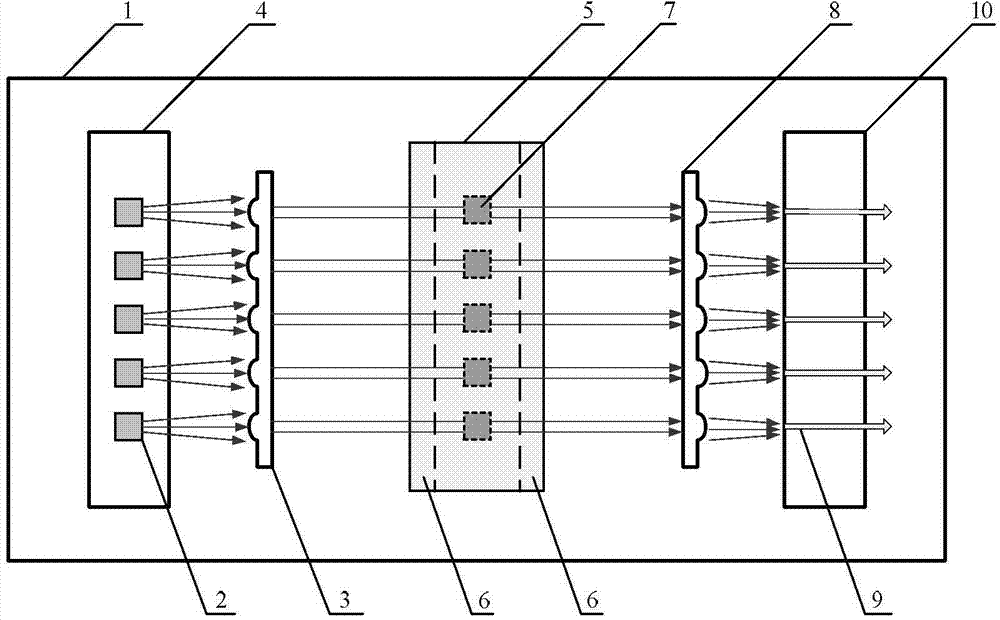

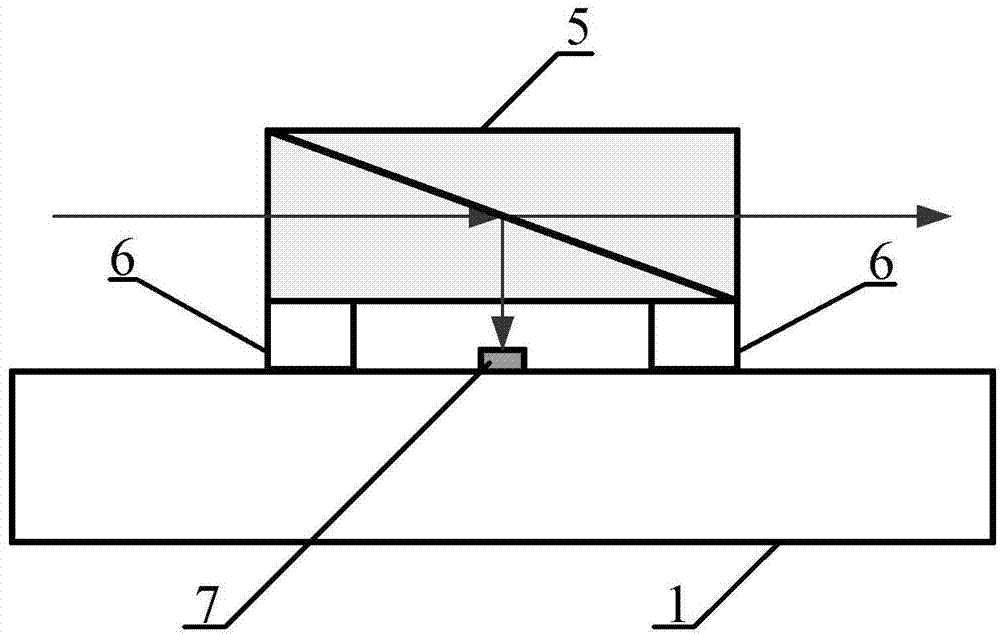

Optical coupling apparatus for packaging optoelectronic integration array chip

InactiveCN104122636AAvoid difficultiesRealize real-time monitoringCoupling light guidesBeam splitterDetector array

The invention discloses an optical coupling apparatus for packaging an optoelectronic integration array chip. The optical coupling apparatus comprises a tube shell or a heat sink, the semiconductor optoelectronic integration array chip, a semiconductor optoelectronic integration array chip substrate, an optical collimating lens array, a beam splitter prism, a beam splitter prism bracket, detector array chips, an optical focusing lens array, a fiber array, and a fiber array bracket. According to the optical coupling apparatus for packaging the optoelectronic integration array chip, by means of installation of the beam splitter prism, partial optical signals output by the semiconductor optoelectronic integration array chip collimated by the optical collimating lens array are introduced into the respective corresponding detector array chips, so that difficulties that a backlight detector cannot be placed due to complicated microwave micro-strip circuits or the requirement for double-end optical coupling in coupling packaging of the semiconductor optoelectronic integration array chip are overcome, and real-time monitoring of optical signals of the semiconductor optoelectronic integration array chip is achieved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

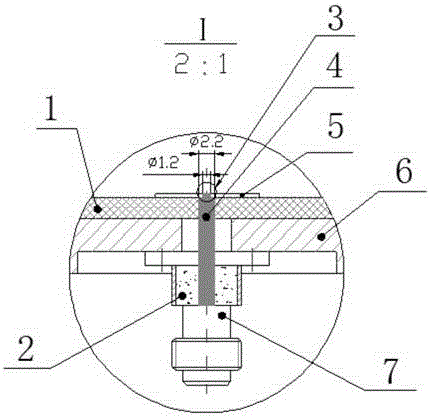

Method for fabricating MEMS friction sensor based on visual alignment

ActiveCN108467007AImprove assembly accuracyHigh precisionDecorative surface effectsForce measurement using piezo-resistive materialsVision basedHemt circuits

The invention discloses a method for fabricating a MEMS friction sensor based on visual alignment. The MEMS friction sensor is decomposed into five parts of a floating component, a silicon microstructure, an electrode substrate, an interface circuit and a package tube. The silicon microstructure and the electrode substrate are fabricated by a MEMS process, the floating component and the package tube are fabricated by precision machining processing technology, and the interface circuit is fabricated by ceramic-based precision micro-strip circuit technology. The MEMS friction sensor uses specialmicro-assembly equipment and micro-assembly process, the micro-assembly equipment consists of a precision vision positioning system, a three-degree-of-freedom micro-operation alignment platform, a vacuum nozzle and an image recognition system, and the assembly of the MEMS friction sensor is completed by using the visual precision positioning and micro-operation alignment technology. The method for fabricating the MEMS friction sensor based on visual alignment provided by the invention improves the processing and assembly precision of the MEMS friction sensor, thereby improving the accuracy ofmeasuring the frictional resistance of the surface in the hypersonic wind tunnel.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

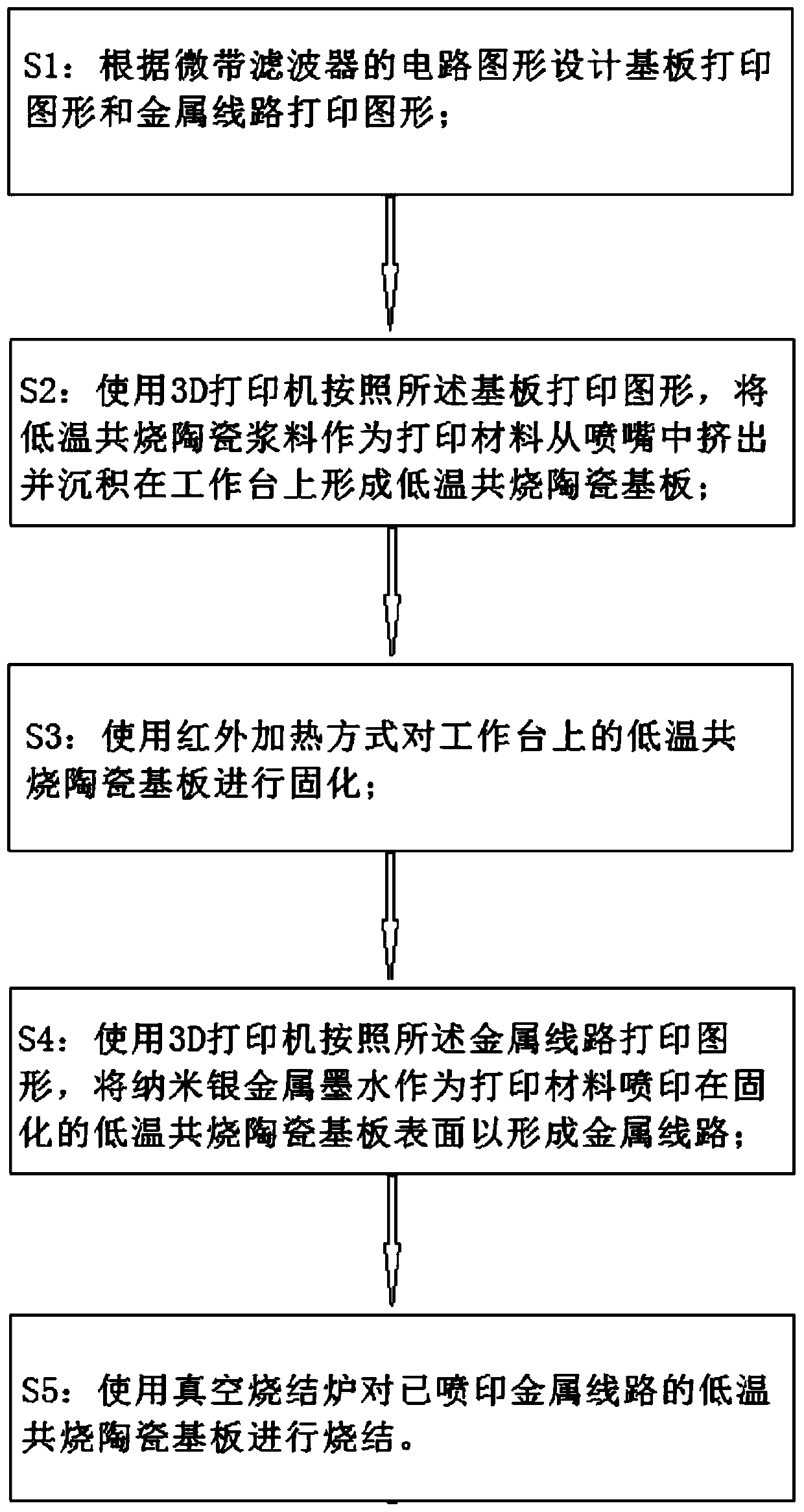

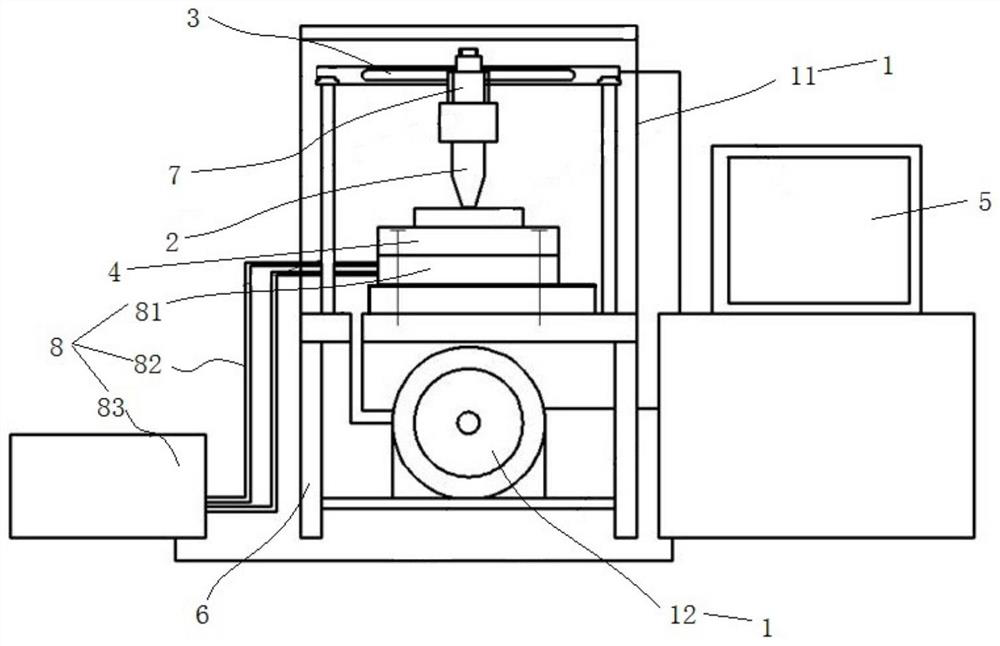

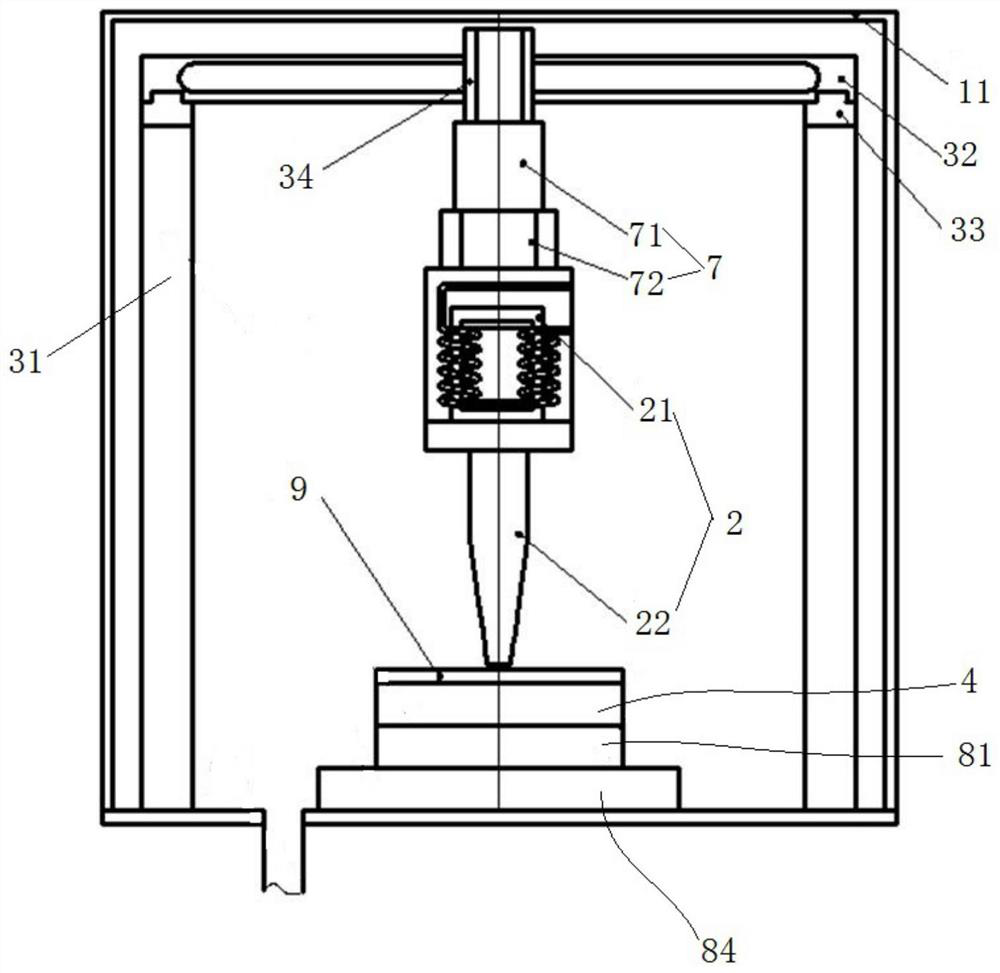

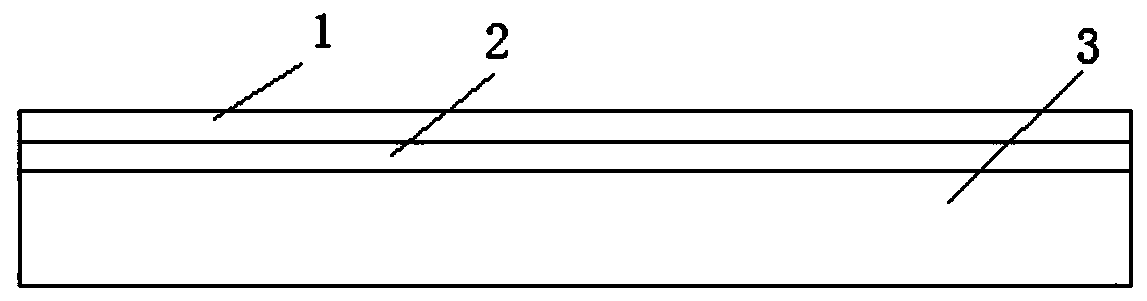

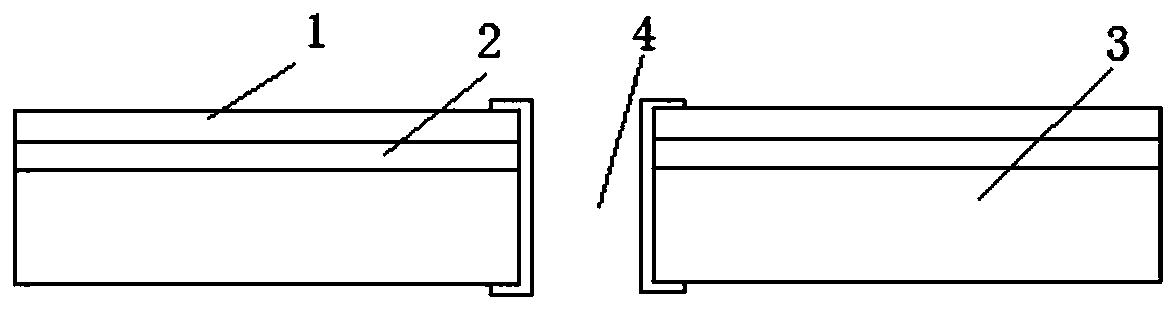

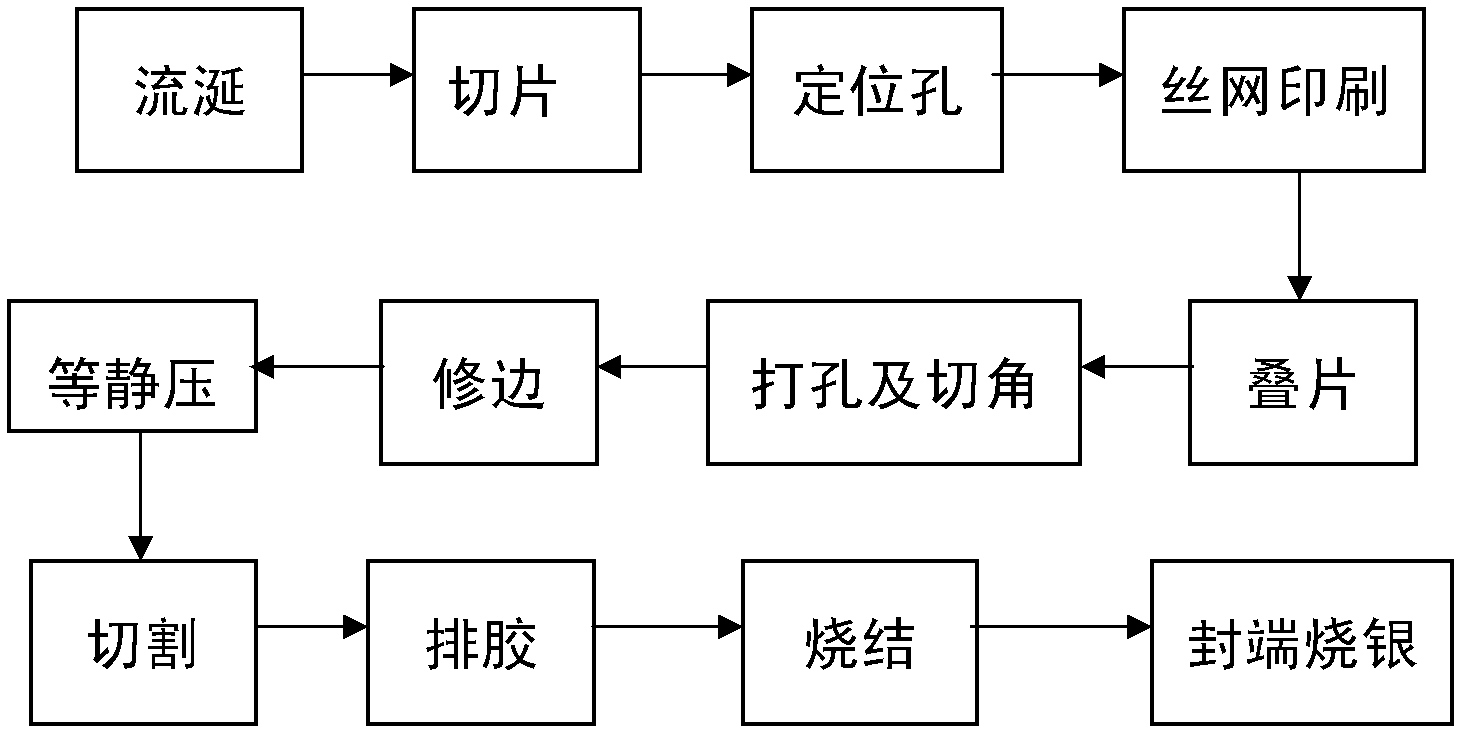

Micro-strip filter 3D printing manufacturing method

PendingCN111065211ARealize personalized creationConducive to solidificationConductive pattern formationComputer printingMicroribbon

The invention discloses a micro-strip filter 3D printing manufacturing method. The method comprises the following steps: S1, designing a substrate printing pattern and a metal circuit printing patternaccording to a circuit pattern of a micro-strip filter; S2, extruding low-temperature co-fired ceramic slurry serving as a printing material out of a nozzle and depositing the slurry on a workbench to form a low-temperature co-fired ceramic substrate by using a 3D printer according to the substrate printing pattern; S3, curing the low-temperature co-fired ceramic substrate on the workbench in aninfrared heating mode; S4, spray-printing nano-silver metal ink serving as a printing material on the surface of the cured low-temperature co-fired ceramic substrate to form a metal circuit by using the 3D printer according to the metal circuit printing pattern; and S5, sintering the low-temperature co-fired ceramic substrate printed with the metal circuit by using a vacuum sintering furnace. Themethod is simple and easy to master, the production cost can be reduced, and a solution is provided for rapid manufacturing and individuation of the micro-strip filter.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

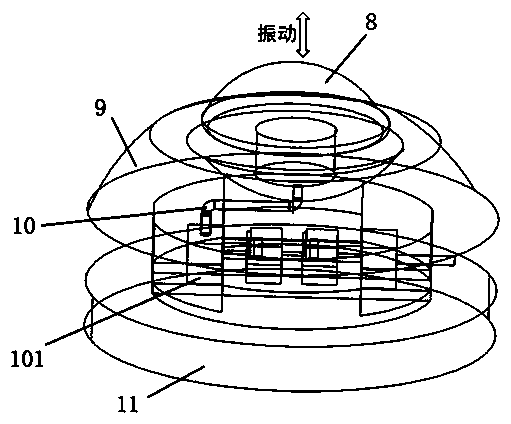

Vacuum-ultrasonic composite brazing device and method

PendingCN112676666AQuality improvementHigh-precision dynamic picking functionSoldering apparatusMetal working apparatusNumerical controlMicroribbon

The invention discloses a vacuum-ultrasonic composite brazing device. The vacuum-ultrasonic composite brazing device comprises a vacuum assembly, an ultrasonic brazing assembly, a computer numerical control (CNC)motion assembly, a heating assembly and a controller, wherein the vacuum assembly comprises a vacuum cover, the CNC motion assembly is connected with the top face of the interior of the vacuum cover, the ultrasonic brazing assembly is connected with the CNC motion assembly, the heating assembly is connected with the bottom face in the vacuum cover, and the controller is connected with the vacuum assembly, the CNC motion assembly, the heating assembly and the ultrasonic brazing assembly. The invention further discloses a brazing method using the method. The vacuum-ultrasonic composite brazing device and method have the beneficial effects that through the ultrasonic degassing effect of the ultrasonic brazing assembly and the vacuum negative pressure in the vacuum cover, high-brazing-penetration-rate and high-strength connection of a microstrip plate on aluminum alloys is efficiently completed under the working condition that scaling powder is not used for the microstrip plate, and high-efficiency, high-reliability and low-cost connection of the microstrip plate on a microwave assembly is realized.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST +1

Reflow-soldering plated-through-hole aluminum-based microstrip plate production process

ActiveCN111586993AImprove joint forceImprove high temperature resistancePrinted element electric connection formationFinal product manufactureScreen printingEtching

The invention discloses a reflow-soldering plated-through-hole aluminum-based microstrip plate production process. The production process sequentially comprises the following steps: blanking, drillingof plated through holes, silk-screen printing of solder resist ink on copper foils, three times of zinc immersion and zinc stripping, chemical plating of multi-element nickel alloy, acid copper plating of a printed board, removal of the silk-screen printing solder resist ink, plasma treatment, hole metallization and full-board copper plating, pattern transfer, pattern copper / nickel gold electroplating, etching, silk-screen printing of solder resist and characters, pasting of a protective adhesive film, secondary drilling, appearance processing and removal of the protective adhesive film; 180-mesh silk screens are adopted for silk-screen printing of the solder resist ink on the copper foils; through pretreatment process of three times of zinc immersion and zinc stripping, the bonding forceof a chemical nickel alloy plating layer and an aluminum base layer is improved; a traditional zinc immersion process is replaced with a chemical multi-element nickel alloy plating process, so that the bonding force between plating layers is enhanced, and the high-temperature resistance of the microstrip plate is improved; and the temperature resistance can reach 300 DEG C, and the requirement ofreflow soldering of the aluminum-based microstrip plate is met.

Owner:SHAANXI LINGYUN ELECTRONICS GROUP

Hard X-ray framing camera and hard X-ray detection method thereof

PendingCN107765506ASimple structureScientific and reasonable designRadiation intensity measurementPhotographyEngineeringMicroribbon

The invention discloses a hard X-ray framing camera and a hard X-ray detection method thereof. The problem that in the prior art, two-dimensional imaging with time resolution capability cannot be carried out on hard X-rays with the energy section range of tens of keV to hundreds of keV is solved. The framing camera comprises a multi-channel hard X-ray detection cathode, a micro-channel plate, a fluorescent screen, a CCD, a pinhole array plate, an electrical control system, a cathode Au micro-strip, a conductive thin layer and a micro-channel plate Au micro-strip. The detection method mainly includes the steps that a target emits hard X-ray pulses to pass through the pinhole array plate, the multi-channel hard X-ray detection cathode, the micro-channel plate and the fluorescent screen, andfinally imaging is conducted on the CCD. The camera is simple in structure, scientific and reasonable in design and convenient to use, and two-dimensional imaging with the time resolution capability can be effectively carried out on the hard X-rays with the energy section range of tens of keV to hundreds of keV.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

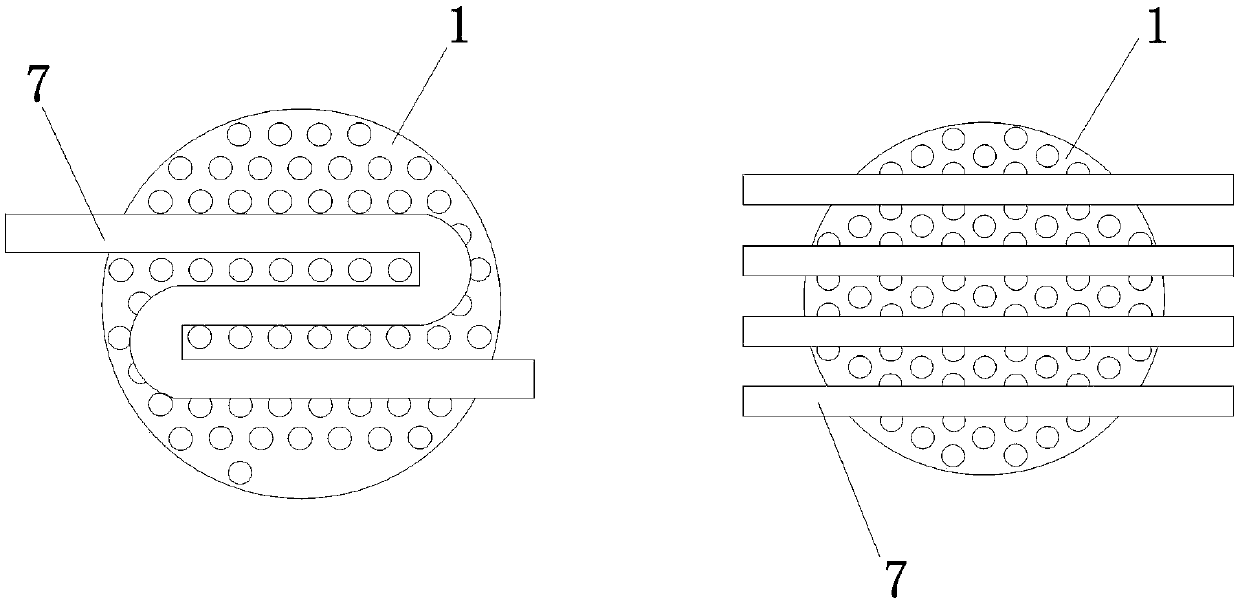

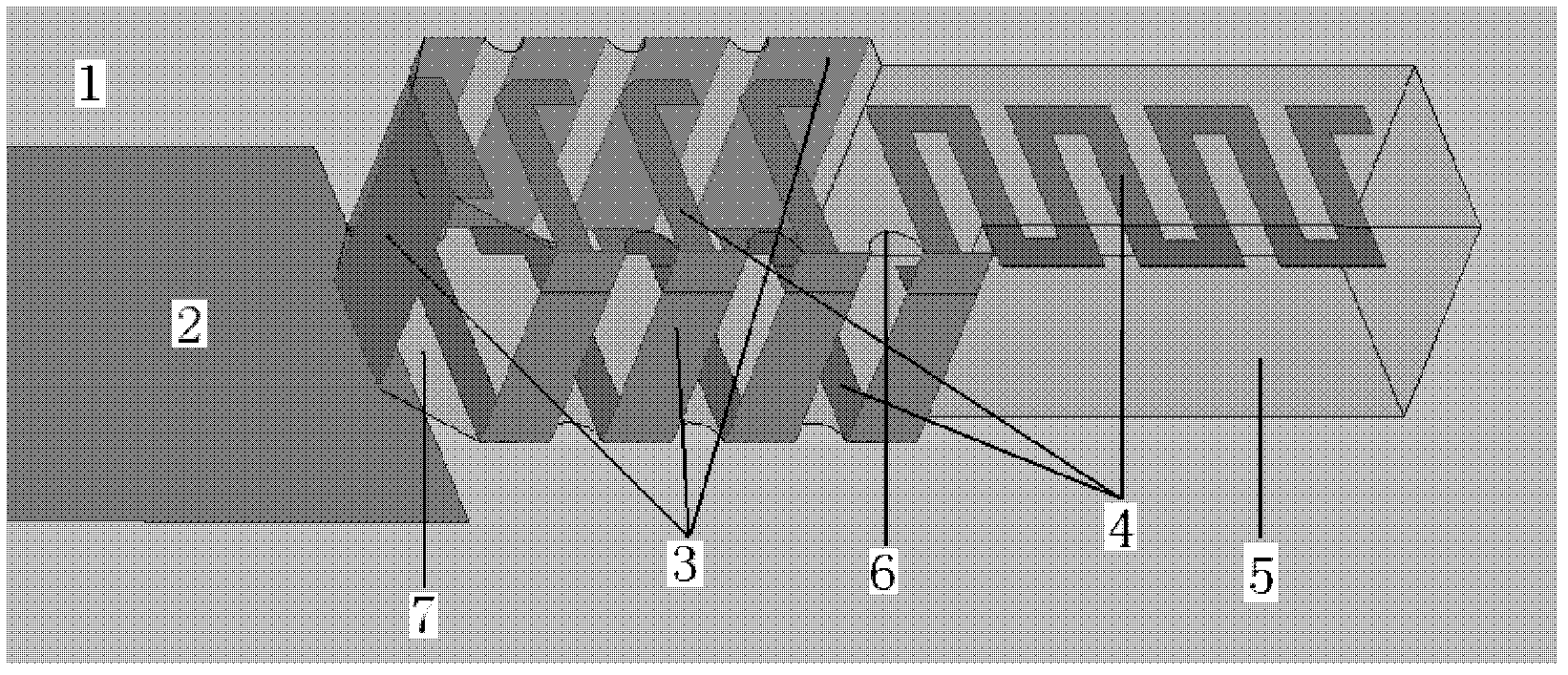

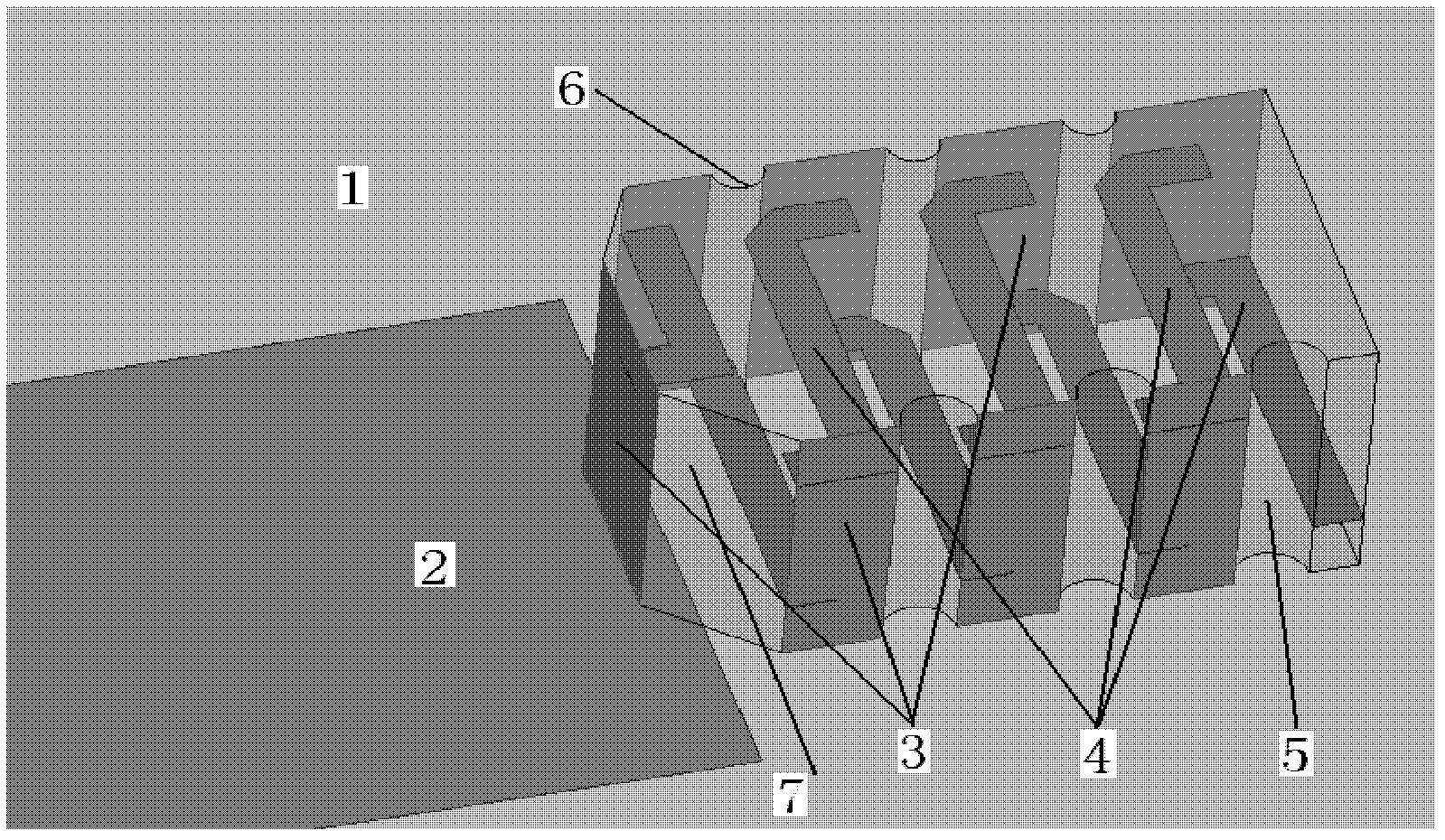

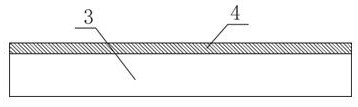

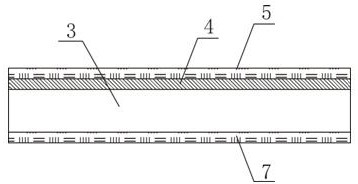

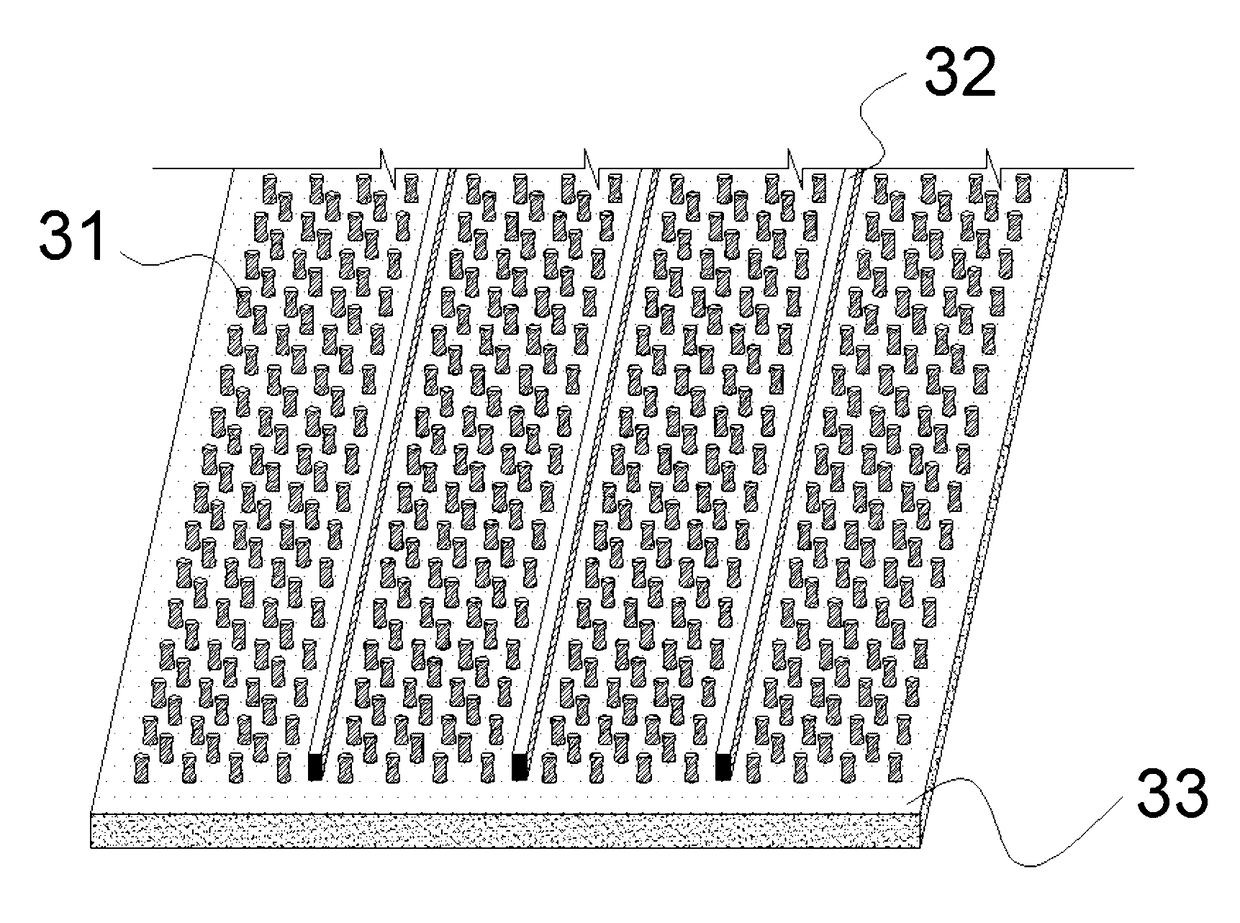

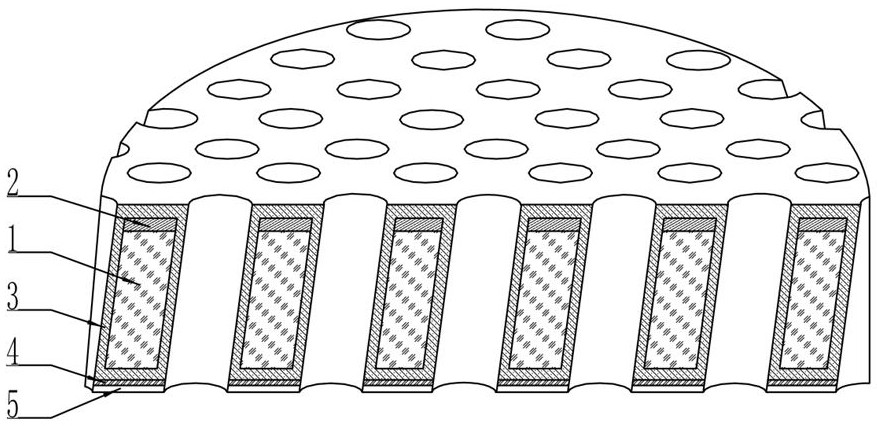

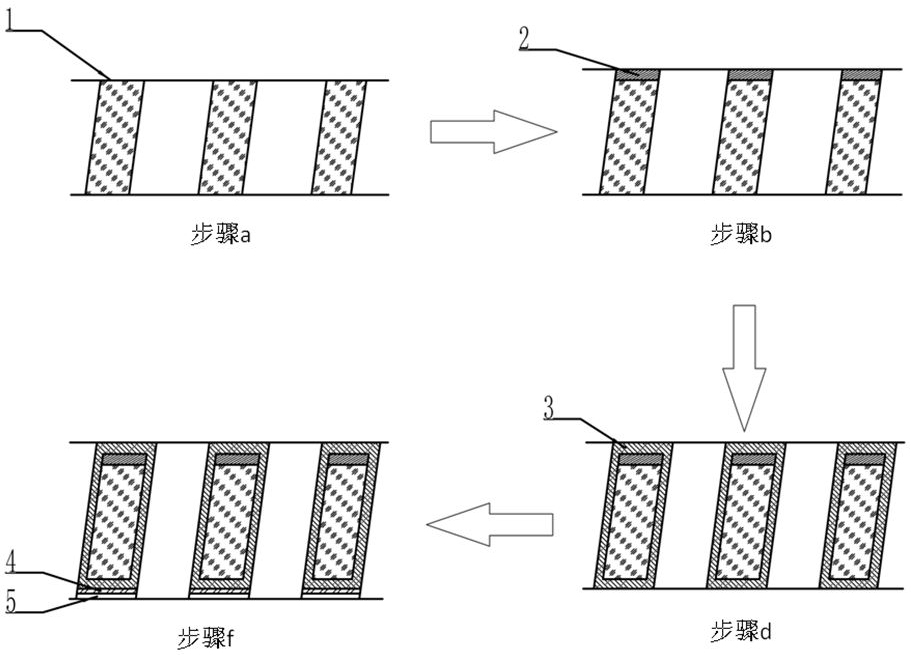

Preparation method of multilayer ceramic antenna

InactiveCN102623799BInterconnectionFirmly connectedRadiating elements structural formsAntennas earthing switches associationElectrical conductorInterconnection

The invention discloses a multilayer ceramic antenna and a preparation method thereof. The ceramic antenna comprises a ceramic medium and multiple layers of radiating conductor belts positioned in the ceramic medium, and is characterized in that the ceramic antenna further comprises peripheral end sealing metal and edge isolating holes, wherein by adopting the edge isolating holes, vertical overlapping parts of the multiple layers of radiating conductor belts protrude from the surface of the ceramic medium; the edge isolating holes are used for isolating adjacent peripheral end sealing metal; and the peripheral end sealing metal is used for interconnecting the multiple layers of radiating conductor belts. The multilayer ceramic antenna disclosed by the invention has the advantages that through the isolating holes and chamfers positioned in appropriate positions of the edge of the periphery of the ceramic medium, the vertical overlapping parts of the multiple layers of radiating conductor belts and the vertical overlapping parts of the multiple layers of radiating conductor belts with an external micro strip feeder line are enabled to protrude from the surface of the ceramic medium and be isolated from each other, and the multiple layers of connectors can be conveniently connected through the end sealing metal, thereby realizing the interconnection among different metal layers under the circumstance that a through-hole is not needed; and besides, a large quantity of ceramic media can be stacked to be edge-punched and chamfered at once.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

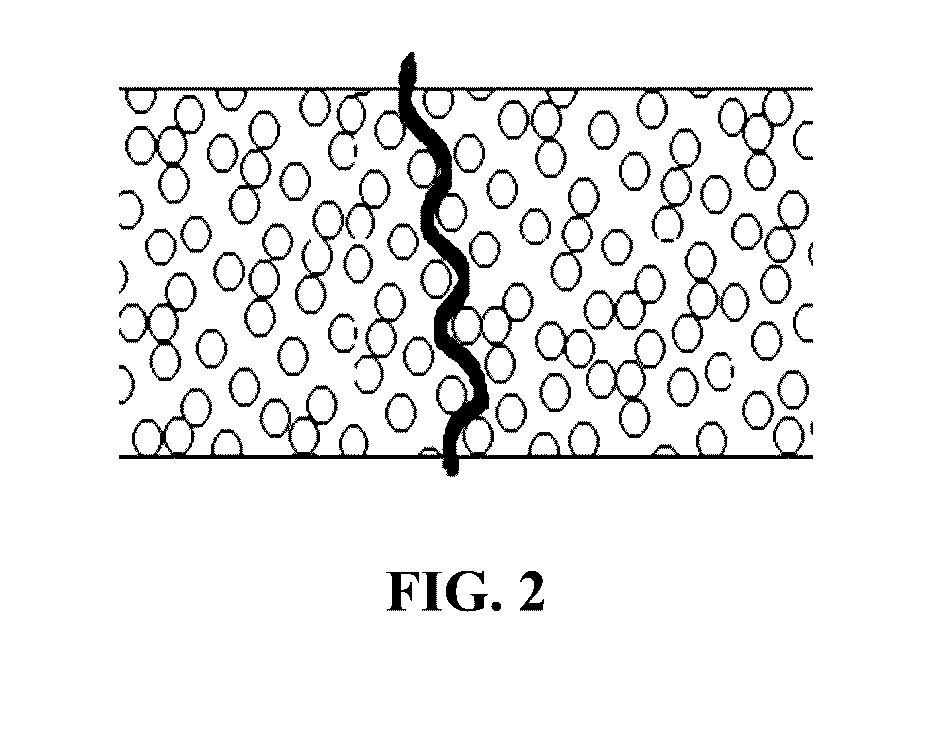

Micro-strip energy collector and broadband fluid energy collector

InactiveCN109428509AIncrease flow rateReduce the difficulty of collectionPiezoelectric/electrostriction/magnetostriction machinesEnergy harvesterEngineering

The invention discloses a micro-strip energy collector, which comprises a fluid inlet, nozzles, flow resistance bodies, miniature cavities, micro-strips and a fluid outlet, wherein the fluid inlet isindependently communicated with the outside and the inlet of each nozzle, and the outlet of each nozzle is communicated with each miniature cavity; the flow resistance bodies are positioned on the positions corresponding to the outlets of the nozzles in the miniature cavities; when fluid enters the miniature cavities through the nozzles and generates a function with the flow resistance bodies, fluttering is generated; the micro-strips are positioned in the miniature cavities, the micro-strips are positioned on one side of a direction where the flow resistance bodies flow along fluid, and keepa set distance with the flow resistance bodies; the fluid outlet is communicated with the inner part and the outer part of each miniature cavity; and the micro-strips are piezoelectric function film materials. By use of the nozzles, the flow rate of the fluid is improved, so that fluid energy collection difficulty is lowered, the flow resistance bodies are added in the inlets of the miniature cavities, so that fluid in the cavities generates vortexes so as to drive the piezoelectric function film materials to generate deformation and generate electric energy.

Owner:青岛因菲尼思微电子科技有限公司

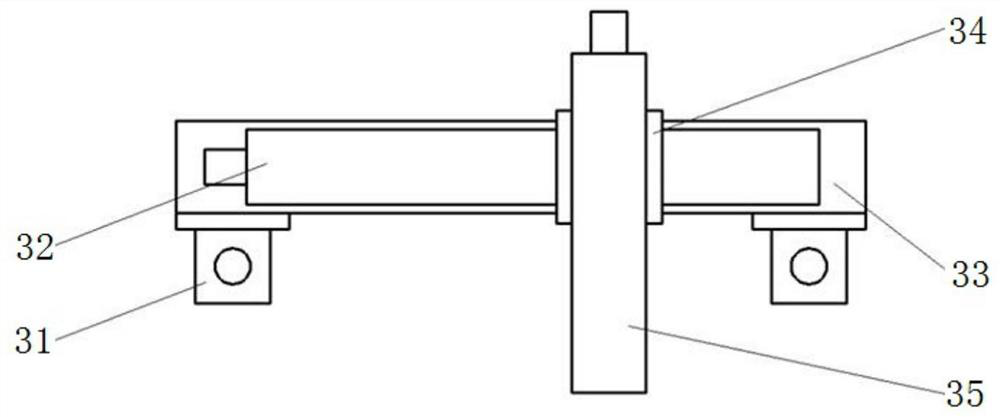

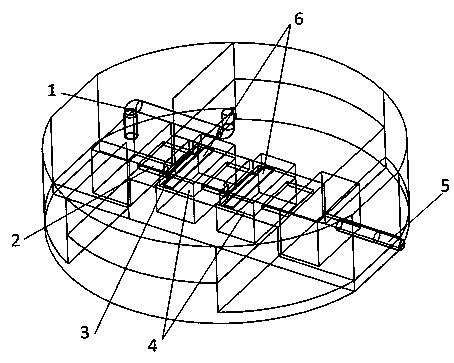

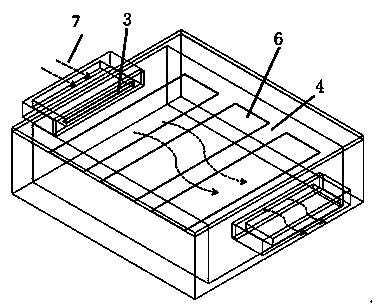

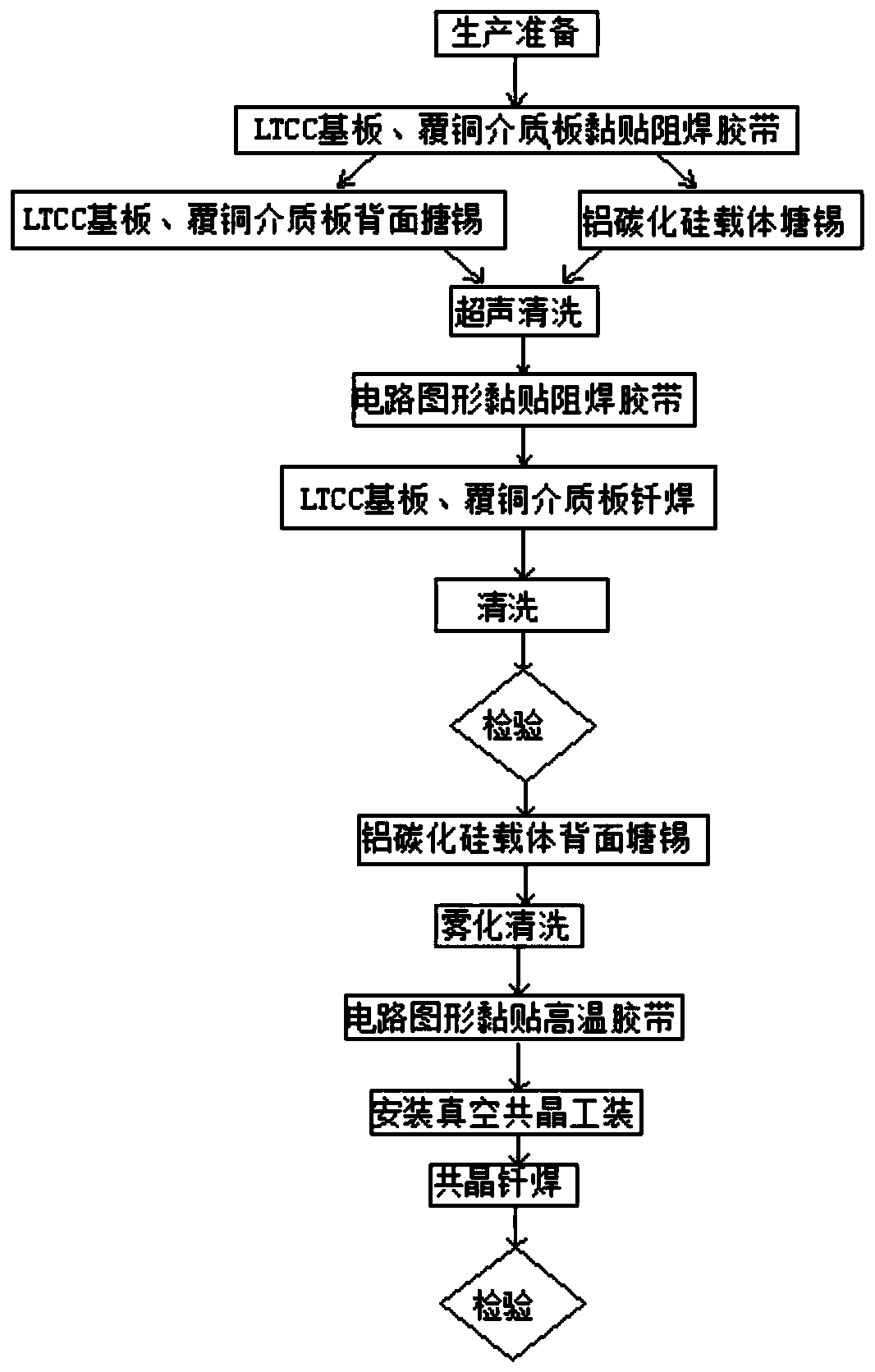

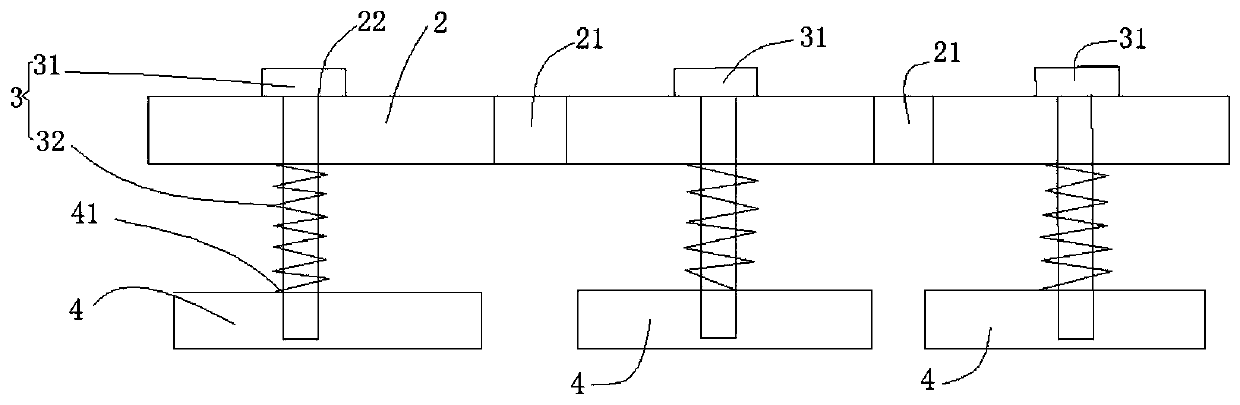

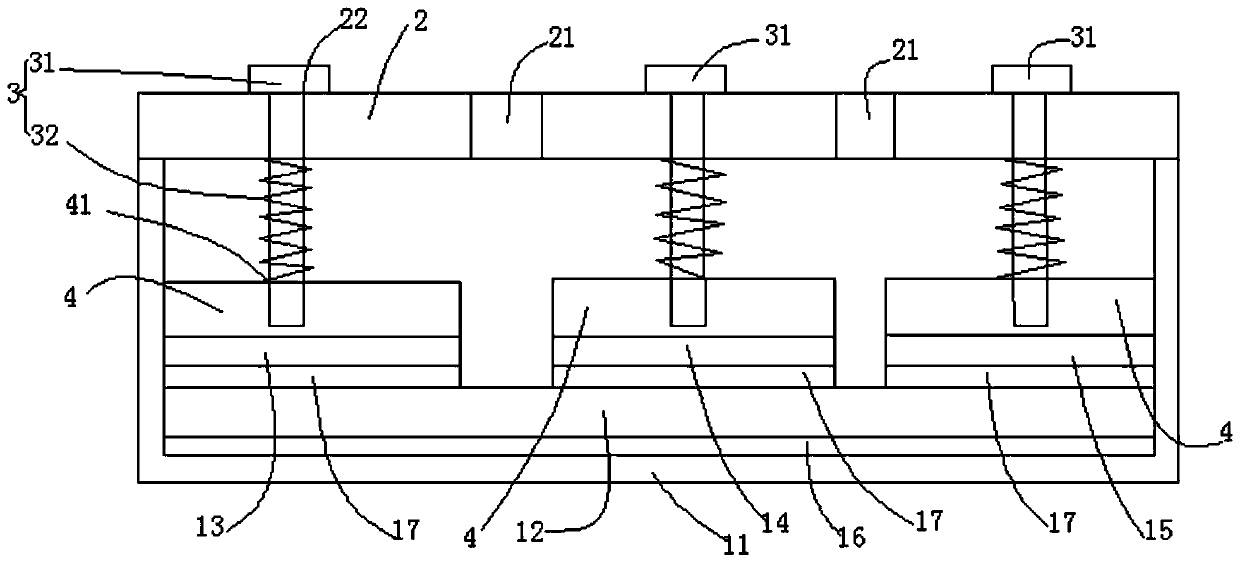

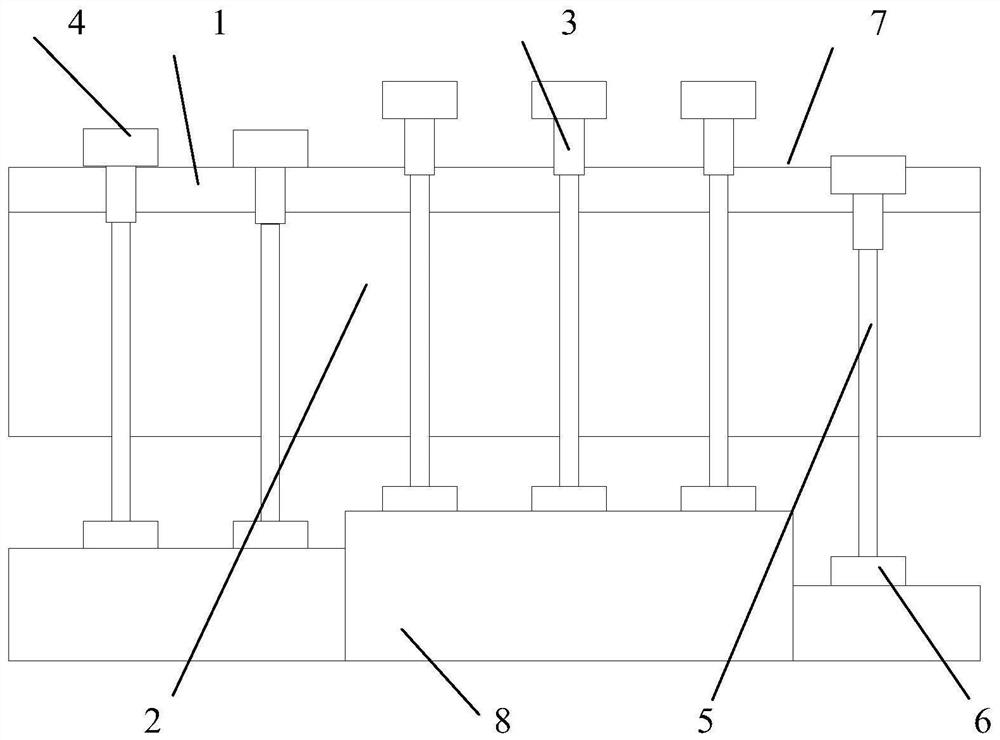

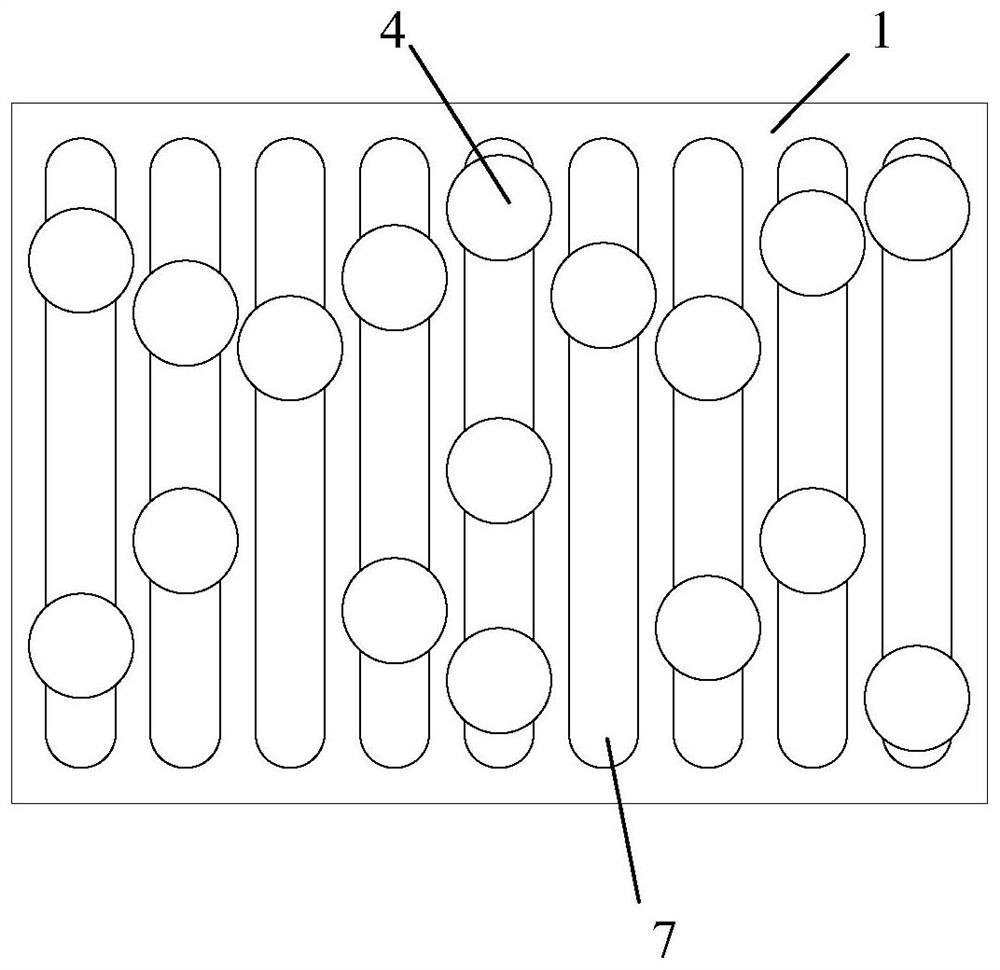

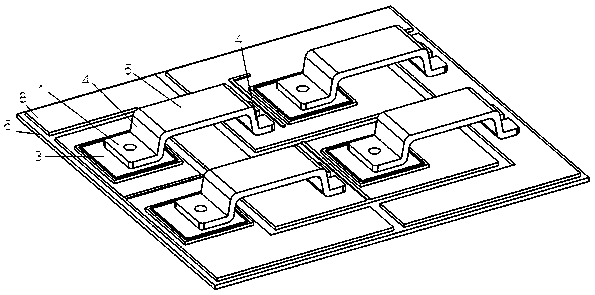

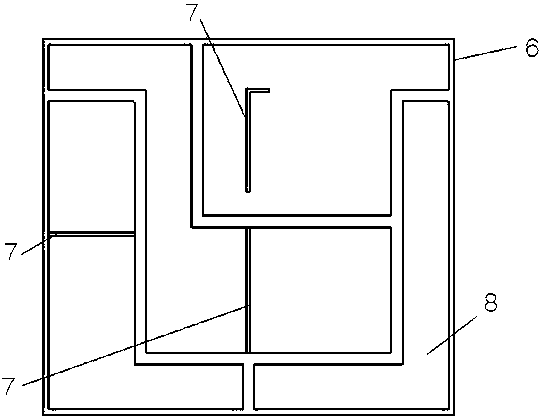

Eutectic brazing fixture and eutectic brazing process for MCM

ActiveCN110587064ASimple structureFacilitates eutectic solderingSoldering auxillary devicesDielectric plateEngineering

The invention discloses a eutectic brazing fixture and eutectic brazing process for an MCM. The eutectic brazing fixture for the MCM is used for applying a uniform pressure on micro-strip sheets, LTCCsubstrates and copper-clad dielectric plates at the upper end of an AlSiC carrier plate in a box body of the MCM separately, and comprises a cover plate arranged at the box opening of the box body ina covering manner, wherein a plurality of press blocks parallel to the cover plate through a plurality of adjustment elements are arranged at one side close to the interior of the box, of the cover plate, and each adjustment element penetrates through the cover plate; moreover, each micro-strip sheet, each LTCC substrate and each copper-clad dielectric plate correspond to one press block separately; each press block adjusts the pressure applied onto the corresponding micro-strip sheet, the corresponding LTCC substrate or the corresponding copper-clad dielectric plate through the adjustment element corresponding to the press block; and a brazing hole penetrating through a position exposed in a manner of corresponding to the upper end of the AlSiC carrier plate in the box body, on the coverplate, is formed in the position. The eutectic brazing fixture for the MCM is simple in structure; and moreover, the uniform and controllable pressure can be applied onto the micro-strip sheets, theLTCC substrates and the copper-clad dielectric plates separately by virtue of the fixture, and layers in the box body are mutually extruded, so that eutectic brazing is facilitated.

Owner:BEIJING INST OF RADIO MEASUREMENT

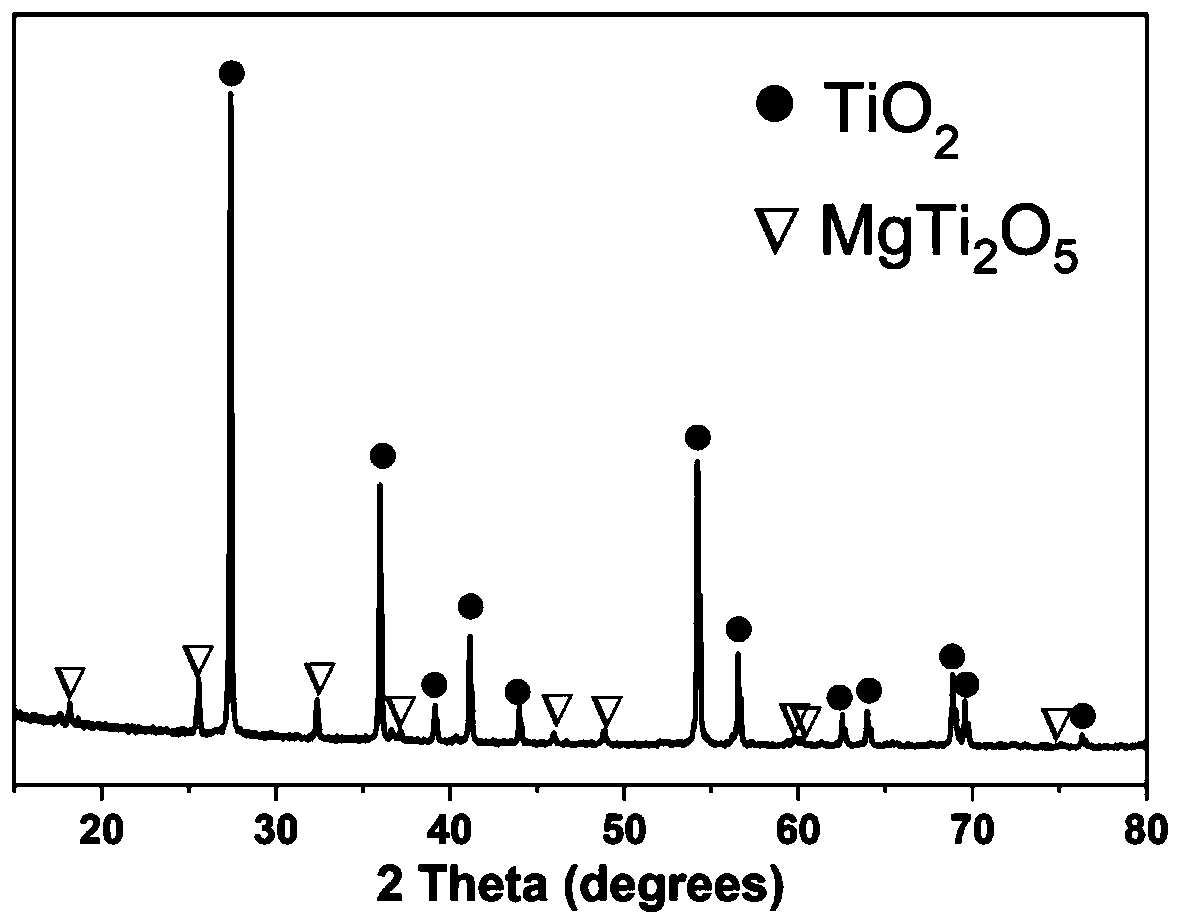

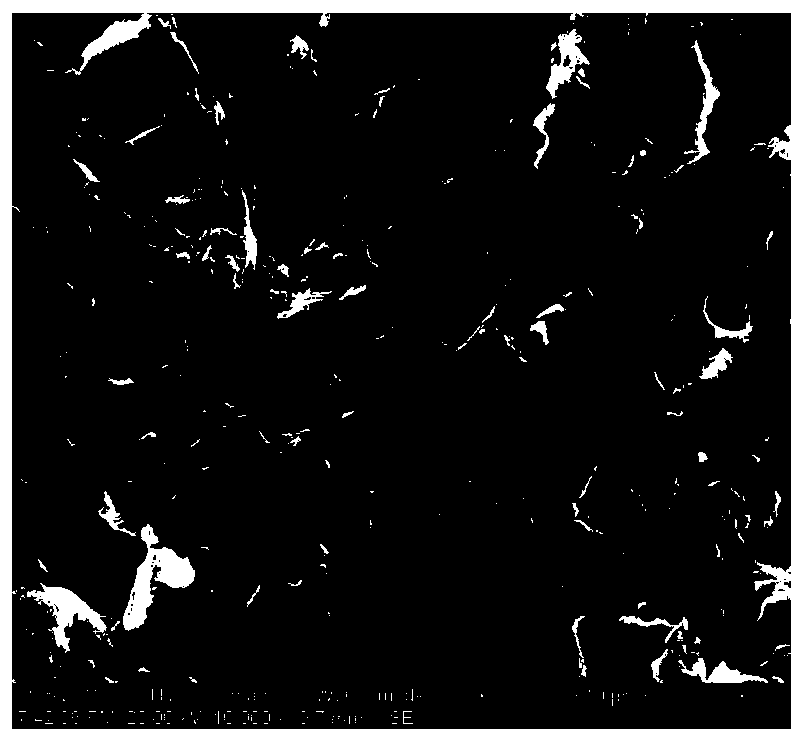

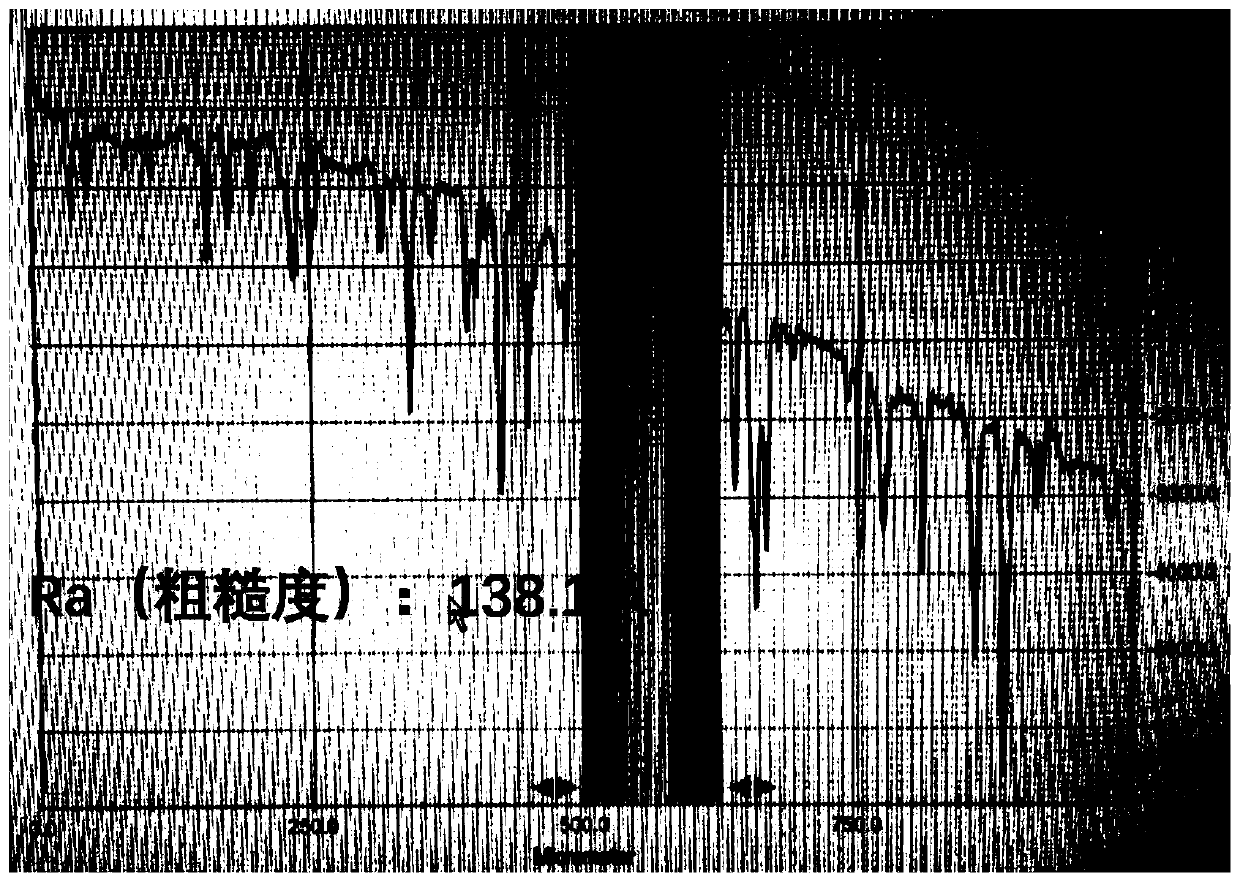

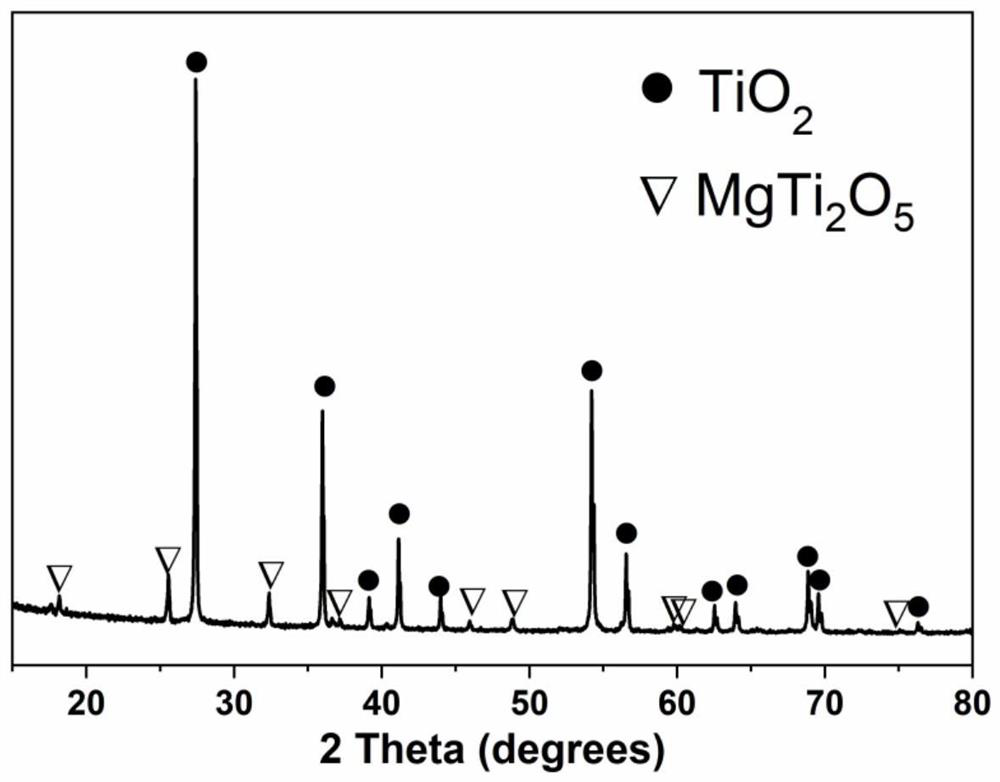

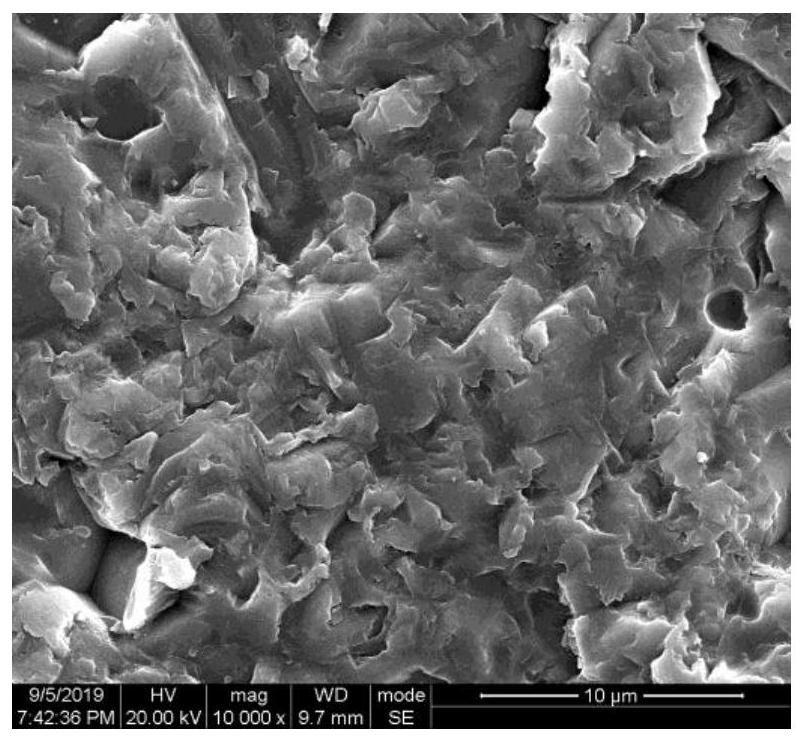

TiO2-based microwave ceramic substrate material and preparation method and application thereof

The invention provides a TiO2-based microwave ceramic substrate material and a preparation method and application thereof. The TiO2-based microwave ceramic substrate material is composed of two crystal phases, namely a ceramic main crystal phase and a second crystal phase, wherein the ceramic main crystal phase is rutile type TiO2, and the second crystal phase is MgTi2O5. Common oxides including ZrO<2>, Nb<2>O<5> and SnO<2> are used as doping agents and enter TiO2 crystal lattices to form a solid solution; and MnCO<3>, CoO, CuO, ZnO and Al<2>O<3> are used as doping agents to play a role in improving the quality factor of the ceramic. The general chemical formula of the material is Ti<1-x>A<x>O<2> + yMgO + zB. The preparation method comprises the steps of burdening, ball milling, granulation, molding and sintering. The TiO2-based microwave ceramic substrate material prepared by the method disclosed by the invention has a relatively high Q*f value (20,000-40,000), a high dielectric constant (80-95) and a series of dielectric constant temperature coefficients (-550 to -900) through laboratory research and tests. The composite ceramic is suitable for manufacturing a substrate materialof a microwave capacitor, and can also be used for manufacturing materials of adjustable microwave devices such as a microstrip filter.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

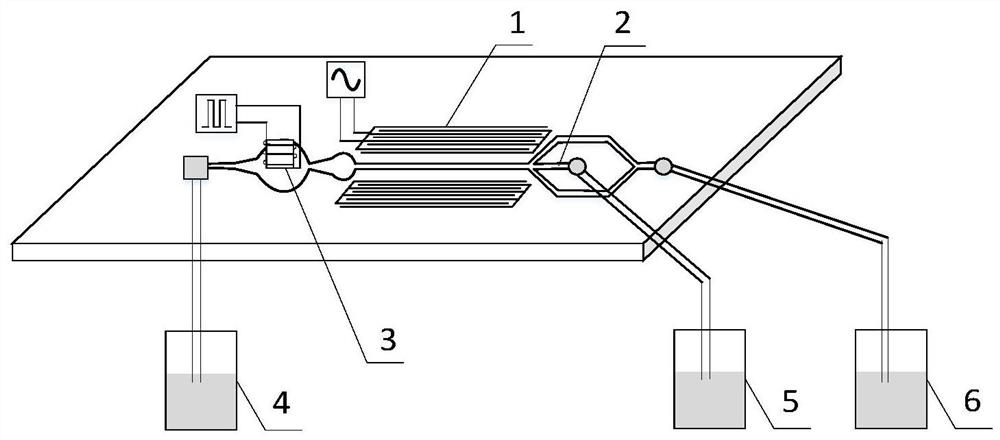

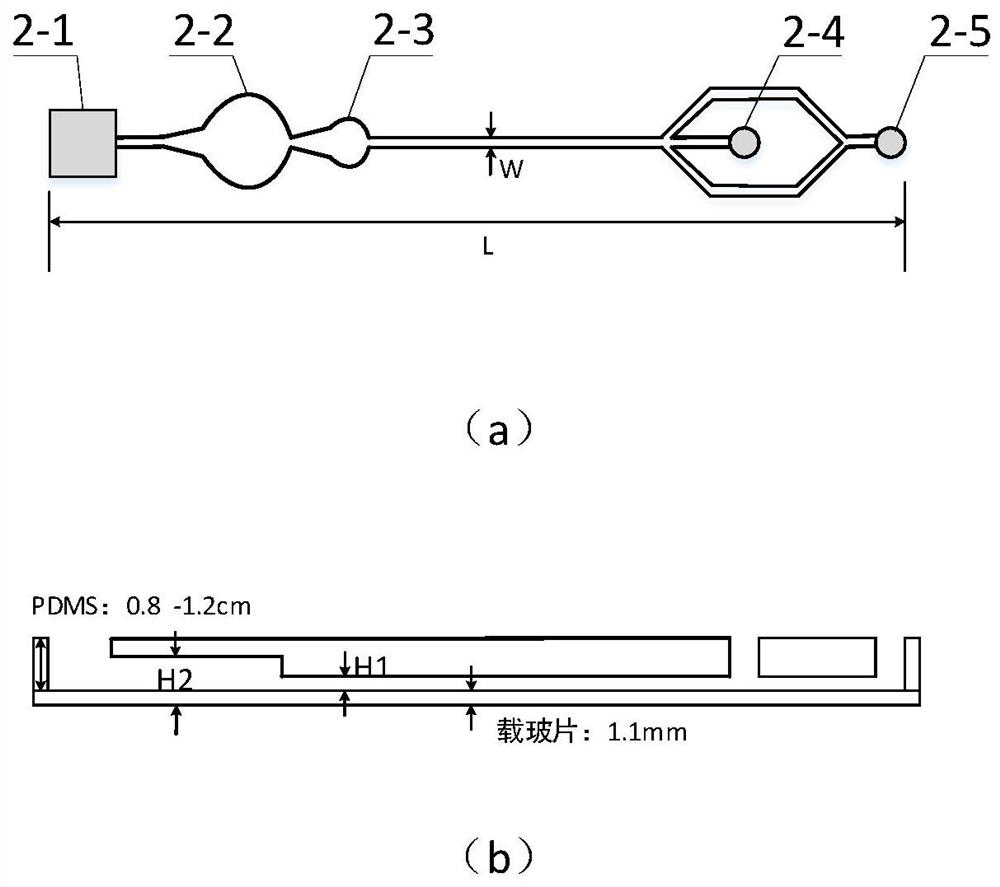

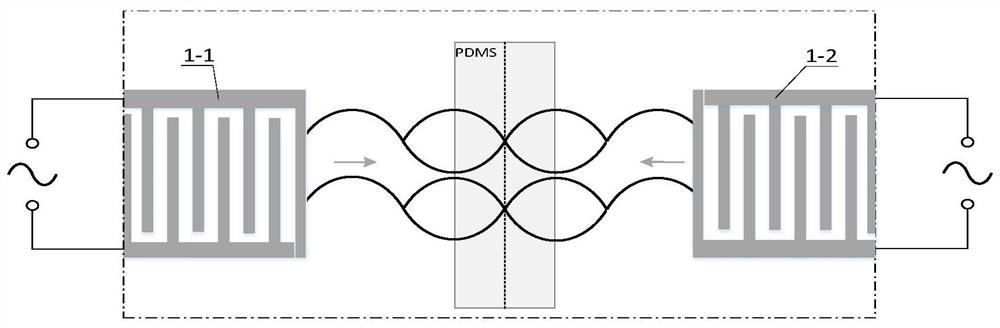

Micro-nano biological particle enrichment and separation device based on acoustophoresis and oscillatory flow effects

The invention relates to a micro-nano biological particle enrichment and separation device based on the acoustophoresis and oscillatory flow effects is ingenious in design, easy to operate, efficient and biologically friendly. A valveless micropump is used for generating oscillatory flow, the design of the oscillatory flow realizes infinite length of a short channel, and acoustic radiation force and inertial lift force are used for driving particles to a narrow enough micro-strip so as to realize enrichment and separation. Compared with single acoustophoresis control, the design has the advantages that the flux is higher, only a shorter straight channel is needed, the sound field intensity is low, and the operation is mild; compared with single inertial control, the design can maintain a lower level of shear stress, can reduce the risk of state change and activity loss of biological particles to a greater extent, and avoids the high-strength manufacturing requirement of a micro-fluidic chip at the same time. The device is simple in structure and high in integration level, can be used for efficient enrichment and separation of rare micro-nano biological particles such as circulating tumor cells and exosomes, and provides a platform for basic medical research and clinical rapid detection application.

Owner:DALIAN UNIV OF TECH

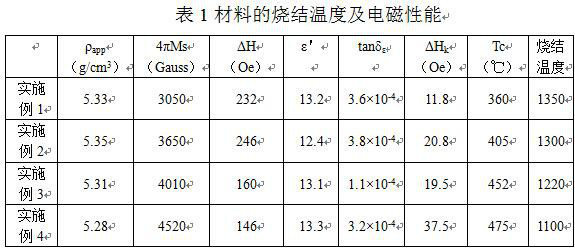

Low-loss spinel microwave ferrite material and preparation method thereof

ActiveCN114702310AWide sintering temperature optional rangeAdjustable power capacityInorganic material magnetismInductances/transformers/magnets manufactureMicrowaveDielectric loss

The invention discloses a low-loss spinel microwave ferrite material and a preparation method thereof, and belongs to the technical field of microwave ferrite materials, the chemical general formula of the low-loss spinel microwave ferrite material is Ni1-a-d + e-gZnaInbDycCodSneMnfCugFe2-b-c-2e-f-deltaO4, 0 < = a < = 0.2, 0 < = b < = 0.3, 0.005 < = c < = 0.02, 0 < = d < = 0.03, 0 < = e < = 0.1, 0 < = f < = 0.1, 0 < = g < = 0.2, delta is iron deficiency, 0 < = delta < = 0.1, 0 < = alpha < = 0.2, 0 < = alpha < = 0.2, 0 < = alpha < = 0.2, 0 < = alpha < = 0.2, 0 < = alpha < = 0.2, 0 < = alpha < = 0.2, 0 The sintering temperature of the spinel NiZn gyromagnetic material is adjustable in the range of 1100-1350 DEG C, the saturation magnetization Ms is in the range of 3000-4500 Gauss, the ferromagnetic resonance line width H is small in the range of 150-250 Oe, the dielectric loss is low, the spin wave line width Hk is adjustable in the range of 10-38 Oe, and the microwave ferrite material has the advantages of being wide in sintering temperature selectable range, small in electromagnetic loss, adjustable in power capacity and the like. The material can be used for compounding and co-firing with dielectric ceramic and garnet with low saturation magnetization to prepare a composite substrate, and the requirements of miniaturization and broadband of microwave devices, especially microstrip devices, are met.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

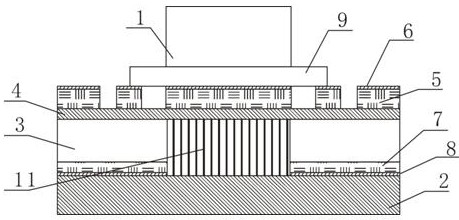

Novel micro-strip circulator based on MEMS technology and processing method thereof

ActiveCN114447552AHigh mechanical strengthMeet strength requirementsTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesDielectric substrateHemt circuits

The novel micro-strip circulator structurally comprises a permanent magnet, a dielectric substrate and an iron bottom plate which are sequentially arranged from top to bottom, the dielectric substrate comprises a silicon wafer, a polyimide film, an upper Cr / Au double-layer film and an upper Au plating layer are sequentially arranged on the upper surface of the silicon wafer, an upper surface circuit is etched on the upper Cr / Au double-layer film, and a lower surface circuit is etched on the lower Cr / Au double-layer film. The upper Au-plated layer is bonded with the permanent magnet through the ceramic substrate; a lower Cr / Au double-layer film is arranged on the lower surface of the silicon wafer, a lower surface circuit is etched on the lower Cr / Au double-layer film, a ferrite groove is further etched in the middle of the silicon wafer, and a lower Au plating layer is further arranged below the lower surface circuit. According to the novel structure and the processing method provided by the invention, two silicon wafers are not needed, wafer-level metal bonding is not needed, the process steps, the complexity and the cost of the circulator can be effectively reduced, the process redundancy is reduced, the size of the device can be reduced, and the development requirement of miniaturization is met.

Owner:SOUTHWEST INST OF APPLIED MAGNETICS

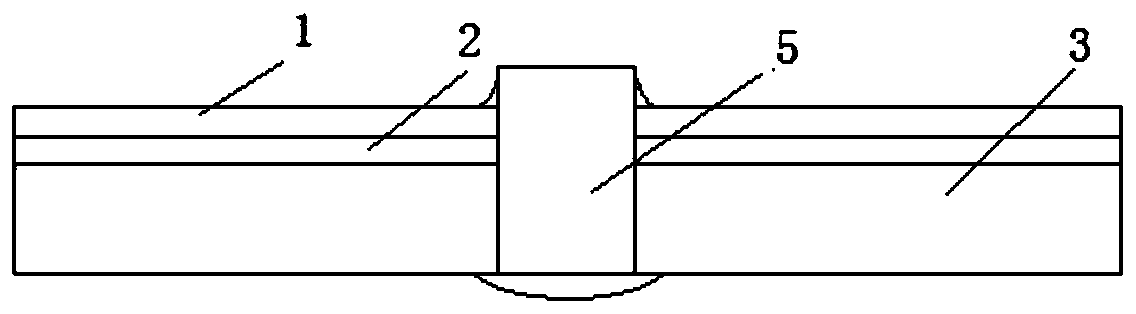

Welding method for microstrip substrate of stepped structure

PendingCN112917039AMeet the requirements of weldingMeet the use requirementsWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMicroribbon

The invention discloses a welding method for a microstrip substrate of a stepped structure, the welding voidage of the microstrip substrate can be reduced, and the microstrip substrate is prevented from warping in the welding process. According to the technical scheme, the welding method comprises the steps that array parallel sliding grooves are designed in a welding tool template, a manual knob adjuster is arranged at one end of each screw of a dumbbell-shaped pressurizing rod and a pressing block controlled to stretch out and retract back in the vertical direction through each screw is designed at the other end of the screw according to the actual assembly position of a stepped microstrip substrate, when combination and installation with a welding tool are carried out, each screw penetrates through a pressing cavity and moves along the corresponding step surface of the step-shaped microstrip substrate, the manual knob adjusters clamp the step-shaped microstrip substrate below the pressing blocks, and each manual knob adjuster presses a step area at each position on the step-shaped microstrip substrate, the step-shaped microstrip substrate is put into vacuum welding equipment, the step-shaped microstrip substrate is welded, and a corresponding welding curve is loaded to complete the welding of the micro-strip substrate.

Owner:10TH RES INST OF CETC

Micro-band electrode

InactiveUS7972487B2Increase surface areaSmall surface areaImmobilised enzymesBioreactor/fermenter combinationsElectricityElectrochemical cell

The invention concerns an electrochemical cell which, either alone or together which a substrate onto which it is placed, is in the form of a receptacle. The electrochemical cell contains a working electrode and a counter electrode, the working electrode being in a wall of the receptacle. At least one of the electrodes has at least one dimension of less than 50 μm. The electrochemical cell is principally intended for use as a micro-electrode suitable for screening water, blood, urine or other biological or non-biological fluids.

Owner:ROCHE DIABETES CARE INC +1

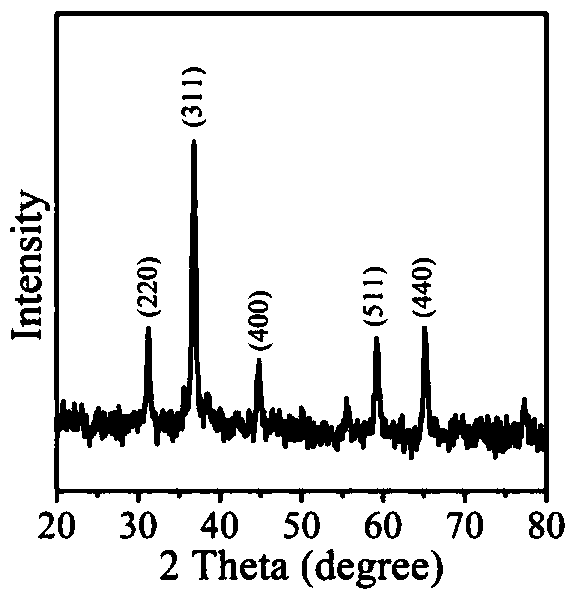

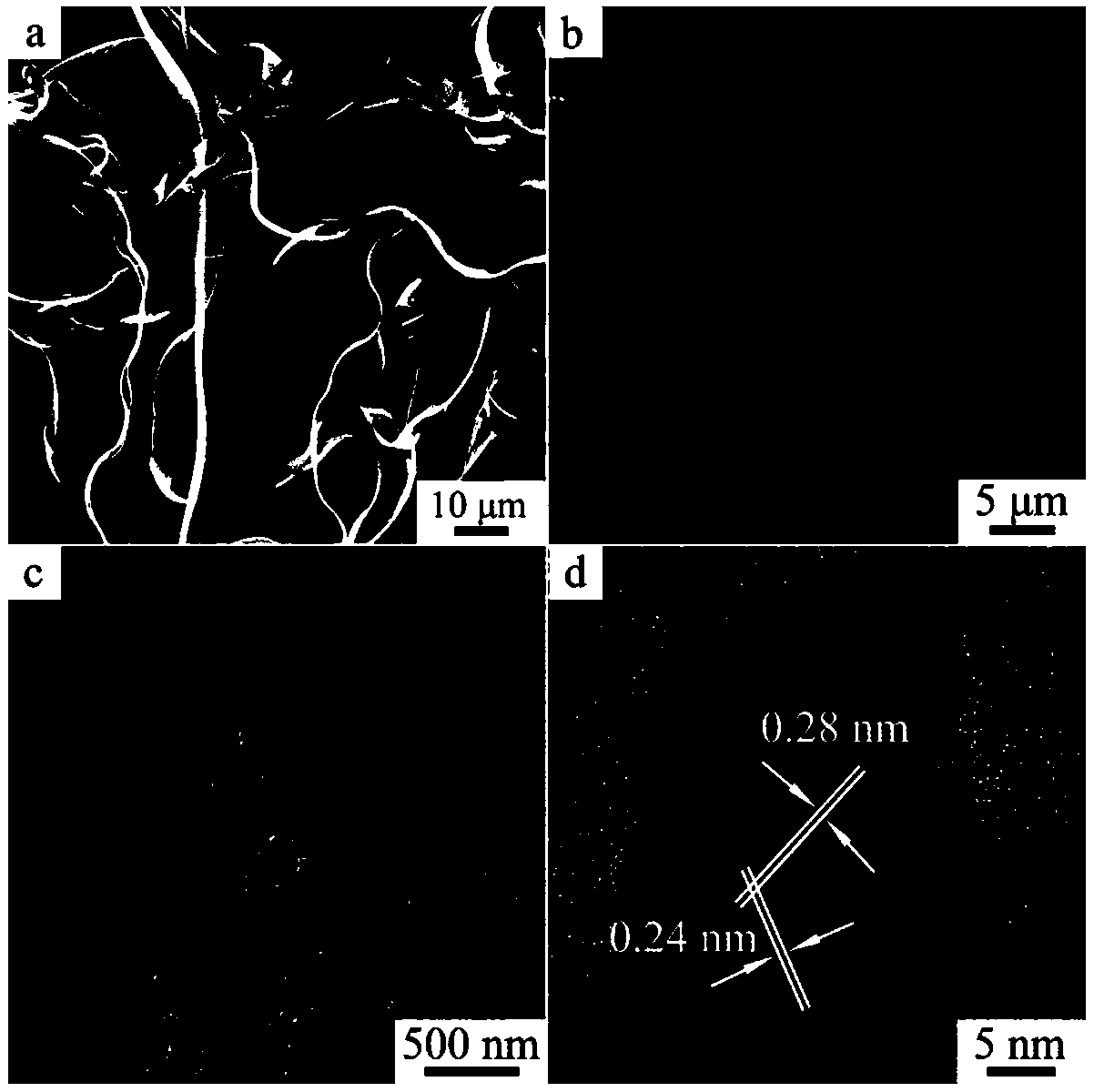

Cobalt tetroxide microbelt with high peroxidase-like activity and stability and preparation method thereof

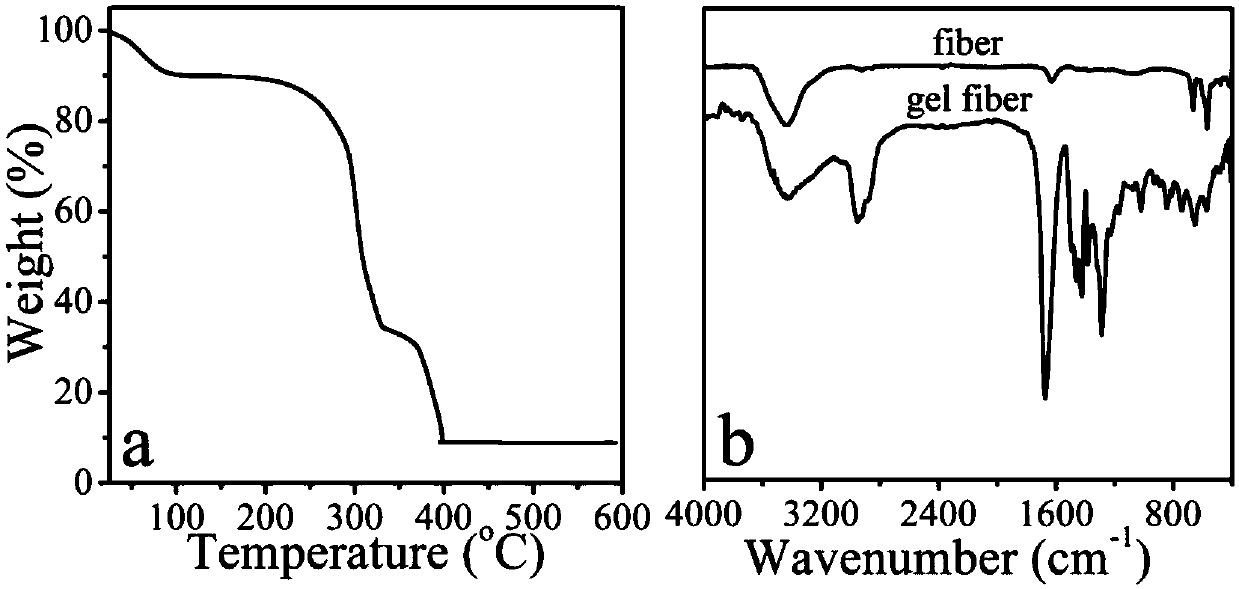

ActiveCN106111140BHigh purityEasy to operateCatalyst activation/preparationColor/spectral properties measurementsFiberCobalt(II,III) oxide

Owner:山东中酶生物科技有限公司

A full bridge circuit and fast recovery diode

ActiveCN107799506BImprove cooling effectWon't breakSemiconductor/solid-state device detailsSolid-state devicesDriving currentFull bridge

The invention relates to a full-bridge circuit and a fast recovery diode, which solves the technical problem of bearing a small driving current. By adopting the full-bridge circuit, the ceramic substrate is provided with a copper-clad microstrip and a chip, and a copper-clad microstrip There is a copper bridge for connection between the strip and the chip. One end of the copper bridge is connected to the chip, and the other end is connected to the copper clad microstrip. The contact between the two ends of the copper bridge and the chip or the copper clad microstrip is the lead foot mechanism; the copper connecting bridge is not in contact with the corresponding chip and is divided into a suspension mechanism, and the technical solution of the hollow space between the suspension mechanism and the ceramic substrate solves this problem better and can be used in semiconductor module packaging.

Owner:南京晟芯半导体有限公司

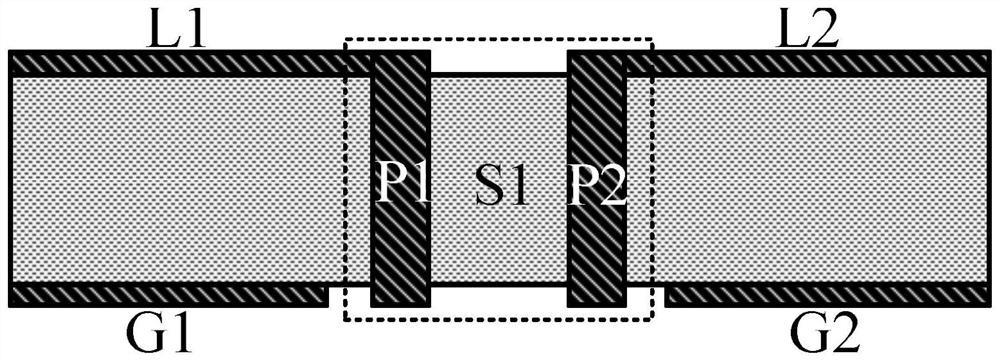

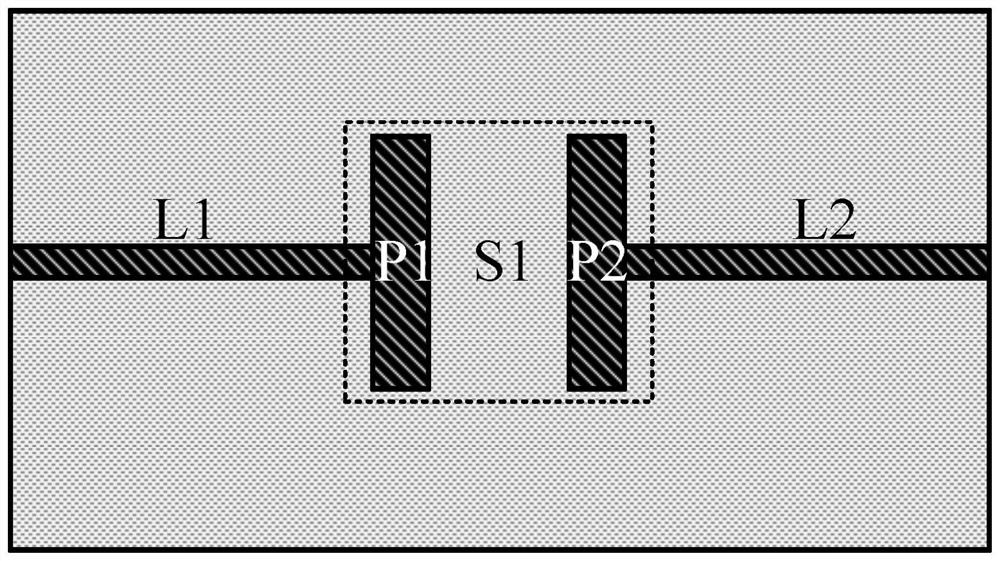

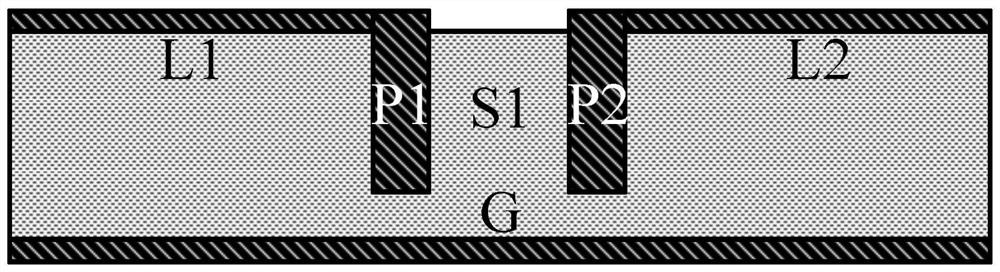

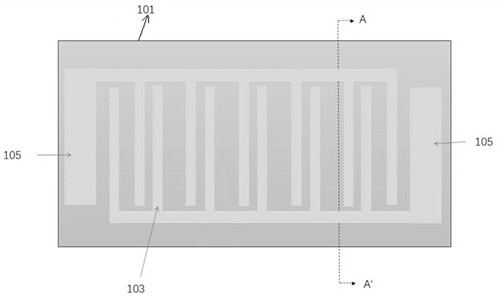

Vertically-arranged MSM capacitor structure and manufacturing method thereof

ActiveCN114566490AOvercoming the inability to integrate 3D integrationOvercome sizeSemiconductor/solid-state device detailsSolid-state devicesCapacitanceDielectric substrate

The vertically-arranged MSM capacitor structure and the manufacturing method thereof disclosed by the invention can be applied to various semiconductor integration / packaging structures with small and medium capacitance values and miniaturization requirements. The structure comprises two flat metalized through grooves or blind grooves inserted into a semiconductor dielectric substrate, and the two flat metalized through grooves, blind grooves or buried grooves which are perpendicular to the surface of the semiconductor dielectric substrate and are separated by a dielectric partition wall S1 are formed in specific positions of the semiconductor dielectric substrate. A dielectric partition wall of a vertically-arranged MSM capacitor structure is perpendicular to the upper surface and the lower surface of the semiconductor dielectric substrate to form a dielectric layer of the capacitor. Two parallel rectangular through grooves, blind grooves or buried grooves are embedded with metal electrode plates P1 and P2 which form homoepitaxy of a capacitor body, and the two metal electrode plates extend to two ends of a dielectric partition wall S1 through a metal layer microstrip connecting line etched on the surface of a semiconductor dielectric substrate to form an electrode structure led out from leading-out ends L1 and L2 of the MSM capacitor. Therefore, a vertically-arranged MSM capacitor equivalent circuit structure is formed.

Owner:10TH RES INST OF CETC

Micropatterned structures for forming a seal with the face skin and other surfaces and method of make

ActiveUS9605181B2Good contact/sealIncrease frictionFilm/foil adhesivesThin material handlingFiberAdhesive

The present invention is directed towards an article suitable for attachment to facial skin or other surfaces, which comprises microfibrils and continuous microribbons. The article provides good sealing when used on a regular skin, and on a challenge skin surface with facial hair, sweat and acnes. The article also provides good adhesion and sealing on any other rough surfaces, and can be used repeatedly against different surfaces. These dry adhesives can be used for improving sealing of mask respirators, swimming goggles, or for other applications such as medical bandage, working gloves, and protective clothing seal.

Owner:METNA

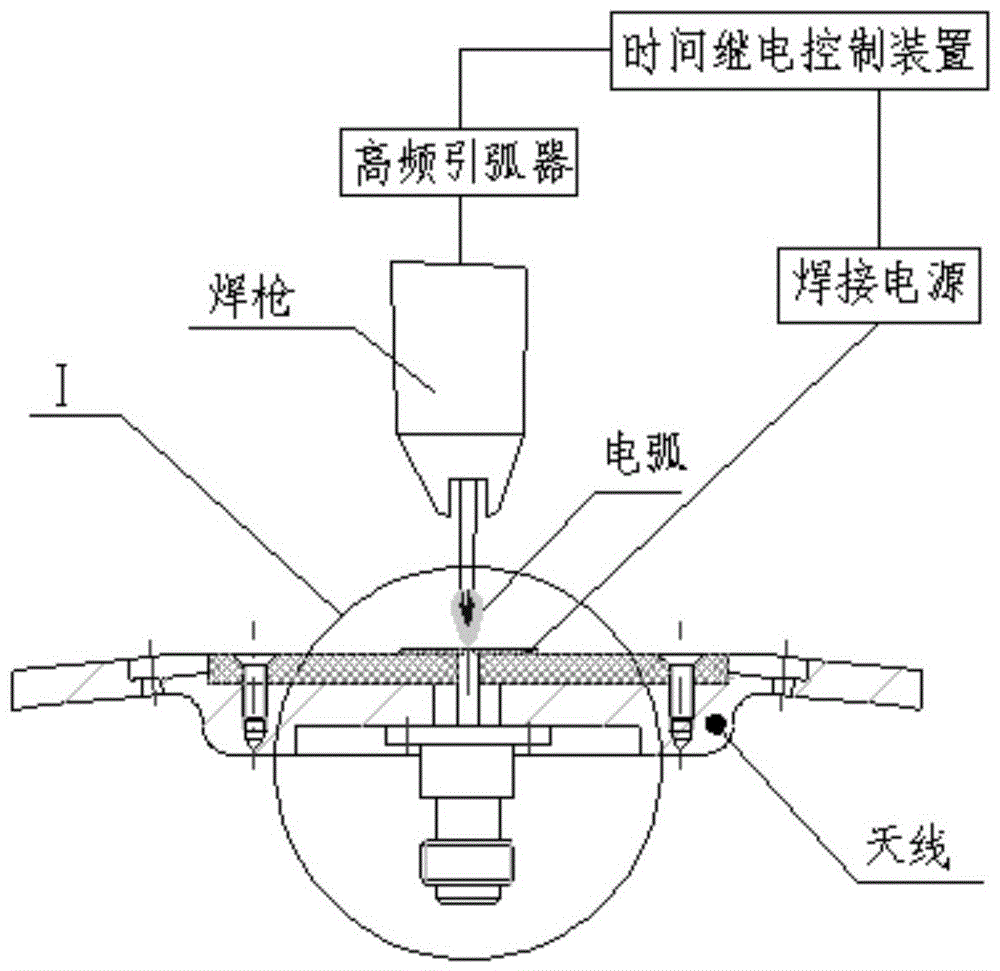

Welding method and welding system for angle measuring antenna

ActiveCN104259630BControl welding heat inputThe process is simple and reliableArc welding apparatusWelding power supplyEngineering

The invention provides a welding method and a welding system of an angle measuring antenna. The welding method comprises the steps of forming a round hole in the center of a circular red copper foil, forming a step matched with the round hole on the kovar alloy micro-strip end of a connector, and then assembling the kovar alloy micro-strip end of the connector with the center of the circular red copper foil by use of the step and the round hole and welding by use of an argon tungsten-arc welding method; the welding method comprises a welding time relay control device, an argon tungsten-arc welding power source, a welding gun and an argon bottle; the argon tungsten-arc welding power source is used for controlling the high-frequency arc starter of the welding gun by use of the welding time relay control device; the welding gun is communicated with the argon bottle. The welding method and the welding system of the angle measuring antenna have the advantages that the welding quality meets the design requirements, a welded metal and a composite material are not damaged, the process is simple and reliable, mass production operations can be realized, and the equipment operating cost is low.

Owner:NO 20 RES INST OF CHINA ELECTRONICS TECH GRP

A framing camera photocathode based on inorganic perovskite and its preparation method

ActiveCN109801821BThe preparation method is simple and easyReduce manufacturing costSecondary and photo emission cathodePhoto-emissive cathodes manufactureMetallic electrodePhotocathode

The invention discloses a framing camera photocathode based on inorganic perovskite and a preparation method thereof. The photocathode is composed of microchannel plate MCP, metal microstrip, inorganic perovskite CsPbI 3 Composed of a photocathode, a metal electrode and an electrode protective film; the preparation method of the photocathode is as follows: clean the MCP, plate a metal microstrip on the upper surface of the MCP, and then put the MCP into the CsPbI 3 Heating in the solution forms a deposited layer of CsPbI on the upper surface of the metal microstrip and the inner wall of the MCP microchannel. 3 After the thin film, the MCP is taken out and dried, and finally the metal electrode and the electrode protection film are sequentially plated on the lower surface of the MCP, that is, the preparation of the photocathode of the framing camera based on the inorganic perovskite is completed. The photocathode is based on the inorganic perovskite CsPbI 3 As a photoelectric conversion material, it has high response sensitivity from visible light to X-rays. CsPbI 3 It has good stability in the atmospheric environment, and does not need to be packaged with the framing camera as a whole in vacuum, which reduces the difficulty and cost of preparation.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

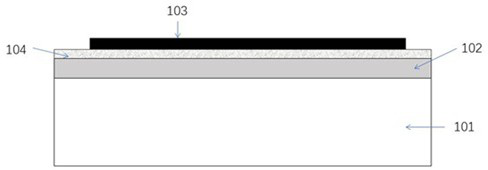

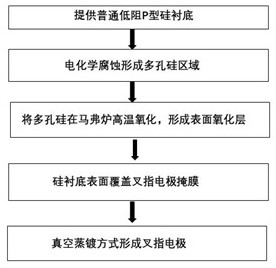

Silicon-based interdigital electrode based on porous silicon, and manufacturing method of silicon-based interdigital electrode

ActiveCN112255287AImprove electrical performanceReduce manufacturing costFinal product manufactureVacuum evaporation coatingSilicon oxideMicroribbon

The invention discloses a silicon-based interdigital electrode based on porous silicon, and a manufacturing method of the silicon-based interdigital electrode. The silicon-based interdigital electrodecomprises a silicon substrate, a porous silicon layer, a gold microstrip interdigital electrode, a silicon oxide layer and input / output interfaces, wherein the porous silicon layer is located above the silicon substrate, and is matched with the gold microstrip interdigital electrode in shape, the silicon oxide layer is located between the porous silicon layer and the gold microstrip interdigitalelectrode, and the two ends of the gold microstrip interdigital electrode are provided with input / output interfaces. According to the invention, common low-resistance P-type silicon is used as a substrate so as to effectively reduce the preparation cost of the device, and the prepared porous silicon structure can significantly improve the surface roughness and the surface-to-surface ratio of the device so as to improve the electrical properties of the electrode; and the manufacturing cost is also reduced.

Owner:ZUNYI NORMAL COLLEGE

Protection method of magnesium alloy workpiece for marine environment

PendingCN114525509AImprove pass rateImprove quality consistencyAnodisationPretreated surfacesMetal coatingMicro arc oxidation

The invention discloses a protection method of a magnesium alloy workpiece for a marine environment, which adopts double-layer protection of an inner layer and an outer layer, and comprises the steps of micro-arc oxidation, conductive paint coating, baking and curing, alkaline chemical nickel plating, acidic chemical nickel plating, sealing and drying, the inner layer adopts a micro-arc oxidation film which is firmly combined with a matrix, and the outer layer adopts a micro-arc oxidation film which is firmly combined with the matrix; the outer layer adopts double-layer nickel plating of a bottom plating layer and a surface plating layer, the bottom plating layer adopts alkaline chemical nickel plating and is plated on the inner layer, the combination is firm, the surface plating layer adopts acid chemical nickel plating and is plated on the bottom plating layer, sealing treatment is performed, the porosity is reduced, the surface is compact, and the finished product is silver gray in appearance, slightly yellow, high in percent of pass, good in quality consistency and free of bubbling or layering phenomenon; through a 200 DEG C thermal shock test, the magnesium alloy micro-arc oxidation film is continuous, uniform, complete and free of pulverization, looseness and scratches, through a 672 h neutral salt spray test, the protection grade Rp is not lower than 9 grade, and the technical bottleneck that the magnesium alloy micro-arc oxidation film is difficult to be plated with a metal coating is broken through.

Owner:CHINA ELECTRONICS TECH GRP CORP NO 14 RES INST

tio 2 Microwave-based ceramic substrate material, preparation method and application

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com