A full bridge circuit and fast recovery diode

A full-bridge circuit and bridge-connecting technology, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of complex manufacturing process, heat accumulation at connections, short-circuit operation, etc., to save space requirements and costs, reduce difficulty and complexity, reducing the undesirable effects of open and short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

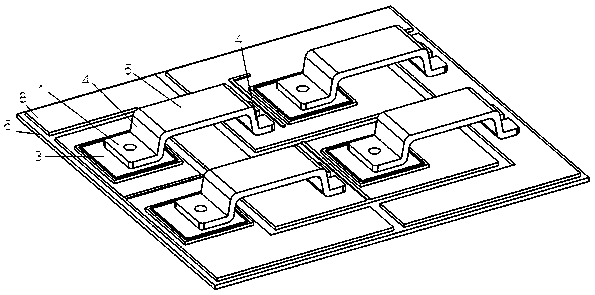

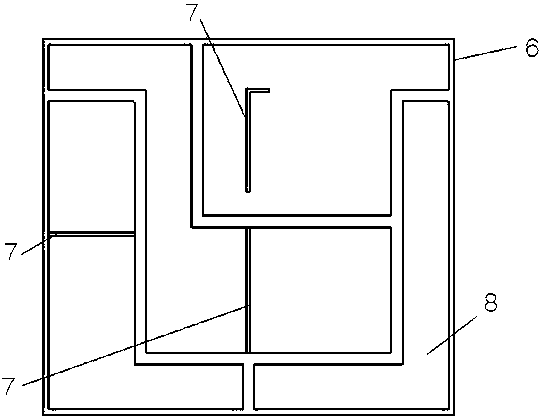

[0030] This embodiment provides a full bridge circuit, such as figure 1 , the full-bridge circuit includes a ceramic substrate 6, a copper-clad microstrip 8 and a chip 3 are provided on the ceramic substrate 6, and a copper bridge for connection is provided between the copper-clad microstrip 8 and the chip 3, and the copper bridge One end is connected to the chip 3, and the other end is connected to the copper-clad microstrip 8. The contact between the two ends of the copper bridge and the chip 3 or the copper-clad microstrip 8 is the pin mechanism 1; the copper bridge is not connected to the corresponding chip 3. The contact mechanism is divided into a suspension mechanism, and the space between the suspension mechanism and the ceramic substrate 6 is hollow.

[0031] In this embodiment: the copper connecting bridge is used to replace the connection of the aluminum wires. Compared with the parallel aluminum wires, the copper connecting bridge has a larger lateral area and a la...

Embodiment 2

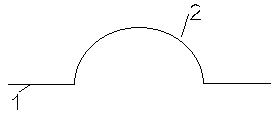

[0039] In this embodiment, the two suspended parts are arc-shaped, and the two ends of the arc are connected with the pin mechanism 1 . In detail, the suspended part 2 such as image 3 As shown, the pin mechanism 1 is arranged horizontally, and the arc part is connected with two pin mechanisms 1 . The hollow portion in the arc is used to form a hollow with the ceramic substrate 6 . Compared with the rectangle, the shape of the arc is more rounded, the gradient is small, and the sudden change is small, so that the impedance mismatch is reduced and the current loss flowing is smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com