Patents

Literature

46 results about "AlSiC" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

AlSiC, pronounced "alsick", is a metal matrix composite consisting of aluminium matrix with silicon carbide particles. It has high thermal conductivity (180–200 W/m K), and its thermal expansion can be adjusted to match other materials, e.g. silicon and gallium arsenide chips and various ceramics. It is chiefly used in microelectronics as substrate for power semiconductor devices and high density multi-chip modules, where it aids with removal of waste heat.

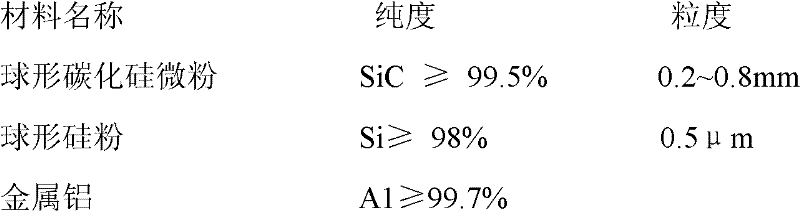

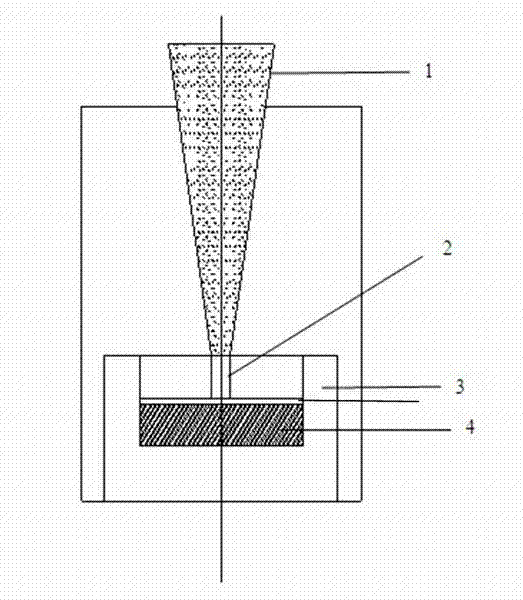

Method for preparing aluminum silicon carbide composite material

The invention discloses a method for preparing an aluminum silicon carbide composite material. Liquid metal aluminum is filled in a porous silicon carbide substrate which is prepared from spherical silicon carbide powder and spherical silicon powder which serve as raw materials and has a three-dimensional through hole structure through an injection molding process so as to form a bicontinuous phase, the density of the aluminum silicon carbide composite material and the product uniformity are improved, and a high-strength AlSiC substrate is obtained by changing molding pressure, adjusting ingredients of the spherical powder with different particle sizes, adding a pore-forming agent, and sintering at the temperature of between 1,400 and 2,400 DEG C. The porous substrate is fixed in a cavityof an injection machine, and the liquid metal aluminum enters the cavity from an injection port and is filled in through holes of the AlSiC substrate through a gas-liquid mixed injection process so as to form the aluminum silicon carbide composite material with a silicon carbide and metal aluminum bicontinuous phase structure. The aluminum silicon carbide composite material prepared by the process has the heat conductivity of 190 to 280 W / mK and the thermal expansion coefficient of 5.5 to 11.5*10(-6)K at room temperature of 200 DEG C, and has high rigidity, low density, high weldability and low machining amount.

Owner:CENT SOUTH UNIV

AlSiC composite material, preparation method thereof, and Ni-plated AlSiC composite material

The invention discloses an AlSiC composite material and a preparation method thereof. The AlSiC composite material comprises an SiC carrier having a porous structure, wherein Al is filled in the pores of the SiC carrier, and the surface of the SiC carrier is covered with an Al layer having a thickness of 30-150mum; and the Al layer and the Al matrix filled in the pores of the SiC carrier are a continuous distribution phase. The invention also provides an Ni-plated AlSiC composite material. The AlSiC composite material provided by the invention has a good surface chemical-coating homogeneity.

Owner:BYD CO LTD

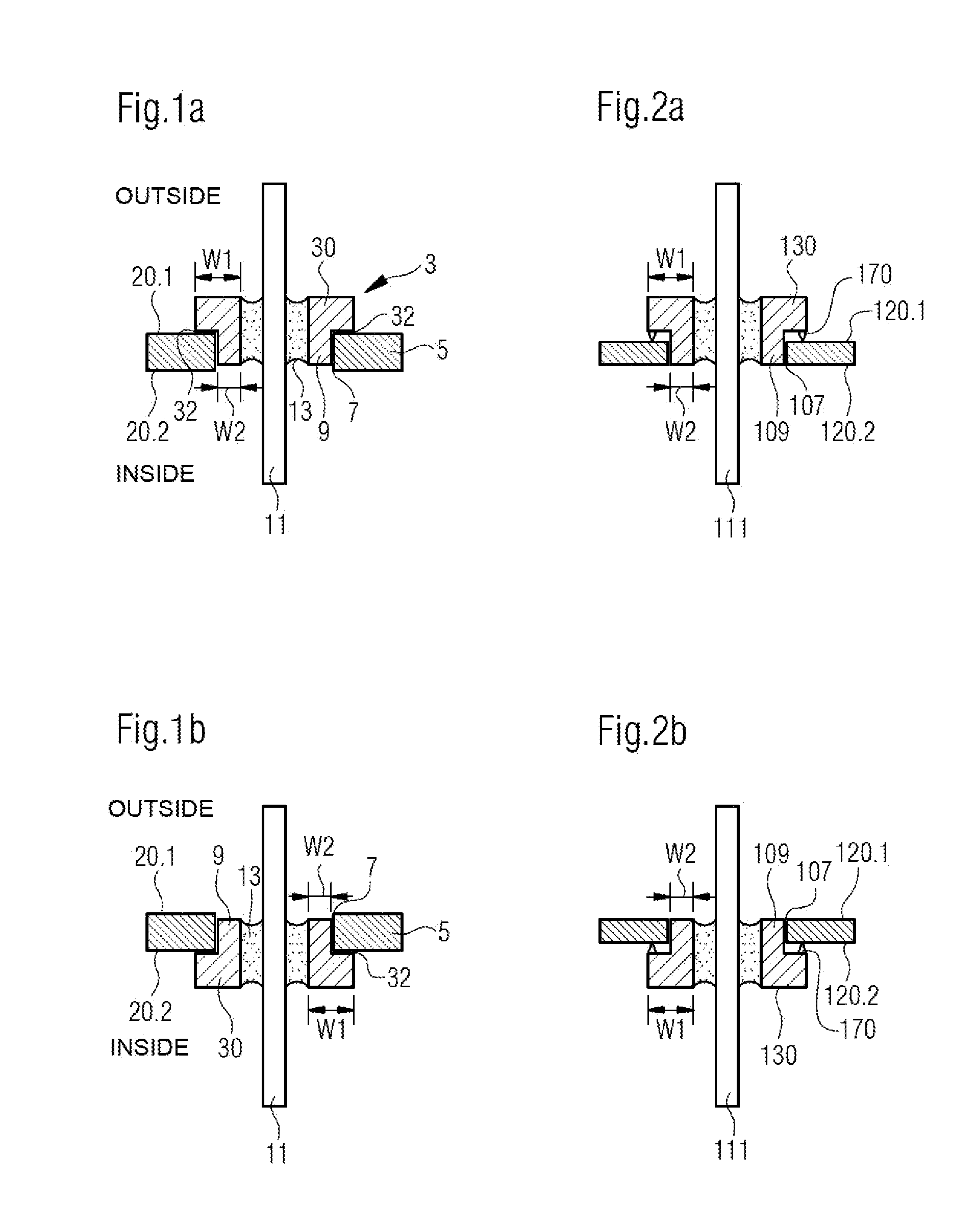

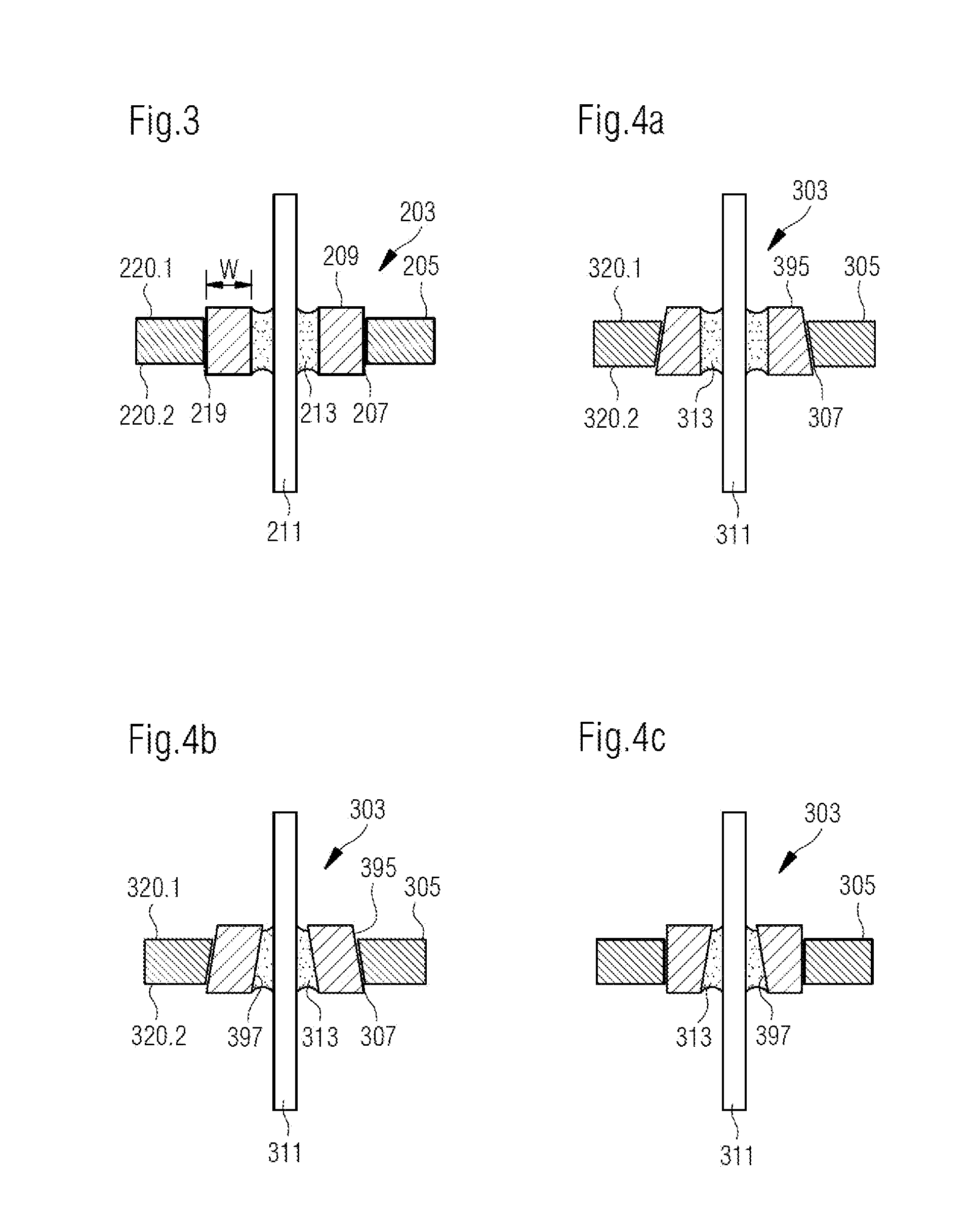

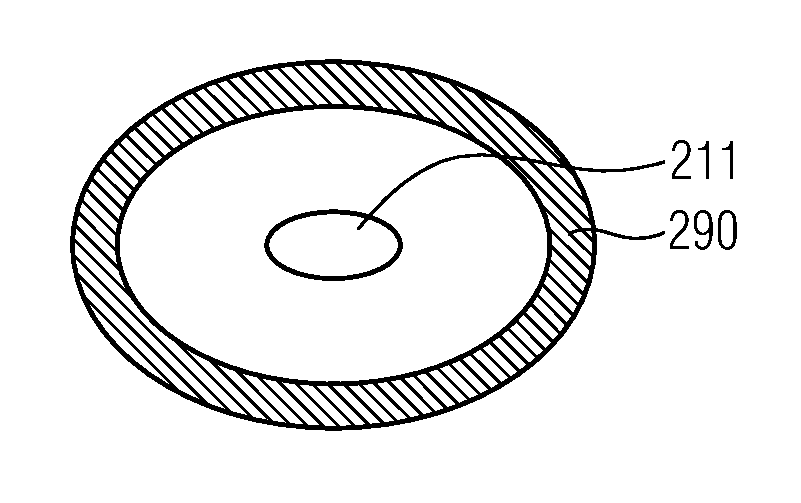

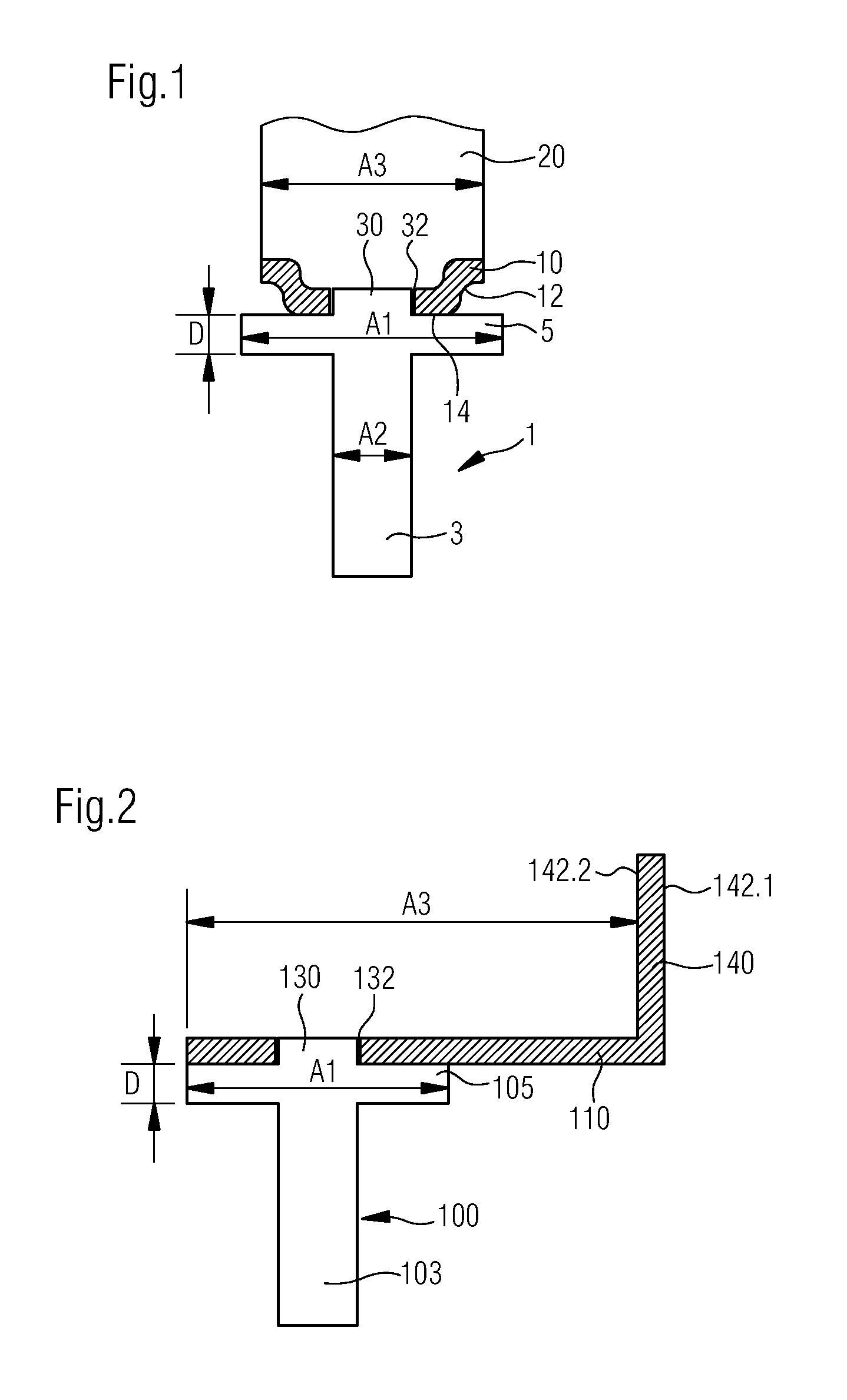

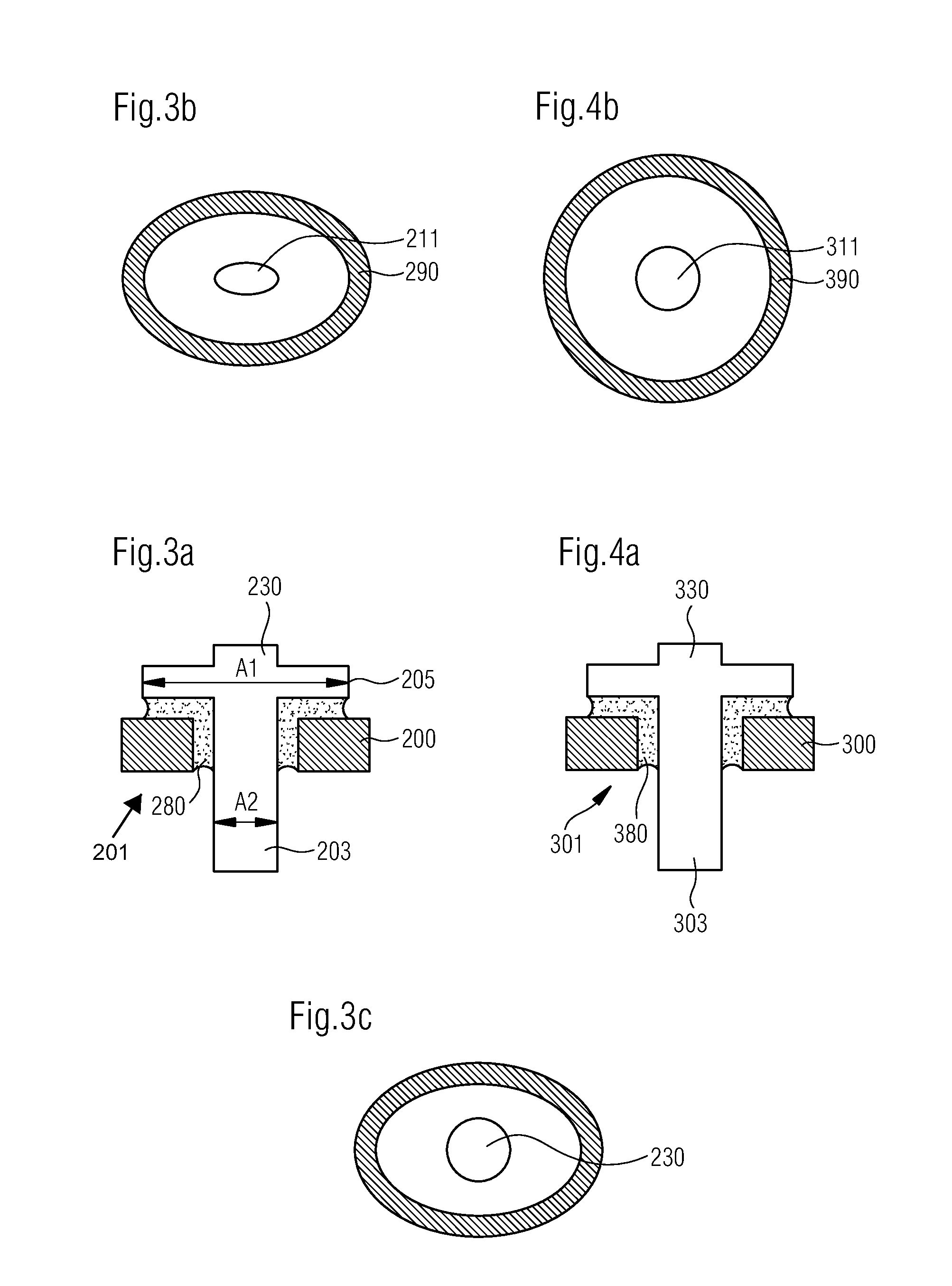

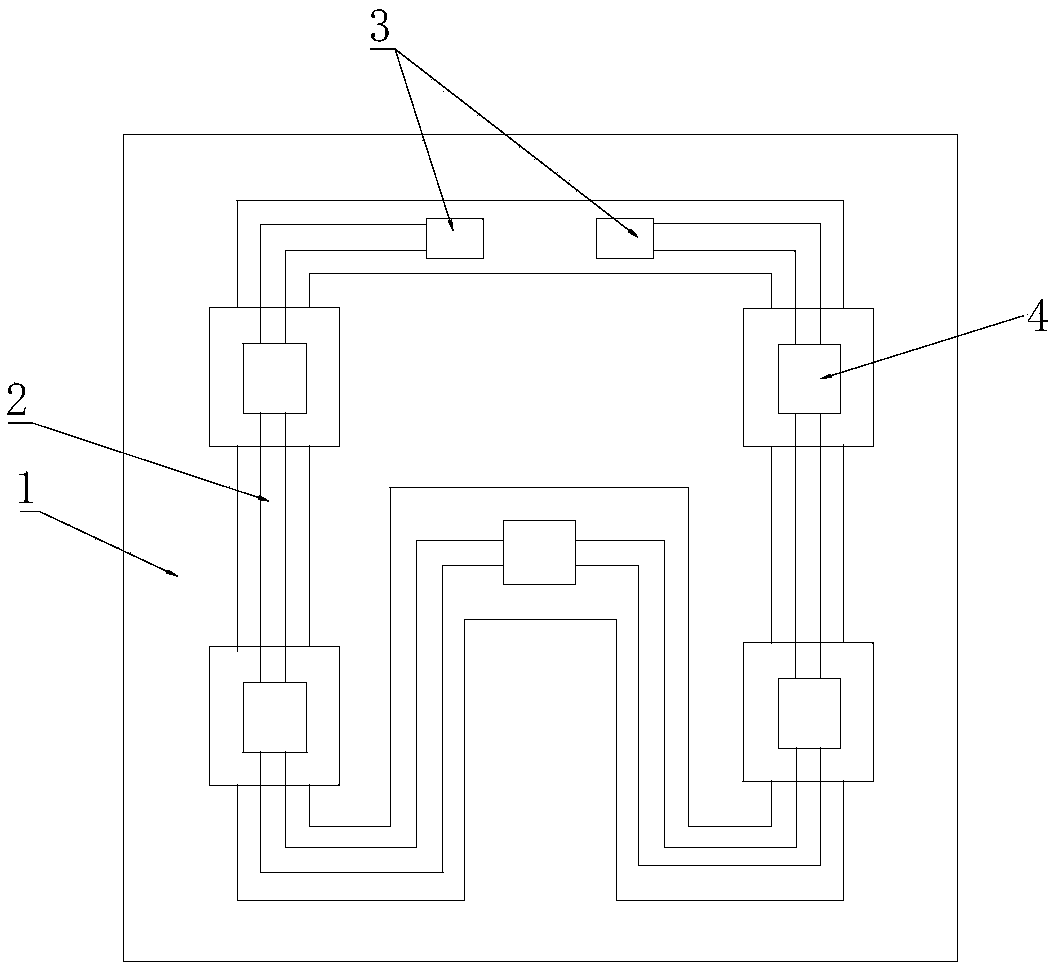

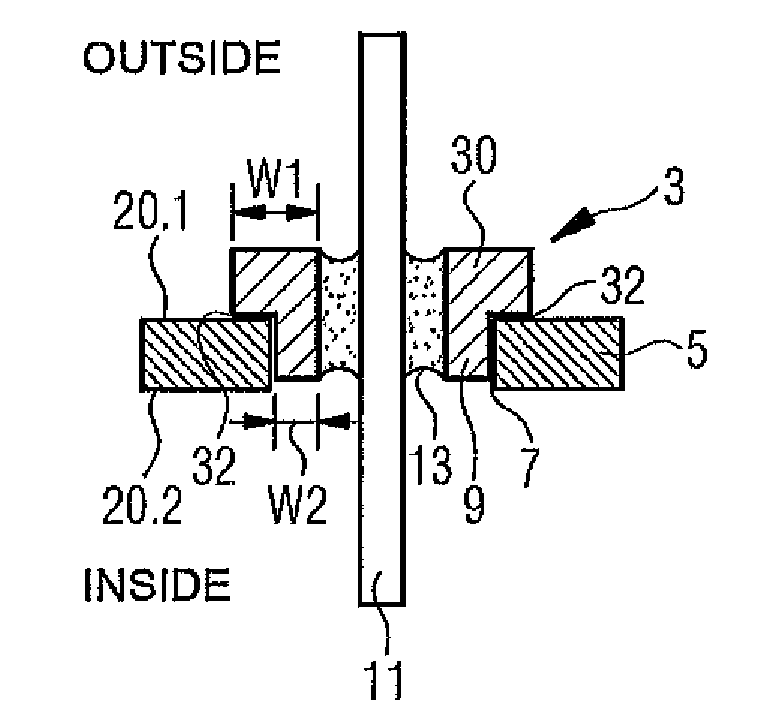

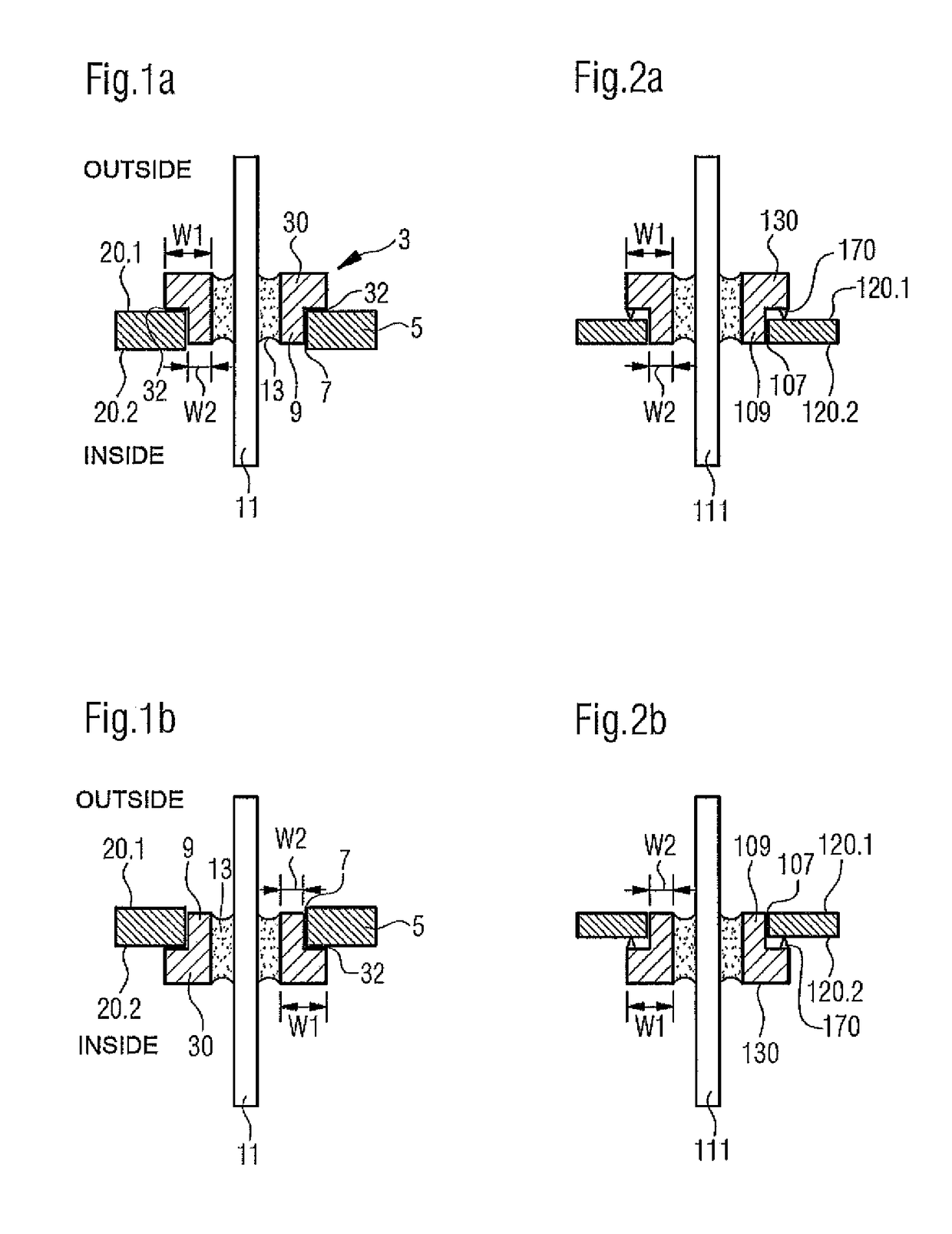

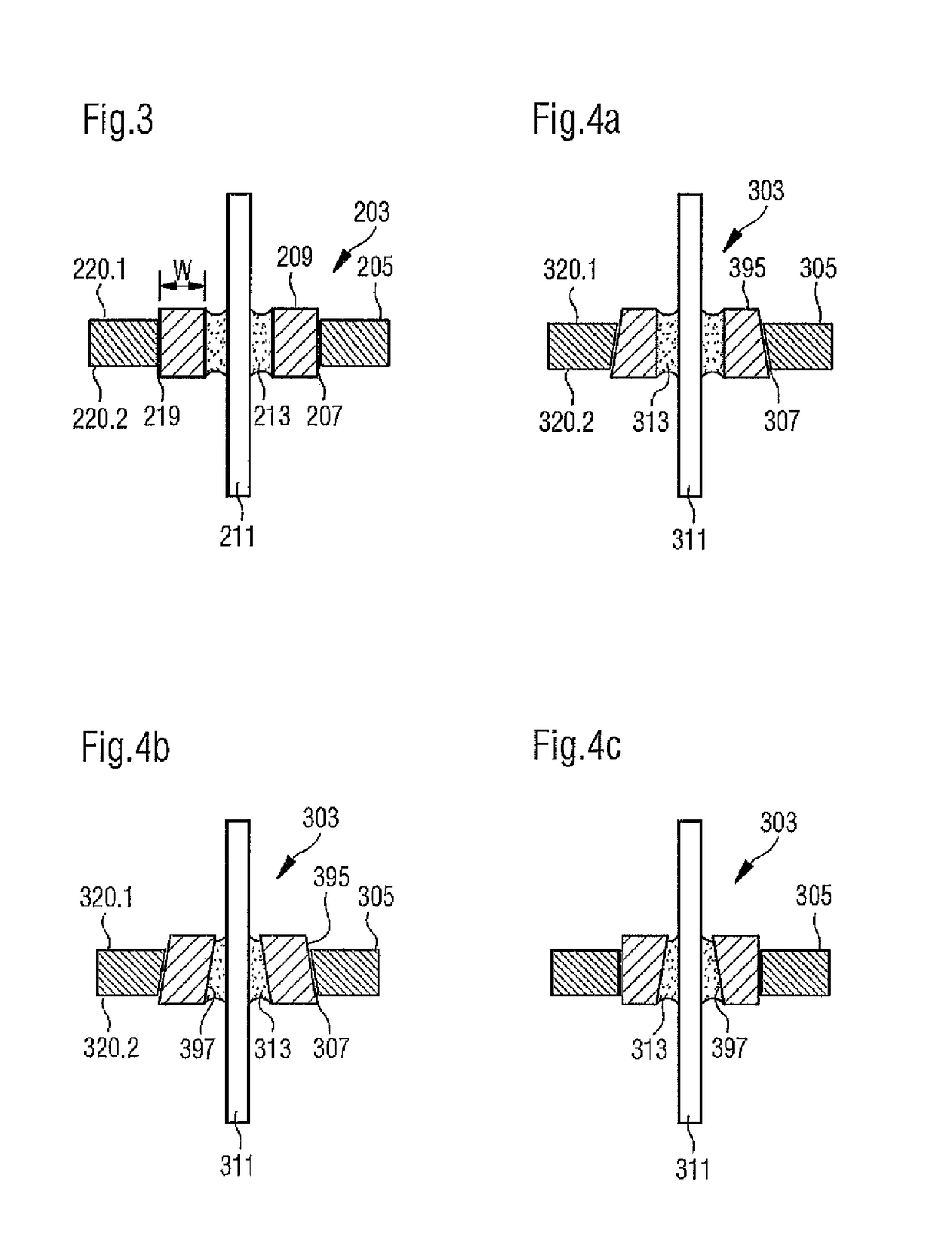

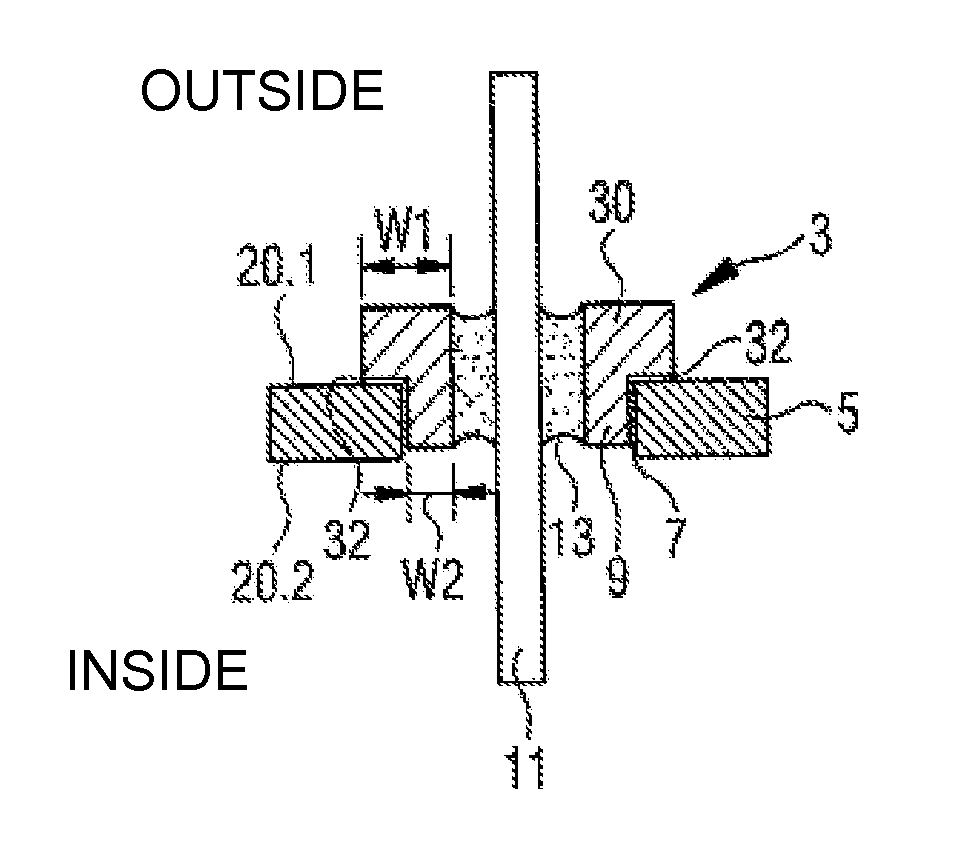

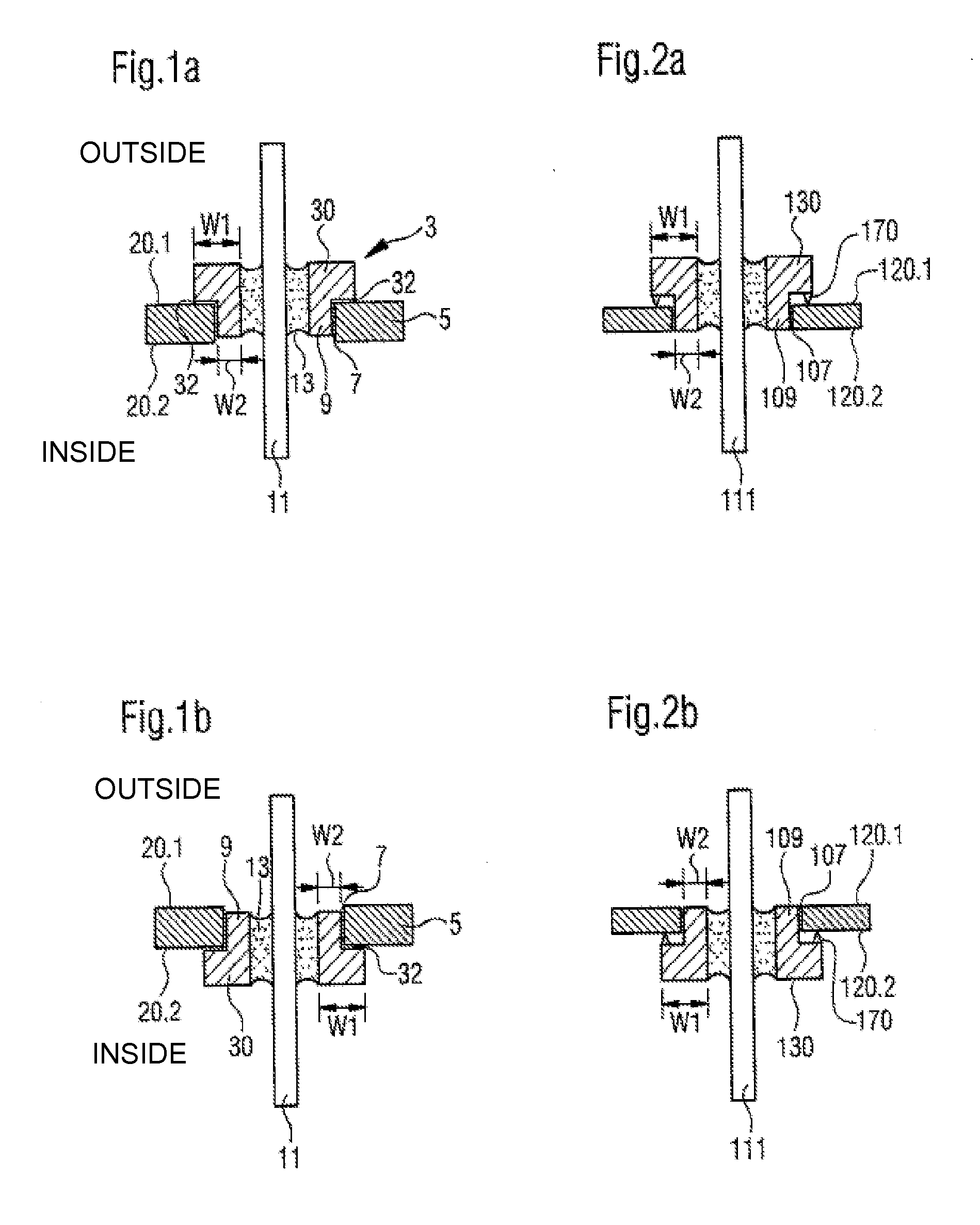

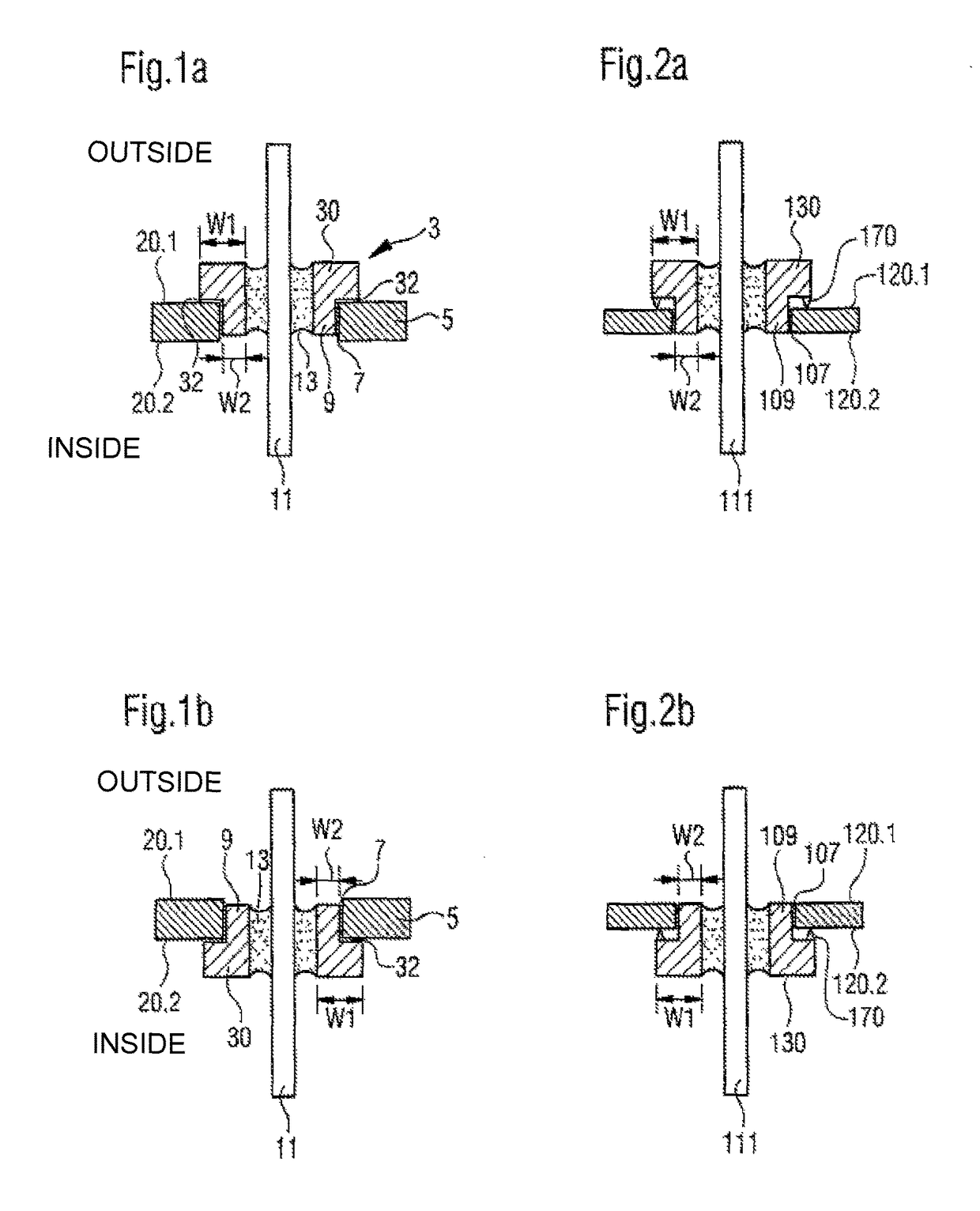

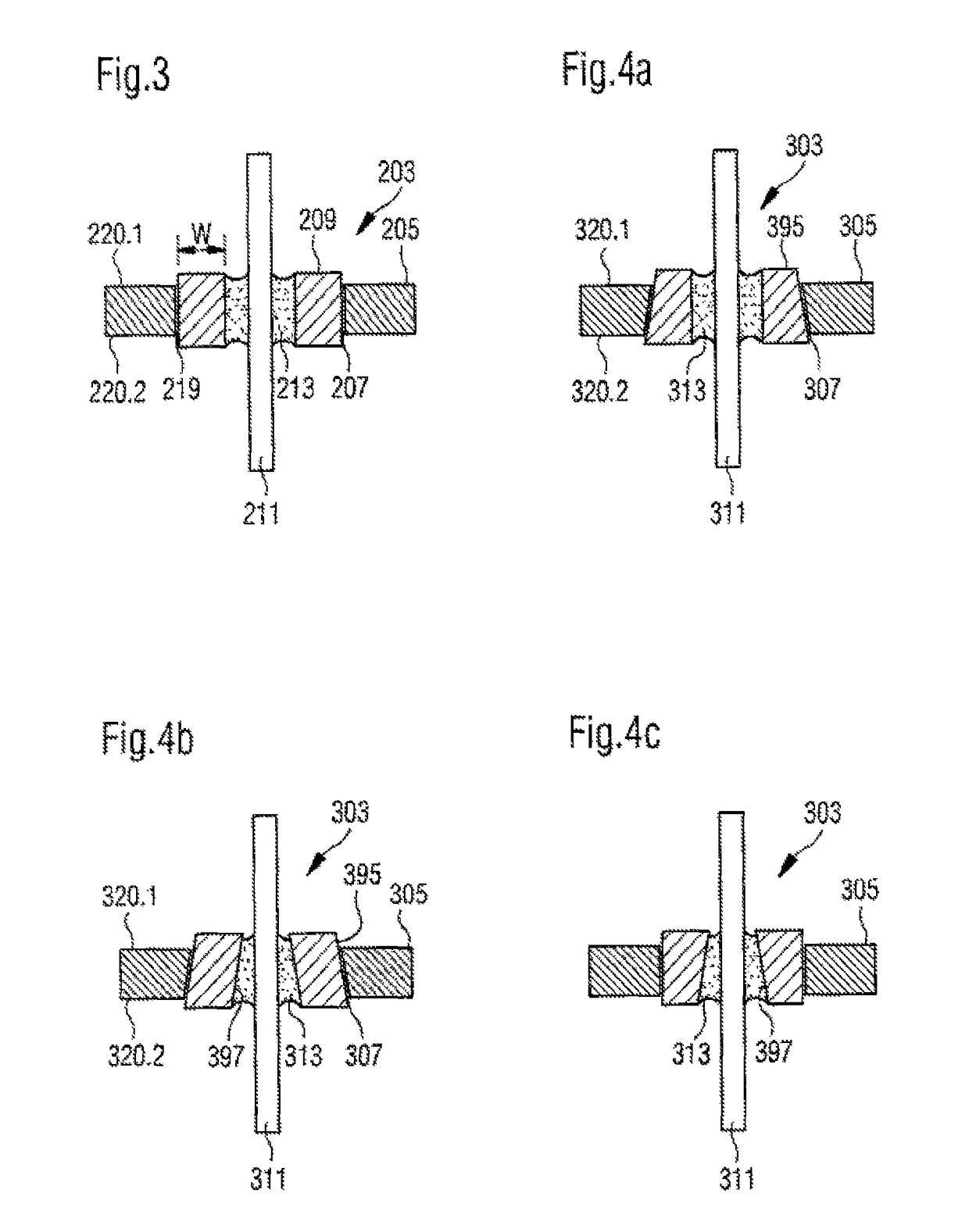

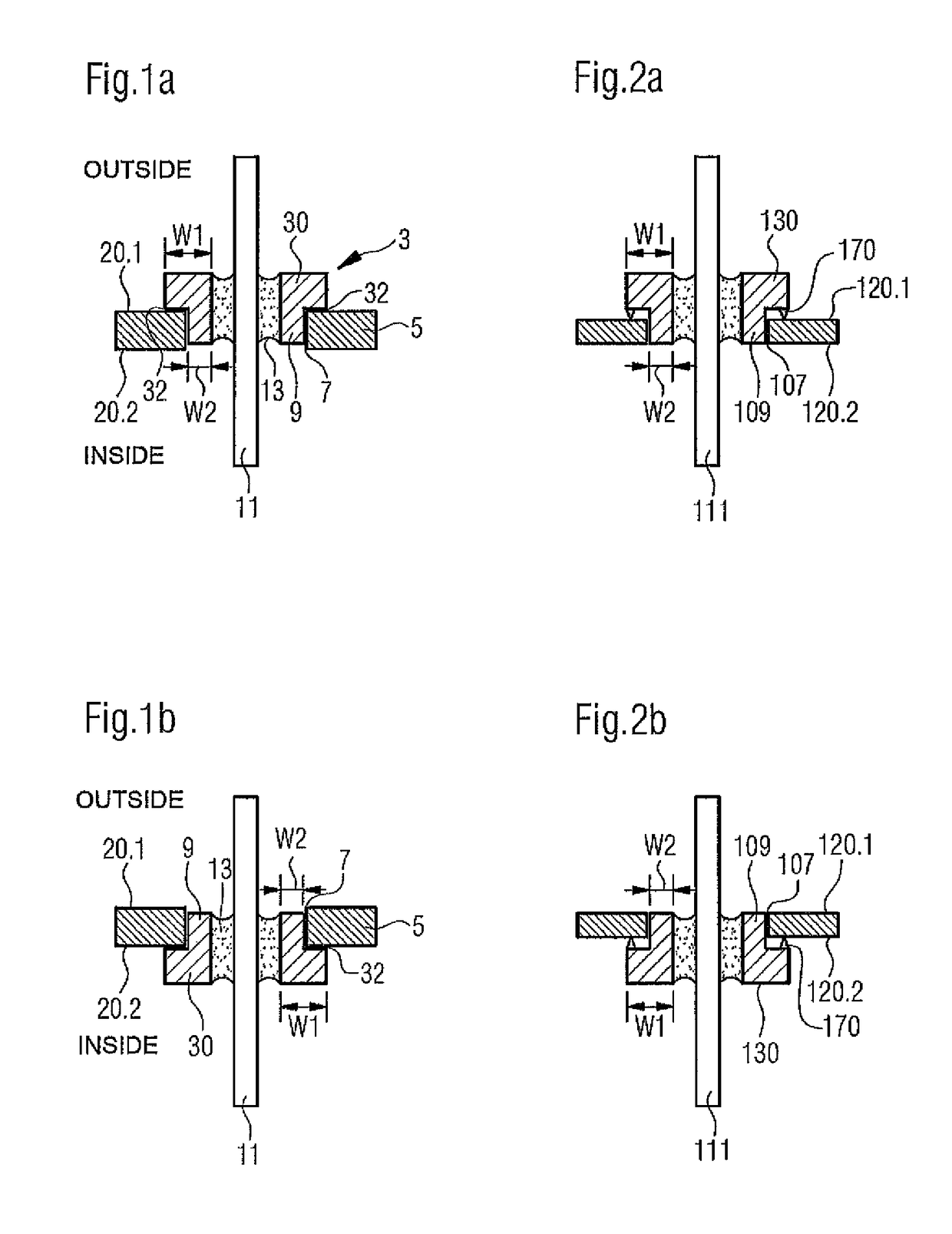

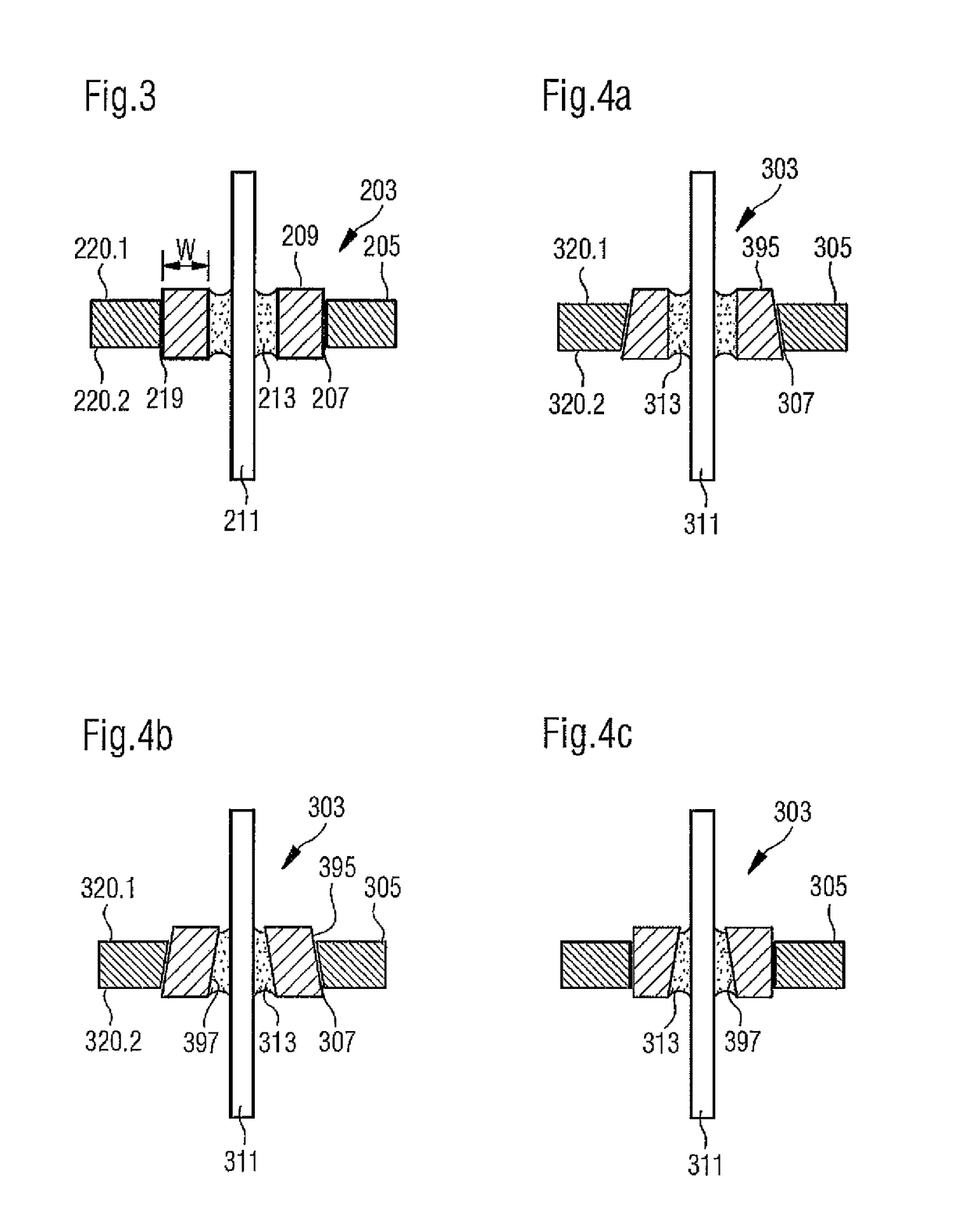

Feed-through

ActiveUS20130337316A1Avoid damageStrength and resistanceExhaust apparatusElectrode carriers/collectorsElectrical conductorTitanium

A feed-through, in particular a feed-through which passes through part of a housing, in particular a battery housing, for example made of metal, in particular light metal, for example aluminum, an aluminum alloy, AlSiC, magnesium, an magnesium alloy, titanium, a titanium alloy, steel, stainless steel or high-grade steel. The housing part has at least one opening through which at least one conductor, in particular an essentially pin-shaped conductor, embedded in a glass or glass ceramic material, is guided. The base body is, for example, an essentially annular-shaped base body.

Owner:SCHOTT AG

Feed-through component

ActiveUS20130330605A1Small spacingImprove stabilityElectrode carriers/collectorsSoldering apparatusElectrical conductorGlass-ceramic

A feed-through component for a conductor feed-through which passes through a part of a housing, for example a battery housing, is embedded in a glass or glass ceramic material and has at least one conductor, for example an essentially pin-shaped conductor, and a head part. The surface, in particular the cross-sectional surface, of the head part is greater than the surface, in particular the cross-sectional surface, of the conductor, for example of the essentially pin-shaped conductor. The head part is embodied such that is can be joined to an electrode-connecting component, for example an electrode-connecting part, which may be made of copper, a copper alloy CuSiC, an aluminum alloy AlSiC or aluminum, with a mechanically stable and non-detachable connection.

Owner:SCHOTT AG

Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device

InactiveCN104244486AImprove wettabilityImprove thermal performanceElectrical apparatusElectroluminescent light sourcesHemt circuitsEngineering

The invention discloses a Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device which is characterized in that the device comprises a substrate and serial rare earth electronic slurry, the serial rare earth electronic slurry is prepared on the substrate in the mode of a thick film circuit, the serial rare earth electronic slurry comprises coating slurry, rare earth resistance slurry, rare earth electrode slurry and rare earth medium slurry. Substrate vacuum impregnation ingredients comprise, by weight ratio, 2-7% of magnesium and 1.5-2.5% of rare earth metal neodymium and scandium together except for aluminum. The Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device is good in compatibility, firm in combination, large in power density, high in thermal shock resistance, high in heat dissipation efficiency, environmentally friendly, capable of saving energy and safe and reliable, and good match of the device and LED chips is achieved.

Owner:王晨 +1

Feed-through

ActiveUS20170149028A1No loss of strain-hardeningSmall dimensionSoldering apparatusSecondary cellsElectrical conductorTitanium

A feed-through, in particular a feed-through which passes through part of a housing, in particular a battery housing, for example made of metal, in particular light metal, for example aluminum, an aluminum alloy, AlSiC, magnesium, an magnesium alloy, titanium, a titanium alloy, steel, stainless steel or high-grade steel. The housing part has at least one opening through which at least one conductor, in particular an essentially pin-shaped conductor, embedded in a glass or glass ceramic material, is guided. The base body is, for example, an essentially annular-shaped base body and is hermetically sealed with the housing part such that the helium leakage rate is smaller than 1*10−8 mbar l / sec.

Owner:SCHOTT AG

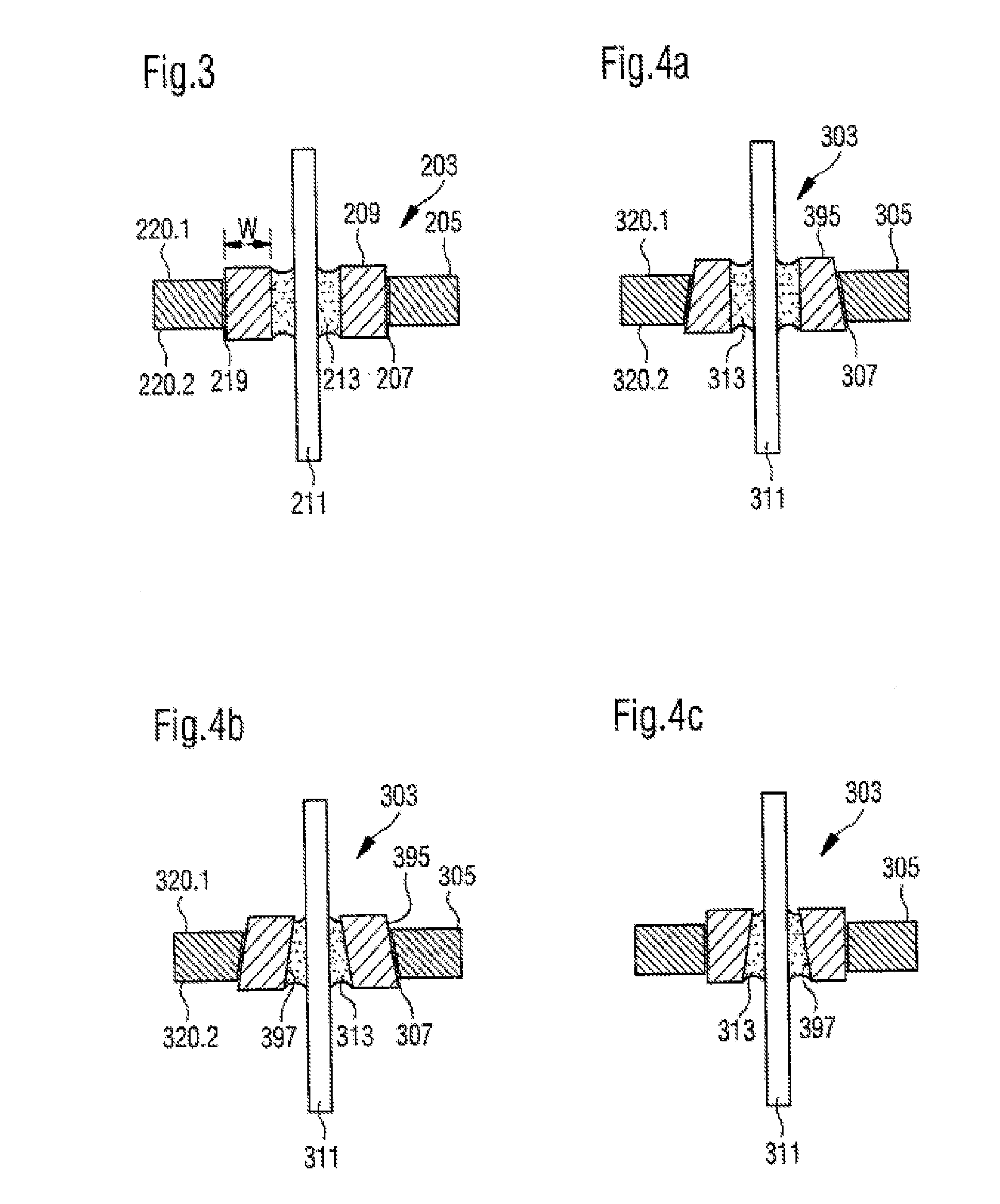

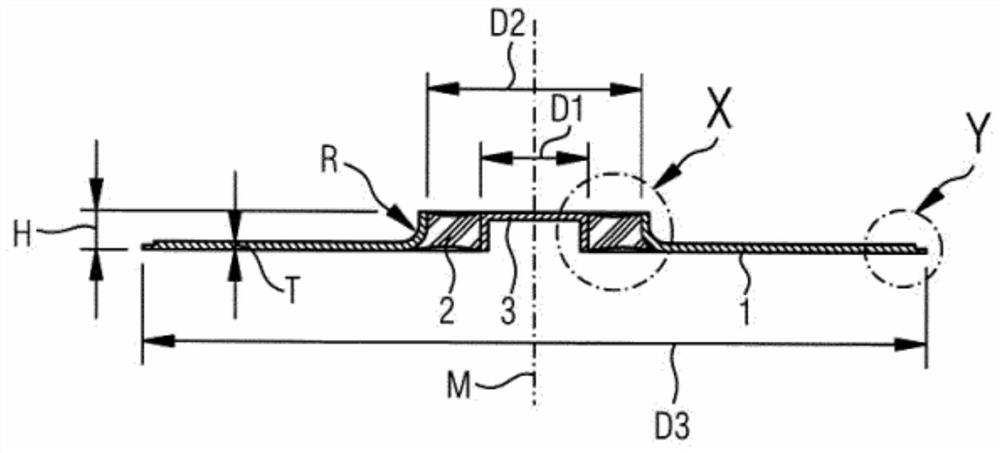

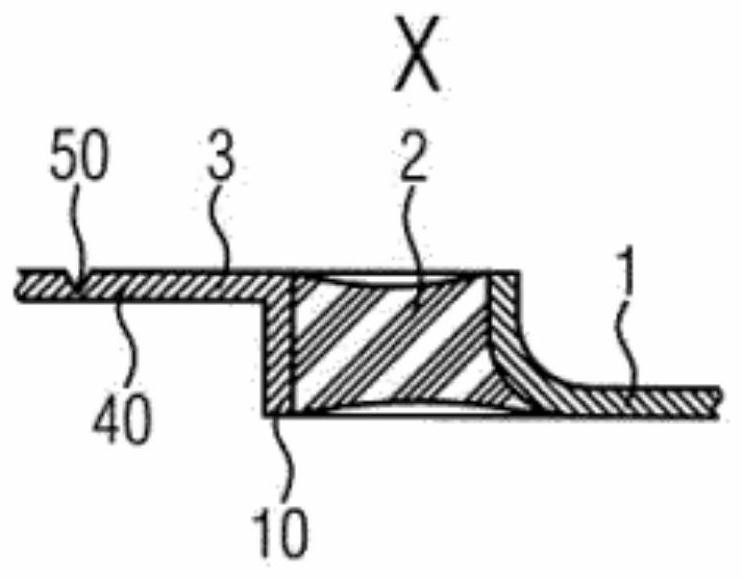

Feedthrough

ActiveUS20140099533A1Low production costSimple adaptationPrimary cellsElectrode carriers/collectorsElectrical conductorTitanium

A feedthrough, for example through a part of a housing, such as a battery housing, is, for example, made of a metal, such as a light alloy, for example aluminum, an aluminum alloy, AlSiC, magnesium, a magnesium alloy, titanium, a titanium alloy, steel, stainless steel or high-grade steel. The housing part has at least one opening through which at least one conductor having a cross-section is guided in a glass or glass ceramic material. The conductor has at least two sections, a first section having a first, substantially round, for example a circular, cross section having a diameter in the region of the feedthrough through the glass or glass ceramic material, and a second section having a second, substantially non-round, for example a substantially rectangular cross-section, and the conductor is formed in one piece.

Owner:SCHOTT AG

Metal matrix composite material with high thermal conductivity and low coefficient of thermal expansion

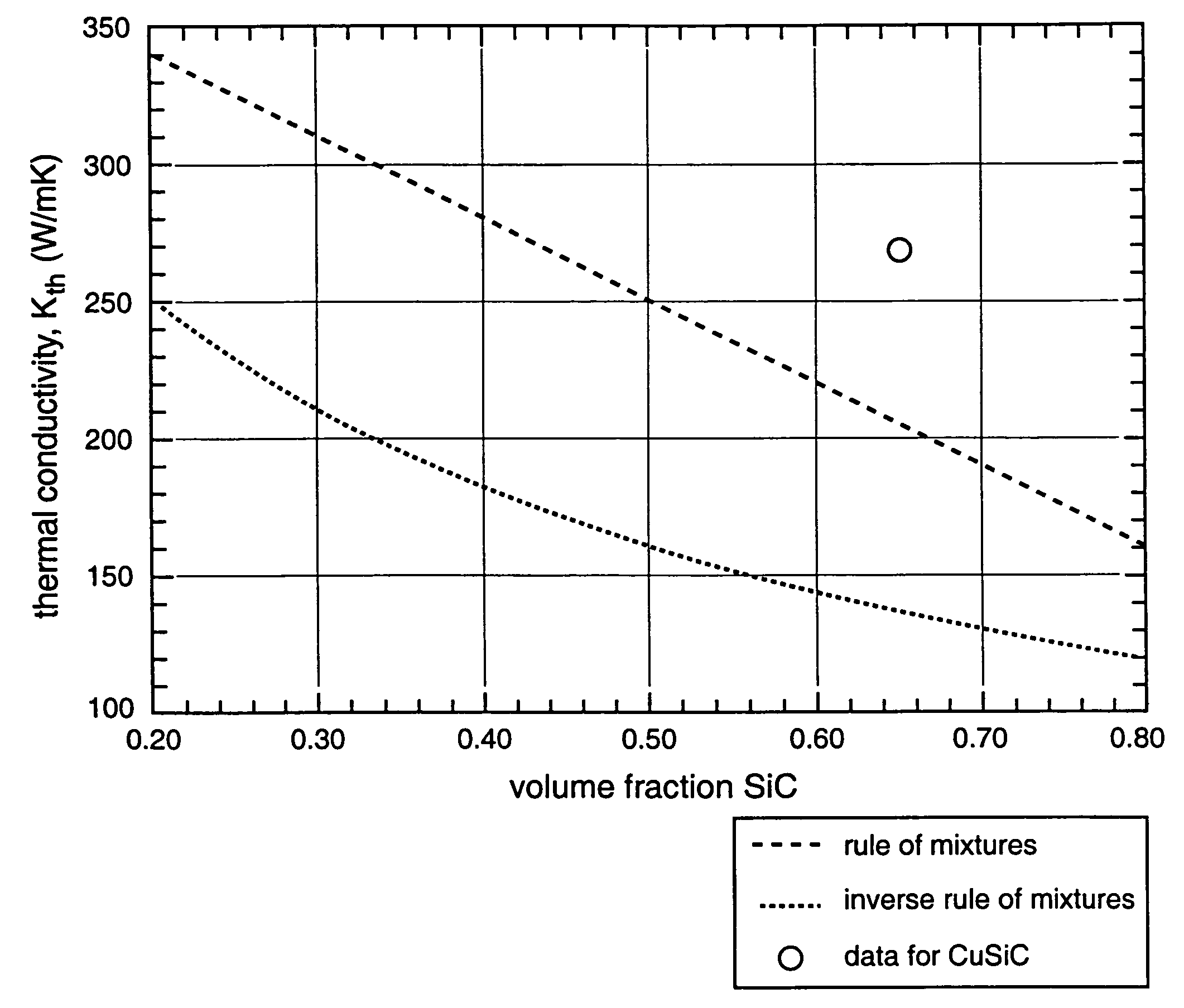

InactiveUS7364692B1Transportation and packagingMetal-working apparatusThermal dilatationMetal matrix composite

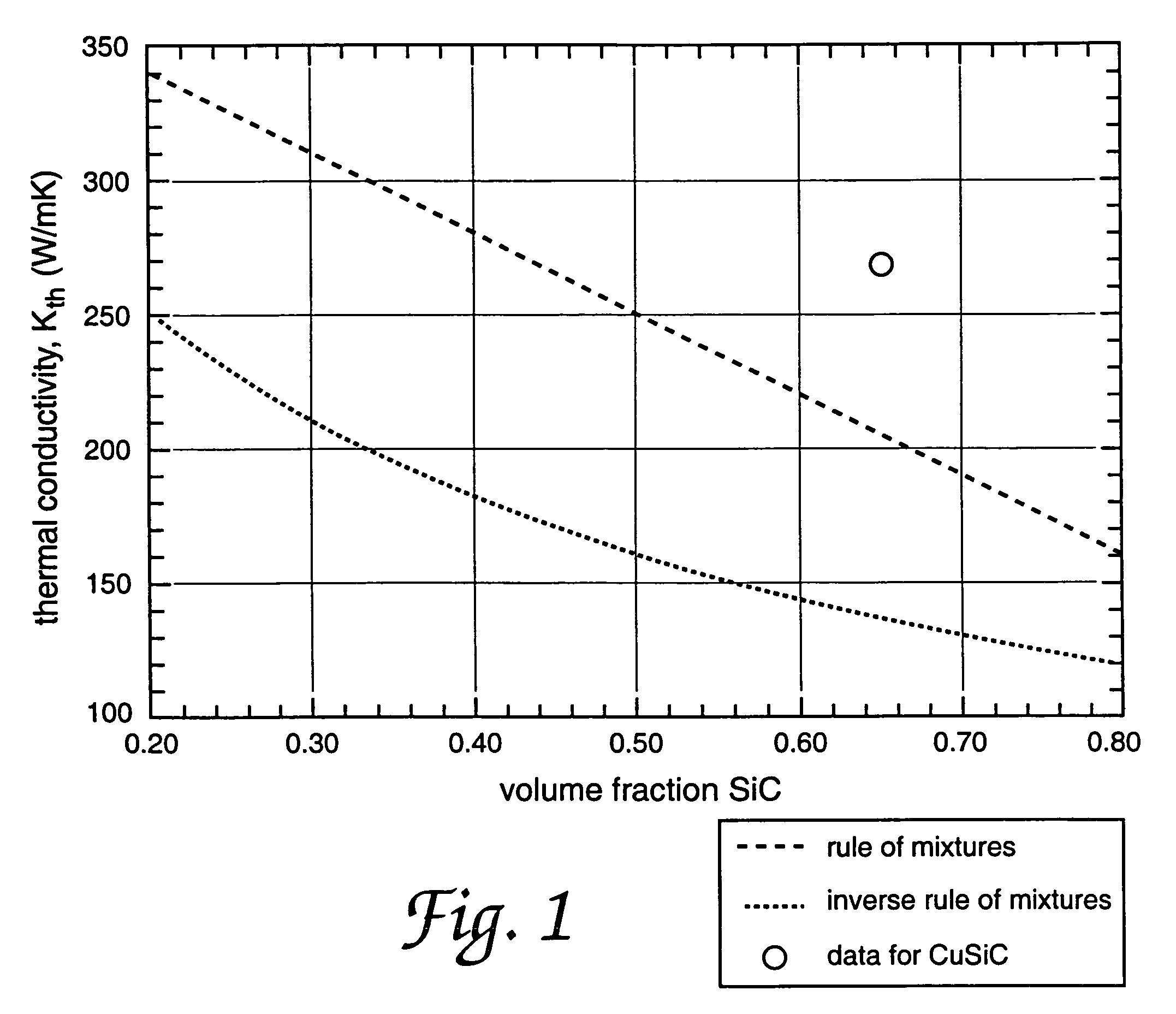

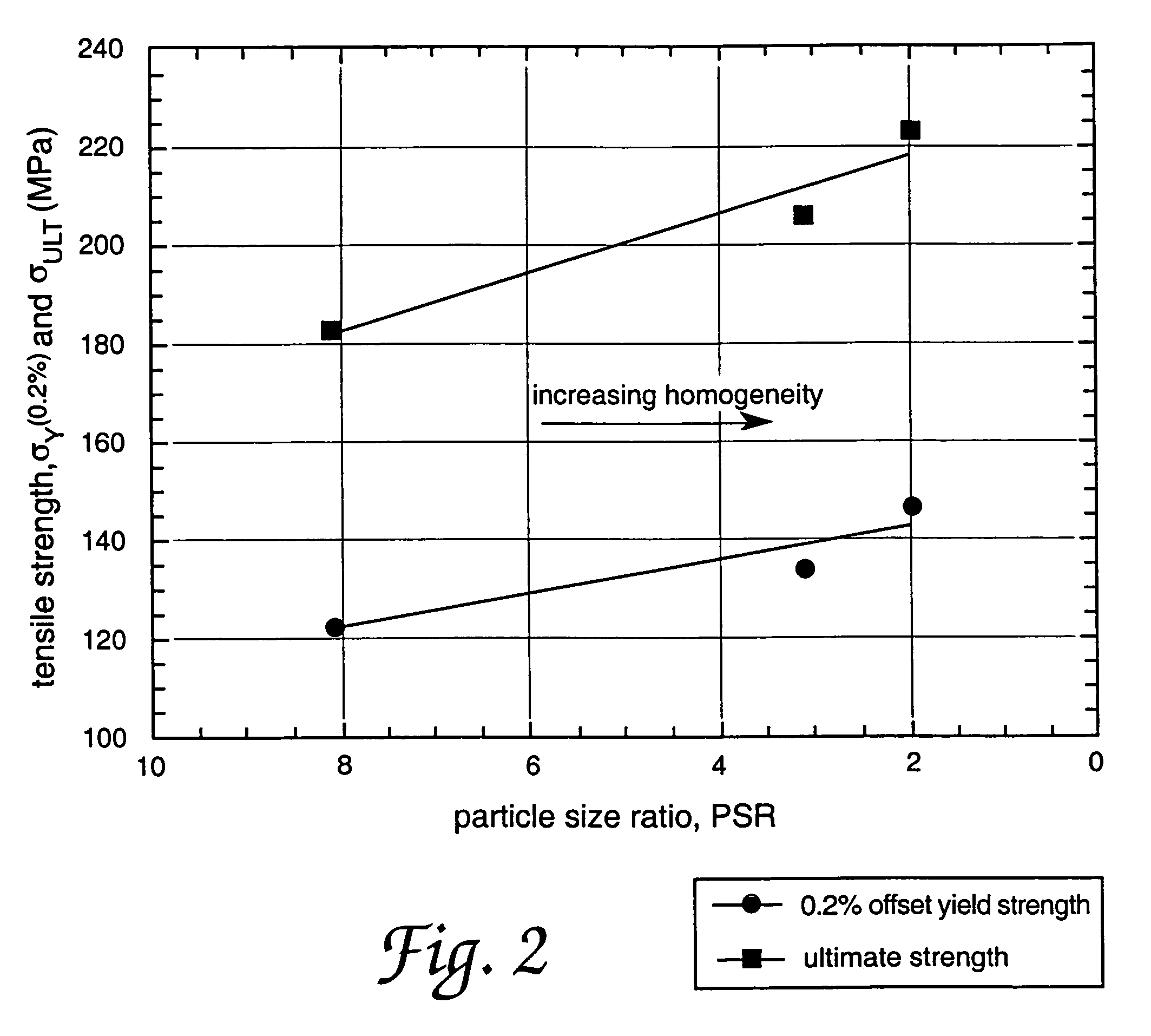

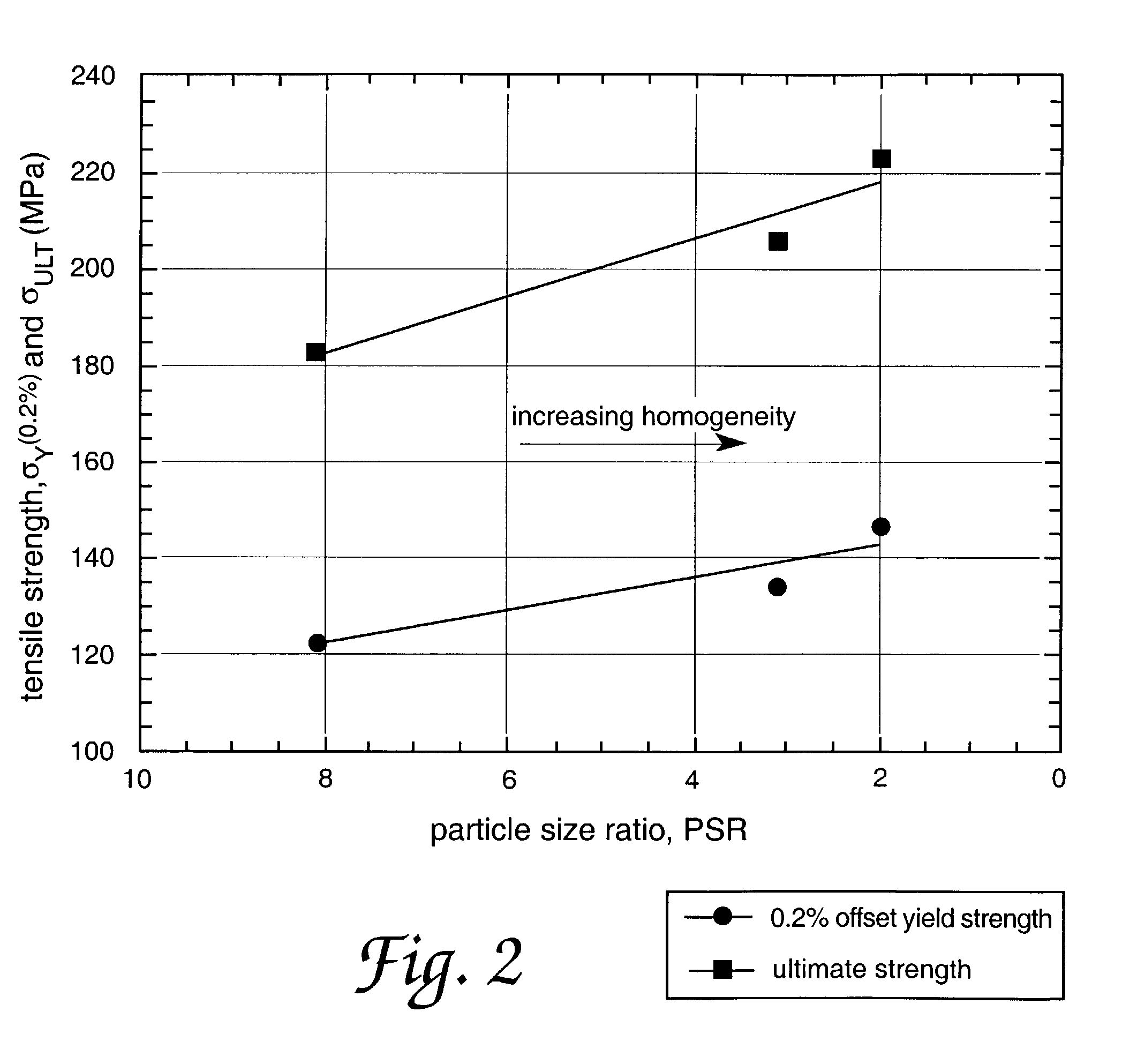

Metal-matrix composites with combinations of physical and mechanical properties desirable for specific applications can be obtained by varying and controlling selected parameters in the material formation processes, particularly by increasing the microstructural homogeneity of the composite, while maintaining a constant mixture ratio or volume fraction. In one embodiment of the invention, a CuSiC composite having increased thermal conductivity is obtained by closely controlling the size of the SiC particles. In another embodiment of the invention, AlSiC composites which exhibit increased ultimate tensile and yield strengths are made by closely controlling the size of SiC and Al particles.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Method for improving tensile properties of AlSiC composites

InactiveUS6972109B1Transportation and packagingMetal-working apparatusMetal matrix compositeUltimate tensile strength

Metal-matrix composites with combinations of physical and mechanical properties desirable for specific applications can be obtained by varying and controlling selected parameters in the material formation processes, particularly by increasing the microstructural homogeneity of the composite, while maintaining a constant mixture ratio or volume fraction. In one embodiment of the invention, a CuSiC composite having increased thermal conductivity is obtained by closely controlling the size of the SiC particles. In another embodiment of the invention, AlSiC composites which exhibit increased ultimate tensile and yield strengths are made by closely controlling the size of SiC and Al particles.

Owner:GOVERNMENT IF THE US SEC THE AIR FORCE THE

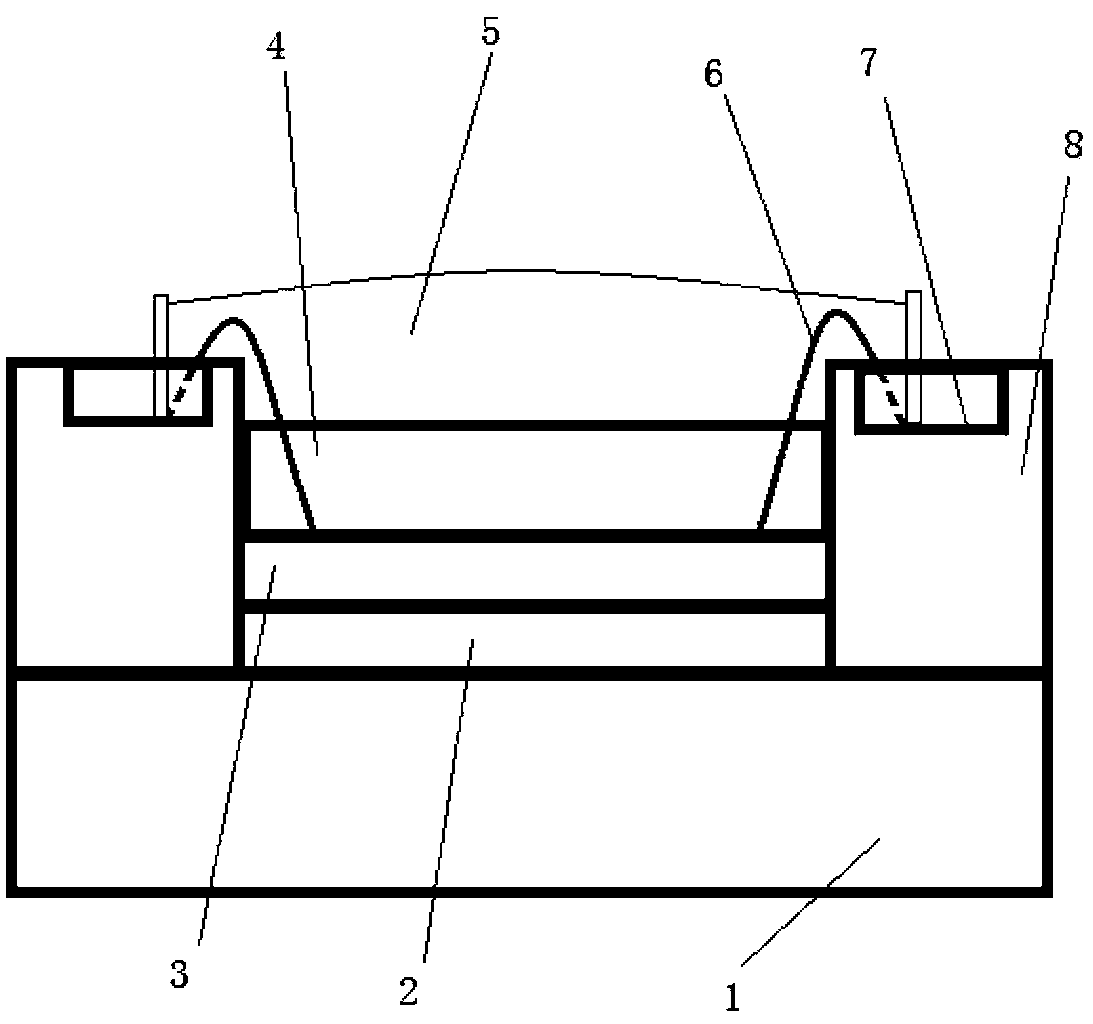

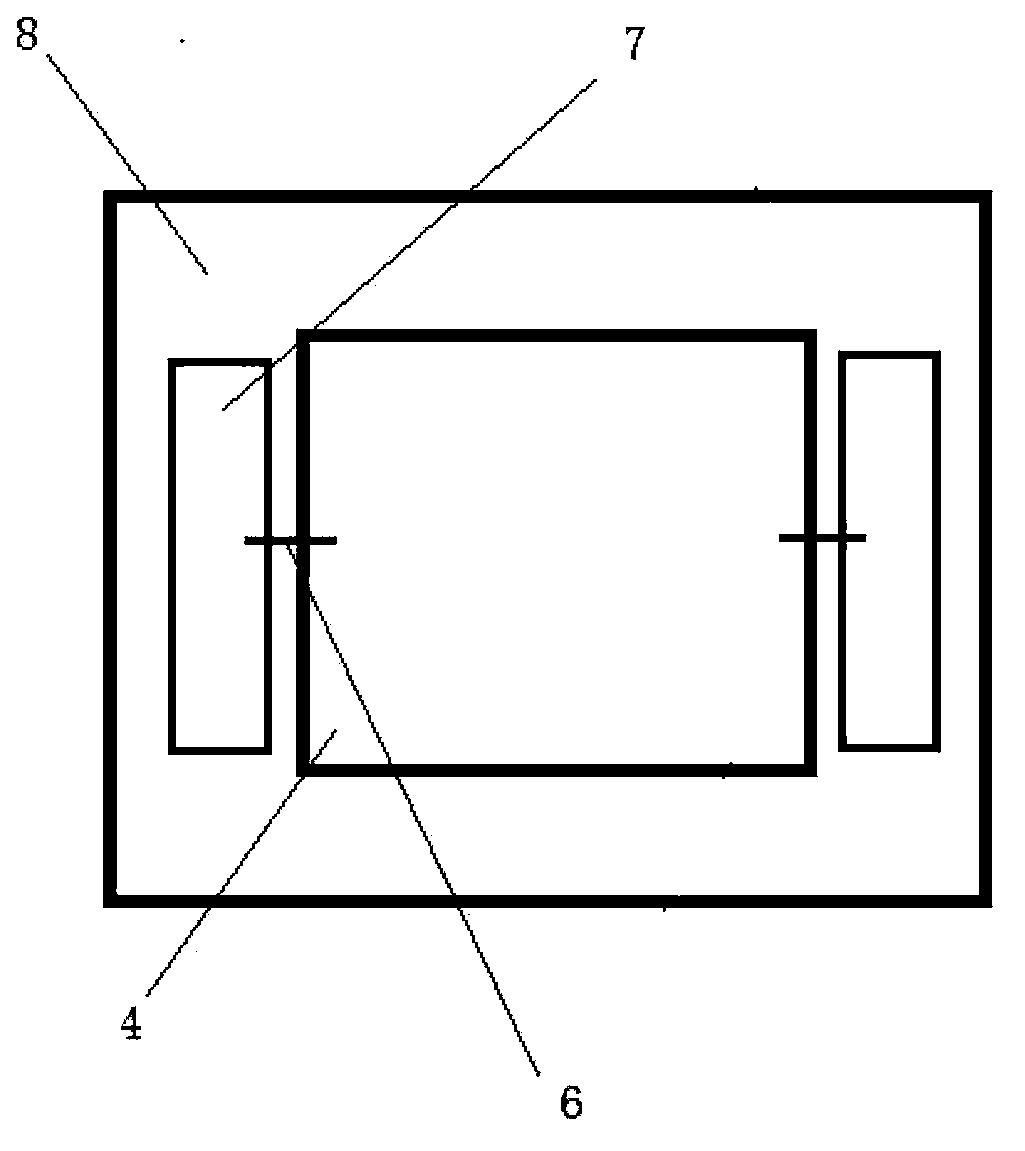

1200V/50A IGBT power module based on rapid sintering nano-silver soldering paste pressure-free interconnection technology

InactiveCN109411464AGood electrical performanceReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesDBcLead bonding

The invention relates to a 1200V / 50A IGBT power module based on a rapid sintering nano-silver soldering paste pressure-free interconnection technology; a bottom plate adopts a nickel-plated thick copper block or AlSiC; two ceramic copper-clad DBC substrates with the same circuit style are arranged on the bottom plate in a reversed mode; the substrates are connected through a connecting bridge; twogroups of IGBT chips and follow-up diode chip parallel branch groups are in interconnection with the substrates; a double-layer printing variable-temperature preheating solder paste method is adopted, and the chips and the DBC substrates are connected in an instant mode through continuous pulse current auxiliary pressure-free sintering nano-silver solder paste; the sintering connection time is not more than 15 seconds; and then steps of lead bonding, vacuum backflow secondary welding, tube shell mounting, and sealing agent filling are carried out to prepare the IGBT module. Compared with commercial IGBT modules of the same grade, the IGBT module of the invention has high electrical performance, lower thermal resistance and better heat dissipation characteristics, and meanwhile has excellent thermal cycling fatigue aging resistance.

Owner:TIANJIN UNIV

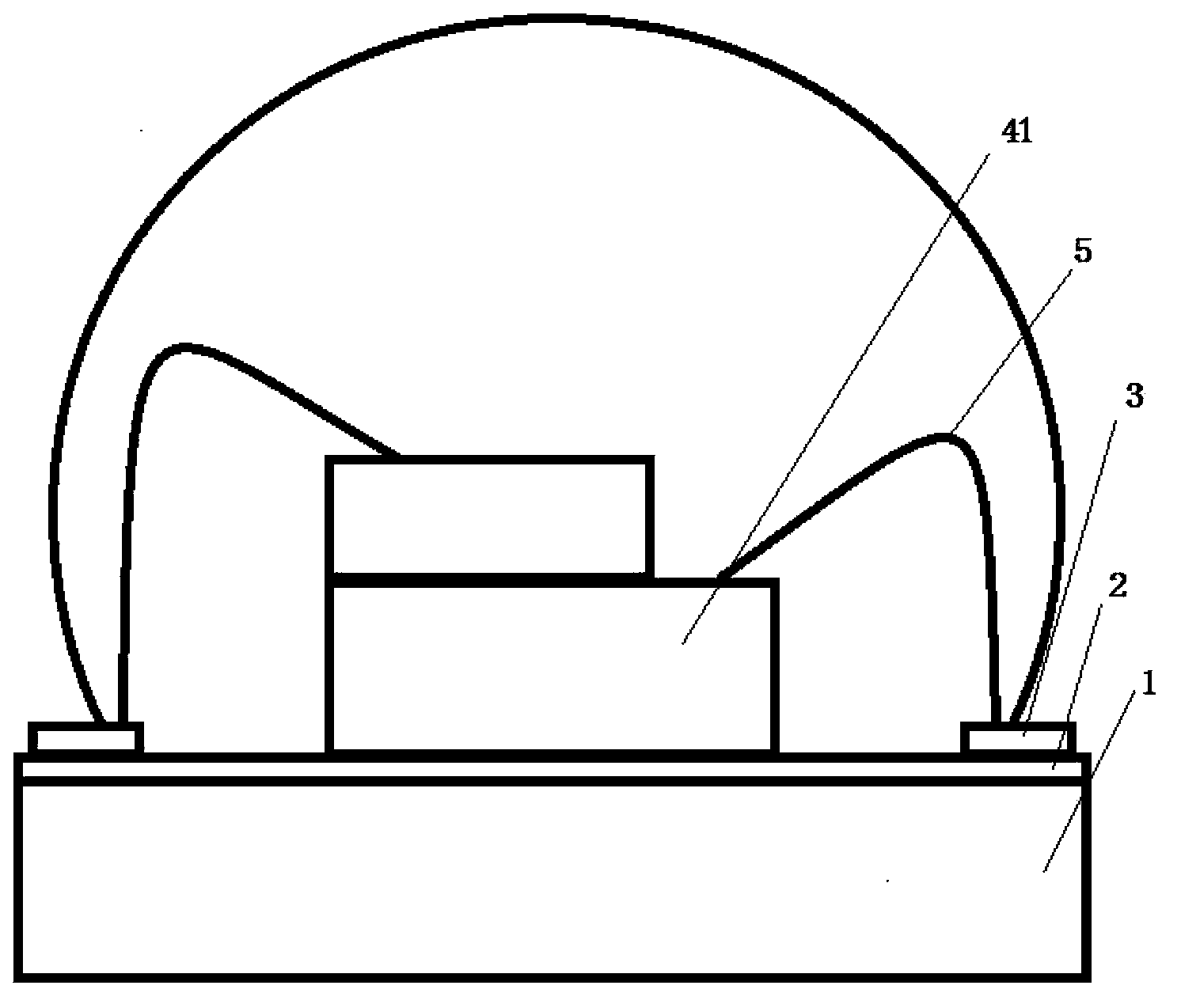

Light-emitting diode (LED) packaged with AlSiC composite substrate

The invention discloses an LED packaged with an AlSiC composite substrate. The LED comprises the AlSiC composite cooling substrate, an LED light source module, gold threads and an alumina ceramic frame, wherein the surface of the AlSiC composite cooling substrate is plated with a copper film and a silver film sequentially; the LED light source module is packaged on the AlSiC composite cooling substrate; the alumina ceramic frame is arranged on the outer side of the LED light source module and adheres to the LED light source module; two copper-film electrodes are plated on the alumina ceramic frame and connected with a positive pole and a negative pole of the LED light source module through the gold threads respectively. According to the LED, thermal expansion coefficients of the AlSiC composite substrate and an LED chip material are matched, so that an LED chip which is packaged on the substrate is not prone to falling, and the service life of the LED is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

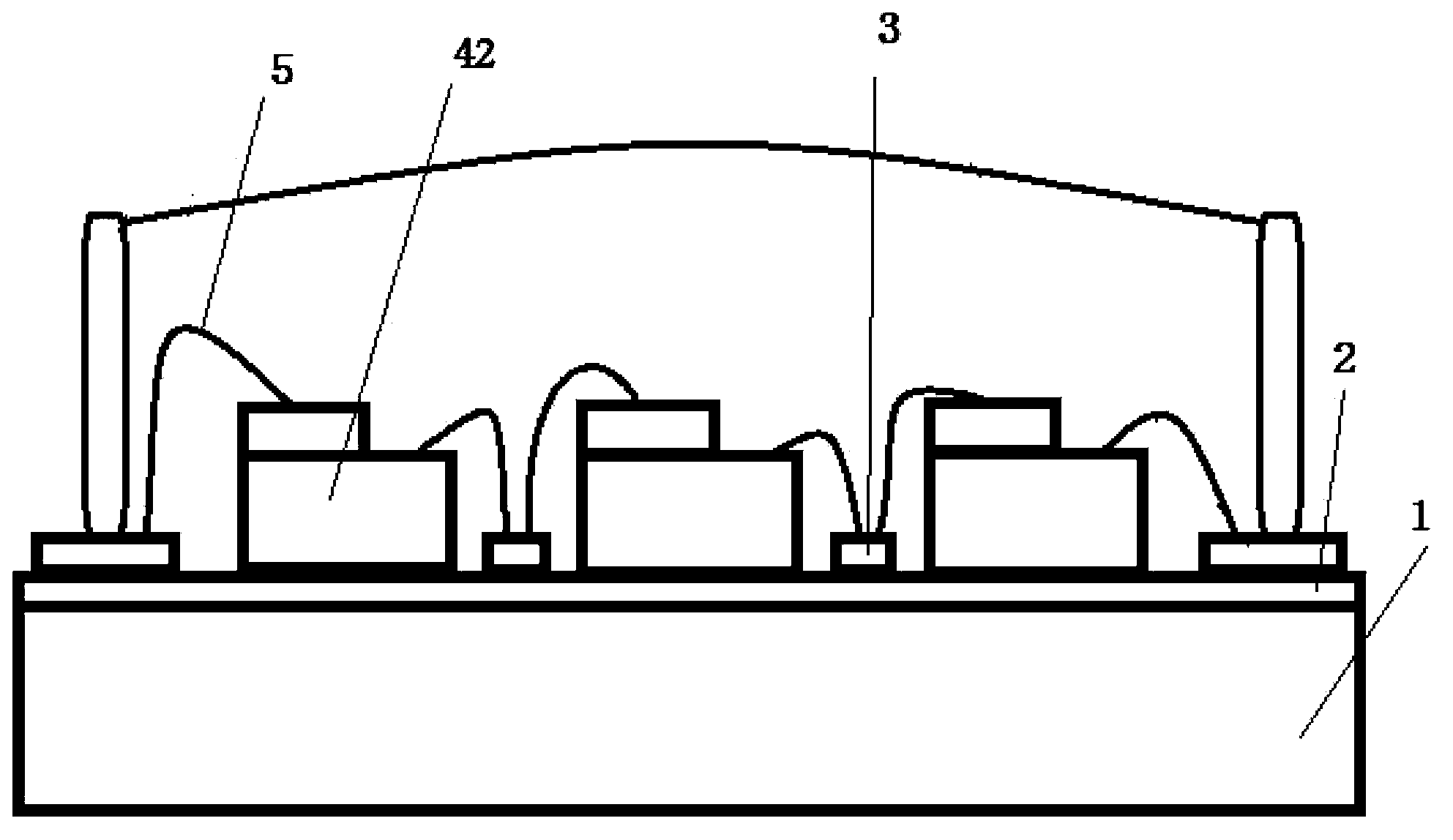

Light-emitting diode (LED) packaged on basis of AlSiC composite substrate

InactiveCN103383985AHigh thermal conductivityAdjustable expansion coefficientSolid-state devicesSemiconductor devicesComposite substrateCopper

The invention discloses a light-emitting diode (LED) packaged on basis of an AlSiC composite substrate. The LED comprises an AlSiC composite radiating substrate coated with an AlN insulating layer, two copper membrane electrodes, an LED chip and golden wires. The LED chip is packaged on the AlSiC composite radiating substrate coated with the AlN insulating layer, the two copper membrane electrodes are plated on the AlN insulating layer and connected with the positive electrode and the negative electrode of the LED chip through the golden wires. The LED packaged on basis of the AlSiC composite substrate is simple in structure, good in radiating performance and long in service life.

Owner:SOUTH CHINA UNIV OF TECH

Copper-covered ALSiC composite radiating substrate and manufacturing method thereof

ActiveCN103515521AHigh thermal conductivityAdjustable expansion coefficientSemiconductor devicesSpinelOptoelectronics

The invention discloses a copper-covered ALSiC composite radiating substrate which comprises an ALSiC substrate body and a copper layer attached to the ALSiC substrate body. A copper-aluminum spinel interface is formed between the copper layer and the ALSiC substrate body. The ALSiC composite radiation substrate is simple in structure, good in radiating performance, capable of solving the problem that the radiating substrate body is not matched with thermal expansion of a chip material, capable of preventing an LED chip packaged on the substrate body from being easily disengaged, capable of prolonging the service life of an LED and applicable to manufacturing of low-cost large-power LEDs.

Owner:惠州雷士光电科技有限公司 +1

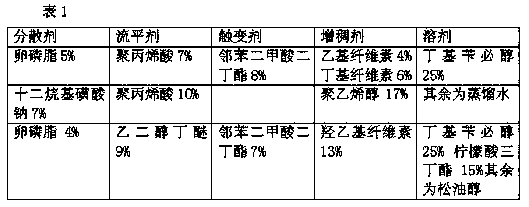

Medium-temperature cured conductive slurry specially used for AlSiC LED support

InactiveCN103996435AImprove conductivityLower sintering temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureOptoelectronicsSlurry

The invention belongs to a preparation technology of an electronic slurry and specifically relates to a medium-temperature cured conductive slurry specially used for an AlSiC LED support. The conductive slurry is uniform in distribution, great in stability, lower in sintering temperature and great in conductivity. The medium-temperature cured conductive slurry specially used for the AlSiC LED support includes a conductive function phase and a carrier phase. The conductive function phase is silver particles, and the carries phase is made of raw materials in the following mass percentage: 2-10% of a dispersant, 5-10% of a flatting agent, 2-5% of a thixotropic agent and 2-10% of a thickening agent, the remaining being a solvent. The silver particles occupy 30-80% of a total mass percentage and are prepared through a specific preparation method.

Owner:西安明科微电子材料有限公司

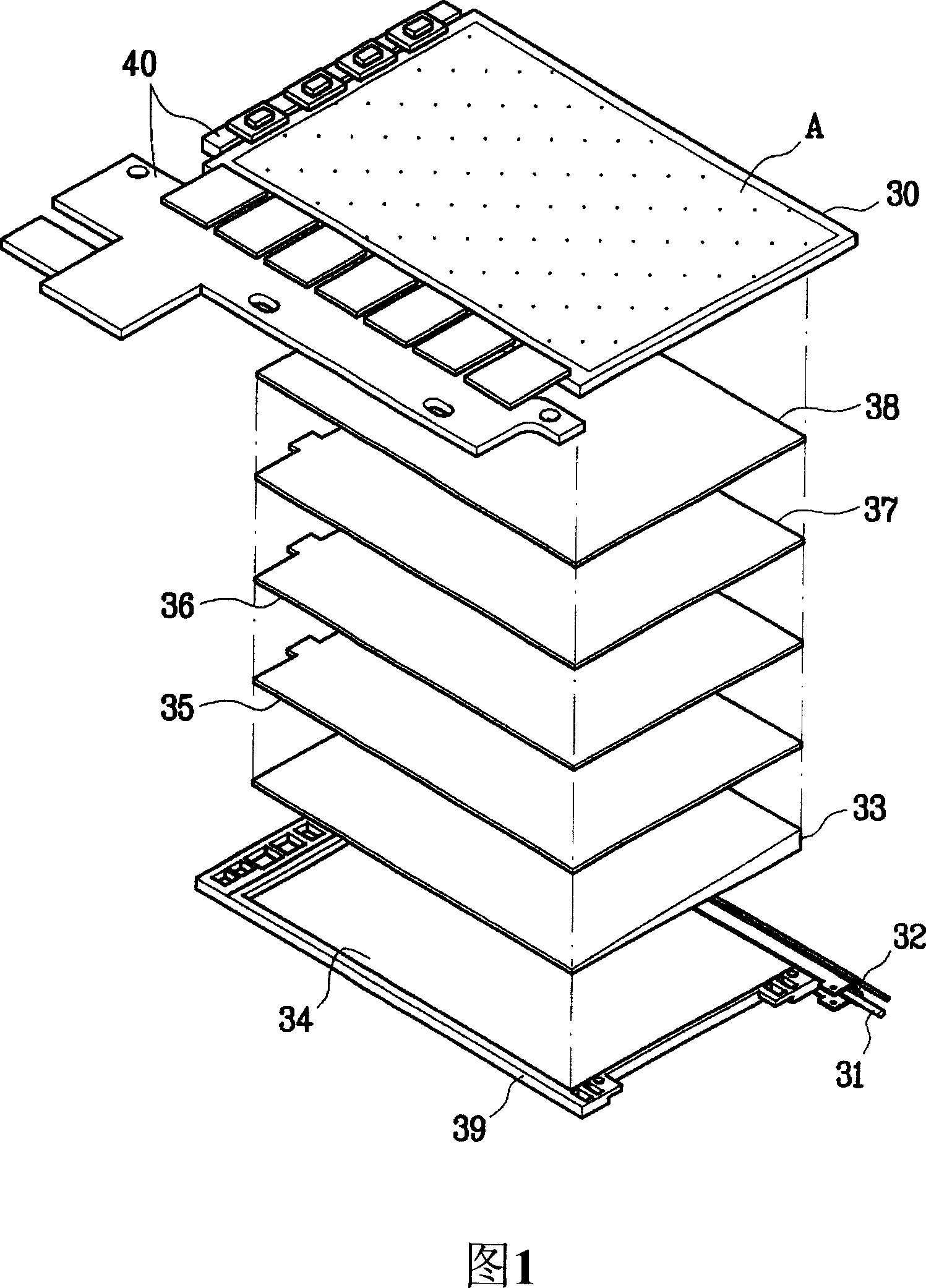

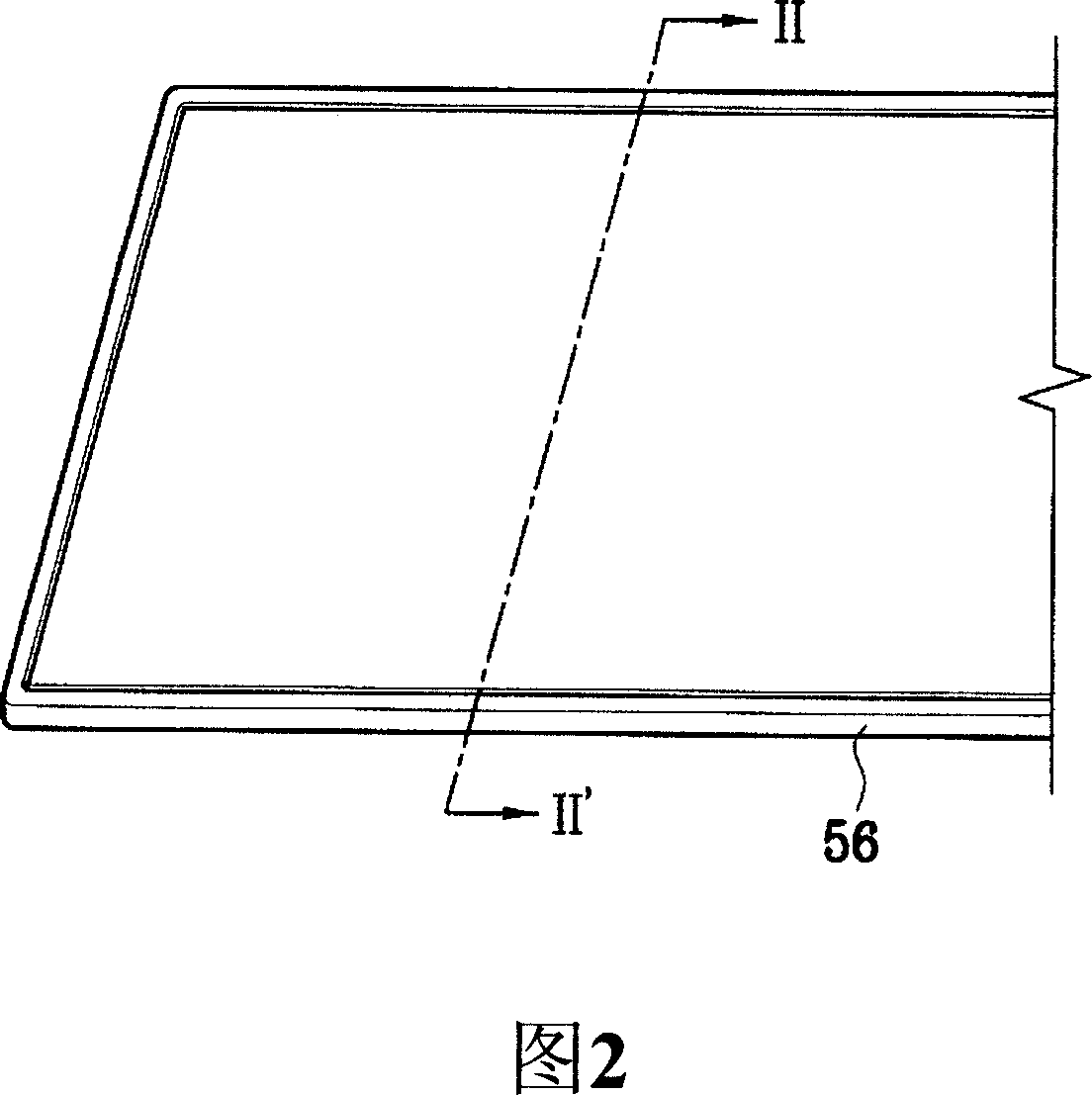

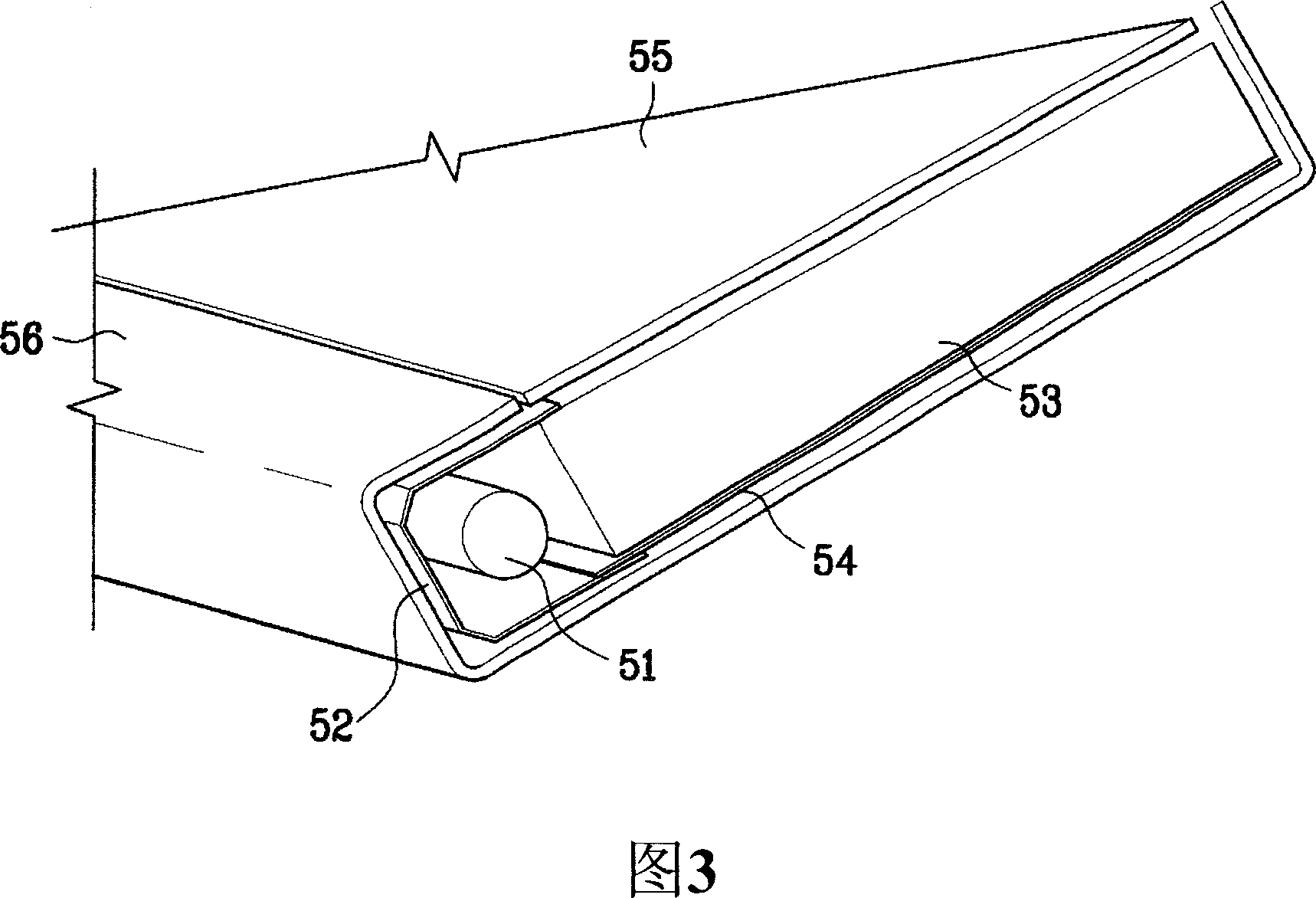

Reflective plate and method for manufacturing the same and backlight unit and liquid crystal display device having the same

InactiveCN1924668AQuality improvementNon-linear opticsOptical elementsLiquid-crystal displayGraphite

The present invention relates to a reflective plate which effectively disperses the heat of the lamp to the outside of the liquid display panel to improve the quality, a method for manufacturing the same and a backlight unit with the same. The reflective plate comprises a graphite, aluminum, copper, CNT in a film shape, in a plate shape or in a power shape, a thermal conduction material for ALSiC, and the reflecting materials, such as Ag, Al2O3, TiO2, Al, PET and the optical fiber.

Owner:LG DISPLAY CO LTD

Feedthrough

ActiveUS9614199B2Low production costSimple adaptationSmall-sized cells cases/jacketsSecondary cellsElectrical conductorTitanium

A feedthrough, for example through a part of a housing, such as a battery housing, is, for example, made of a metal, such as a light alloy, for example aluminum, an aluminum alloy, AlSiC, magnesium, a magnesium alloy, titanium, a titanium alloy, steel, stainless steel or high-grade steel. The housing part has at least one opening through which at least one conductor having a cross-section is guided in a glass or glass ceramic material. The conductor has at least two sections, a first section having a first, substantially round, for example a circular, cross section having a diameter in the region of the feedthrough through the glass or glass ceramic material, and a second section having a second, substantially non-round, for example a substantially rectangular cross-section, and the conductor is formed in one piece.

Owner:SCHOTT AG

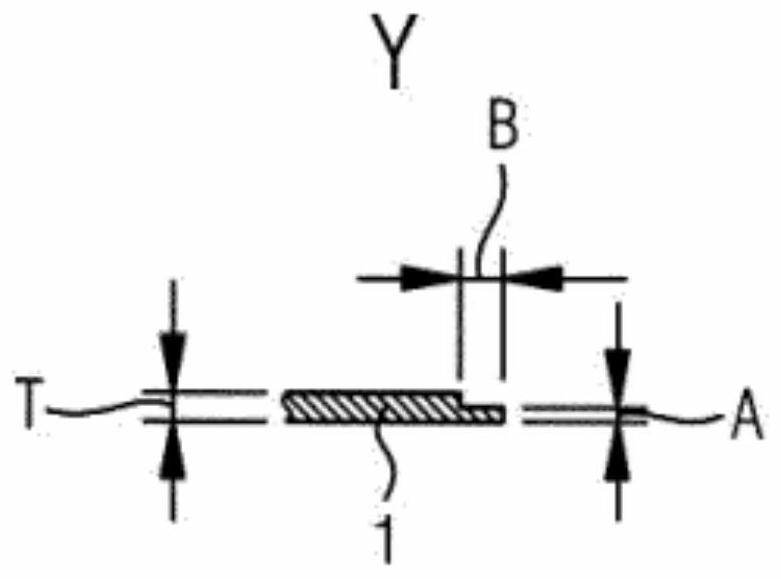

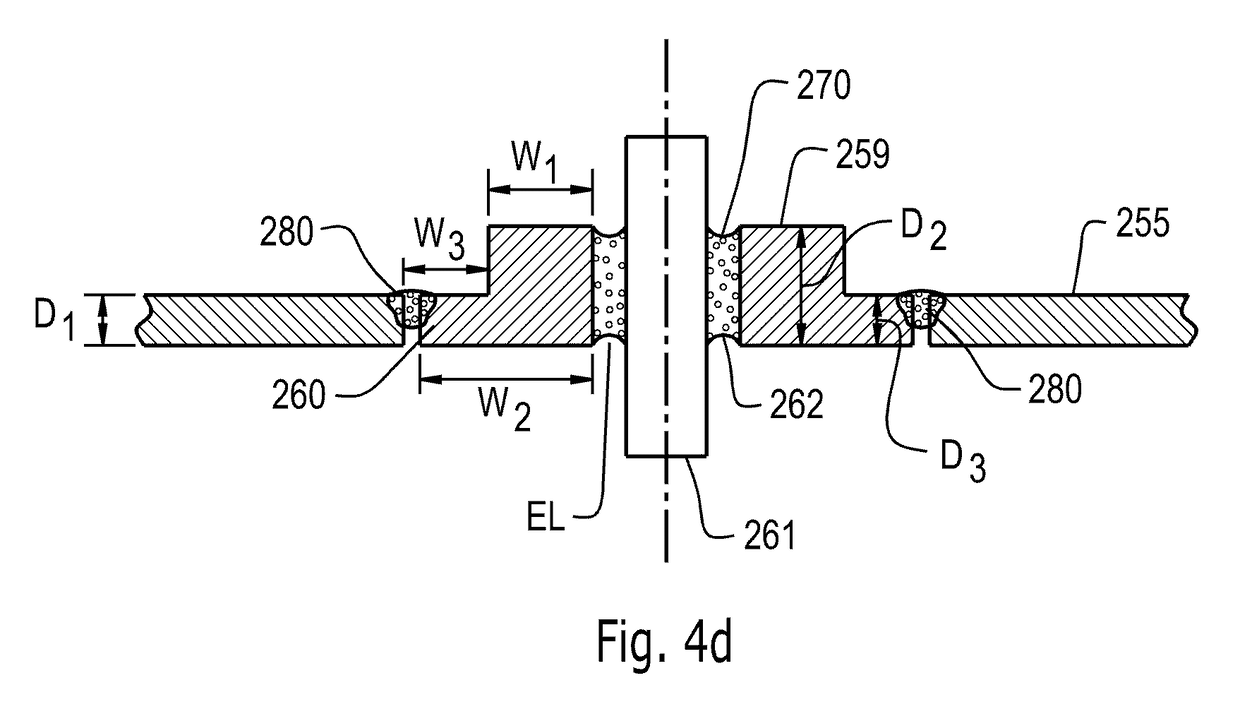

Electrical feedthrough glass-metal electrodes

PendingCN113196430AElectrolytic capacitorsSmall-sized cells cases/jacketsMetallic electrodeElectrical battery

The invention relates to an electrical device, in particular an electrical storage device or sensor housing, preferably a battery, in particular a micro-battery or capacitor, having a feedthrough through a housing part which has the material thickness T of the housing of the device and is made of a metal, in particular iron, iron alloys, iron-nickel alloys, iron-nickel-cobalt alloys, KOVAR, steel, stainless steel, aluminum, aluminum alloys, AlSiC, magnesium, magnesium alloys, titanium or titanium alloys, wherein the housing part has at least one opening, the opening receiving a contact element, in particular a conductor, made of a conductive material in a glass or glass ceramic material. The invention is characterized in that the housing part has a flange in the region of the opening and thus forms an inner wall of the through-opening of the height H, EL which is greater than the material thickness T, the glass length EL of the glass or glass ceramic material preferably corresponding to the height H.

Owner:SCHOTT AG

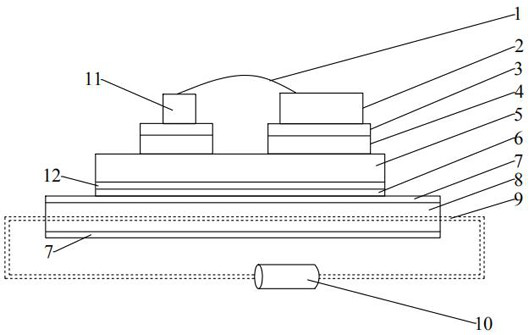

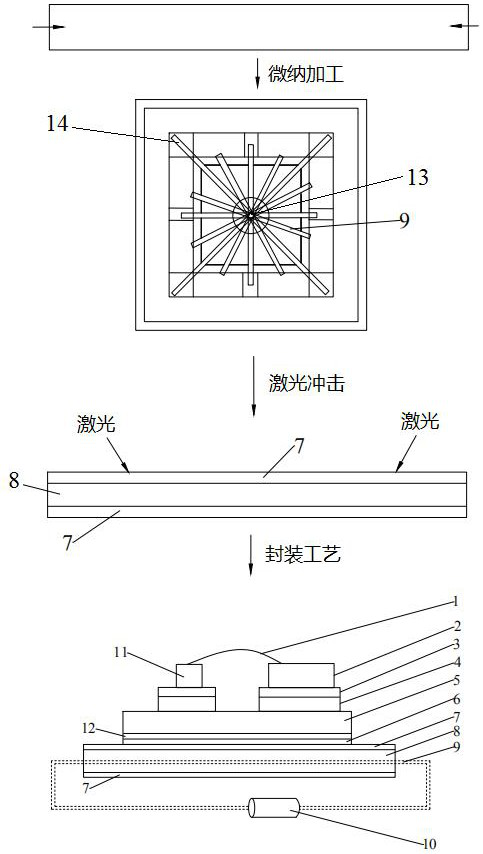

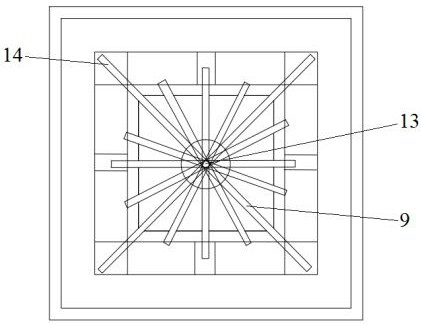

Power electronic device IGBT (Insulated Gate Bipolar Translator) module with heat dissipation structure and preparation method

ActiveCN114334872AImprove reliabilityExtended service lifeSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationThermodynamics

The invention relates to a power electronic device IGBT (Insulated Gate Bipolar Translator) module with a heat dissipation structure and a preparation method, and belongs to the technical field of power electronic manufacturing and sealing testing. The power electronic device IGBT module with the heat dissipation structure comprises a bonding wire, an IGBT chip, an FRD chip, a solder layer, a DBC substrate, a heat conduction grease layer, the heat dissipation structure and a micropump. The heat dissipation structure comprises a micro-channel copper substrate, wherein AlSiC dielectric layers are machined on the two faces of the micro-channel copper substrate. The AlSiC dielectric layers are processed to the two sides of the micro-channel copper substrate through a laser shock peening manufacturing process, so that the heat dissipation structure has a low thermal expansion coefficient, a high-strength heat conduction coefficient and low cost, heat generated by a module can be efficiently dissipated, and rapid cooling is achieved. The problems that an existing IGBT module heat dissipation system is large in weight, high in manufacturing cost and poor in heat dissipation performance are solved, the problem that heat dissipation of a radiator is unbalanced can be effectively solved, and therefore the reliability of a device is improved, and the service life of the device is prolonged.

Owner:合肥阿基米德电子科技有限公司

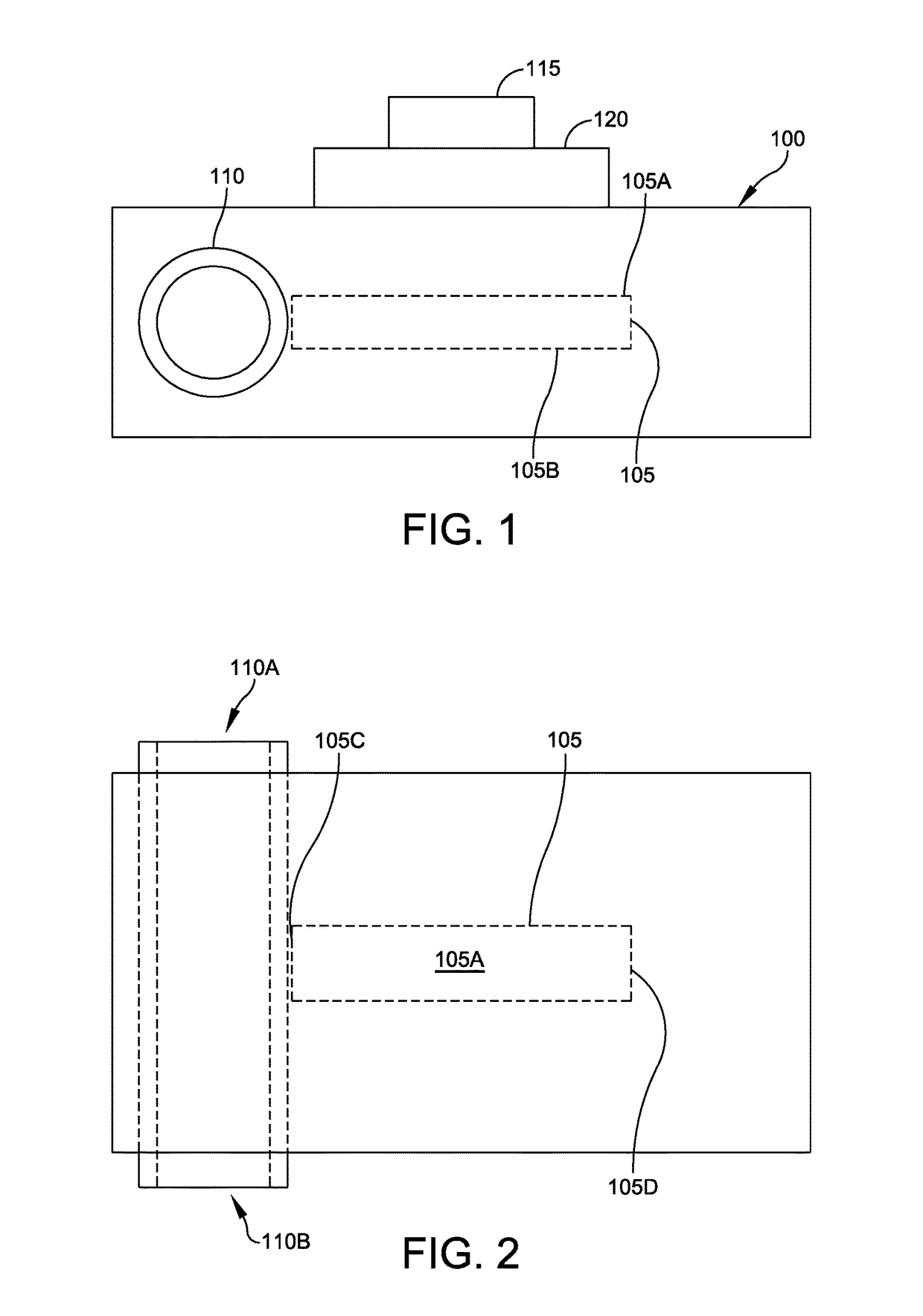

Thermal management device for heat generating power electronics incorporating high thermal conductivity pyrolytic graphite and cooling tubes

ActiveUS20180014435A1Maximum heat transfer efficiencyImproved thermal managementSemiconductor/solid-state device detailsSolid-state devicesThermal expansionHeat transfer efficiency

The present invention is a system for cooling high power, heat generating devices. The system includes a metal matrix composite (AlSiC) having a coefficient of thermal expansion substantially equal to that of the heat generating device. The metal matrix composite (MMC) includes interior cooling channels and at least one Pyrolytic Graphite insert laterally positioned against the cooling channels. The heat generating device is placed on the metal matrix composite top surface in a substantially parallel relationship with the Pyrolytic Graphite insert surface area for maximum heat transfer efficiency.

Owner:CPS TECH

Anti-corrosion graphite fiber AlSiC composite for electronic packaging and preparation method of composite

InactiveCN106567020AIncrease roughnessHigh strengthSemiconductor/solid-state device detailsSolid-state devicesFiberPhosphoric acid

The invention discloses an anti-corrosion graphite fiber AlSiC composite for electronic packaging. The composite is prepared from raw materials in parts by weight as follows: 11-13 parts of graphite fibers, 75-78 parts of SiC, 95-100 parts of a 6061 aluminium alloy, 0.4-0.6 parts of aluminum oxide, 4-4.3 parts of phosphoric acid, 13-14 parts of a pore-forming agent, 2-2.5 parts of PVP, a proper amount of dichloromethane, a proper amount of DMF, 1.3-1.5 parts of nano lanthanum borate, 1.5-1.8 parts of flaky carbon powder, 1.1-1.4 parts of nano aluminum hydroxide, 1.6-1.8 parts of germanium diboride and 43-45 parts of ethyl alcohol. The graphite fibers are added, a linear heat dissipation path is formed, and the heat dissipation performance is better than that of separate point contact of SiC; the germanium diboride is used, and the molten metal etching resistance, the active gas corrosion resistance, abrasion resistance and the oxidation resistance of the composite are improved; and the flaky carbon powder and the nano aluminum hydroxide are used cooperatively, and the heat dissipation performance and the strength of the composite are improved.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

A kind of copper-clad alsic composite heat dissipation substrate and preparation method thereof

ActiveCN103515521BHigh thermal conductivityAdjustable expansion coefficientSemiconductor devicesSpinelThermal expansion

The invention discloses a copper-covered ALSiC composite radiating substrate which comprises an ALSiC substrate body and a copper layer attached to the ALSiC substrate body. A copper-aluminum spinel interface is formed between the copper layer and the ALSiC substrate body. The ALSiC composite radiation substrate is simple in structure, good in radiating performance, capable of solving the problem that the radiating substrate body is not matched with thermal expansion of a chip material, capable of preventing an LED chip packaged on the substrate body from being easily disengaged, capable of prolonging the service life of an LED and applicable to manufacturing of low-cost large-power LEDs.

Owner:惠州雷士光电科技有限公司 +1

AlSiC/AlSi two-phase material and preparation method thereof

InactiveCN110272280AImprove thermal conductivityAdjustable expansion coefficientCeramicwareSlurryCeramic substrate

The invention relates to the technical field of composite materials, and in particular relates to a preparation method of an AlSiC / AlSi two-phase material, and the AlSiC / AlSi two-phase material prepared by the preparation method. According to the method provided by the invention, firstly a porous silicon carbide ceramic substrate M6 is prepared by using powder formed by silicon carbide powder with different particle sizes, aluminum oxide, kaolin and Suzhou soil, a ceramic substrate M9 with combined silicon and silicon carbide surface layer diffusion is prepared from silicon wax slurry M7 containing silicon powder with different particle sizes on the basis of the ceramic substrate M6, and finally aluminum is infiltrated into the ceramic substrate M9 to form the composite material having two phases of AlSiC and AlSi; and the composite material combines the advantages of the AlSiC and the AlSi in one, and has the advantages of high thermal conductivity, an adjustable expansion coefficient, a low density and good strength.

Owner:西安明科微电子材料有限公司

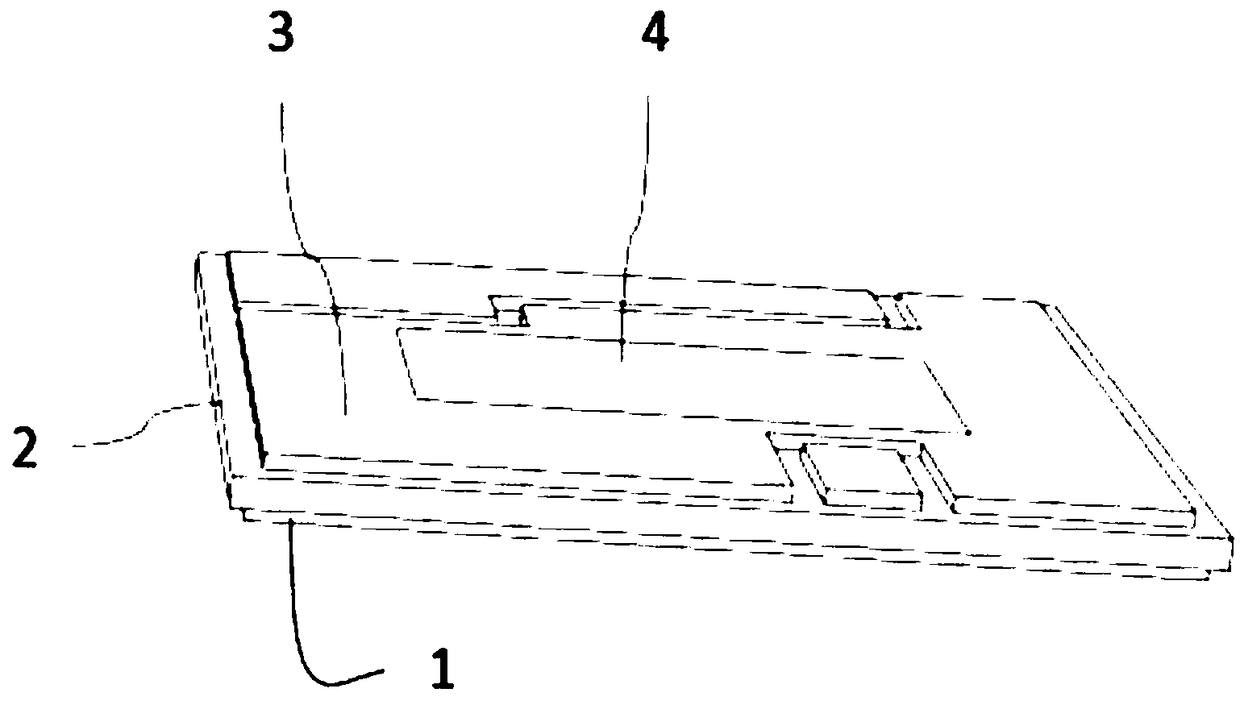

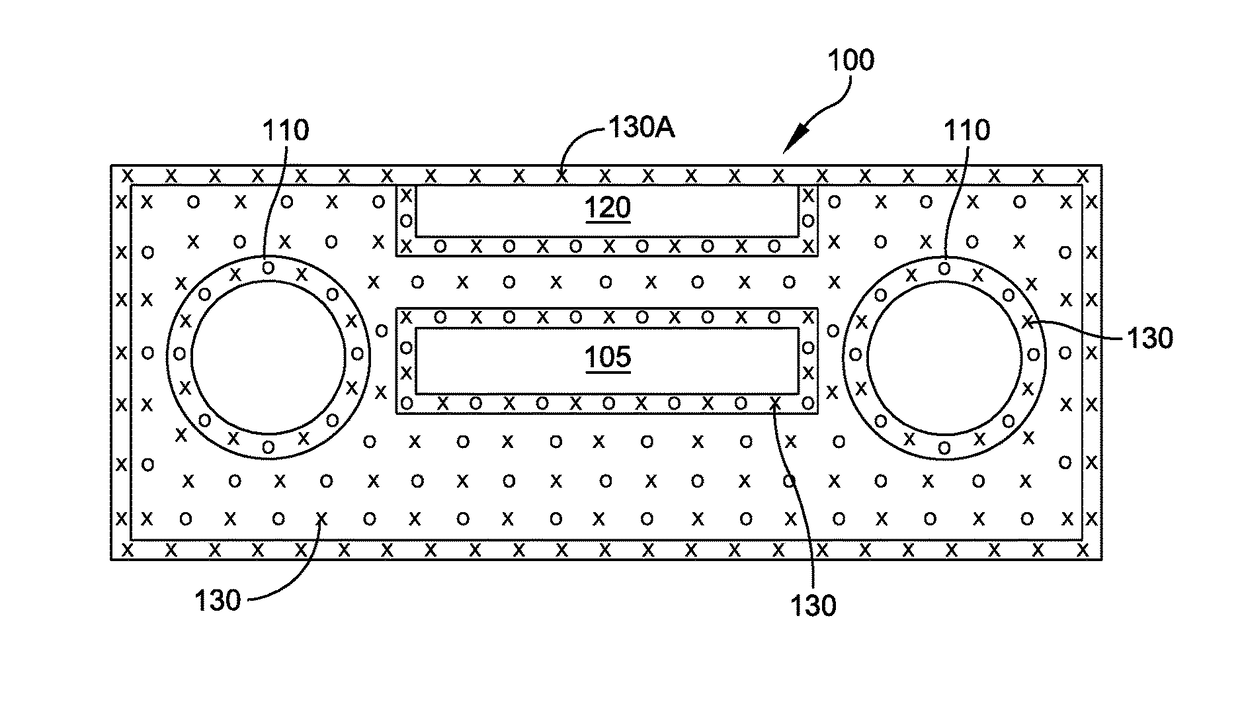

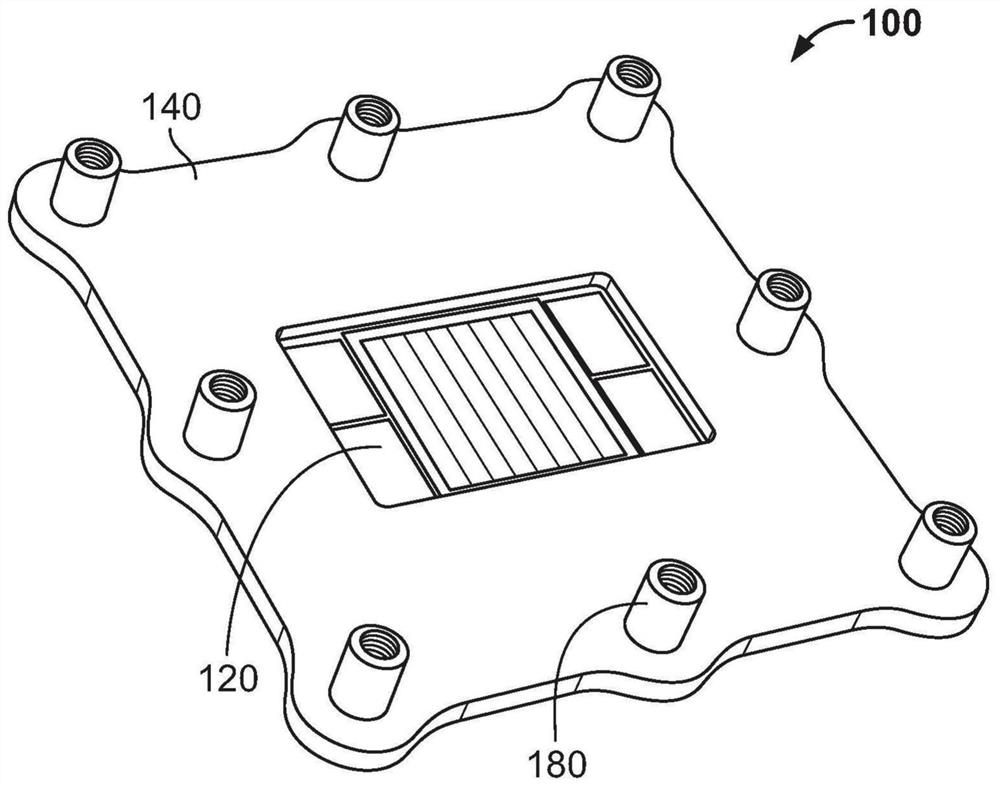

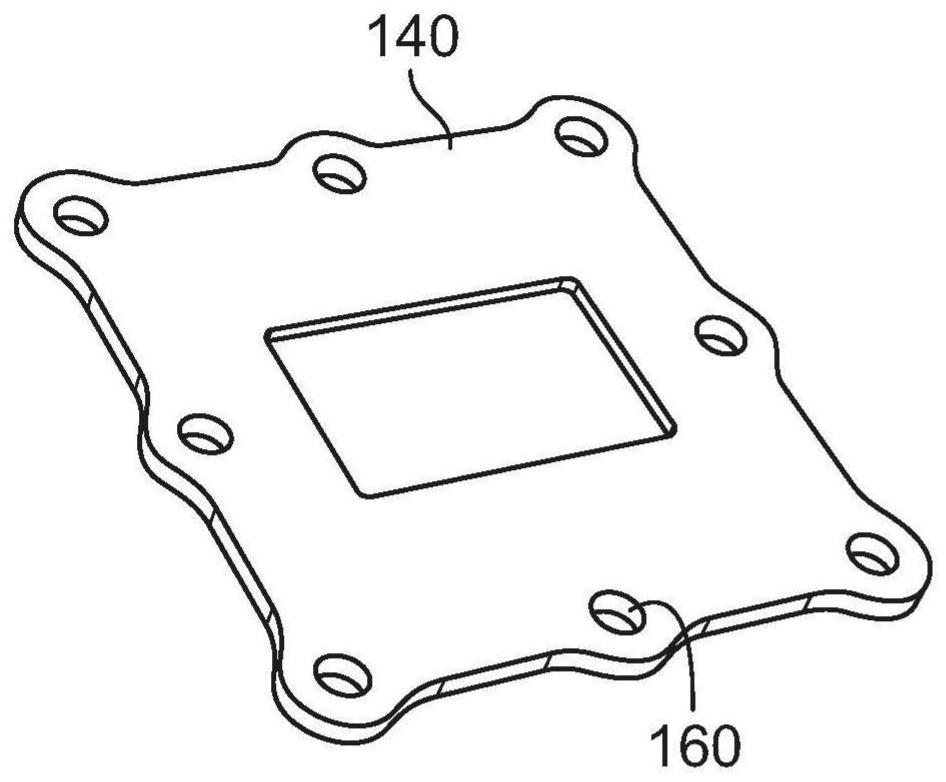

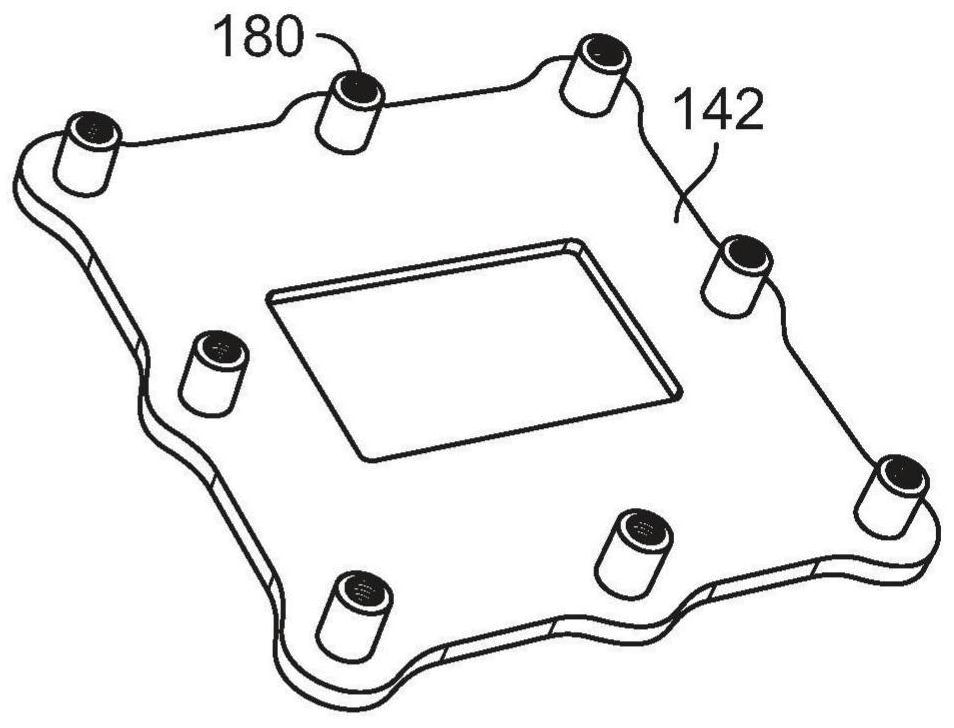

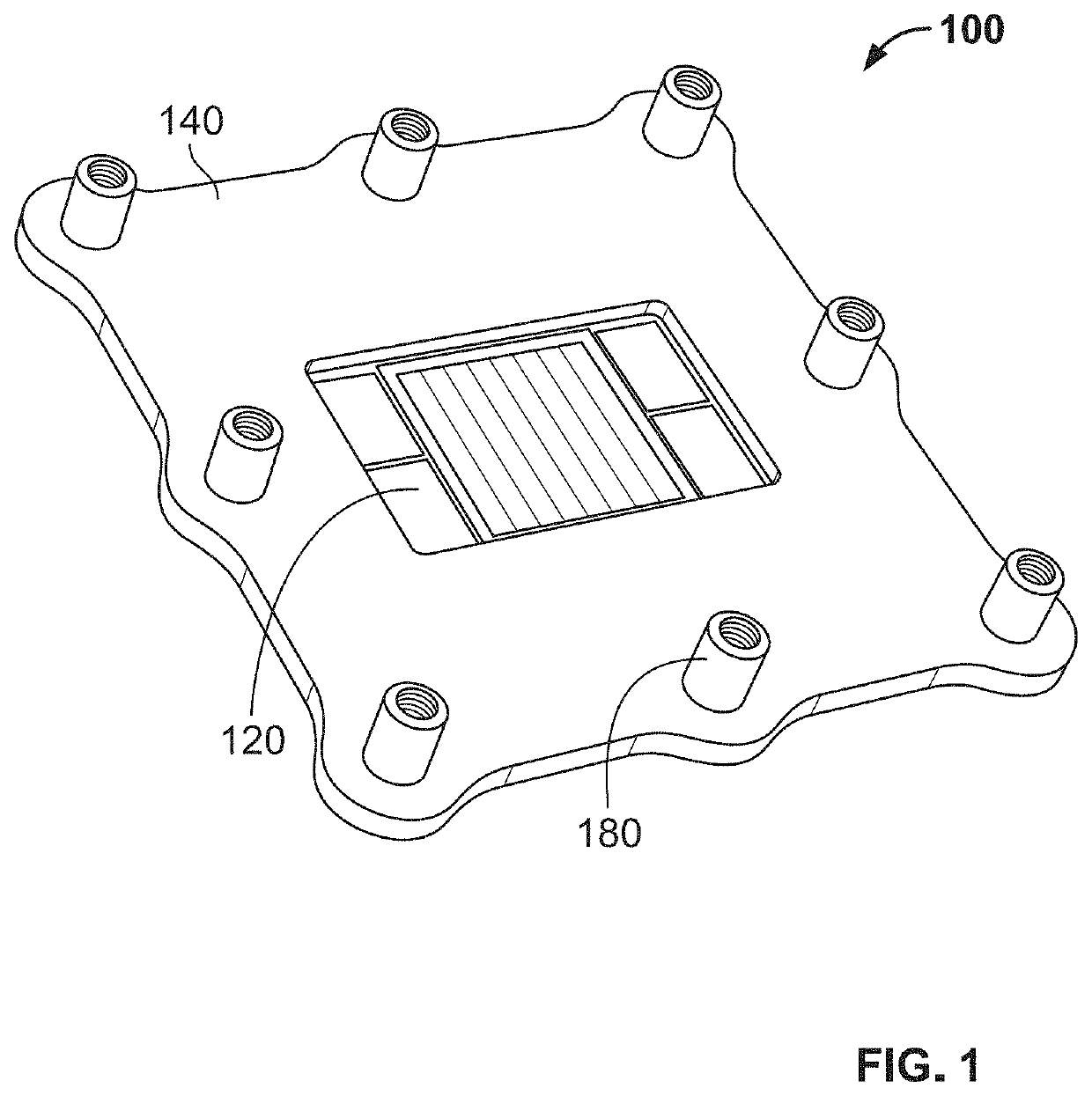

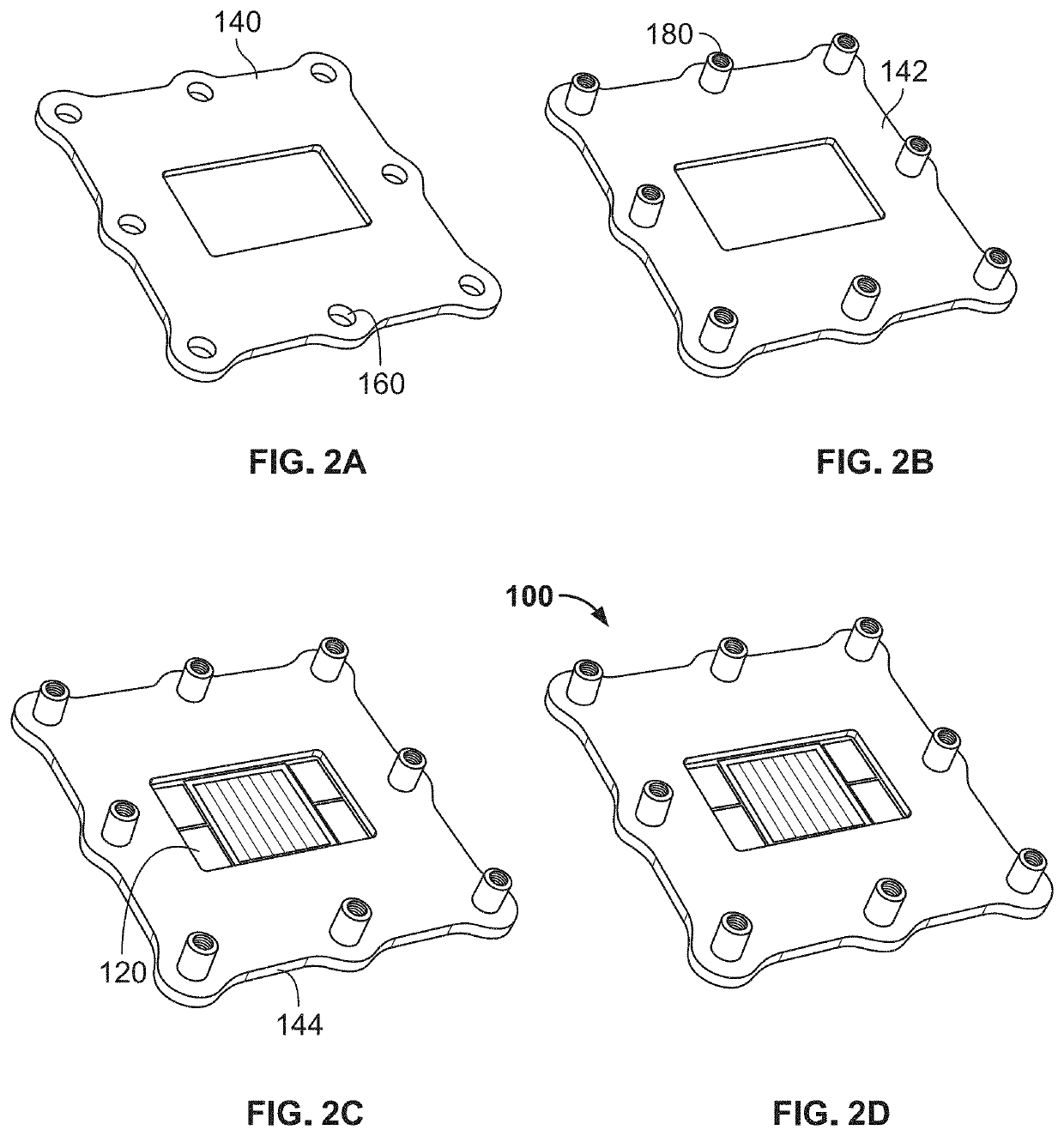

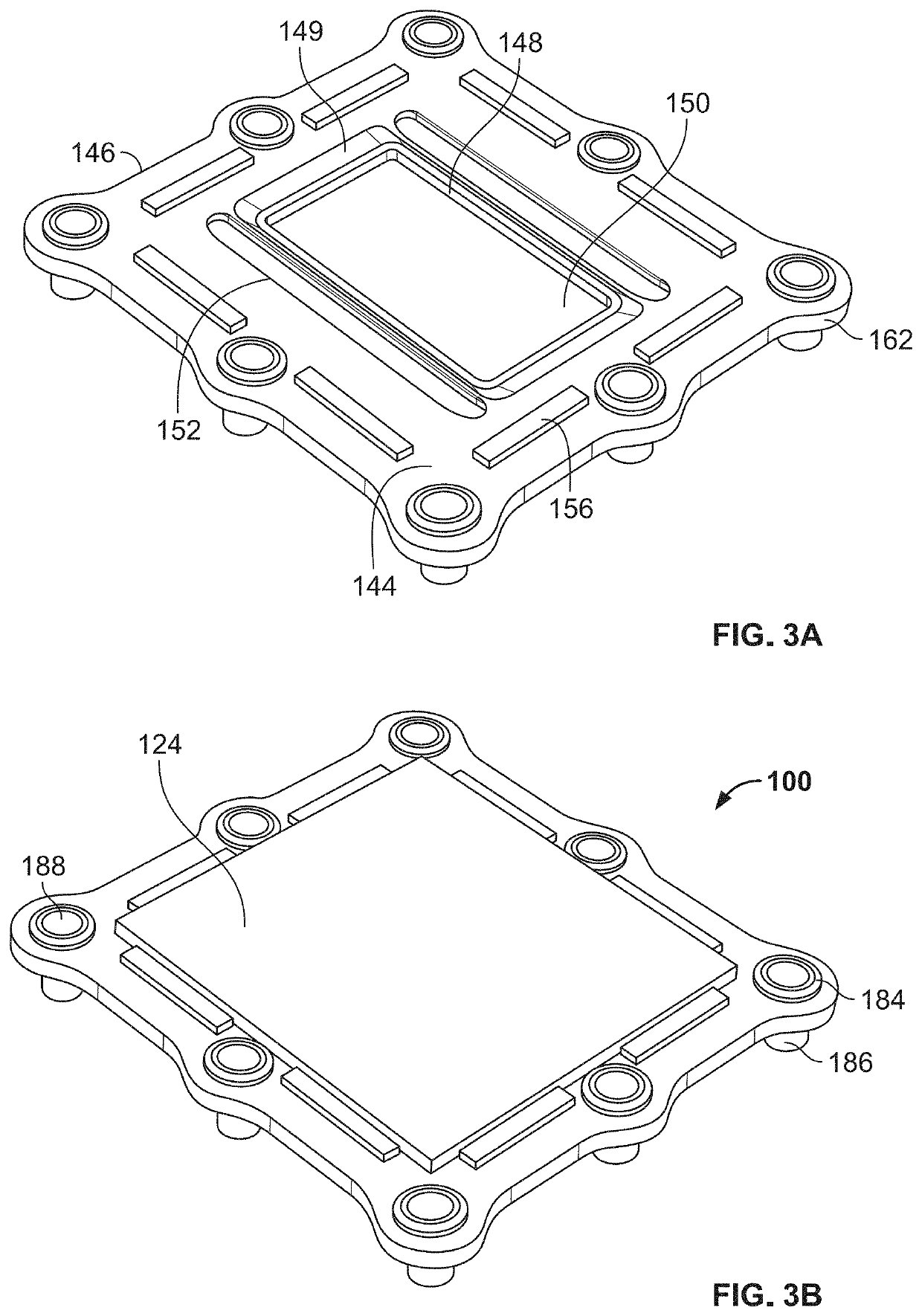

Weight-optimized stiffener and sealing structure for direct liquid cooling module

PendingCN112185906ASemiconductor/solid-state device detailsSolid-state devicesDevice materialDirect liquid cooling

The invention relates to a weight-optimized stiffener and seal structure for a direct liquid cooling module. A weight-optimized stiffener for a semiconductor device is disclosed. In one example, the reinforcement is made of AlSiC due to the weight and thermal characteristics of AlSiC. The O-shaped ring provides a seal between the top surface of the stiffener and a component of the semiconductor device, and the adhesive provides a seal between the bottom surface of the stiffener and another component of the semiconductor device. The stiffener provides warpage control for the lidless package while achieving direct liquid cooling of the chip or substrate.

Owner:GOOGLE LLC

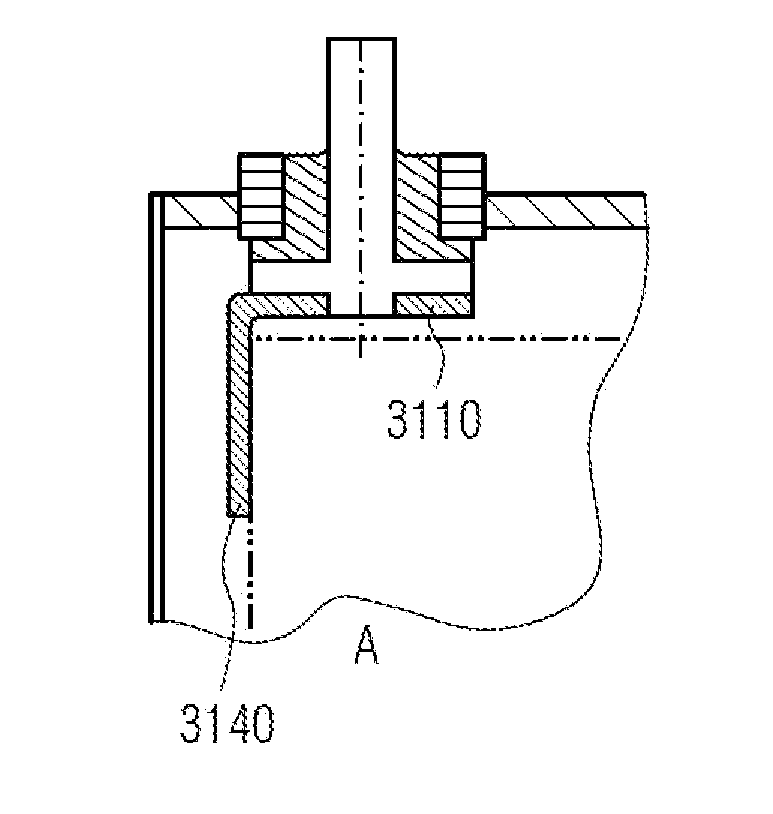

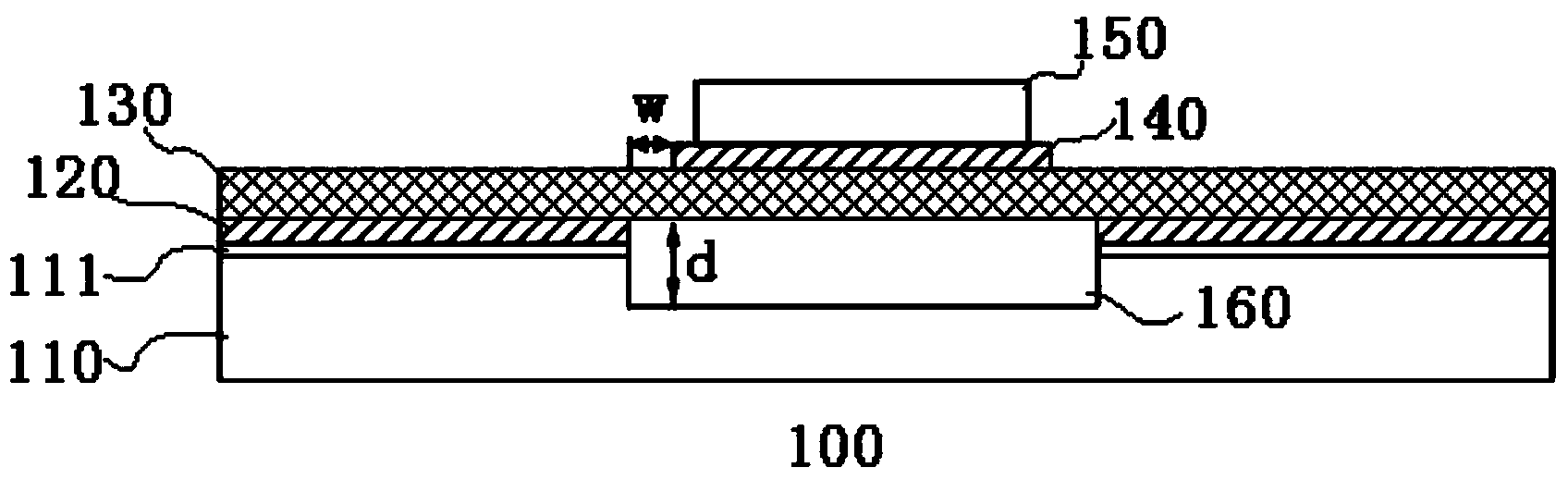

Substrate for IGBT module and encapsulation method for IGBT module

ActiveCN104952809AEliminate arcReduce roughnessSemiconductor/solid-state device detailsSolid-state devicesMetallurgyLiquid state

The invention discloses a substrate for an IGBT module and a method for encapsulating an IGBT module. The substrate comprises an AlSiC layer and an aluminium alloy layer, wherein the aluminium alloy layer is located on the surface of the bottom of the AlSiC layer to form a layer to be machined. The method comprises the following steps: (1) producing the substrate; accumulating SiC powder to form a uniform prefabricated part with a porous structure at first, and then infiltrating liquid-state aluminium alloy into the prefabricated part to form the AlSiC layer; continuing to inject the liquid-state aluminium alloy, and forming the aluminium alloy layer on the surface of the substrate; (2) sinking inwards the bottom of the substrate after using the substrate for finishing IGBT encapsulation, at this moment, levelly machining the bottom of the substrate to eliminate the radian sunk inwards. The substrate and the method disclosed by the invention have the advantages of being simple and convenient to machine, low in machining cost, capable of improving reliability, and the like.

Owner:ZHUZHOU CRRC TIMES SEMICON CO LTD

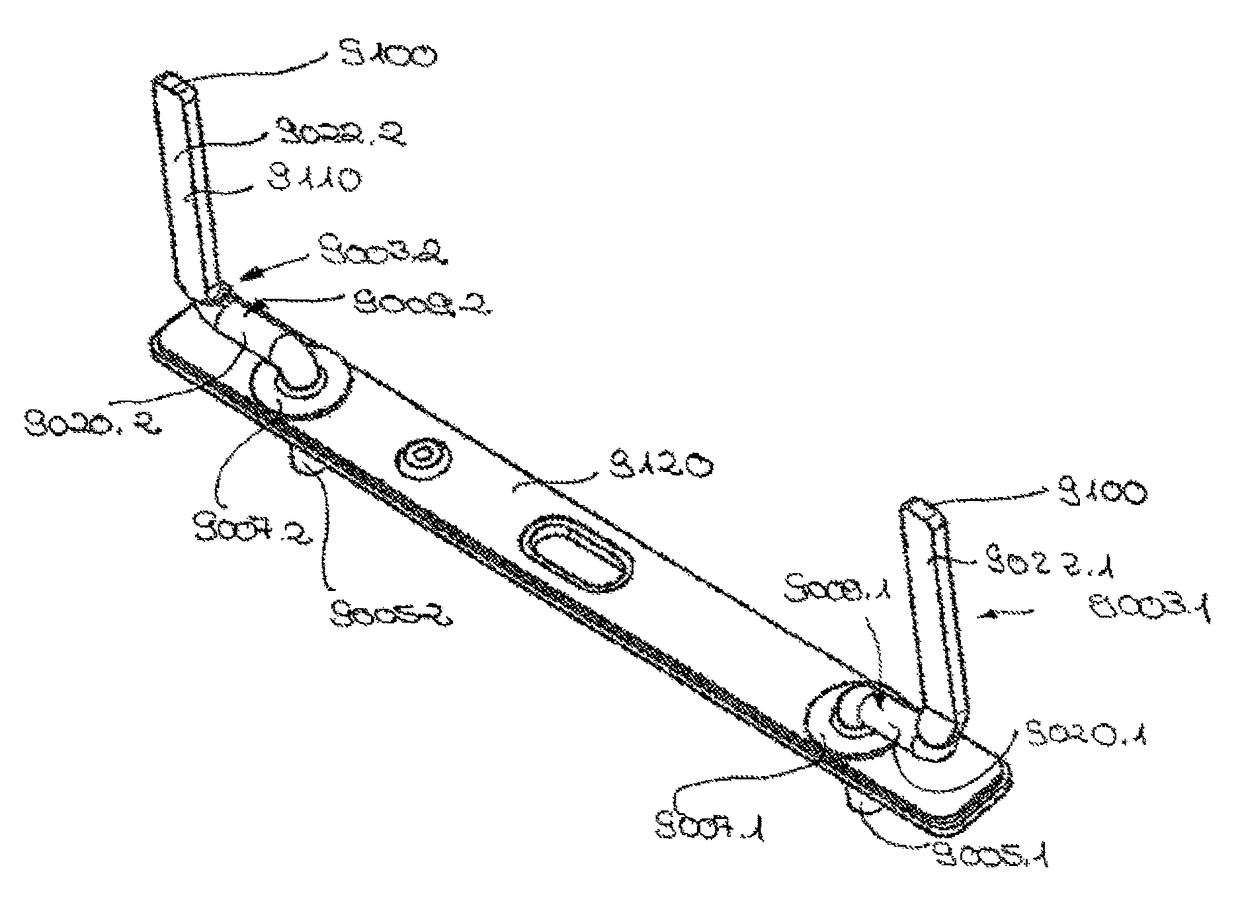

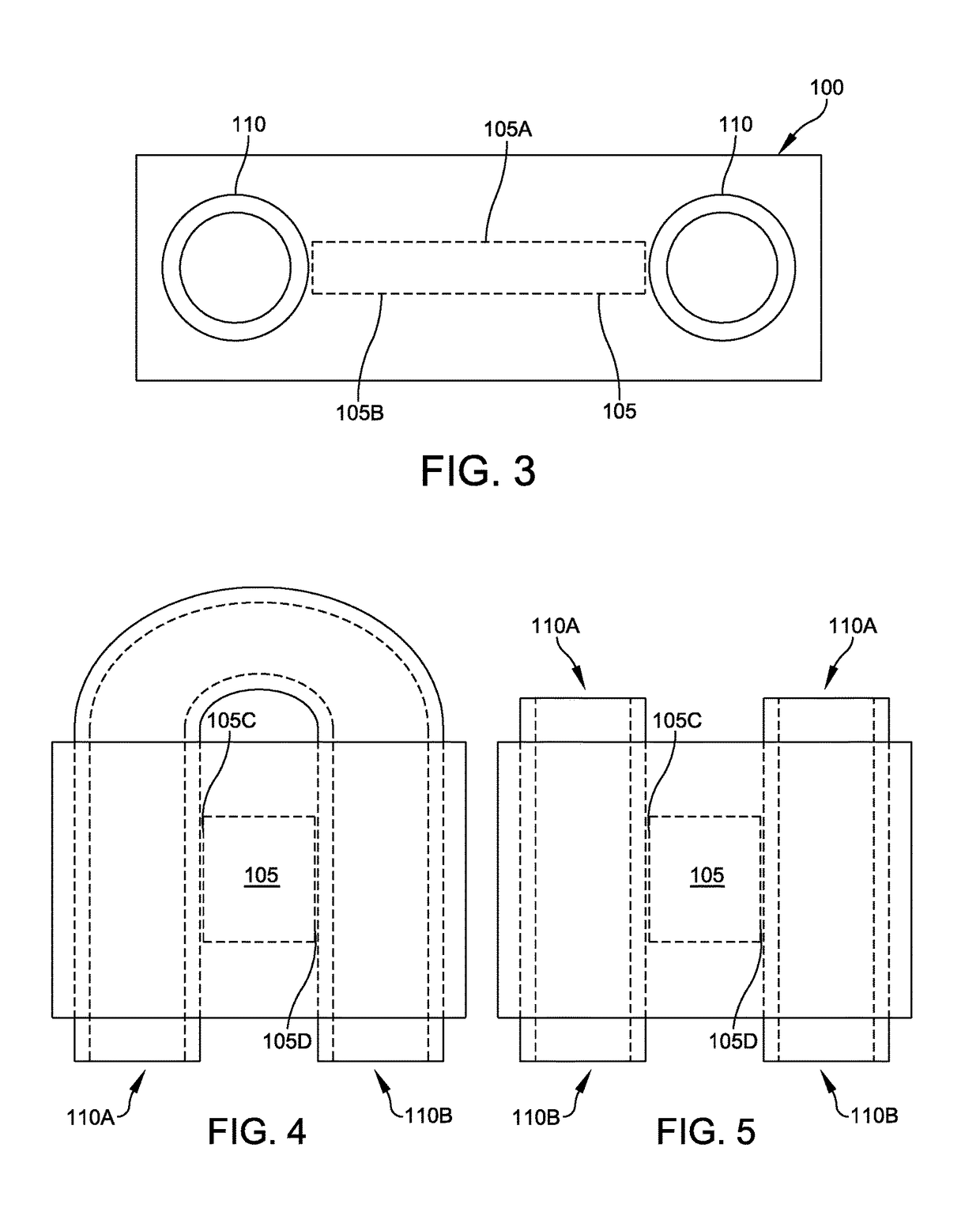

Weight Optimized Stiffener and Sealing Structure for Direct Liquid Cooled Modules

ActiveUS20210366841A1Reduce the total massSemiconductor/solid-state device detailsSolid-state devicesDevice materialDirect liquid cooling

A weight optimized stiffener for use in a semiconductor device is disclosed herein. In one example, the stiffener is made of AlSiC for its weight and thermal properties. An O-ring provides sealing between a top surface of the stiffener and a component of the semiconductor device and adhesive provides sealing between a bottom surface of the stiffener and another component of the semiconductor device. The stiffener provides warpage control for a lidless package while enabling direct liquid cooling of a chip or substrate.

Owner:GOOGLE LLC

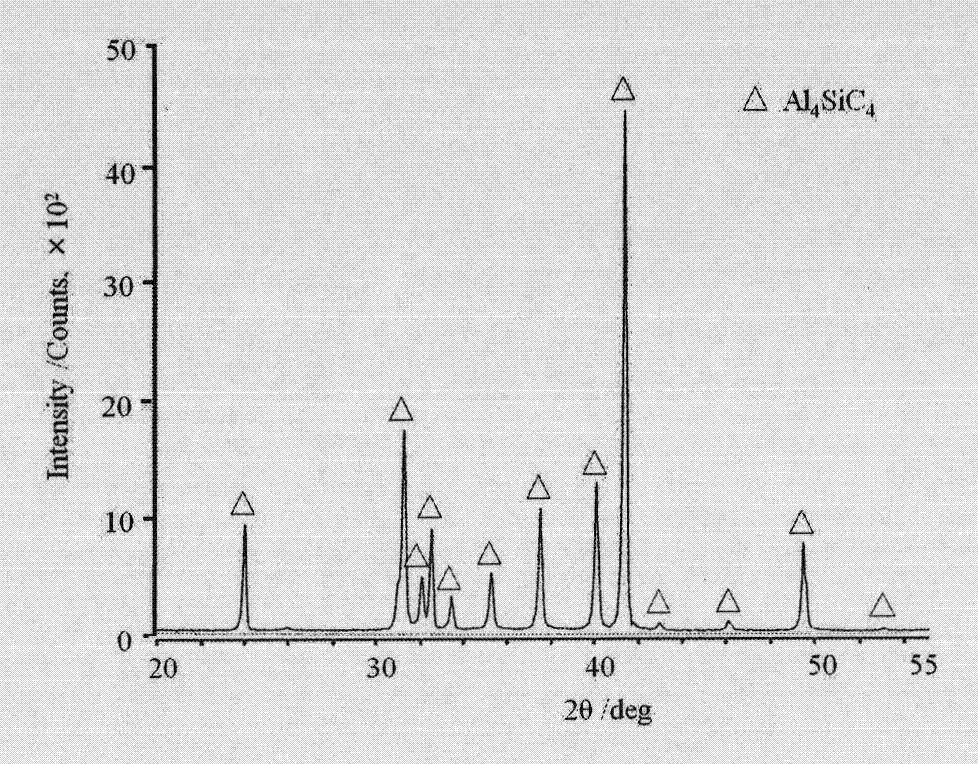

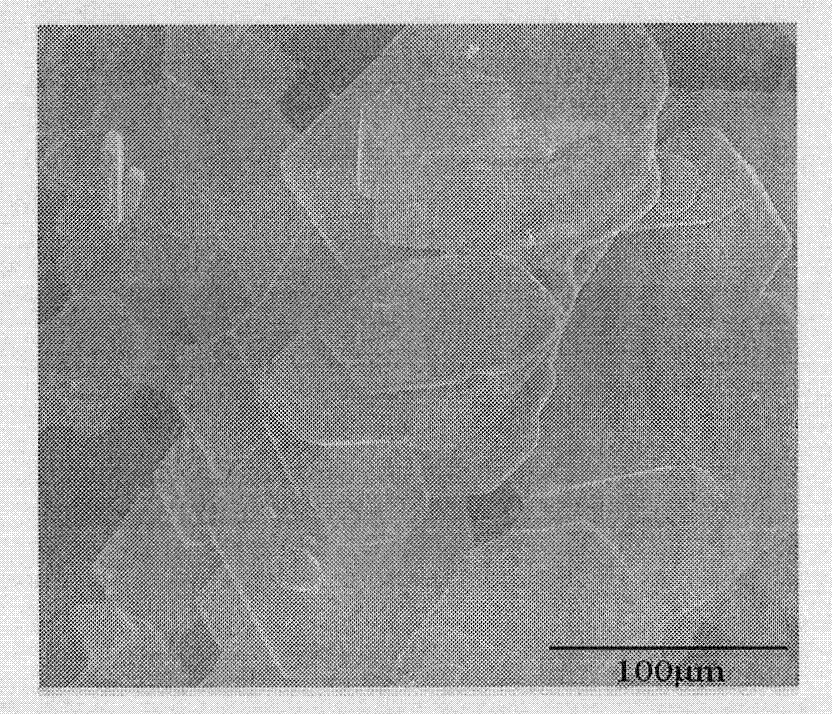

Synthesis method of high-purity AlSiC flaky powder

The invention discloses a preparation method of an AlSiC flaky powder. The method comprises the following steps: 1) mixing weighed raw materials so as to obtain a mixture, wherein the raw materials comprise the following components by weight percent: 45-60% of Al2O3 raw material, 10%-20% of SiO2 raw material, 25-40% of carbon raw material and 14% of SiC raw material; and 2) heating the mixture for 2-5 hours at the temperature of 1900-2200 DEG C at the mixed atmosphere of CO and Ar, cooling, and then removing the impurity layer on the surface of the product so as to obtain the AlSiC flaky powder, wherein the total pressure of the mixed atmosphere is 1 atmosphere pressure. The method in invention is simple and practicable and is suitable for scale production, and the yield and purity of theobtained product are high; and the length and width sizes of the obtained AlSiC flaky powder are 50-200 mu m, and the thickness of the AlSiC flaky powder is 4-5 mu m. The flaky structure of AlSiC is beneficial to enhancement of a ceramic product structure and improvement of product strength, thermal shock resistance and chemical corrosion resistance.

Owner:TSINGHUA UNIV

Easy-to-process graphite fiber AlSiC composite for electronic packaging and preparation method of composite

The invention discloses an easy-to-process graphite fiber AlSiC composite for electronic packaging. The composite is prepared from raw materials in parts by weight as follows: 11-13 parts of graphite fibers, 75-78 parts of SiC, 95-100 parts of a 6061 aluminium alloy, 0.4-0.6 parts of aluminum oxide, 4-4.3 parts of phosphoric acid, 13-14 parts of a pore-forming agent, 2-2.5 parts of PVP, a proper amount of dichloromethane, a proper amount of DMF, 1.3-1.5 parts of nano lanthanum borate, 1.3-1.5 parts of BeC, 1.2-1.4 parts of silver-coated TiO2 microspheres, 0.7-0.9 parts of graphite fluoride and 43-45 parts of ethyl alcohol. The graphite fibers are added, a linear heat dissipation path is formed, the heat dissipation performance is better than that of separate point contact of SiC, and the thermal expansion coefficient is further reduced; the BeC, the silver-coated TiO2 microspheres and the graphite fluoride are used, the machinability and the formability of the composite are improved, the size is accurate, and the heat dissipation performance is good.

Owner:HEFEI LONG DUO ELECTRONICS SCI & TECH

A led packaged with alsic composite substrate

The invention discloses an LED packaged with an AlSiC composite substrate. The LED comprises the AlSiC composite cooling substrate, an LED light source module, gold threads and an alumina ceramic frame, wherein the surface of the AlSiC composite cooling substrate is plated with a copper film and a silver film sequentially; the LED light source module is packaged on the AlSiC composite cooling substrate; the alumina ceramic frame is arranged on the outer side of the LED light source module and adheres to the LED light source module; two copper-film electrodes are plated on the alumina ceramic frame and connected with a positive pole and a negative pole of the LED light source module through the gold threads respectively. According to the LED, thermal expansion coefficients of the AlSiC composite substrate and an LED chip material are matched, so that an LED chip which is packaged on the substrate is not prone to falling, and the service life of the LED is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

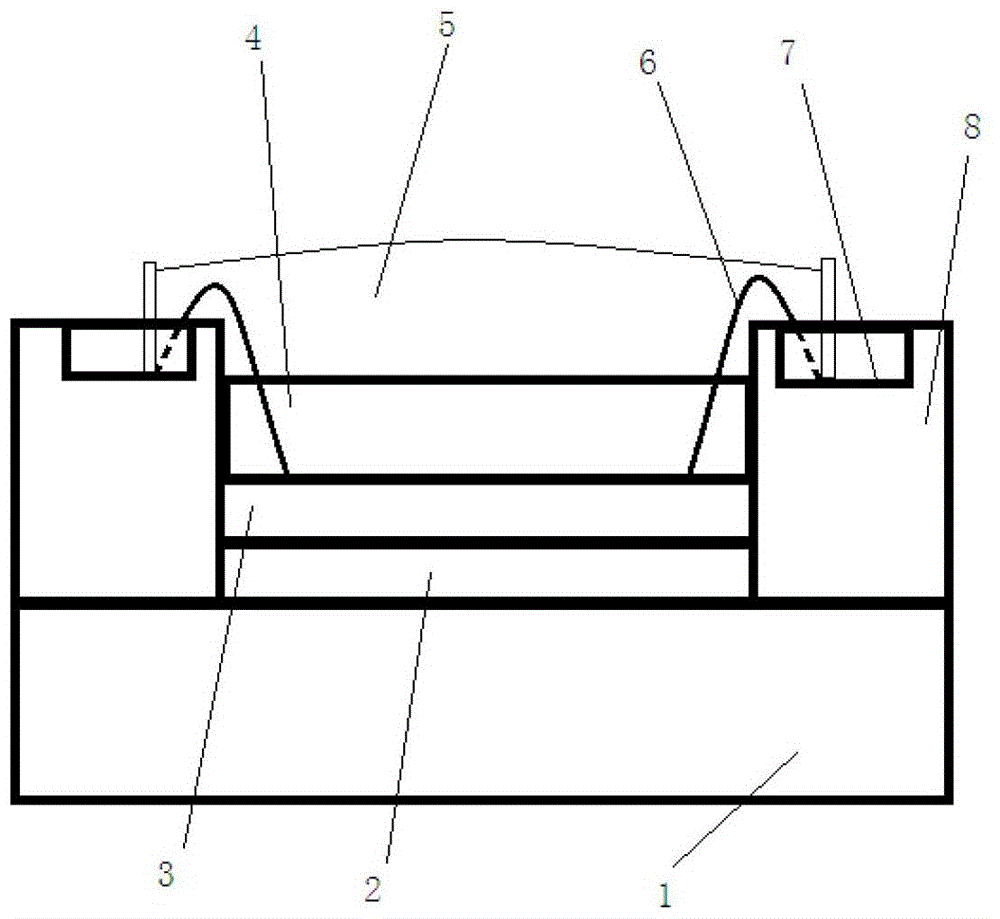

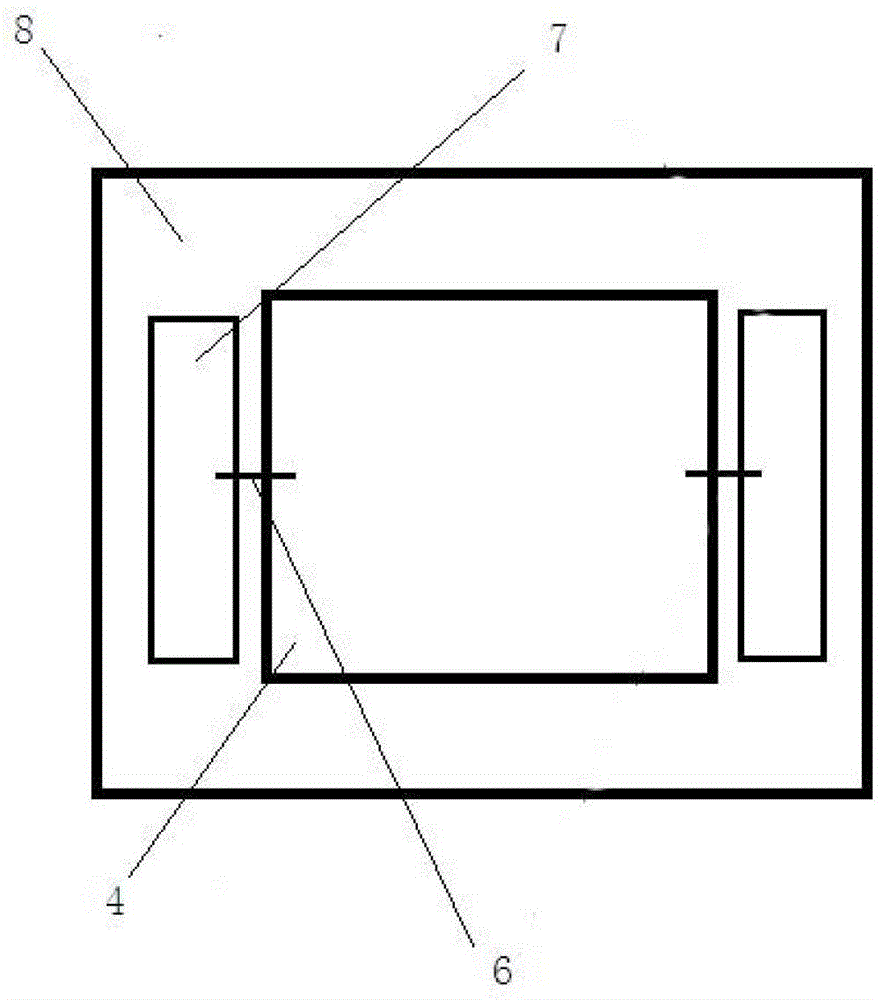

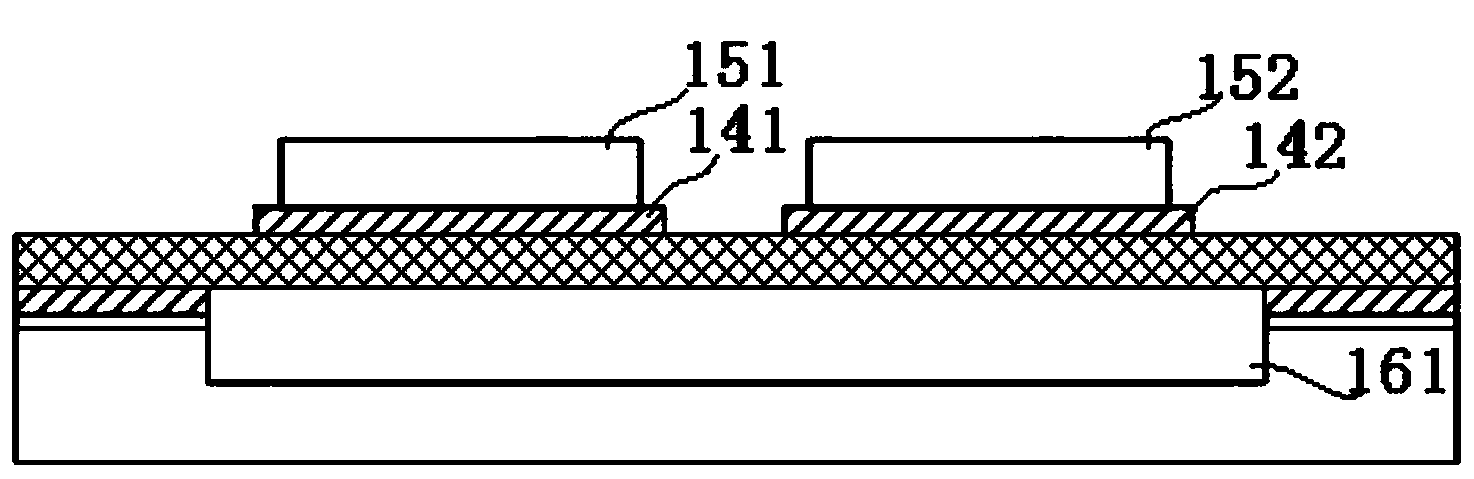

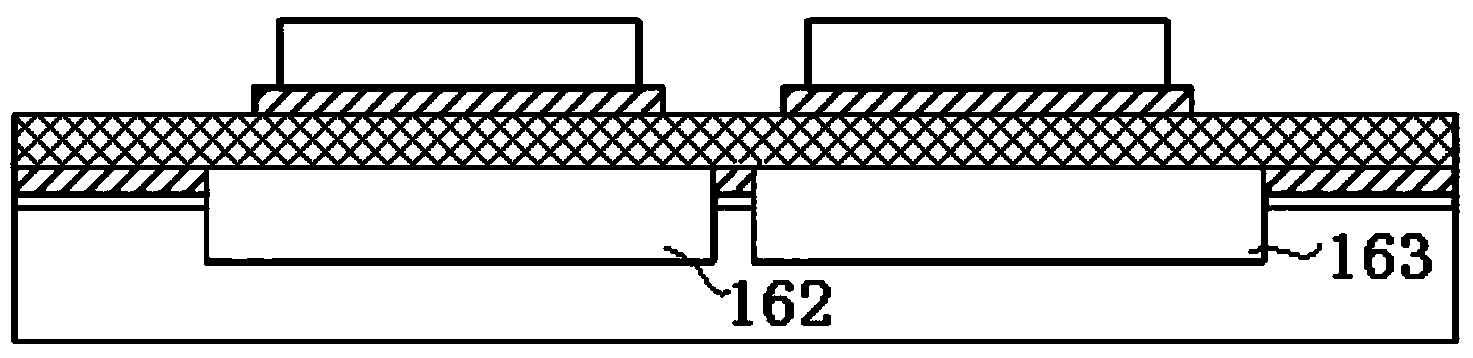

IGBT (insulated gate bipolar transistor) modular structure

InactiveCN103633035AReduce chargeImprove discharge performanceSemiconductor/solid-state device detailsSolid-state devicesCopper coatingCarbide

An IGBT (insulated gate bipolar transistor) modular structure comprises an ALSIC (aluminum silicon carbide) substrate, a copper coating, an ALN (aluminum carbide) insulating ceramic layer, a metal welding pad and a chip. The copper coating is positioned on the ALSIC substrate, the ALN insulating ceramic layer is positioned on the copper coating, the metal welding pad is positioned on the ALN insulating ceramic layer, the chip is positioned on the metal welding pad, and a cavity is formed between the ALN insulating ceramic layer and the ALSIC substrate and is positioned below the chip. Through the cavity positioned below the chip, the electric field intensity at a position with a maximum electric-field value is lowered, apparent charge of partial discharging is reduced, partial discharging is avoided, and discharge performance of modules is improved.

Owner:XIAN YONGDIAN ELECTRIC

Feed-through

ActiveUS10224521B2Avoid damageStrength and resistanceSmall-sized cells cases/jacketsSoldering apparatusElectrical conductorTitanium

A feed-through, in particular a feed-through which passes through part of a housing, in particular a battery housing, for example made of metal, in particular light metal, for example aluminum, an aluminum alloy, AlSiC, magnesium, an magnesium alloy, titanium, a titanium alloy, steel, stainless steel or high-grade steel. The housing part has at least one opening through which at least one conductor, in particular an essentially pin-shaped conductor, embedded in a glass or glass ceramic material, is guided. The base body is, for example, an essentially annular-shaped base body and is hermetically sealed with the housing part such that the helium leakage rate is smaller than 1*10−8 mbar l / sec.

Owner:SCHOTT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com