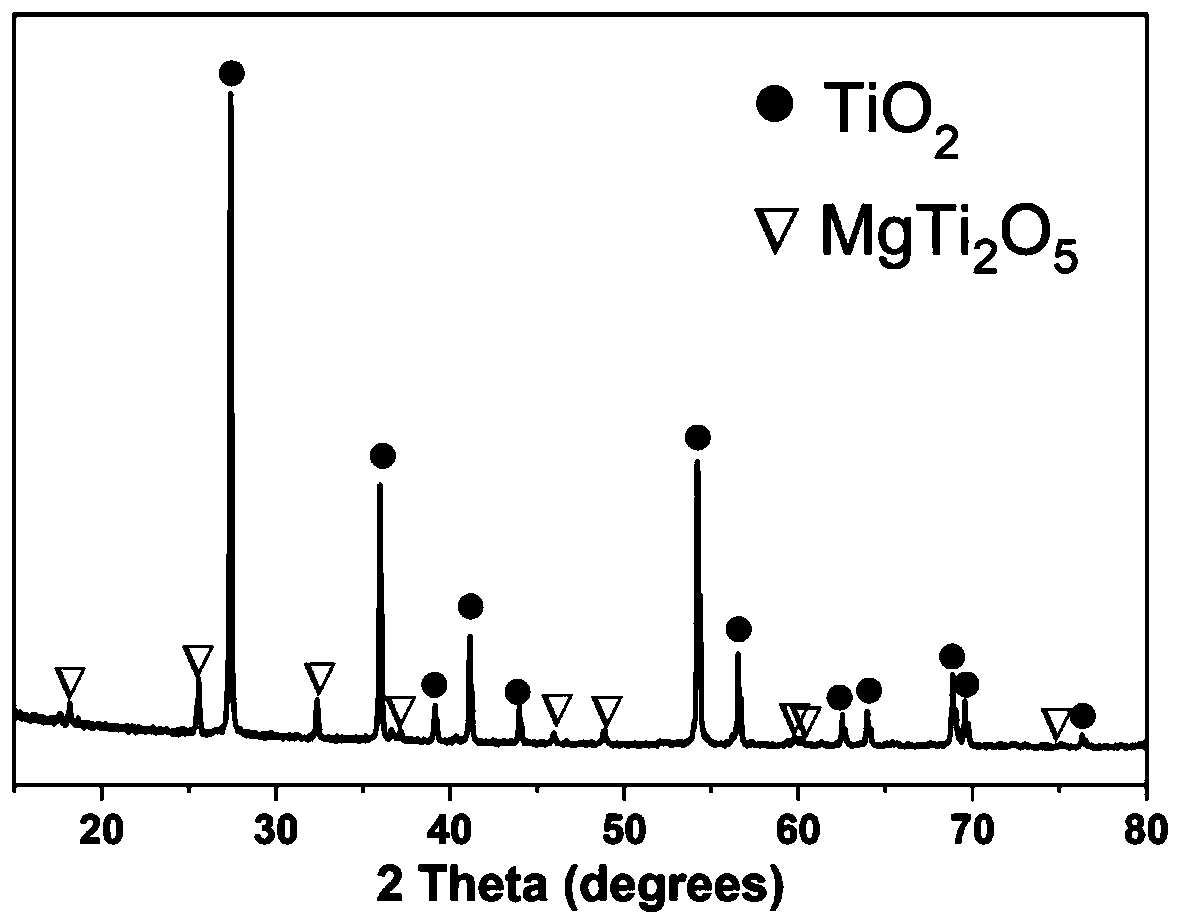

TiO2-based microwave ceramic substrate material and preparation method and application thereof

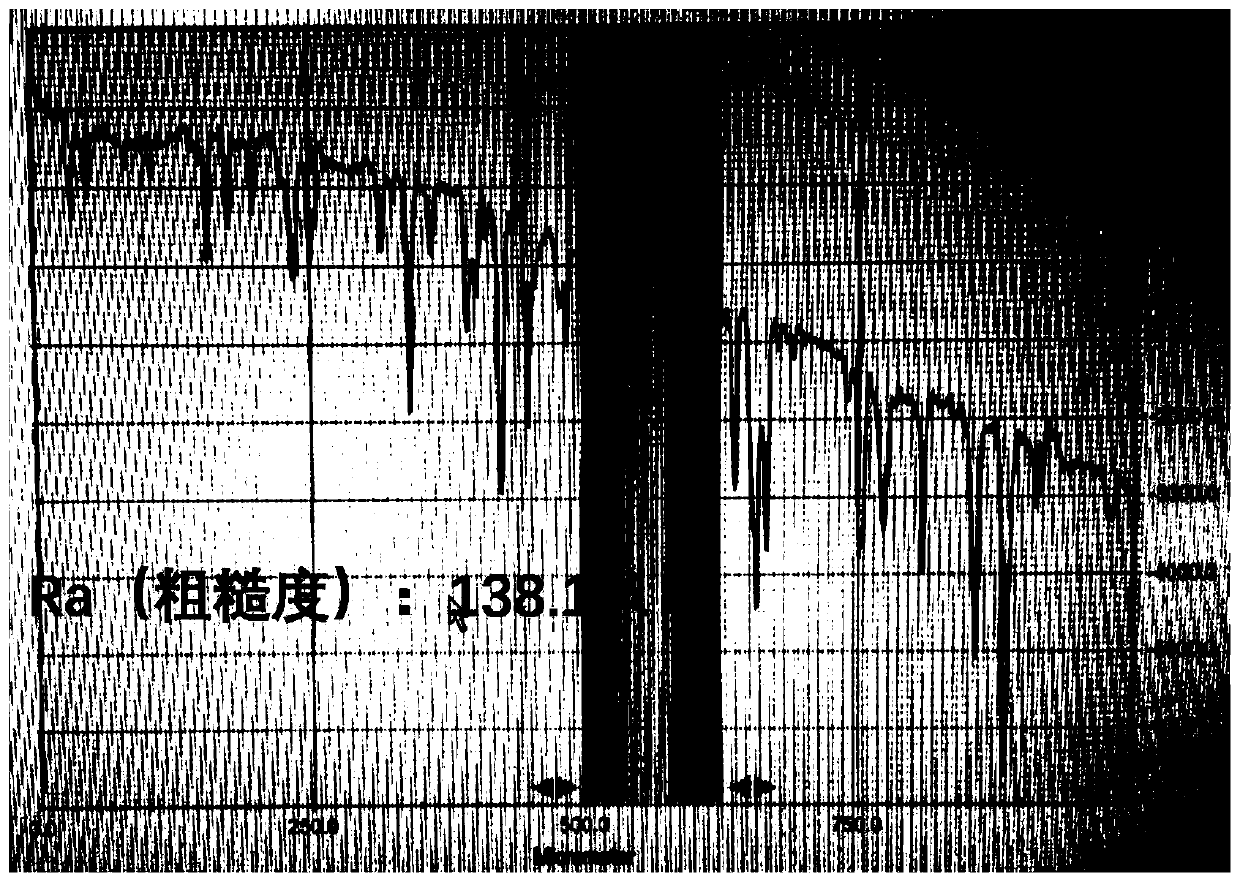

A technology of microwave ceramics and substrates, which is applied in the direction of waveguide devices, electrical components, circuits, etc., can solve the dielectric temperature coefficient of untested TiO2 ceramic materials, cannot evaluate the processing requirements of fine grain structure on the surface of microstrip filters, and cannot determine the actual Application requirements and other issues, to achieve the effect of easy control and adjustment, easy material performance, and structural control improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

[0039] (1) Ingredients: with a purity of 99.5% titanium dioxide, 99% basic magnesium carbonate, 99.5% zirconium dioxide, 99% tin dioxide, 99% niobium pentoxide, 99% manganese carbonate, 99.9% % cobalt monoxide, 99.5% copper oxide, 99.8% zinc oxide, and 99.9% aluminum oxide are the starting materials, and the mixture is obtained by batching according to the general chemical formula; the general chemical formula is Ti 1-x A x o 2 +yMgO+zB, where A=Zr, Sn, Nb, B=MnCO 3 , CoO, CuO, ZnO, Al 2 o 3 , based on molar percentage, 0.01≤x≤0.04, 0.01≤y≤0.05, 0.01≤z≤0.04;

[0040] (2) One-time ball milling and sieving: put the above mixture into a ball mill, use zirconia balls as the ball milling medium, and use deionized water as the solvent. According to the weight ratio of mixture: balls: water is 1: (3 ~ 5): (1-2) Grinding for 4-16 hours, discharging; then drying in an oven at 110°C for 12 hours, and sieving with a 60-mesh sieve after drying;

[0041] (3) Pre-sintering: the sieved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com