Novel micro-strip circulator based on MEMS technology and processing method thereof

A processing method and a technology of a circulator, which are applied in the process for producing decorative surface effects, waveguide devices, metal material coating processes, etc., can solve problems such as high cost and complicated process, and achieve the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

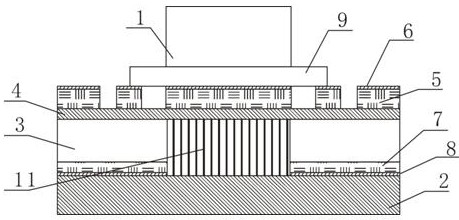

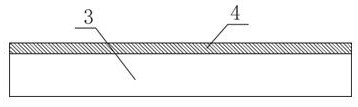

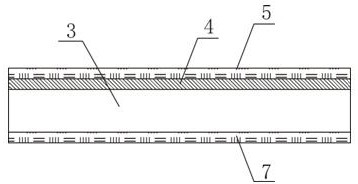

[0054] Embodiment 1: see Figure 1-Figure 6 , a new microstrip circulator based on MEMS technology, including a permanent magnet 1, a dielectric substrate, and an iron substrate 2 arranged in sequence from top to bottom, the dielectric substrate includes a silicon wafer 3 arranged horizontally, and the silicon wafer 3 The upper surface is provided with a polyimide film 4;

[0055] The upper surface of the polyimide film 4 is provided with an upper Cr / Au double-layer film 5, the upper surface circuit is etched on the upper Cr / Au double-layer film 5, and an upper Au plating layer 6 is arranged on the upper surface circuit. Au layer 6 is bonded to permanent magnet 1 through ceramic substrate 9;

[0056] The lower surface of the silicon wafer 3 is also provided with a lower Cr / Au double-layer film 7, and the lower surface circuit is etched on the lower Cr / Au double-layer film 7, and a ferrite groove 10 is also etched in the middle of the silicon wafer 3. Both ends of the ferrite...

Embodiment 2

[0079] Example 2: see Figure 1 to Figure 6 , on the basis of Example 1, we prepared a 5~13GHz microstrip circulator, the best insertion loss is 0.7dB, which matches the design result. Due to the nested structure of the broadband microstrip circulator prepared by this technology, the ferrite magnetization is more uniform than the traditional microstrip circulator, and has better low field loss. Compared with the traditional microstrip circulator in the broadband microstrip circulator devices have clear advantages.

[0080] The thickness of the microstrip circulator prepared by this method is 0.2mm smaller than that of traditional silicon-based MEMS, which reduces the size of the device and meets the development needs of miniaturization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com